Patents

Literature

282 results about "Dissolved air flotation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

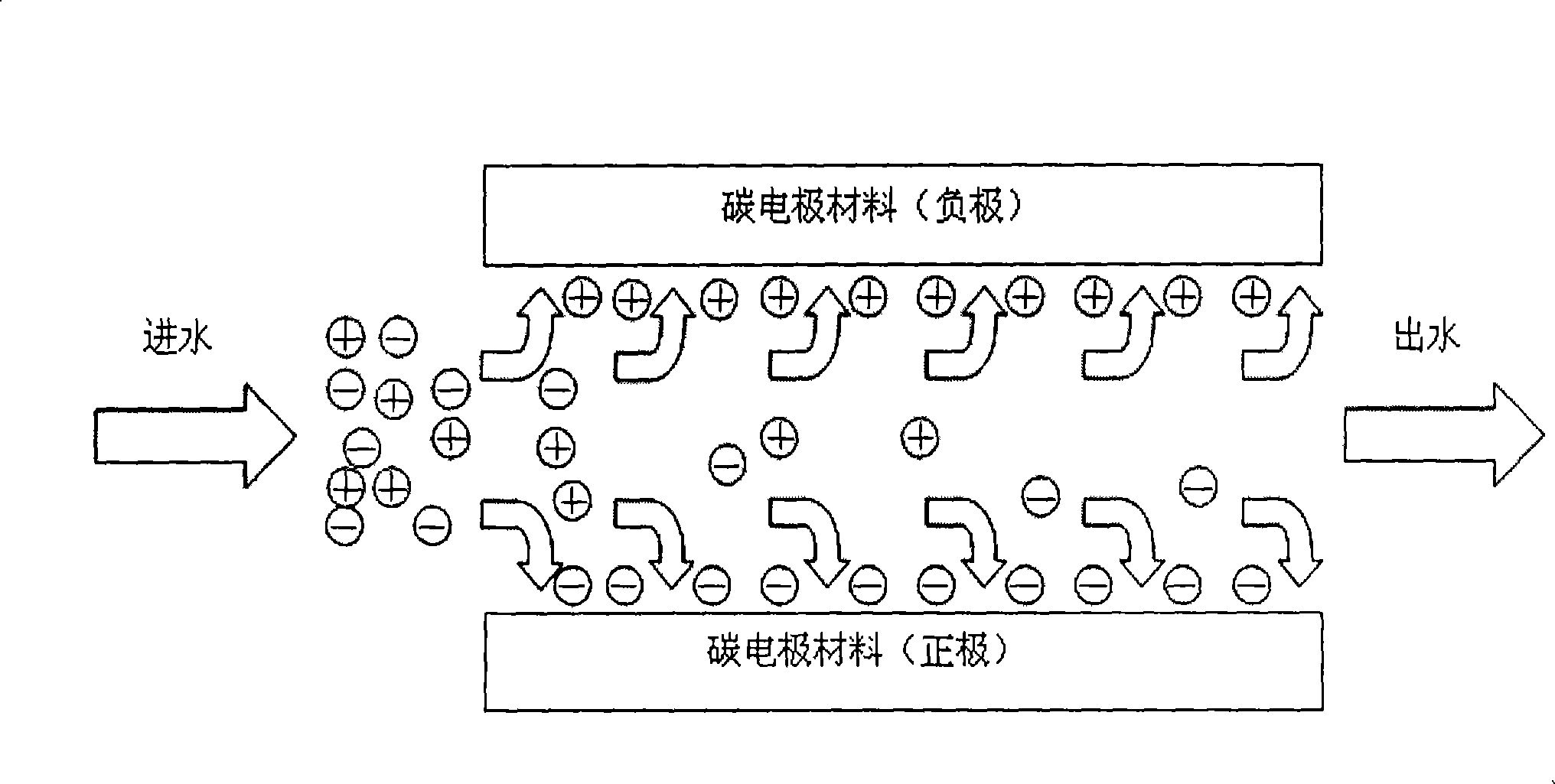

Dissolved air flotation (DAF) is a water treatment process that clarifies wastewaters (or other waters) by the removal of suspended matter such as oil or solids. The removal is achieved by dissolving air in the water or wastewater under pressure and then releasing the air at atmospheric pressure in a flotation tank basin. The released air forms tiny bubbles which adhere to the suspended matter causing the suspended matter to float to the surface of the water where it may then be removed by a skimming device.

Methods for removing heavy metals from water using chemical precipitation and field separation methods

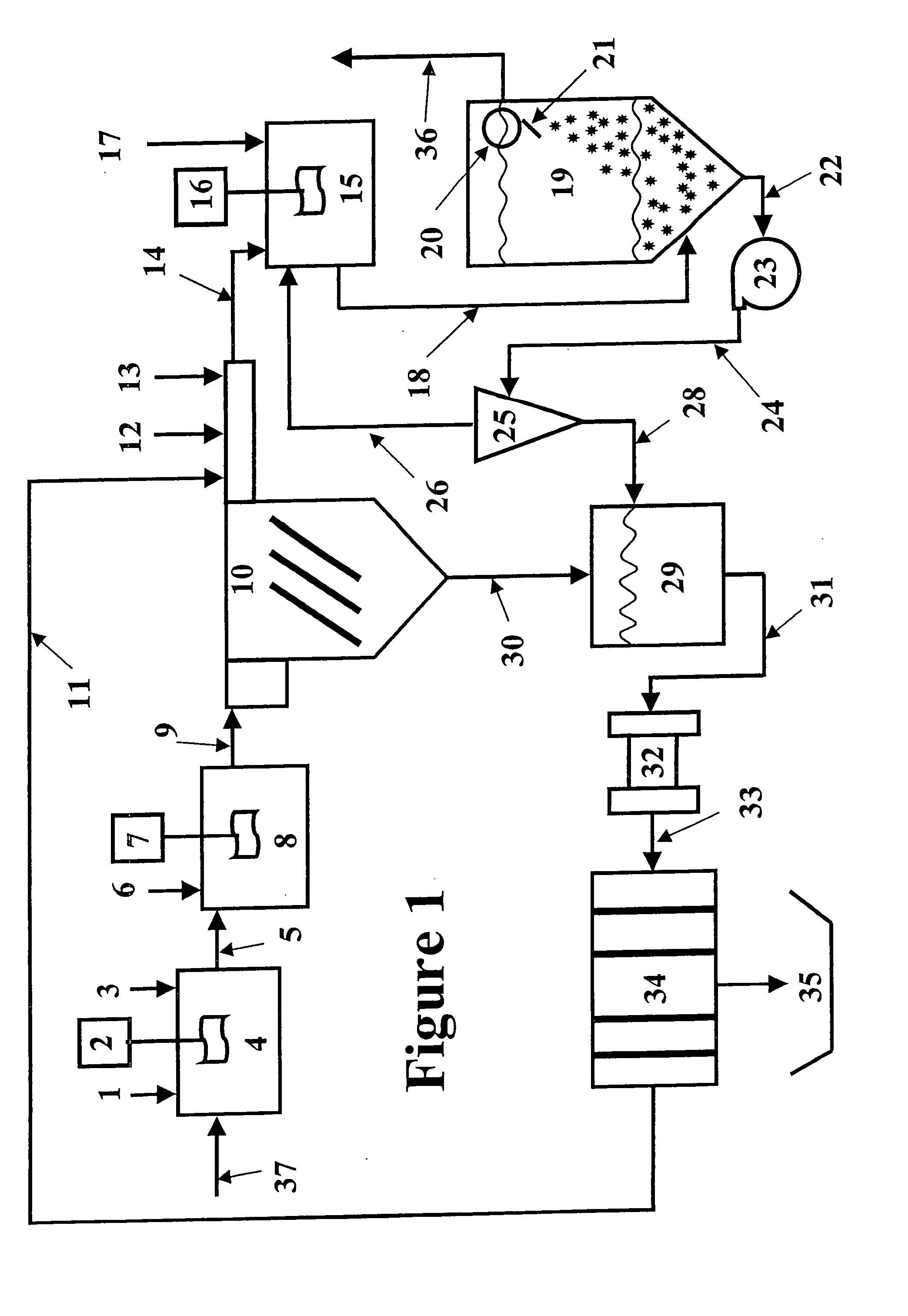

InactiveUS20050258103A1Efficient removalEasy to disassembleSedimentation separationDifferential sedimentationParticulatesSulfide

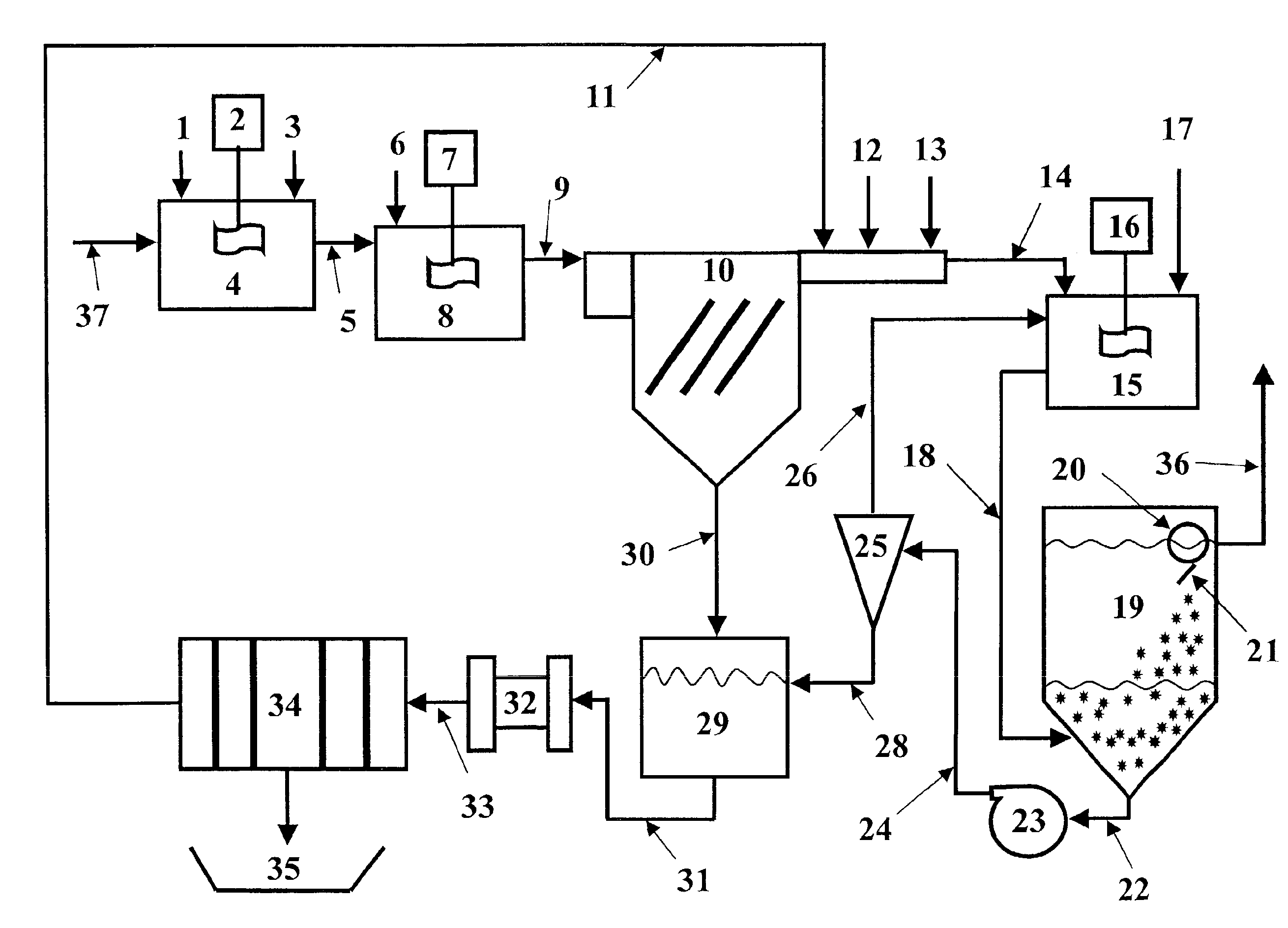

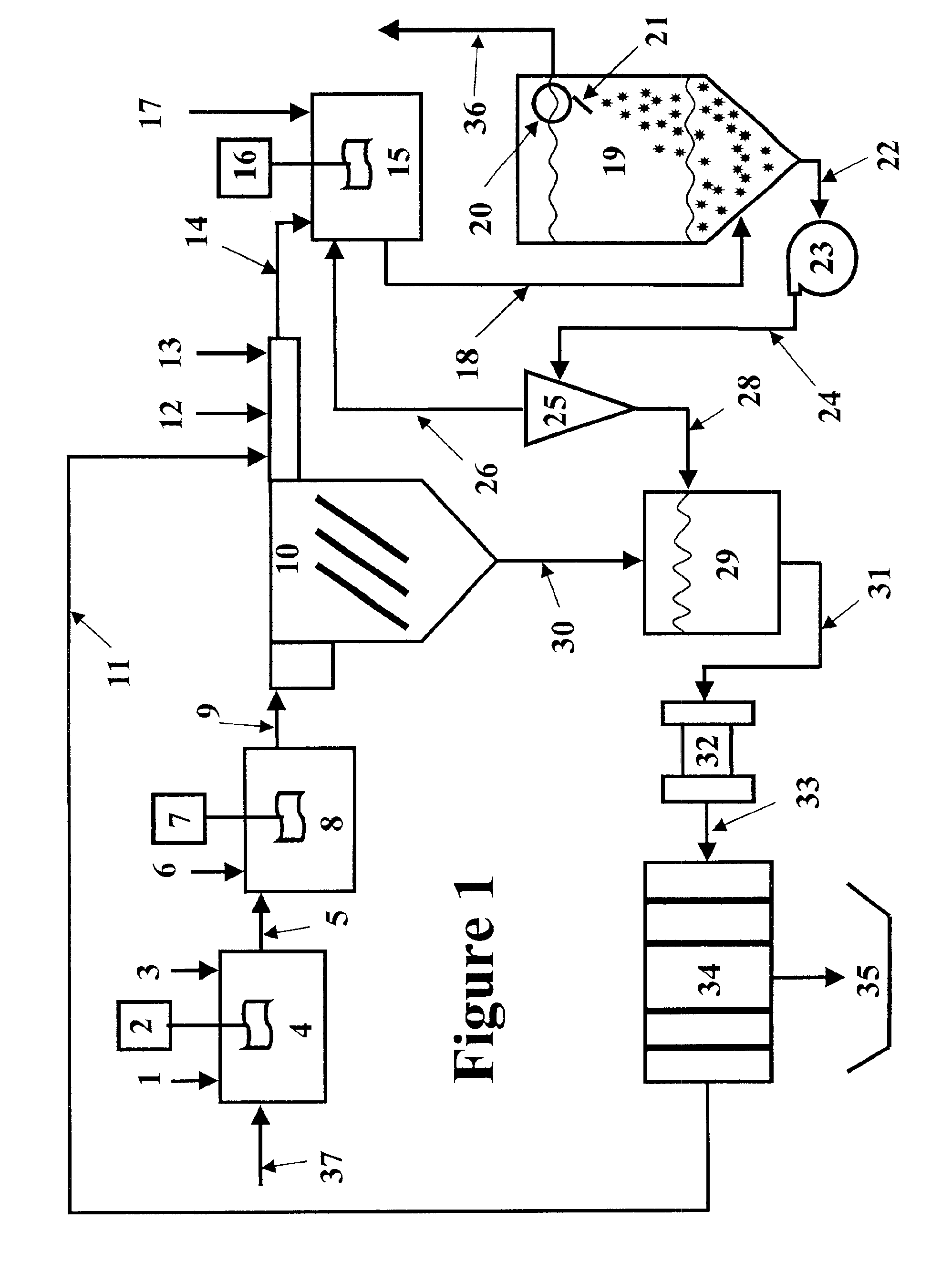

A two-step chemical precipitation process involving hydroxide precipitation and sulfide precipitation combined with “field separation ” technology such as magnetic separation, dissolved air flotation, vortex separation, or expanded plastics flotation, effectively removes chelated and non-chelated heavy metal precipitates and other fine particles from water. In the first-step, the non-chelated heavy metals are precipitated as hydroxides and removed from the water by a conventional liquid / solids separator such as an inclined plate clarifier to remove a large percentage of the dissolved heavy metals. The cleaned water is then treated in a second precipitation step to remove the residual heavy metals to meet discharge limits. In the second precipitation step, any metal precipitant more effective than hydroxide for metal precipitation can be used. The invention improves metal removal, lowers cost because fewer chemicals are used, produces less sludge, and reduces the discharge of toxic metals and metal precipitants to the environment. Magnetic separation is preferred for the separation of particles precipitated in the second stage. Similar methods can be employed for separation of other particulates from water. Particulates can also be removed by causing them to adhere to particles of expanded plastic, forming a floc lighter than water, so that the floc can be removed by flotation.

Owner:CORT CHERYL J

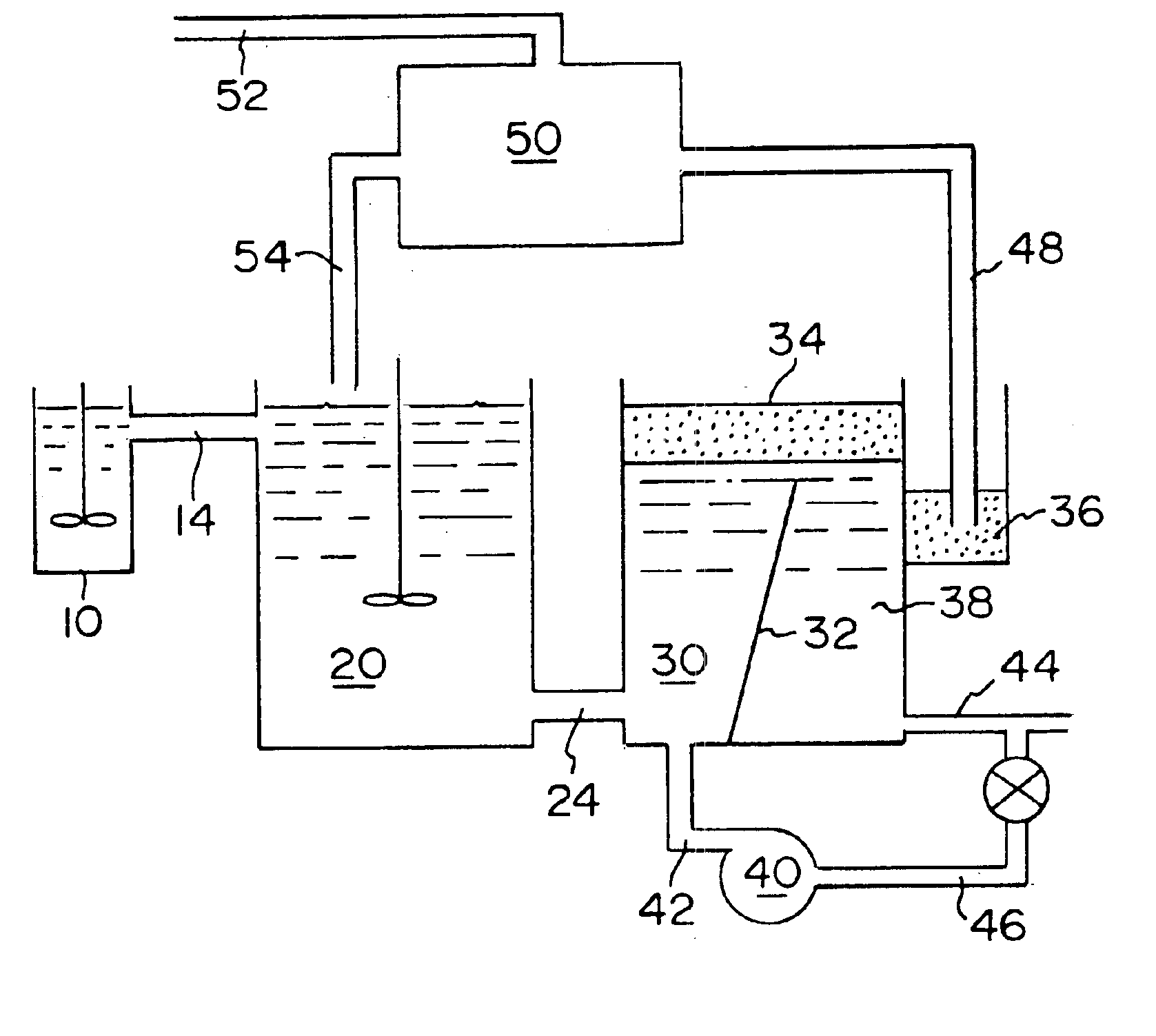

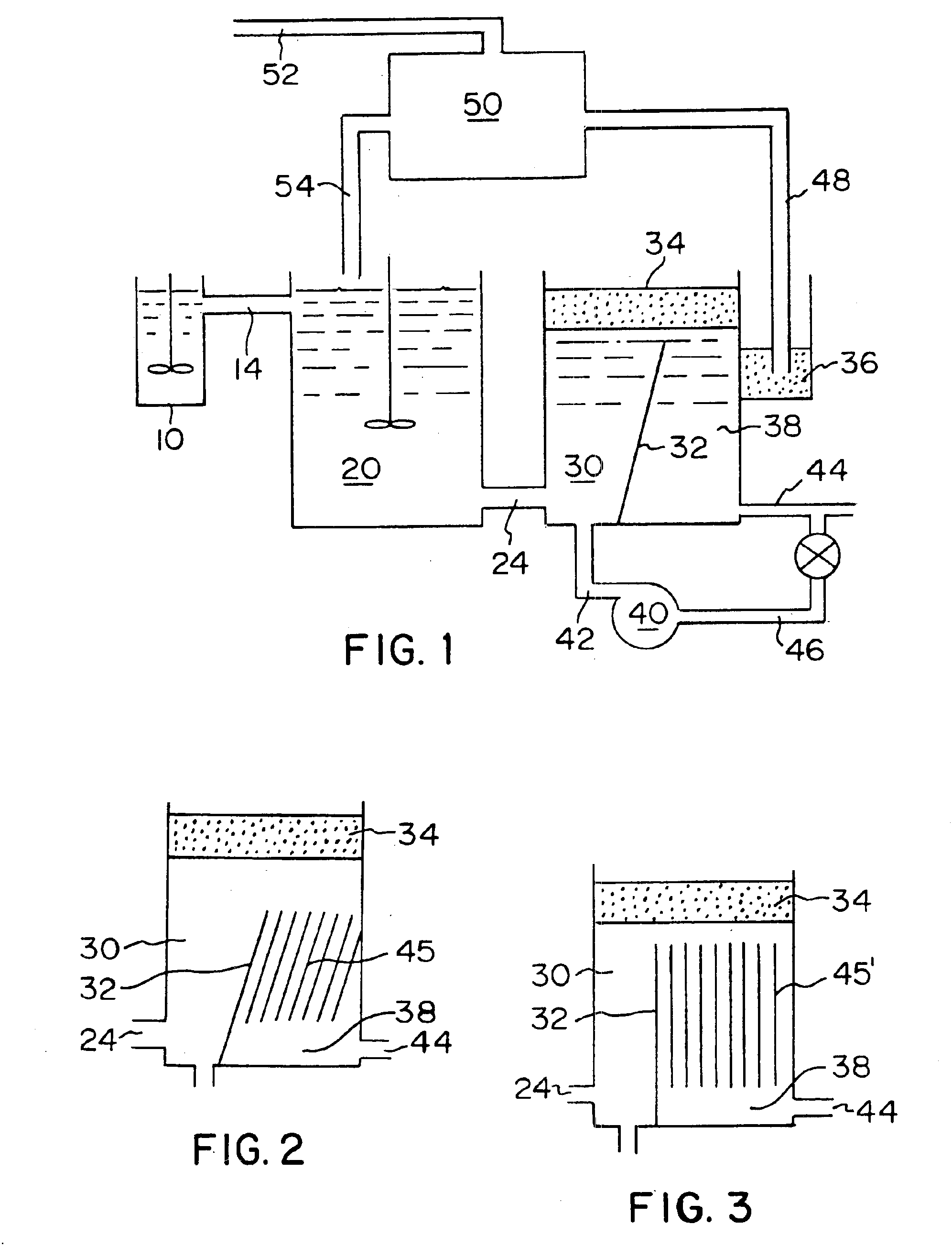

Buoyant media flotation

InactiveUS6890431B1Less energyLower the volumeOther chemical processesSolid sorbent liquid separationEngineeringBuoyancy

A clarification system for fluids in which particles are separated from the fluid by flotation and in which the buoyant media inducing the flotation is recycled. Flotation can be assisted by a flotation assistance device, such as dissolved air flotation.

Owner:XYLEM WATER SOLUTIONS ZELIENOPLE LLC

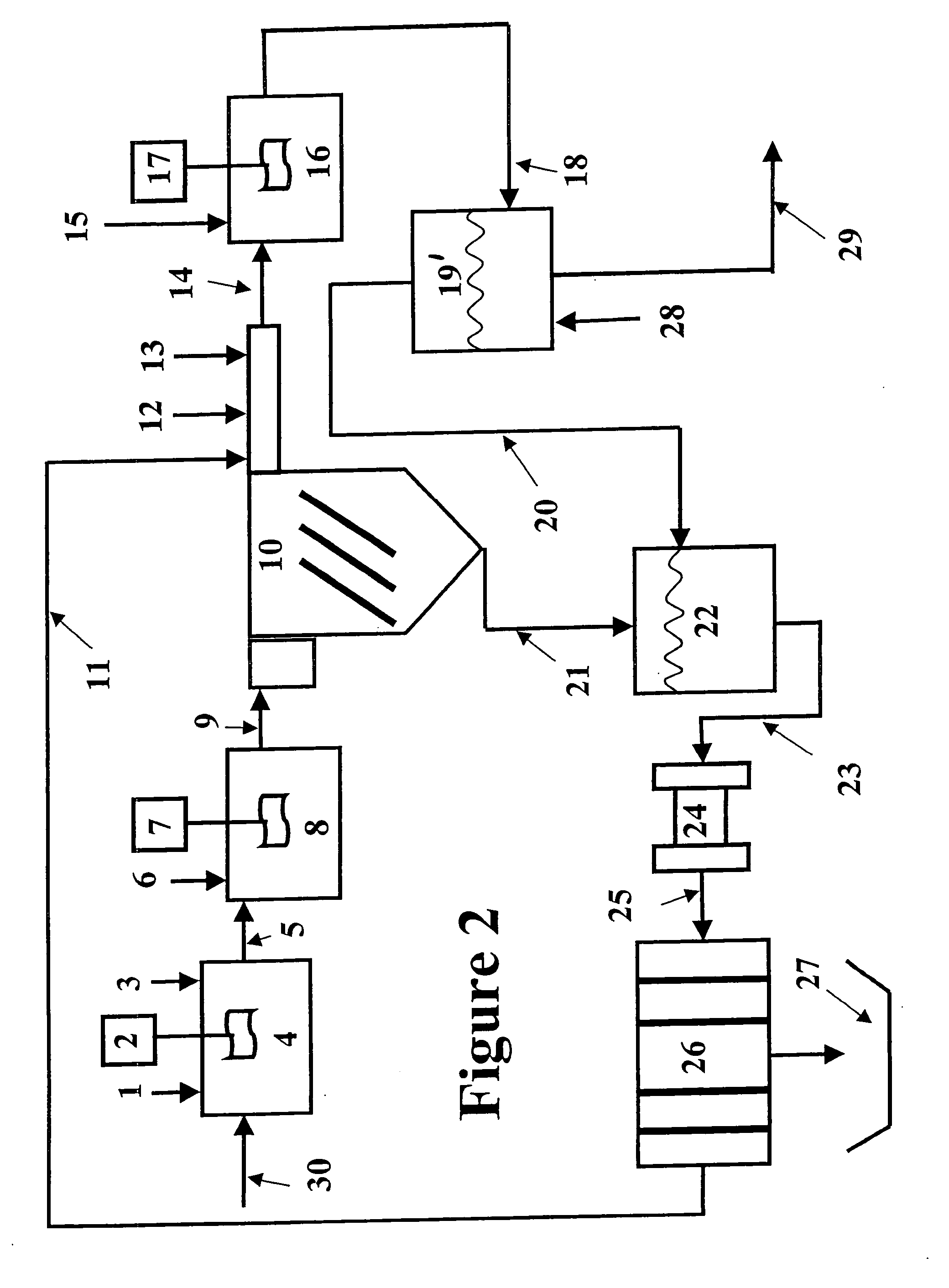

Methods for removing heavy metals from water using chemical precipitation and field separation methods

InactiveUS7255793B2Cost- and chemically-effectiveSedimentation separationWater/sewage treatment by neutralisationParticulatesSulfide

A two-step chemical precipitation process involving hydroxide precipitation and sulfide precipitation combined with “field separation ” technology such as magnetic separation, dissolved air flotation, vortex separation, or expanded plastics flotation, effectively removes chelated and non-chelated heavy metal precipitates and other fine particles from water. In the first-step, the non-chelated heavy metals are precipitated as hydroxides and removed from the water by a conventional liquid / solids separator such as an inclined plate clarifier to remove a large percentage of the dissolved heavy metals. The cleaned water is then treated in a second precipitation step to remove the residual heavy metals to meet discharge limits. In the second precipitation step, any metal precipitant more effective than hydroxide for metal precipitation can be used. The invention improves metal removal, lowers cost because fewer chemicals are used, produces less sludge, and reduces the discharge of toxic metals and metal precipitants to the environment. Magnetic separation is preferred for the separation of particles precipitated in the second stage. Similar methods can be employed for separation of other particulates from water. Particulates can also be removed by causing them to adhere to particles of expanded plastic, forming a floc lighter than water, so that the floc can be removed by flotation.

