Patents

Literature

37results about How to "Achieve resource recycling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A treating method of fluorine-containing waste water

ActiveCN104512972AAvoid the impact of the defluoridation processEffective in removing fluorideWater contaminantsMultistage water/sewage treatmentChemical compoundSludge

A treating method of fluorine-containing waste water is disclosed. The fluorine-containing waste water comprises F-, SO4<2-> and Al<3+>. The method includes: adjusting the pH value of the fluorine-containing waste water to be not lower than 5 so as to subject the F- to neutralization and sedimentation reactions; bringing the fluorine-containing waste water after the neutralization and sedimentation reactions and coagulant aids into contact; separating solid and liquid to obtain first sludge and a first liquid phase; bringing the obtained first liquid phase and an aluminum-containing compound capable of adsorbing the F- in the waste water into contact to perform coagulating sedimentation; separating liquid and solid to obtain second sludge and a second liquid phase; bringing the obtained second liquid phase and coagulant aids into contact; and performing liquid-solid separation to obtain third sludge and discharged treated water. The method can perform effective fluorine removal treatment for the fluorine-containing waste water having high contents of the F-, the SO4<2-> and the Al<3+>.

Owner:CHINA PETROLEUM & CHEM CORP +1

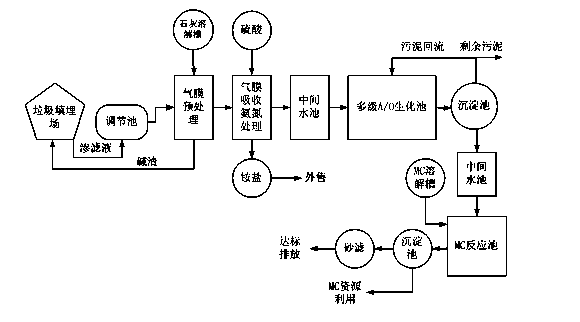

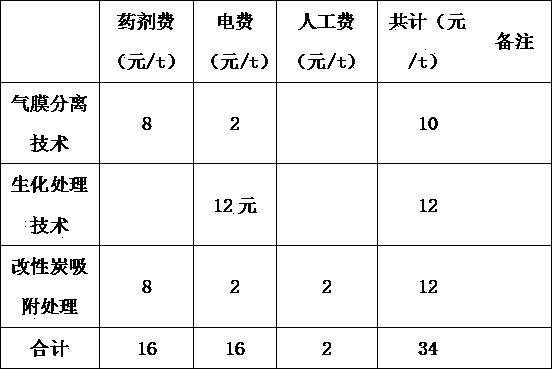

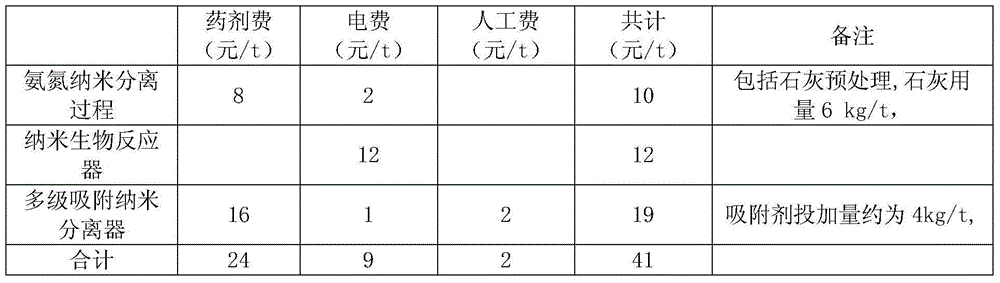

Method for processing city household garbage leachate

InactiveCN103626353AImprove economyStable emissionsMultistage water/sewage treatmentHigh concentrationSolubility

The invention discloses a method for processing city household garbage leachate. Aiming at the garbage leachate's characteristics of high ammonia nitrogen content and difficult biodegradation, people develop the processing method by combining and optimizing the following technologies: lime pretreatment, gas-film acid absorption, high efficient multi-grade AO biochemical treatment, and modified carbon absorption. The processing method comprises the following steps: subjecting the garbage leachate to a foam separation process so as to reduce the grease and surfactant content in the garbage leachate; adding lime into the garbage leachate so as to adjust the pH value of the garbage leachate and convert the ammonia nitrogen into a free state; subjecting the garbage leachate to processes of micro-filtration and ultrafiltration so as to eliminate macromolecular organic substances, then subjecting the garbage leachate to a gas-film acid absorption treatment so as to effectively eliminate the nitrogen ammonia with a high concentration in the garbage leachate to meet the requirements of biochemical treatment, subjecting the garbage leachate to go through an AO biochemical treatment system so as to further eliminate the pollutants such as total nitrogen, ammonia nitrogen, COD, BOD, and the like in the garbage leachate, so that after the processes mentioned above, only organic matters that are difficult to degrade and soluble are left in the garbage leachate, adopting modified carbon as an absorbent and a counter-current multi-grade absorption technology to effectively eliminate the organic matters difficult to degrade in the garbage leachate to make the garbage leachate meet the national discharging standard, and finally discharging the qualified garbage leachate.

