Patents

Literature

85results about How to "Stable process flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

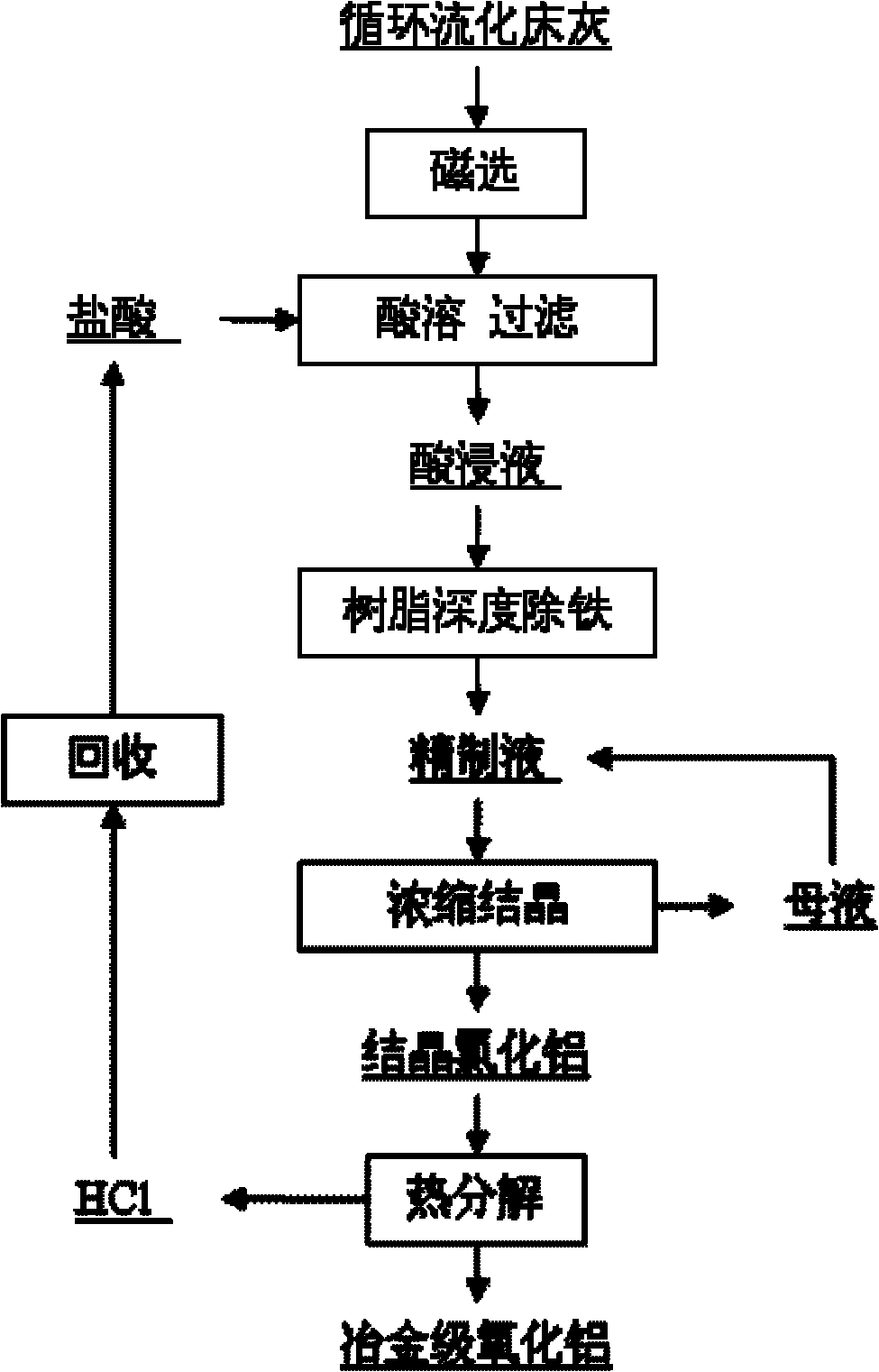

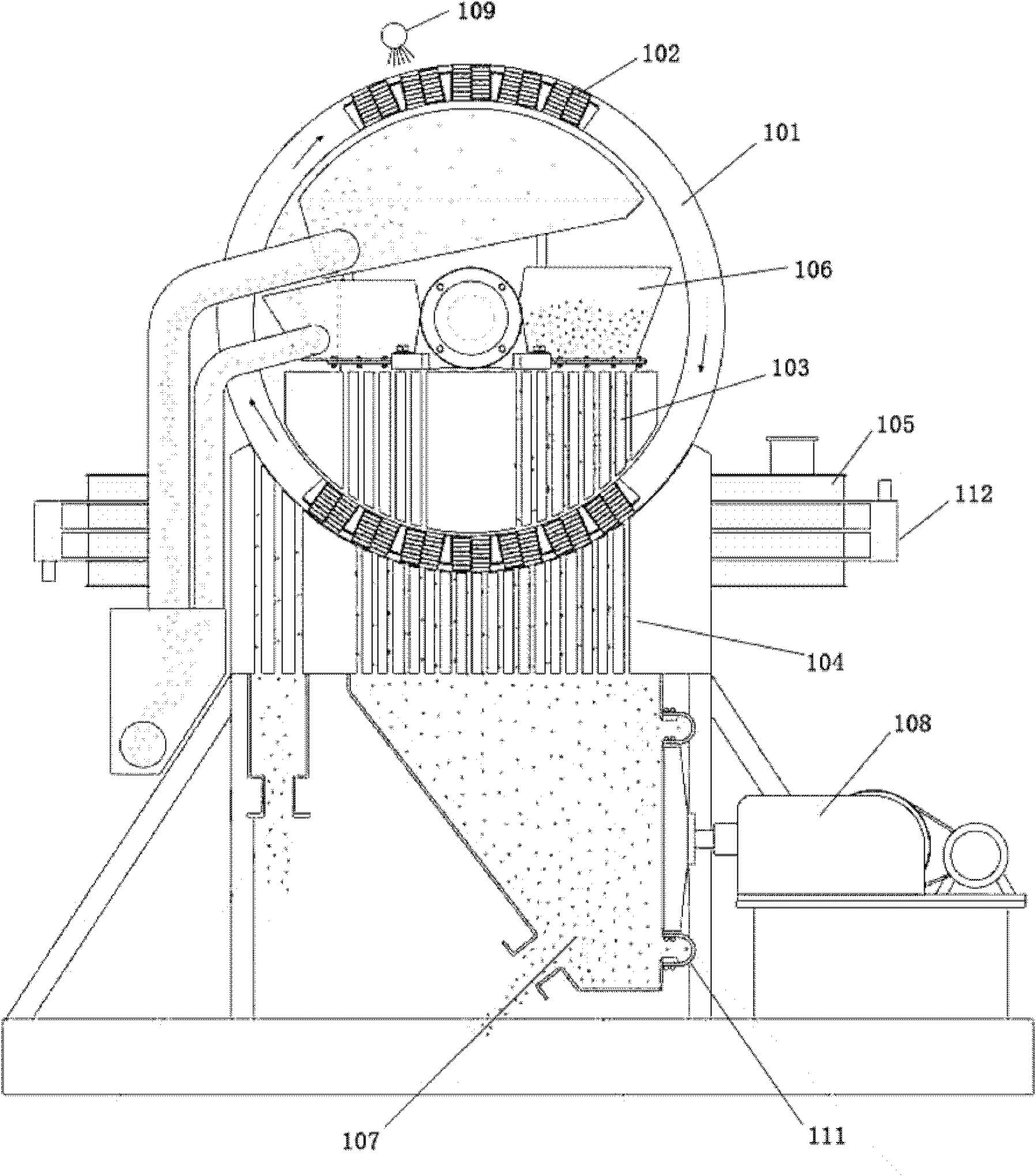

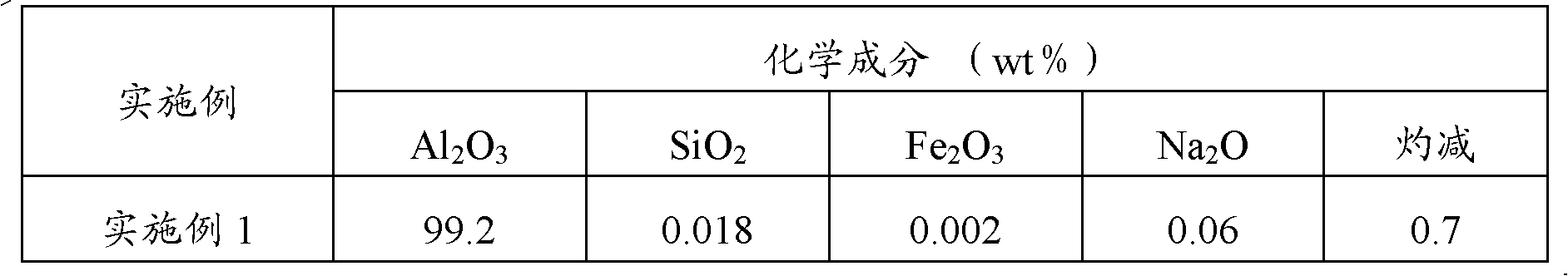

Method for preparing metallurgy-level aluminum oxide by using fluidized bed pulverized fuel ash

ActiveCN102145905AHigh extraction rateReduce manufacturing costSolid waste disposalTransportation and packagingAluminium chloridePulverized fuel ash

The invention discloses a method for preparing metallurgy-level aluminum oxide by using fluidized bed pulverized fuel ash as a raw material. The method comprises the following steps of: a) grinding the pulverized fuel ash, and removing iron by a wet magnetic separation method; b) reacting the pulverized fuel ash subjected to magnetic separation with hydrochloric acid to obtain hydrochloric acid immersion liquid; c) allowing the hydrochloric acid immersion liquid to pass through a large pore type cation resin column for further iron removal to obtain refined aluminum chloride solution; d) concentrating the refined aluminum chloride solution, and crystallizing to obtain an aluminum chloride crystal; and e) calcining the aluminum chloride crystal and decomposing to obtain the metallurgy-level aluminum oxide. The method has a simple process and an easily-controlled production process, and is high in aluminum oxide extraction efficiency, low in production cost and stable in product quality.

Owner:CHINA SHENHUA ENERGY CO LTD

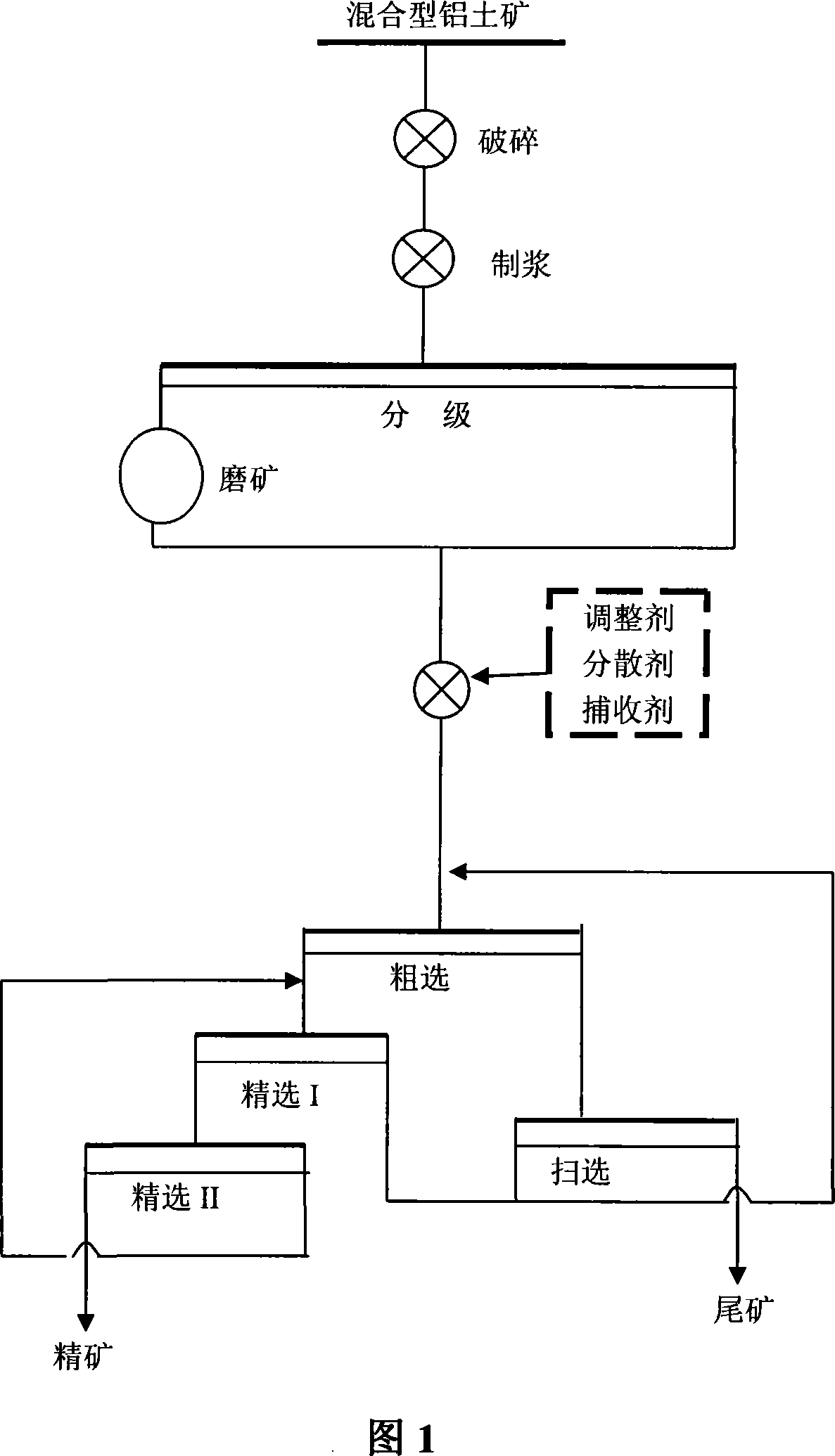

Method for ore dressing and desilicating mixed type bauxite

ActiveCN101176859ASolve the problem of beneficiation and desiliconizationSimple technical processFlotationWet separationHybrid typeSlurry

The invention relates to a mill run desiliconizing method for the mixed alumyte, in particular to a mill run desiliconizing method for the mixed alumyte with the gibbsite. The invention is characterized in that: smashing the mixed alumyte, adding the water to make slurry and make the ore smash, abstracting the coarse fraction mineral and the fine fraction mineral in the products by means of a screen separation craft or a grade craft, fine grinding the coarse fraction mineral which is abstracted, then mixing the milling grinding products and the fine fraction mineral which is abstracted by means of the screen separation craft or the grade craft, and carrying through a floatation. After the invention is carried into execution, the mill run desiliconization of the mixed alumyte with the gibbsite in middle or low grade is realized; the invention has a higher coefficient of recovery under the condition of guaranteeing A / S ratio of the ore concentrate. The invention has the advantages of simple and steady technological process, strong operability, capability of enlarging the resource supply of alumyte and providing a technical support for economy when the alumyte resources are needed, and important economic meaning and a social meaning for the sustainable development of the alumina industry.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

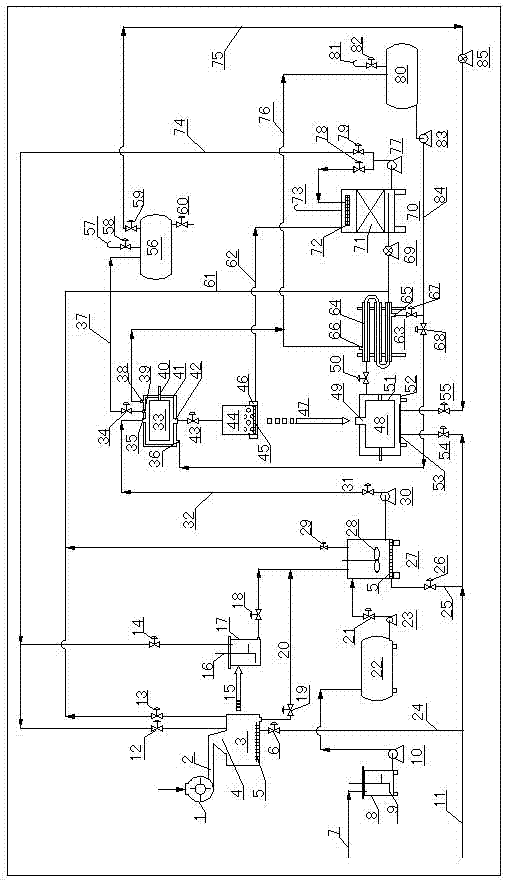

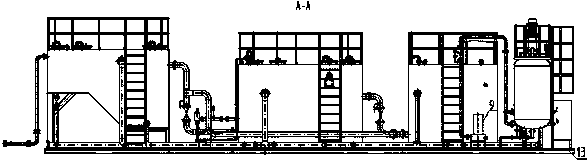

Low-emission solid organic waste treatment system realizing methane and active carbon production

ActiveCN103240264AEasy to handleReduce energy consumptionBioreactor/fermenter combinationsBiological substance pretreatmentsTreatments waterClean energy

The invention discloses a low-emission solid organic waste treatment system realizing methane and active carbon production. The technical method of the low-emission solid organic waste treatment system realizing methane and active carbon production uses a waste crushing treatment system, an anaerobic digestion raw material pre-treatment and blending system, an anaerobic digestion reactor system, an anaerobic digestion residuum dehydrating system, an anaerobic digestion residuum carbonizing system, a carbonized gas collecting, heat-exchanging and purifying system, and a treatment water recycling system. The technical integration of the low-emission solid organic waste treatment system realizing methane and active carbon production is capable of finishing the optimal treatment of the biomass solid organic waste, and the final product is the clean energy methane and environment-friendly material active carbon. The partial required energy can be produced by the technical method, the energy recycling rate is high, and the treatment on the exhaust gas and effluent can be finished in the production link, the system is energy-saving and environment-friendly. By sufficiently considering the influence of various factors and the coherence among various links, the period of anaerobically treating the biomass organic solid waste can be obviously shortened, and the treatment efficiency of the organic solid waste can be sufficiently improved.