Owner:CORT CHERYL J

Methods for removing heavy metals from water using chemical precipitation and field separation methods

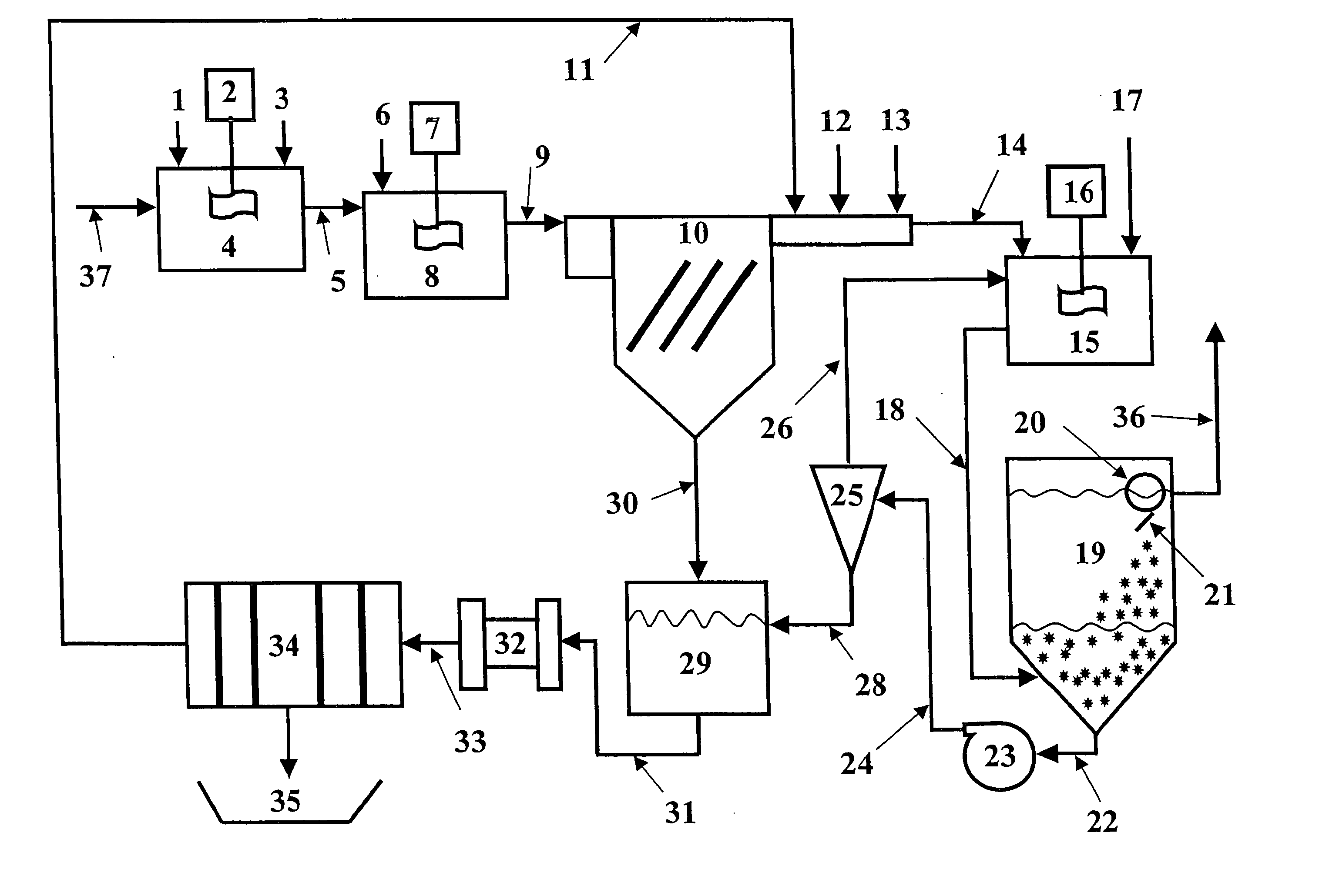

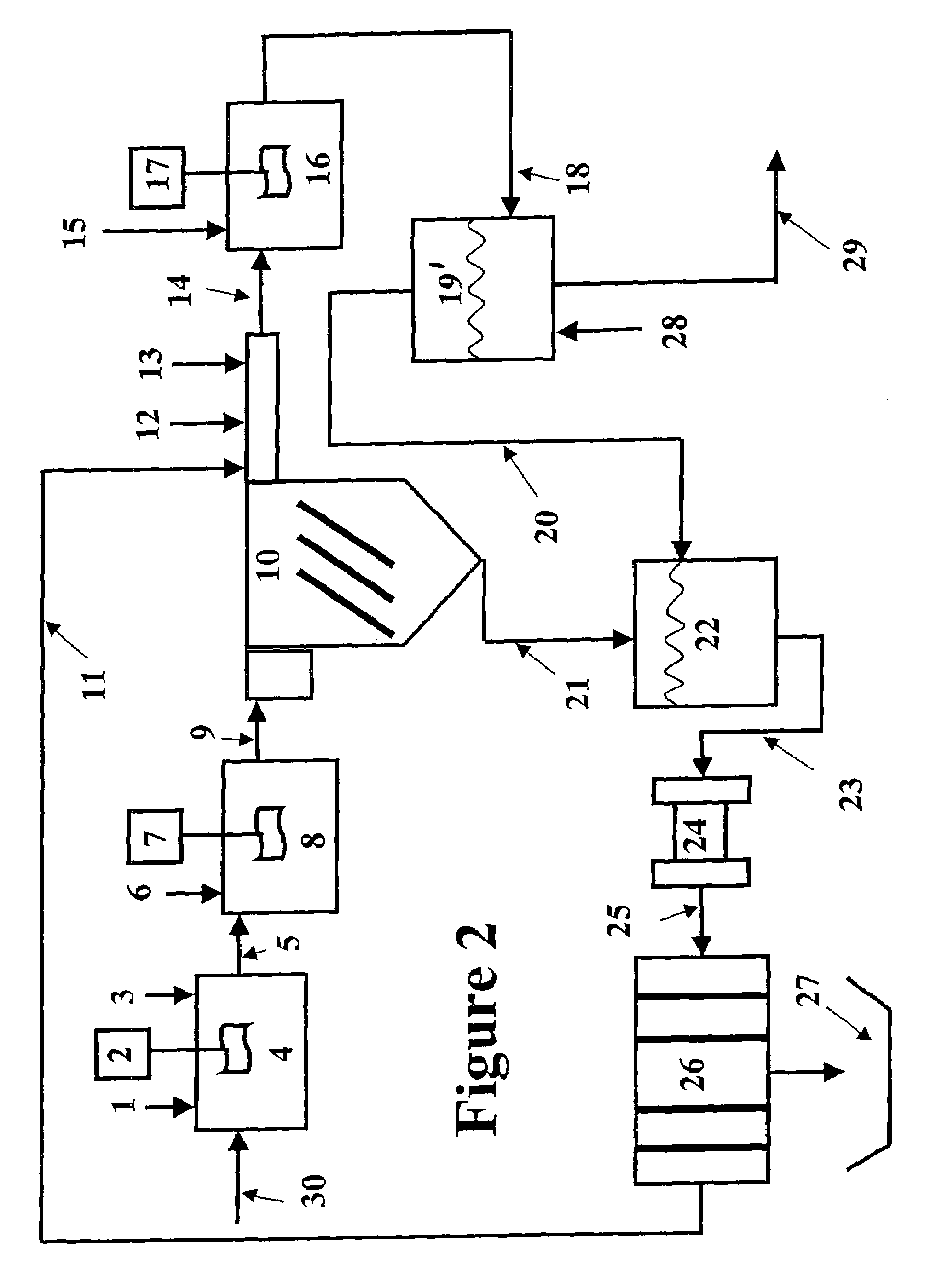

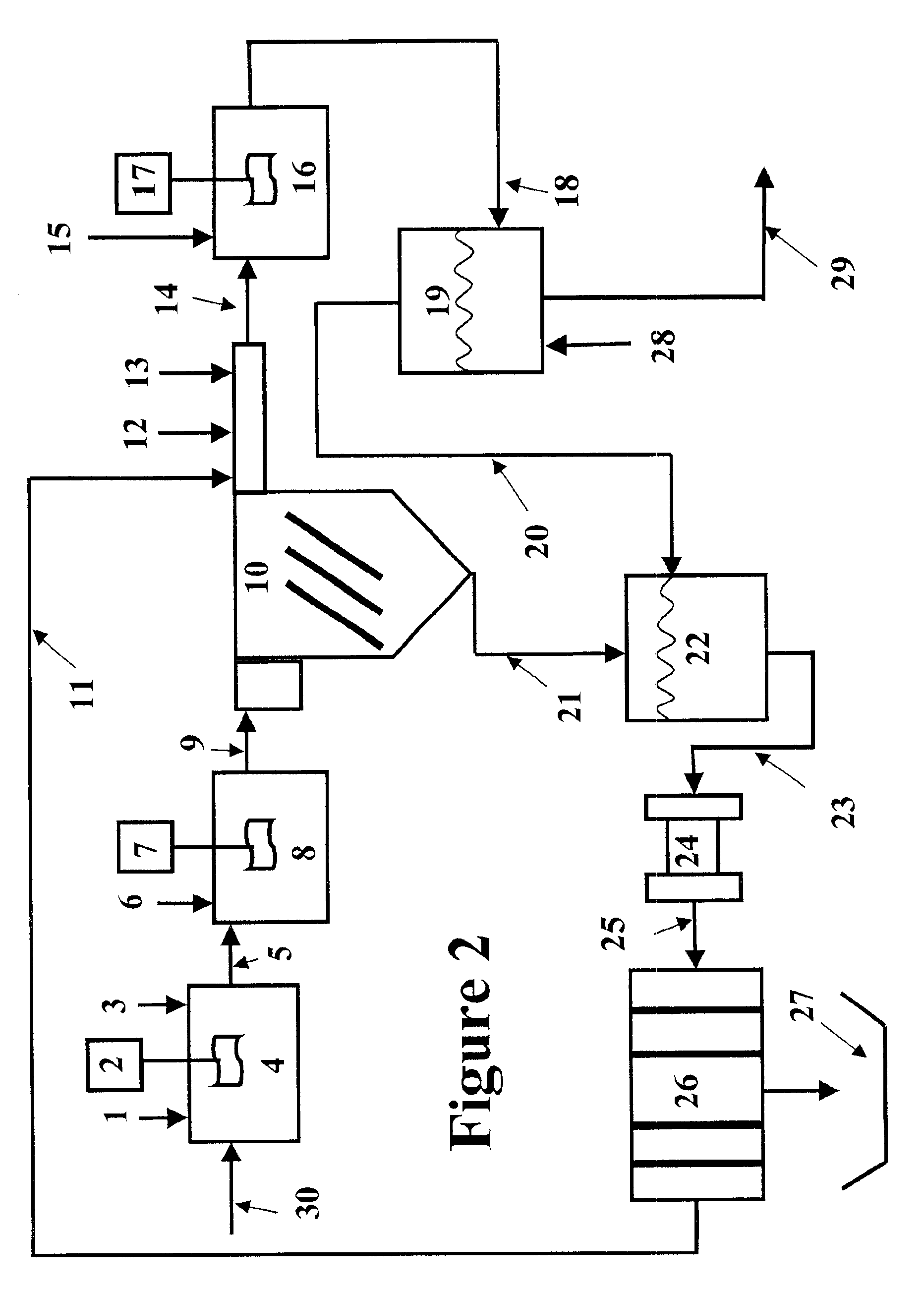

InactiveUS6896815B2Small sizeChemical cost reductionSolid sorbent liquid separationGold compoundsWater useSludge

A two-step chemical precipitation process involving hydroxide precipitation and sulfide precipitation combined with “field separation” technology such as magnetic separation, dissolved air flotation, vortex separation or expanded plastics flotation, effectively removes chelated and non-chelated heavy metal precipitates and other fine particles from water. In the first-step, the non-chelated heavy metals are precipitated as hydroxides and removed from the water by a conventional liquid / solids separator such as an inclined plate clarifier to remove a large percentage of the dissolved heavy metals. The cleaned water is then treated in a second precipitation step to remove the residual heavy metals to meet discharge limits. In the second precipitation step, any metal precipitant more effective than hydroxide for metal precipitation can be used. The invention improves metal removal, lowers cost because fewer chemicals are used, produces less sludge, and reduces the discharge of toxic metals and metal precipitants to the environment.

Owner:CORT STEVEN L

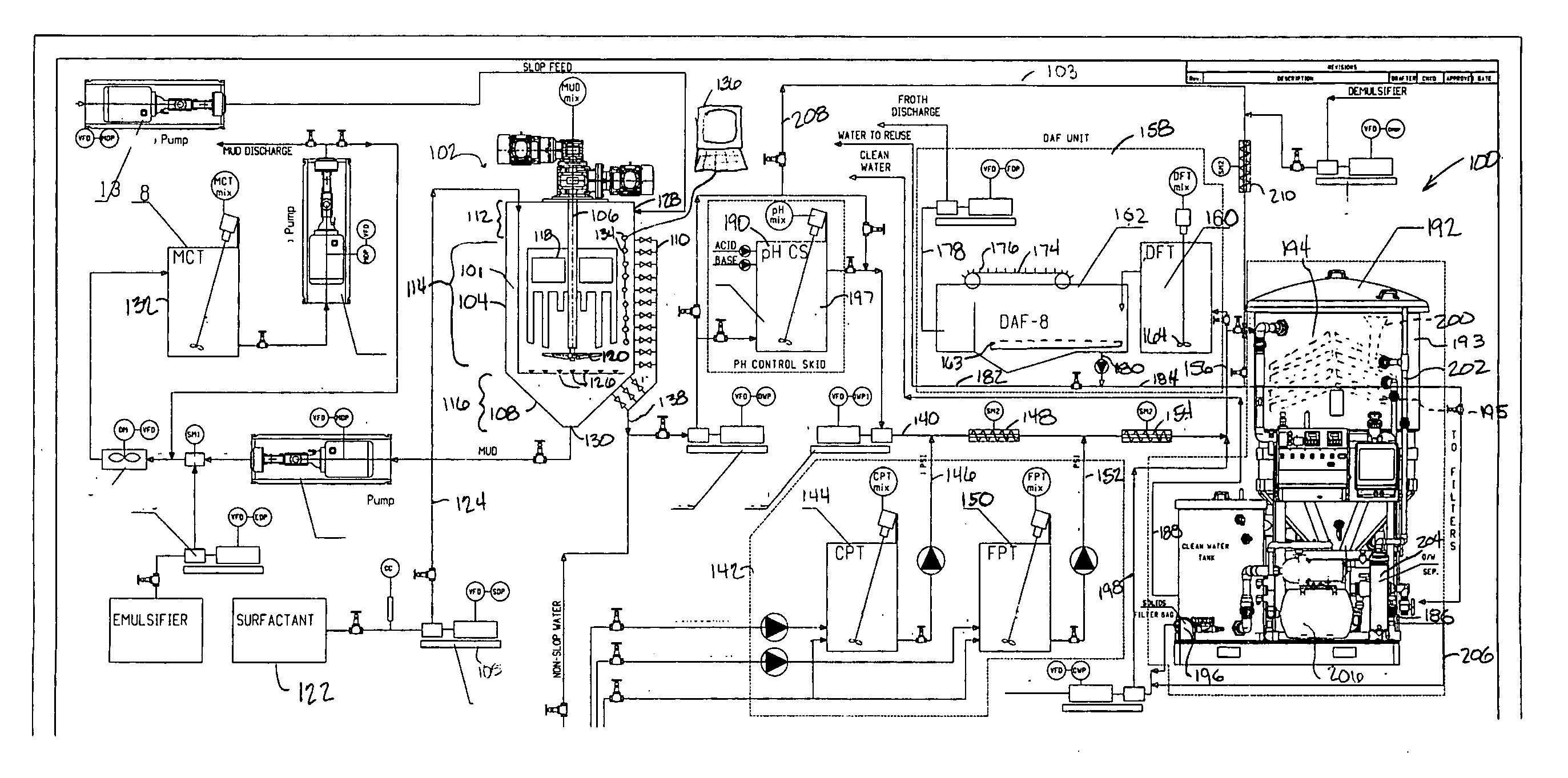

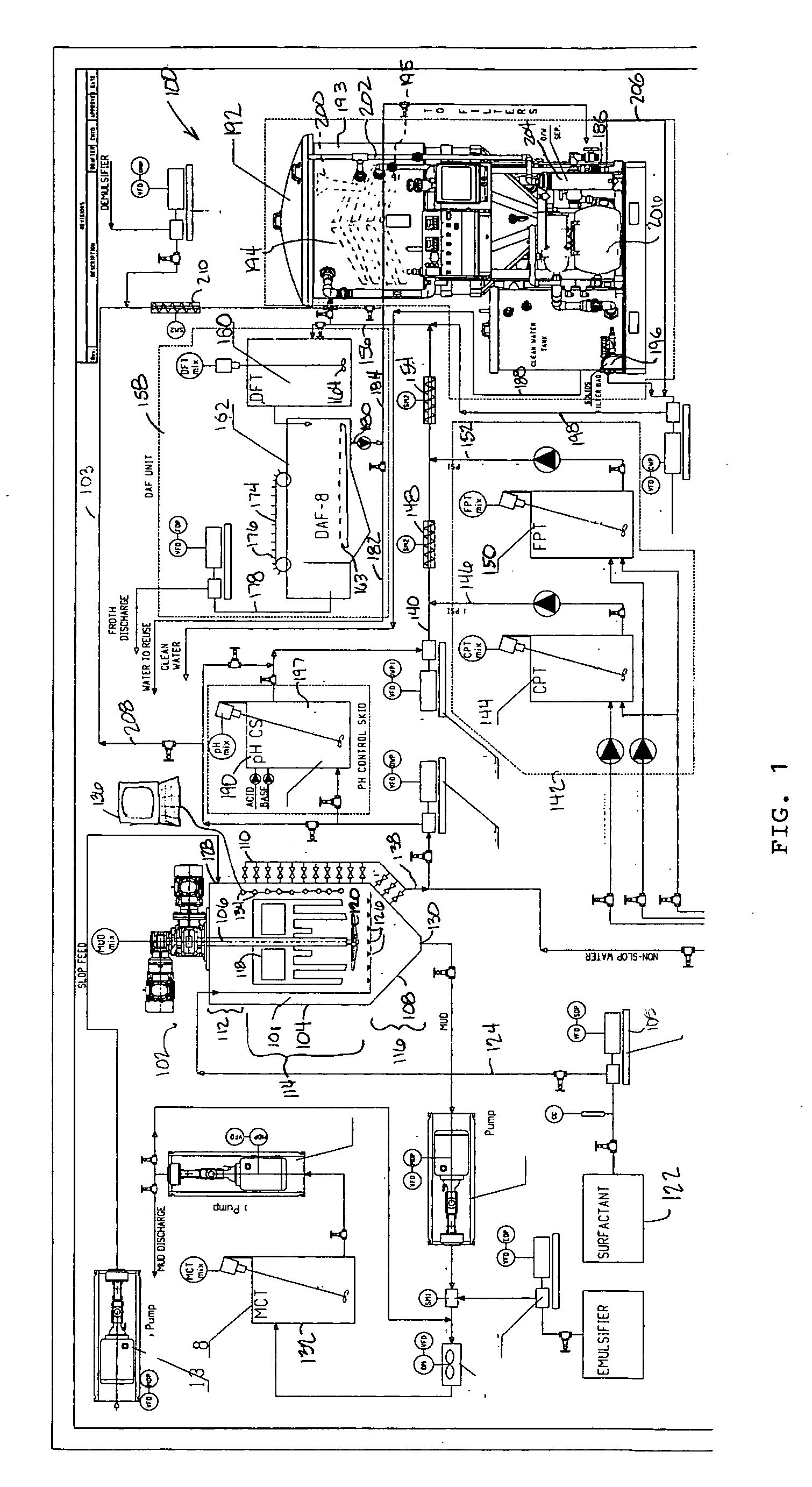

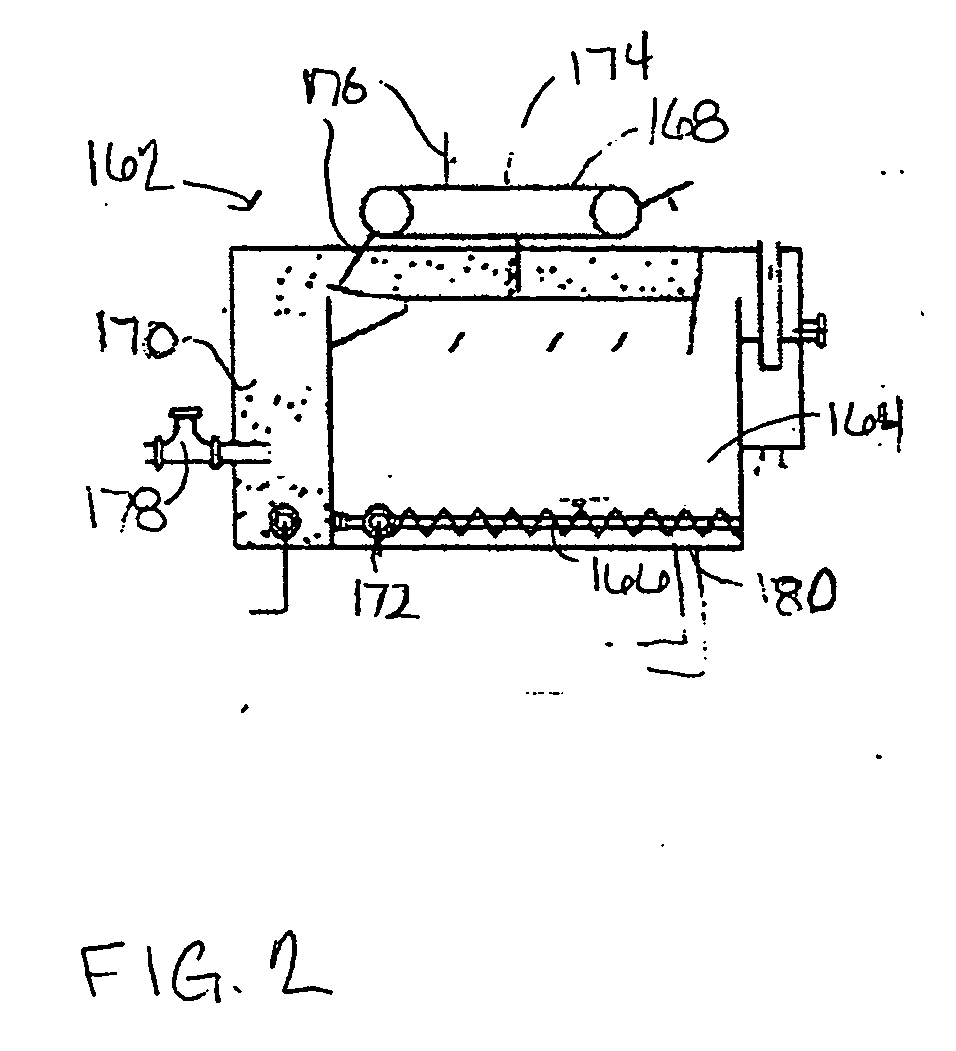

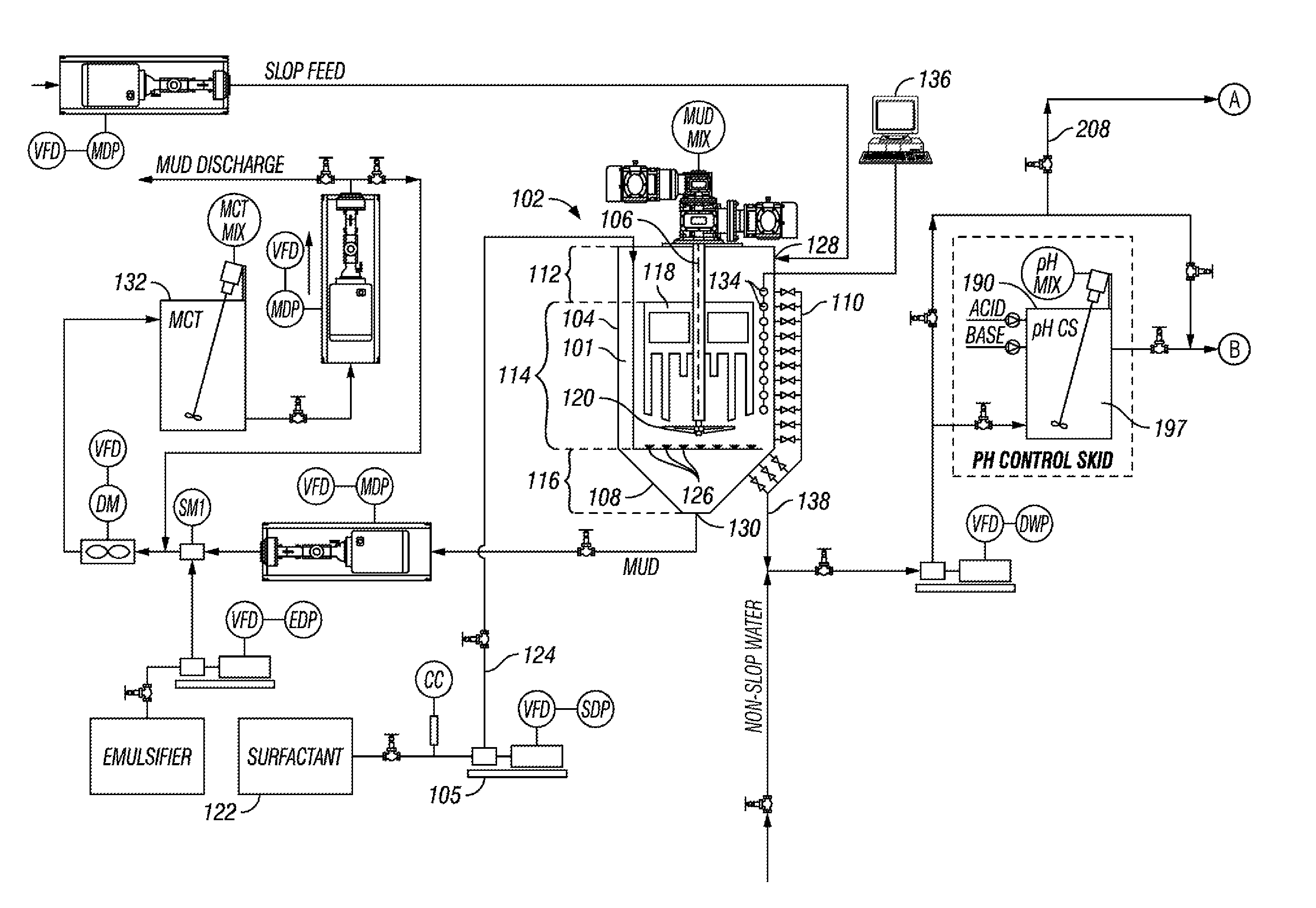

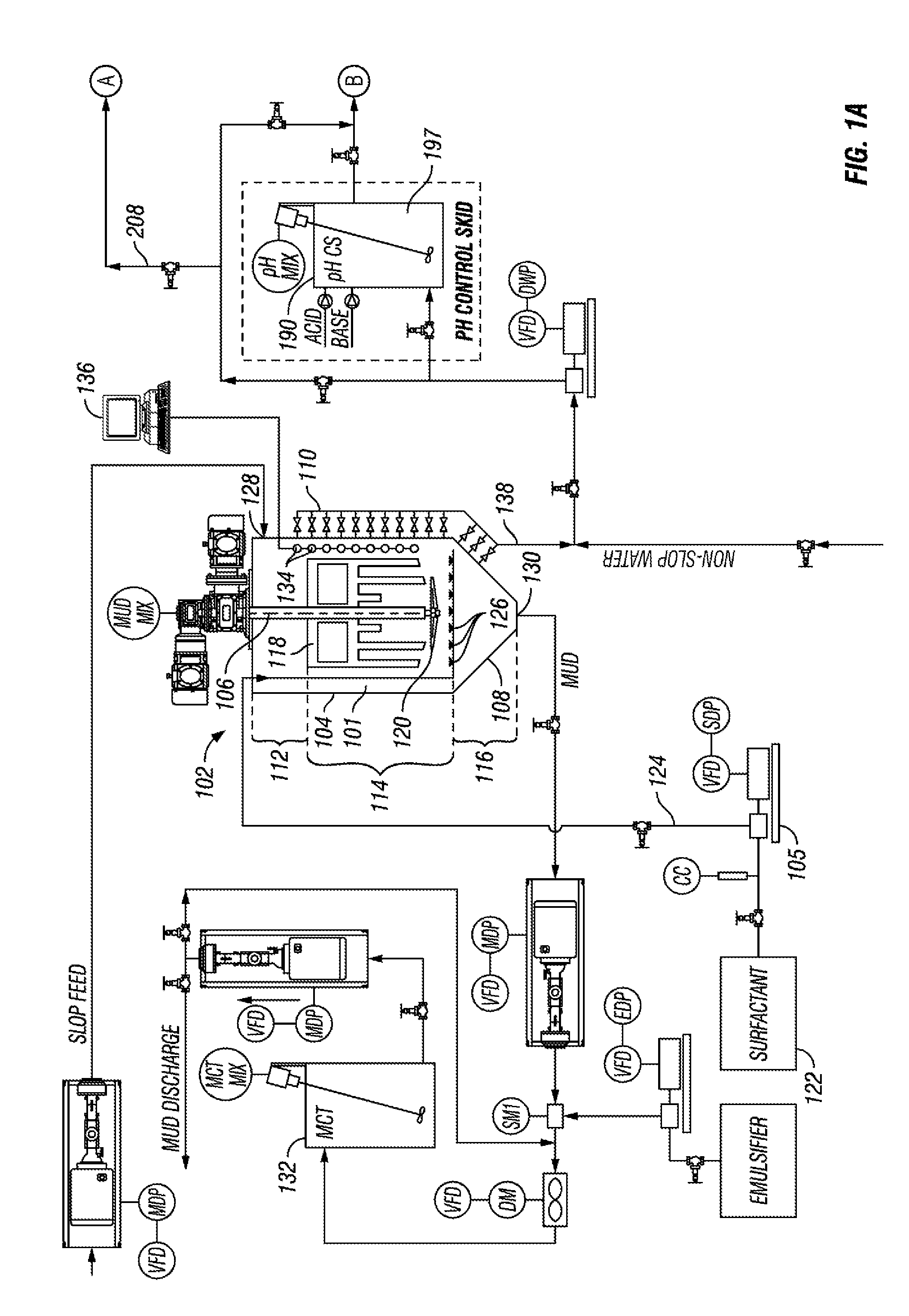

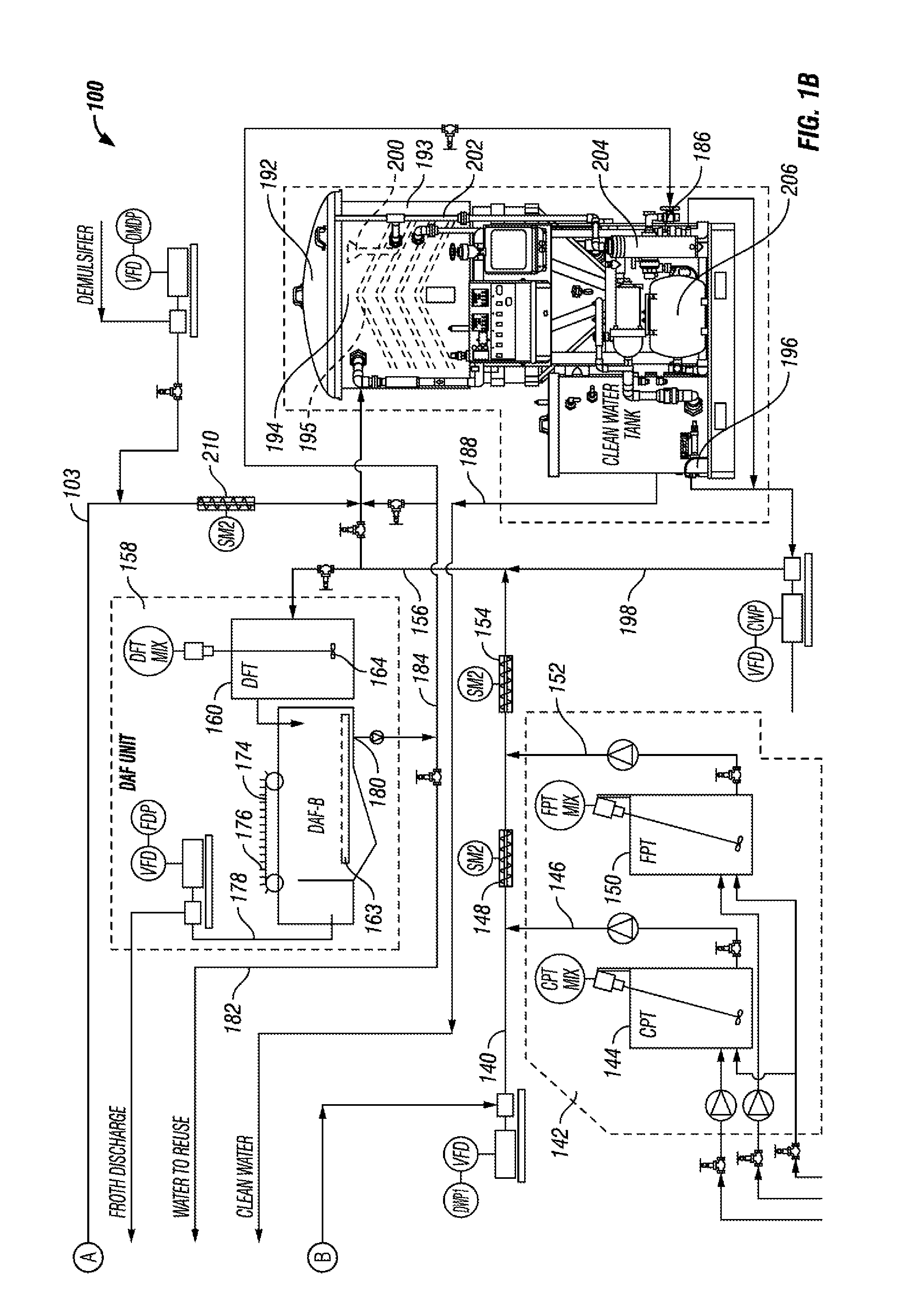

Apparatus for separation of water from oil-based drilling fluid and advanced water treatment

InactiveUS20060186056A1Shorten the timeIncrease the number ofWaste water treatment from quariesTreatment involving filtrationChemical treatmentFiltration

An apparatus for separating water from oil-based drilling fluid includes an separation tank, a chemical treatment apparatus having one or more de-oiling polymer preparation tanks, and a dissolved air flotation unit. Slop mud is directed into the separation tank where surfactant is added to separate the drilling fluid from oily water. The drilling fluid is drained for further processing. The oily water is removed by an outlet arrangement from the separation tank and directed to an initial treatment line. One or more de-oiling polymers are added to the oily water in the initial treatment line and mixed therewith. The mixture may then be directed to the dissolved air flotation unit where dissolved air is released into the bottom of the mixture. The dissolved air adheres to suspended solids in the mixture and lifts them to the top surface as a froth. The froth is skimmed from the top surface of the mixture and collected. The de-frothed water is reused or directed to a filtration system where it is prepared for discharge. A clarifying tank may be included after the de-oiling polymers are added to further separate the oil and water. The oil is removed from the top surface by a weir while the water is directed to the filtration system and discharged.