Owner:宋乾武 +1

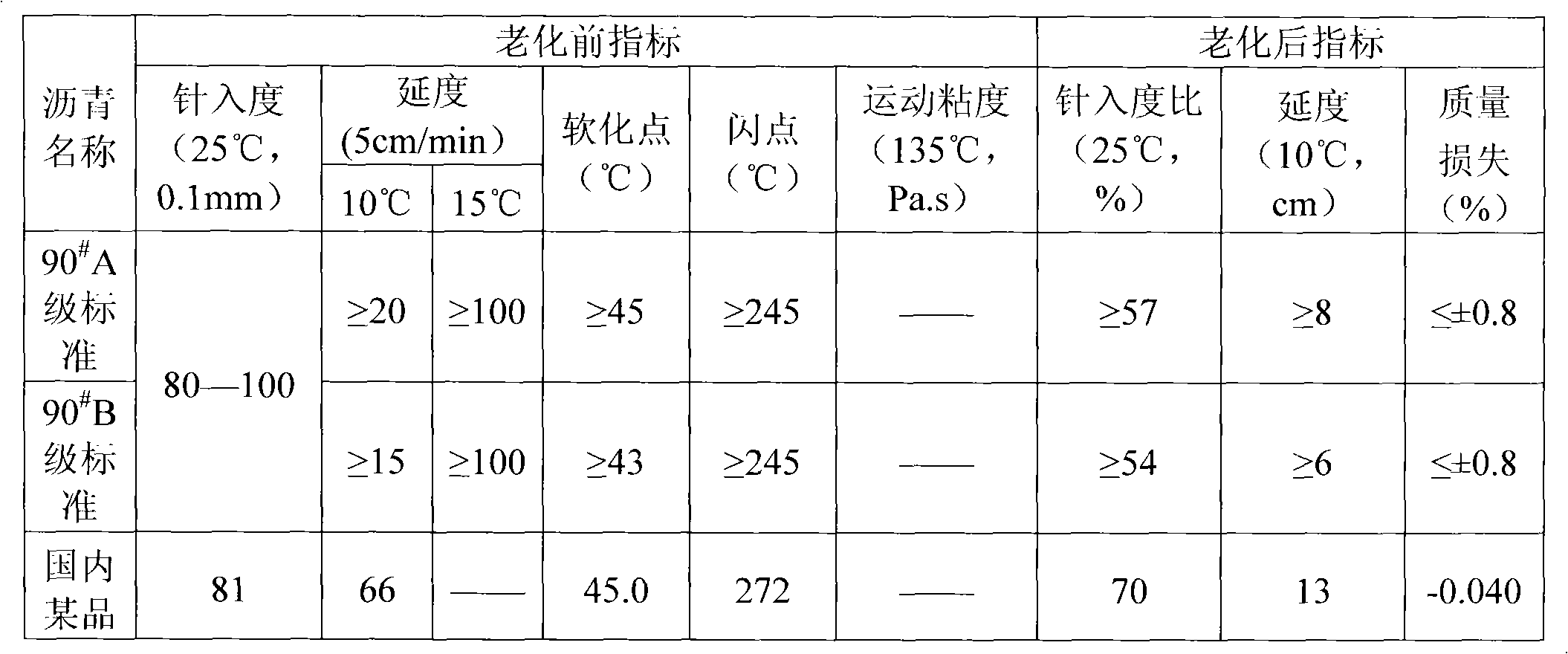

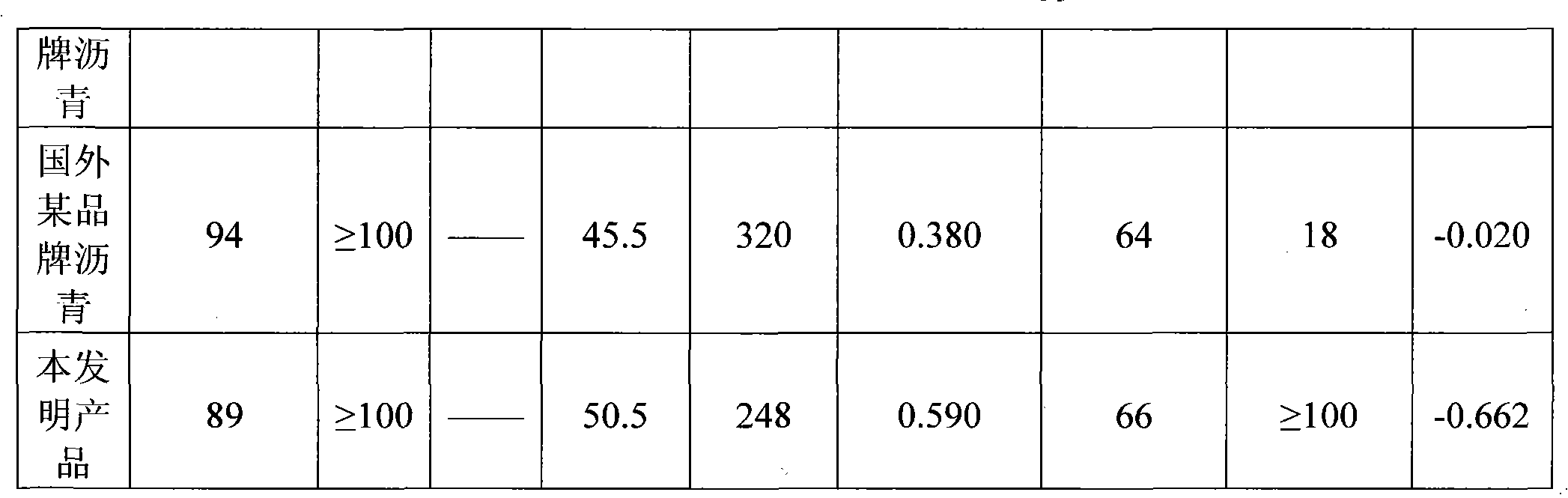

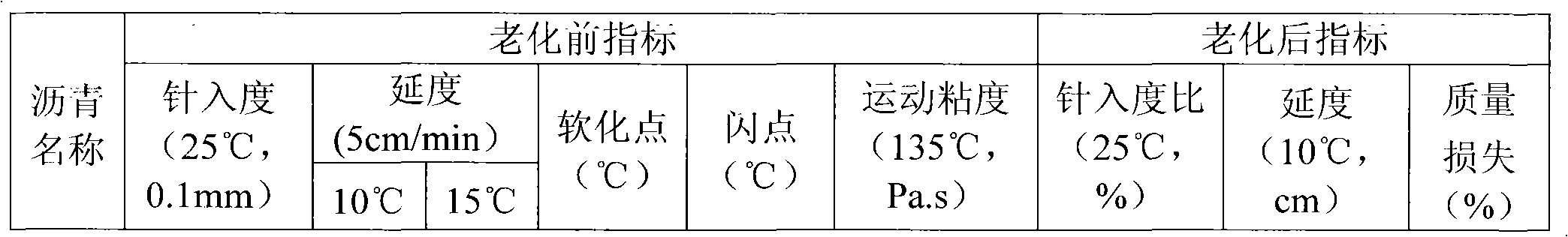

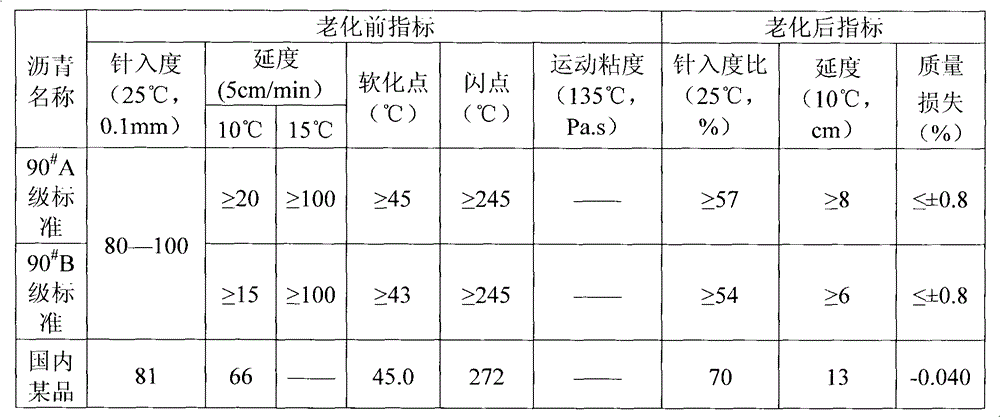

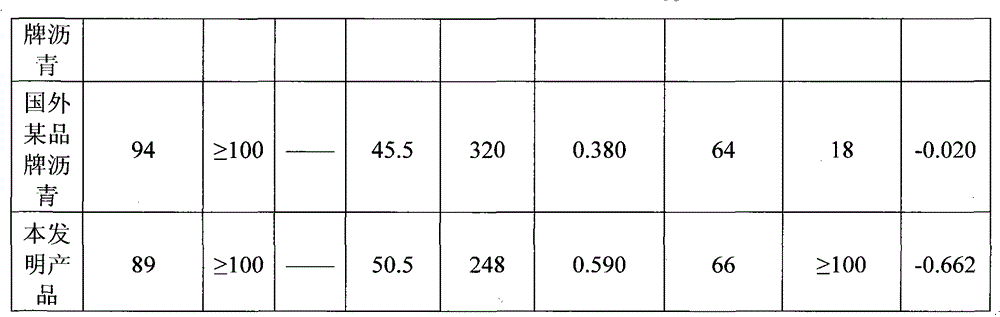

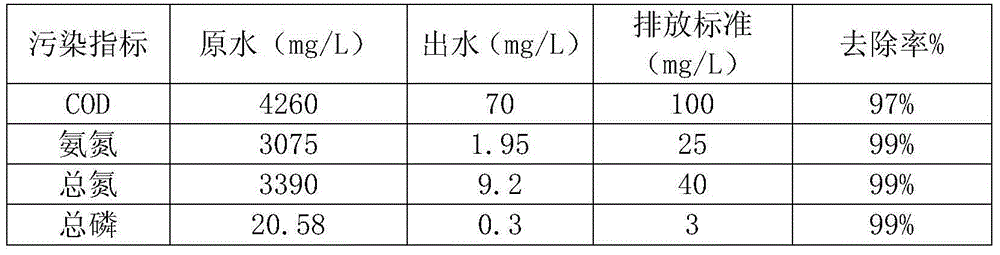

High-quality pavement petroleum asphalt material and preparation method thereof

ActiveCN101629021AImprove flexibilityImprove low temperature performanceBuilding insulationsBituminous materialsPetroleum

The invention discloses a high-quality pavement petroleum asphalt material and a preparation method thereof, belonging to the pavement engineering material technical field. The petroleum asphalt material is prepared from the raw materials according to the parts by weight: 80-95 parts of main asphalt, 5-20 parts of formulated asphalt, 0.01-2 parts of macromolecular crosslinking agent and 0.001-0.25 part of heat stabilizer. The invention adopts chemical