Owner:INST OF URBAN ENVIRONMENT CHINESE ACAD OF SCI

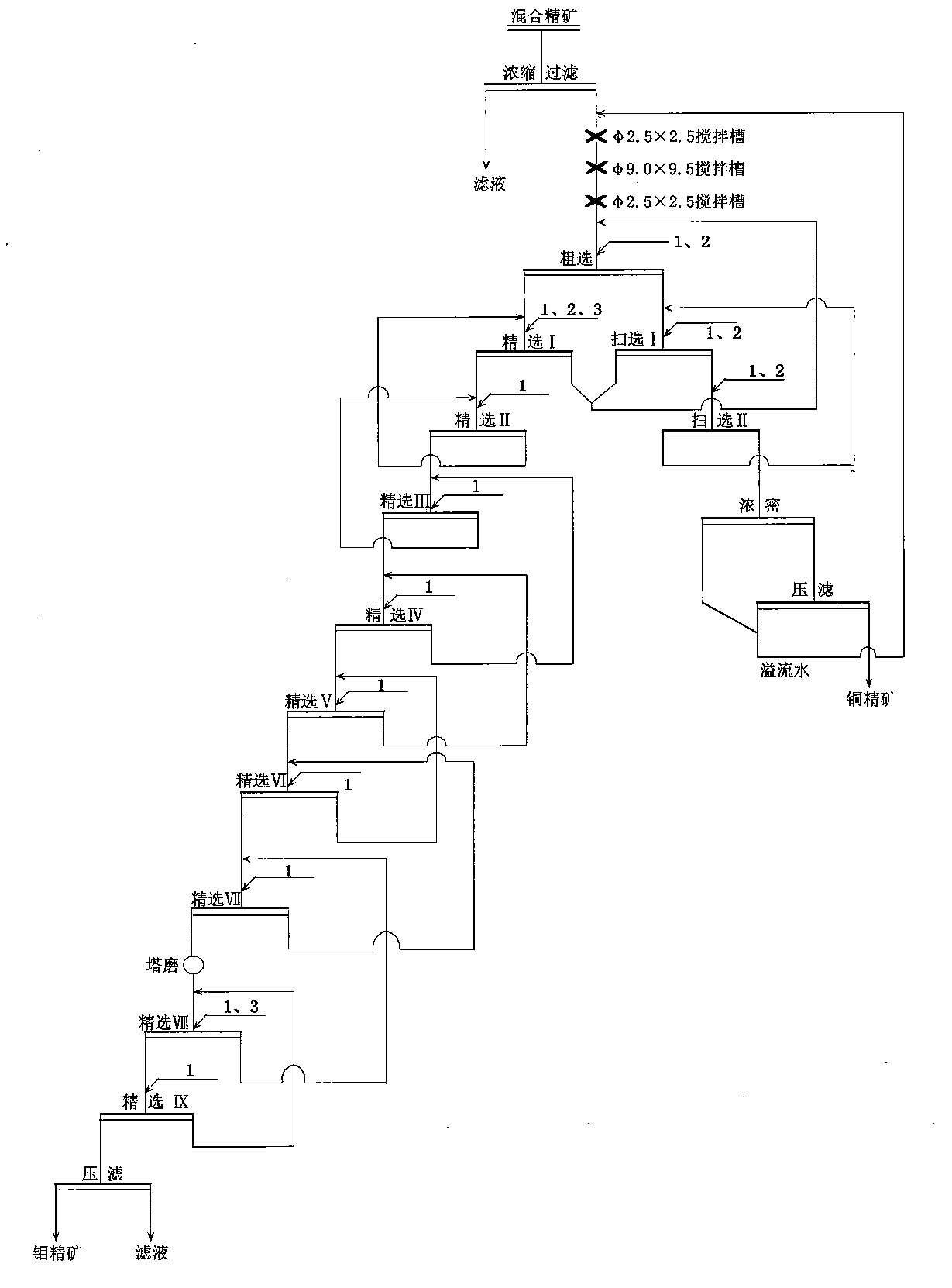

Method for separating copper-molybdenum mixed concentrate high in secondary copper content

InactiveCN103521347AEfficient separationSave waterSolid separationWater resourcesSodium hydrosulfide

The invention discloses a method for separating copper-molybdenum mixed concentrate high in secondary copper content. The method includes the steps of concentrating and filtering, water returning and size mixing, floatation separation, concentrate filtering and the like. The method abides by floatability property difference between copper molybdenum minerals, adopts sodium hydrosulfide to effectively inhibit primary copper and secondary copper and realizes high-efficiency separation of the copper-molybdenum mixed concentrate according to an idea of 'light pressing and slow selecting'. Copper concentrate going through dense overflow water can be used for size mixing of the copper-molybdenum mixed concentrate after concentrating and filtering, so that water resources are saved, and pollution caused by discharging of medicament is reduced. The method has the advantages of simplicity in medicament system and flowage structure, easiness in management operation, stability in technical process and production index and the like.

Owner:CHANGCHUN GOLD RES INST +1

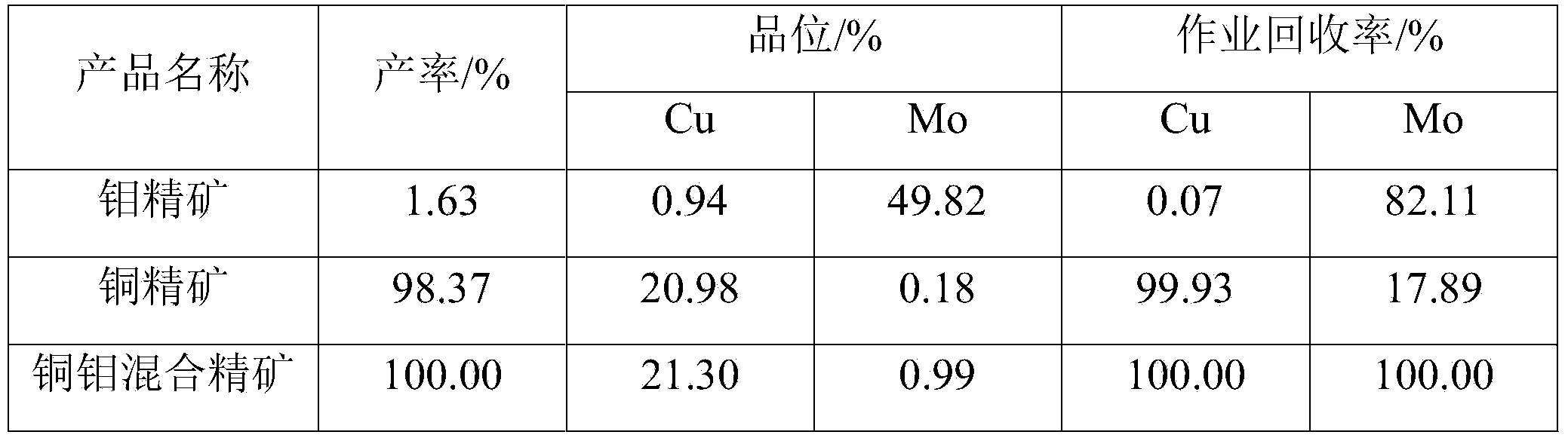

Beneficiation method for separating molybdenum-tungsten oxide ore and molybdenum sulfide ore from molybdenum tungsten ore

InactiveCN106076590AEliminate the need for deslimingThe beneficiation process is simpleFlotationMagnetic separationNon magneticMagnetic characteristic

The invention relates to a beneficiation method for separating molybdenum-tungsten oxide ore and molybdenum sulfide ore from molybdenum tungsten ore. The beneficiation method comprises the steps that magnetic separation is conducted on raw separation molybdenum sulfide ore at least twice, so that the raw separation molybdenum sulfide ore subjected to magnetic separation is divided into magnetic ore containing molybdenum-tungsten oxide and non-magnetic ore containing molybdenum sulfide; and a molybdenum-tungsten oxide flotation process is conducted on the magnetic ore, and a molybdenum sulfide flotation process is conducted on the non-magnetic ore, so that molybdenum-tungsten oxide concentrate and molybdenum sulfide concentrate are obtained. According to the beneficiation method for separating the molybdenum-tungsten oxide ore and the molybdenum sulfide ore from the molybdenum tungsten ore, the magnetic ore containing molybdenum-tungsten oxide and the non-magnetic ore containing molybdenum sulfide are separated out before ore grinding by means of the magnetic characteristic of iron-bearing ore in skarn in a magnetic separation and flotation combined way, so that the floatability of the ore is improved, the beneficiation feed grades of the molybdenum sulfide ore and the and molybdenum-tungsten oxide ore subjected to flotation are increased, and a subsequent flotation technological process is simplified; and in addition, grading index fluctuation caused by the change of the characteristics of the ore is reduced, and the mine production cost can be reduced easily.

Owner:ZHENGZHOU MINERALS COMPOSITIVE UTILIZATION RES INST CHINESE GEOLOGICAL ACAD

Process for preparing organic selenium pine pollen

InactiveCN101129174AHigh nutritional valueHigh medicinal valueFertilising methodsOrganic fertilisersBiotechnologyMicroorganism

The invention relates to a making method of organic selenium pine pollen belonging in biotechnological field with the purpose of providing the making method that can amplify utility of the pine pollen and improve nutrition and medicinal value of the organic selenium pine pollen, which is characterized by the following: converting inorganic selenium to be the organic selenium; using straw of agronomic crop as base material to add absorbent and water-loss agent to produce the organic selenium agent; getting the organic selenium pine pollen with 10-50mg Se / kg selenium through reasonable cultivating and biotransformation. In comparison with the general, the organic selenium pine pollen improves the nutrition and medicinal values greatly with selenium that is 100-500 times as high as the general, which can be adopted in fields of food, health products, drug and medical treatment extensively because of the selenium being organic state with more stable and secure. In addition, the technique can be controlled to operate easily and the raw material can be purchasing easily with the low production cost and high added value of the product.

Owner:安徽省华鼎生物科技有限公司

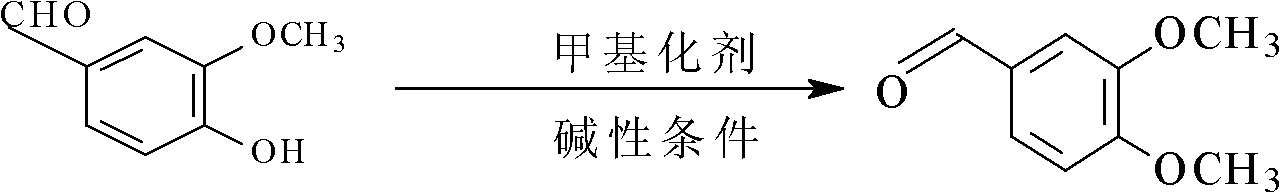

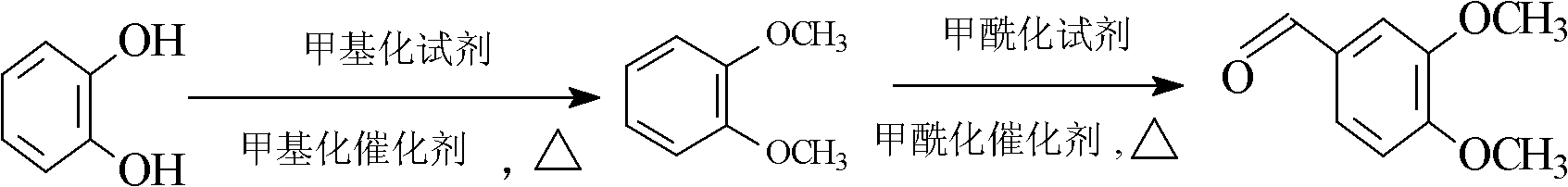

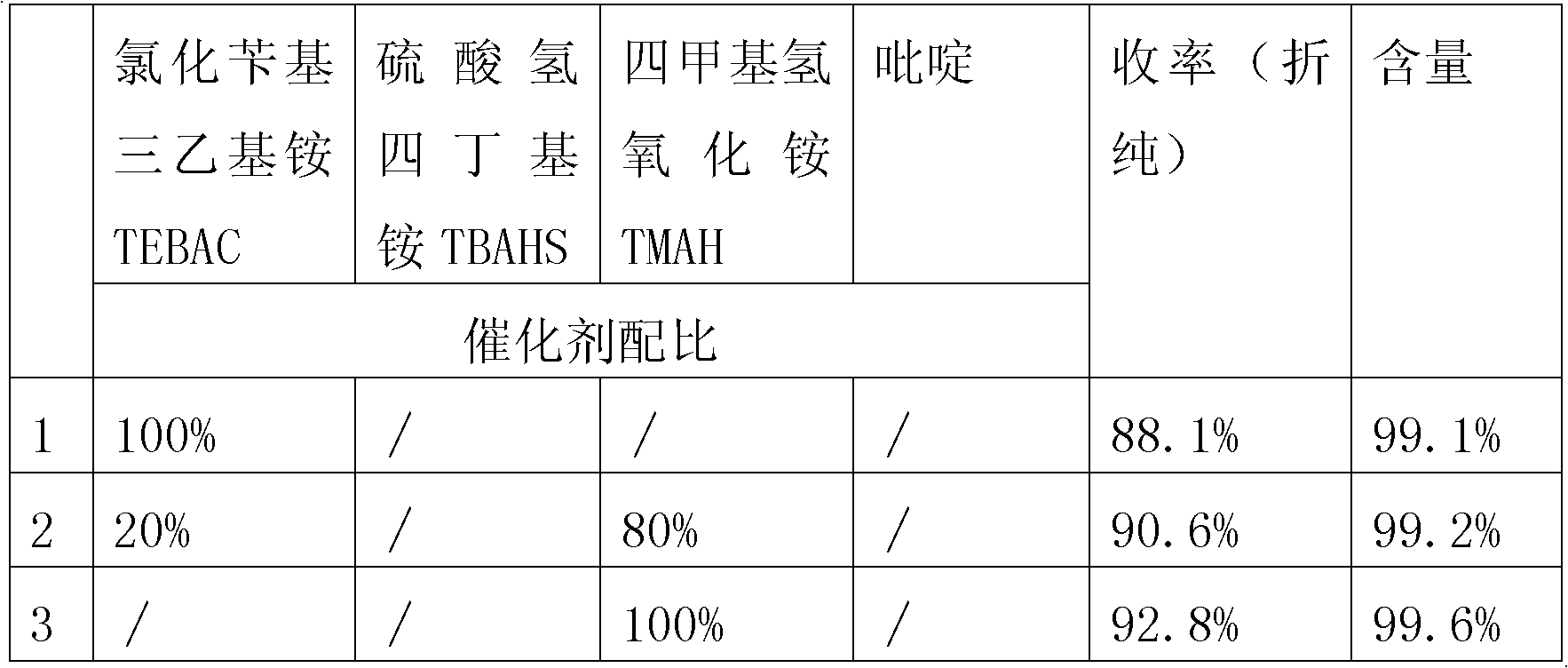

Method for synthesizing veratraldehyde

InactiveCN102070421AShort process routeLow costOrganic compound preparationCarbonyl compound preparationFormylation reactionGuaiacol

The invention discloses a method for synthesizing veratraldehyde. In the method, a methylation reaction and a formylation reaction are performed on catechol serving as a raw material in turn to generate the veratraldehyde, wherein the methylation reaction comprises two reaction stages: guaiacol is mainly generated at the first reaction stage, and the veratrole is generated at the second reaction stage; and during the formylation reaction, the veratrole and a formylation reagent are synthesized to obtain the veratraldehyde. Through comprehensive utilization of a methylation reagent and the formylation reagent, the current situation that the veratraldehyde can only be synthesized by expensive vanillin in the conventional industrial production is changed, the process route for synthesizing the veratraldehyde is effectively shortened, and the cost of a product is reduced; both the yield and the content of the veratraldehyde prepared by the method are greater than those of the veratraldehyde prepared in the prior art; due to the increase of the yield and the content of the veratraldehyde, the process for synthesizing the veratraldehyde is effectively controlled; thus the entire process flow is smooth and stable.

Owner:四川鸿康药物化学有限公司

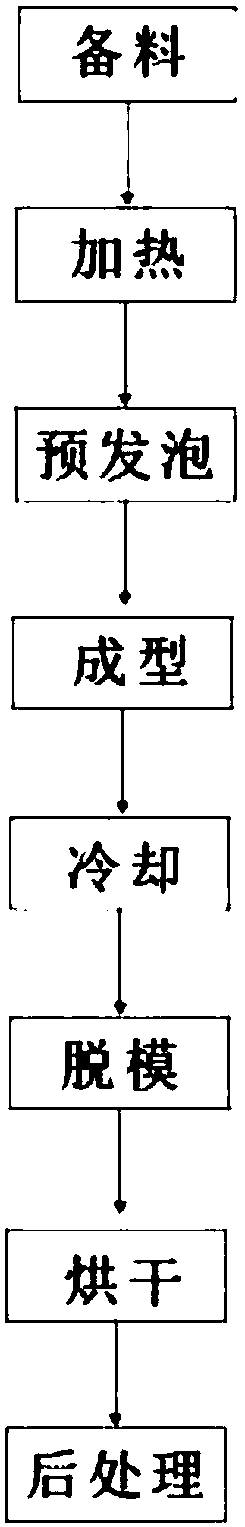

EPS foam article and production technology thereof

The invention discloses an EPS foam article which comprises an EPS raw material and a foaming agent; and the mass of the foaming agent is 4.5-7.2% of that of the EPS raw material. The invention further discloses a production technology of the EPS foam article. The production technology comprises the following steps of S1, stock preparation, S2, heating, S3, pre-foaming, S4, curing, S5, moulding, S6, cooling, S7, drying and S8, aftertreatment. The EPS foam article is low in apparent density and high in flexural strength, is of a closed cell structure internally provided with a large number of fine air bubbles and is long in service life. The production technology of the EPS foam article is stable and simple in technological process; the cooling is carried out through a cooling system, so that manual operation is reduced, the cooling effect is good, and the drying time is shortened; cooled water is subjected to settlement by a settling pool, so that pipe clogging is avoided; and the water is softened by water treatment equipment, so that a mould of a forming machine is effectively protected, the service life of the mould is prolonged, the maintenance cost is reduced, and the rate offinished EPS foam is raised.

