Autoclaving-free light ultra-high-performance concrete and preparation method thereof

An ultra-high performance, concrete technology, applied in the field of building materials, can solve the problems of the size and self-weight of prefabricated bridge components, difficult transportation and hoisting, low apparent density, etc. The effect of apparent density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

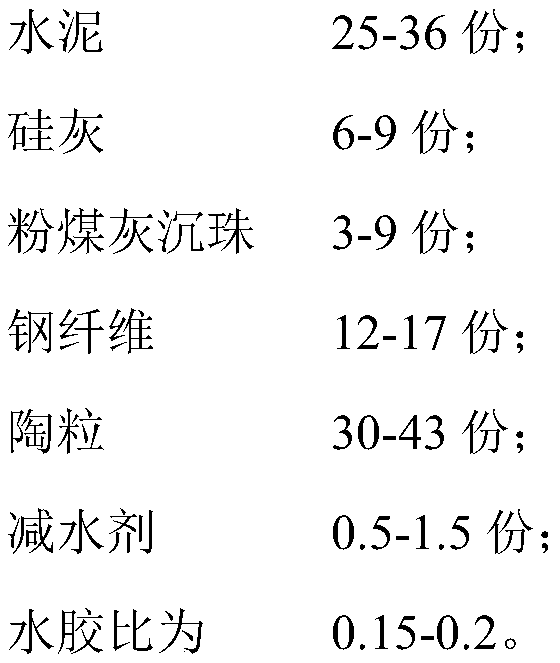

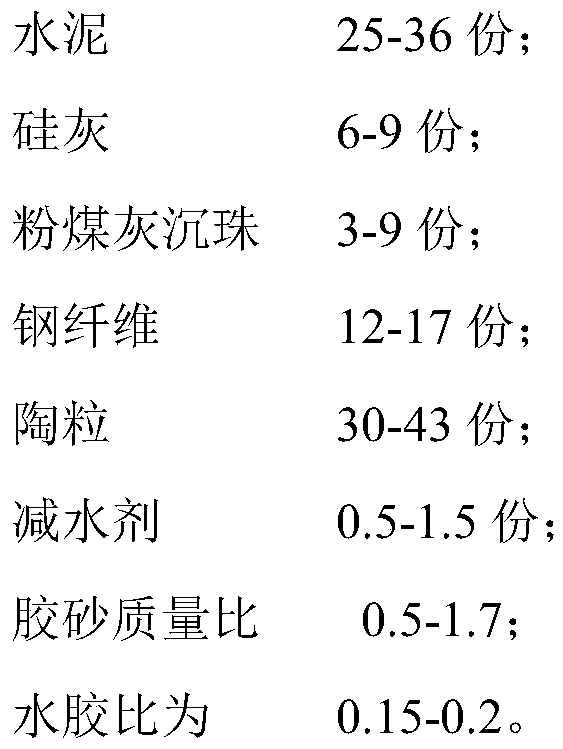

[0031] Example 1 Calculation of the cementitious material mix ratio according to the closest packing theory

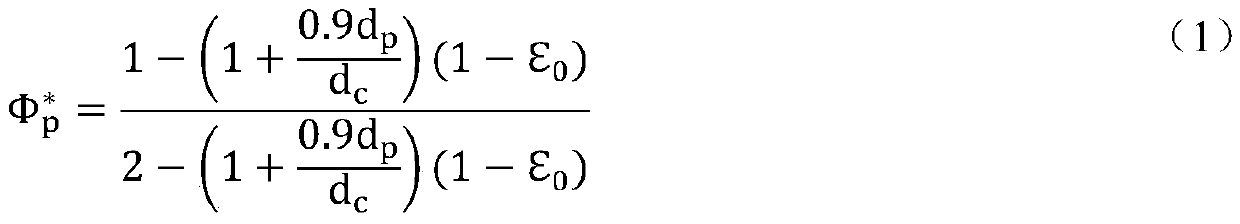

[0032] According to the closest packing theory, the maximum packing density of cement-silica fume-fly ash ternary system is calculated by Aim-Goff model and its relative mass fraction is determined, and the maximum packing density is calculated according to Aim-Goff model. At this time, pozzolanic materials The maximum volume fraction Φ of p * It can be calculated with (1):

[0033]

[0034] ① among Φ p p * , the packing density Φ of the system can be calculated by formula (2):

[0035]

[0036] ② among Φ p >Φ p * , the packing density Φ of the system can be calculated by formula (3):

[0037]

[0038]In the formula: dp is the average particle size of pozzolanic particles; dc is the average particle size of cement particles; Φp is the volume fraction of pozzolanic materials; ε0 is the porosity of a single material. Finally, the bulk density of the cem...

Embodiment 2

[0039] Embodiment 2 Calculation of ceramsite gradation

[0040] Calculation principle of ceramsite gradation: The fineness and gradation of aggregate have a great influence on the porosity of concrete, so improving the gradation of aggregate particles can improve the mechanical properties of concrete. The aggregate gradation is calculated by the modified Andreasen&Andersen method, which considers the gradation of the largest and smallest particle sizes, and the expression is:

[0041]

[0042] In the formula: p' is the mass fraction of all aggregate particles with a particle size smaller than d; d min , d max are the smallest particle size and the largest particle size, q is the distribution modulus, the value is 0.23, the range of ceramsite particles is 0.15mm-2.00mm, and the particle sizes of five different particle sizes of shale ceramsite are 10-20 mesh , 20-40 mesh, 40-60 mesh, 60-80 mesh, 80-100 mesh. Through calculation, the mass ratio of shale ceramsite with five...

Embodiment 3

[0045] Steam-cured lightweight ultra-high performance concrete includes the following components by weight: 32 parts of cement; 8 parts of silica fume; 4 parts of fly ash sinking beads; 13 parts of steel fiber, 43 parts of pre-wet ceramsite, and 0.5 The cementitious materials are cement, silica fume, and fly ash, and the mass ratio between them is 1:0.25:0.125 based on the maximum bulk density; the water-binder ratio is 0.18. Among them, the cement used is ordinary Portland cement with P.O 52.5; the specific surface area of silica fume used is 18000m 2 / kg, SiO 2 The content is 90%; the density of fly ash beads used is 2.5g / cm 3 , bulk density 0.7kg / m 3 The steel fiber used is copper-plated steel fiber, with a diameter of 0.22mm, a length of 13mm, and a compressive strength of 2850MPa; the ceramsite used is a mixture of five different particle sizes of shale ceramsite, and the bulk density is 800-1900kg / m 3 , the particle size range is 0.15mm~2.00mm, and the particle size...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com