crosslinking, heat stabilizer and the combination of cutting and milling to promote the matching of the four components of asphalt to be further optimized and develop in the direction of forming stable colloid structure, improving the pavement performance of the formulated asphalt material and increase the stability of the formulated asphalt product. The invention makes full use of the vacuum residue of residual oil and heavy crude which are treated through vacuum deep extraction and increases the use value so as to reach the effect of resource recycling and environmental protection.

Owner:XIAN ZHONGLI ASPHALT CO LTD

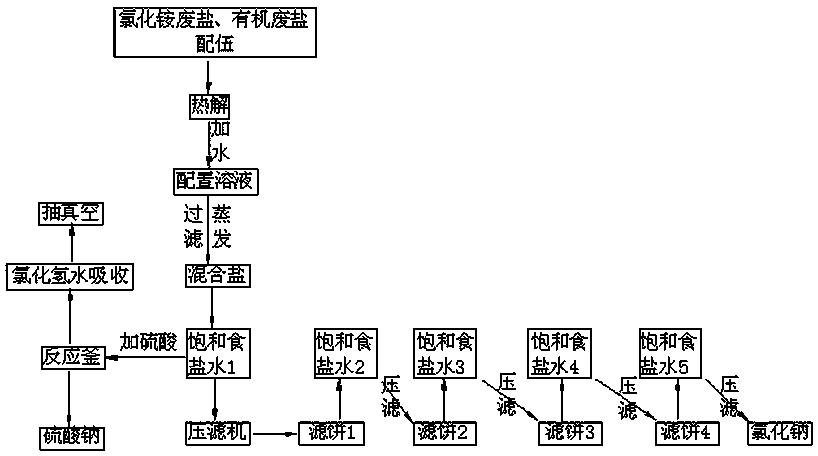

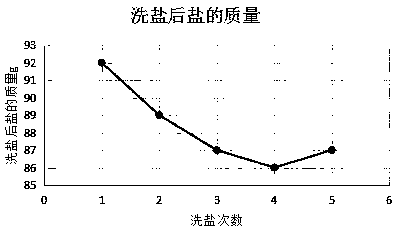

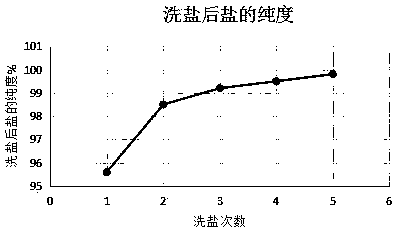

Method for recycling industrial waste salt

InactiveCN110711761AReduce corrosionLow pyrolysis temperatureWaste processingSolid waste disposalIndustrial wasteEnvironmental chemistry

