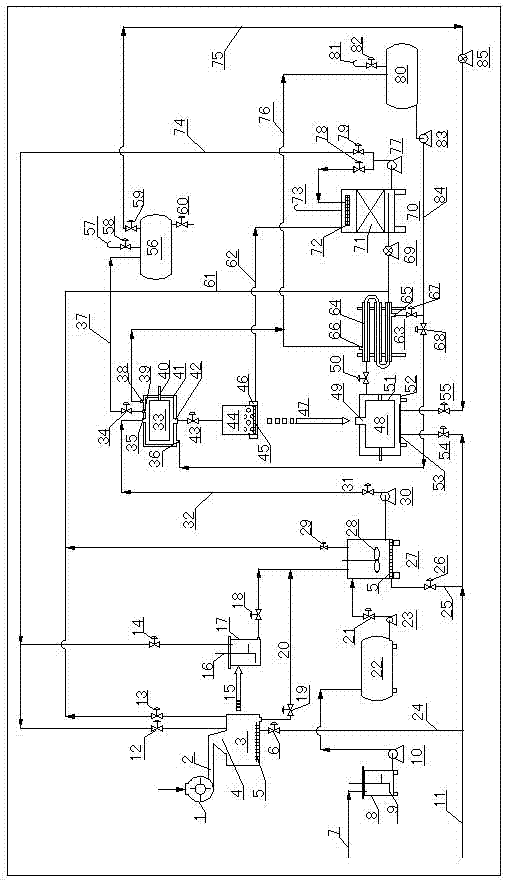

Low-emission solid organic waste treatment system realizing methane and active carbon production

A technology for the production of organic waste and activated carbon, which is used in biomass post-treatment, biomass pre-treatment, and solid waste removal to achieve the effects of rapid treatment, convenient transportation and installation, and reduced dependence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings, but the embodiments of the present invention are not limited thereto. Accompanying drawing is a kind of preferred form of technological scheme technological process of the present invention, and the operating process and principle of each unit device are as follows.

[0024] Raw material pretreatment unit: high-fiber wastes such as straw and gardens are physically crushed into segments smaller than 2 cm in the straw crusher 1, and the crushed materials pass through the material pipeline 2 and enter the material inlet 4 from the aerobic bioreactor I 3 Load into reactor I 3, the volume of the reactor is 80 L, and stay for 24-168 hours. The material after aerobic treatment is transported to the beater 17 with a volume of not less than 10 L through the material transfer device 15, and is pulped under the action of the stirring paddle 16. The pulped material passes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com