Technological process for advanced treatment and recycle of cold rolling water

A technology of advanced treatment and process method, which is applied in the field of water treatment, can solve the problems of increasing operating costs, increasing pretreatment investment costs, and high requirements for influent water quality, and achieves low production and operating costs, stable treatment effects, and reduced load shocks Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

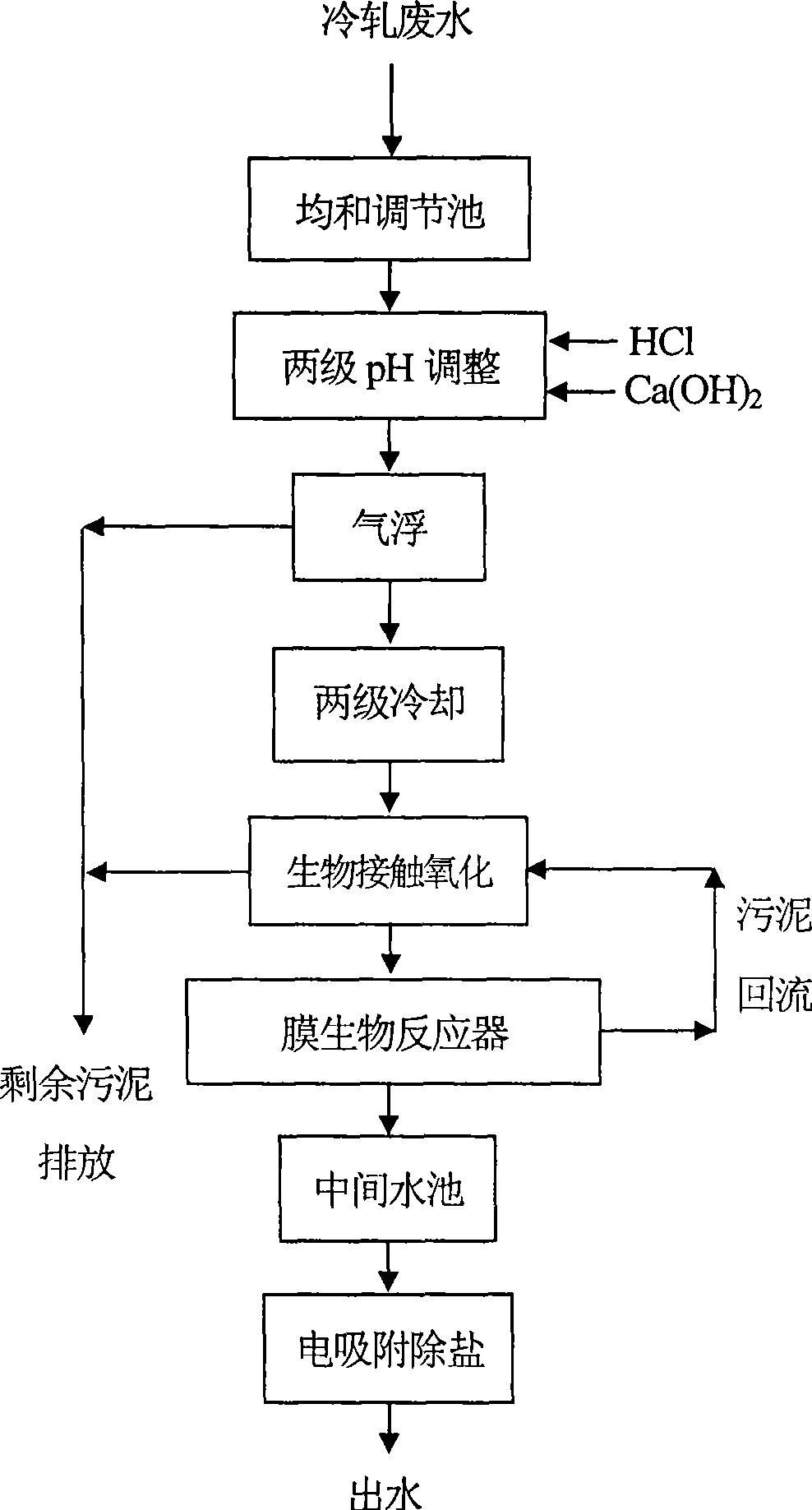

[0023] see figure 1 , according to a cold rolling wastewater advanced treatment and reuse process method of the present invention, it includes a pretreatment step, a biochemical secondary treatment step and an electro-adsorption desalination treatment step.

[0024] The pretreatment step is a combination of homogenization and aeration adjustment, two-stage pH value adjustment, dissolved air flotation, and two-stage cooling. The cold rolling wastewater first enters the equalization and aeration adjustment tank, and after the water quality and water volume are equalized, it is lifted from the adjustment tank to the first-level pH value adjustment tank, and then passes through the second-level pH value adjustment tank to control the pH value of the wastewater at 6~ 9. The adjusted wastewater is added with Jingshuiling and coagulant before entering the dissolved air flotation to enhance the removal effect.

[0025] Then the waste water flows into the dissolved air flotation to r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com