Owner:南通市金马包装材料有限公司

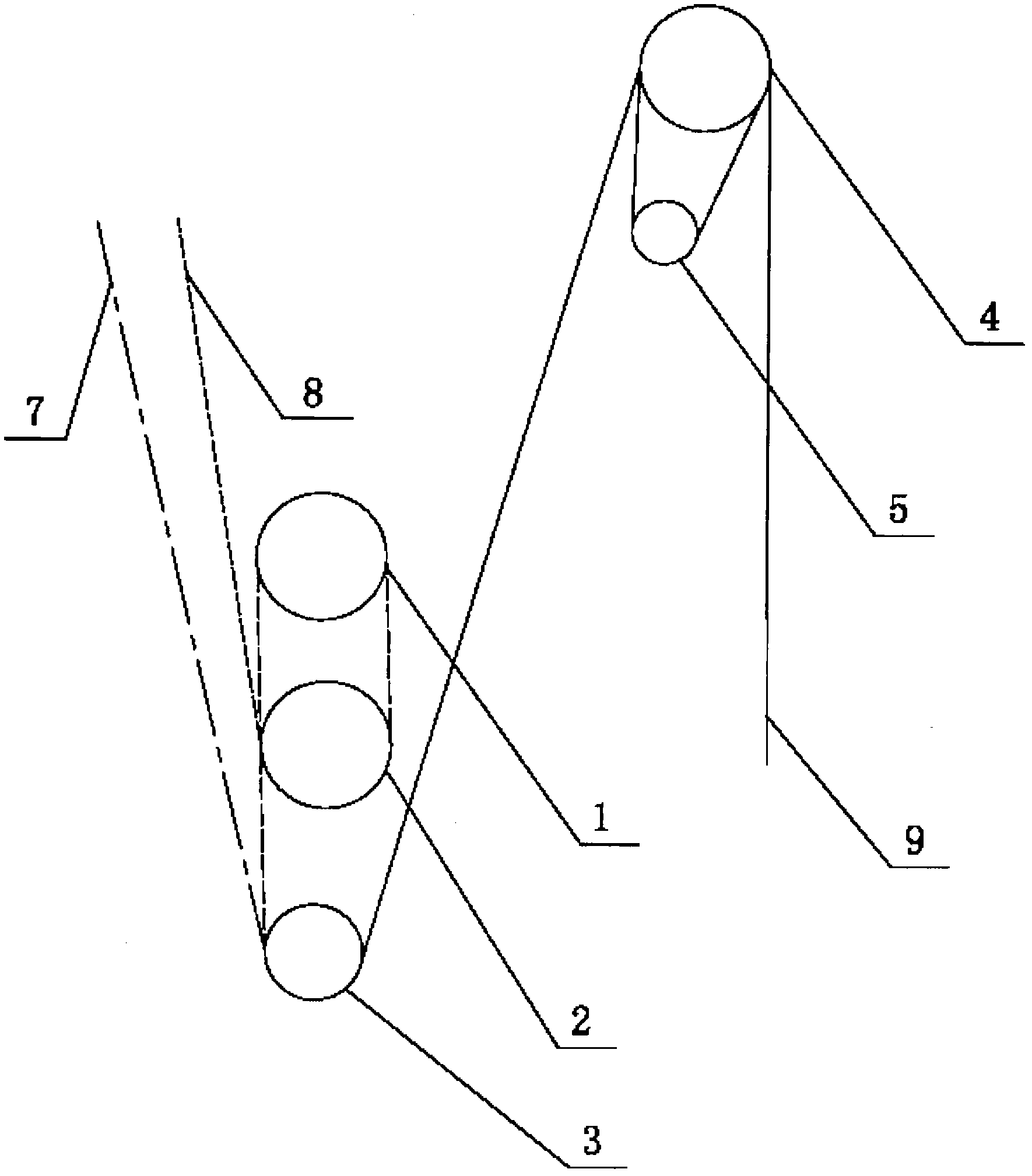

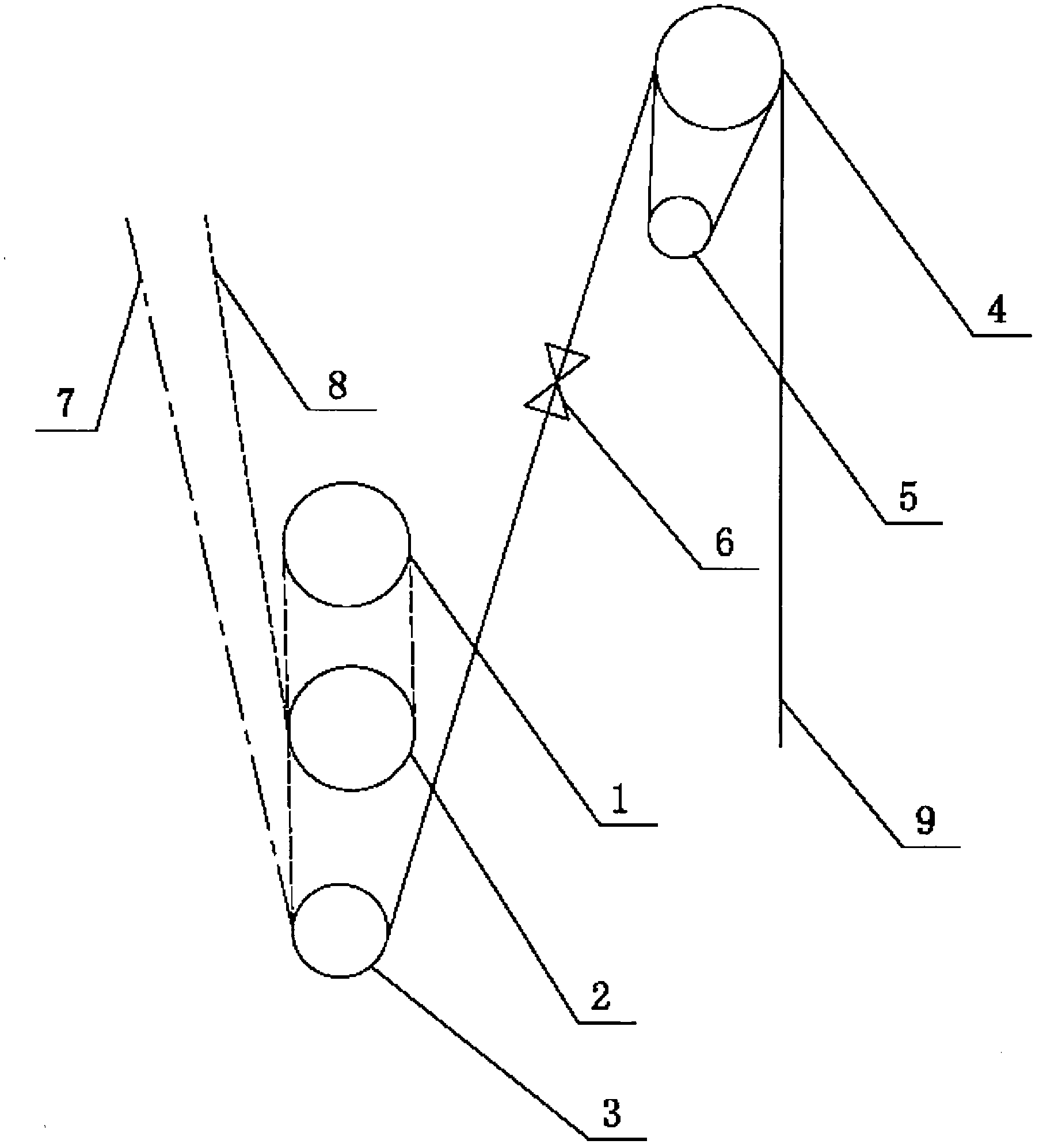

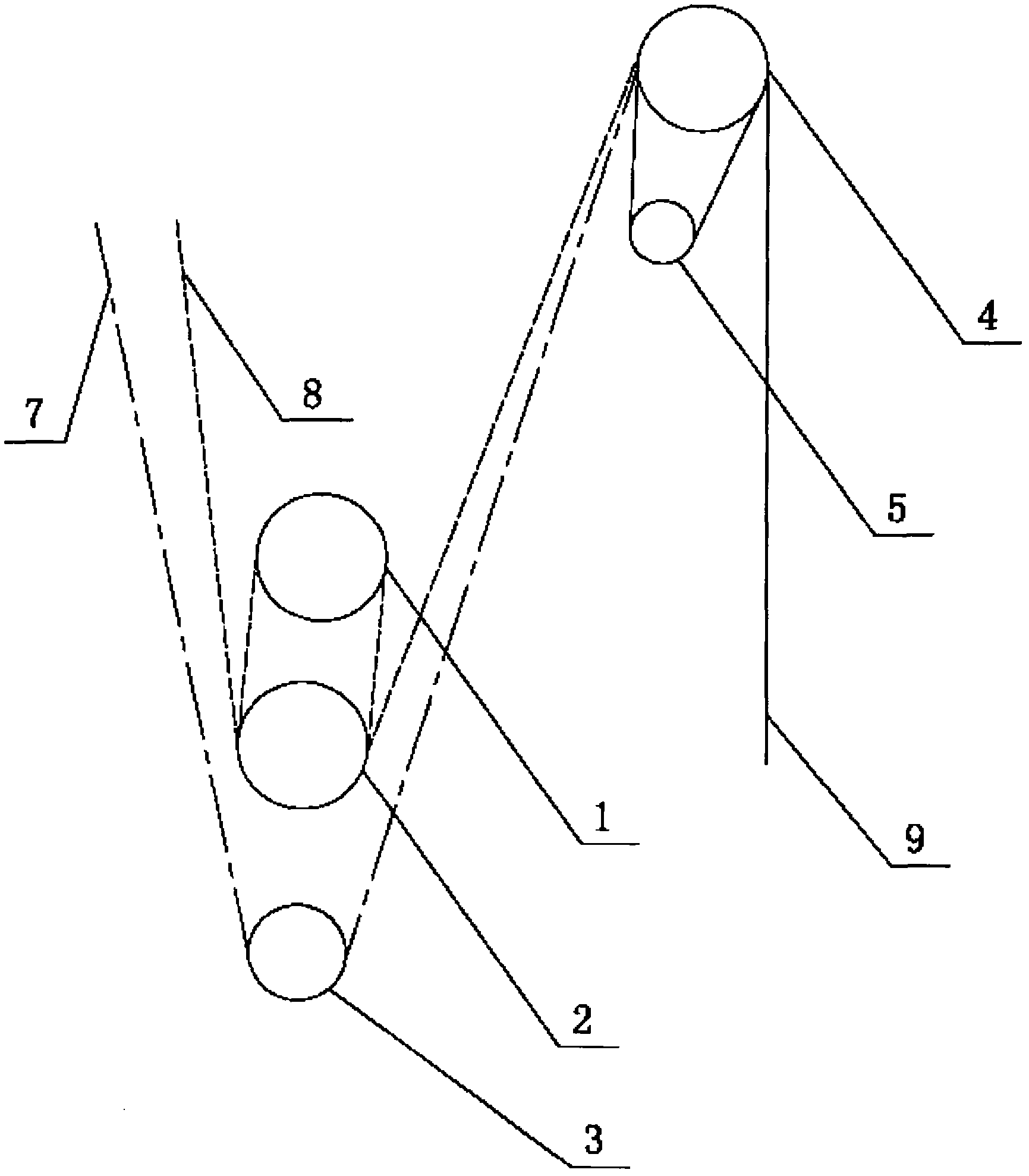

Production method for chemical fiber and polyester composite yarns

InactiveCN102618983AReliable qualityProcess stabilityArtificial filament heat treatmentStretch-spinning methodsYarnMaterials science

The invention relates to a production method for chemical fiber and polyester composite yarns, in particular to a method for producing chemical fiber and polyester composite yarns of partially oriented yarns (POY) and fully drawn yarns (FDY) by one kind of equipment through a one-step method. The POY and the FDY are subjected to composite spinning on the same winding frame, and the spinning process can simultaneously meet process flows required by producing the two kinds of yarns; the FDY and the POY enter a draft area from the same side of a first pair of drawing rollers, wherein the FDY pass through the first pair of drawing rollers consisting of a large-diameter heat roller and a large-diameter heat roller, and, together with the POY, pass through a yarn guide roller below the first pair of drawing rollers, and the FDY and the POY are combined and compounded into a bundle of yarns on the yarn guide roller; and the composite yarn bundle passes through a second pair of drawing rollers consisting of a large-diameter heat roller and a non-heating small-diameter separator roller to form the composite yarns. The effects of saving a production space and saving energy are obvious, the processed fiber composite yarns are reliable in quality, stable in process and high in cohesiveness and the dying property is superior to that of the conventional product.

Owner:北京德厚朴化工技术股份有限公司

Strip steel temperature process transition method

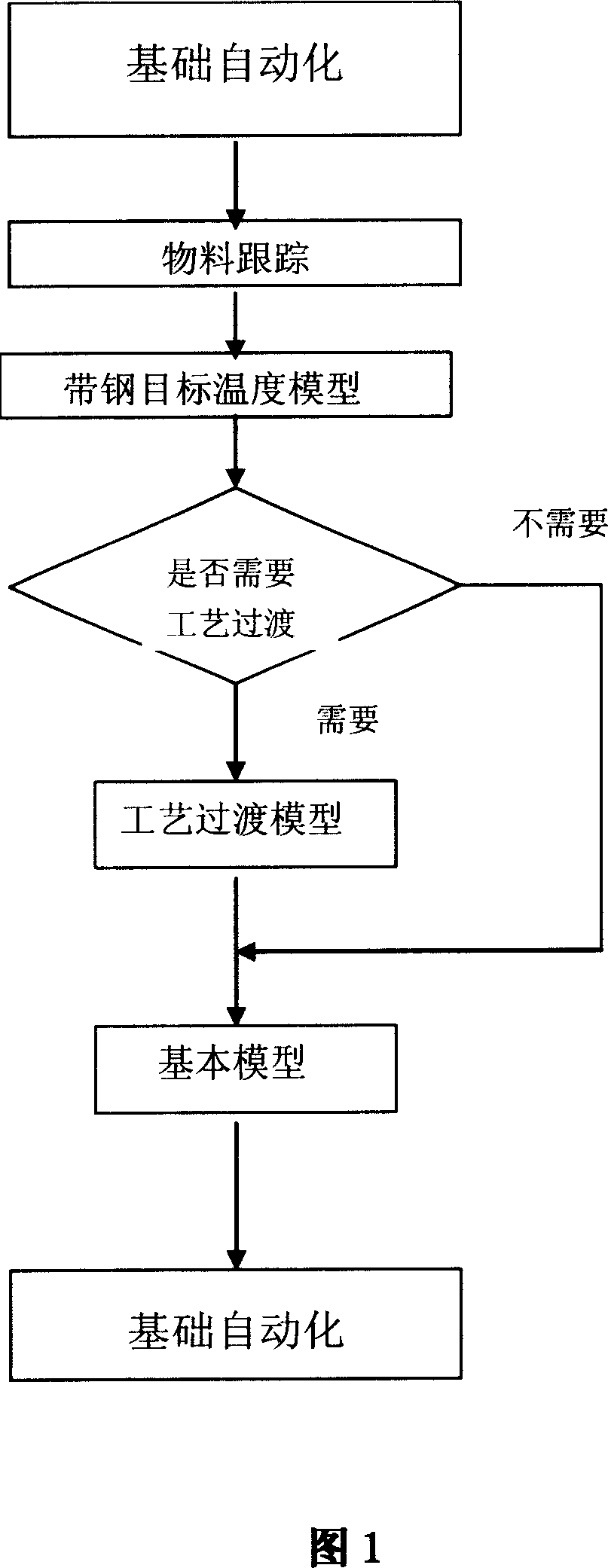

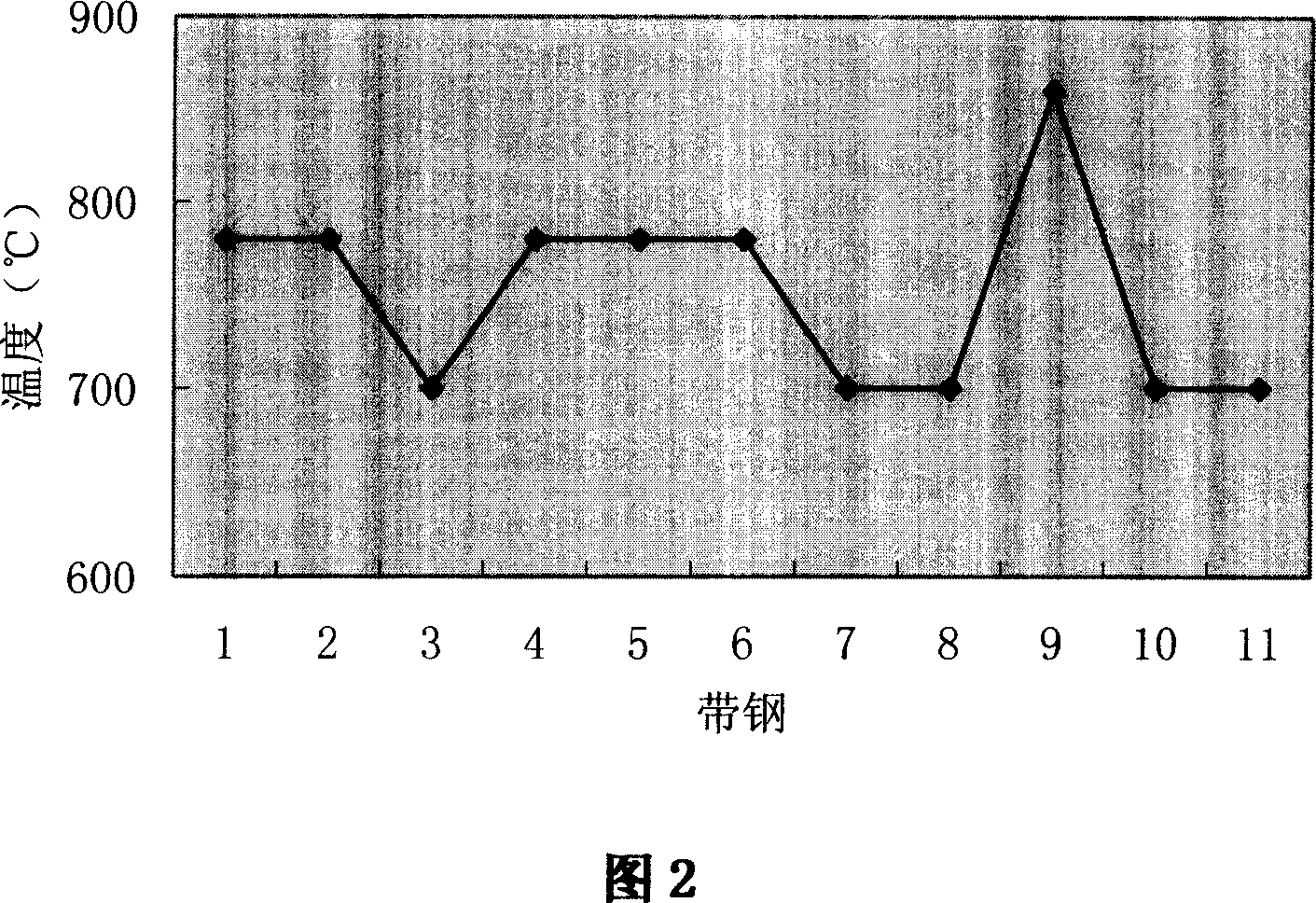

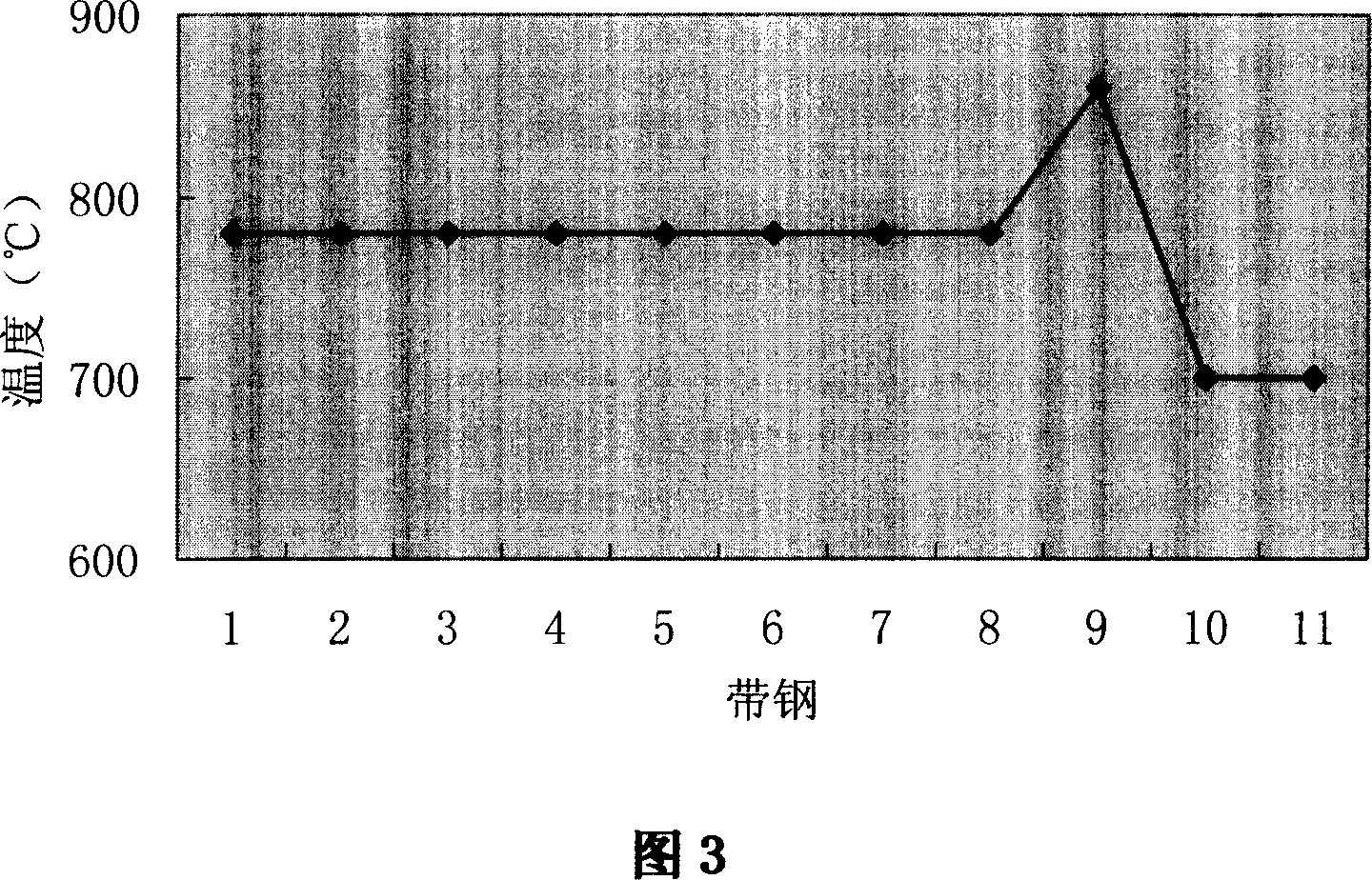

InactiveCN101033502AIncrease productionQuality improvementFurnace typesHeat treatment process controlAutomatic controlStrip steel

The invention discloses a method of strip still temperature technology transition, which can realize automatic control even when the aim temperature of strip goals is greater than 20deg.C. During the strip still temperature technology transition, it uses the principle of high temperature priority when the original aim temperature is different, and when facing the hypothermia step, it omits hypothermia. When the strip still transits from low to high temperature, it warms the still in advance according to specification and speed of subasembly.