The invention discloses a method for recycling industrial waste salt. The method comprises the following steps: taking waste salt containing relatively high ammonium chloride and organic waste salt for compatibility; heating and pyrolyzing the compatible waste salt to remove organic matters; cooling the pyrolyzed waste salt, and adding water for dissolving to prepare a solution; filtering the solution, and evaporating to obtain a mixed salt solid; preparing a plurality of tanks of saturated sodium chloride solutions, and performing salt washing on the mixed salt to obtain an industrial productsodium chloride; and adding sulfuric acid into the replaced saturated sodium chloride solution of sodium sulfate, absorbing hydrogen chloride gas in a reaction product by water to be converted into hydrochloric acid, filtering the sodium sulfate solution, and drying to prepare industrial sodium sulfate. The waste salt used in the method mainly contains ammonium chloride waste salt and organic waste salt, so that the problems that high-salt leachate is difficult to treat and the like after the waste salt is buried can be solved, meanwhile, sodium chloride and sodium sulfate are recycled, and resource recycling is achieved.

Owner:SHANGYU ZHONGLIAN ENVIRONMENTAL PROTECTION CO LTD

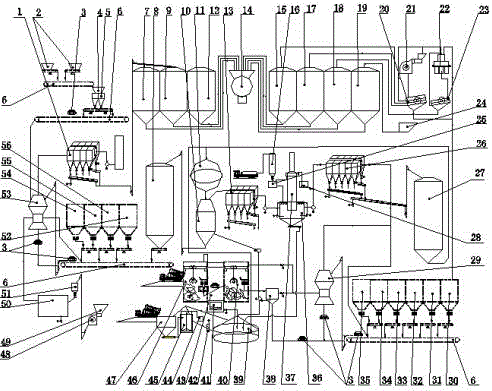

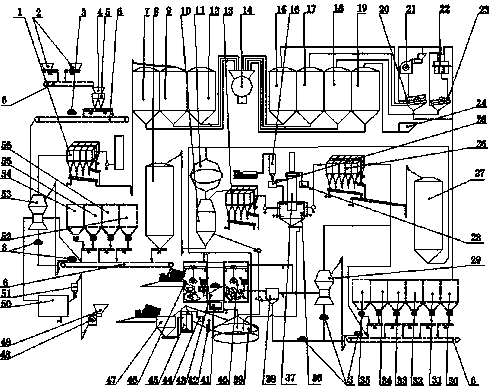

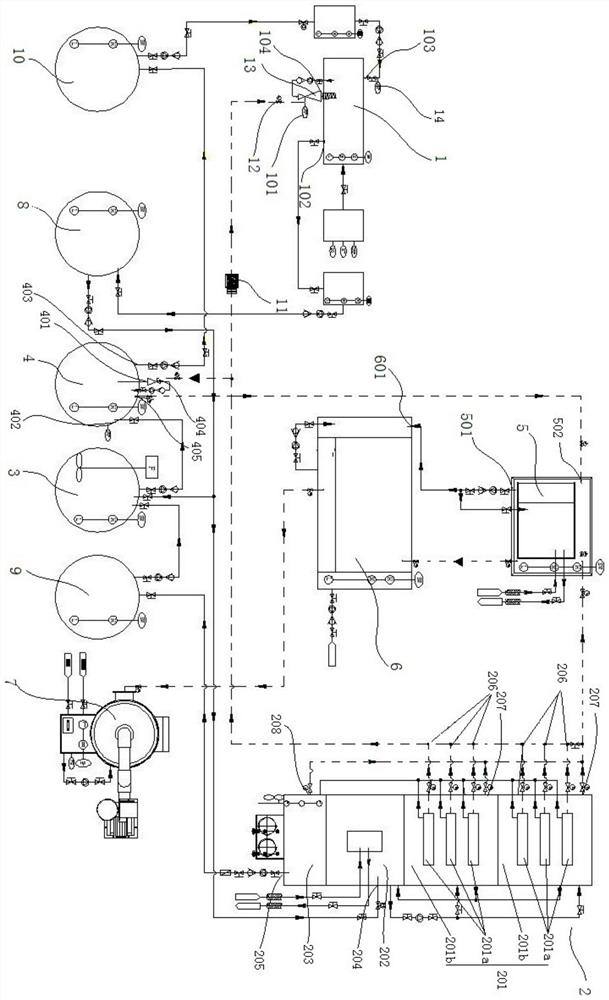

A set of concrete production environmental protection equipment and concrete production process

