Method for processing landfill leachate

A technology of landfill leachate and treatment method, which is applied in the field of waste treatment, and achieves the effects of wide applicability, strong adaptability and good economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

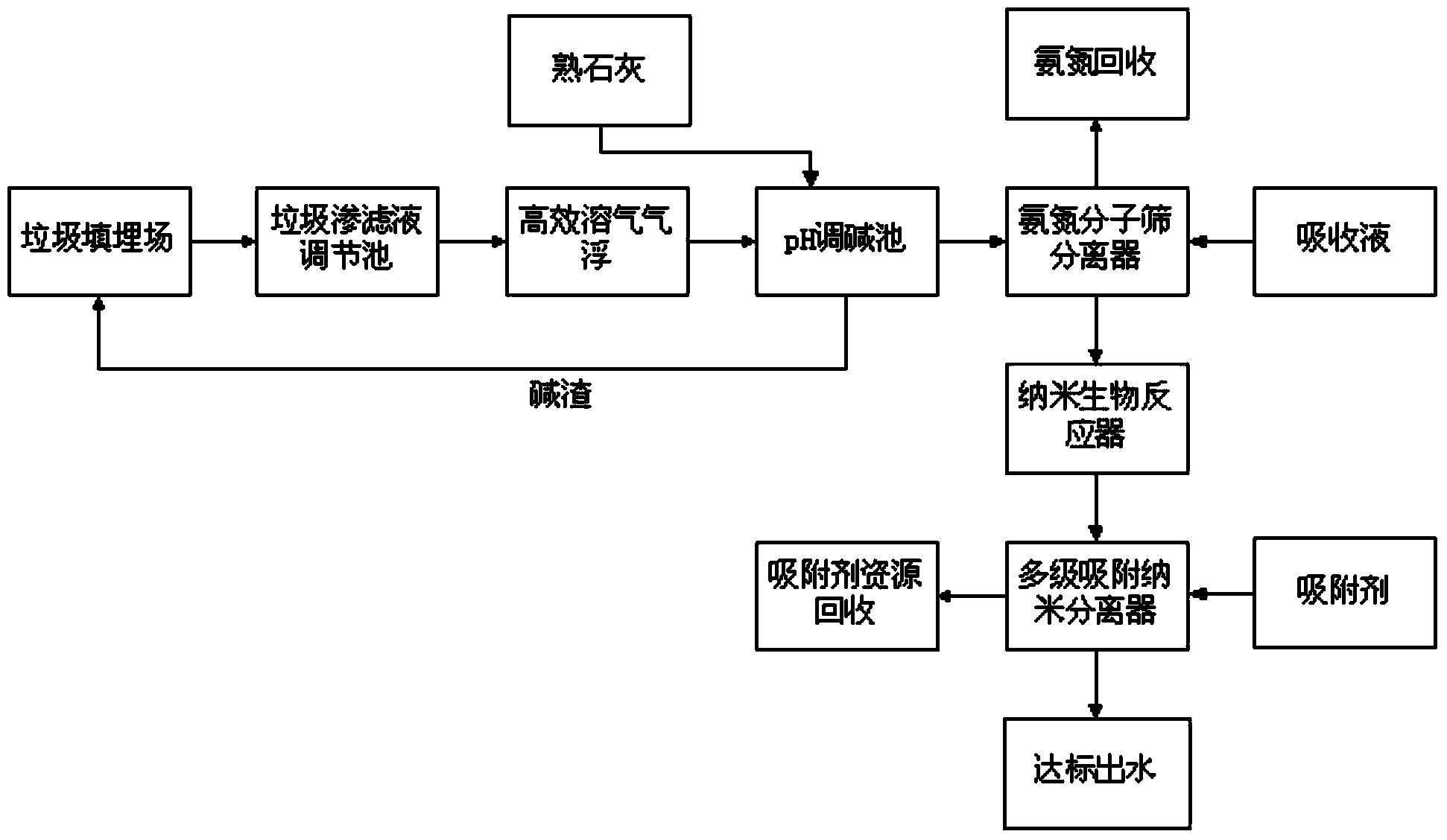

Method used

Image

Examples

Embodiment 1

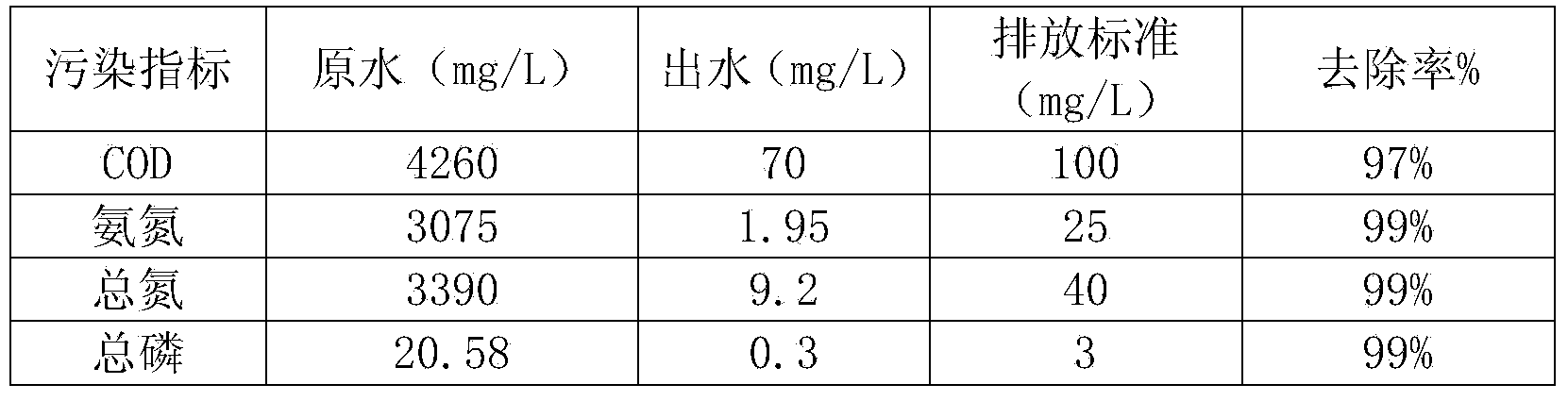

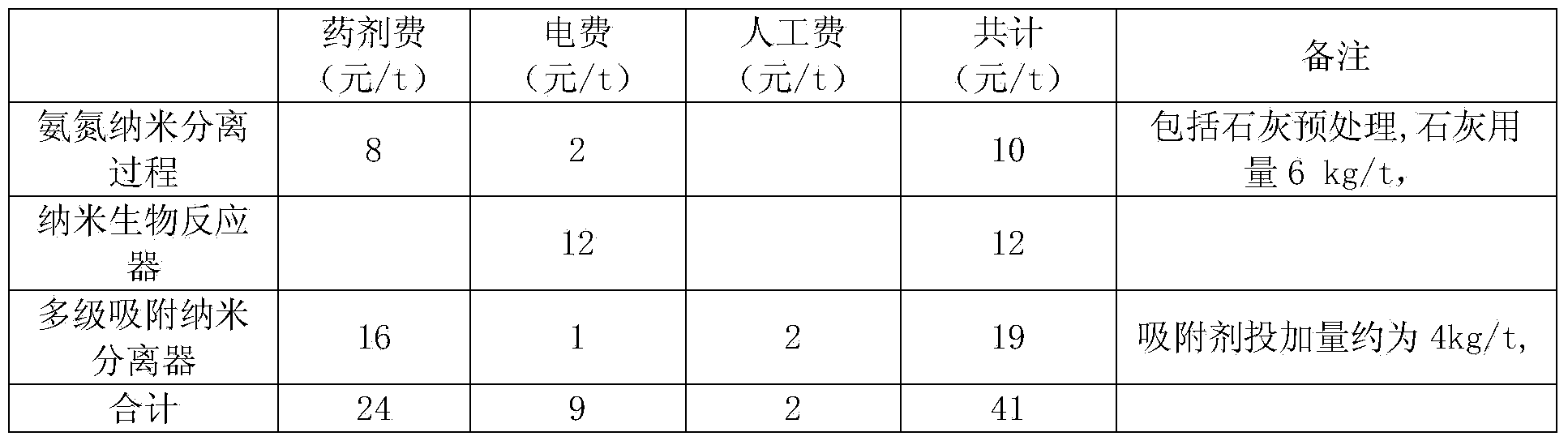

[0042] After the landfill leachate is collected in the adjustment tank, high-efficiency dissolved air flotation is carried out; slaked lime is added to the landfill leachate after air flotation treatment for alkali adjustment treatment, and the pH is adjusted to 11, and the alkali residue is returned to the garbage Landfill: Send the landfill leachate after alkali adjustment to the ammonia nitrogen molecular sieve separator. After removing suspended impurities and colloidal organic substances in the landfill leachate, separate the ammonia nitrogen molecular sieve and recover ammonia nitrogen by adding sulfuric acid to form ammonium sulfate; recover ammonia nitrogen The final landfill leachate enters the nano bioreactor for biochemical treatment to remove organic matter, nitrogen, and phosphorus in the landfill leachate; the landfill leachate after biochemical treatment is subjected to multi-stage countercurrent adsorption with modified carbon, and then discharged up to the stand...

Embodiment 2

[0044] After the landfill leachate is collected in the adjustment tank, high-efficiency dissolved air flotation is carried out; slaked lime is added to the landfill leachate after air flotation treatment for alkali adjustment treatment, and the pH is adjusted to 12, and the alkali residue is