Owner:SHANGHAI BAOSIGHT SOFTWARE CO LTD

Method for directly deoxygenizing ferro-nickel in shaft furnace by using laterite nickel ore as raw material

The invention provides a method for directly deoxygenizing ferro-nickel in a shaft furnace by using a laterite nickel ore as a raw material, which relates to a method for deoxygenizing the ferro-nickel. The method aims to solve the problems that the prior method for smelting the ferro-nickel has high investment, high production cost, low automation degree, high carbon content in the produced ferro-nickel and low productivity. The method comprises the following steps: selecting the laterite nickel ore as the raw material of which the mass of the nickel accounts for 0.75 to 2.60 percent of the total mass of the laterite nickel ore and the iron mass accounts for 8.00 to 55.0 percent of the total mass of the laterite nickel ore; and filling the laterite nickel ore and a reducing agent into the shaft furnace according to the weight ratio of 1.00:0.08-0.25, and then performing preheating and drying, heating deoxygenization, tapping, crushing, ball milling, magnetic separation and briquetting to obtain the qualified directly deoxygenized ferro-nickel, wherein the preheating and drying temperature is between 700 and 900 DEG C, the preheating and drying time is between 2 and 4 hours, the heating deoxygenization temperature is between 900 and 1,300 DEG C, and the heating deoxygenization time is between 4 and 8 hours. The method has the advantages of less investment, high productivity, stable process, simple operation, low carbon content in the produced ferro-nickel, high degree of mechanization, and low operating cost.

Owner:章宇

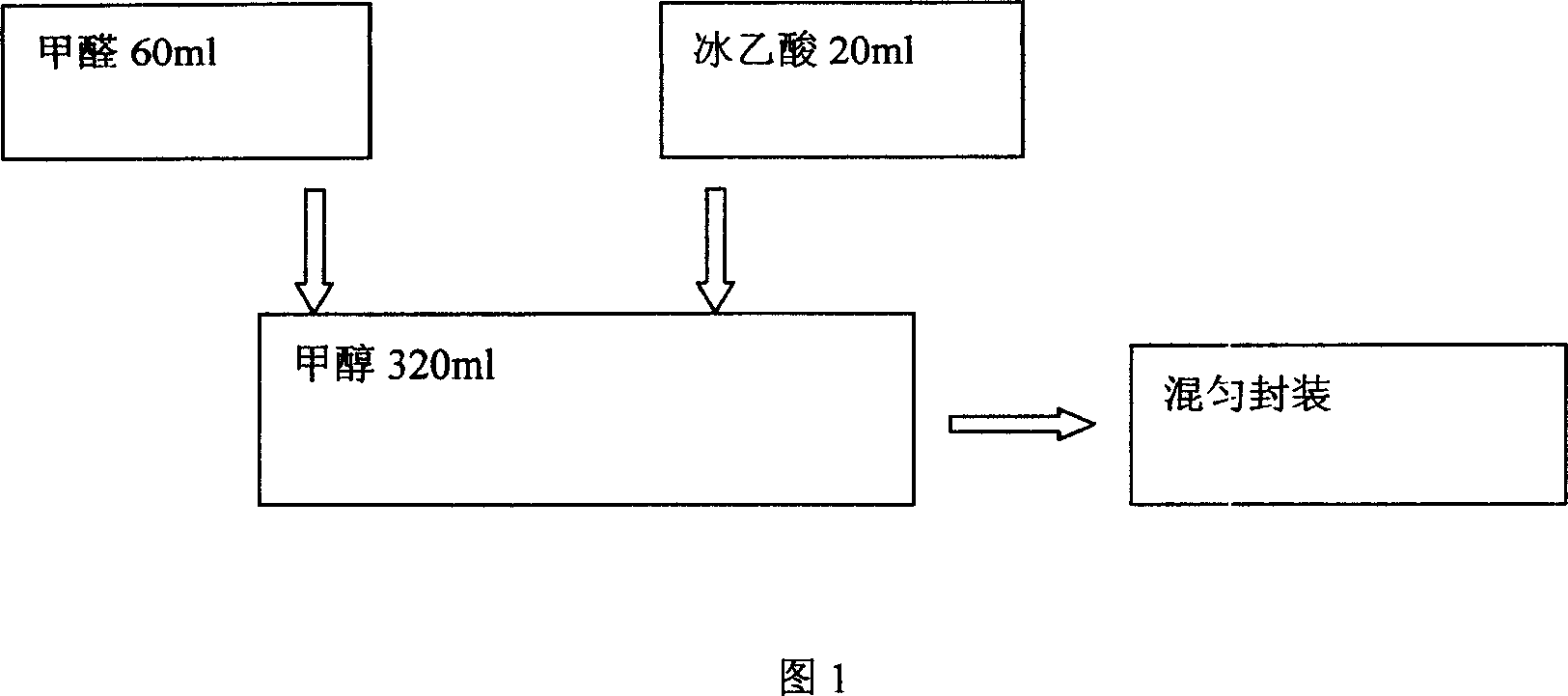

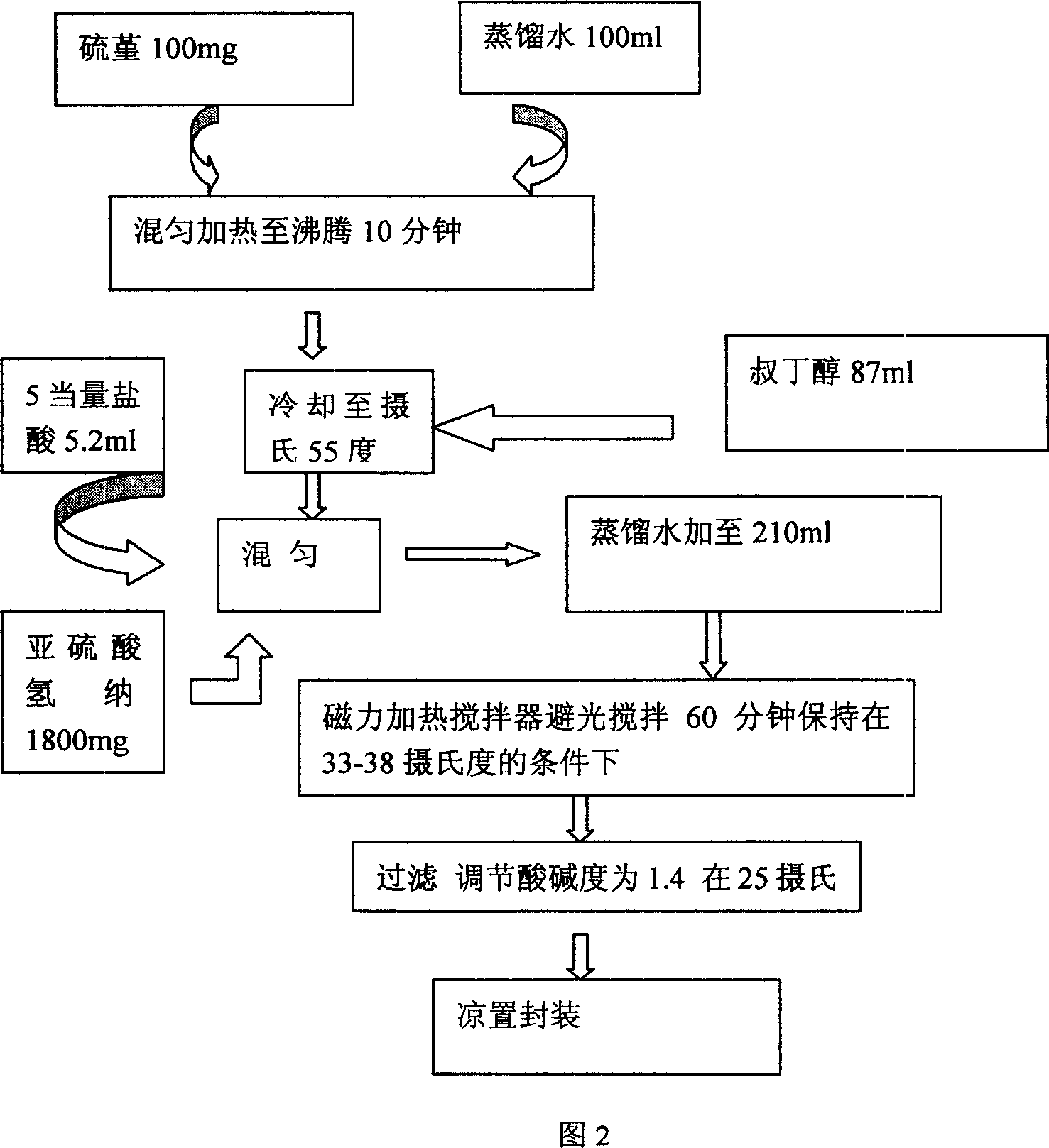

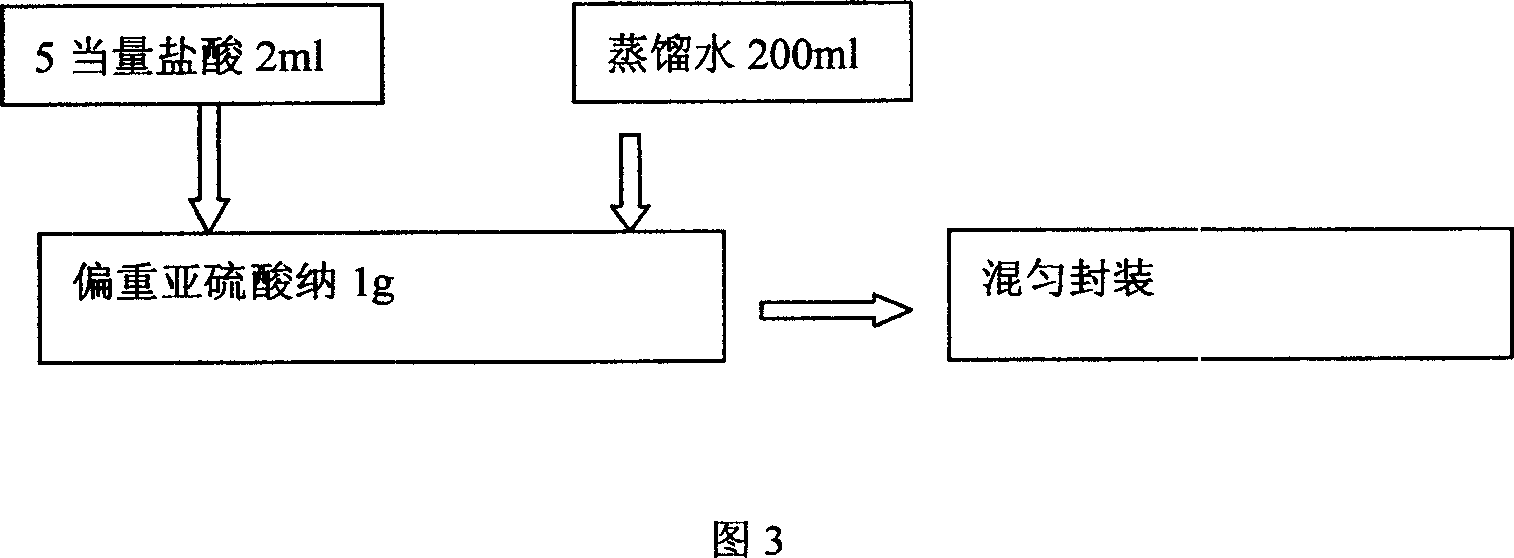

Cell DNA staining kit and its prepn process

InactiveCN101046434AEasy to manufactureEasy to useMicrobiological testing/measurementPreparing sample for investigationBiological cellHuman medicine

The present invention is cell DNA staining kit for use in life science and medicine, especially the sole staining of cell nucleus, and its preparation process. The kit includes DNA staining solution, DNA fixing solution and DNA rinsing liquid in the volume ratio of 1.05 to 2 to 1. It is prepared through the following steps: preparing DNA staining solution, preparing DNA fixing solution, preparing DNA rinsing liquid, preparing cell preserving solution, and setting slide glass, the DNA staining solution, the DNA fixing solution, the DNA rinsing liquid and the cell preserving solution into a box to constitute the cell DNA staining kit. The present invention facilitates cell DNA staining and raises the accuracy.

Owner:SOUTHEAST UNIV

Melting method for HIC (Hydrogen Induced Crack)-resistant pipeline steel

ActiveCN109161630AReduce the burden of decarbonizationReduce oxidationManufacturing convertersProcess efficiency improvementHydrogenMolten steel

The invention provides a melting method for HIC (Hydrogen Induced Crack)-resistant pipeline steel. The melting method comprises the following steps: performing pretreatment on molten iron, melting ina converter, performing primary LF refining, performing RH vacuum treatment, performing secondary LF refining, performing VD vacuum treatment and performing continuous casting. The invention providesa stable control process for melting molten steel with ultra-low carbon, ultra-low sulphur, ultra-low phosphorus and high cleanliness; in the molten steel, C is less than or equal to 0.04, S is less than or equal to 0.001, P is less than or equal to 0.006, Ca is between 0.002 and 0.003, and the ratio of acid soluble aluminium to all aluminium is greater than or equal to 0.95; the component controlrequirements of the HIS-resistant pipeline steel on the ultra-low carbon, the ultra-low sulphur, the ultra-low phosphorus and the high cleanliness are met.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

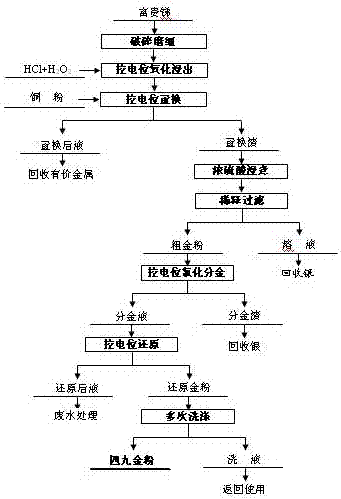

Method for enriching and preparing pure gold from antimony-gold alloy through potential control

ActiveCN107460337AImprove direct yieldTo achieve the purpose of separationProcess efficiency improvementSulfite saltSlurry

Provided is a method for enriching and preparing pure gold from an antimony-gold alloy through potential control. The method for enriching and preparing the pure gold from the antimony-gold alloy through potential control comprises the following steps that after the antimony-gold alloy is crushed and levigated to a required particle size, hydrogen peroxide is added into a pure hydrochloric acid system to conduct potential controlling and oxidizing leaching, slurry after being leached is added into copper powder to conduct potential controlling and displacing, raw gold powder is obtained after displacement residue is soaked and digested in concentrated sulfuric acid, the hydrogen peroxide is added into a hydrochloric acid solution containing the raw gold powder to conduct potential controlling and gold leaching by chlorination, gold leaching liquid is added into sodium hydroxide and sodium sulfite to conduct potential controlling and reduction, and gold powder is obtained, and pure gold powder is obtained after the gold powder is washed. According to the method for enriching and preparing the pure gold from the antimony-gold alloy through potential control, a potential control mode is adopted to achieve the purpose that the processes of oxidation leaching, displacement, gold leaching by chlorination, reduction and the like are adjustable and controllable, and the direct recovery rates of gold and silver reach to over 99.9% and 99.0% correspondingly. The method has the advantages of being good in metal separation effect, stable in technical index, short in technological process and the like.

Owner:CENT SOUTH UNIV

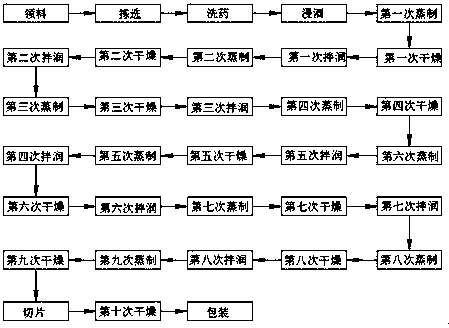

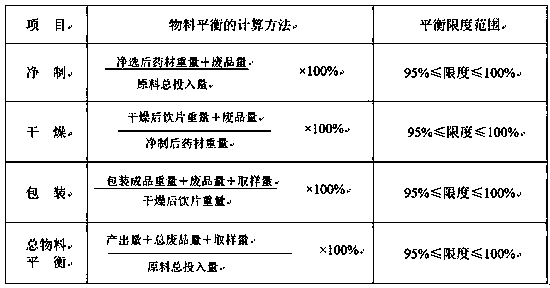

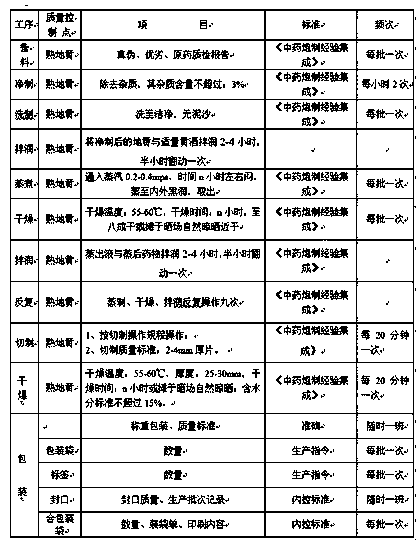

Technological process of nine-steamed and nine-processed radix rehmanniae preparata

InactiveCN107929418AStable process flowStandardization of production operationsPlant ingredientsRadix Rehmanniae PreparataEngineering

The invention discloses a technological process of nine-steamed and nine-processed radix rehmanniae preparata. Specifically, the technological process comprises the following steps: S1, fetching materials; S2, selecting the materials; S3, washing the drugs (the materials); S4, soaking the drugs in wine; S5, conducting steaming for the first time; S6, conducting drying for the first time; S7, conducting blending and wetting for the first time; S8, conducting steaming for the second time; S9, conducting drying for the second time; S10, conducting blending and wetting for the second time; S11, conducting steaming for the third time; S12, conducting drying for the third time; S13, conducting blending and wetting for the third time; S14, conducting steaming for the fourth time; S15, conductingdrying for the fourth time; S16, conducting blending and wetting for the fourth time; S17, conducting steaming for the fifth time; S18, conducting drying for the fifth time; S19, conducting blending and wetting for the fifth time; S20, conducting steaming for the sixth time; S21, conducting drying for the sixth time; S22, conducting blending and wetting for the sixth time; S23, conducting steamingfor the seventh time; S24, conducting drying for the seventh time; S25, conducting blending and wetting for the seventh time; S26, conducting steaming for the eighth time; S27, conducting drying forthe eighth time; S28, conducting blending and wetting for the eighth time; S29, conducting steaming for the ninth time; S30, conducting drying for the ninth time; S31, conducting slicing; S32, conducting drying for the tenth time; and S33, implementing packaging. The technological process provided by the invention conforms to practical production and management requirements of GMP.