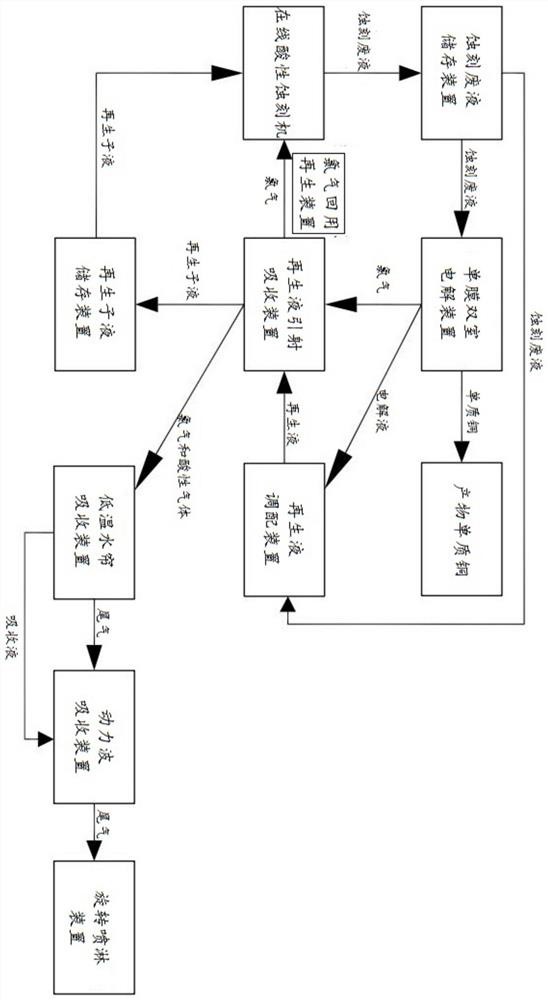

ActiveCN105965699ASave on moving costsSave money on burningMixing operation control apparatusPretreatment controlEnvironmental resistanceControl signal

The invention discloses a set of concrete production environmental protection equipment and a concrete production process. The set of concrete production environmental protection equipment comprises a DCS central control system and a remote monitoring system, wherein the DCS central control system controls an aggregate production line, a cement and mineral powder production line, a cement kiln sludge processing equipment, raw material processing domestic garbage equipment and concrete mixing plant equipment to produce concrete through a control signal; and the remote monitoring system is connected with and monitors the aggregate production line, the cement and mineral powder production line, the cement kiln sludge processing equipment, the raw material processing domestic garbage equipment and the concrete mixing plant equipment through optical fibers. With adoption of the set of concrete production environmental protection equipment, the concrete production process can be carried out. The set of concrete production environmental protection equipment has the advantages that no dusts, not leakage and no secondary pollution and transportation are generated due to full-automation sealing production, the energy is saved, the environment is protected, environmental pollution of atmosphere and soils is reduced, toxic and harmful substances are prevented from damaging human health through processing, and the economic benefit in virtuous circle and the value-added effect of the building material industry are reached.