Owner:MI

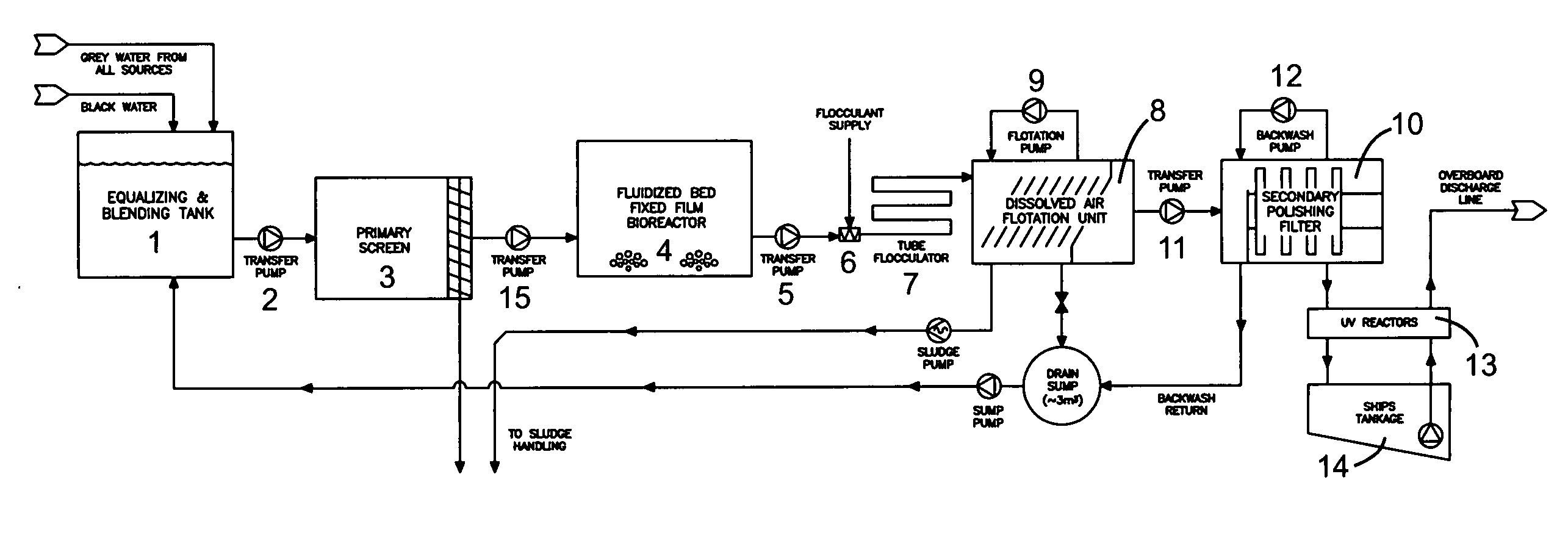

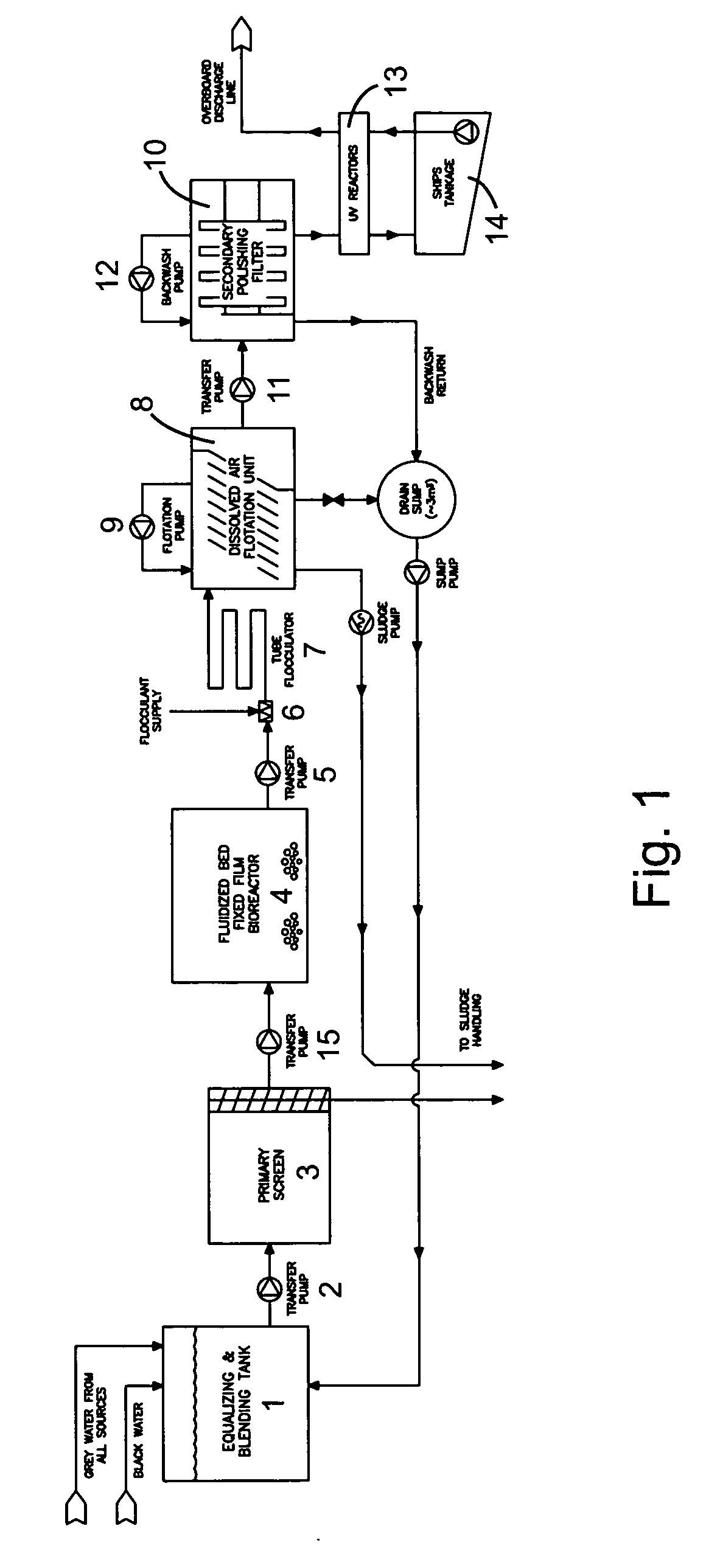

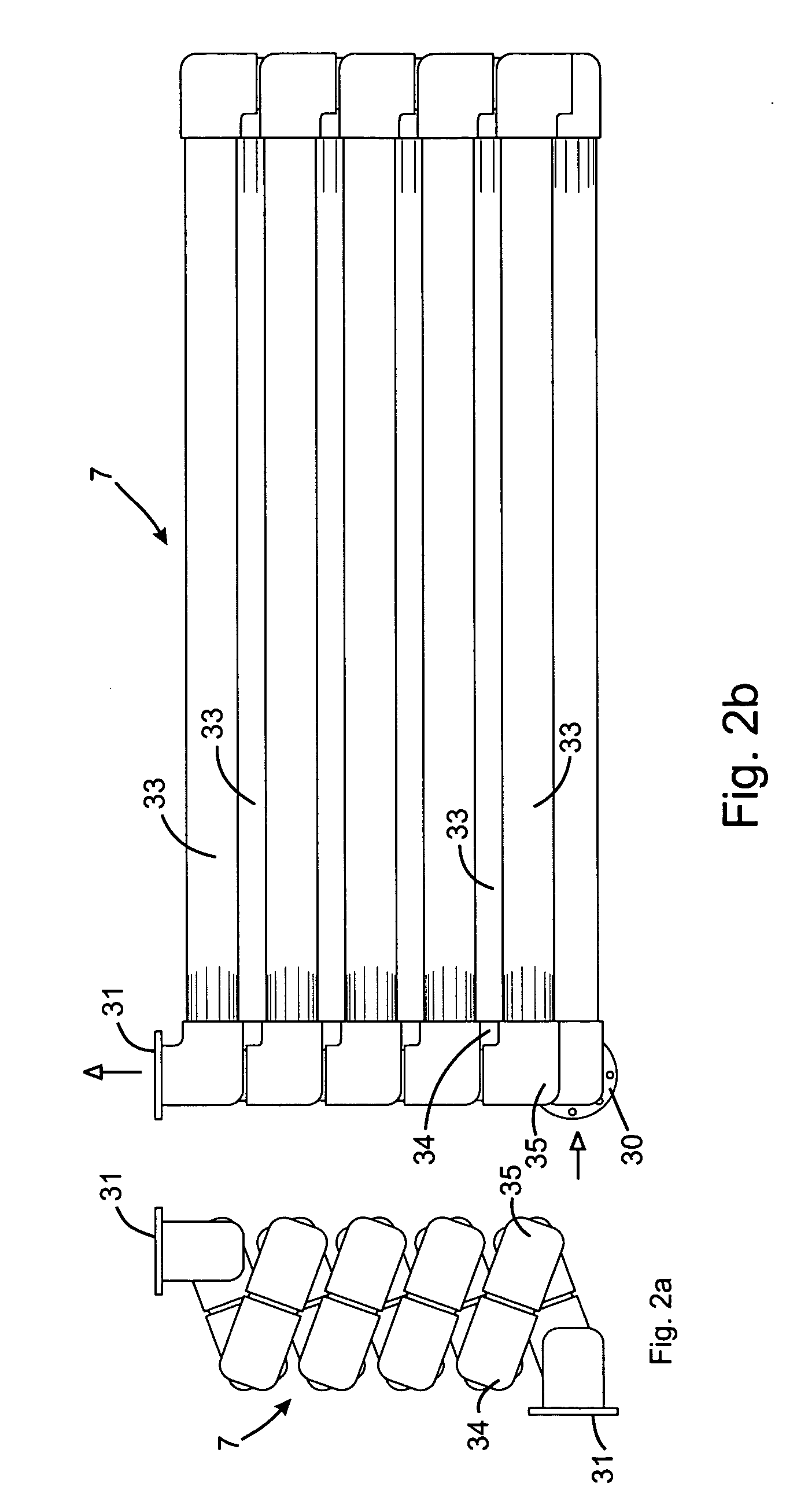

Wastewater treatment system for a marine vessel

InactiveUS20070114182A1Reduce movementAvoid erratic movementTreatment using aerobic processesTreatment involving filtrationCompound (substance)Membrane bioreactor

A wastewater treatment system for use on a marine vessel comprising an aerobic fixed film biological reactor, a tubular flocculator and a dissolved air flotation (DAF) unit. The process units desirably include means for reducing erratic movement of the wastewater due to sea-induced movement of the marine vessel. The DAF unit includes a plurality of inclined baffles arranged to create a plurality of parallel inverted U-shaped flow paths that effect combined co-current and counter-current flotation separation while reducing erratic movement of the wastewater. The selection of process units and operating conditions advantageously reduces the footprint of the wastewater treatment system and reduces cost and complexity associated with the handling of wastewater treatment chemicals.

Owner:HYDROXYL SYST

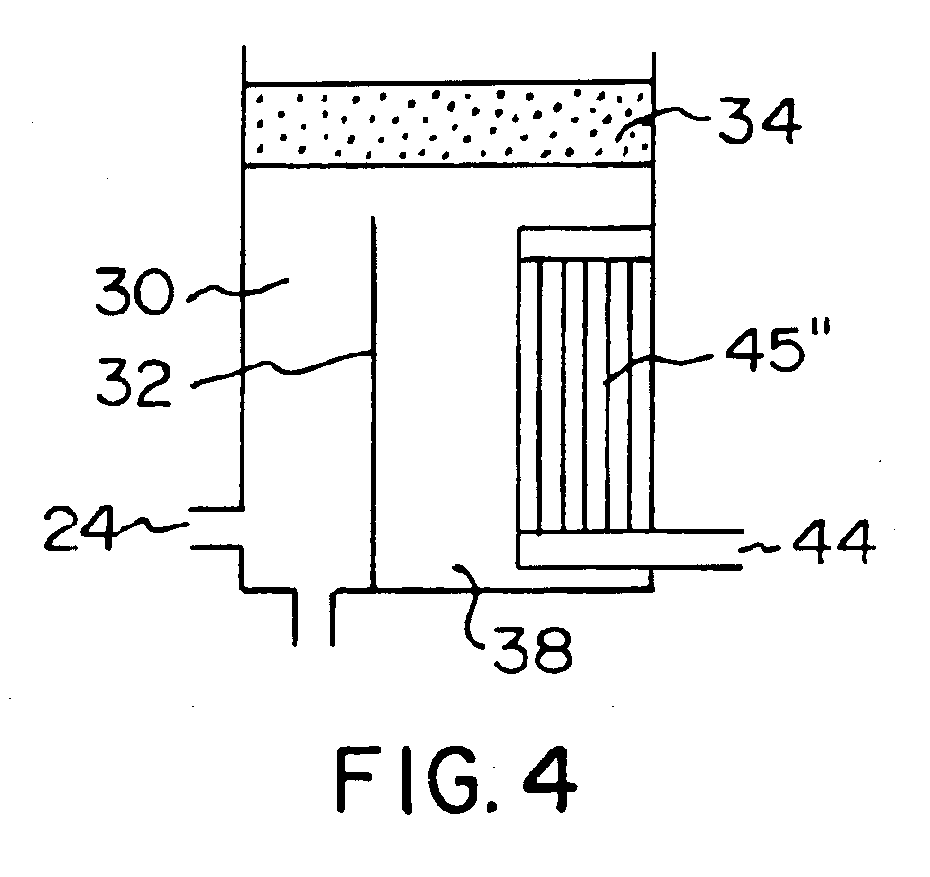

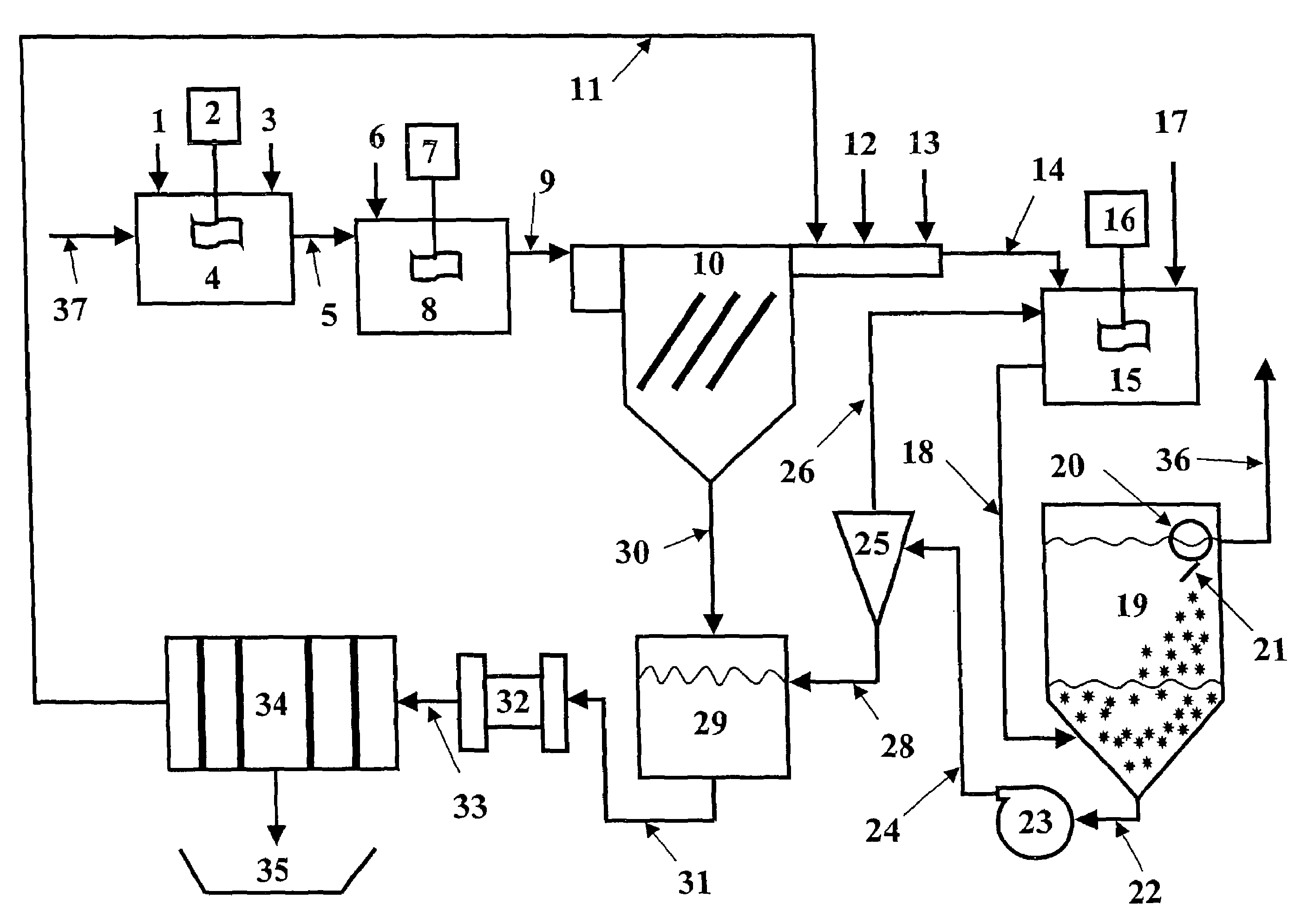

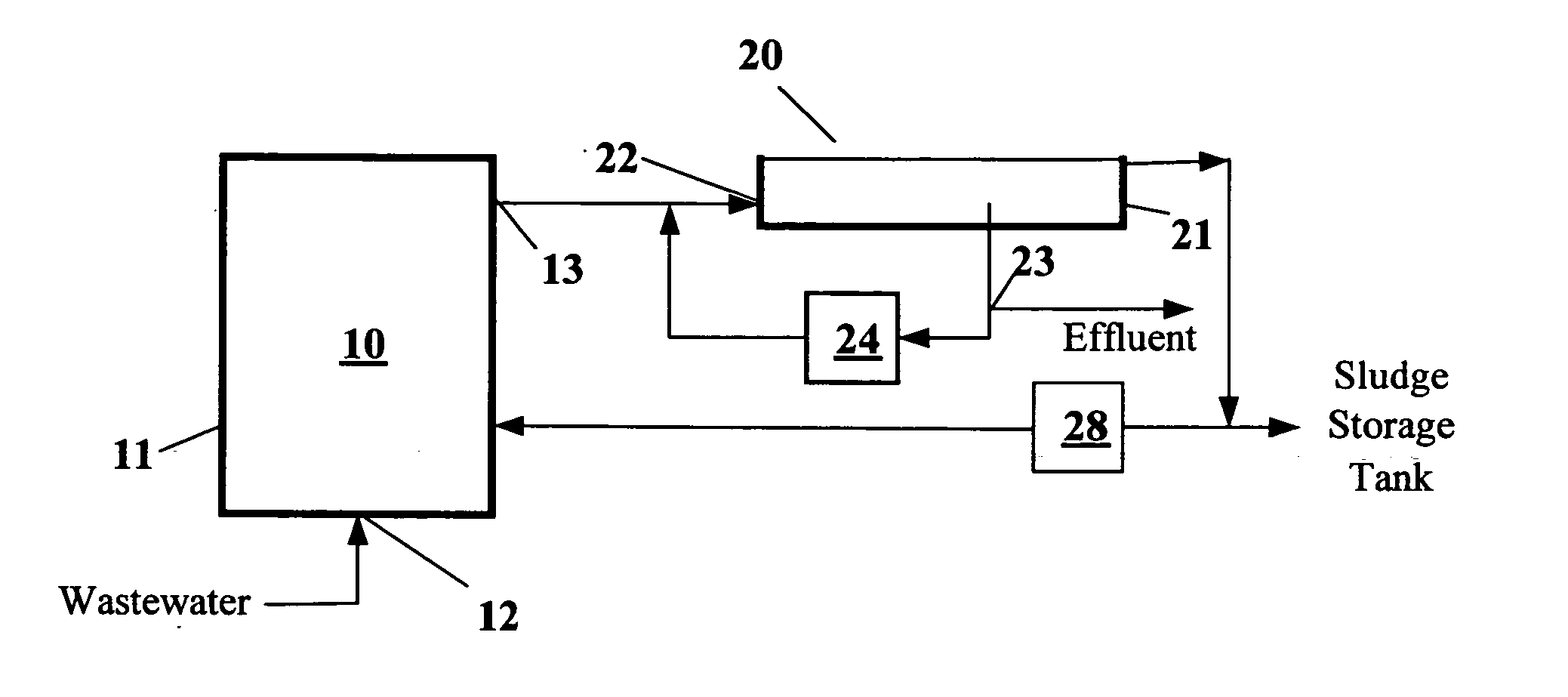

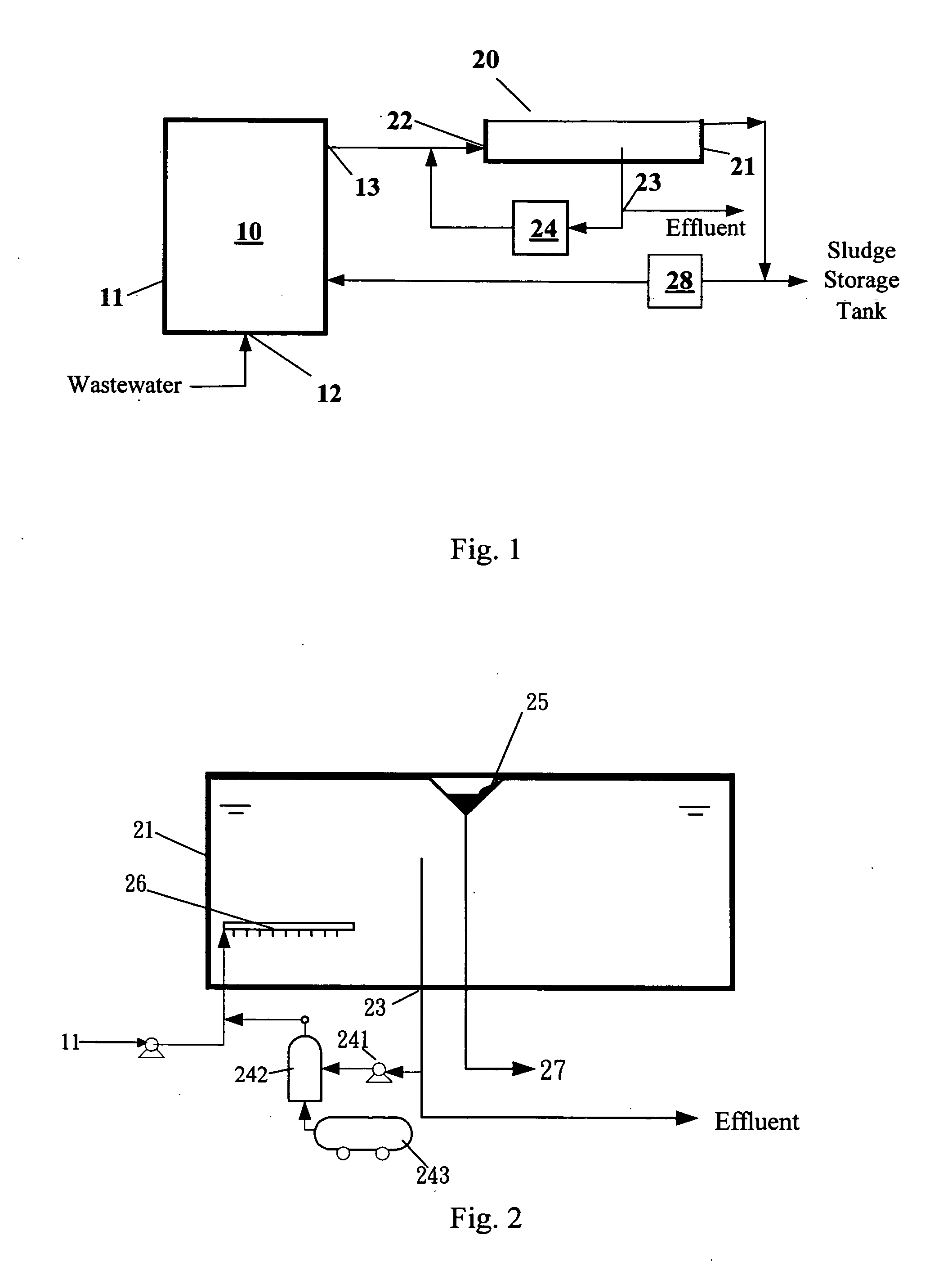

Anaerobic biological wastewater treatment system and process

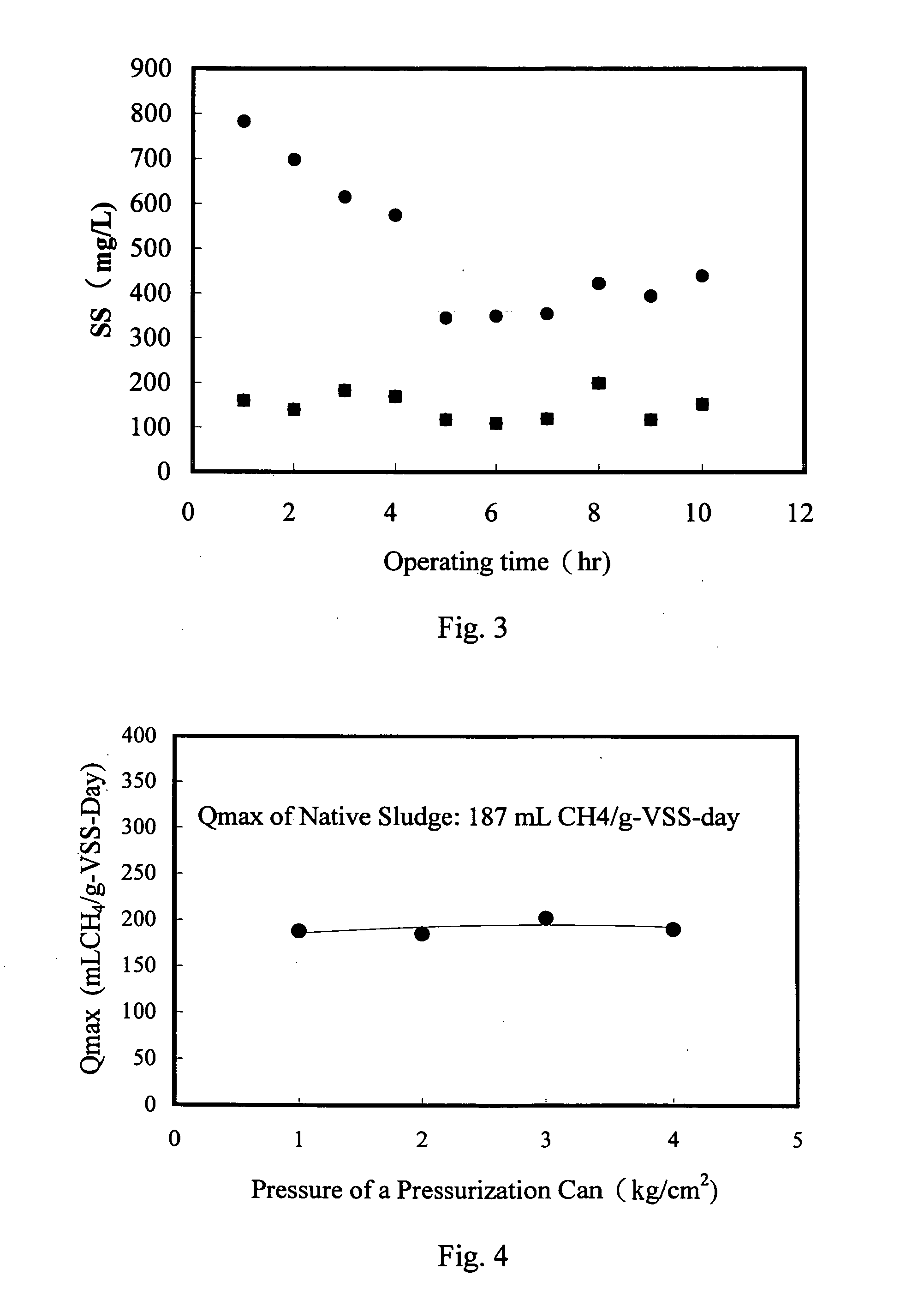

ActiveUS20060131231A1Improve volume efficiencyLower initial installation costsTreatment with anaerobic digestion processesTreatment with aerobic and anaerobic processesAnaerobic microorganismsTreatment system

The present invention discloses an anaerobic biological wastewater treatment system for treating wastewater containing organic contaminants, which includes an anaerobic sludge bed reactor and a dissolved-air flotation tank. The anaerobic sludge bed reactor is used to decompose organic contaminants by way of an anaerobic biological treatment. The dissolved-air flotation tank is used to carry out liquid-solid separation on effluent from the anaerobic sludge bed reactor, so that anaerobic microorganisms entrained in the effluent can be recovered and recycled to the anaerobic sludge bed reactor, thereby enhancing the hydraulic loading of the anaerobic sludge bed reactor.