Owner:安徽华善堂中药饮片有限公司

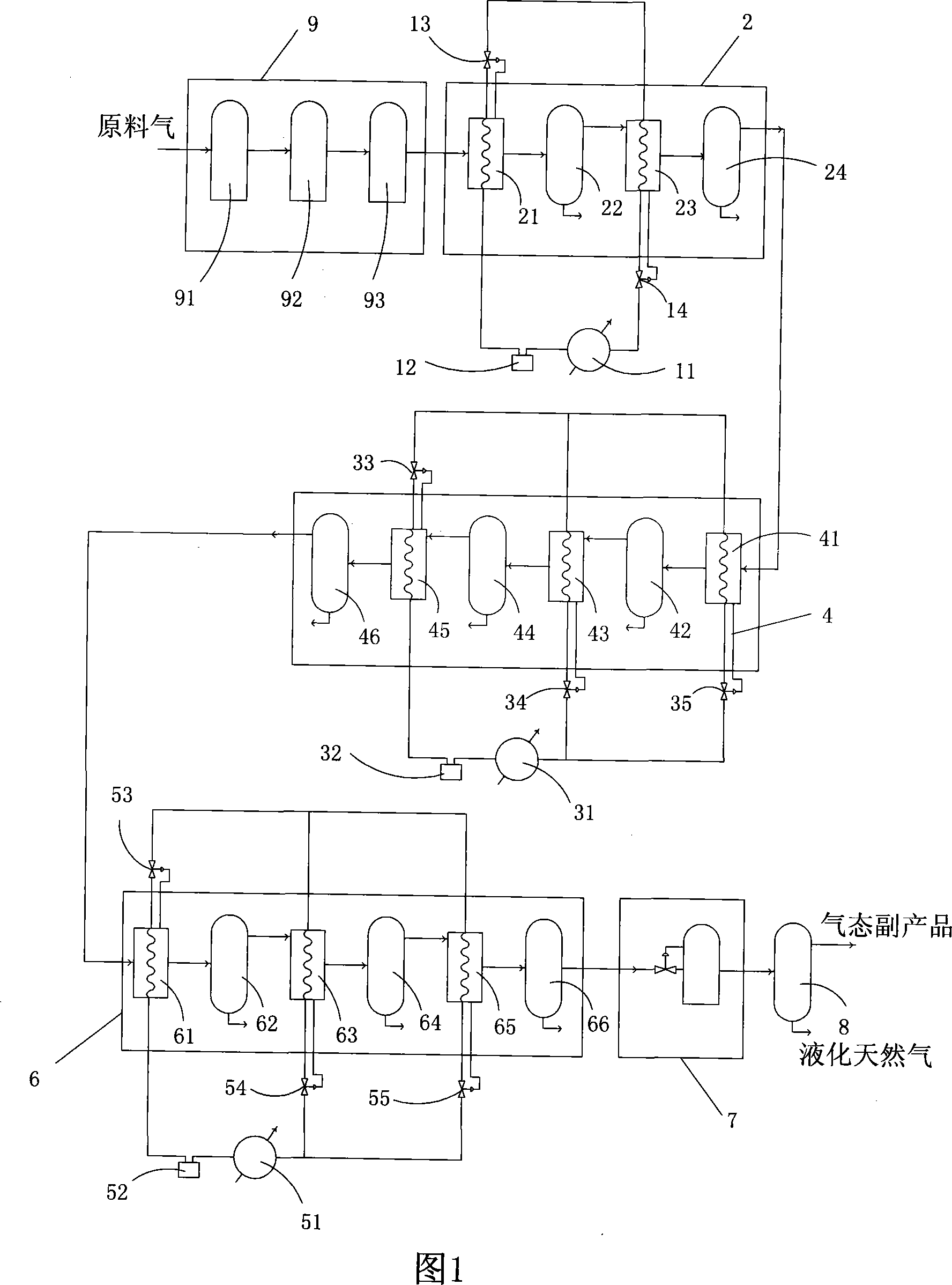

Cascade connection method for preparing liquefied natural gas

The invention discloses a cascading style preparation method of liquefied natural gas, comprising the following steps: (1) pretreatment: that carbon dioxide, sulfureted hydrogen and water contain in raw gas are removed; (2) raw gas primary cooling treatment: the raw gas passes through a first multi-level heat exchanging and a separating device of a first refrigeration cycle system to finish the primary cooling treatment; (3) raw gas secondary cooling treatment: the raw gas is sent by a second multi-level heat exchanging and the separating device of a second refrigeration cycle system in sequence to finish the secondary cooling treatment; (4) raw gas tertiary cooling treatment: the raw gas is sent by a third multi-level heat exchanging and the separating device of a third refrigeration cycle system in sequence to finish the tertiary cooling treatment; (5) finished product making: the raw gas is made to expand and then the temperature of the raw material is lowered to -162 DEG C to -163 DEG C, thereafter a combination of liquefied nature gas and gaseity nature gas is made; the combination passes through a gas-liquid separating tower to make the final product of the liquefied natural gas. The invention has the advantages that beneficial by-products can be obtained in the process of natural gas liquefaction.

Owner:林寿贵

Acetonitrile continuous negative pressure distillation extraction technology

ActiveCN105968028AImprove stabilityHigh purityExtractive distillationCarboxylic acid nitrile purification/separationWater contentAmmonium sulfate

The invention relates to an acetonitrile continuous negative pressure distillation extraction technology. The technology comprises preheating crude acetonitrile to a temperature of 70-80 DEG C, feeding the crude acetonitrile into a dehydrating tower, carrying out rectification separation, thoroughly removing ammonium sulfate in the crude acetonitrile at the tower bottom, simultaneously separating a part of water, feeding acetonitrile with content of 70% or more from the tower top into an extraction and rectification tower, simultaneously adding glycol with water content of 0.2% into the extraction and rectification tower, carrying out extraction water-removal purification, congealing acetonitrile with a concentration of 99% from the extraction and rectification tower top through an external condenser of the extraction and rectification tower, storing the acetonitrile in an acetonitrile receiving tank for finished product storage, feeding hydrous ethylene glycol from the tower bottom into an ethylene glycol dehydrating tower, carrying out deep dehydration, returning the ethylene glycol with water content less than 0.2% obtained by the ethylene glycol dehydrating tower to the extraction and rectification tower, and carrying out circular extraction and rectification. The technology has the advantages of energy saving, cost saving, stable processes, operation easiness and high purification degree.

Owner:XINXIANG RUICHENG TECH DEV

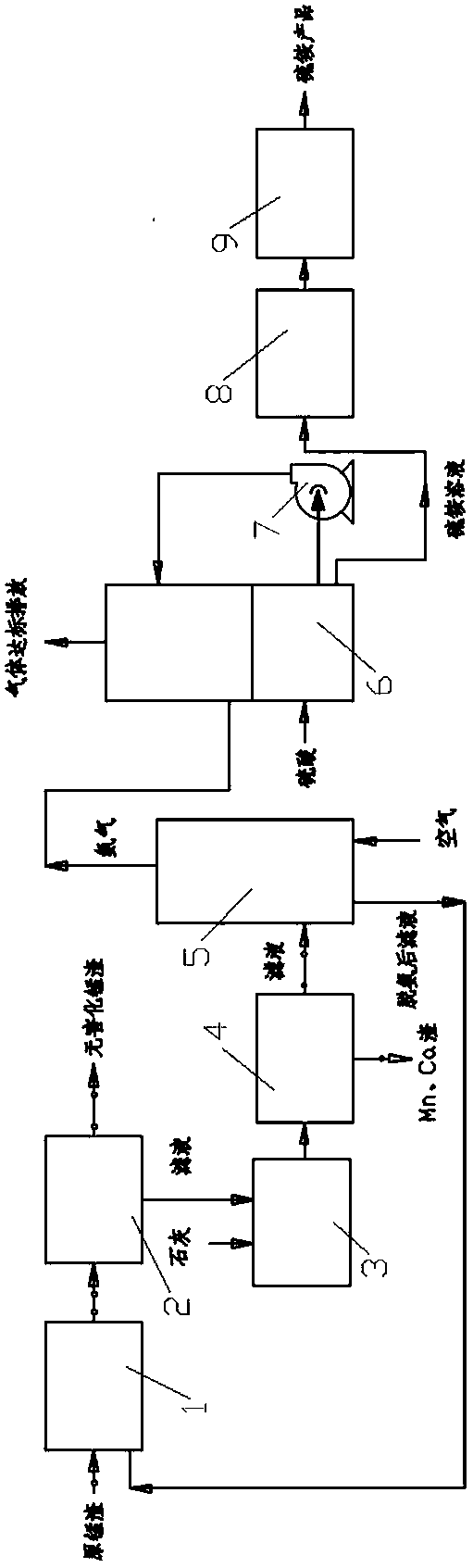

Electrolytic manganese residue innocent treatment method and device thereof

The invention discloses an electrolytic manganese residue innocent treatment method and a device thereof, belongs to the field of common industrial solid waste treatment, and aims to solve the problems that in an existing electrolytic manganese residue innocent treatment method, soluble manganese cannot be effectively utilized and manganese residue innocent treatment is in sore need of being realized. The electrolytic manganese residue innocent treatment method can be adopted to effectively realize innocent treatment on electrolytic manganese residues, and effectively solves the problem that electrolytic manganese residues are greatly accumulated and pollute the environment. The electrolytic manganese residue innocent treatment method is adopted to treat electrolytic manganese residues, sothat equipment investment cost is relatively small, energy consumption is relatively low, and treatment cost and operation cost can be effectively reduced. Meanwhile, the electrolytic manganese residue innocent treatment method is short in process flow, is stable in operation, is high in reliability, can meet industrial and large-scale production and application needs, has a relatively high application value and a relatively good application prospect in treating electrolytic manganese residues, and is worthy of being popularized and applied on a large scale. Besides, products treated by the electrolytic manganese residue innocent treatment method are stored and transported conveniently, use is wide, dosage is great, and economic values are relatively high.

Owner:四川恒泰环境技术有限责任公司

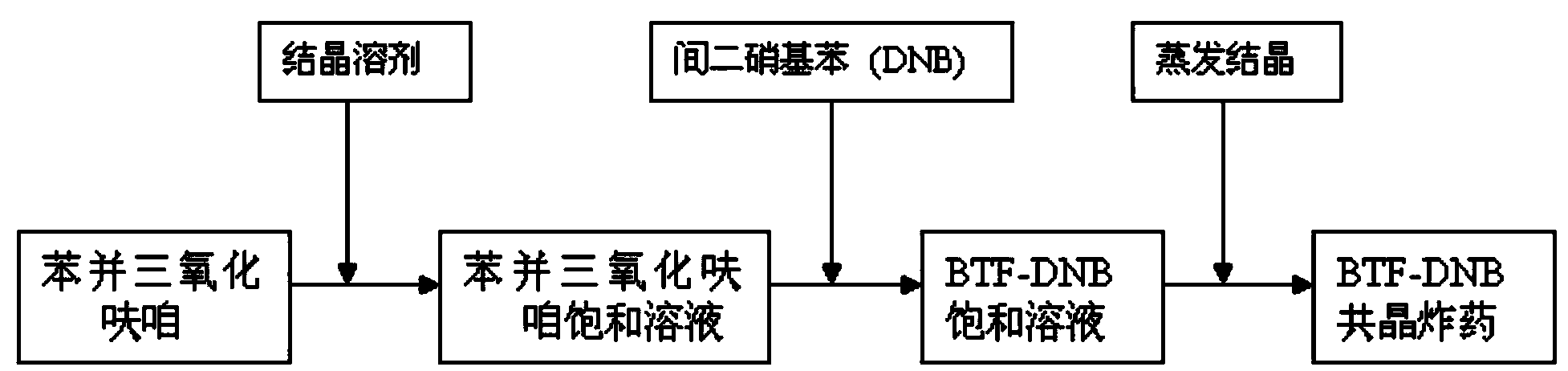

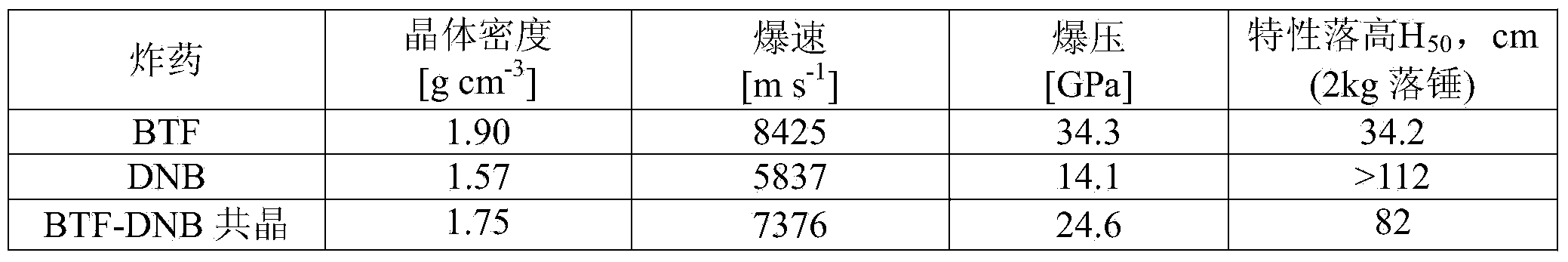

Preparation method for benzotrifuroxan and m-dinitrobenzene eutectic explosive

ActiveCN103435426AImprove securityImprove detonation performanceExplosive working-up apparatusNitrated aromatic explosive compositionsBenzeneDetonation

The invention discloses a preparation method for a benzotrifuroxan and m-dinitrobenzene eutectic explosive. The preparation method comprises the following steps: firstly, preparing a benzotrifuroxan and m-dinitrobenzene saturated solution through a crystallization solvent; secondly, evaporating the solvent of the saturated solution by a constant temperature incubator and crystallizing to form the benzotrifuroxan and m-dinitrobenzene eutectic explosive. The benzotrifuroxan and m-dinitrobenzene eutectic explosive has the benefits of excellent safety, good detonation performance and good free-running property, can serve as a component of a novel booster explosive, has a good application prospect in high-energy low-sensitive ammunitions, and is simple and stable in preparation method and process flow, convenient to operate, moderate in reaction conditions, good in safety and high in quality.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

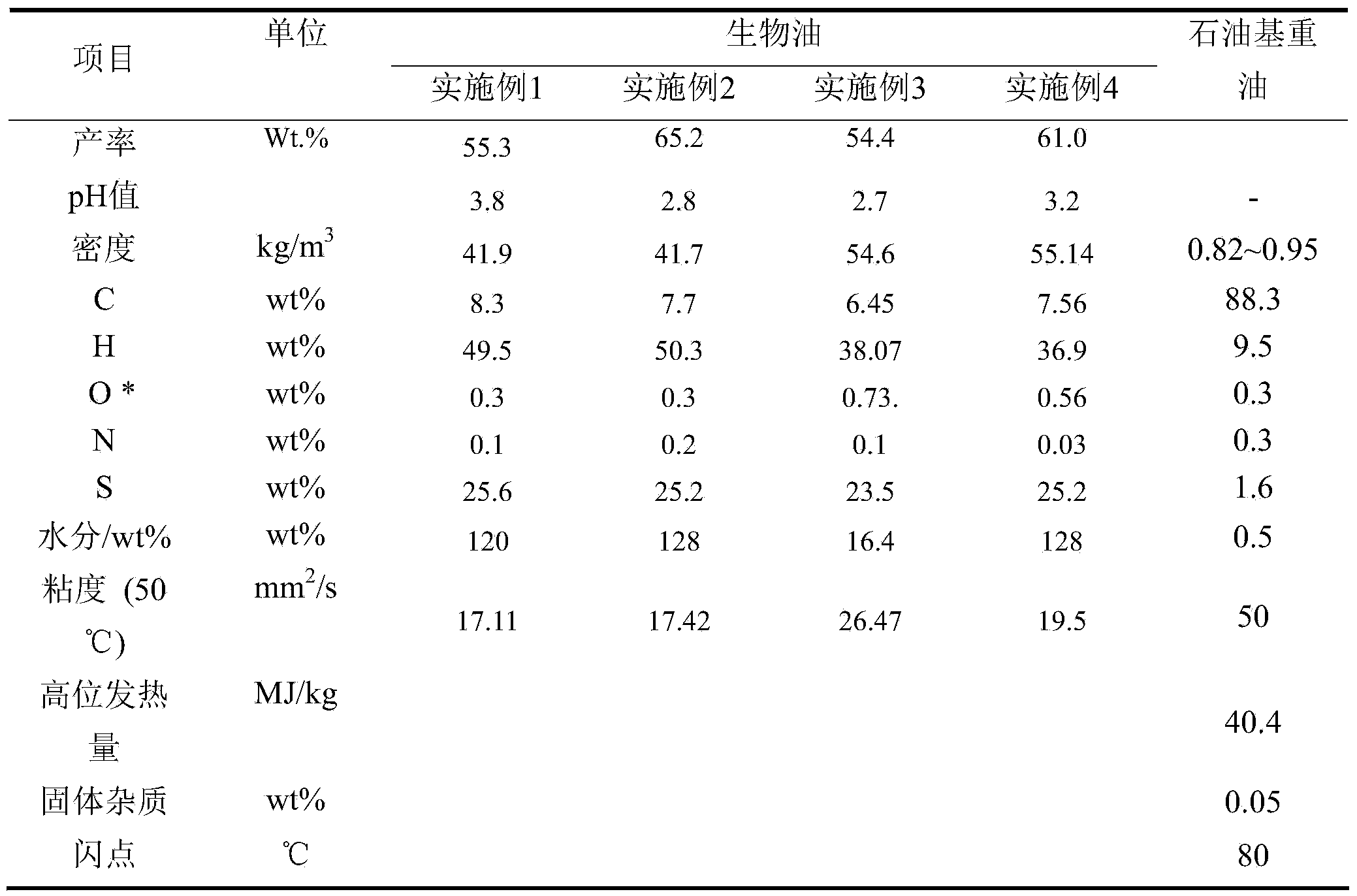

Method for preparing oil via pyrolysis of biomasses

ActiveCN103849410AAdaptableTroubleshoot technical problems with clogged pipesDirect heating destructive distillationBiofuelsNitrogen gasRaw material

The invention discloses a method for preparing an oil via pyrolysis of biomasses. The method comprises the following steps: (1) smashing the biomasses taken as raw materials and drying; (2) drying quartz sand; (3) adding the quartz sand into a fluidized bed; (4) controlling the temperature of the fluidized bed, continuously blowing the fluidized bed by taking a preheated nitrogen gas or recycled gas as a carrier gas so as to form a non-oxygen atmosphere in the fluidized bed and controlling the pressure; (5) feeding the biomass particles into the fluidized bed through a spiral feeder by simultaneously feeding the nitrogen gas as a material-blowing wind so as to carry out a pyrolytic reaction to obtain the materials in a fluidized state; and (6) separating carbon residues from a product generated by a pyrolysis reaction through a cyclone separator and feeding the product into a condenser for condensation so as to obtain a biological oil and a non-condensable gas, wherein combusting one part of non-condensable gas by using a gas combustor so as to heat the fluidized bed and a preheater and taking the other part of non-condensable gas as the recycled gas. The method can be used for treating all agricultural wastes and has a high biological oil yield; and the non-condensable gas taken as a by-product can be recycled. In addition, the discharge of waste residues, waste water and waste gas is avoided.