Owner:陈更

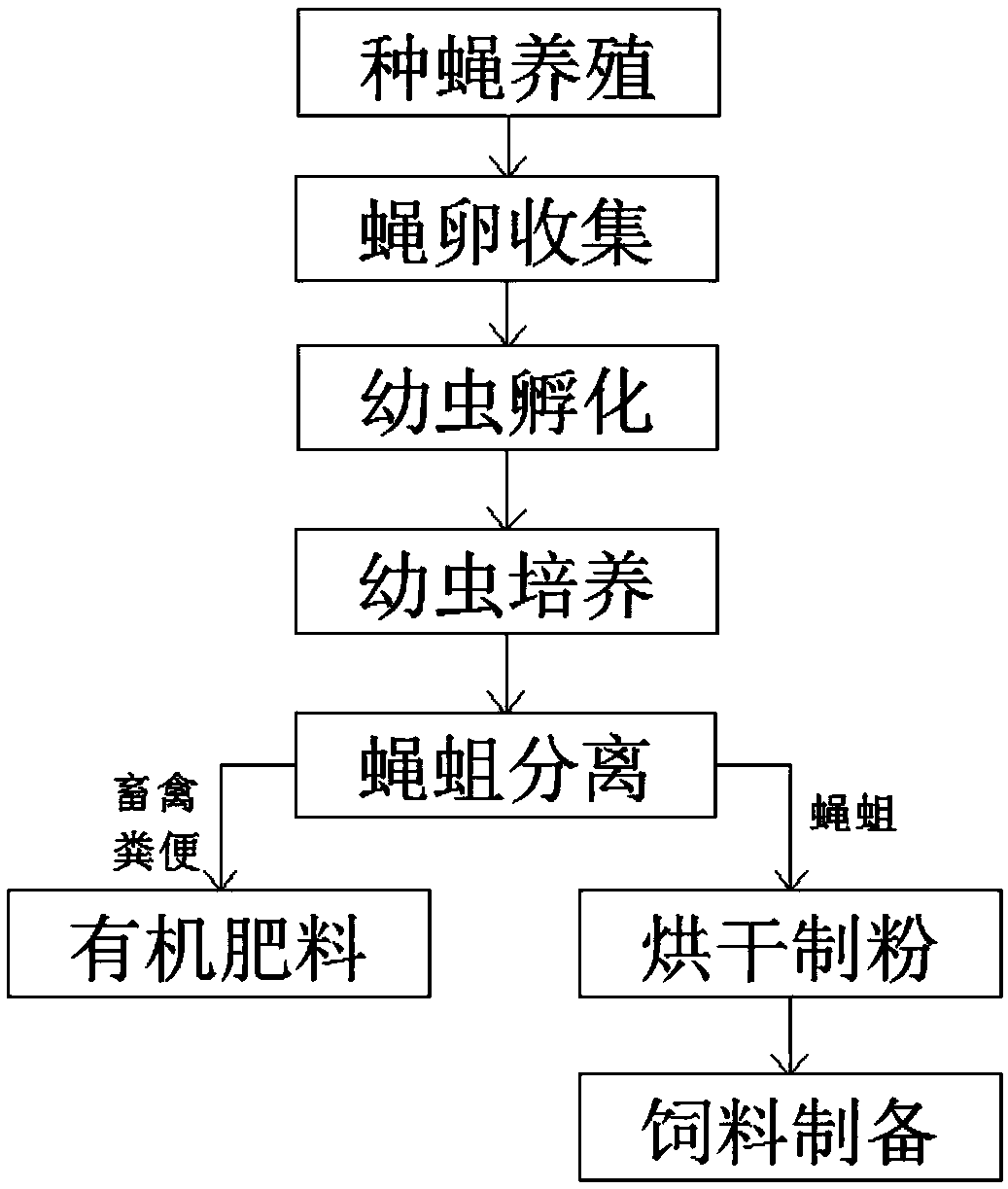

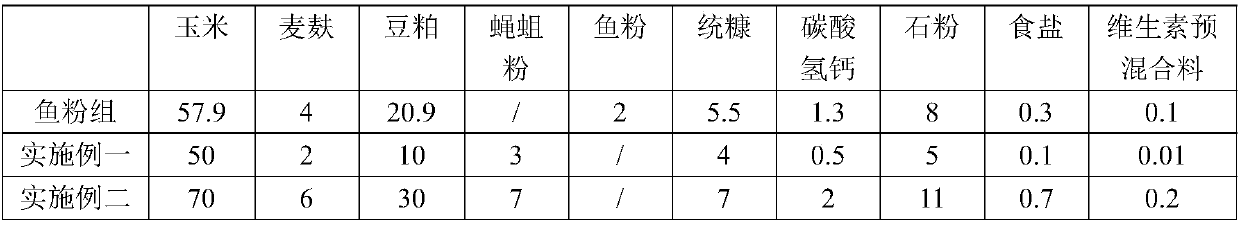

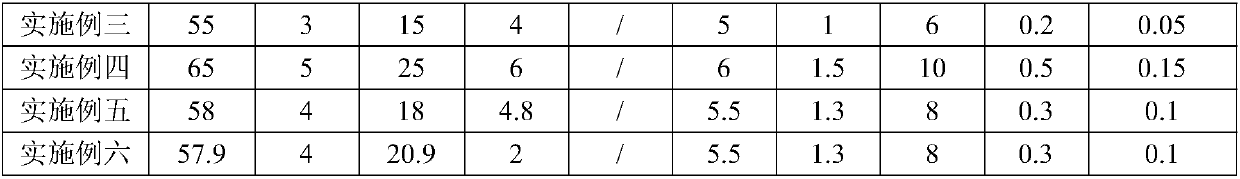

Antibiotic-free hormone-free laying hen feed utilizing fly maggot protein powder to replace fish meal and preparation method of laying hen feed

InactiveCN109673866ALow costQuality improvementFood processingAnimal feeding stuffBiotechnologyCalcium biphosphate

The invention provides an antibiotic-free hormone-free laying hen feed utilizing fly maggot protein powder to replace fish meal and a preparation method of the laying hen feed, and belongs to the technical field of cattle breeding feed. The antibiotic-free hormone-free laying hen feed is prepared from the following components in parts by weight: 50-70 parts of corn flour particle, 2-6 parts of wheat bran, 10-30 parts of bean pulp, 3-7 parts of the fly maggot protein powder, 4-7 parts of rice bran and hull, 0.5-2 parts of calcium hydrophosphate, 5-11 parts of mountain flour, 0.1-0.7 part of salt, and 0.01-0.2 part of a vitamin premix. A laying hen fed by adopting the antibiotic-free hormone-free laying hen feed provided by the invention has the advantages of a high laying rate, a low deathrate, good quality of laid eggs and the like.

Owner:朱纪

Defluorination and dephosphorization method of PSRY molecular sieve production wastewater

ActiveCN104556460AAvoid the influence of fluorine and phosphorus removal processSufficient supplyWater contaminantsMultistage water/sewage treatmentMolecular sieveWastewater

The invention relates to a defluorination and dephosphorization method of PSRY molecular sieve production wastewater. The method comprises the following steps: (1) solid waste residues generated during treatment process of PSRY molecular sieve production wastewater and other molecular sieve production wastewater are mixed, and aluminum in the solid waste residues is dissolved in the form of Al<3+> in the wastewater, wherein pH value of the mixed system during the dissolution process is less than 4.5; (2) pH value of the mixed system obtained from the step (1) is adjusted to more than 6 to make Al<3+> reacts with F<-> and PO4<3-> so as to fully precipitate F<-> and PO4<3->; and (3) a coagulant aid is added into the mixed system obtained from the step (2), and solid-liquid separation is carried out on the mixed system which has undergone coagulantion enhancement, wherein dosage and dissolution conditions of the solid waste residues in the step (1) enable Al<3+> in the step (2) to fully precipitate F<-> and PO4<3->. By the method, fluorine and phosphor in the PSRY molecular sieve production wastewater can be effectively removed.