returned to the garbage Landfill: Send the landfill leachate after alkali adjustment to the ammonia nitrogen molecular sieve separator. After removing suspended impurities and colloidal organic substances in the landfill leachate, separate the ammonia nitrogen molecular sieve and recover ammonia nitrogen by adding sulfuric acid to form ammonium sulfate; recover ammonia nitrogen The final landfill leachate enters the nano bioreactor for biochemical treatment to remove organic matter, nitrogen, and phosphorus in the landfill leachate; the landfill leachate after biochemical treatment is subjected to multi-stage countercurrent adsorption with modified carbon, and then discharged up to the stand...

Embodiment 3

[0046] After the landfill leachate is collected in the adjustment tank, high-efficiency dissolved air flotation is carried out; slaked lime is added to the landfill leachate after air flotation treatment for alkali adjustment treatment, and the pH is adjusted to 13, and the alkali residue is returned to the garbage Landfill: send the landfill leachate after alkali adjustment to the ammonia nitrogen molecular sieve separator, after removing suspended impurities and colloidal organic substances in the landfill leachate, separate the ammonia nitrogen molecular sieve and recover ammonia nitrogen by adding hydrochloric acid to form ammonium chloride; ammonia nitrogen The recovered landfill leachate enters the nano-bioreactor for biochemical treatment to remove organic matter, nitrogen, and phosphorus in the landfill leachate; the landfill leachate after biochemical treatment is subjected to multi-stage countercurrent adsorption with modified carbon, and then discharged up to the stan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com