Owner:TIANJIN UNIV

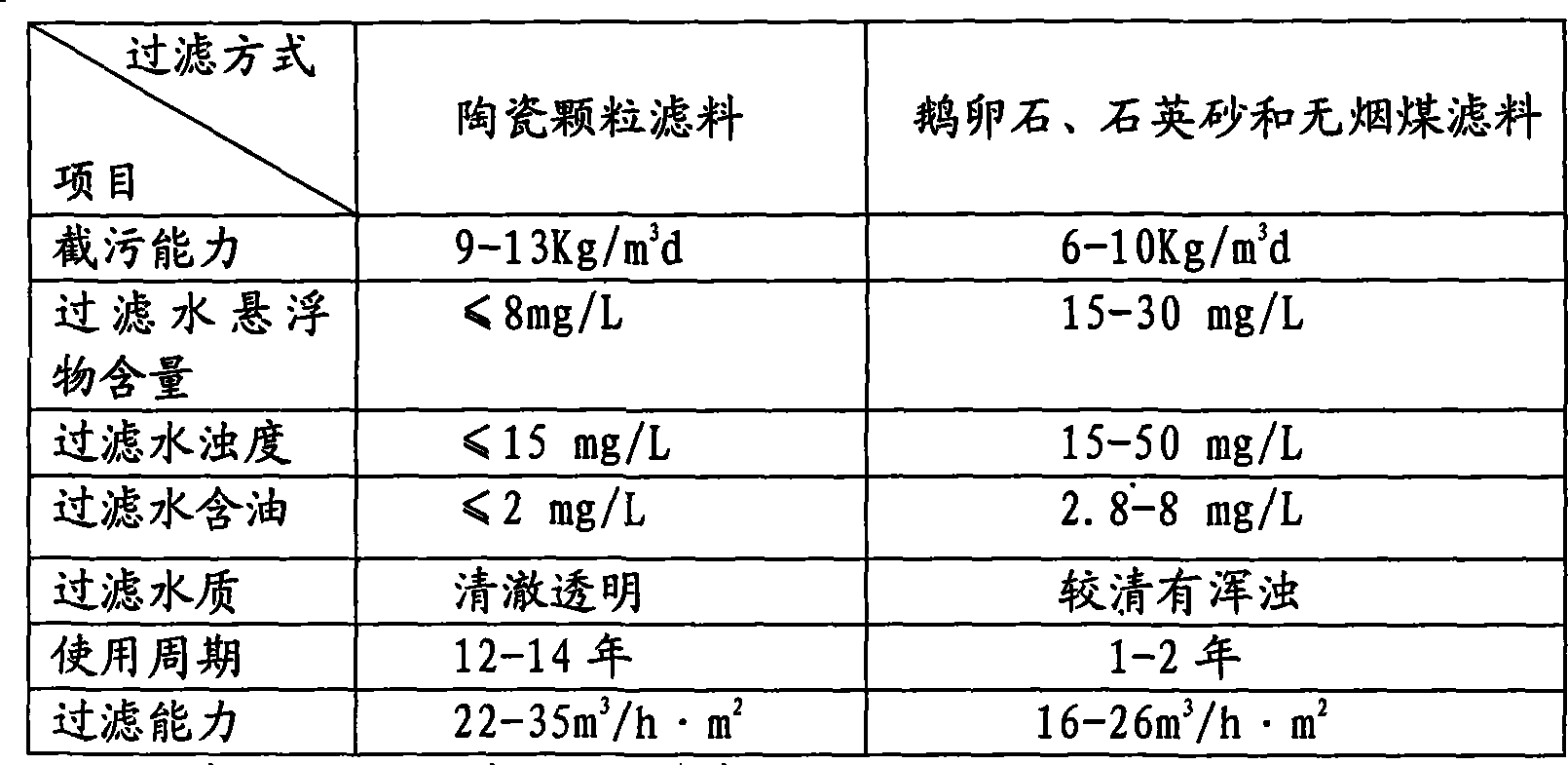

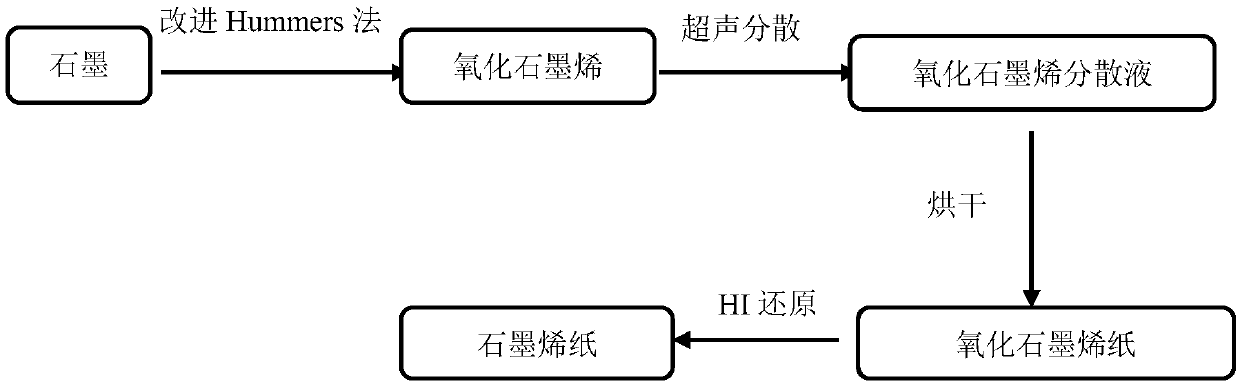

Technical method of applying filter material of ceramics granules to treating wastewater from iron and steel industry

InactiveCN101092255AHigh compressive strengthHigh hardnessWaste water treatment from metallurgical processWater/sewage treatment by sorptionWater qualityIron industry

This invention discloses a method for utilizing granular ceramic filter materials in treating wastewater of iron and steel industry. The method comprises: filling granular ceramic filter materials into the filtration tank of treatment apparatus of wastewater of iron and steel industry, performing a first time sedimentation and a second time advection sedimentation on wastewater of iron and steel industry, sending into the filtration tank from the top, intercepting and adsorbing by the granular ceramic filter material, separating water and pollutants, and discharging clear water. The granular ceramic filter materials comprise haydite filter material, porcelain sand filter material, and ceramic ball filter material. The method utilizes granular ceramic filter materials to replace oval, quartz sand and anthracite filter materials, and thus has such advantages as simple process, low production cost, high treatment efficiency, good working environment, good filtration and purification effect, clear filtered water, long filter material usage cycle, low yearly filter material cost (saved by 40-50%), high filtration and sewage interception ability (raised by more than 30%), and zero wastewater discharge.

Owner:王福绵

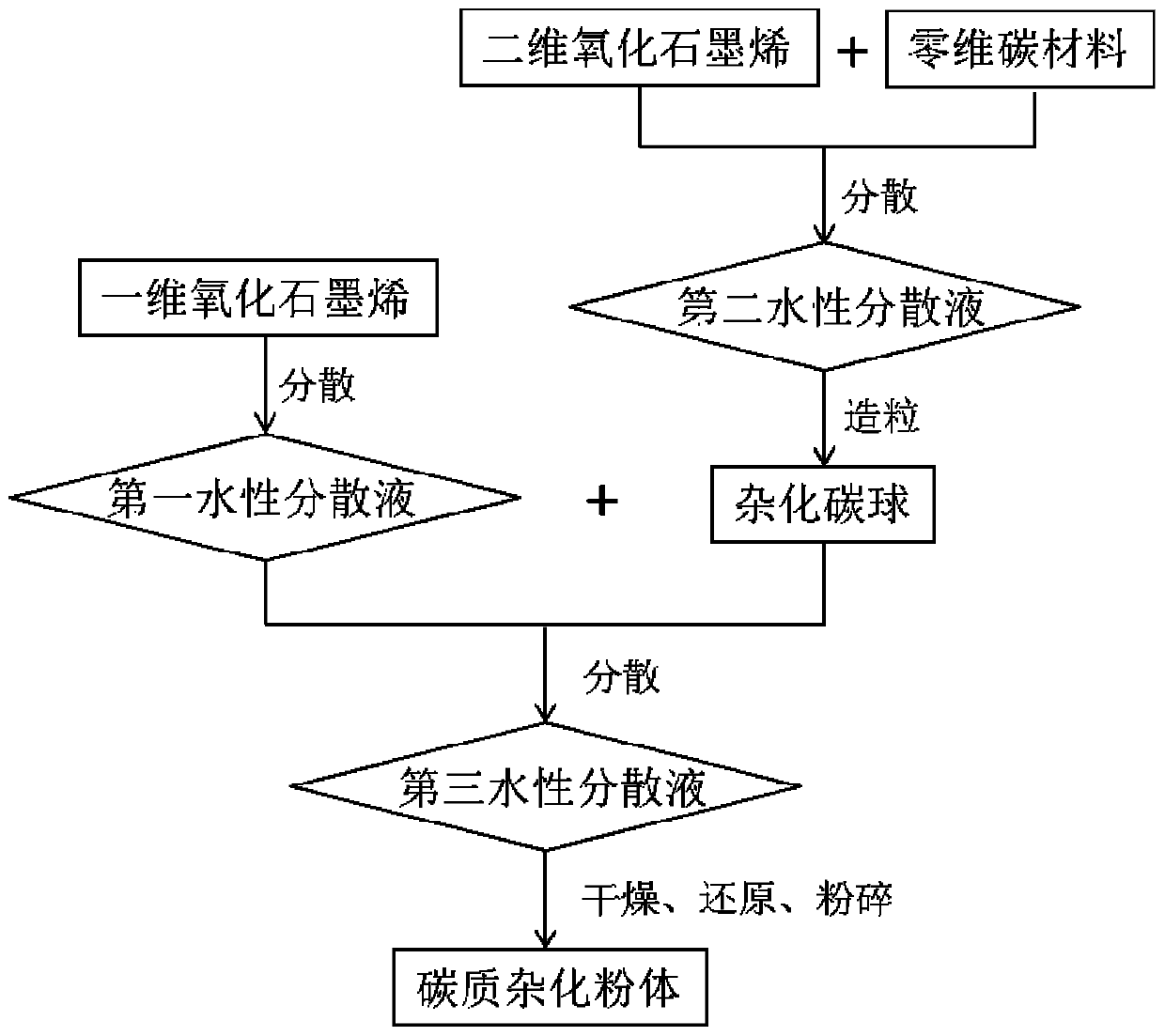

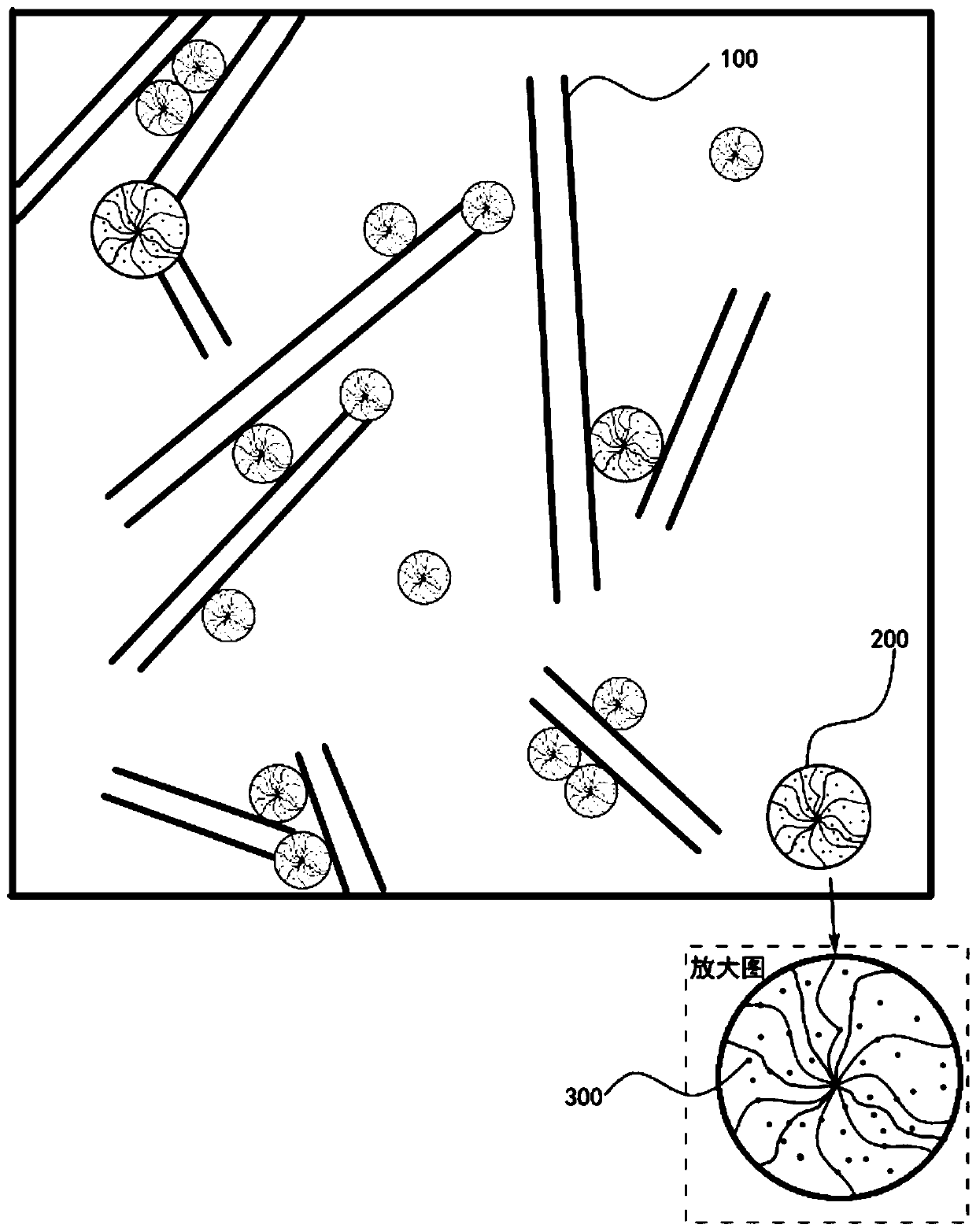

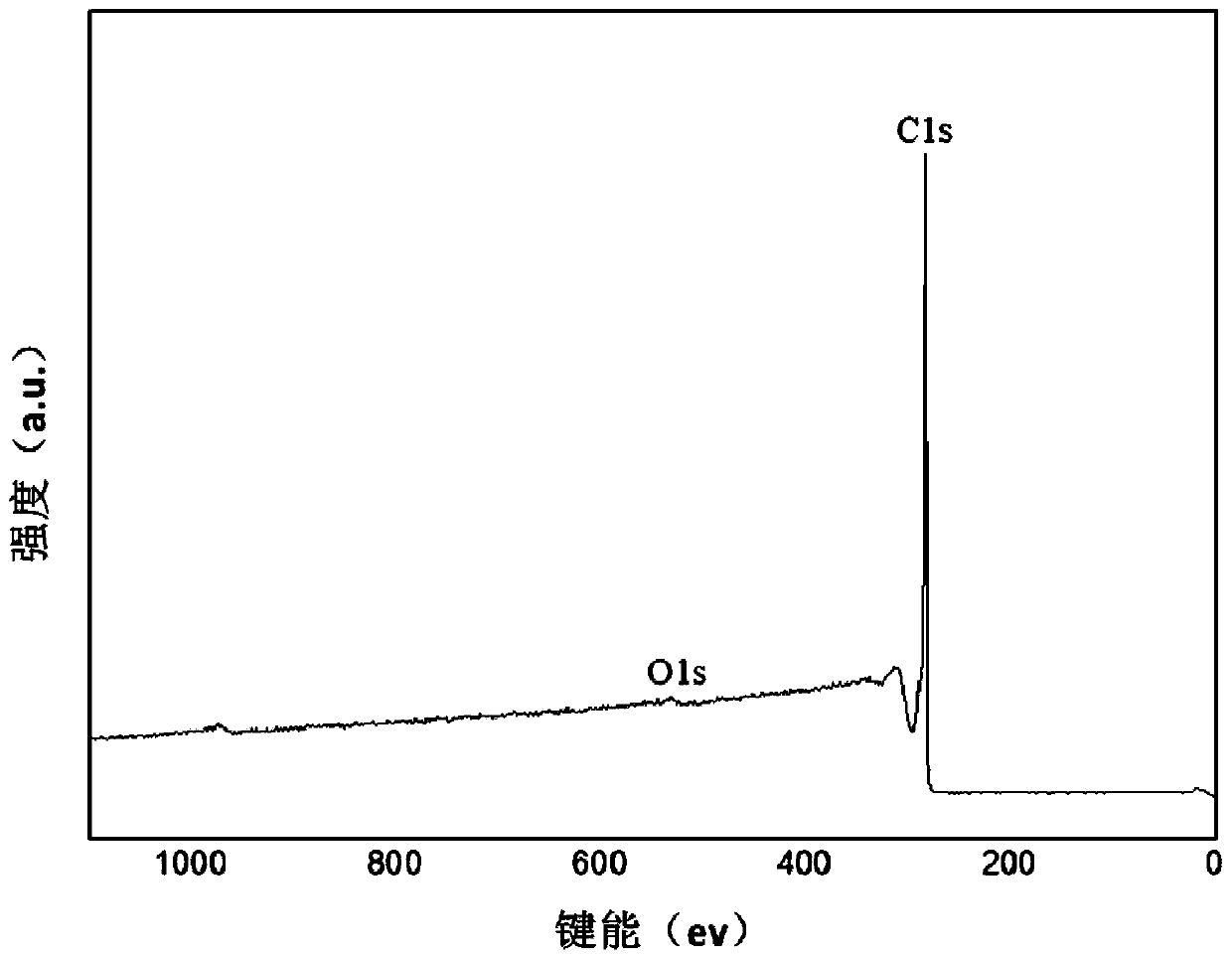

Carbonaceous hybrid powder and preparation method thereof

PendingCN111470491AThe process is non-toxicStable structureMaterial nanotechnologyCarbon compoundsCarbon nanotubeEngineering

The invention provides carbonaceous hybrid powder and a preparation method thereof. The method comprises the steps that: dispersing one-dimensional carbon nanotubes in water to obtain a first aqueousdispersion liquid; mixing two-dimensional graphene oxide with a zero-dimensional carbon material, dispersing an obtained mixture in water to obtain a second aqueous dispersion liquid, and performing solvent removal granulation on the second aqueous dispersion liquid to obtain hybrid carbon spheres; dispersing the hybrid carbon spheres in the first aqueous dispersion liquid to obtain a third aqueous dispersion liquid; and carrying out drying, reduction and crushing treatment on the third aqueous dispersion liquid to obtain the carbonaceous hybrid powder. The method is simple in process, environmentally friendly, free of pollution and suitable for industrial large-scale production, and the obtained carbonaceous hybrid powder is stable in structure and excellent in performance and has good application prospects.