Owner:IND TECH RES INST

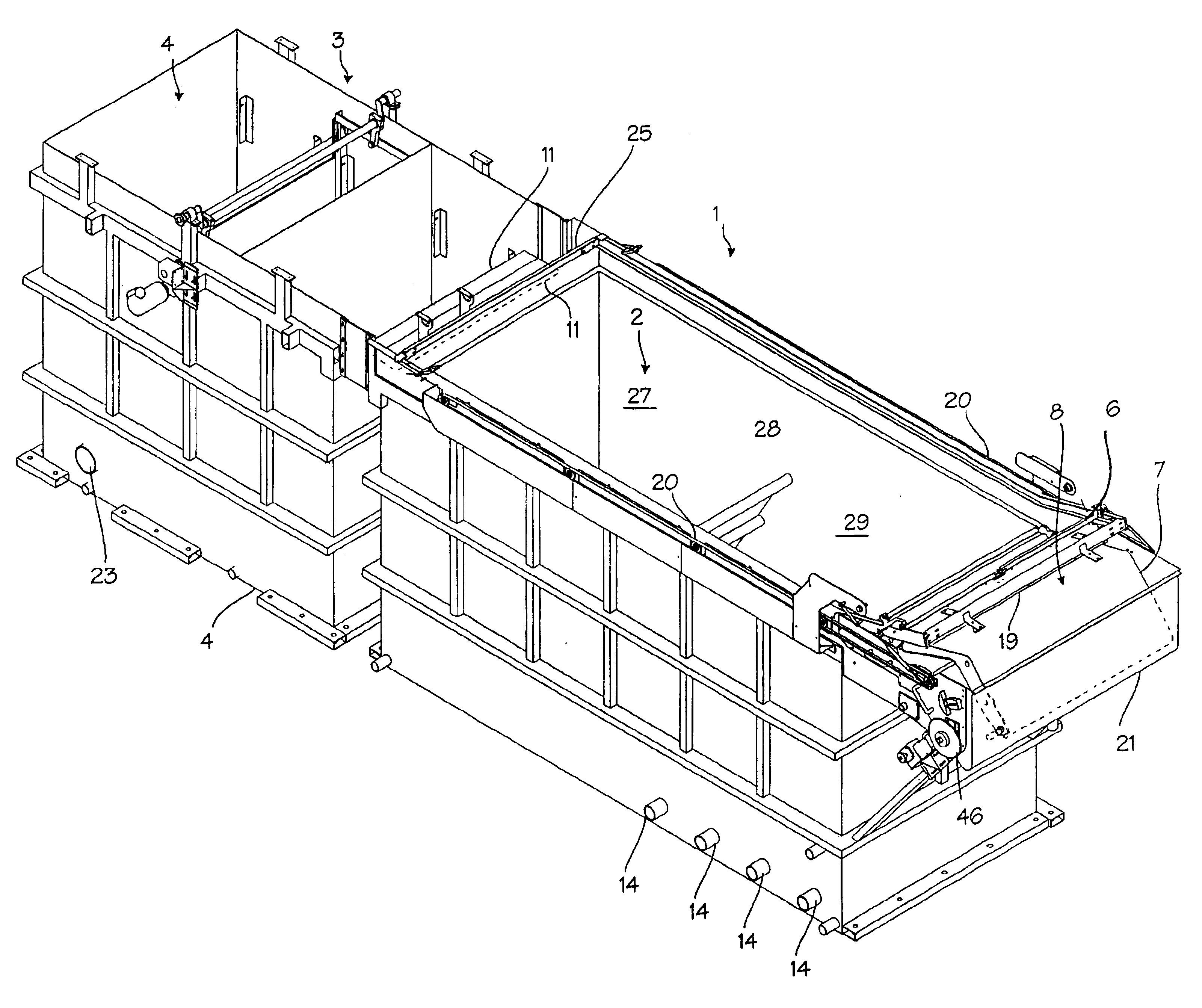

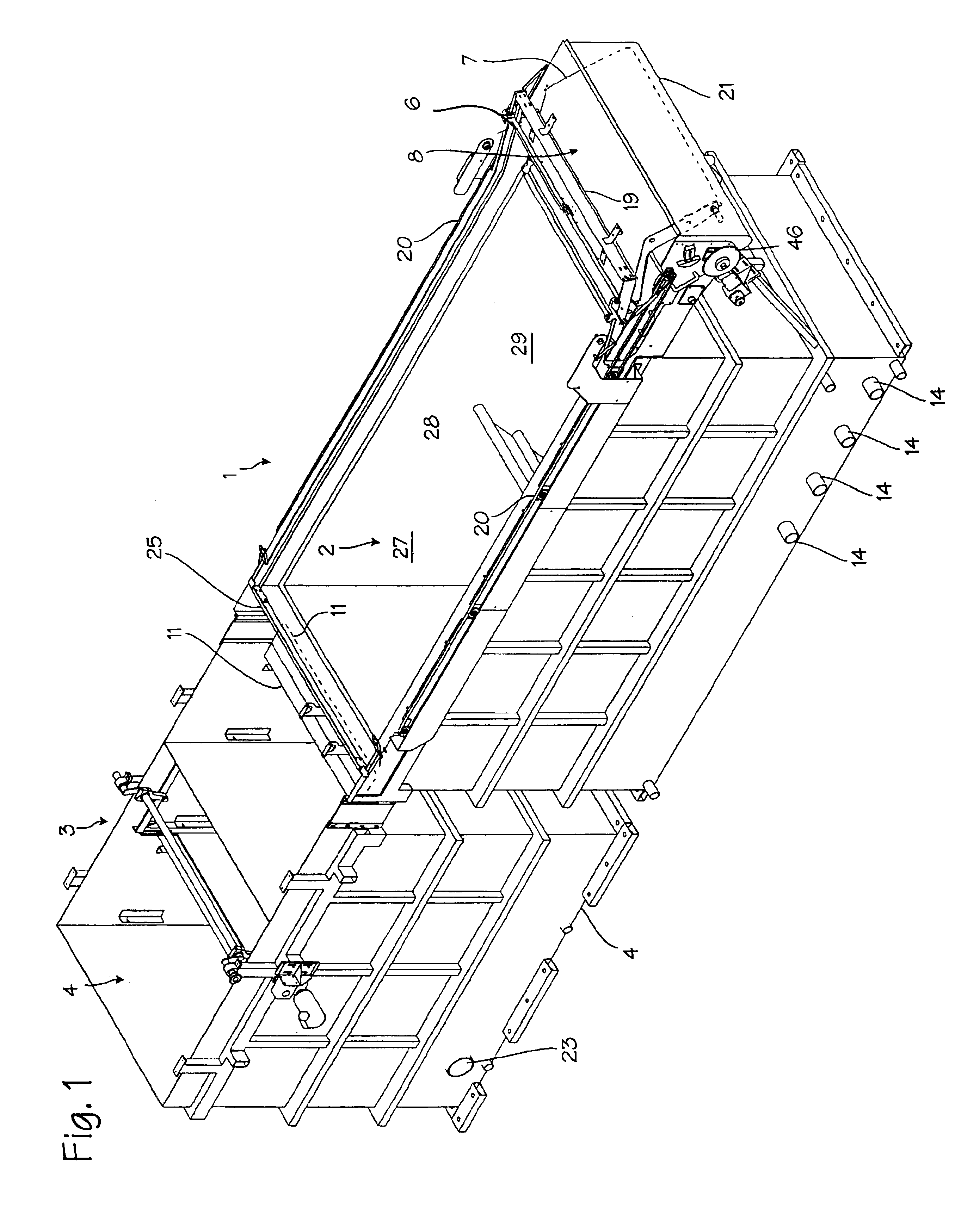

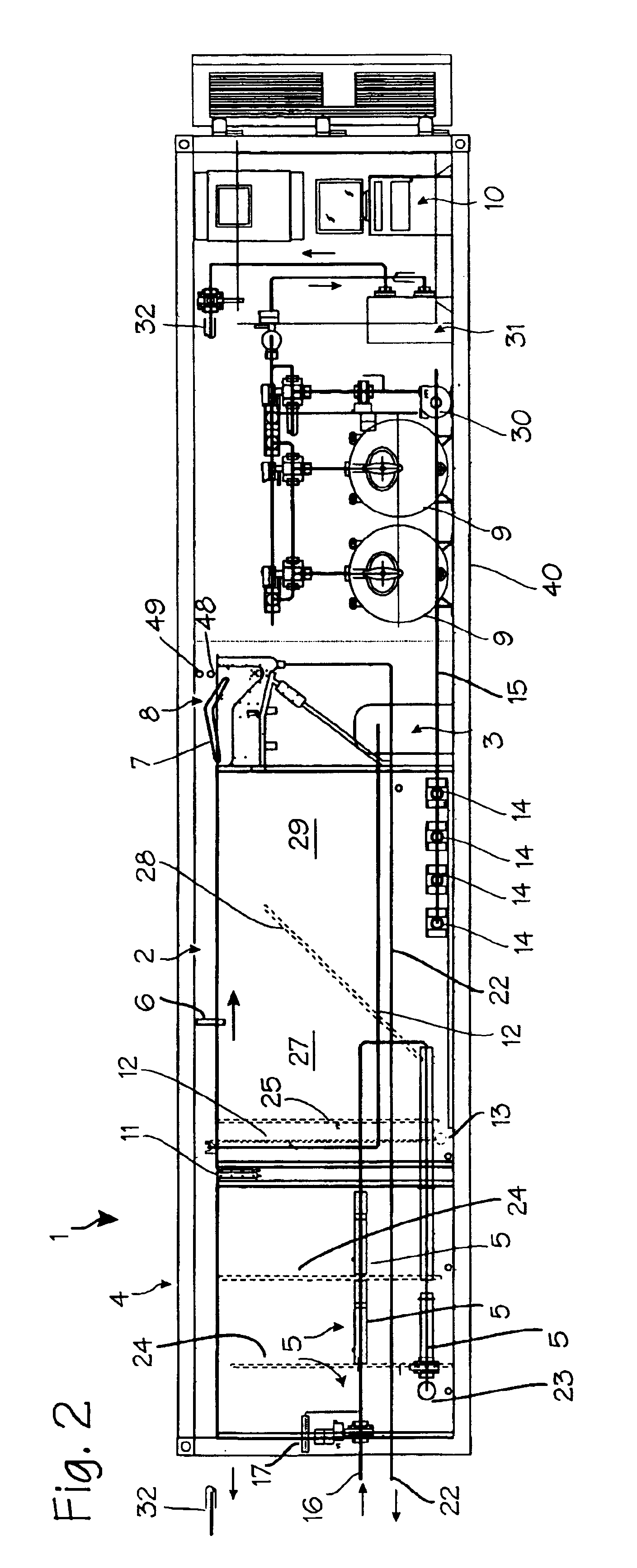

Apparatus for separation of water from oil-based drilling fluid and advanced water treatment

InactiveUS7497954B2Shorten the timeIncrease the number ofWaste water treatment from quariesTreatment involving filtrationChemical treatmentFiltration

An apparatus for separating water from oil-based drilling fluid includes an separation tank, a chemical treatment apparatus having one or more de-oiling polymer preparation tanks, and a dissolved air flotation unit. Slop mud is directed into the separation tank where surfactant is added to separate the drilling fluid from oily water. The drilling fluid is drained for further processing. The oily water is removed by an outlet arrangement from the separation tank and directed to an initial treatment line. One or more de-oiling polymers are added to the oily water in the initial treatment line and mixed therewith. The mixture may then be directed to the dissolved air flotation unit where dissolved air is released into the bottom of the mixture. The dissolved air adheres to suspended solids in the mixture and lifts them to the top surface as a froth. The froth is skimmed from the top surface of the mixture and collected. The de-frothed water is reused or directed to a filtration system where it is prepared for discharge. A clarifying tank may be included after the de-oiling polymers are added to further separate the oil and water. The oil is removed from the top surface by a weir while the water is directed to the filtration system and discharged.

Owner:MI

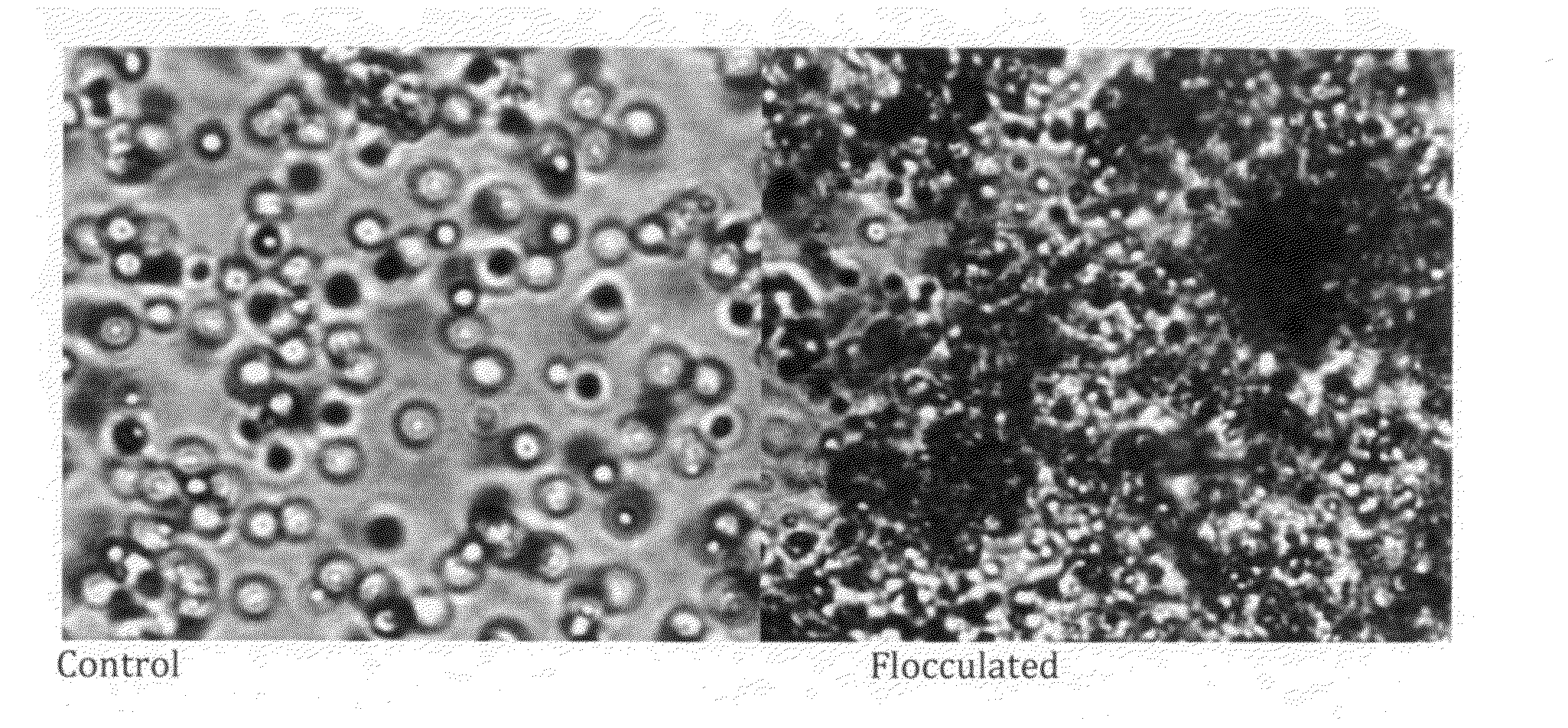

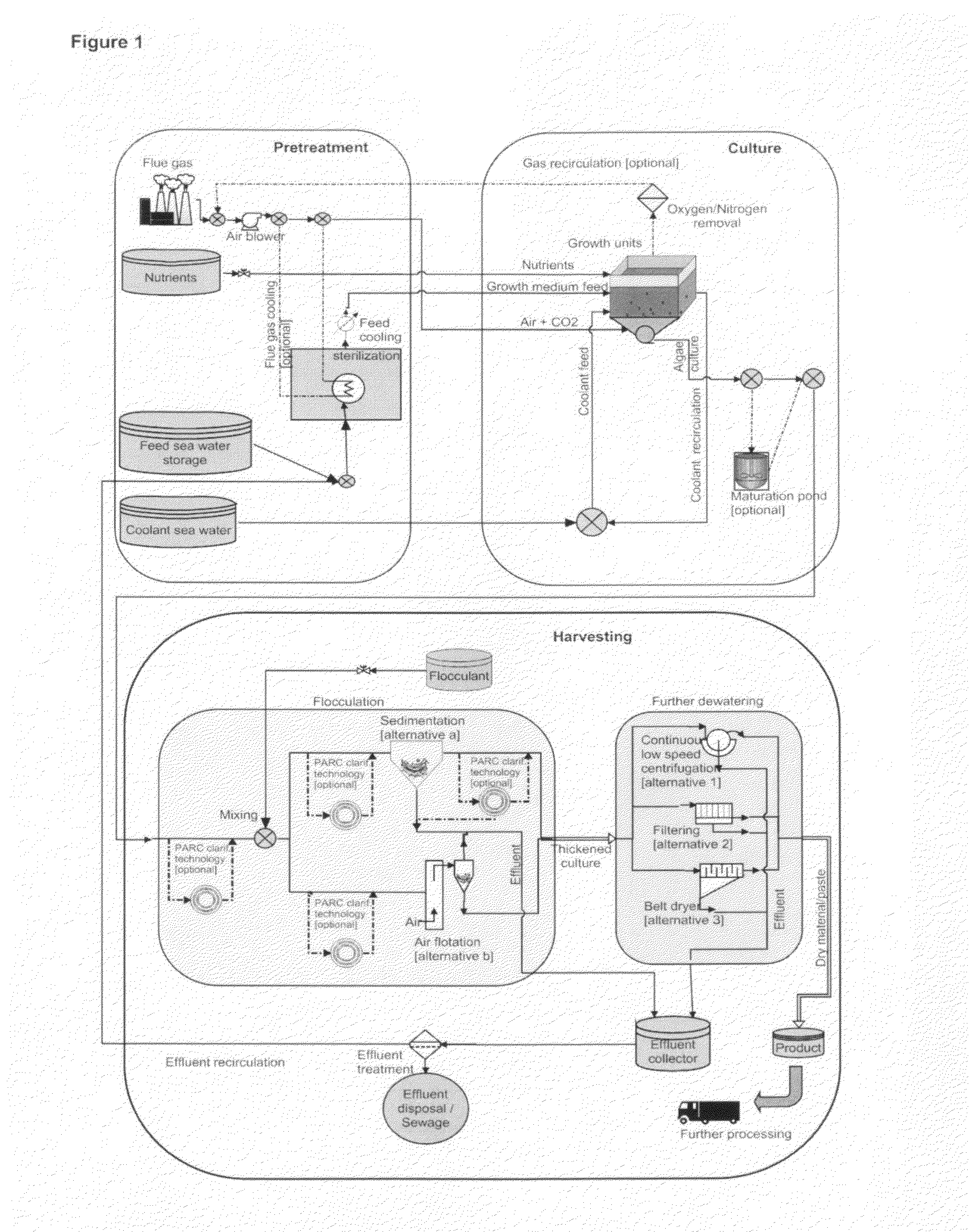

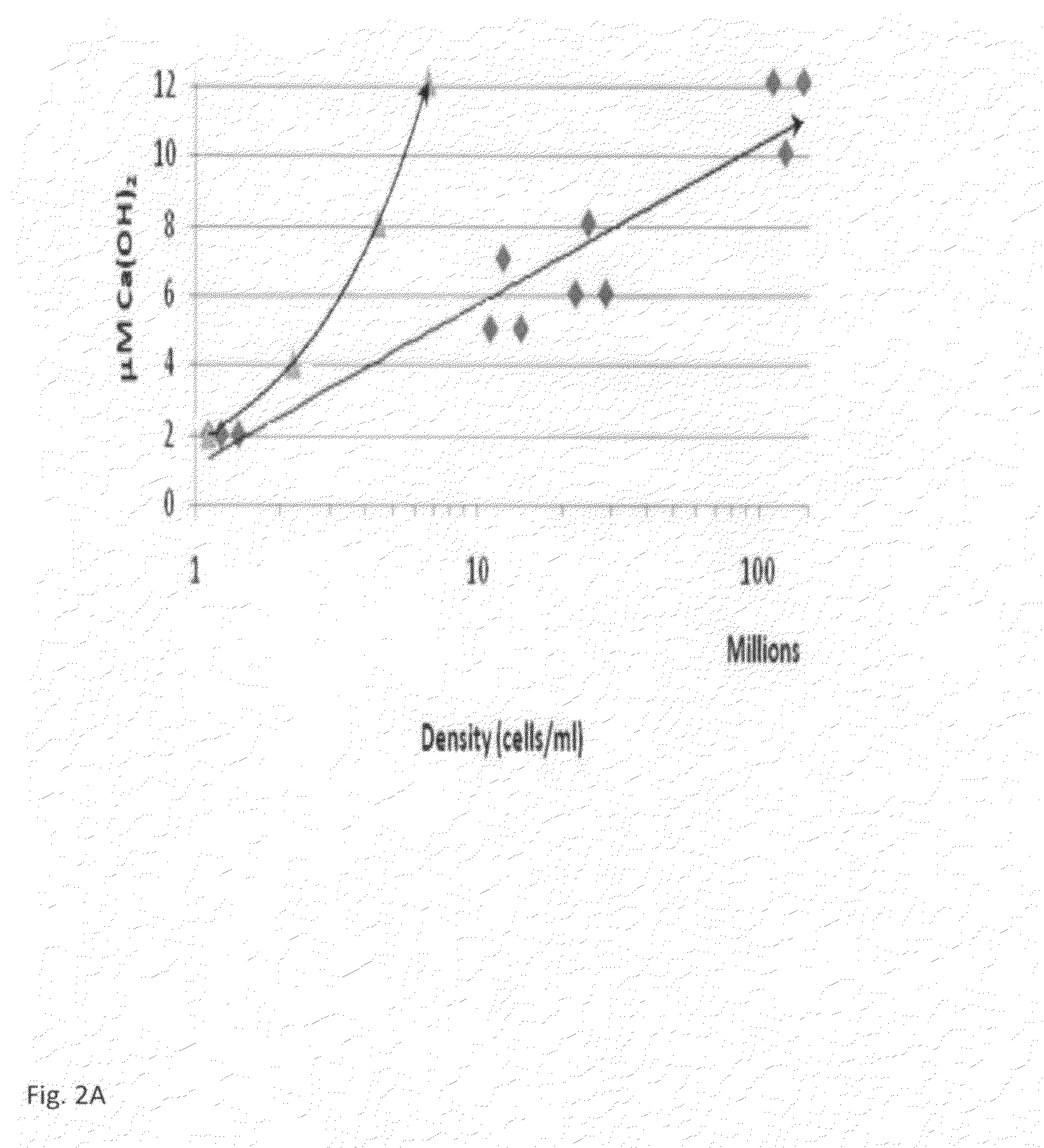

Method and system for efficient harvesting of microalgae and cyanobacteria

The high-speed centrifugation heretofore required for harvesting micro algae and cyanobacteria cultured for biofuels and other co-products is a major cost constraint. Mixing algae / cyanobacteria at high-density culture with far less alkali than previously assumed is sufficient to flocculate the cells. The amount of flocculant required is a function of the logarithm of cell density, and is not a linear function of cell density as had been thought. The least expensive alkali treatments are with slaked limestone or dolomite (calcium hydroxide and magnesium hydroxides). Further water can be removed from the floc by sedimentation, low speed centrifugation, dissolved air flotation or filtration, prior to further processing to separate oil from valuable co-products.

Owner:TRANSALGAE ISRAEL

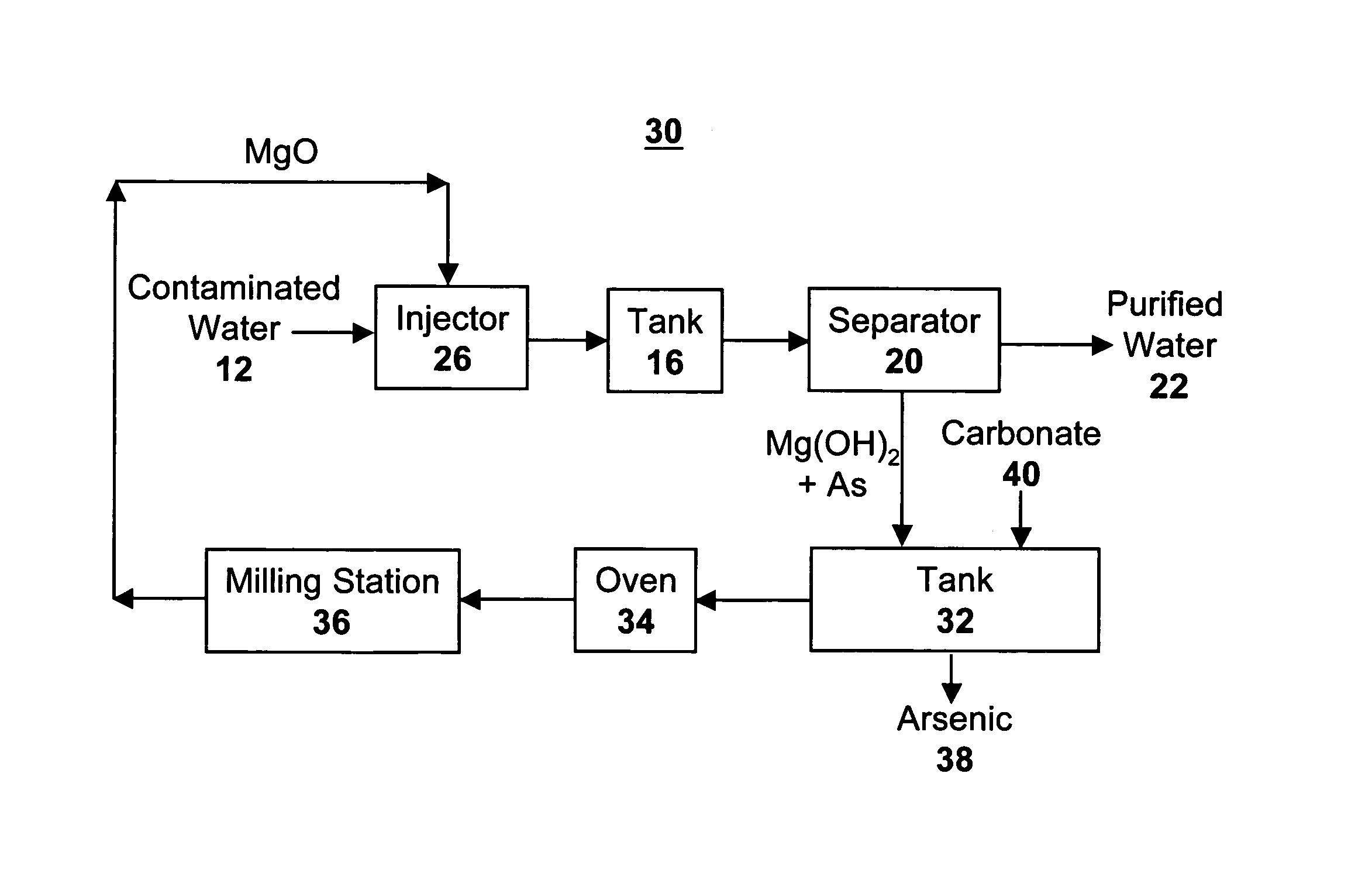

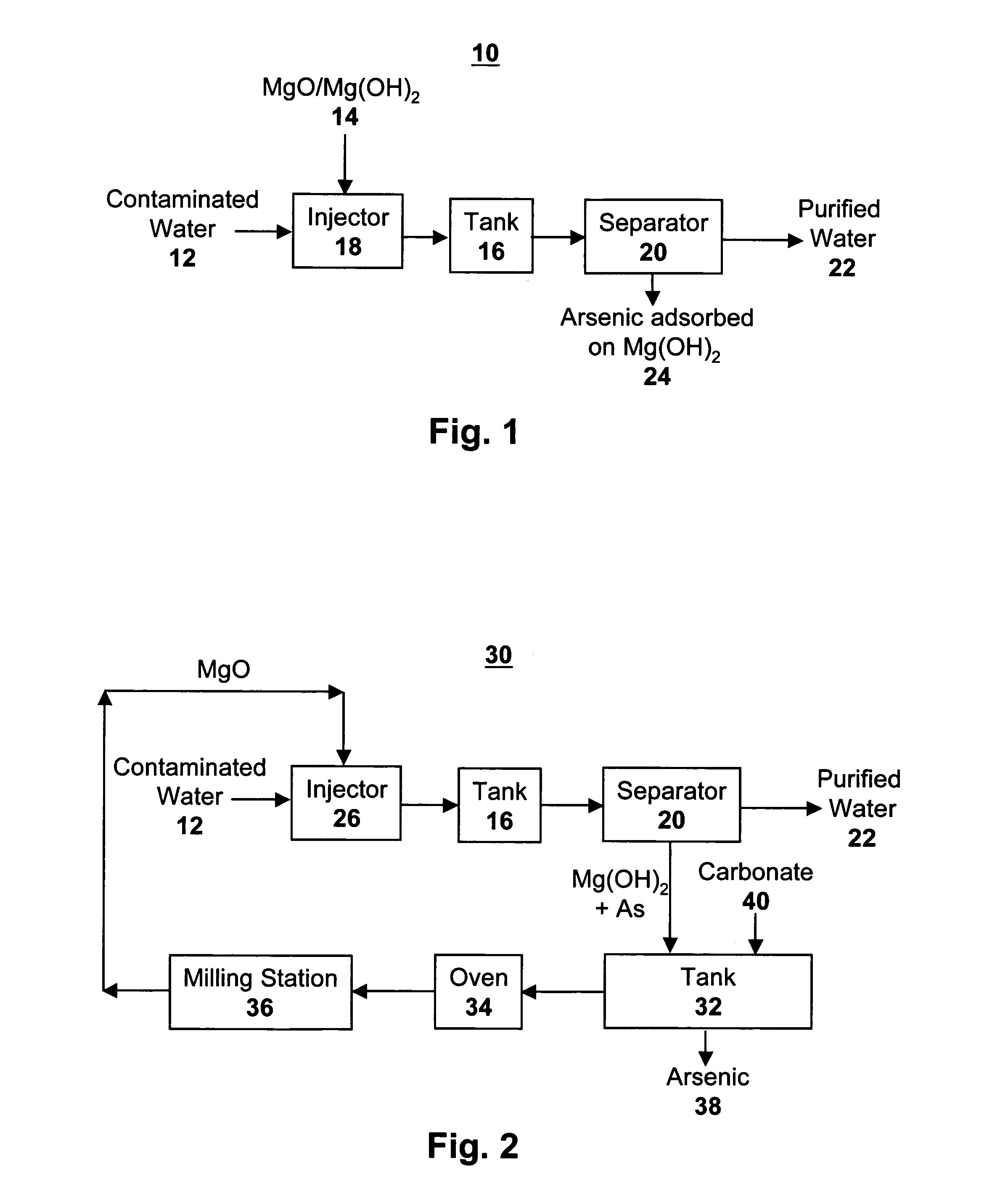

Arsenic removal from water

InactiveUS7247242B1Easy to quantifyEnhance chemical affinityIon-exchanger regenerationWater contaminantsCalcium hydroxideFiltration

Methods for removing arsenic from water by addition of inexpensive and commonly available magnesium oxide, magnesium hydroxide, calcium oxide, or calcium hydroxide to the water. The hydroxide has a strong chemical affinity for arsenic and rapidly adsorbs arsenic, even in the presence of carbonate in the water. Simple and commercially available mechanical methods for removal of magnesium hydroxide particles with adsorbed arsenic from drinking water can be used, including filtration, dissolved air flotation, vortex separation, or centrifugal separation. A method for continuous removal of arsenic from water is provided. Also provided is a method for concentrating arsenic in a water sample to facilitate quantification of arsenic, by means of magnesium or calcium hydroxide adsorption.

Owner:SANDIA NAT LAB

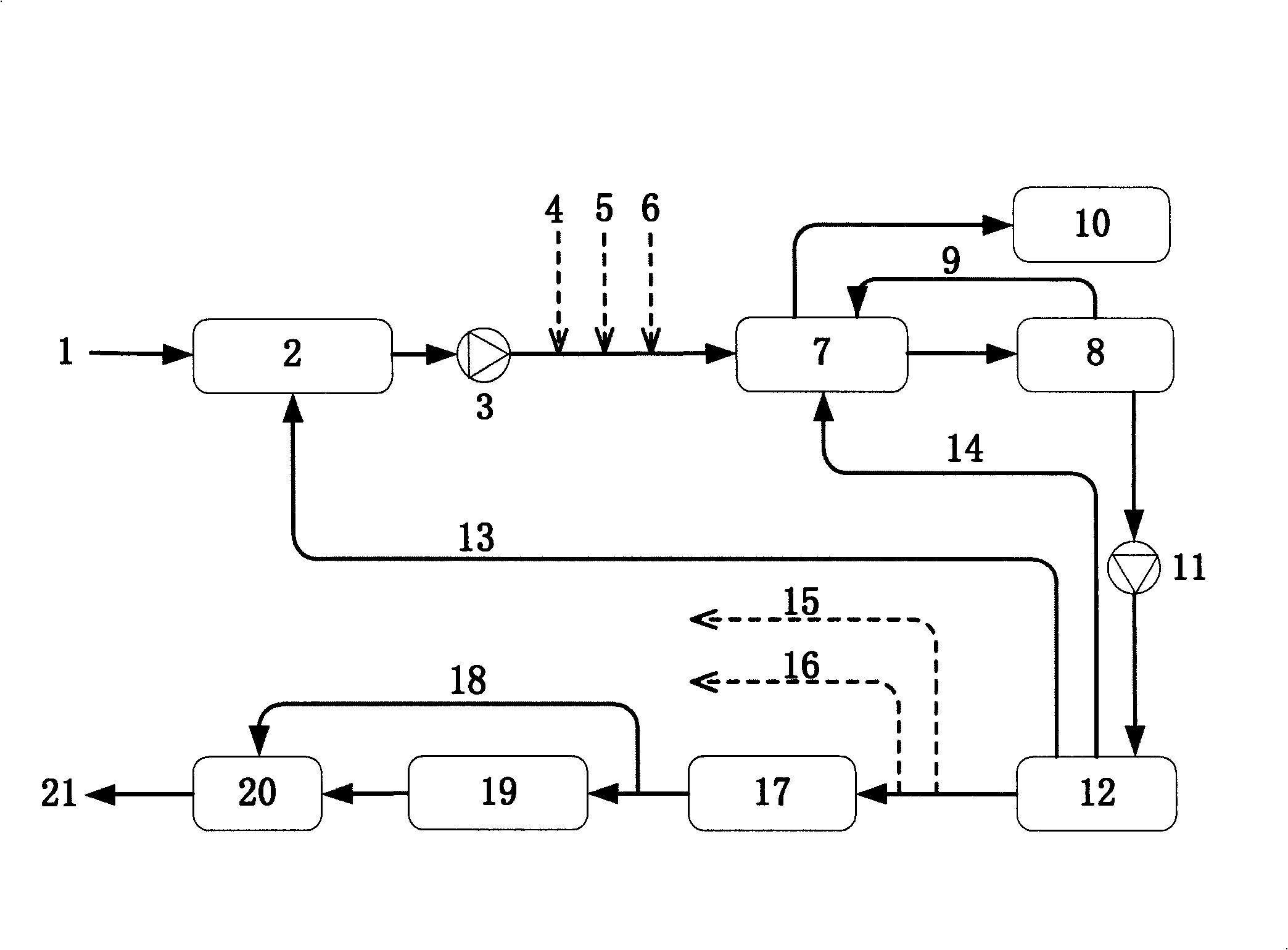

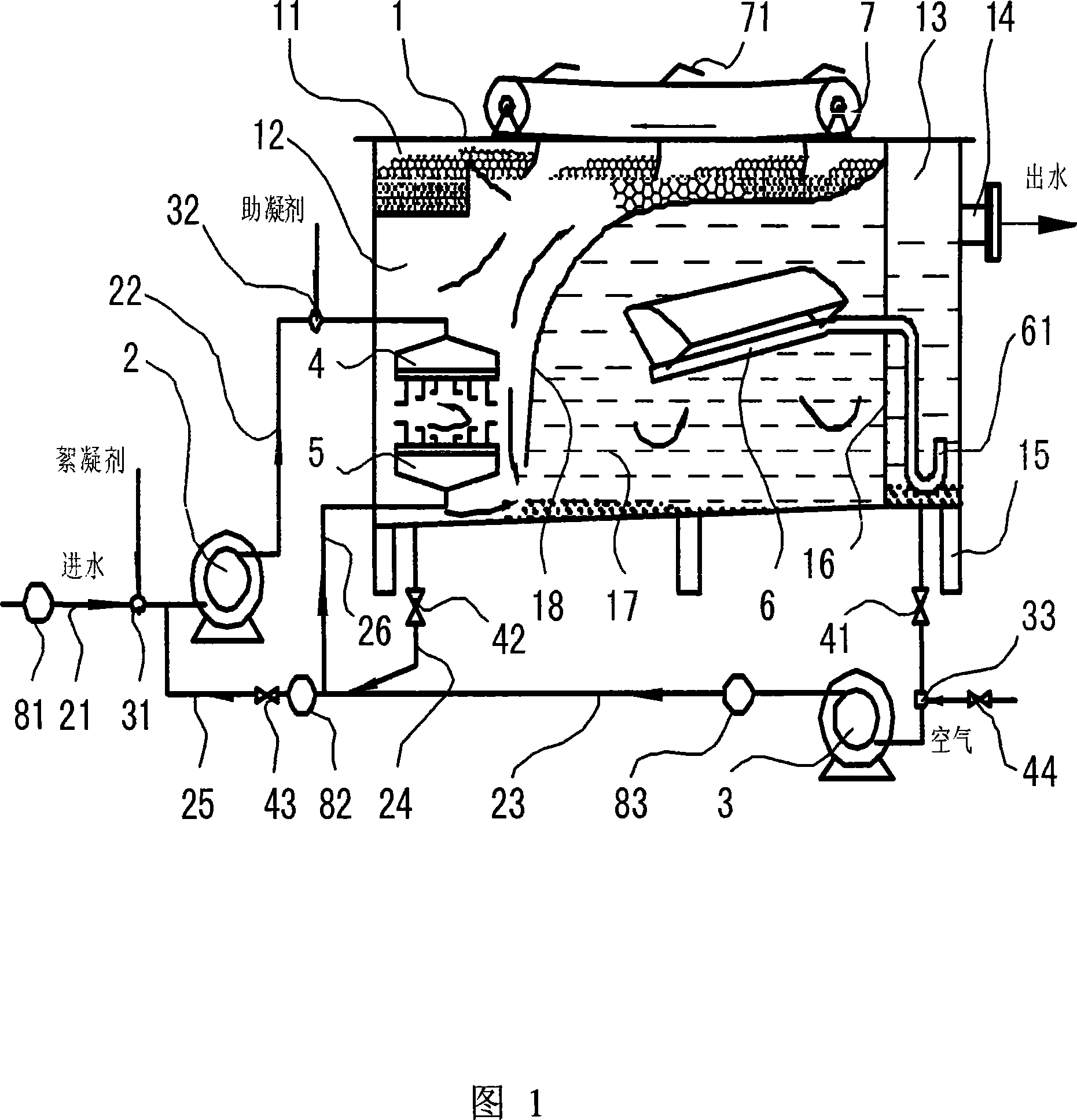

Method and device for treating a great variety of waste emulsion of high concentration using hyperfiltration membrane method

ActiveCN101311127AGood demulsification effectEasy to handleUltrafiltrationWater/sewage treatment bu osmosis/dialysisHigh concentrationLiquid waste

The invention discloses a method for treating the waste emulsion with high concentration and a plurality of varieties by an ultrafiltration membrane method and a device thereof, which belongs to the technical field of waste water and waste liquid treatment. The main technique of the invention is 'dissolved air flotation-ultrafiltration membrane-electrolysis floatation', which can effectively reduce the dosage of medicament and improve emulsion breaking effect by adopting an efficient dissolved air flotation system, moreover, the water for dissolved air flotation, which is taken from a subsequent intermediate water tank, can flexibly adjust and dilute the concentration of the waste water, thus improving the running stability and the shock resistant loading capability of the system. An ultrafiltration membrane with large flux, high separative efficiency and long service life is adopted in an ultrafiltration system to realize oil-water separation and to concentrate the emulsion for a plurality of times and then floating oil is recovered, the waste water generated in ultrafiltration washing is treated again after reflow, thus reducing waste liquid discharging. Electrolysis floatation can remove residual emulsified oil and dissolved oil in the waste water, thus further lowering the COD value of yielding water. When the quality of raw water is changed, an activated carbon adsorption unit can guarantee the quality of the yielding water to be standard. The method and the device of the invention can process waste emulsion with high concentration and a plurality of varieties and have simple and reasonable technique, good quality of yielding water, compact layout of the device, thus facilitating automatic control and realizing recovery of emulsion and recycle economy as well as changing waste to be profitable simultaneously.

