EPS foam article and production technology thereof

A production process and product technology, which is applied in the field of EPS foam products and its production process, can solve the problems of affecting the reliability of solenoid valve action, the accuracy of mechanical action, the large amount of instantaneous use, and the waste of water resources, etc., to shorten the drying time, Low apparent density and low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

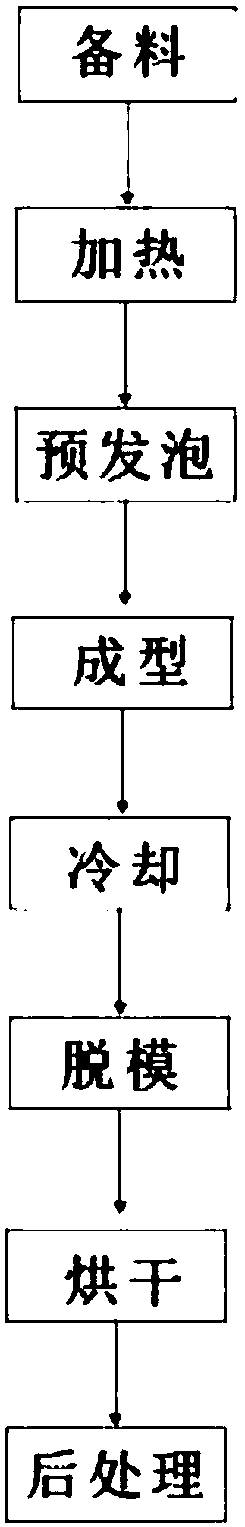

Method used

Image

Examples

Embodiment 1

[0034] The invention discloses an EPS foam product, which comprises EPS raw material and foaming agent, the mass of the foaming agent is 4.5% of the mass of the EPS raw material, and the EPS foam product is prepared from the EPS raw material under the action of the foaming agent . The particle size of the EPS raw material is 0.6 mm. The blowing agent is n-pentane.

Embodiment 2

[0036] The invention discloses an EPS foam product, which comprises EPS raw material and foaming agent, the mass of the foaming agent is 6% of the mass of the EPS raw material, and the EPS foam product is prepared from the EPS raw material under the action of the foaming agent . The particle size of the EPS raw material is 0.7 mm. The blowing agent is isopentane.

Embodiment 3

[0038] The invention discloses an EPS foam product, which comprises EPS raw material and foaming agent, the mass of the foaming agent is 7% of the mass of the EPS raw material, and the EPS foam product is prepared from the EPS raw material under the action of the foaming agent . The particle size of the EPS raw material is 0.5 mm. The blowing agent is n-pentane or isopentane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com