Color regulating plate for solid light source projector

A solid light source and projector technology, which is applied to optical elements, optics, optical elements and other directions for changing the spectral characteristics of emitted light, can solve the problems of difficult heat dissipation of solid light sources, increase in size of projectors, and increase in cost, and achieves Solve the effect of difficult heat dissipation, poor safety and high power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

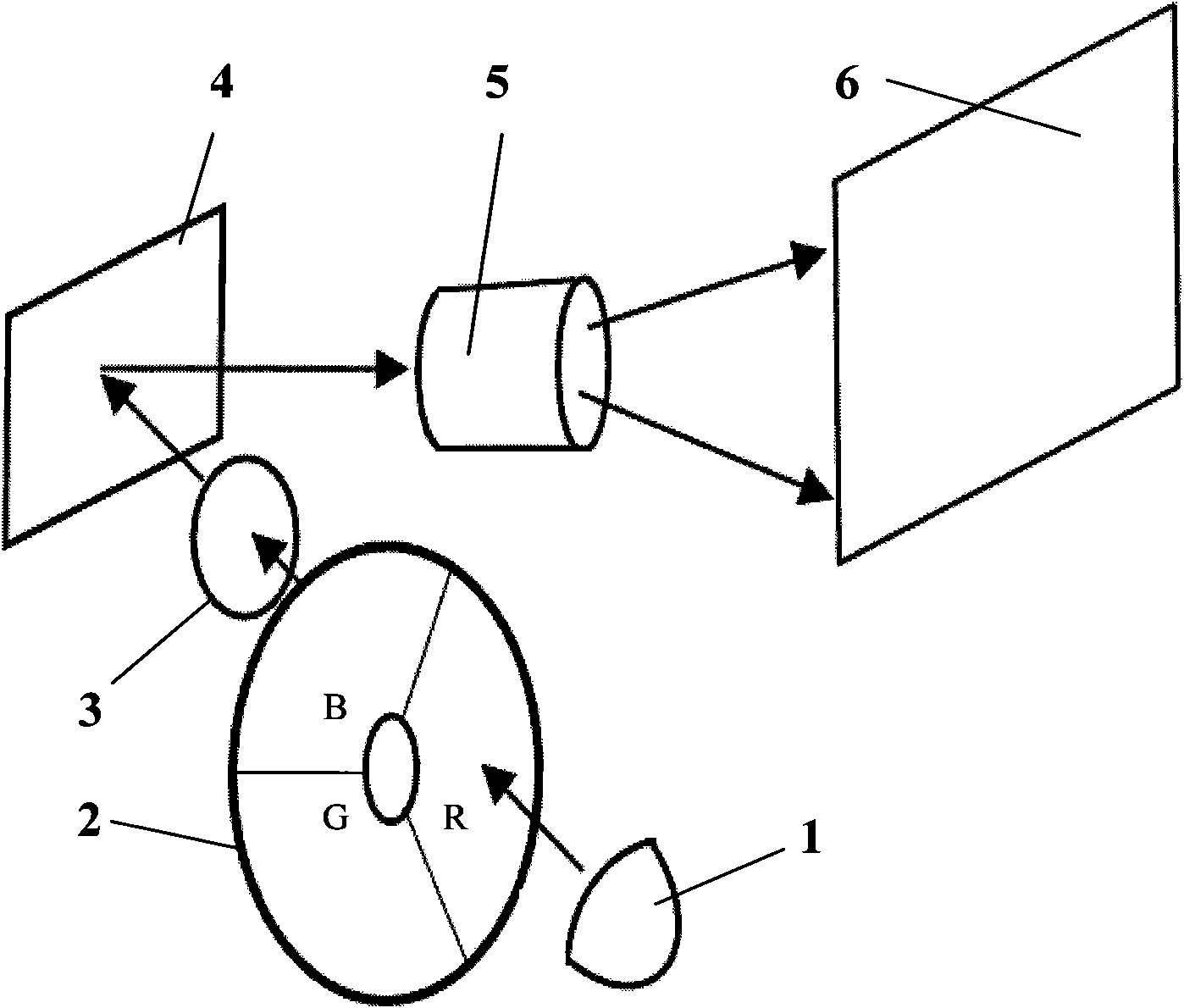

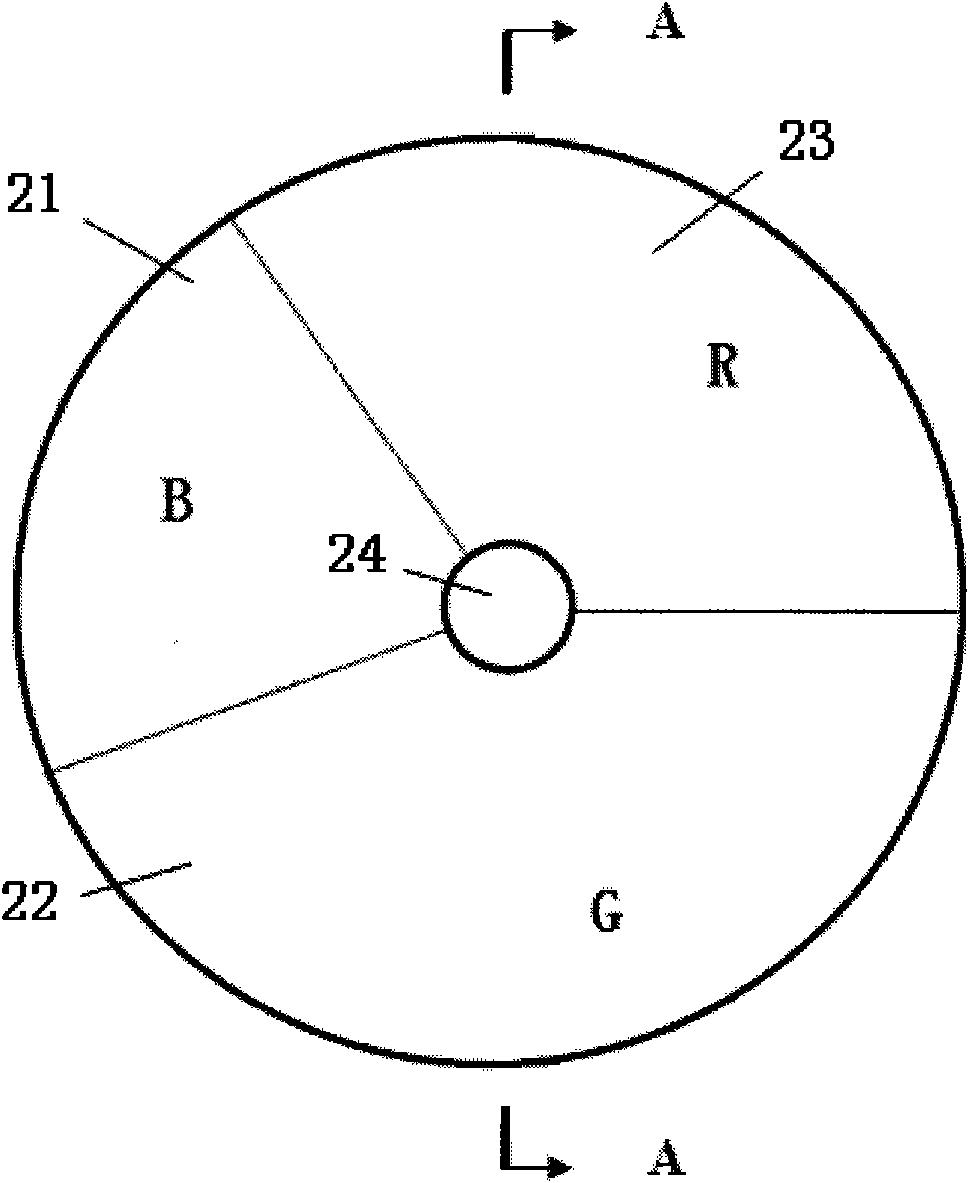

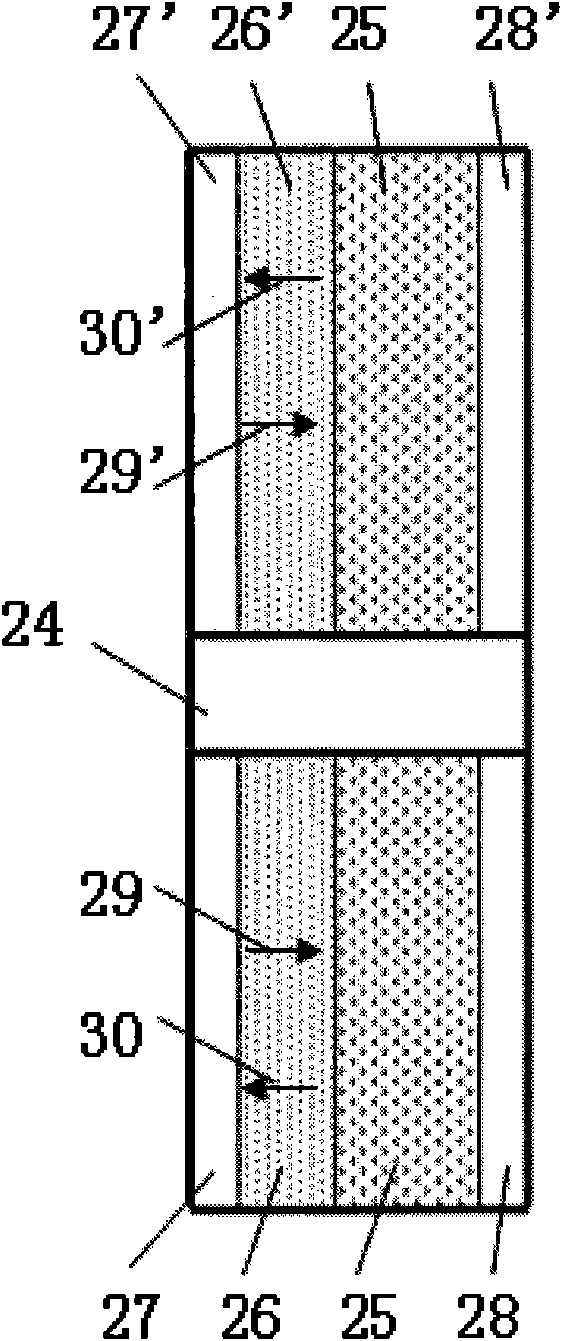

[0019] As a specific implementation example of the present invention, the schematic diagram of a solid light source projector is as follows figure 1 shown. figure 1 Among them, the solid light source 1 (LED or LD) is used as the lighting source of the projector, and its emitted light wavelength is the blue light of 460-470nm; the color modulation disc 2 of the present invention is used to produce blue (B), green (G), Red (R) trichromatic light, wherein the blue light is directly obtained from the blue light with a wavelength of 460-470nm emitted by the solid light source 1, and the green light is obtained by exciting the green phosphor layer with the blue light with a wavelength of 460-470nm emitted by the solid light source 1 , the red light is obtained by exciting the red phosphor layer with blue light with a wavelength of 460-470nm emitted by the solid light source 1; (R) The three primary colors are collimated and incident on the digital micromirror device 4 (Digital Micr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com