Oily sewage all-in-one processing apparatus

A treatment device and an integrated machine technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems that cannot meet the production needs of enterprises, the sewage cannot be directly discharged, and the adsorption effect is poor and other problems, to achieve the effect of compact structure, small footprint and stable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

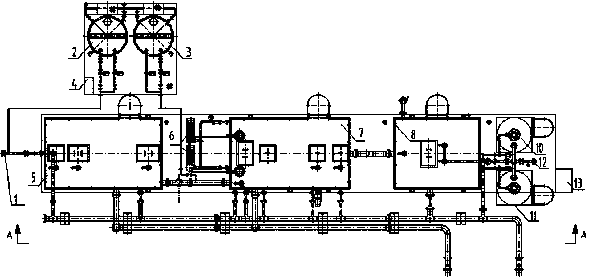

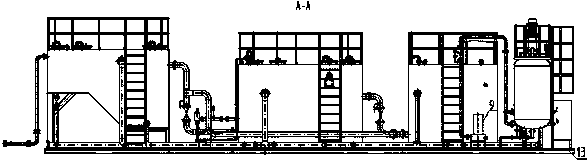

[0010] Oily sewage integrated machine treatment device, the device is set on the integrated base 13, which includes water inlet 1, demulsifier dosing device 2, flocculant dosing device 3, dosing device control cabinet 4, CPI degreaser 5, Air flotation water inlet lifting pump 6, DAF dissolved air flotation 7, intermediate water tank 8, filter lifting pump 9, walnut shell filter 10, activated carbon filter 11 and water outlet 12, the CPI oil remover 5, DAF Dissolved air flotation 7, walnut shell filter 10 and activated carbon filter 11 are connected successively, and described water inlet 1 is communicated with CPI degreaser 5 through pipeline, and this pipeline is provided with demulsifier dosing device 2; The CPI degreaser 5 is connected to the DAF dissolved air flotation 7, and the inlet of the DAF dissolved air flotation 7 is provided with a flocculant dosing device 3, and the treatment device also includes a dirty oil sludge tank, and the CPI degreaser The oiler 5 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com