Technology for treating and recovering sewage obtained by crushed coal pressure gasification

A technology for pressurized gasification of crushed coal and sewage treatment, applied in the field of water treatment, can solve the problems of long process and hydraulic retention time, high content of ammonia nitrogen and suspended solids, incomplete nitrification, etc. The effect of long, short processing flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

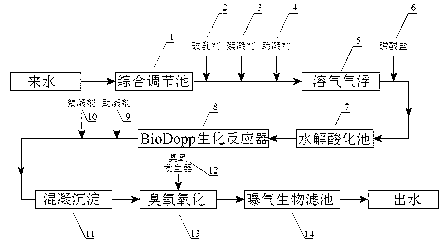

[0023] A broken coal pressurized gasification sewage treatment and reuse process involved in the present invention is connected to the following devices in sequence through sewage pipelines: such as figure 1 As shown, comprehensive adjustment tank 1, dissolved air flotation 5, hydrolytic acidification tank 7, BioDopp biochemical reaction tank 8, coagulation sedimentation 11, ozone oxidation 13, biological aerated filter 14, among them before dissolved air flotation 5 Add demulsifier 2, flocculant 3 and flocculant 4 to the sewage pipeline, add phosphate 6 to the sewage pipeline before the hydrolysis acidification tank 7, add coagulant 9 and flocculant 10 to the sewage pipeline before coagulation and sedimentation 11 , Pass the ozone that ozone generator 12 produces in ozonation 13.

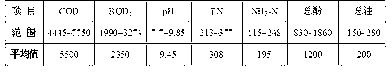

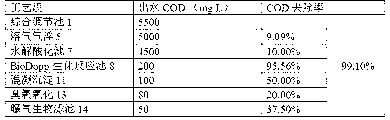

[0024] Taking the process involved in this invention as an example for the sewage treatment of a crushed coal pressurized gasification plant, the water quality of the sewage is shown in figure 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com