Owner:北京石墨烯研究院有限公司

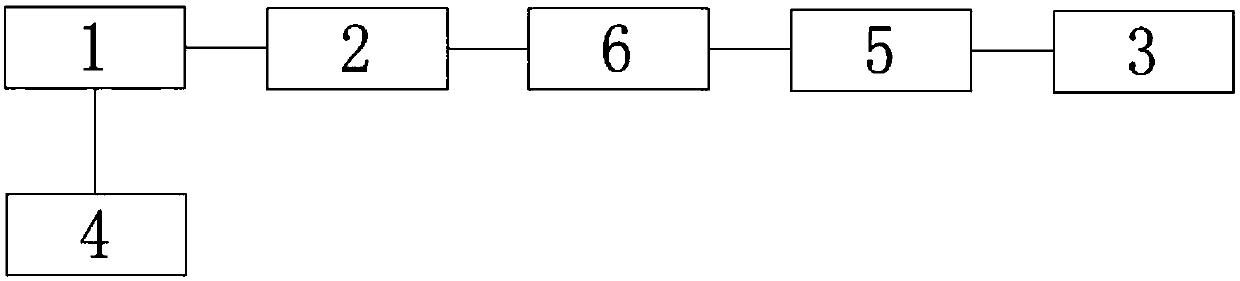

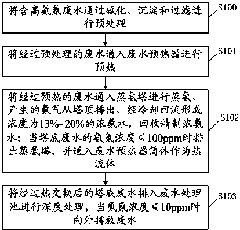

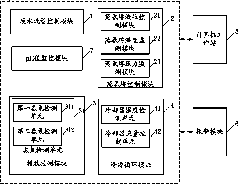

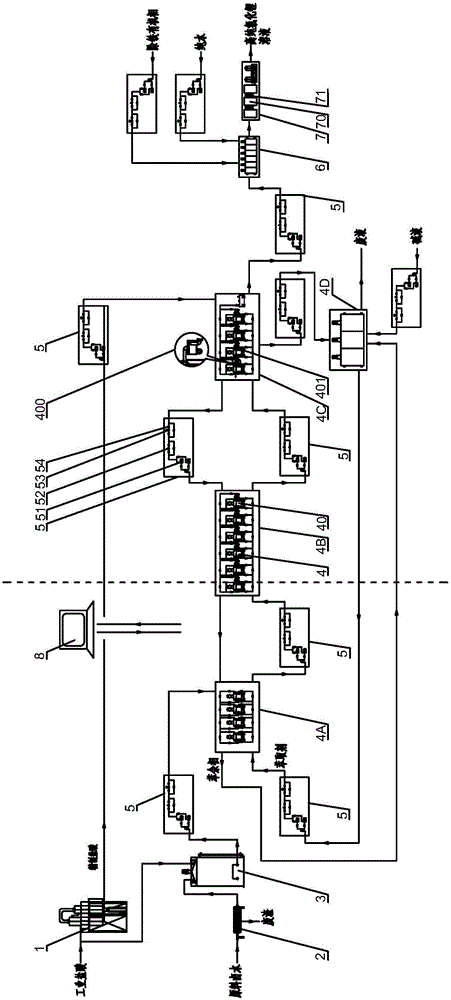

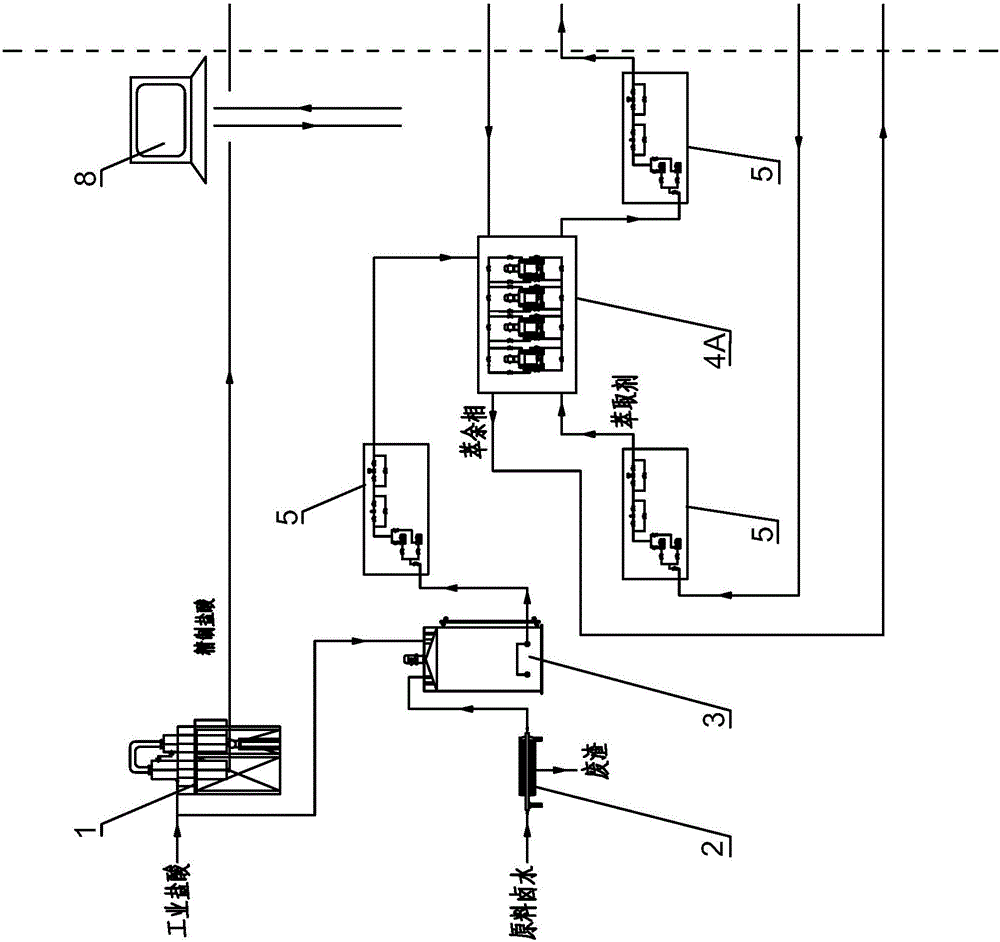

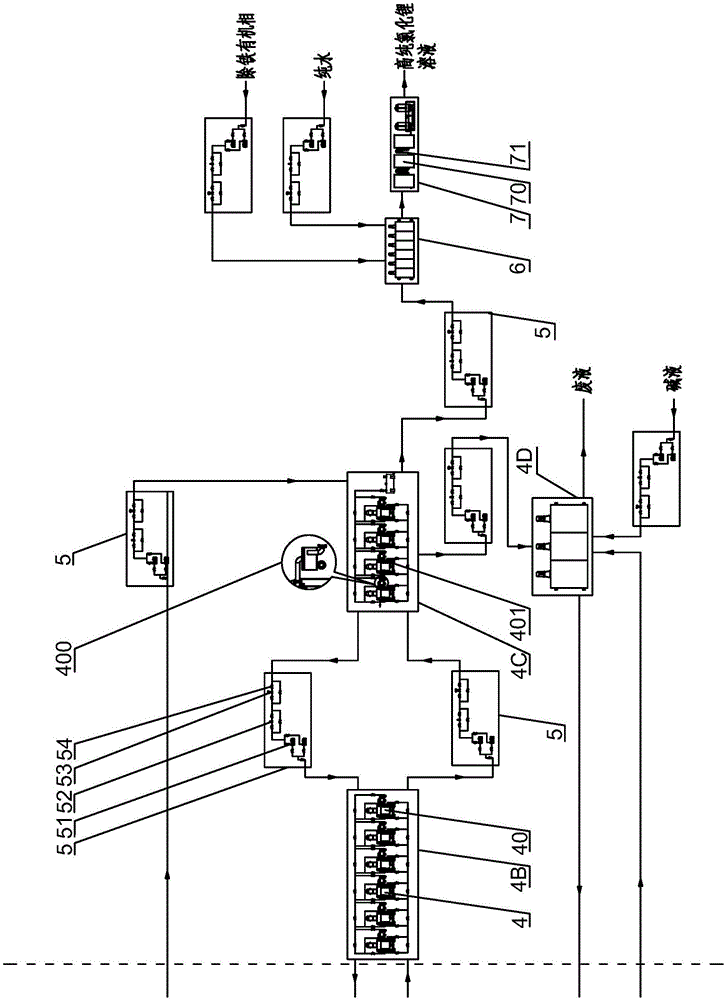

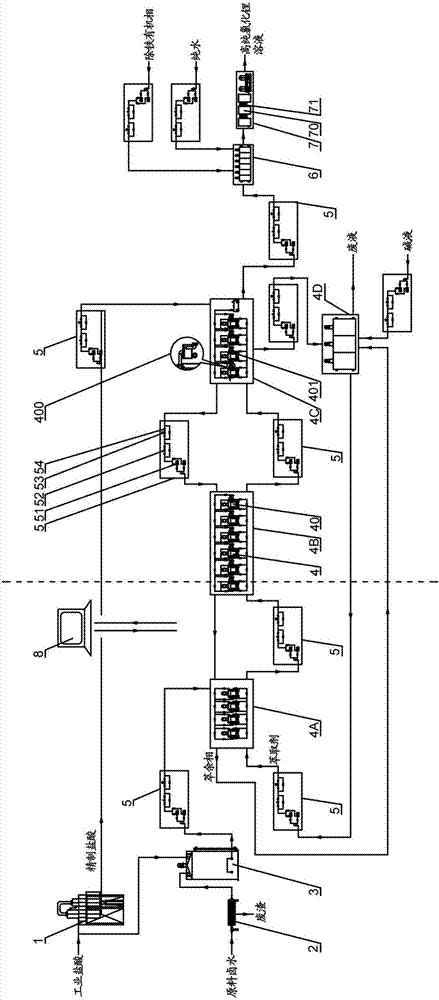

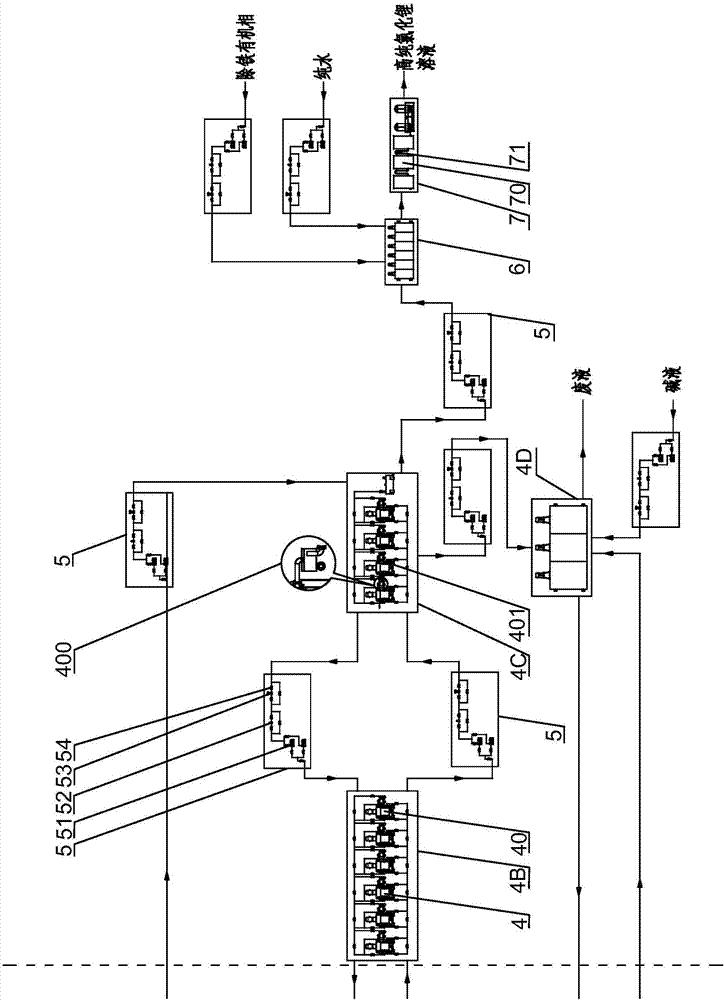

Monitor system of resource utilization of wet method rare earth smelting high ammonia-nitrogen wastewater

ActiveCN103991996AThe process flow is normalStable process flowWaste water treatment from metallurgical processMultistage water/sewage treatmentDistillationResource utilization

The invention discloses a monitor system of resource utilization of wet method rare earth smelting high ammonia-nitrogen wastewater, and the monitoring system comprises the following modules: a wastewater flow control module used to control flow of flowing-in wastewater; an ammonia distillation tower control module used for monitoring the ammonia distillation tower liquid level, temperature and pressure; a discharge control module using ammonia nitrogen detection units arranged at the ammonia distillation tower bottom and a comprehensive treatment tank to detect ammonia nitrogen concentration in wastewater and controlling a lift pump to discharge the wastewater; a cold source circulating module used for real-time monitoring of cooler wastewater temperature and cooler liquid level and control of discharge value of two outlet of a cooler; and a computer workstation which is respectively connected with the wastewater flow control module, the ammonia distillation tower control module, the discharge control module and the cold source circulating module for acquisition and display of process data and process information; when the process data and process information cannot be acquired or exceed thresholds, an information alarm is generated. The monitor system can strengthen the wastewater discharge and cold source circulation control and realize the monitoring of the whole process of recovery.

Owner:GUANGDONG XINTAILONG ENVIRONMENTAL PROTECTION GRP CO LTD

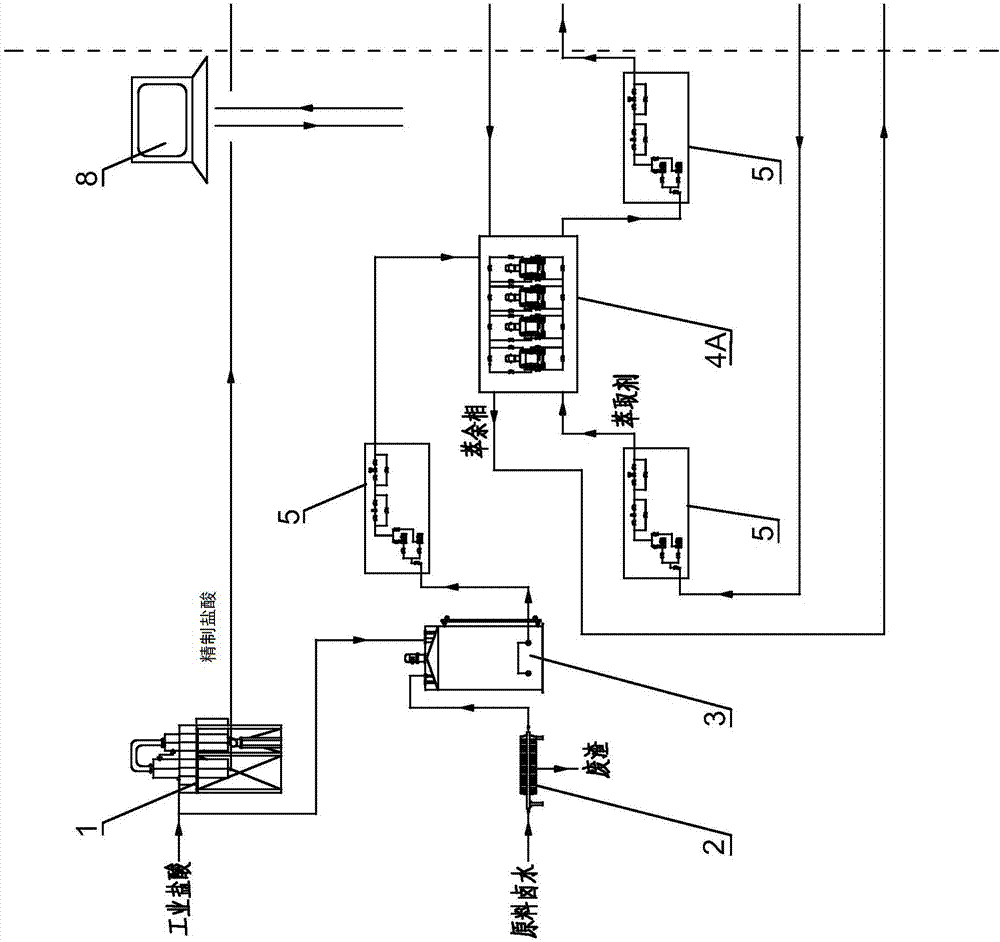

High-purity lithium chloride extraction device

ActiveCN106219579AImprove extraction efficiencyPhase equilibrium establishment time is fastLithium halidesSolventChemistry

The invention discloses a high-purity lithium chloride extraction device. The high-purity lithium chloride extraction device comprises a filter press, a blending tank, an extraction system, a washing system, a reverse extraction system, a deironing system and an oil removal system which are sequentially connected through a pipeline, the blending tank is used for acid regulating treatment, and the extraction system, the washing system and the reverse extraction system are respectively formed by connecting multiple stages of centrifugal extractors in series. The reverse extraction solution outlet end of the reverse extraction system is connected with the washing system, the organic phase output end of the reverse extraction system is connected with a saponification system, and the saponification system is connected with the extraction system. A circulating loop is formed by the extraction system, the washing system, the reverse extraction system and the saponification system. The device is further provided with a data analysis system, and the work positions of the abnormal centrifugal extractors can be automatically switched to a standby centrifugal extractor through the system. Variable-frequency closed-loop flow control systems are arranged at the material input ends of all the systems in the circulating loop for obtaining the precise flow-input phase ratio through timely adjustment. The device is high in extraction efficiency, short in phase balance setting time, small in solvent needing amount, low in solvent consumption and continuous and reliable in process.

Owner:HEFEI GENERAL MACHINERY RES INST

High-purity lithium chloride production technology

The invention discloses a high-purity lithium chloride production technology. An apparatus in the production technology comprises a filter press, a blending pot for acid adjusting treatment, an extraction system, a washing system and a back-extraction system connected by the multistage centrifugation extraction machines in series respectively, an iron-removal system and an oil removing system which are connected in order through the pipelines, wherein, an output terminal of a back extraction solution of the back-extraction system is connected with the washing system, an organic phase output terminal of the back-extraction system is connected with a saponification system, the saponification system is connected with the extraction system; and the extraction system, the washing system, the back-extraction system and the saponification system form a circulation loop. The apparatus also comprises a data analysis system capable of switching an abnormal centrifugation extraction machine station to a backup centrifugation extraction machine. A frequency-conversion closed loop flow control system is arranged at a material input of each system of the circulation loop, and the accurate flowing and input phase ratio can be obtained by appropriate adjusting. The apparatus has the advantages of high extraction efficiency, fast establishing time for phase equilibrium, small solvent required amount, small consumption of a solvent, and continuous and reliable processes.