Owner:CHINA PETROLEUM & CHEM CORP +1

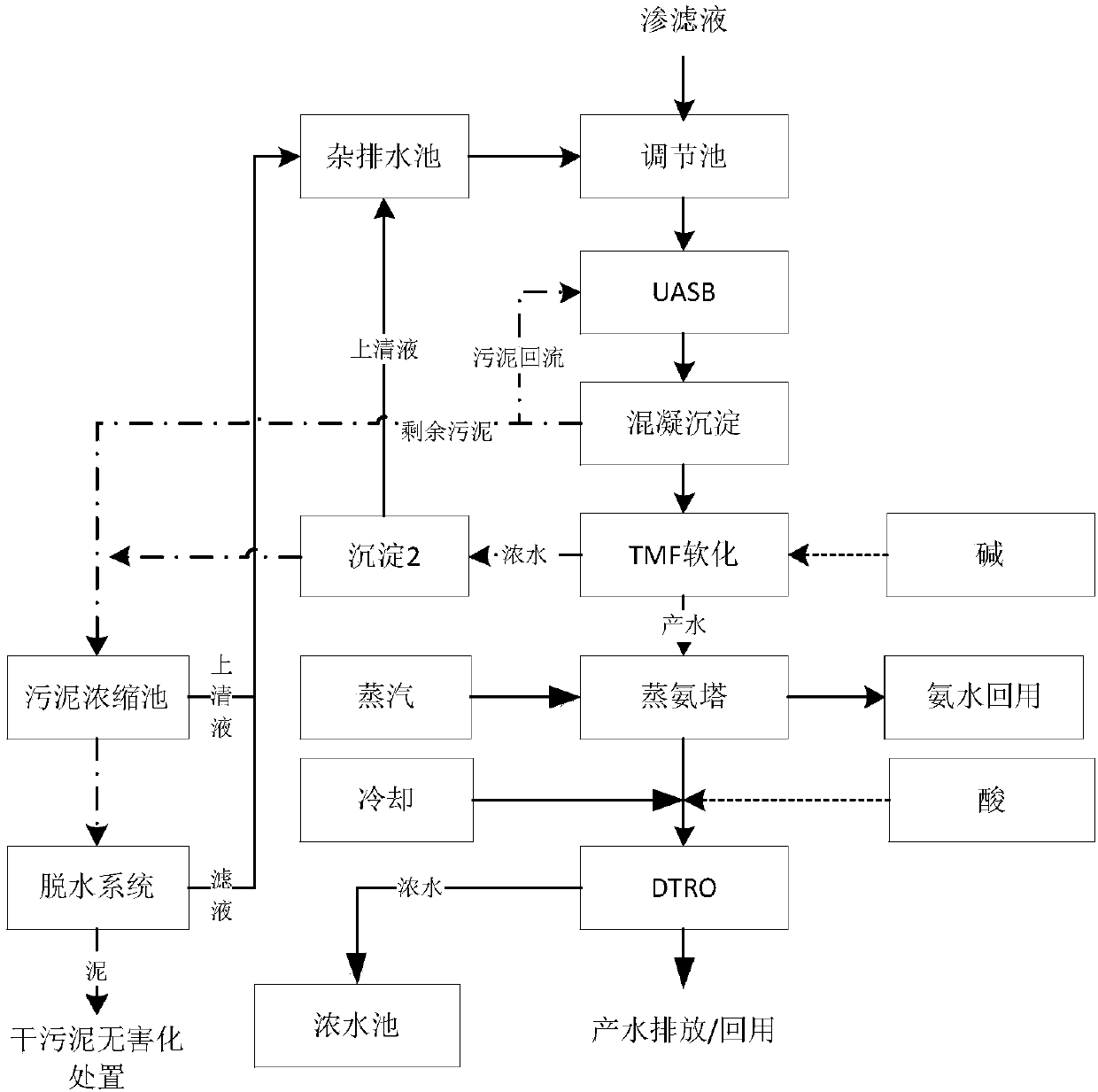

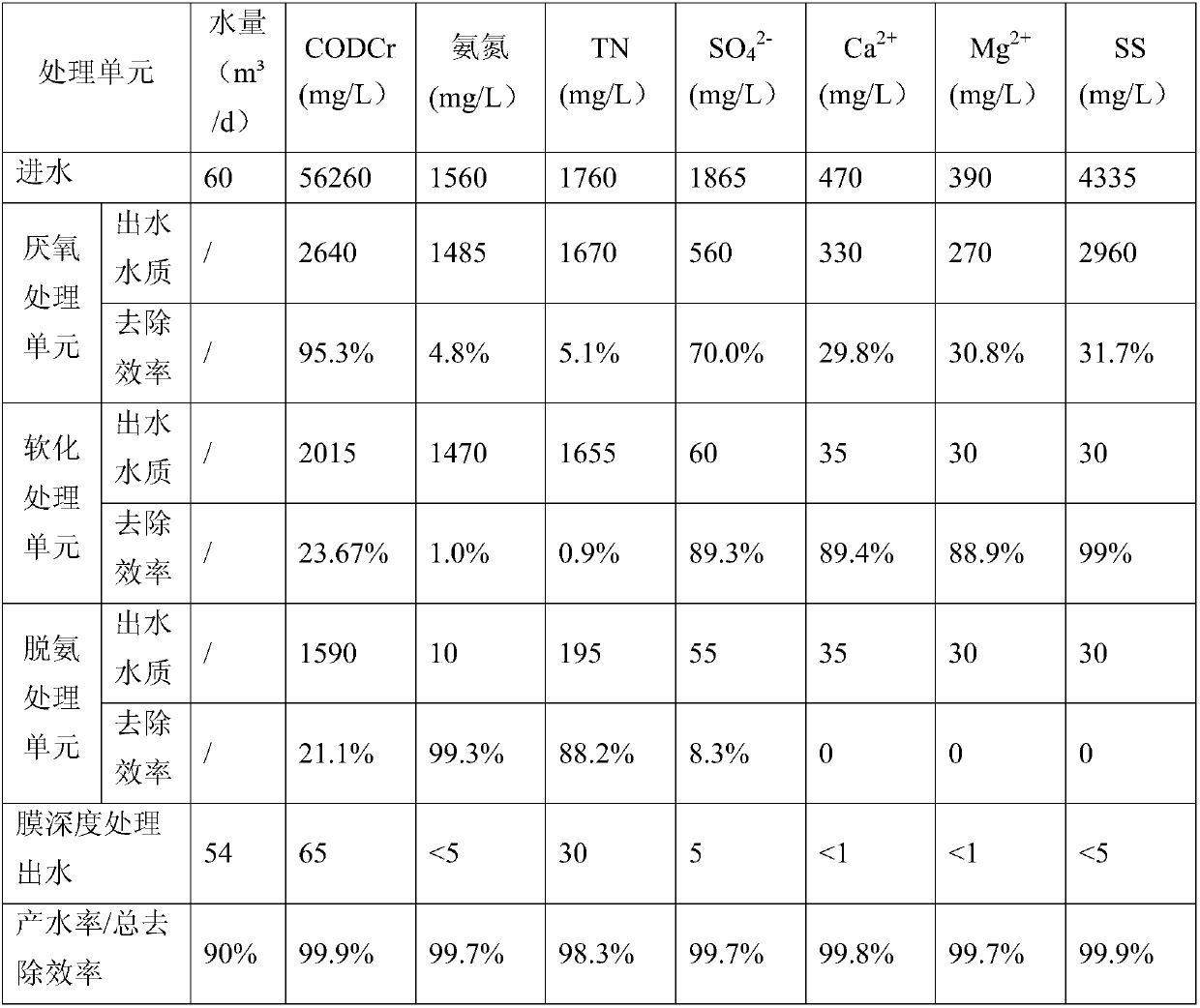