Owner:GO HIGHER ENVIRONMENT GRP CO LTD

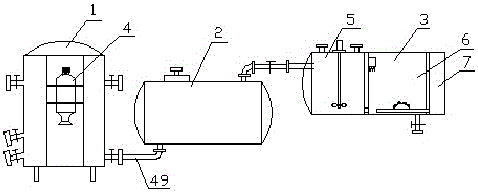

Oil removing pretreatment technology for petroleum oil refining wastewater

ActiveCN106007209AStructural scienceSimple processFatty/oily/floating substances removal devicesTreatment involving filtrationCycloneWater based

The invention discloses an oil removing pretreatment technology for petroleum oil refining wastewater. According to the oil removing pretreatment technology, a water collecting tank with gratings is used for separating sand and sludge; a three-phase cyclone liquid separation floating oil collecting and discharging adjusting tank is used for achieving separation of water, oil and residues; a cyclone oil coarse graining polymerization oil-water separator is used for removing fine oil grains; a dissolved air flotation device is used for demulsification and flocculation reaction, wherein air bubbles and suspended solids in wastewater make contact for adhesion and float upwards, and the standard is met through residue scraping. The technology is simple, the structure is scientific, the three-phase cyclone liquid separation floating oil collecting and discharging adjusting tank, the cyclone liquid coarse graining polymerization oil-water separator and the dissolved air flotation device jointly serve as the core treatment scheme, oily wastewater is pretreated through the density difference of oil and water based on the fluid dynamics principle, a physical method and a chemical method act jointly, and the oil content in the pretreated oily wastewater is smaller than or equal to 20 mg / L and reaches the standard. The oil removing pretreatment technology is large in daily treatment amount, high in oil removing efficiency, remarkable in oil collecting effect and considerable in economic benefit, and the water content of the recycled waste oil is 5% or lower.

Owner:江苏中嘉华新环保科技有限公司

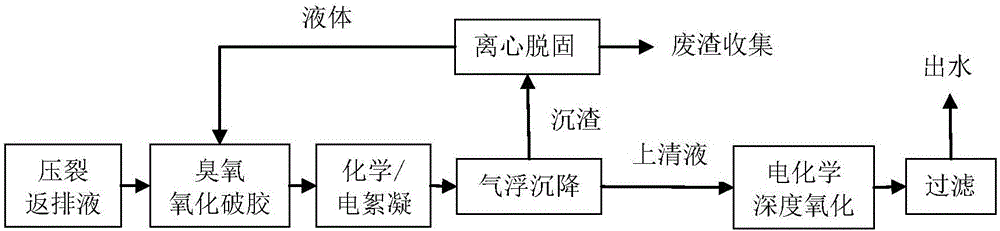

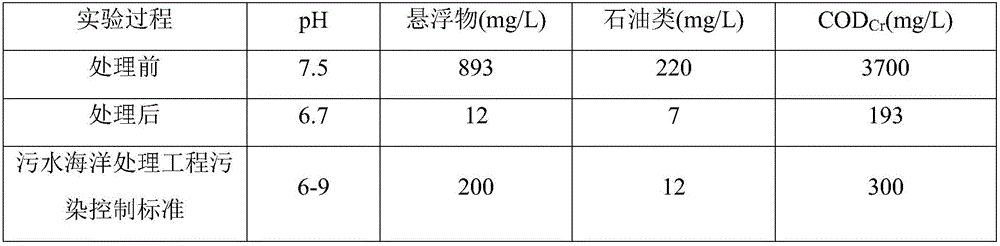

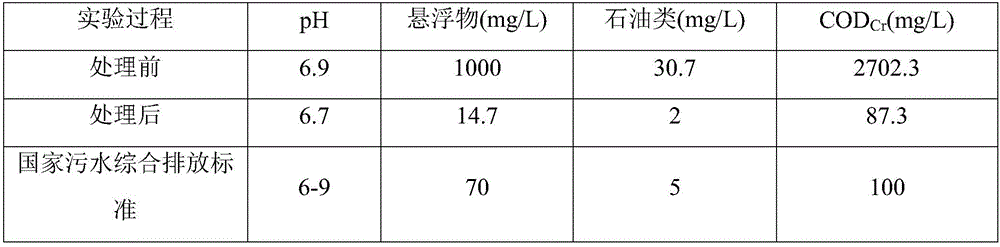

Method for treating backflow fracturing fluid

InactiveCN106242132AReduce the introductionReduce dosageWaste water treatment from quariesWater/sewage treatment by centrifugal separationLiquid wasteSolubility

The invention discloses a method for treating backflow fracturing fluid. The method is characterized by comprising steps of carrying out electric flocculation on the guar gum backflow fracturing fluid; carrying out air flotation sedimentation on waste fluid obtained after electric flocculation is carried out; carrying out electrochemical advanced oxidation treatment on supernatant fluid obtained after air flotation sedimentation is carried out; carrying out filtration treatment on waste fluid obtained after electrochemical advanced oxidation treatment is carried out and draining the waste fluid backwardly or externally. The method has the advantages that chemical flocculation and chemical oxidation are replaced by electric flocculation and electrochemical oxidation, dissolved air flotation and filtration are carried out, accordingly, introduction and dosage of new chemical agents can be effectively reduced, secondary intervention of chemically soluble interference ions in wastewater can be relieved, and the method is beneficial to reducing secondary pollution risks and the costs; the treated backflow fracturing fluid can be recycled for preparing fracturing fluid or being injected to strata again.

Owner:INST OF SINOPEC OILFIELD EQUIP CORP +1

Deoiling of SAGD produce water

ActiveUS20110147316A1Waste water treatment from quariesWater/sewage treatment by centrifugal separationInduced gas flotationReverse osmosis

Methods of deoiling oily water such as SAGD and frac produce water. The oily water is treated with a natural coagulant selected from tannins and chitosan. A cationic and / or anionic flocculant may also be added to the treated oily water. The thus treated oily water may be subjected to conventional mechanical oil separation techniques such as hydrocyclonic separation, dissolved air flotation, entrapped air flotation, induced gas flotation, gravity filters, reverse osmosis filters, API, or Voraxial® bulk separators and the like.

Owner:BL TECH INC

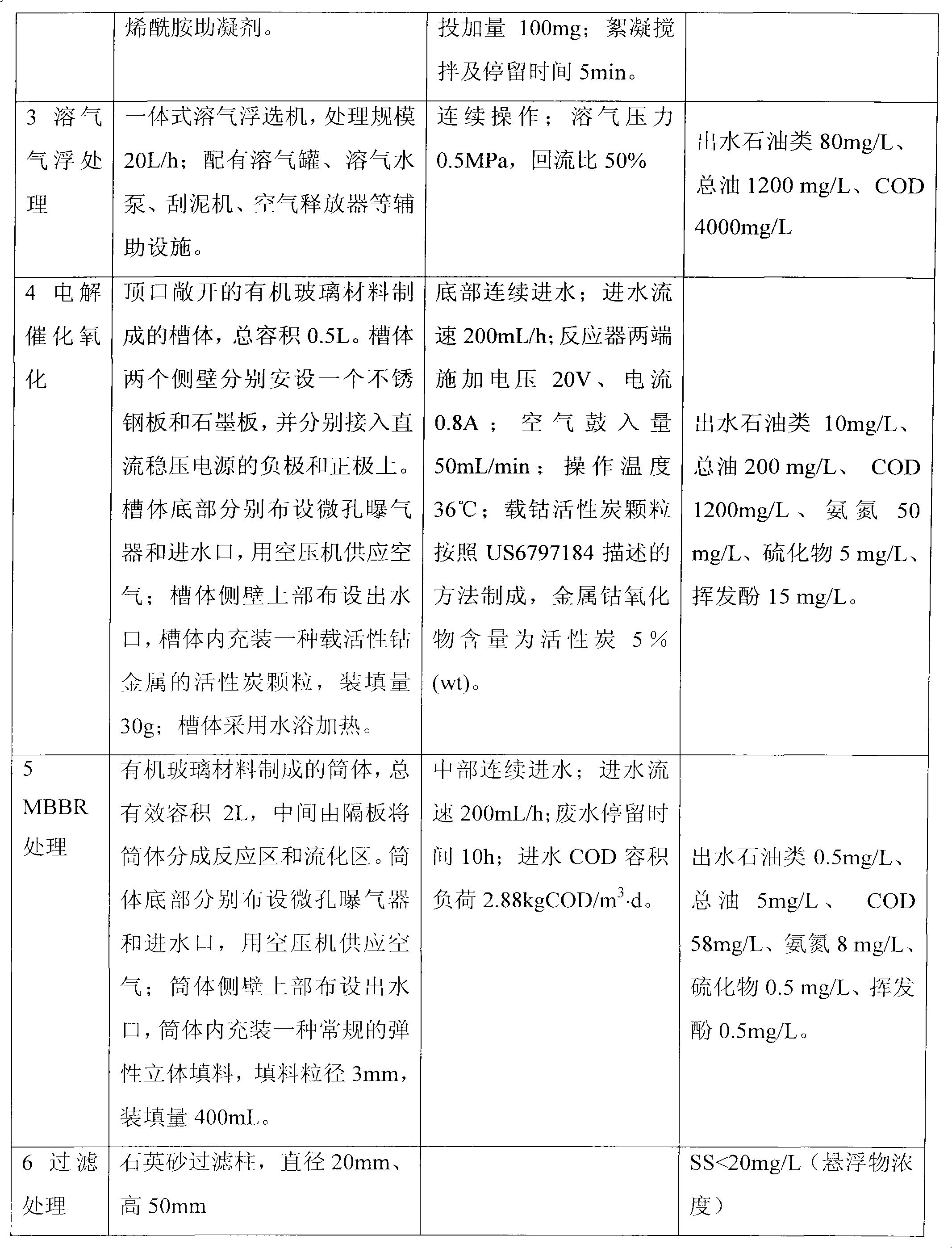

System for advanced treatment and recycle of cold rolling wastewater

ActiveCN101428939AEfficient removalAchieve the goal of energy saving and emission reductionDispersed particle separationWaste water treatment from metallurgical processCooling towerEngineering

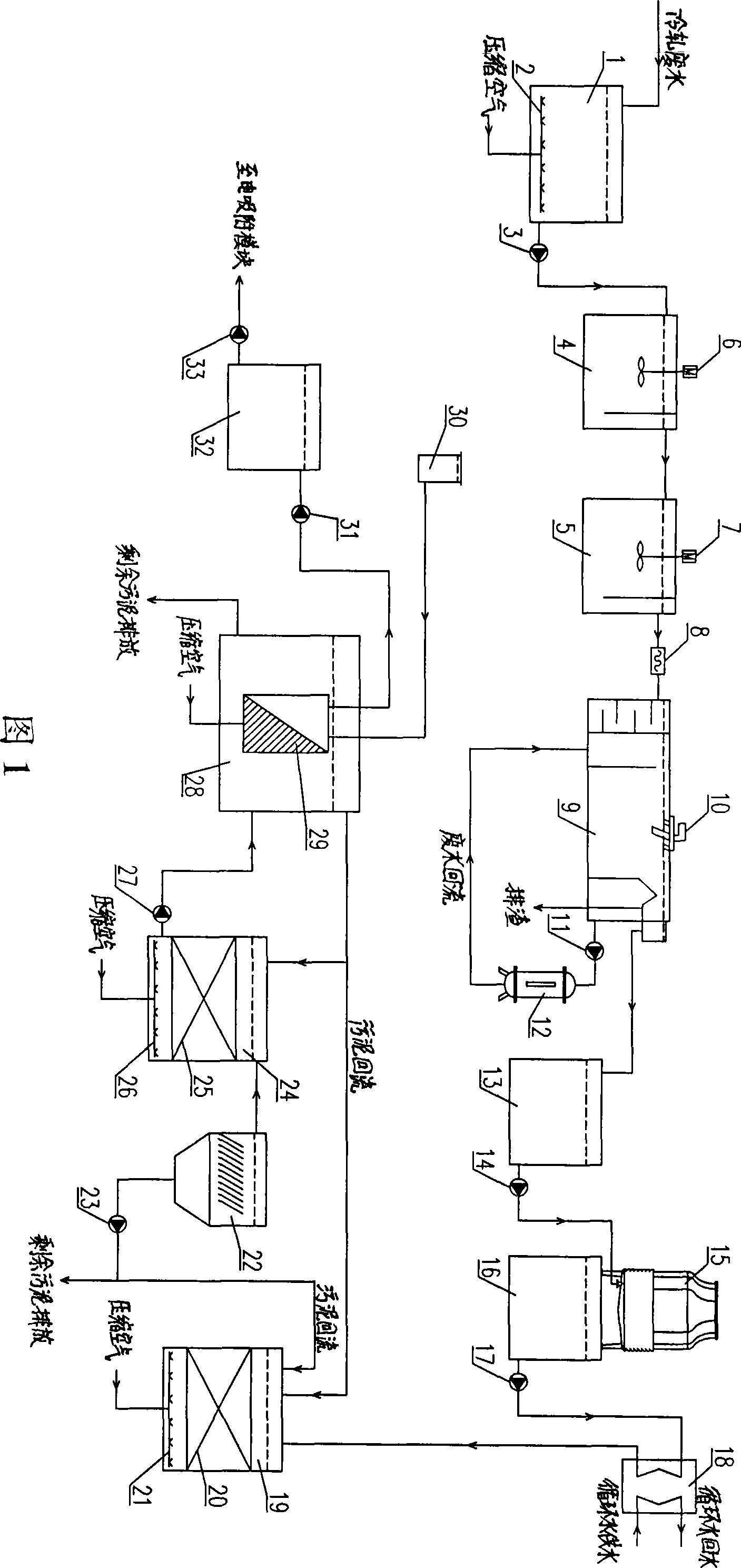

The invention relates to a cold rolling waste water advanced treatment reuse system, which comprises a pretreatment process, a biological two-stage treatment process and an electric adsorption desalting treatment process. The pretreatment process comprises a uniformly-adjusting tank, a two-stage pH adjusting groove, a dissolved-air float, a middle pond, a cooling tower, a cooling pond, a plate type heat exchanger and the like. The biological two-stage treatment process comprises a biological contact oxidation pond, an inclined plate settling tank, a membrane biological reaction tank, a reactor, a cleaning box, a suction pump and the like. The electric adsorption desalting treatment process comprises an electric adsorption raw water pool, an electric adsorption moudle, a clean water tank, a reuse water pump, a regeneration pump, a sewage drain pump, an electric adsorption enriched water tank and the like. The cold rolling waste water undergoes the pre-treatment process comprising the uniform aeration adjustment, the two-stage pH adjustment and the dissolved-air flotation, the biological two-stage treatment step provided with the membrane biological reactor for contact oxidation and the electric adsorption deep desalting treatment process, thereby effectively removing pollutants in the cold rolling waste water, reutilizing the cold rolling waste water and achieving the aim of energy conservation and emission reduction.

Owner:宝武水务科技有限公司

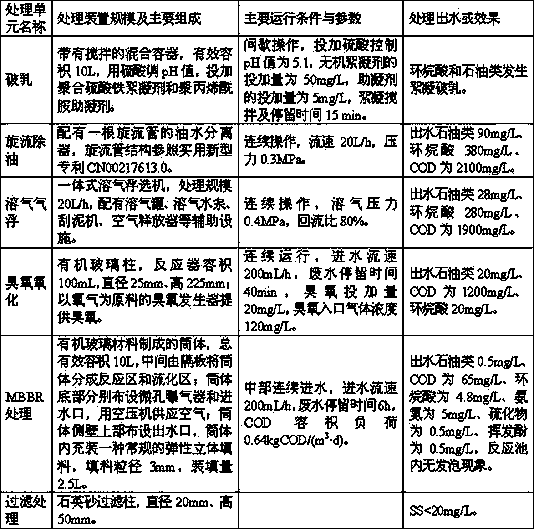

Treatment method for waste water from processing acid-containing crude oil

ActiveCN103771652ASolve the failure to meet the standardSolve processingMultistage water/sewage treatmentAfter treatmentOil separation

The invention relates to a treatment method for waste water from processing acid-containing crude oil, and the method is used in the treatment of waste water containing naphthenic acid from the refining process of acid-containing crude oil. The method adopts a combined process including demulsification, cyclone oil removal, dissolved air flotation, ozone oxidation, MBBR and filtering to treat the wastewater containing naphthenic acid discharged from an electric desalting device in the crude oil refining process, and the outlet water after treatment reaches discharge standards. The method can prevent the treatment process of other waste water, such as oil-containing sewage and salt-containing waste water from the influence from naphthenic acid, and benefit the stable operation of oil separation, flotation, biochemical treatment and depth treatment units in final sewage works, so as to solve the problems of unqualified waste water from processing acid-containing crude oil and foaming of biochemical treatment, and provide a good basis for waste water reuse.

Owner:CHINA PETROLEUM & CHEM CORP +1

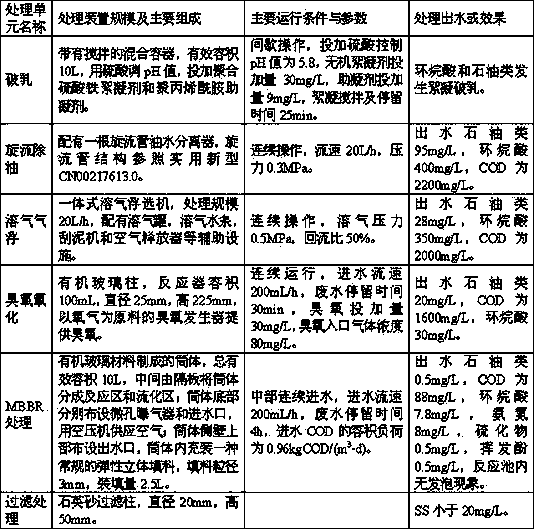

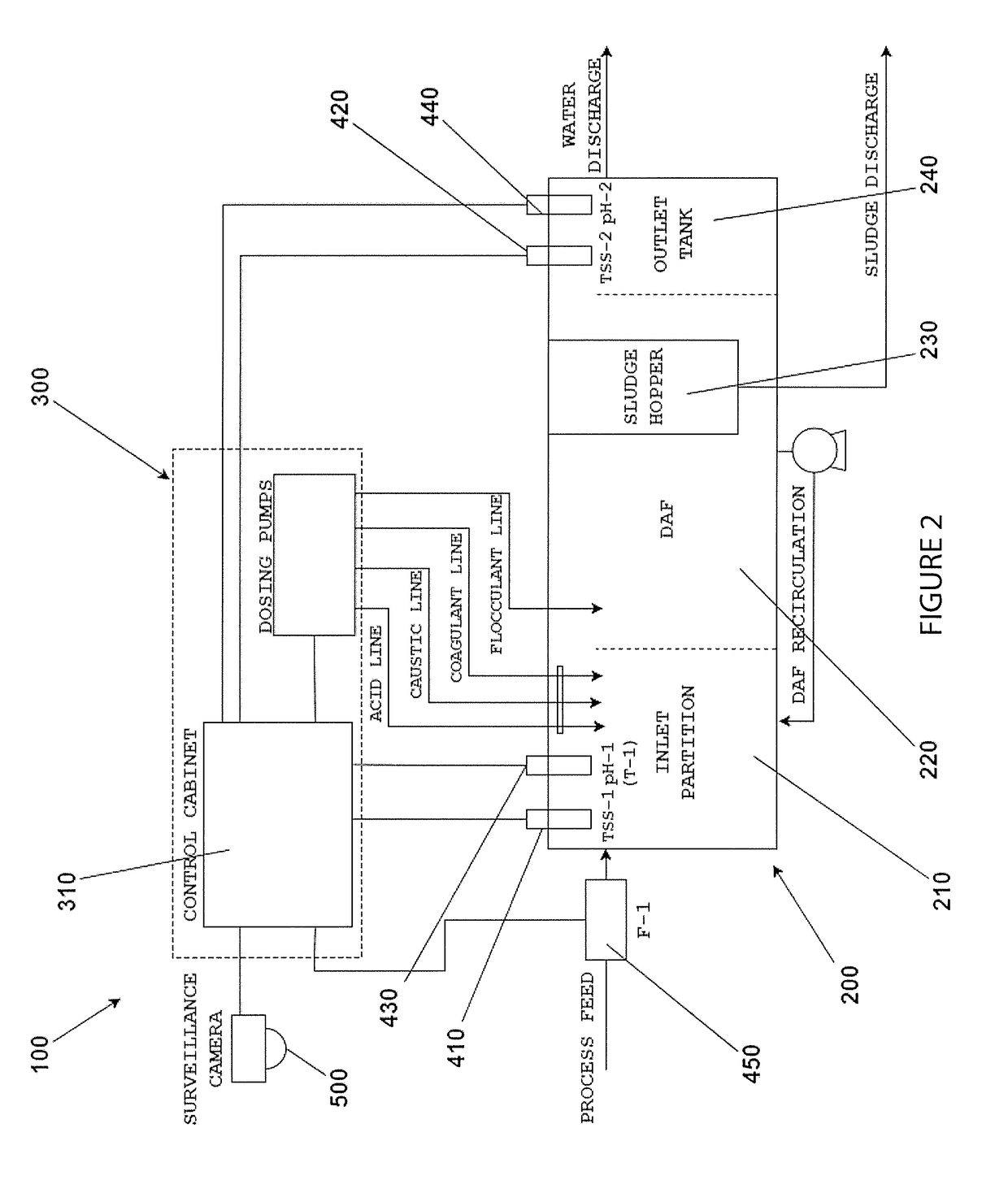

Water treatment system and method

ActiveUS20170297929A1Discharge costReduce and even eliminate non-complianceWater treatment parameter controlNature of treatment waterWater treatment systemNatural-gas processing

Disclosed herein is a water treatment system for connection to a water treatment plant (e.g. a dissolved air flotation device). The plant may have an inlet for the receipt of feed water (e.g. waste water) and an outlet for the discharge of treated water. The treatment system may comprise a first sensor disposed such that it is in fluidity communication with the feed water, and a second sensor disposed such that it is in fluidity communication with the treated water. The first and second sensors may be configured to sense parameters of the feed and treated water. The system may further comprise a first applicator (e.g. a pump) that is configured to discharge a treatment source (e.g. a chemical source) to the plant to treat the feed water. The disclosed system may be used to treat waste water (e.g. the treatment of effluent from oil refineries, petrochemical and chemical plants, natural gas processing plants, paper mills and general water treatment). The system has analogous applications in other processing methods that also use DAF, or very similar, systems, such as the processing of mineral ores and other such solid extraction processing methods.

Owner:WATERWERX TECH PTY LTD

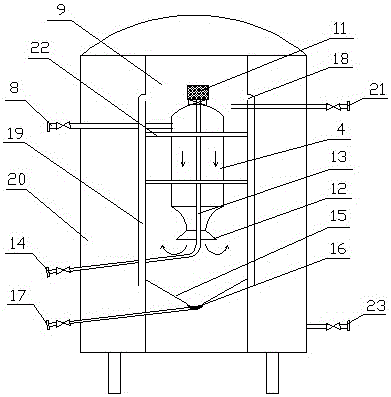

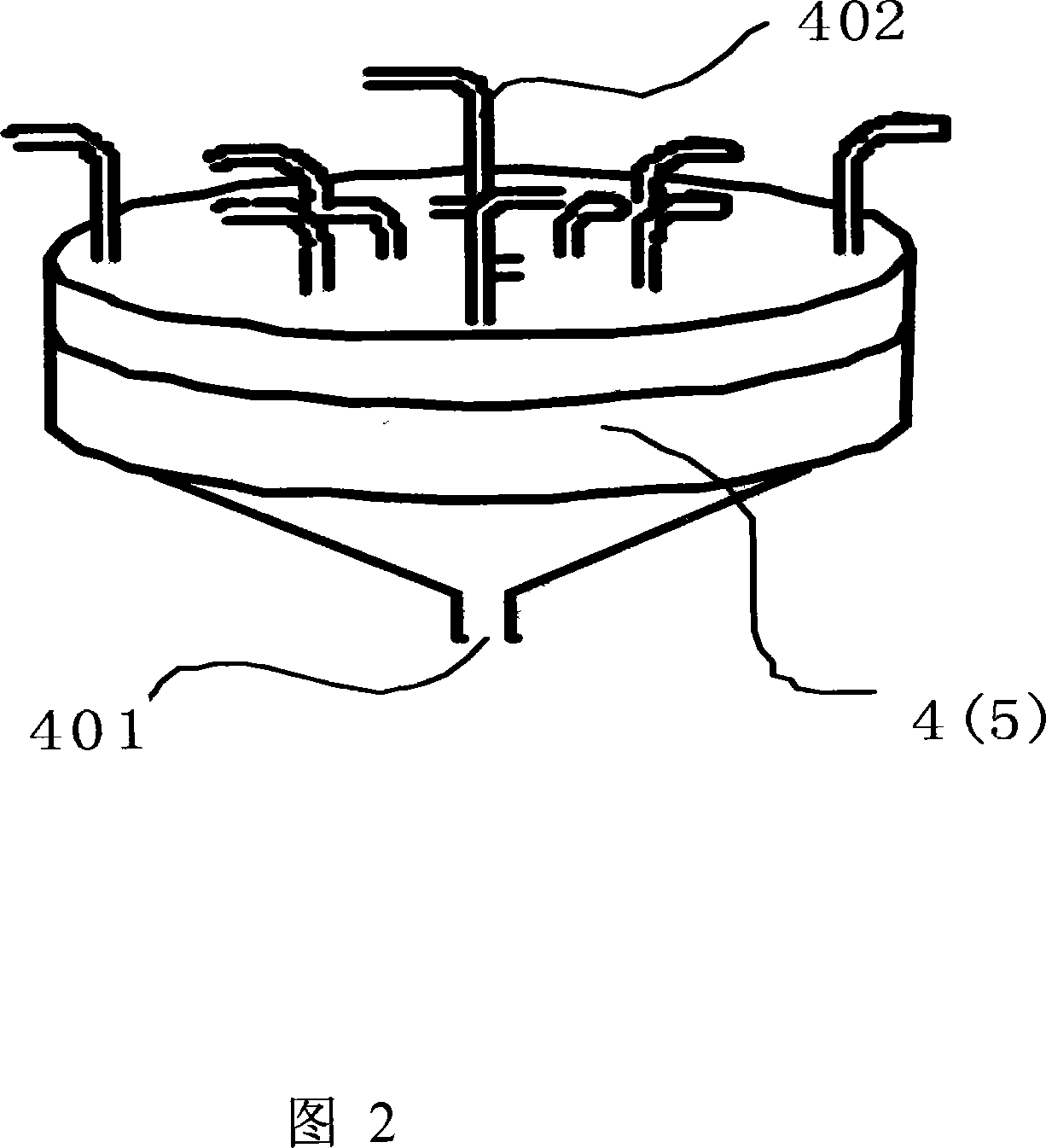

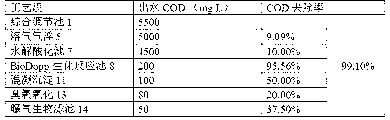

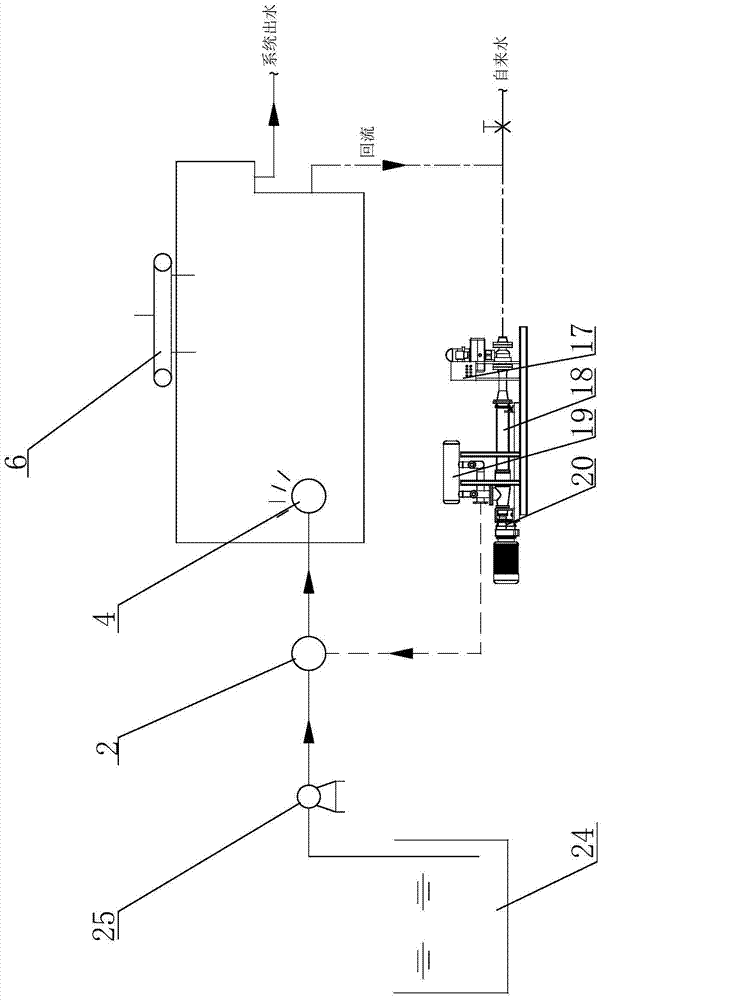

Backflow air-floating device for water-arrangement optimization multi-phase flow pump

The invention relates to a multi-phase flow pump reflux dissolved air flotation device, which is used for the treatment of oil-containing, papermaking and other industrial waste water and urban sewage. The device includes a water inlet pump, a multiphase flow dissolved air pump, an inlet water swirl distribution head, a backflow dissolved air swirl distribution head, a clear water collection pipe, a slag scraper, and a slag collection tank. Because the device adopts multi-phase flow pump to dissolve air and dynamic swirl to distribute water, it saves air compressors, dissolved air tanks and other equipment, and has the characteristics of simple structure, small footprint, energy saving and high removal efficiency.

