Backflow air-floating device for water-arrangement optimization multi-phase flow pump

A multi-phase flow pump and multi-phase flow technology, applied in the direction of flotation water/sewage treatment, etc., can solve the problems of high power consumption, complex structure and high operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

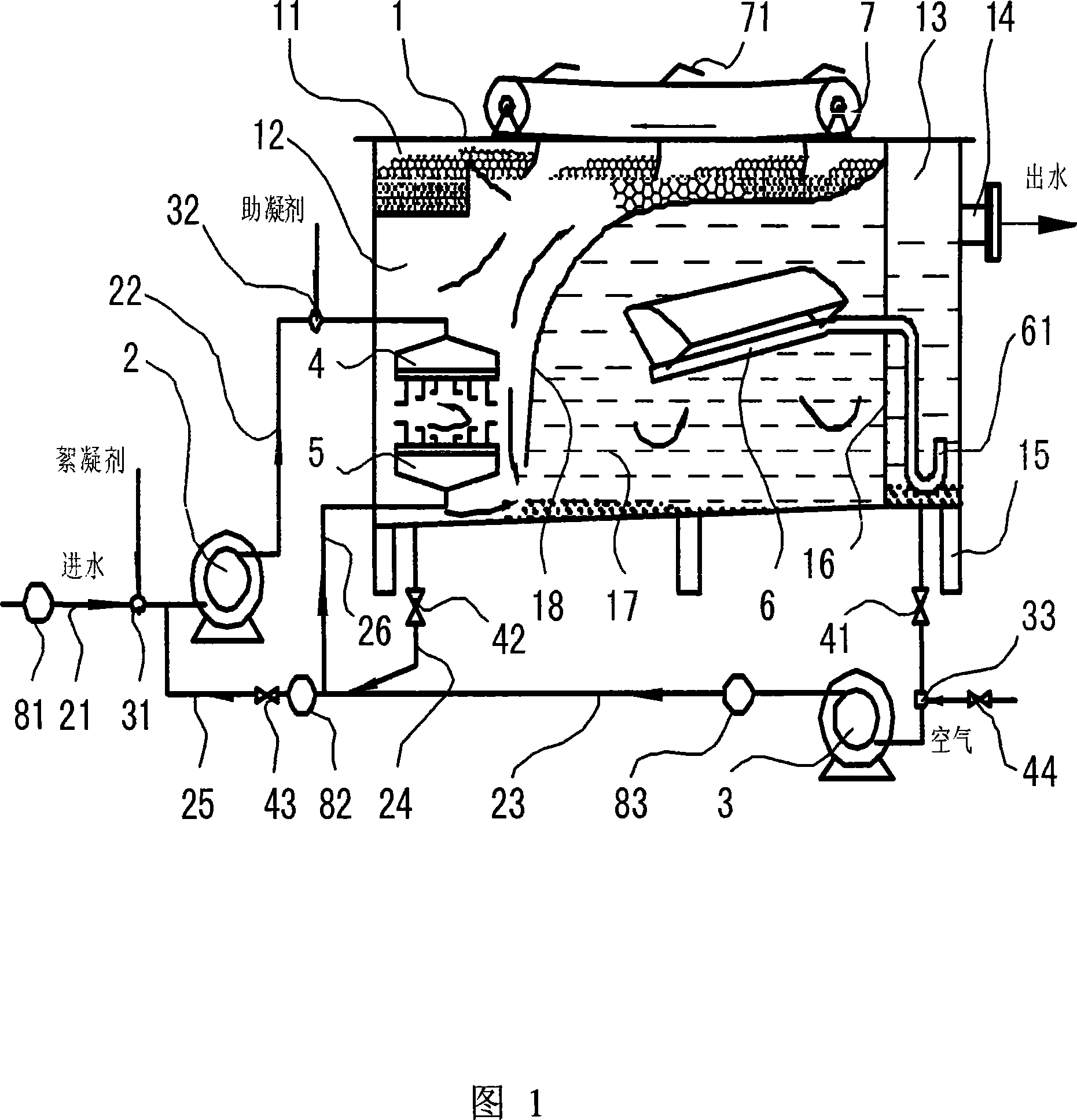

[0034] The specific implementation of the device of the present invention will be described below in conjunction with the accompanying drawings.

[0035] As shown in FIG. 1 , the sewage or waste water to be treated is pumped by the water inlet pump 2 and enters the air flotation chamber 12 of the air flotation tank 1 from the sewage water inlet 21 and the water inlet pipe 22 . A flocculant dosing port 31 is provided before the pump of the water inlet pipeline, and a flocculant polyaluminum chloride (PAC) is added in a certain amount, and a coagulant dosing port 32 is provided near the entrance of the air flotation tank after the pump, Add coagulant polyacrylamide (PAM) in a certain amount. The reason why the two agents are not added at the same dosing point is that adding the coagulant after a certain period of flocculation reaction has the best effect. When the air flotation tank is not full of water in the first operation, the water enters the air flotation chamber from the...

Embodiment 2

[0040] Utilize the device of the same example 1 provided by the present invention to process a kind of oily waste water, its water quality water quantity is: oil content 153mg / L, COD cr 786mg / L, continuous treatment of water about 1200m per day 3 (50m 3 / h). Addition amount of PAC40mg / L, PAM2mg / L, continuous dosing. The reflux ratio is adjusted to 25%, and the treated water quality is 5.5mg / L oil content, COD cr 43mg / L, the removal rate reaches 96.4% of oil removal rate and 94.5% of COD removal rate.

Embodiment 3

[0042] Utilize the device of the same example 1 provided by the present invention to process the white water of a papermaking enterprise with an annual output of 5,000 tons of toilet paper, and its water quality and quantity are: COD cr 650mg / L, SS (suspended solids) 485mg / L, continuous treatment of water about 1800m per day 3 (75m 3 / h). The amount of medicine added is PAC60mg / L, PAM1mg / L, continuous dosing. The reflux ratio is adjusted to 20%, and the index COD of the treated water cr 54.5mg / L, SS46mg / L, COD removal rate is 91.6%, suspended matter removal rate is 90.5%, and the effluent reaches the national first-class discharge standard.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com