Owner:HEFEI GENERAL MACHINERY RES INST

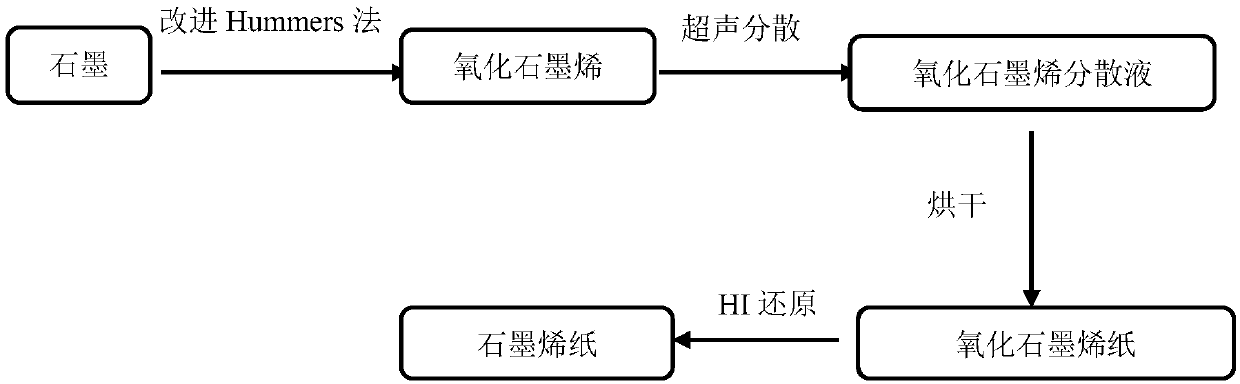

Method for preparing large-area graphene paper by utilizing hydroiodic acid

The invention provides a method for preparing large-area graphene paper by utilizing hydroiodic acid. The method comprises the following steps: (1) preparing oxidized graphene by utilizing an improved Hummers method; (2) dispersing the oxidized graphene prepared in the step (1) in deionized water with ultrasonic to form uniformly dispersed oxidized graphene solution, and drying the oxidized graphene solution to obtain oxidized graphene paper; (3) putting the oxidized graphene paper obtained in the step (2) in a glass-substrate container; and (4) washing the reactant with deionized water after the reducing reaction is completed, and drying to obtain the large-area graphene paper. The method can be used for simply and quickly preparing graphene paper by utilizing hydroiodic acid reducing culture dish and other glass-substrate oxidized graphene paper, has simple, efficient, stable and controllable process flow, has the cost far lower than those of conventional graphene paper preparation methods, and has a wide application value in supercapacitors, electrodes, optoelectronic devices and the like.

Owner:SOUTHEAST UNIV

Technical method of applying filter material of ceramics granules to treating wastewater from iron and steel industry

InactiveCN100519430CHigh compressive strengthHigh hardnessWaste water treatment from metallurgical processWater/sewage treatment by sorptionFiltrationWater quality

The invention discloses a process method for the application of ceramic particle filter material in the iron and steel industry wastewater treatment. In the filter tank of the iron and steel industry wastewater treatment device, the ceramic particle filter material is filled, and the ceramic particle filter material includes ceramsite filter material, porcelain sand The filter material and the ceramic ball filter material are filled in the filter tank in layers from top to bottom. The wastewater from the iron and steel industry enters from the upper end of the filter tank after the first sedimentation and the second advection sedimentation. Through the interception and adsorption of the ceramic particle filter material, the water Separation from suspended pollutants to discharge clear water. Using ceramic particle filter material instead of cobblestone, quartz sand and anthracite filter material in the past not only simplifies the process flow, reduces the cost of production, improves the processing efficiency, and improves the working environment; but also has a good filtration and purification effect, and the filtered water quality is clear without turbidity. Although the one-time filling cost is high, the service life of the filter material is increased by at least 6 times, the annual cost of the filter material is 40-50% lower than the annual cost of the traditional filter material, and the wastewater treatment and filtration interception capacity is increased by more than 30%. Zero discharge of waste water can be realized.

Owner:王福绵

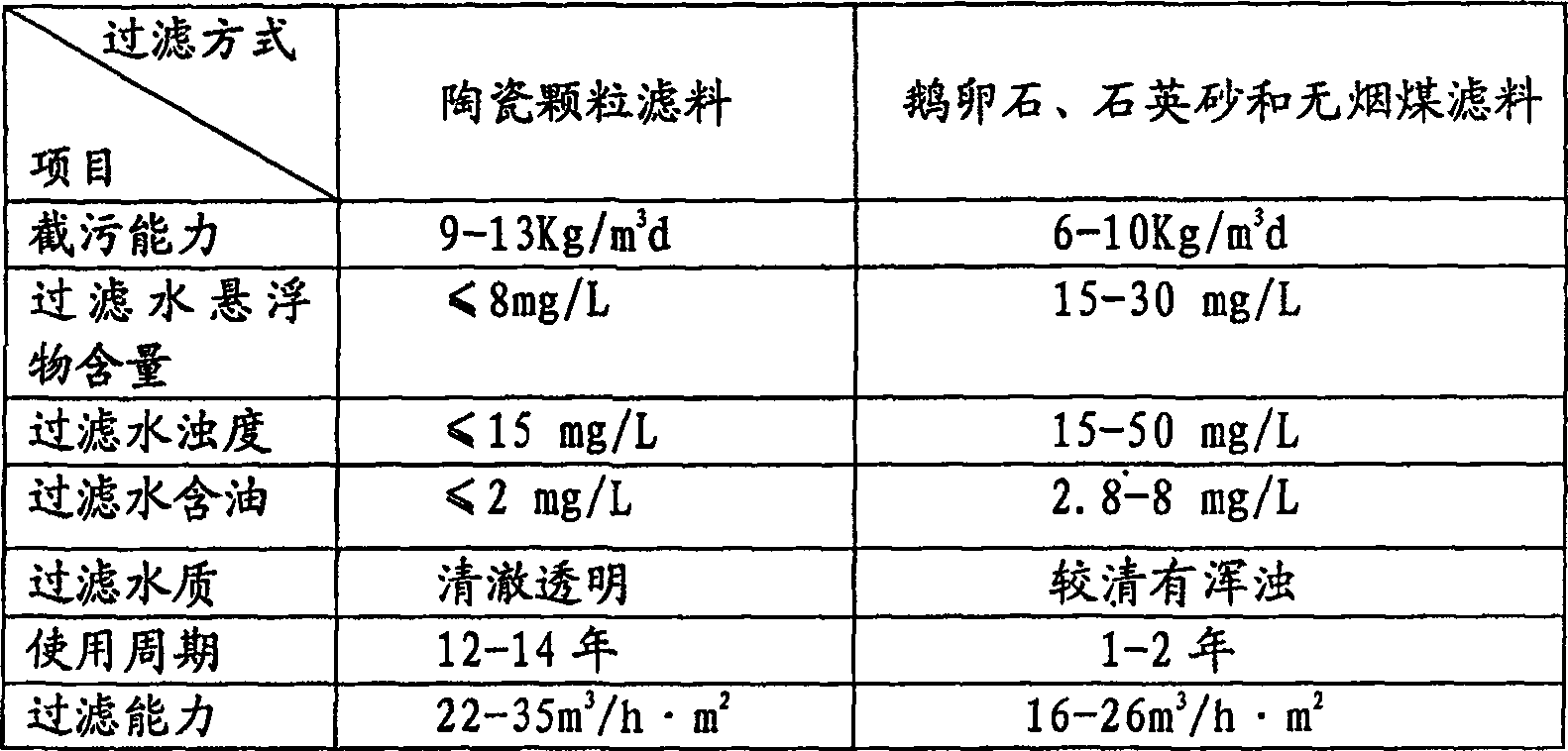

Oily sewage all-in-one processing apparatus

InactiveCN104230038ACompact structureGood degreasing effectMultistage water/sewage treatmentWalnut NutDemulsifier

The invention relates to an oily sewage all-in-one processing apparatus. The apparatus is arranged on an integrated pedestal and contains a water inlet, a demulsifier dosing device, a flocculating agent dosing device, a dosing device control cabinet, a CPI degreaser, an air floatation inflow lift pump, a DAF dissolved air flotation, a middle water tank, a walnut shell filter, an activated carbon filter and a water outlet. The CPI degreaser, the DAF dissolved air flotation, the walnut shell filter and the activated carbon filter are connected successively. The water inlet is communicated to the CPI degreaser through a pipeline which is provided with the demulsifier dosing device. The CPI degreaser is communicated to the DAF dissolved air flotation, an inlet of which is provided with the flocculating agent dosing device. The oily sewage all-in-one processing apparatus has advantages of compact structure, good degreasing effect, small floor area, convenient usage and stable operation.

Owner:扬州绿都环境工程设备有限公司

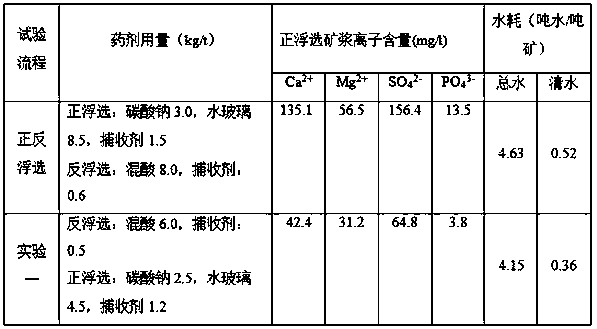

Reverse-direct flotation method for siliceous-calcareous collophanite

The invention relates to a reverse-direct flotation method for siliceous-calcareous collophanite. According to the method, after raw ore is ground, a flotation process sequentially comprising reverseflotation magnesium removal and direct flotation desilicication operation is adopted, reverse flotation return water enters a reverse flotation water return pool and then returns to reverse flotationmagnesium removal so as to be used, direct flotation return water enters a direct flotation water return pool and then returns to direct flotation desilicication operation, and surplus direct flotation return water is fed into the reverse flotation water return pool so as to be used for reverse flotation. According to the invention, with the method, water can be saved, all wastewater can be recycled, and the treatment cost is low; by using a flotation process sequentially comprising reverse flotation and direct flotation, less water is needed, and reverse flotation return water enters the reverse flotation return water pool and then is reused for reverse flotation; and on the premise that the indexes of the concentrate yield, the grade and the recovery rate are similar to those in the prior art, the dosage of chemicals is small, the ion content of ore pulp in direct flotation operation is low, and water consumption is small.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

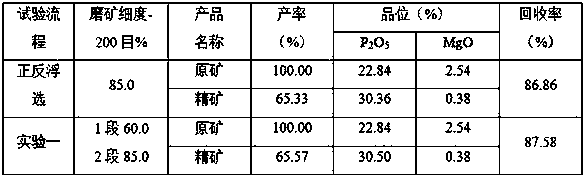

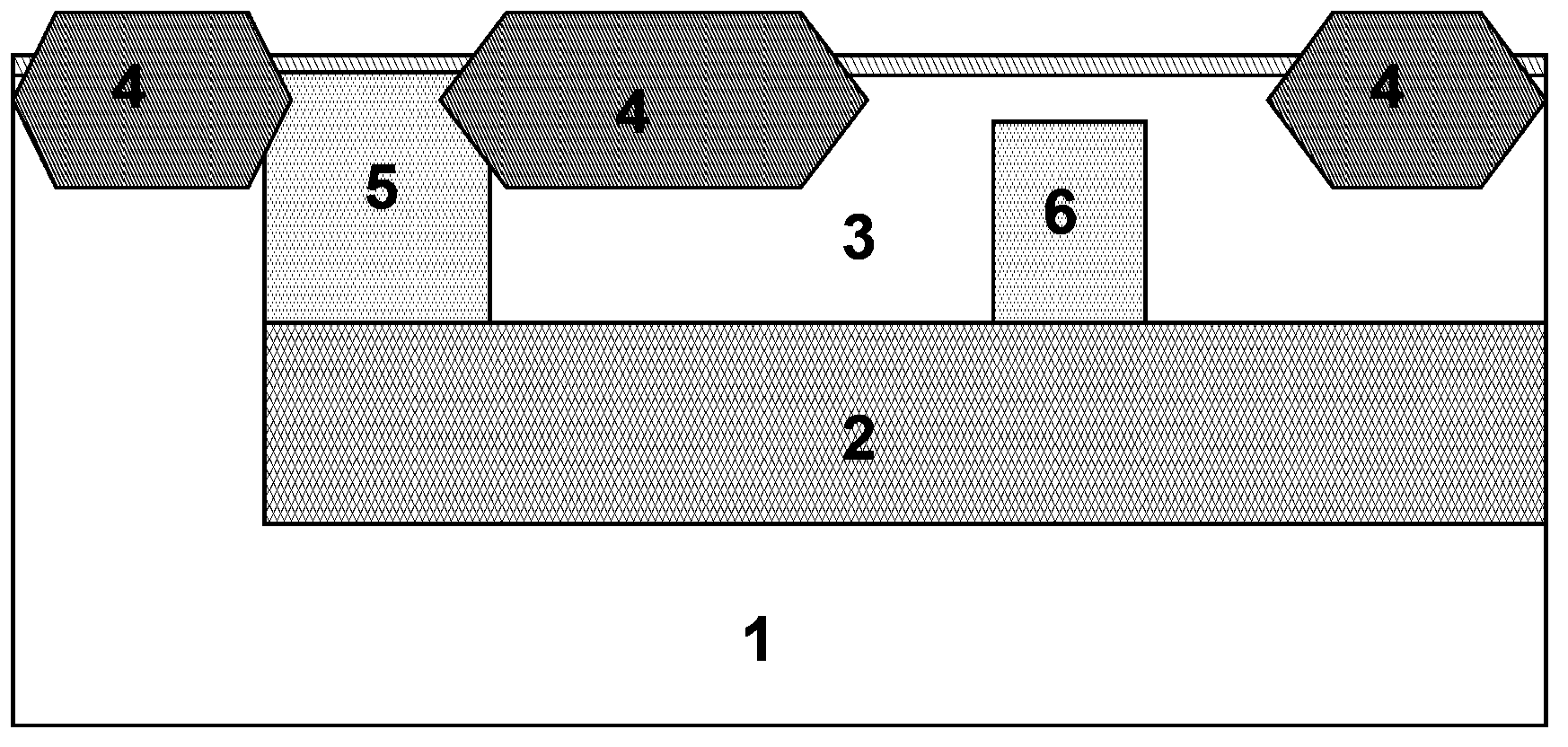

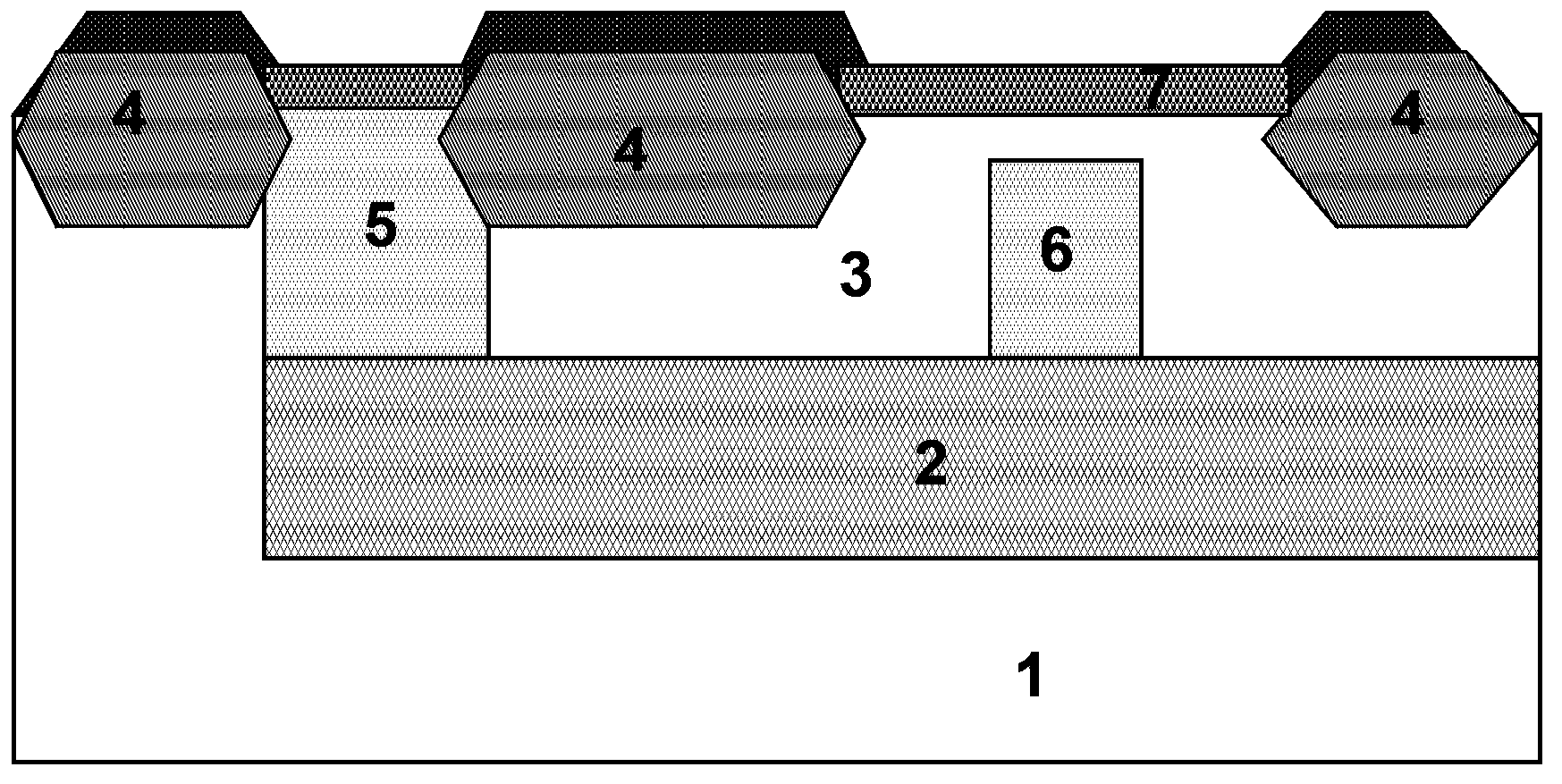

Manufacturing method of germanium-silicon heterojunction bipolar triode device

ActiveCN103456628AFlat thicknessLower resistanceSemiconductor/solid-state device manufacturingSurface cleaningHigh doses

The invention discloses a manufacturing method of a germanium-silicon heterojunction bipolar triode device. The method includes that a current collecting area is prepared by a low-doping N-type epitaxial process, a heavy N-type doped low-resistance buried layer passage is arranged at the bottom, and high-dose middle-energy N-type ions are injected in a current collecting electrode active area to form a current collecting electrode leading-out end; after an isolation area is formed, surface cleaning and growing of a germanium-silicon epitaxial layer of a thick buffering layer are performed, the germanium-silicon epitaxial layer outside a base area and an outer base area is defined by photoetching and removed by dry-etching; an emitting electrode window medium is deposited, an emitting electrode window and the whole current collecting electrode active area are opened by photoetching, dry-etching and wet-etching, N-type heavily-doped emitting electrode polysilicon is deposited, and an N-type emitting electrode-base electrode junction and a lower-resistance passage are formed. Polysilicon thickness of the outer base area is increased by adjusting thickness of the germanium-silicon buffering layer, so that resistance performance of the base area is guaranteed, process cost is lowered, and more stable technological process and higher product yield are acquired.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com