Owner:CHINA NAT OFFSHORE OIL CORP +1

High-suspension easy-to-biochemically treated wastewater treatment method

InactiveCN103833188AReduce consumptionFully intelligent operation monitoring and controlMultistage water/sewage treatmentHigh concentrationProcess systems

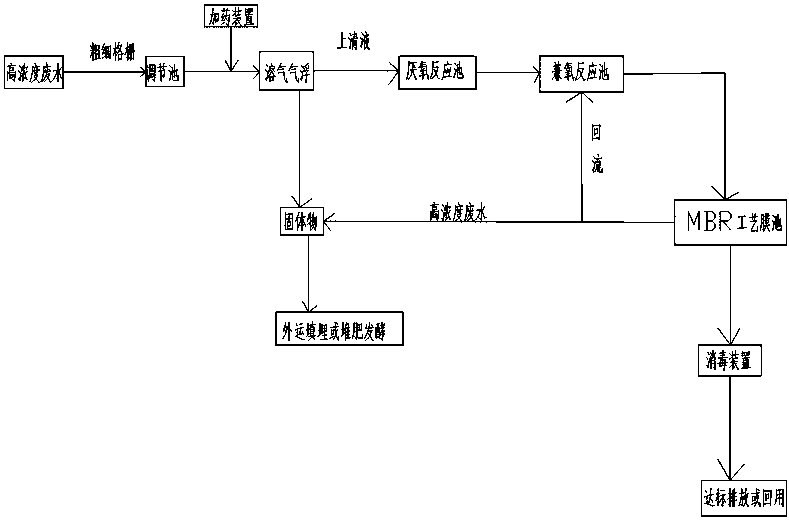

The invention discloses a high-suspension easy-to-biochemically treated wastewater treatment method, which is applied to the treatment of various kinds of high-concentration easy-to-biochemically treated organic wastewater. The method comprises the following steps of 1, collecting wastewater, and performing advanced solid-liquid separation in a dissolved air flotation way; 2, performing anaerobic decomposition on the separated wastewater by using anaerobic and facultative tanks; 3, causing the decomposed wastewater to enter an MBR (membrane biological reactor) process system; and 4, disinfecting and sterilizing effluent obtained by an MBR process to discharge water reaching standards by using sodium hypochlorite. According to the wastewater treatment method, high-concentration easy-to-biochemically treated wastewater can be effectively treated, the construction fund can be greatly saved, a small land is occupied, and the method is stable in running, low in cost and particularly suitable for industrial production.

Owner:蒲晓斌

Bio tank/oxygen replenishment system

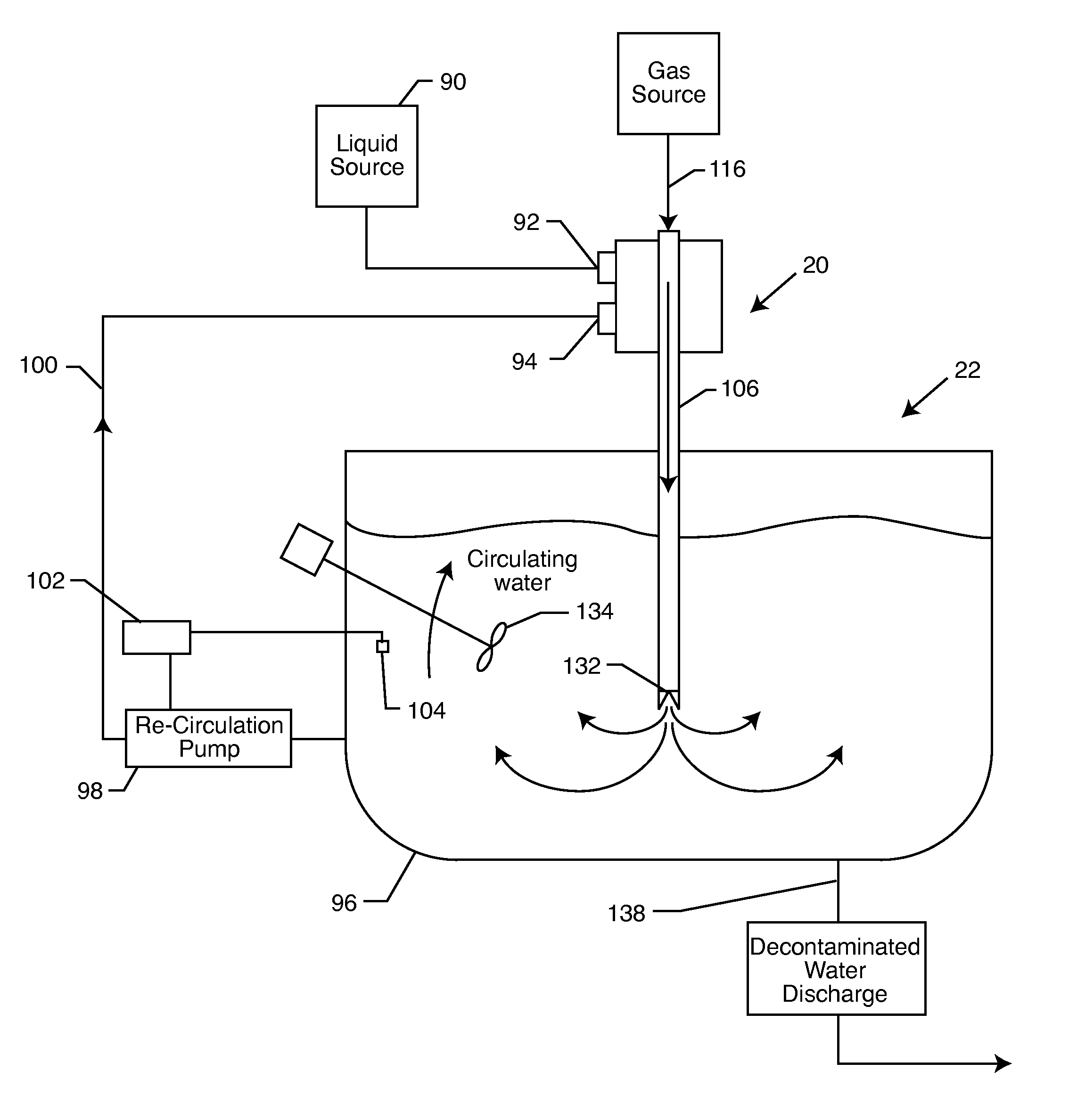

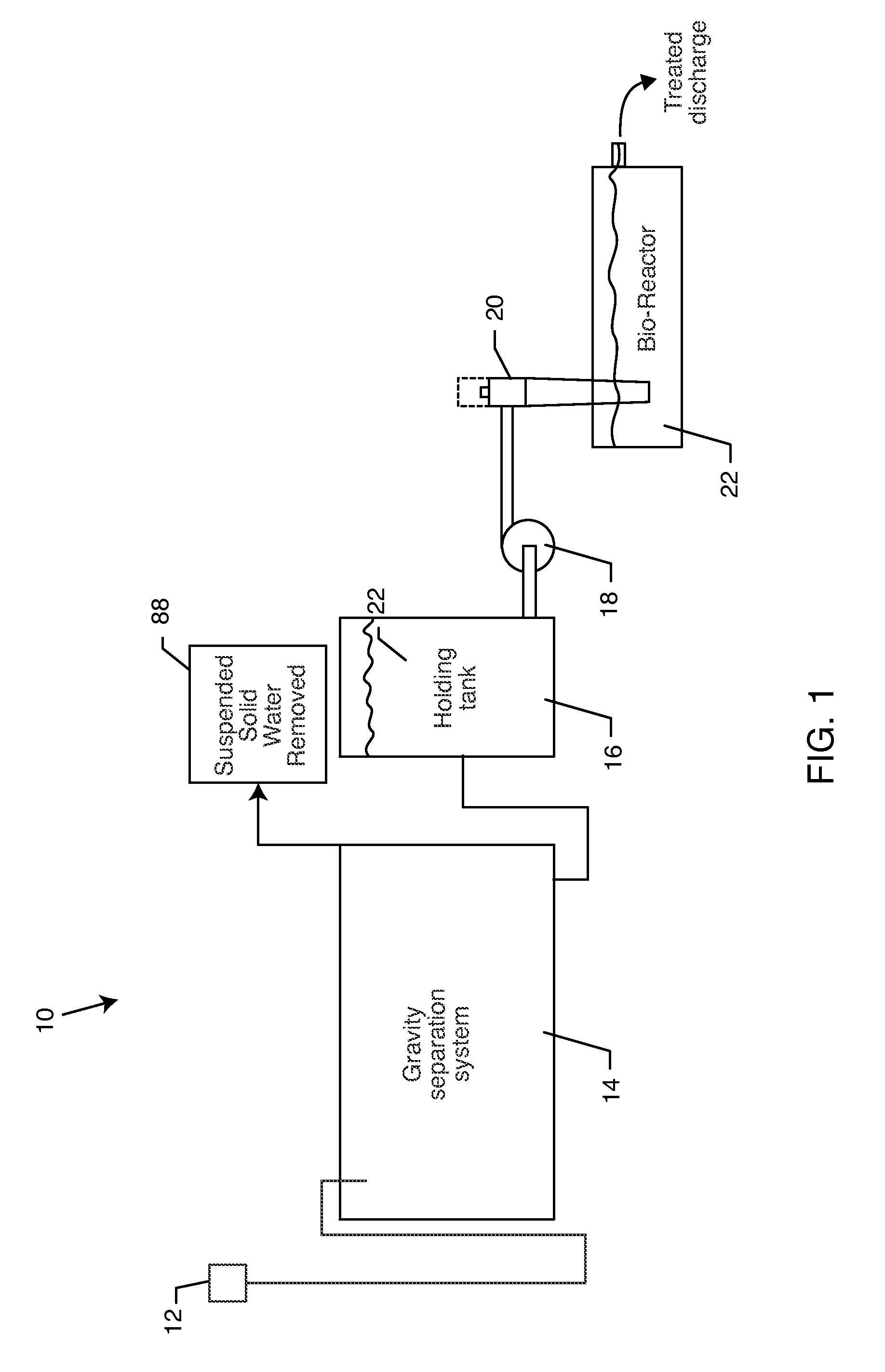

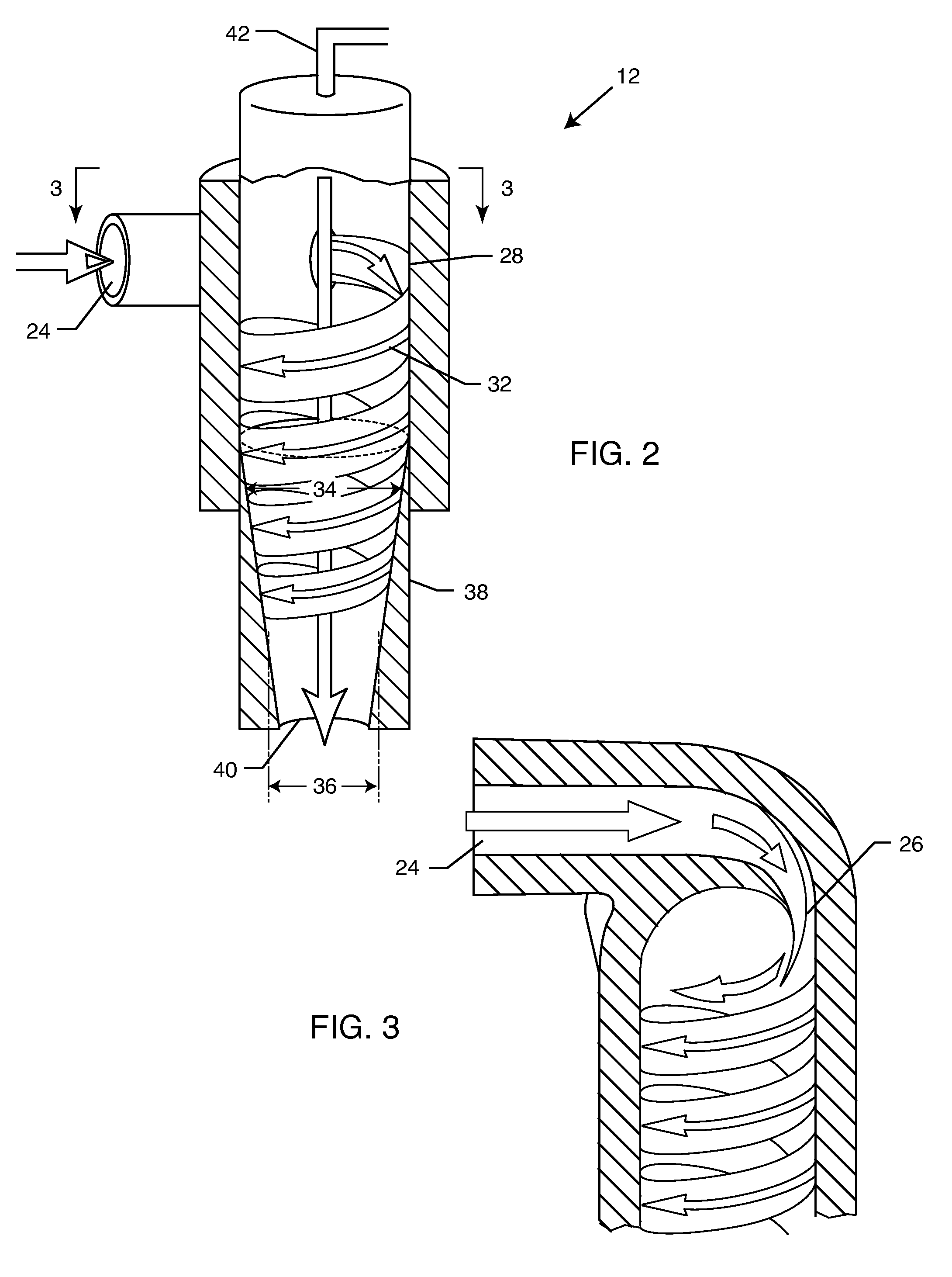

ActiveUS20080041773A1Bioreactor/fermenter combinationsBiological substance pretreatmentsPre treatmentBiological species

A system is disclosed herein for treating wastewater liquid by utilizing aerobic biological species. The contaminated wastewater stream is pretreated in a dissolved air flotation system to remove suspended solid waste, including large particles such as fats, grease, and physically emulsified oils. The purified wastewater containing dissolved waste is thereafter oxygenated and further decontaminated in a bioreactor tank. Biological species in the bioreactor tank consume oxygen and perform bodily functions that converts dissolved waste into easily removable carbon dioxide and suspend solids. Oxygen consumed by the biological species is replenished by pumping the wastewater though a liquid-oxygen mixer. A controller regulates the speed of the pump based on real-time oxygen concentration measurements provided by a corresponding oxygen probe disposed within the wastewater in the bioreactor tank.

Owner:WORLD WATER TECH

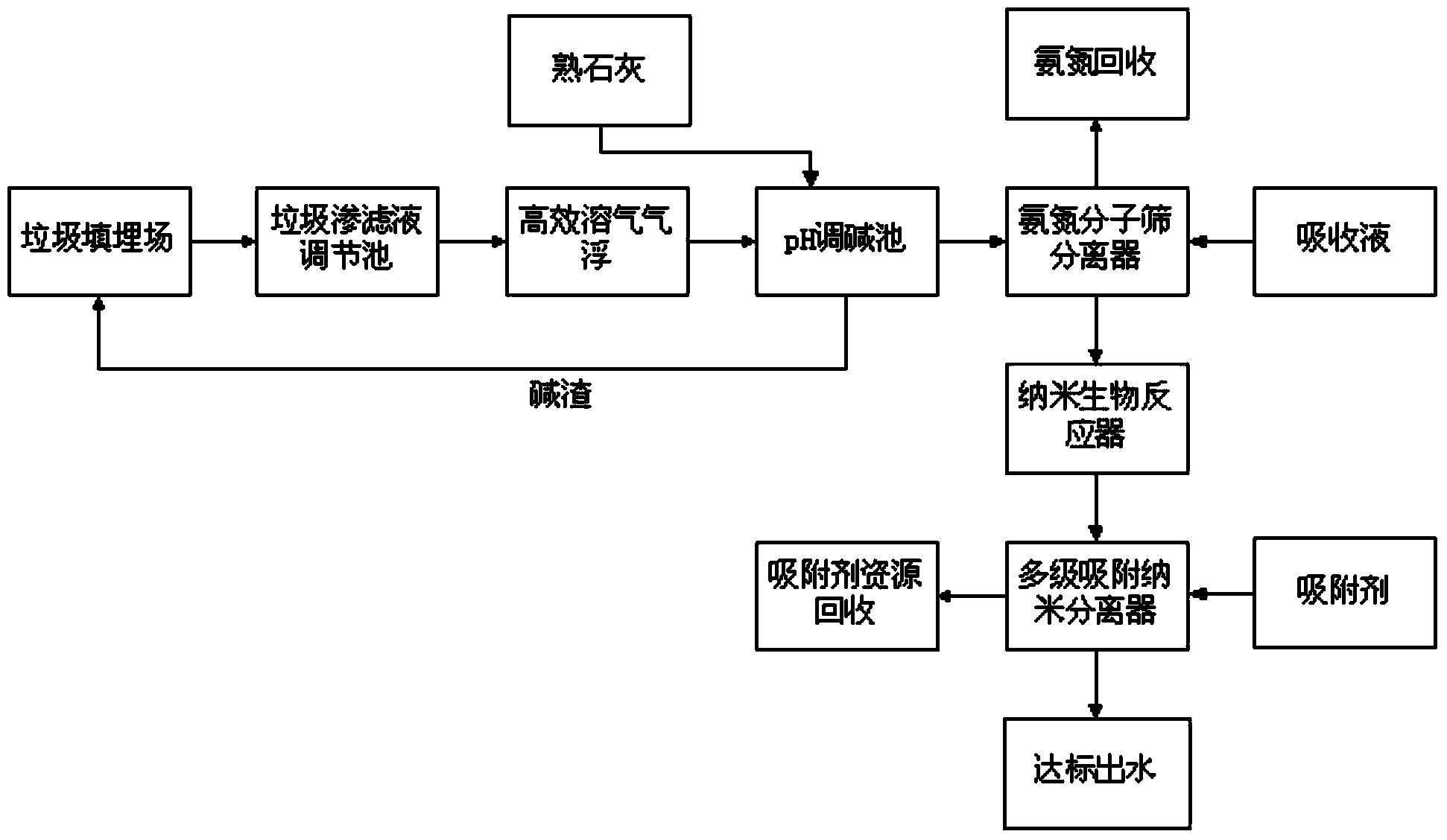

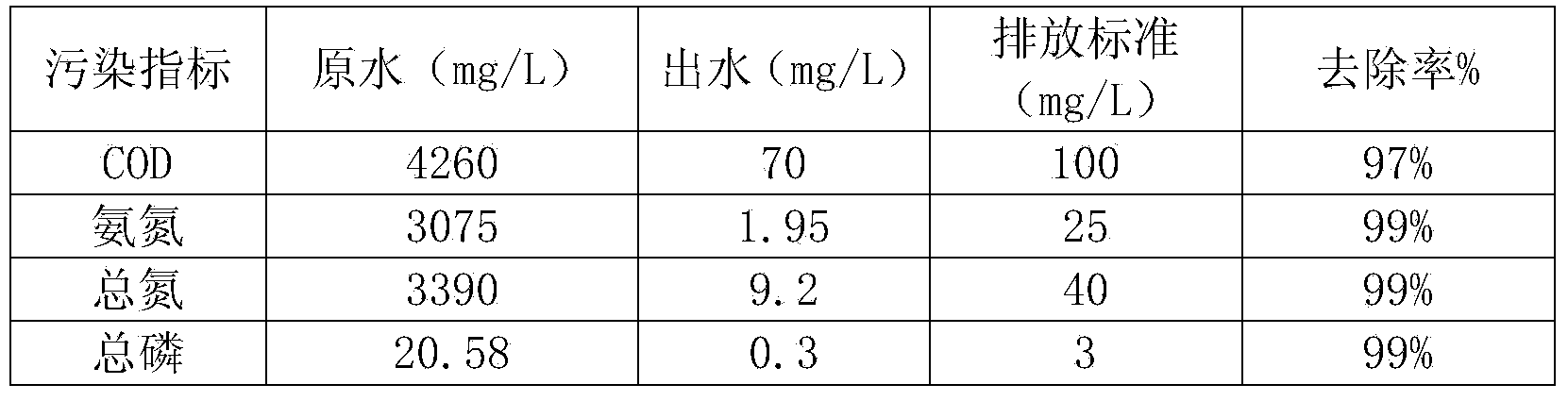

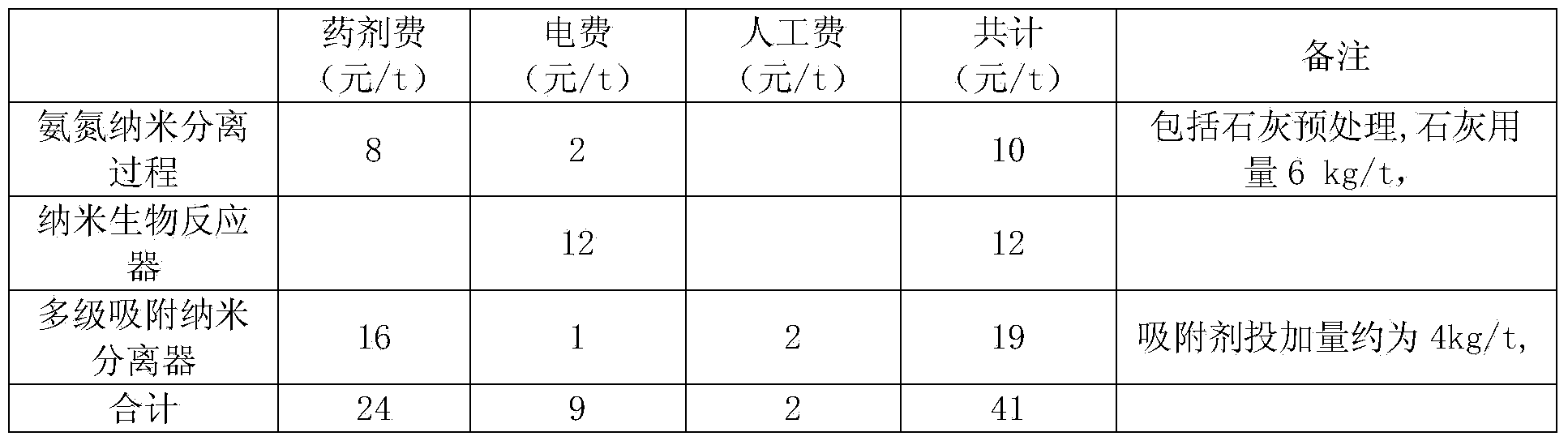

Method for processing landfill leachate

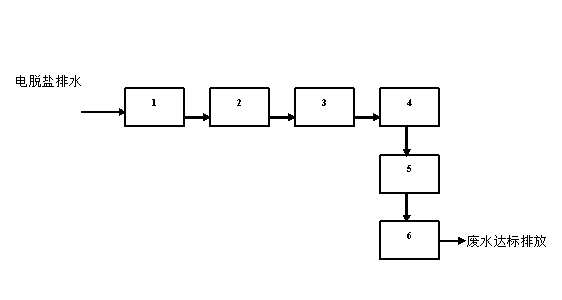

ActiveCN103880245AAchieve emission standardsRealize recycling of resourcesMultistage water/sewage treatmentHazardous substanceChemistry

The invention relates to a method for processing landfill leachate. The method comprises the following steps: carrying out efficient dissolved air flotation after collecting landfill leachate; adding slaked lime to the landfill leachate after air flotation treatment to carry out alkali adjustment; carrying out ammonia-nitrogen molecular sieve separation on the landfill leachate after alkali adjustment, and adding an acid to form an ammonium salt to recover ammonia nitrogen; carrying out biochemical treatment on the landfill leachate after ammonia nitrogen recovery; removing an organic matter, nitrogen and phosphorus in the landfill leachate; discharging up to the standard after multi-stage reflux adsorption on the landfill leachate after biochemical treatment. The landfill leachate is processed by using the technique disclosed by the invention, toxic and harmful substances such as high-strength ammonia nitrogen, non-biodegradable organic pollutants, heavy metal and the like in the landfill leachate are thoroughly removed, recycling of ammonia nitrogen resources is achieved, and the landfill leachate is discharged up to the standard.

Owner:北京博力扬环保科技有限公司

Automated wastewater treatment system and methods

ActiveUS20180099890A1Sludge treatmentWater/sewage treatment by flocculation/precipitationChemical treatmentWater treatment system

A machine and methods using electro-chemical treatments, sedimentation processes and dissolved air flotation technologies for clarification of several kind of wastewater produced in industries, sewages, ponds, lakes, canals etc. The machine comprises of, feeding lines with multiple feeding point, a tank and further a collection tank. The wastewater is passed into the feeding line which may comprises of several feeding points for coagulants, flocculants, and other chemicals dosing into the flow of wastewater and may also comprises of a static mixer for mixing the coagulants, flocculants, and other chemicals with wastewater to agglomerate any solid particles and to accelerate separation of the solid particles in the tank. Once the solid are formed, they can go up or down, therefore to remove the suspended solids the outlet are rearranged depending on the suspended solids. Further, the machine is used for treatment of wastewater utilising multi pass concept to produce clean water.

