Pressure air-dissolving air-float system

A dissolved air flotation and pressure technology, used in flotation water/sewage treatment, flocculation/sedimentation water/sewage treatment, etc., can solve the problem of excessive volume, large floor space, reduction of dissolved air time and pressure dissolved air tank volume and other issues, to achieve the effect of increasing treatment capacity, reasonable structure and layout, and shortening sewage treatment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0039] The symbols used for the components of the pressure dissolved air flotation system in the present invention and the components in the existing system, so the structure, function and principle of the components with the same symbols will not be further explained.

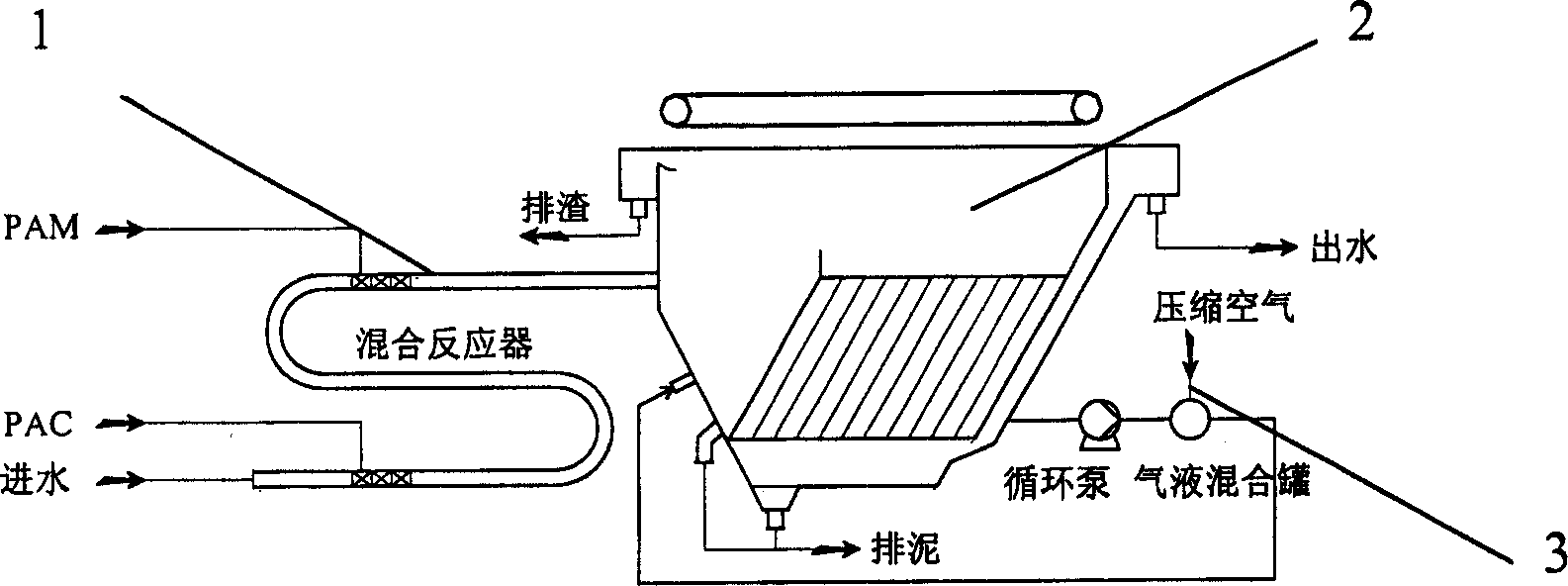

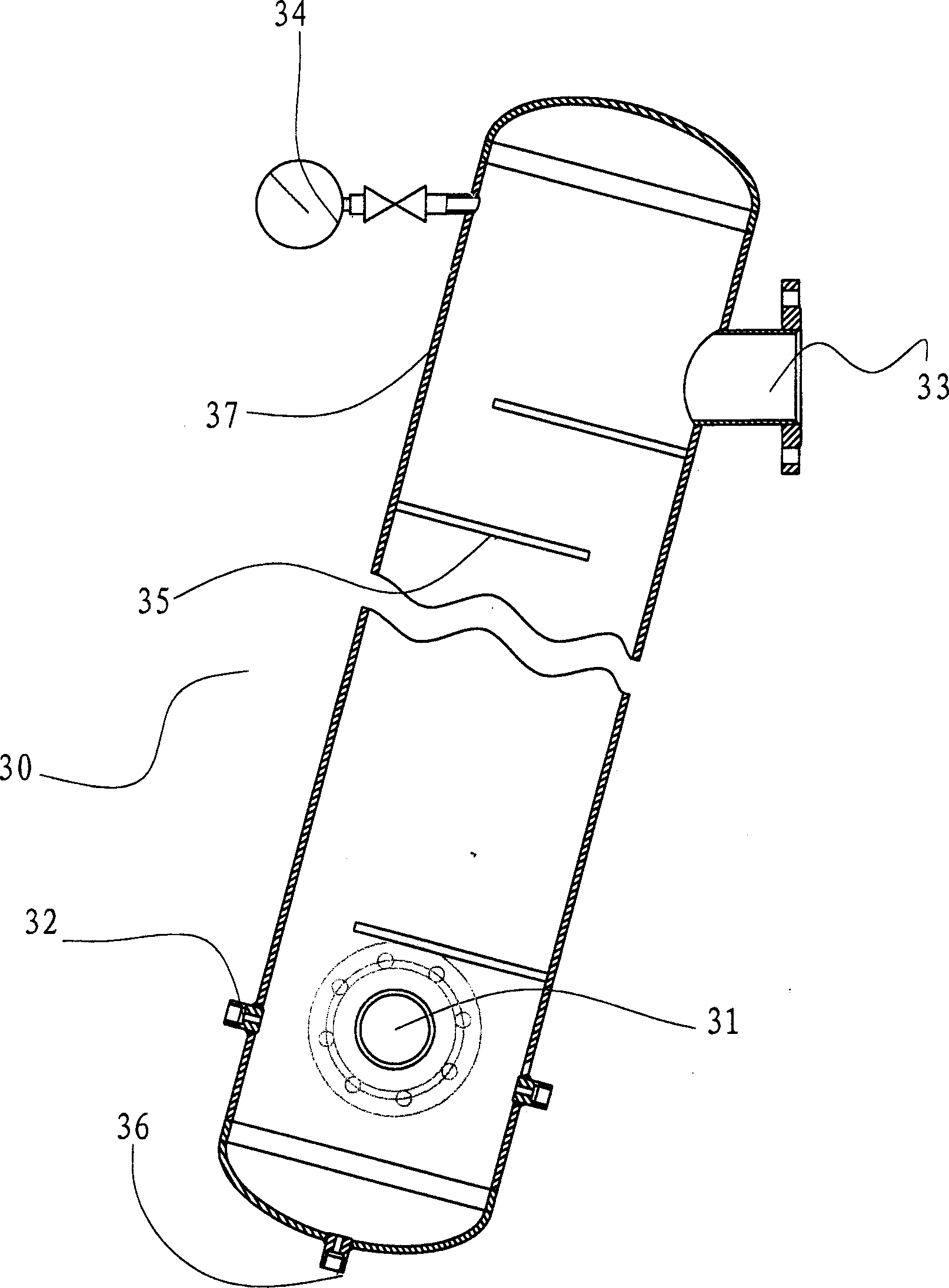

[0040] like figure 1 As shown, the pressure dissolved air flotation system in the present invention includes a dosing device (not shown in the figure), a tubular mixing reactor 1 , an air flotation device 2 and a pressure dissolved air device 3 .

[0041] The dosing device is existing equipment, so it is not described in detail.

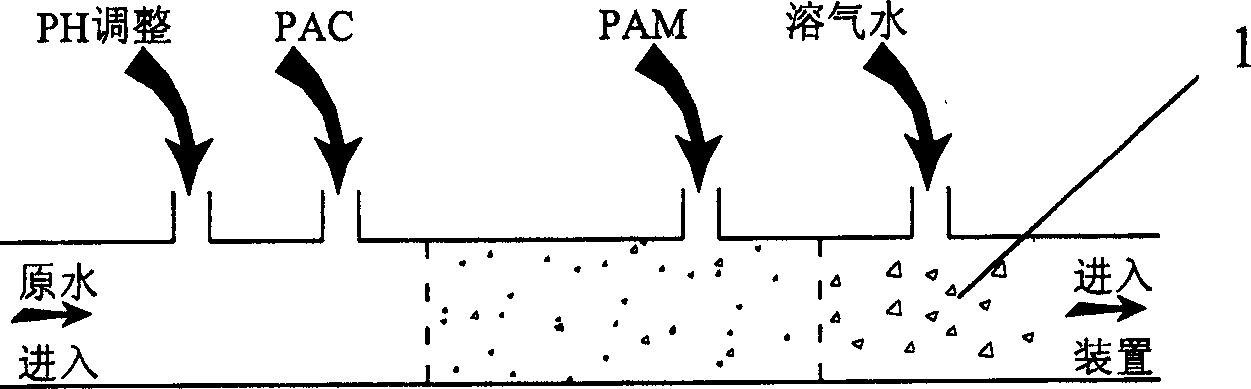

[0042] The working principle of tubular mixing reactor 1 is the combination of pipeline mixing and reaction, such as figure 2As shown, different chemicals are added through the drug dosing device at different stages, and the different ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com