Method for treating wastewater of fibre-board plant

A technology for wastewater treatment and fiberboard, which is applied in the process of wastewater treatment, biological water/sewage treatment, flotation water/sewage treatment, etc. It can solve the problems of long design residence time, large one-time investment, unbearable for enterprises, etc. The effect of saving tap water consumption, low operating costs, and small equipment footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

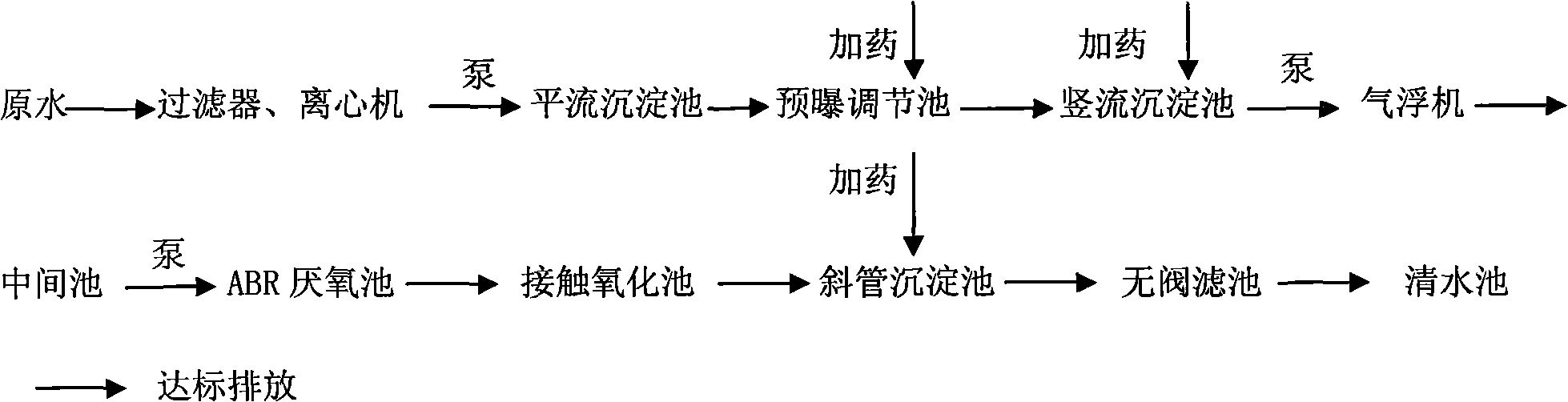

[0032] After the production wastewater passes through the bow screen filter and centrifuge to remove large particles of wood slag, short fibers, silt and other substances, most of the wastewater is reused for washing wood chips, and the effluent is sent to the advection sedimentation tank, pre-aeration adjustment tank, and iron aeration Pool, air flotation, ABR anaerobic treatment, three-stage contact oxidation tank, inclined tube settler, valveless filter unit process combination.

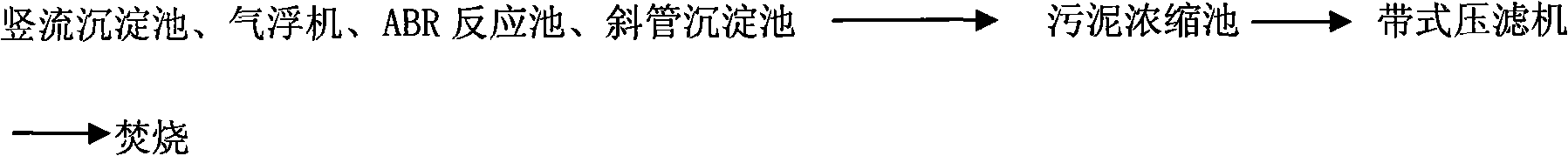

[0033] Process indicators and descriptions of each unit:

[0034]

[0035]

[0036] The waste water treatment system adopting the above combination process, the depth index of the effluent water quality after treatment meets the first-level discharge standard in the "Integrated Wastewater Discharge Standard" (GB8978-1996), the main water quality index:

[0037] project

[0038] By adopting the above-mentioned combined process technology, the consumption of running water is saved, ...

Embodiment 2

[0040] The production wastewater in this example is partially reused after separation of slag, and the effluent is sent to advection sedimentation, pre-aeration adjustment tank, vertical flow sedimentation, air flotation, ABR anaerobic treatment, three-stage contact oxidation tank, inclined tube settler, valveless filter Pool unit process combination.

[0041] Process indicators of each unit:

[0042]

[0043]

[0044]The waste water treatment system adopting the above combination process, the depth index of the effluent water quality after treatment meets the first-level discharge standard in the "Integrated Wastewater Discharge Standard" (GB8978-1996), the main water quality index:

[0045] project

[0046] By adopting the above-mentioned combined process technology, the consumption of running water is saved, and the production waste water is discharged less. The invention plays a powerful role in promoting the energy saving and emission reduction advocated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com