Owner:SYAL ASHOK

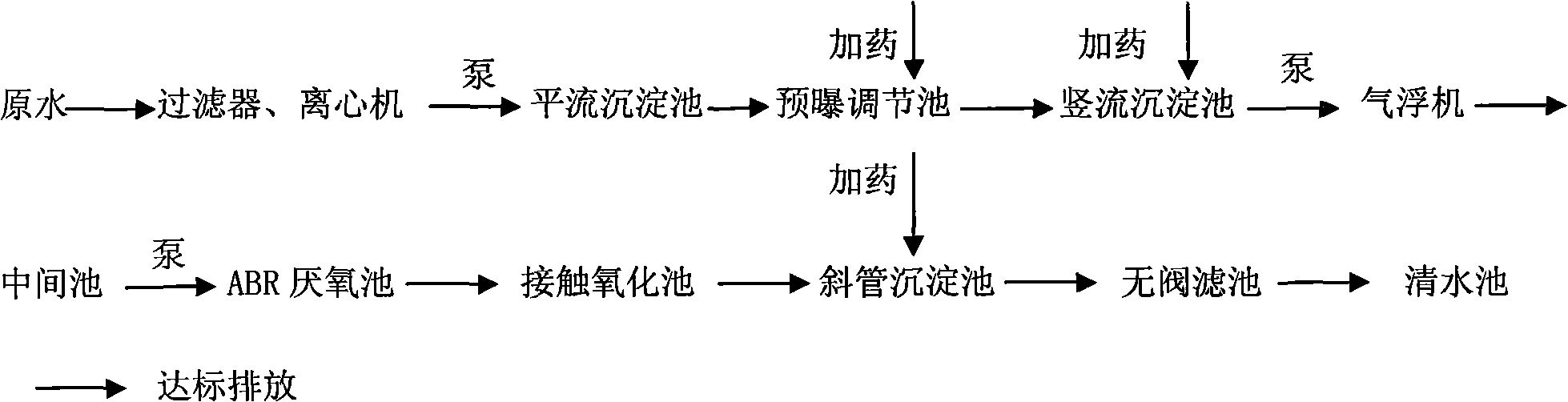

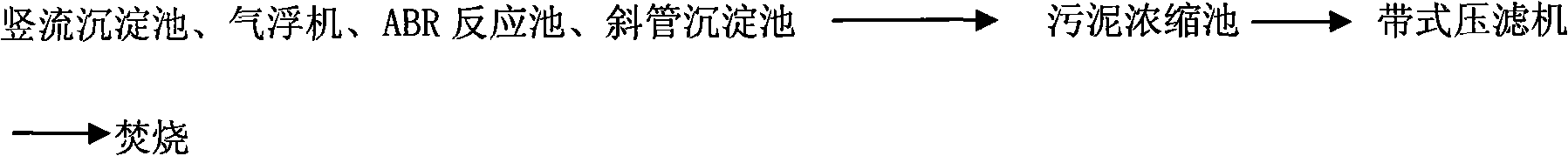

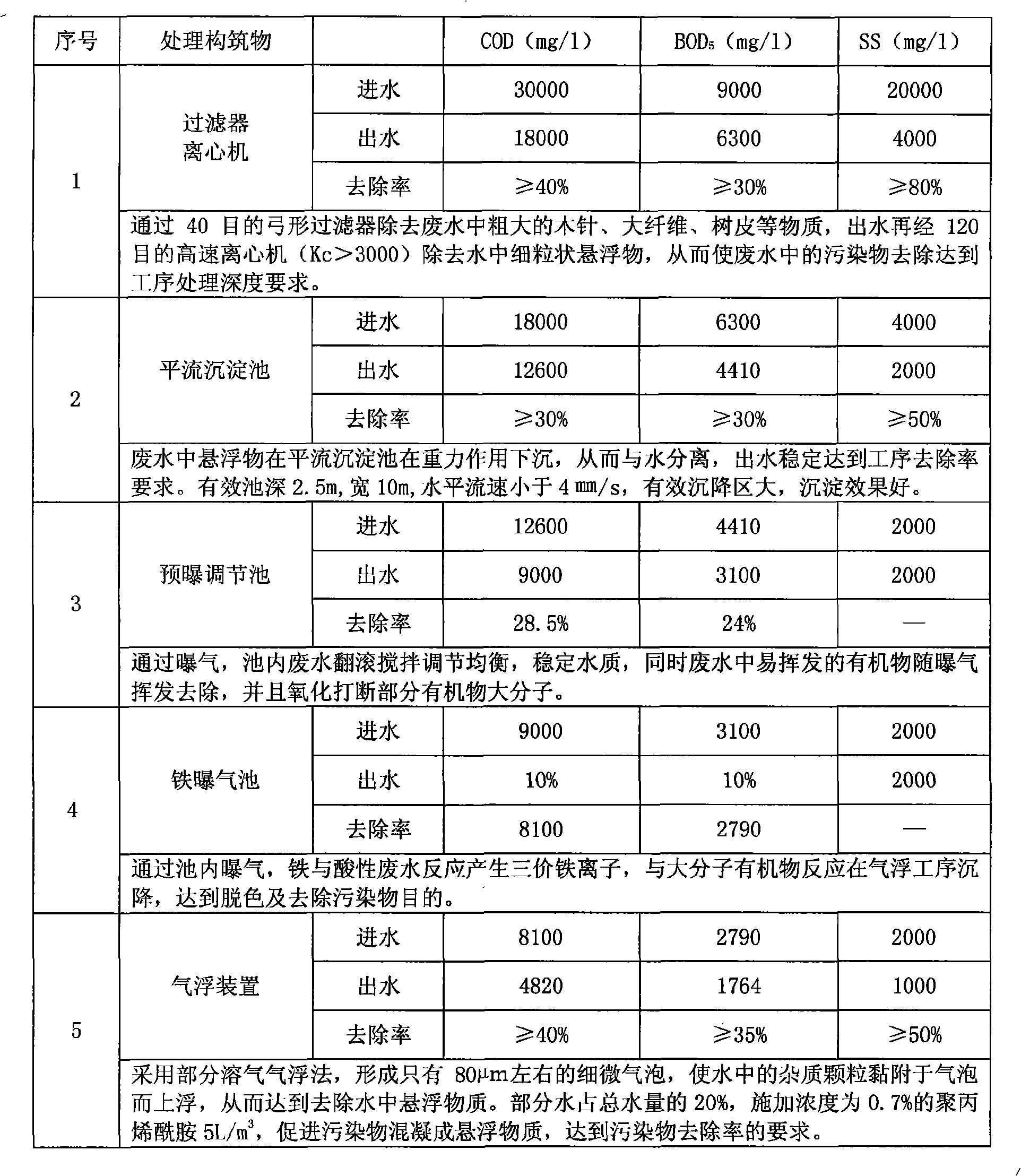

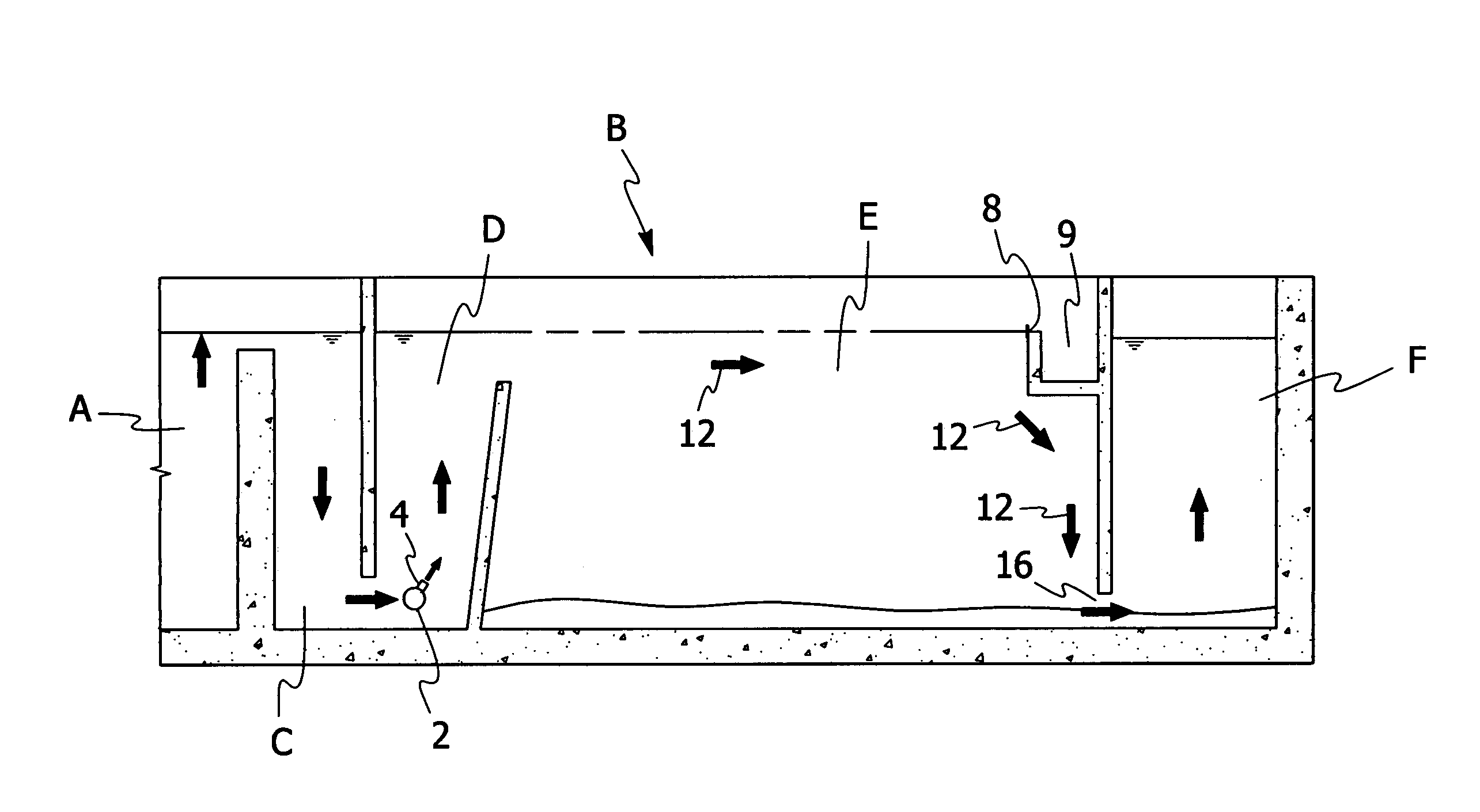

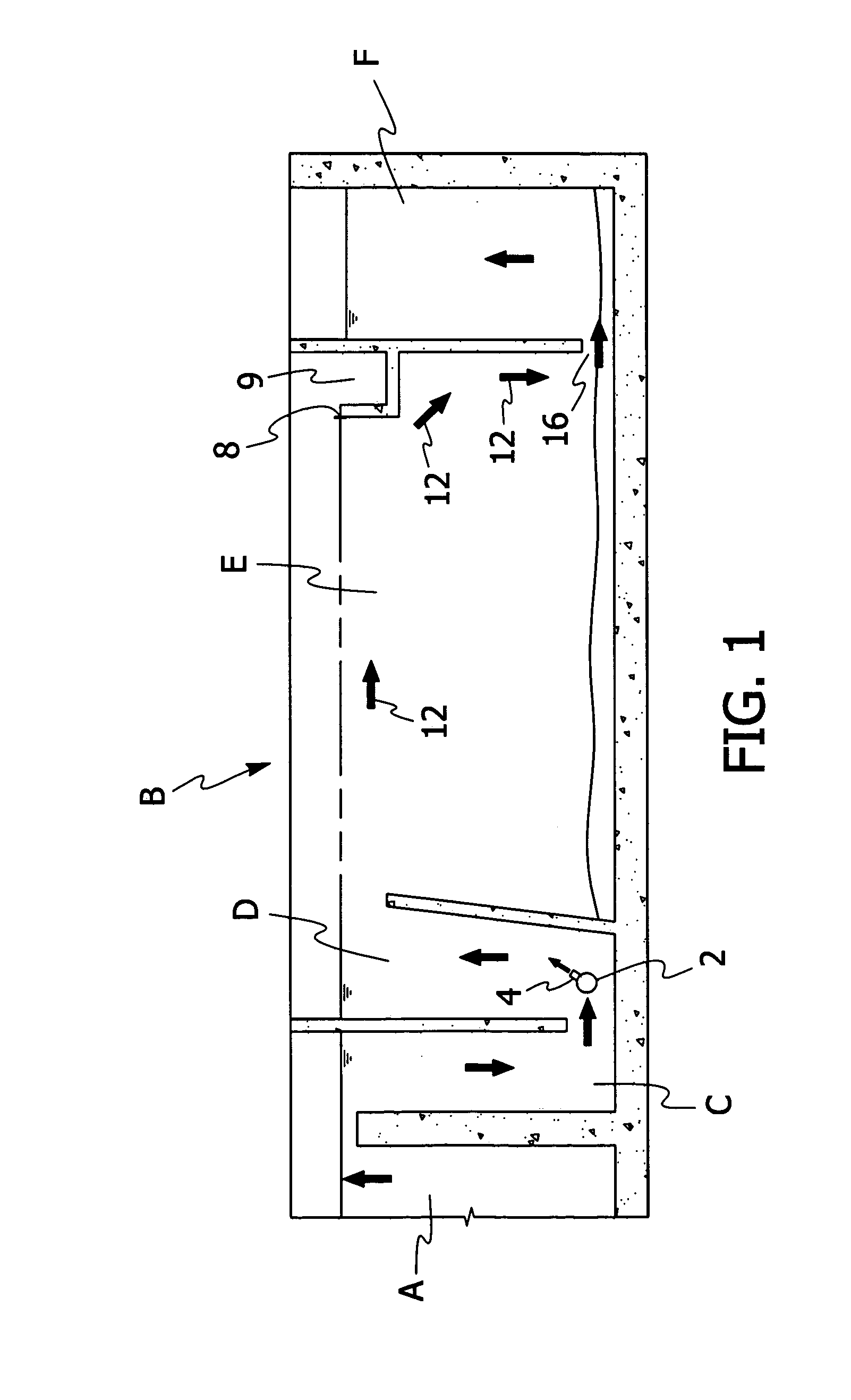

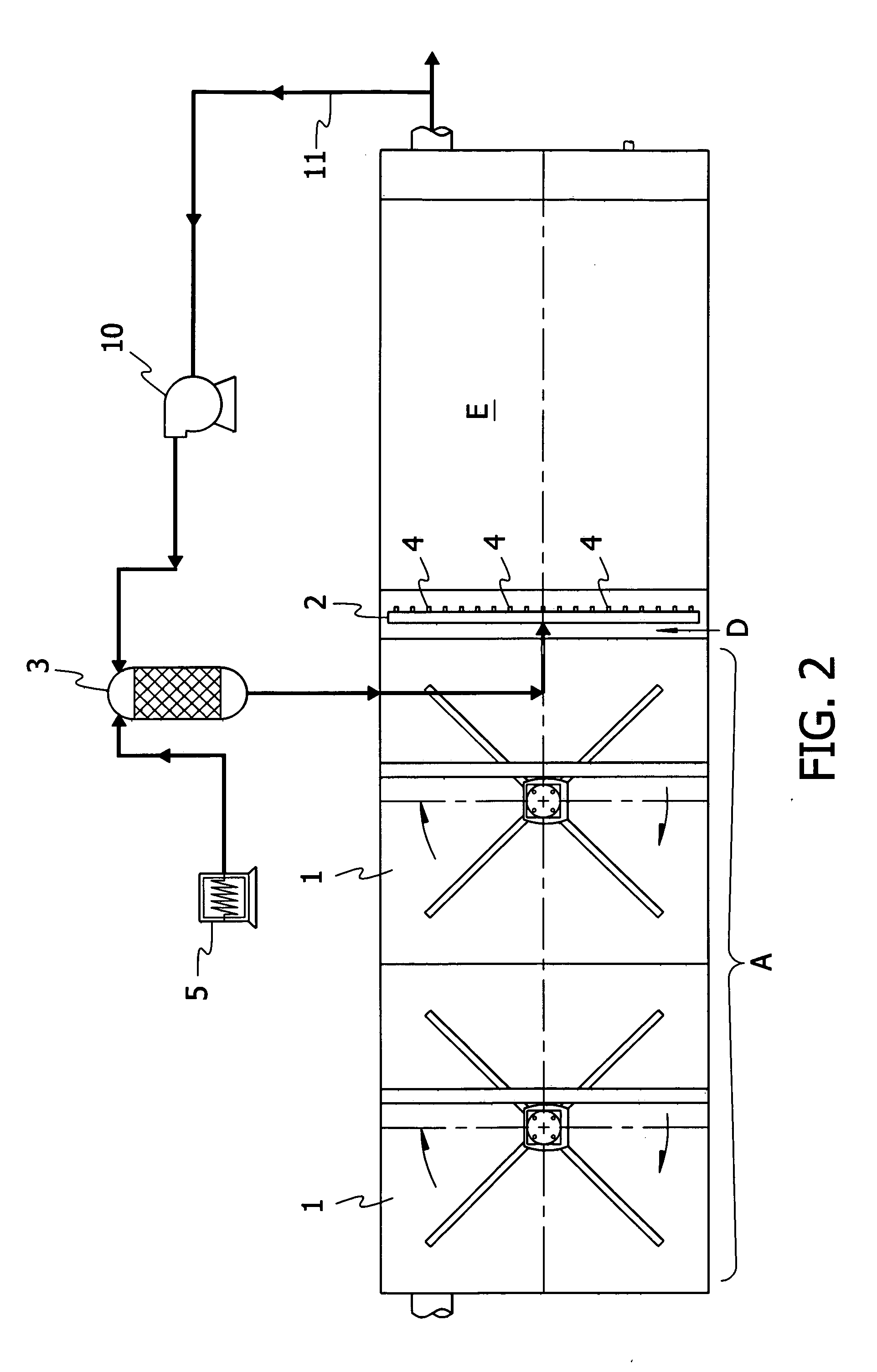

Method for treating wastewater of fibre-board plant

InactiveCN101575162AImprove removal efficiencyPromote recycling ratesTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentFiberSludge

The invention discloses a method for treating wastewater of a fibre-board plant. The method is characterized by including the combination of technical skills of the following three parts: a pretreatment system, a biochemical treatment system and an aftertreatment system; wastewater from production is respectively led into a filter and a centrifuger; after being processed by the step of slag removal, the wastewater flows into a horizontal sedimentation tank, a pre-aeration regulation tank and an iron aeration tank or a vertical sedimentation tank and then is processed by dissolved air flotation; the discharged water is respectively pumped into a turn-back flow anaerobic tank with filter materials and an oxidation tank and then flows into an inclined-tube sedimentation tank to settle; and after suspended substances in the wastewater are removed by a filtration tank, the wastewater is discharged while reaching standards. The method has the advantages that the efficiency of removing the suspended substances is high, water is circularly and repeatedly used, water consumption is reduced, the discharge amount of the wastewater can be reduced by more than 300 tons each day, the occupation of land of equipment is low, the operation is simple, and the running cost is low. Extruded wood slag and sludge can be used as energy to be led into an energy centre to combust, secondary pollution is not caused, and the treated wastewater can meet the requirement of primary standard in the Integrated Wastewater Discharge Standard GB8978-1996.

Owner:GUANGXI FENGLIN WOOD IND GRP CO LTD

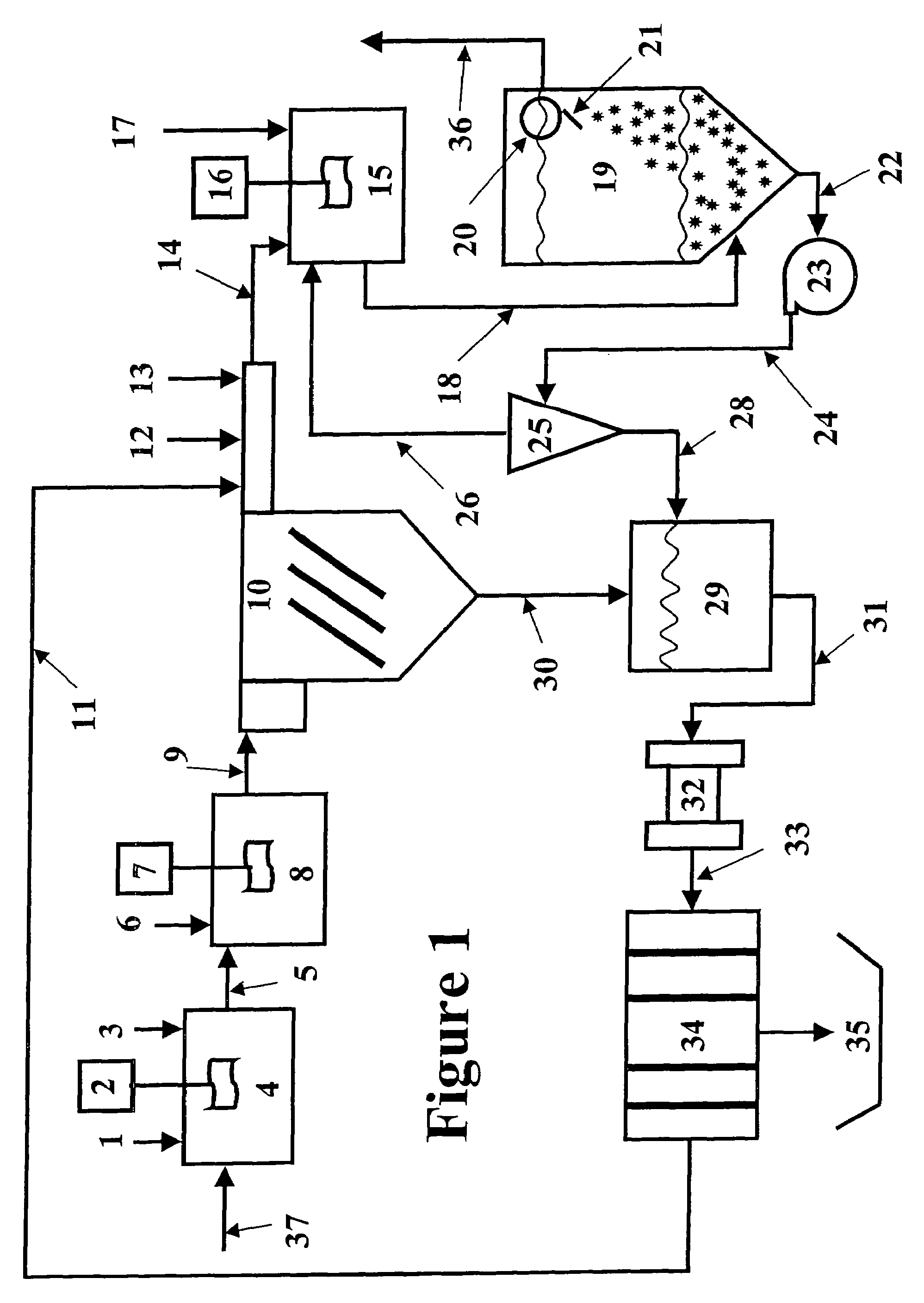

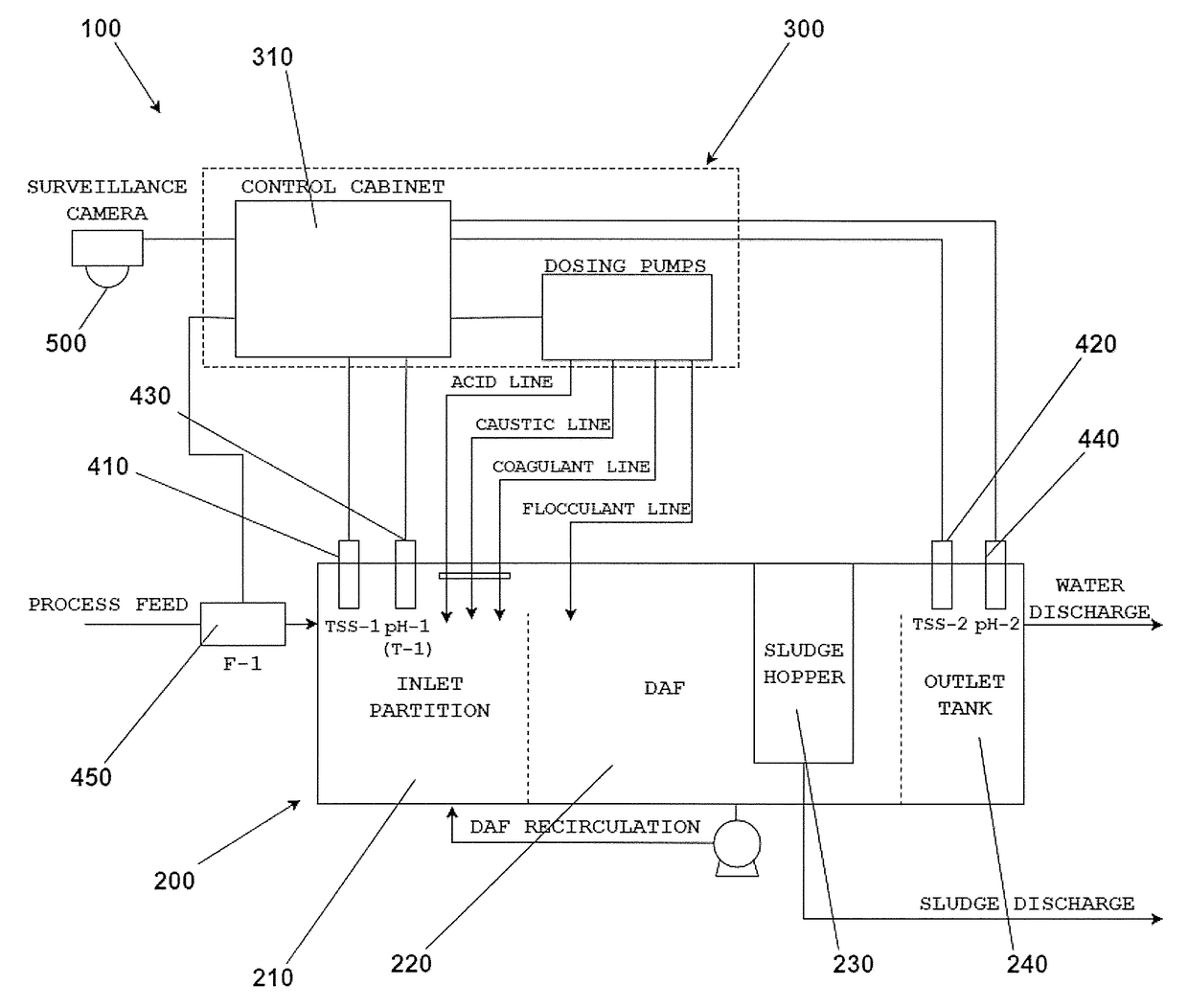

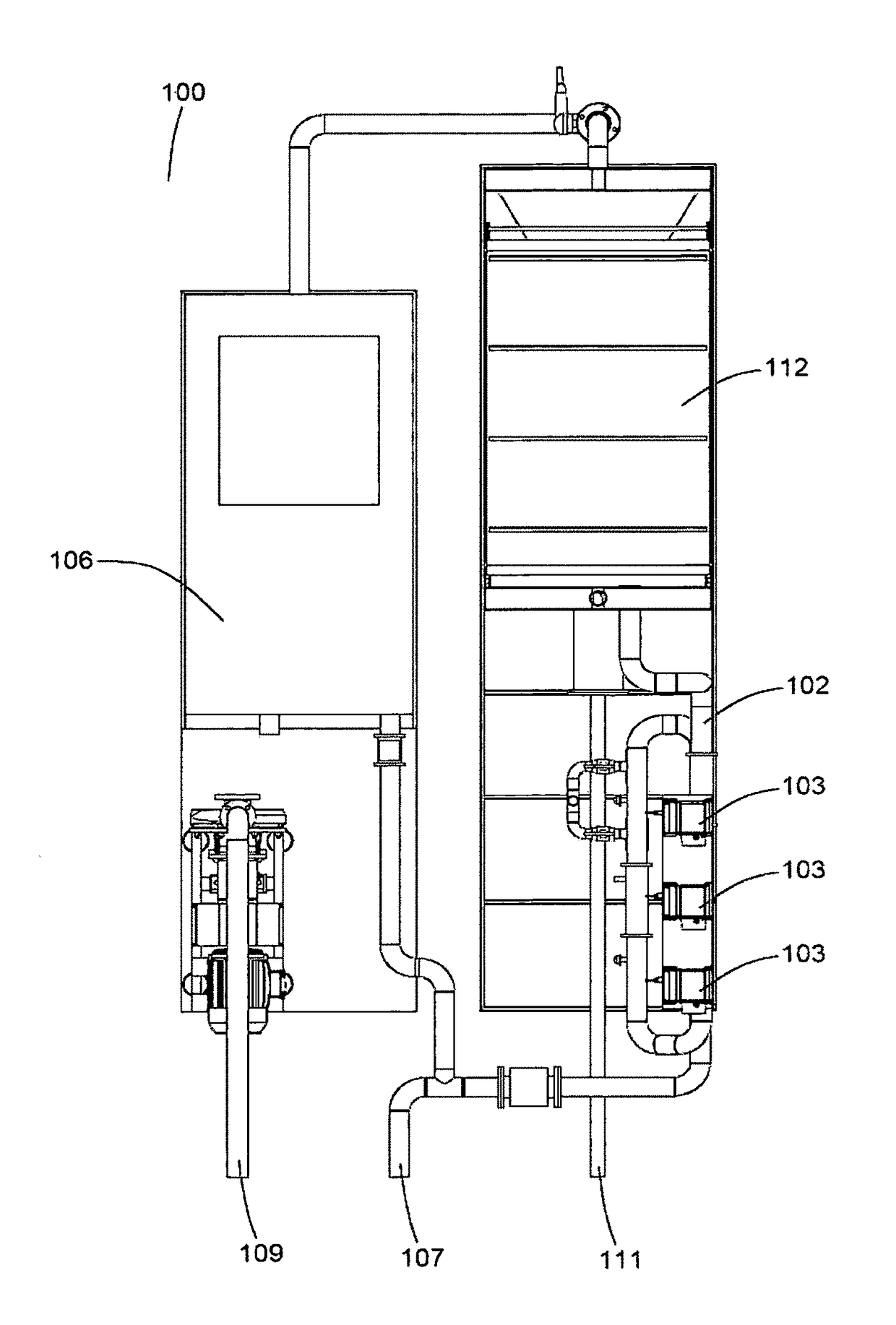

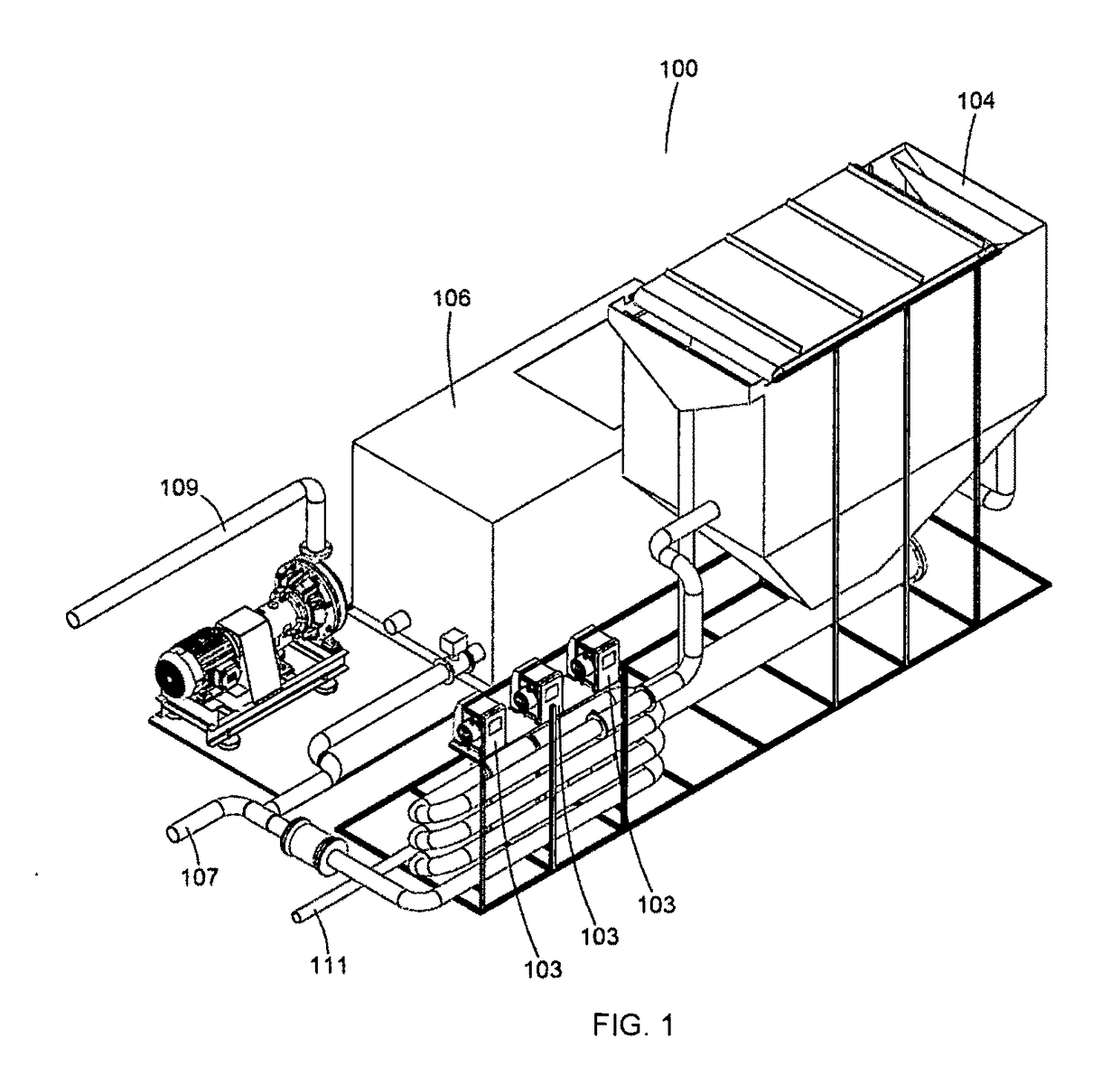

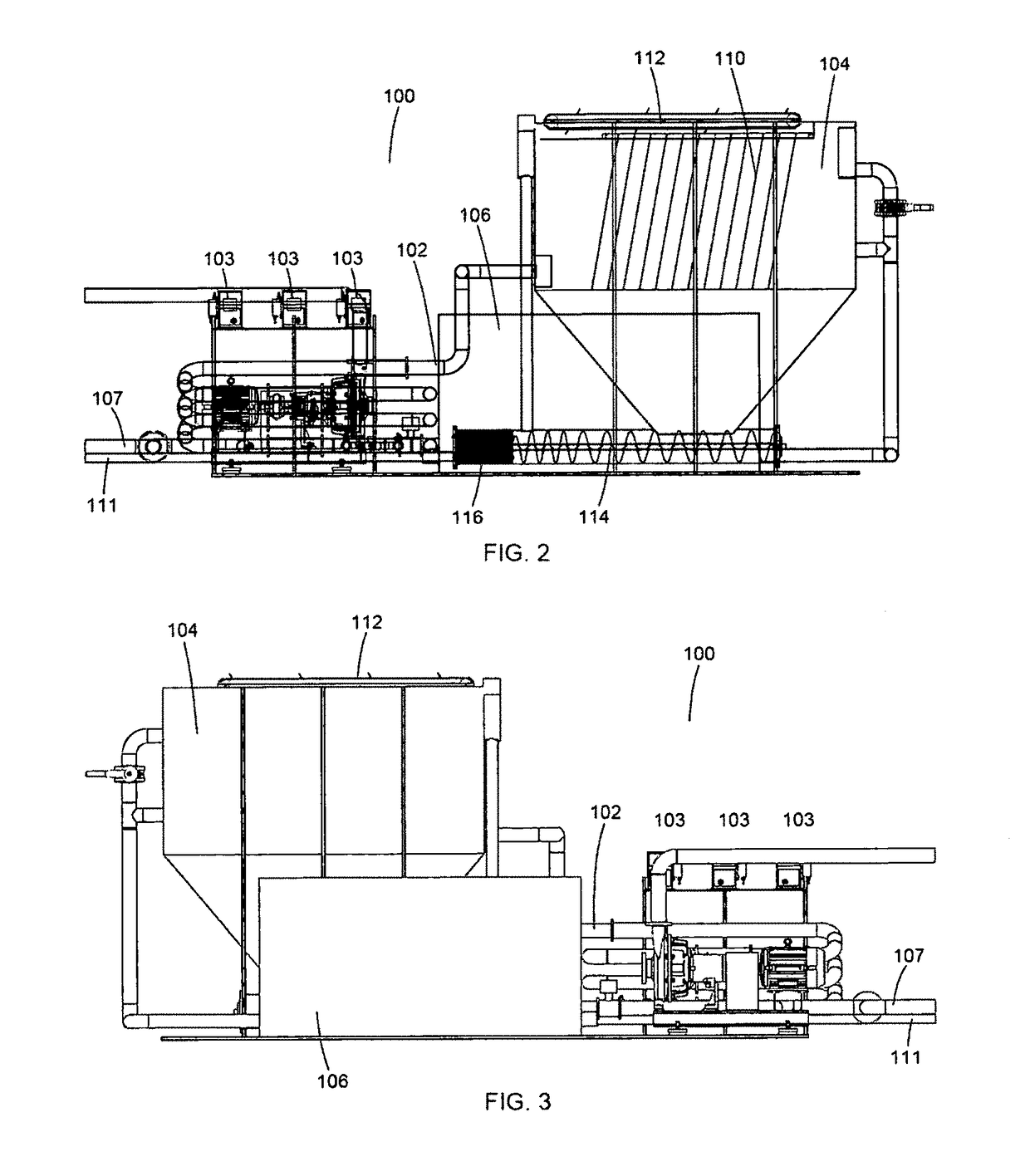

Dissolved air flotation clarifier

InactiveUS20110114565A1Increase flow rateIncrease heightEvaporationMultistage water/sewage treatmentMicrobubblesReaction zone

A dissolved air flotation clarifier for removing impurities from a liquid to be clarified. The dissolved air flotation clarifier includes a housing having an inlet for receiving a liquid to be clarified. The housing further includes a reaction zone, a clarification zone and an effluent channel. The reaction zone has at least one saturated water distributor and at least one dissolved air flotation nozzle operably connected to the at least one saturated water distributor to receive saturated water from the at least one saturated water distributor. The dissolved air flotation nozzle is configured to release micro-bubbles from a saturated water so that the micro-bubbles can mix with the liquid to be clarified to remove impurities from the liquid to be clarified. The clarification zone includes a flow control member for controlling the flow of the mixture of micro-bubbles and liquid in the clarification zone to ensure that the area surrounding the inlet to the effluent channel has little or no micro-bubbles to prevent or significantly reduce micro-bubbles from becoming entrained in a clarified liquid passing through the effluent channel.

Owner:RG DELAWARE

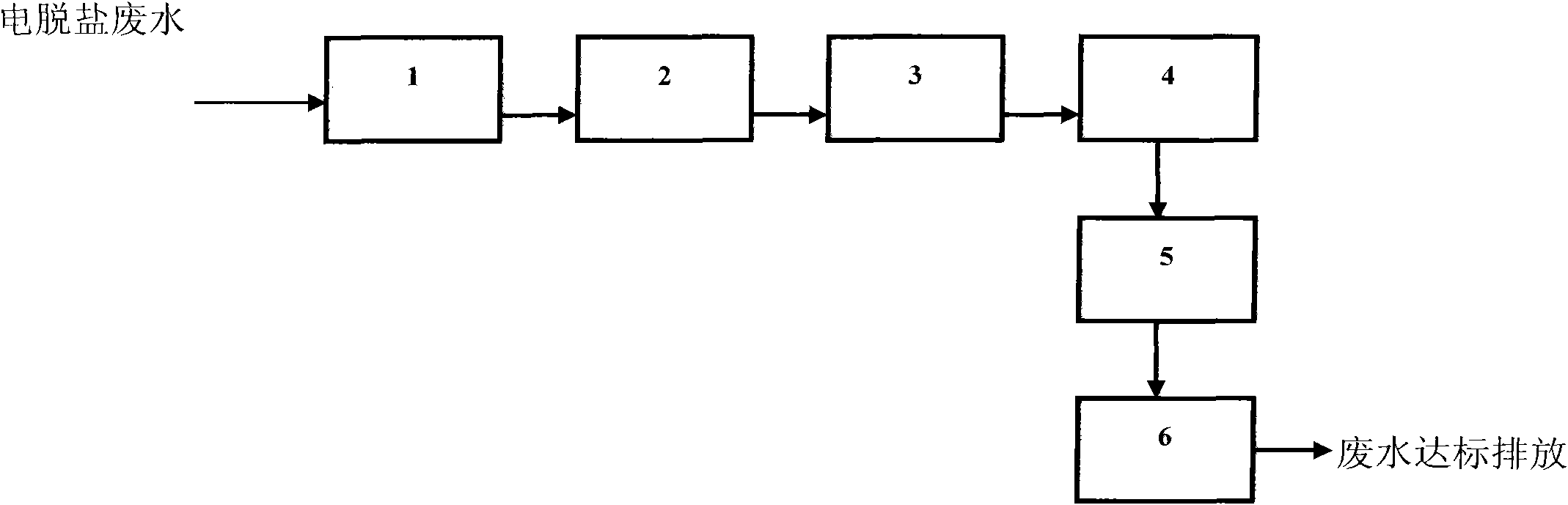

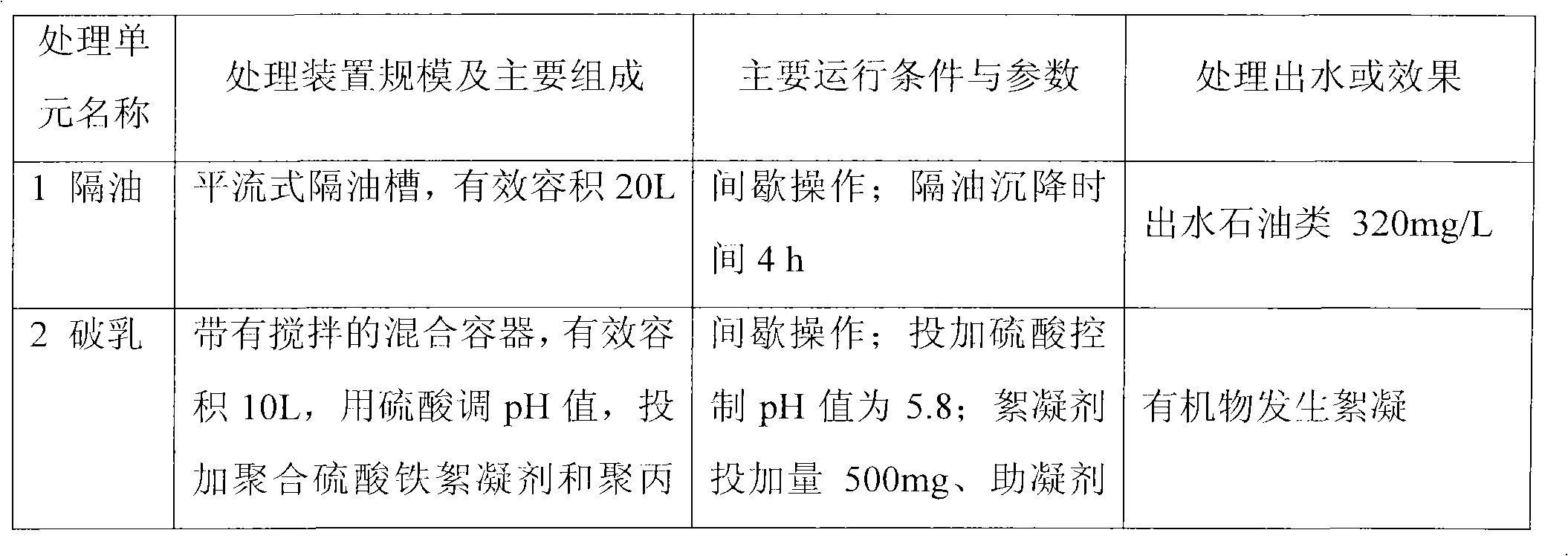

Treatment method for wastewater generated by processing high-acid crude oil

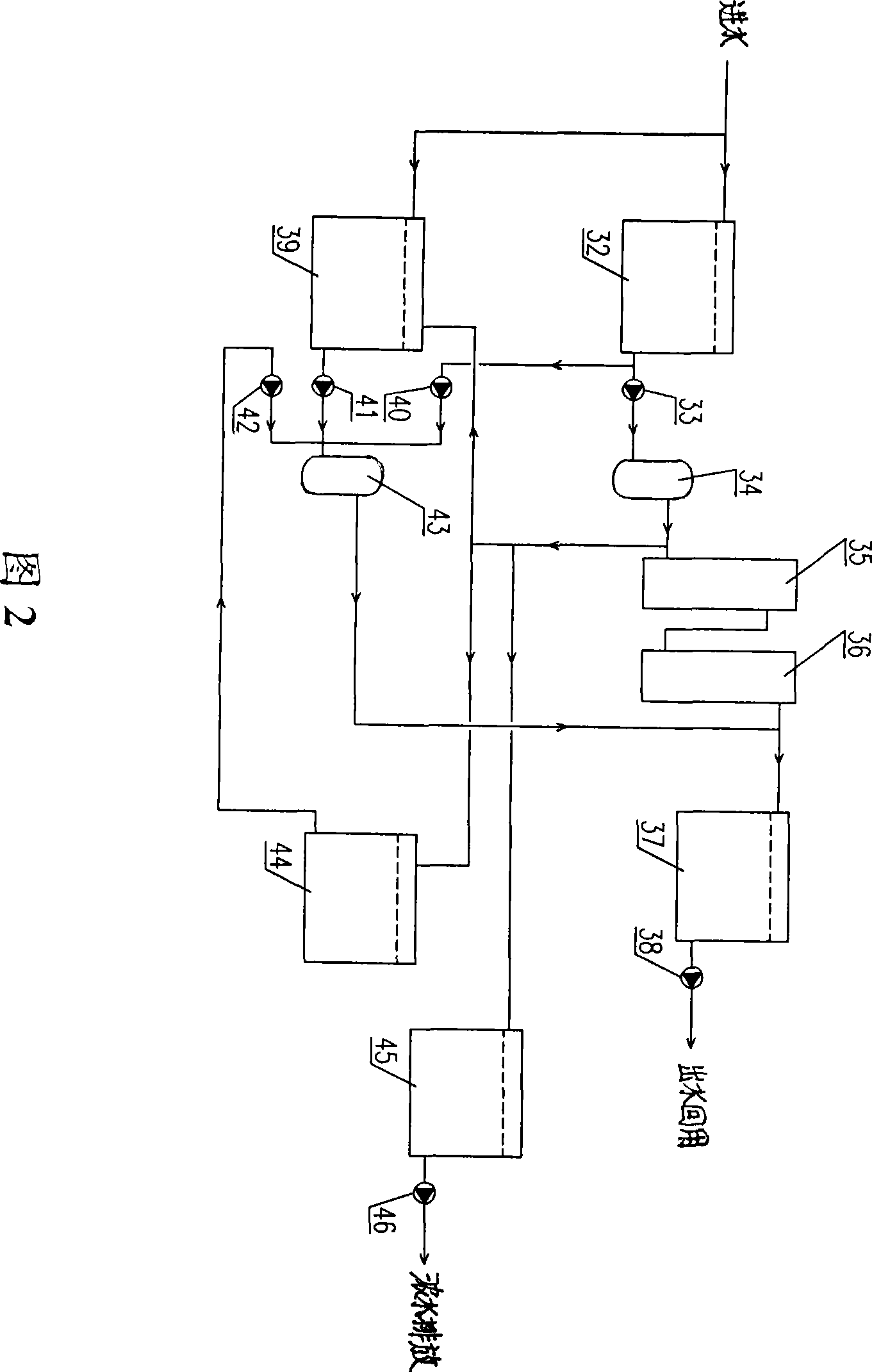

ActiveCN102311204AEasy to handlePromote demulsificationMultistage water/sewage treatmentNature of treatment waterElectrolysisCatalytic oxidation

The invention relates to a treatment method for wastewater generated by processing high-acid crude oil, which adopts the combined processes of oil isolation, demulsification, dissolved air flotation, electrochemical catalytic oxidation, biological membrane moving bed reactor and filtering. The electro-desalting wastewater in the high-acid crude oil refining process is treated. When the method provided by the invention is adopted, the treatment process of other wastewater such as oil-containing wastewater, salt-containing wastewater and the like in the high-acid crude oil processing process can not be influenced by the high-acid crude oil wastewater, and the beneficial effects are brought for the stable operation of the oil isolation, the flotation, biochemistry and deep treatment units ofthe final sewage treatment field, so the problem that the wastewater generated by processing the high-acid crude oil at present can not reach the standard is solved, and the good basis is provided for the sewage reuse.

Owner:CHINA PETROLEUM & CHEM CORP +1

Technological process for advanced treatment and recycle of cold rolling water

ActiveCN101434447AEfficient removalAchieve the goal of energy saving and emission reductionTreatment using aerobic processesDispersed particle separationWater qualityTherapeutic effect

The invention relates to an advanced treatment and recycling technique of cold rolling wastewater; wherein, a pretreatment step is carried out by combining conciliated aeration regulation, two-stage pH value regulation, dissolved air flotation and two-stage cooling. Firstly, the cold rolling wastewater enters a conciliated aeration regulation pool, water quality and water amount after conciliation are promoted to a first-stage pH valve regulation jar, then passes through a second-stage pH valve regulation jar, and the pH value of the wastewater is controlled to be between 6 and 9; the wastewater after regulation flows automatically into the dissolved air flotation, and oil contained in the wastewater and part suspended matters are removed; and dissolved air floats up from water and is subjected to two stages of cooling. A biochemical secondary treatment step adopts the technique of combing biological contact oxidation with a membrane bioreactor. An electrical adsorption desalting treatment step adopts an electrical adsorption desalting device to carry out deep desalting treatment. The technique has stable treatment effect, thus effectively removing pollutants such as the organic matters, the suspended matters, the oil and the salts, and the like contained in the cold rolling wastewater, and causing the cold rolling wastewater to be recycled so as to achieve energy saving and discharge reduction.

Owner:上海宝汇环境科技有限公司

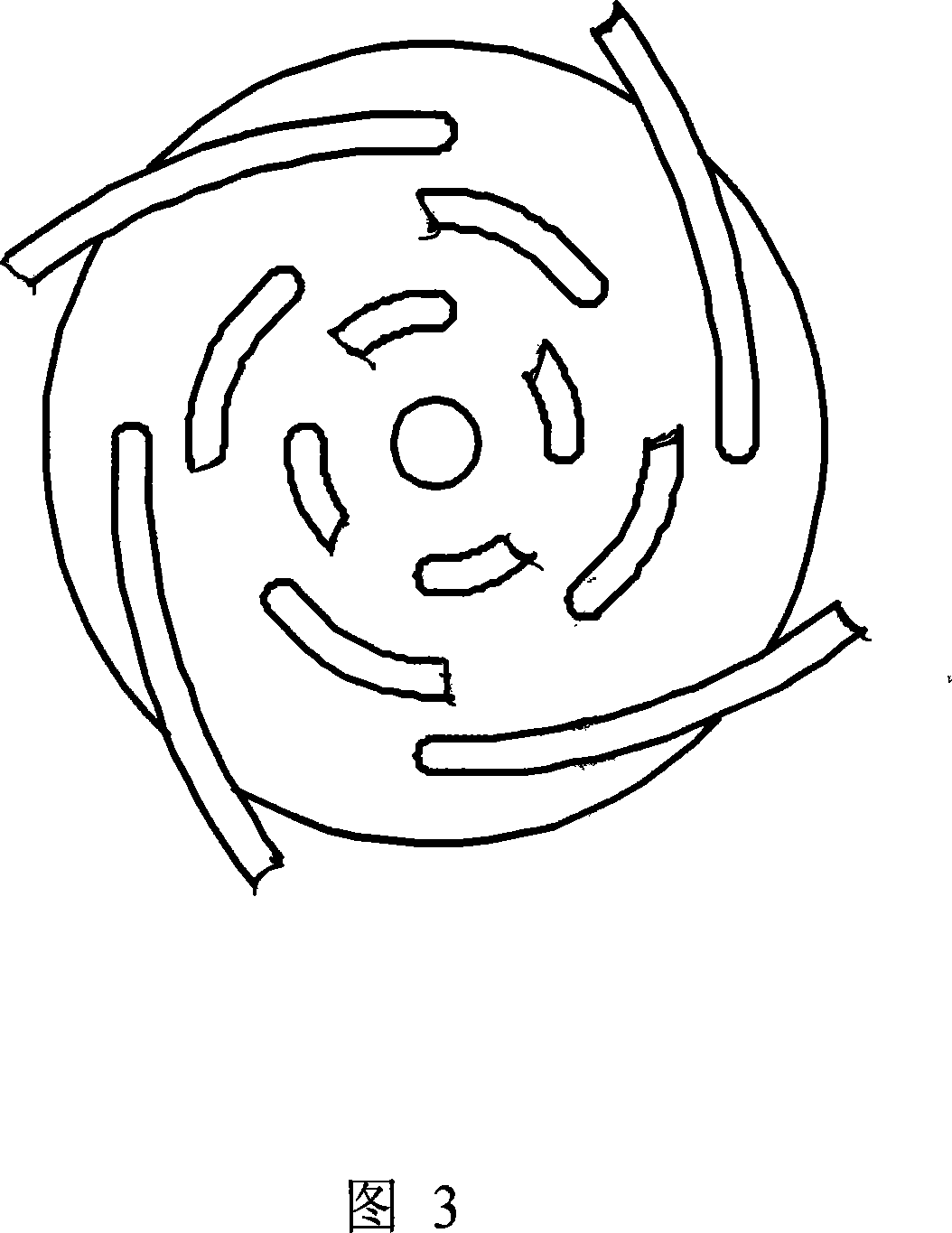

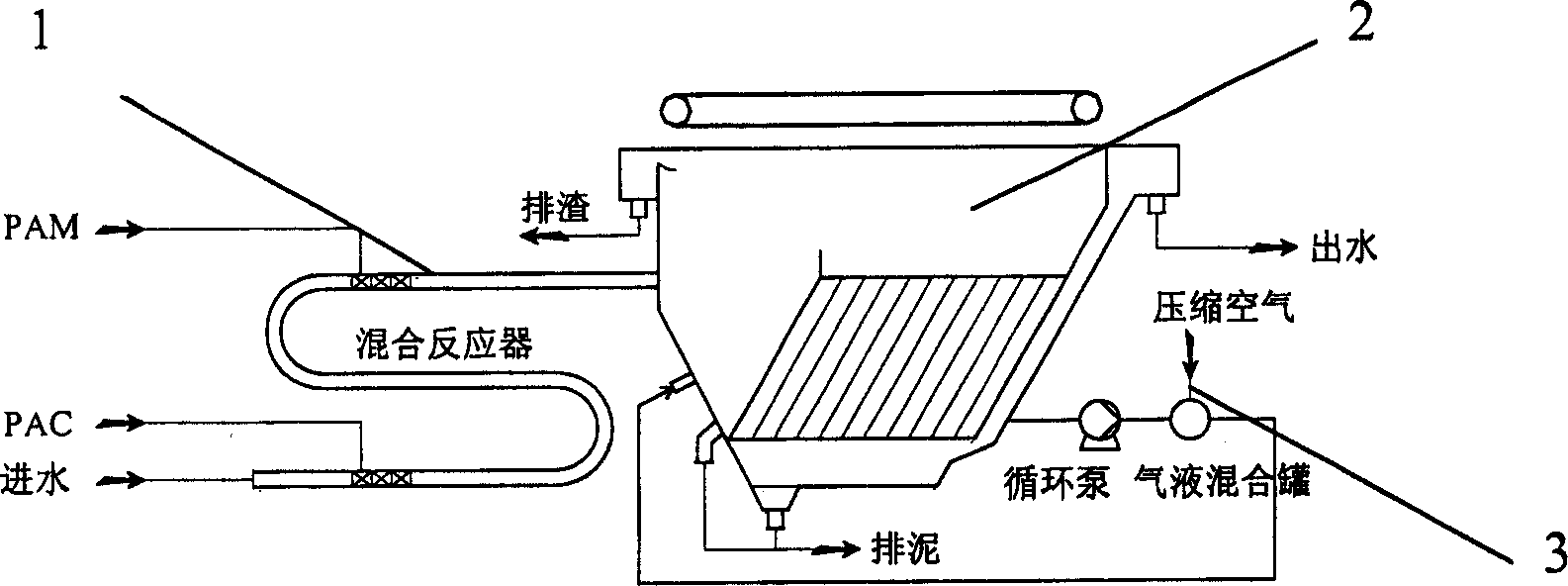

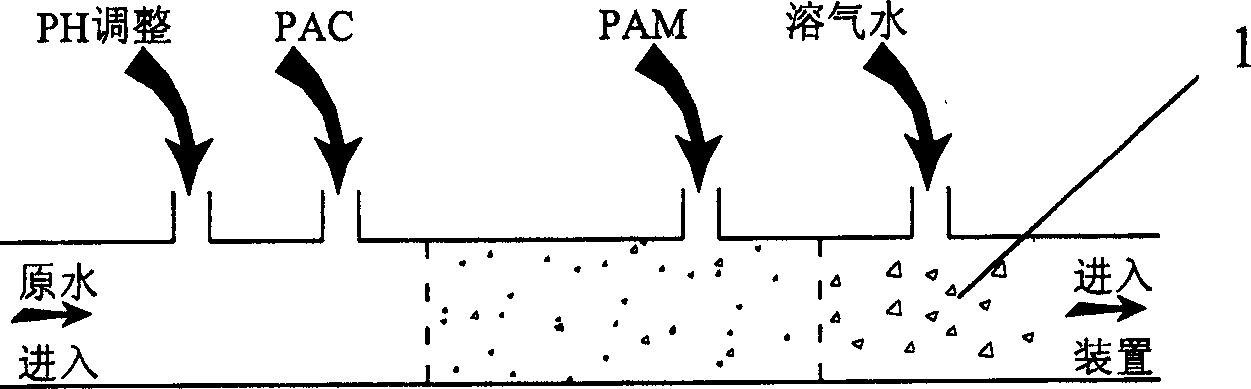

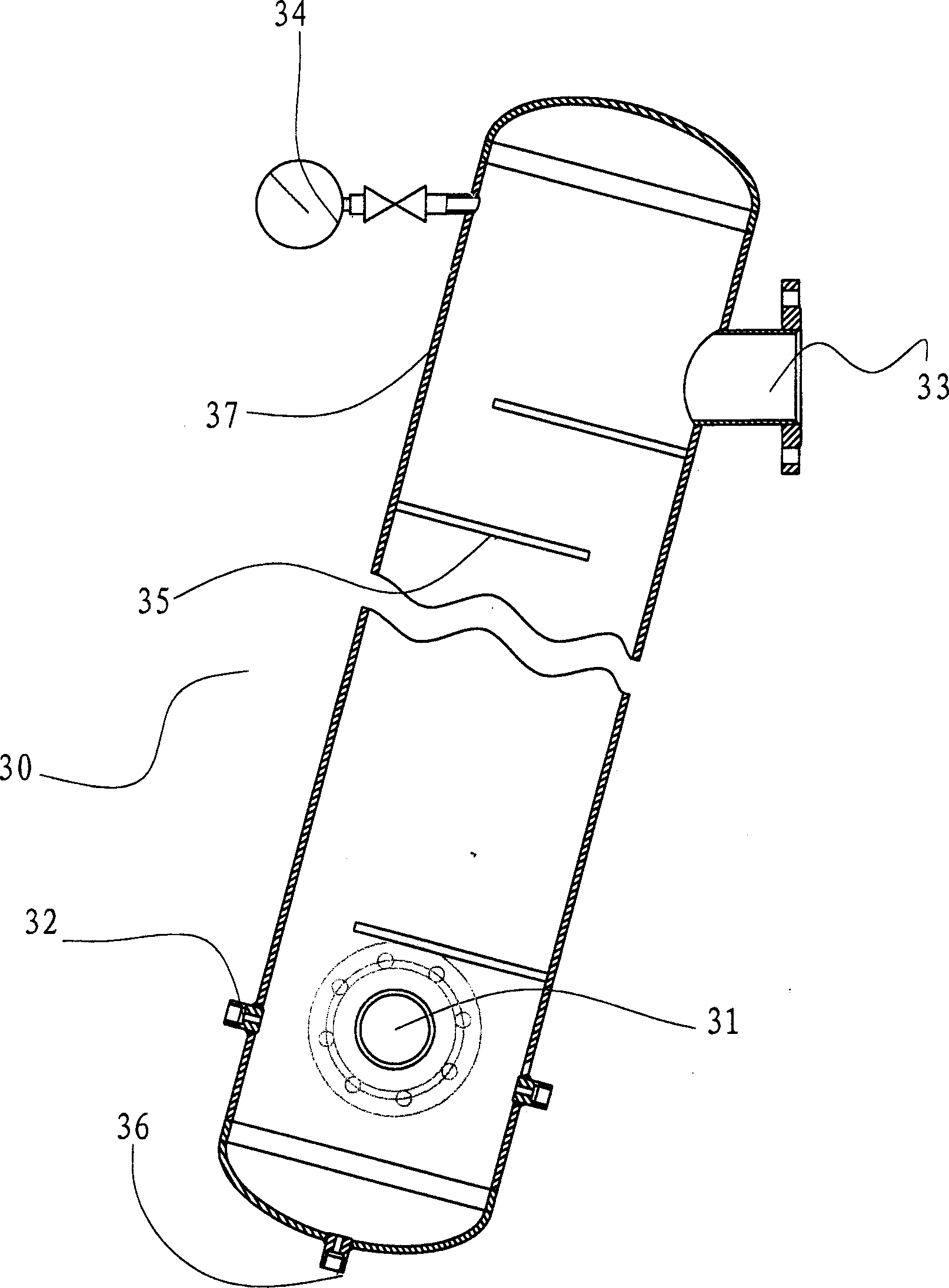

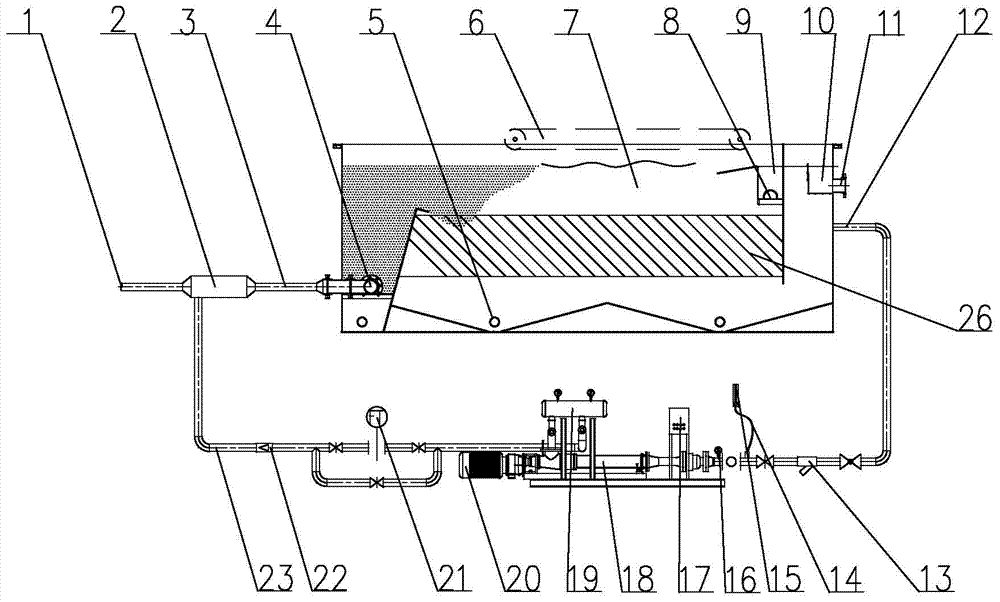

Pressure air-dissolving air-float system

ActiveCN1907880ASolution volumeSolution areaWater/sewage treatment by flocculation/precipitationWater/sewage treatment by flotationFlocculationGas cylinder

The invention discloses a pressure dissolved air flotation system, which includes an interconnected processing facility, a mixed reactor, a flotation device and a pressure dissolved air device. The process comprises adding wastewater in the mixed reactor and forming separable flocculation with the pharmaceutical added by dosing device, placing the wastewater treated by the mixed reactor in the flotation device and mixing it with dissolved air solution provided by the two dissolved air system pressure devices to make the bubble released from dissolved air solution adhere on the flocculation, and separating and discharging through the deslagging mouth of the flotation device. Through the pressure of dissolved air flotation device and the flotation device improved, it will reduce the volume of pressure dissolved gas cylinder, shorten the time required for dissolving air, prevent the plugging, and has compact structure and reasonable process.

Owner:LIAONING HUAFU ENVIRONMENTAL ENG

Dissolved air flotation system

InactiveUS6921478B2Continuous operationEasy disposalIon-exchanger regenerationSolid sorbent liquid separationFresh waterClean water

A dissolved air flotation system and method for purifying fresh water. The system is self-contained within a standard shipping container, with all components disposed in-line within the shipping container. Float is removed from the flotation tank with a skimmer that drives float downstream onto a conveyor belt, and the conveyor belt conveys float away from the flotation tank, in the downstream direction, and deposits the float in a collection tank. Clean water may be drawn from the flotation tank continuously, while float may be removed periodically.

Owner:SIONIX CORP

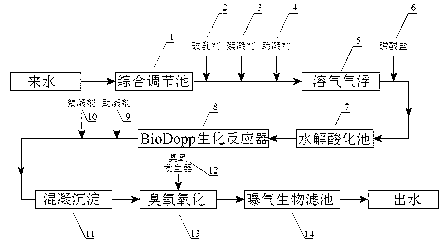

Technology for treating and recovering sewage obtained by crushed coal pressure gasification

InactiveCN102730897ASimple processLess investmentTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentWater useHydrolysis

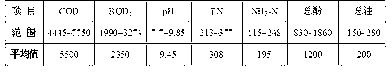

The invention provides a technology for treating and recovering sewage obtained by crushed coal pressure gasification. The technology comprises the following steps that coal gasification sewage obtained by a crushed coal pressure gasification factory passes through a combined adjustment tank, a dissolved air flotation tank, a hydrolysis acidification tank, a BioDopp biochemical reaction tank, a coagulating sedimentation tank, an ozone oxidation tank, and an aeration biofilter so that most of organic pollutants, ammonia nitrogen, suspended matters, phenols and oil in the sewage are removed and recycle water which can be supplied to a circulating water system can be obtained. The technology has a simple process route, can run stably, and has a low cost of treatment on each ton of sewage. Product water treated by the technology can be supplied to circulating water so that sewage obtained by crushed coal pressure gasification can be fully recovered after being treated by the technology and thus emission reduction is realized.

Owner:陈凯华 +1

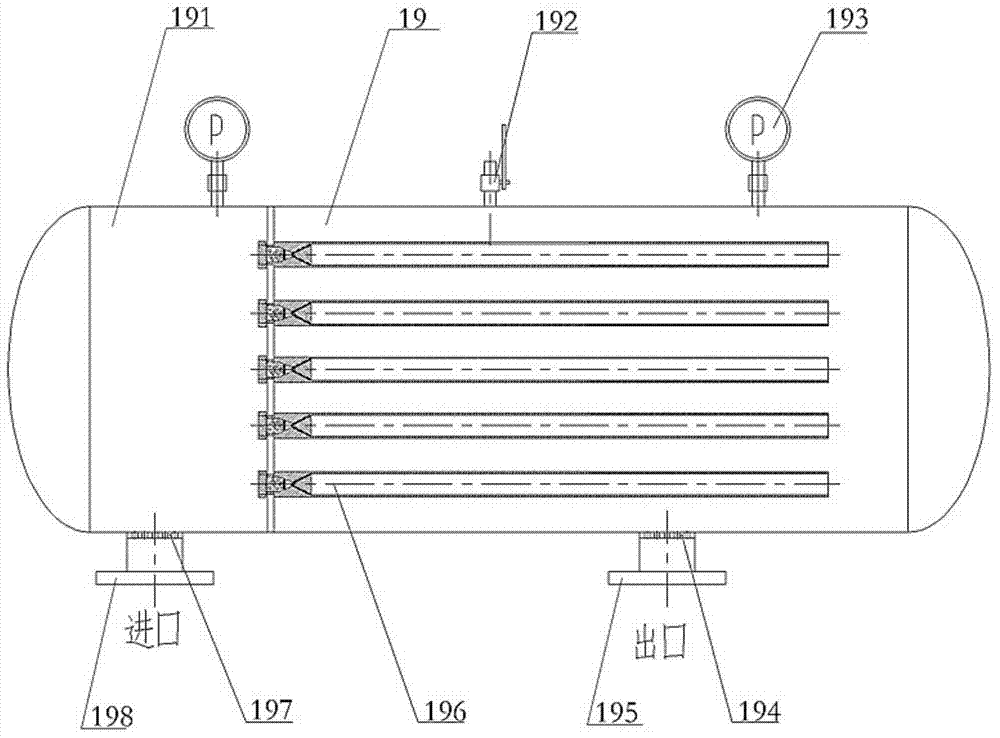

High-efficiency dissolved air flotation system

InactiveCN103936093AImprove stabilitySmall footprintWater/sewage treatment by flotationMicrobubblesSlag

The invention relates to a high-efficiency dissolved air flotation system which comprises an air flotation tank, a slag scraper, a slag discharge device, a water outlet device and an air-liquid mixing pump water inlet pipe, wherein the slag scraper, the slag discharge device and the water outlet device are arranged in the air flotation tank; the air-liquid mixing pump water inlet pipe is led out from the tail end of the air flotation tank, the air-liquid mixing pump water inlet pipe is provided with an air inlet pipe and connected with an air-liquid mixing pump and a microbubble generator through an air-liquid mixing pipe; a high-pressure saturated dissolved air water pipe led out from the microbubble generator and an external sewage inlet pipe are communicated with a dissolved air releaser positioned on the tail end of the water inlet pipe of the air floatation tank through a T-shaped mixer. Compared with the prior art, the high-efficiency dissolved air flotation system has the beneficial effects that dissolved air generated through the system is good in water stability and high in bubble density, microbubbles with grain diameters of about 5 micrometers and generated through the system are more easily adhered to suspended substances and oil droplets which are contained in sewage and a better removing effect can be achieved because the dissolved air ratio of dissolved air water inside the system can achieve 30%-35% and is simple in structure, easy to debug, stable in operation, stable and reliable in operation, conserved in energy, reduced in consumption and high in automation degree.

Owner:辽宁华霆环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com