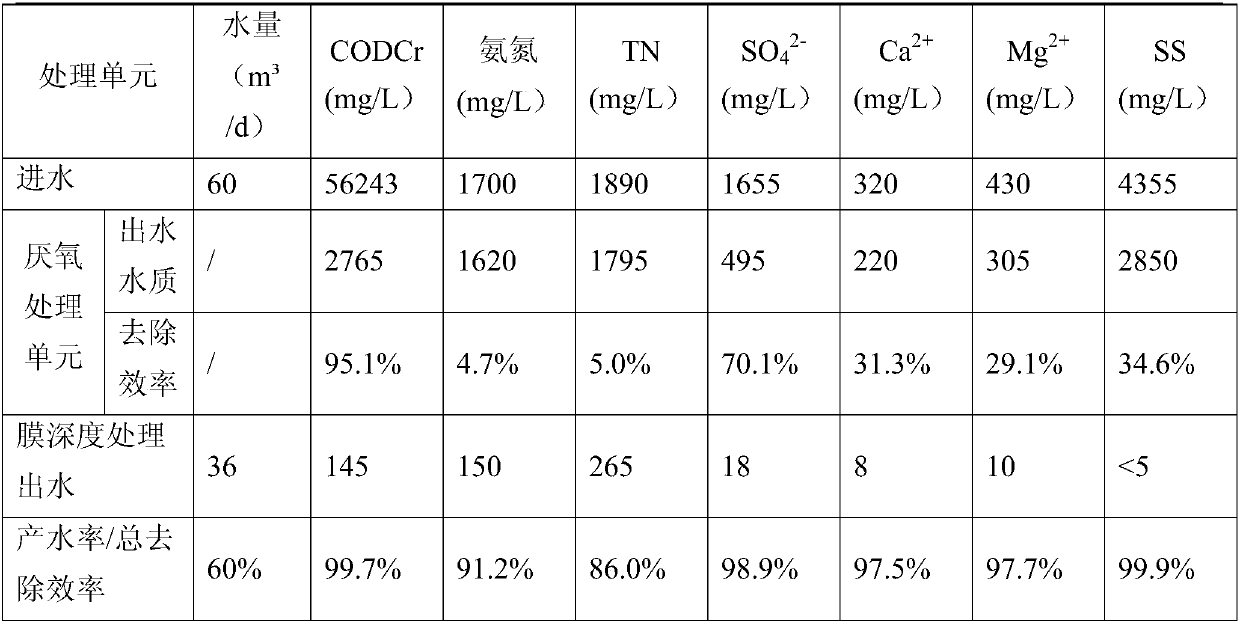

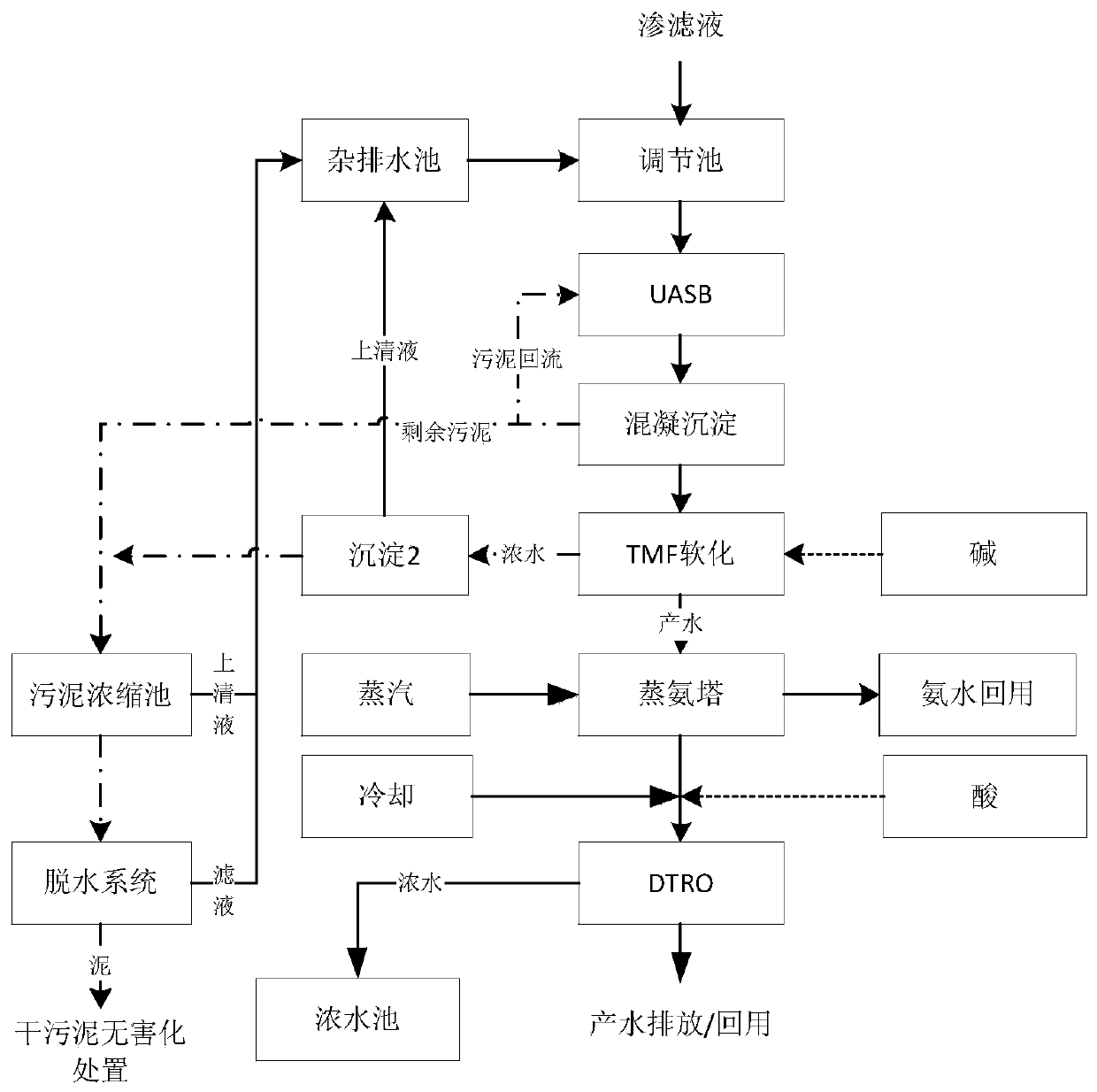

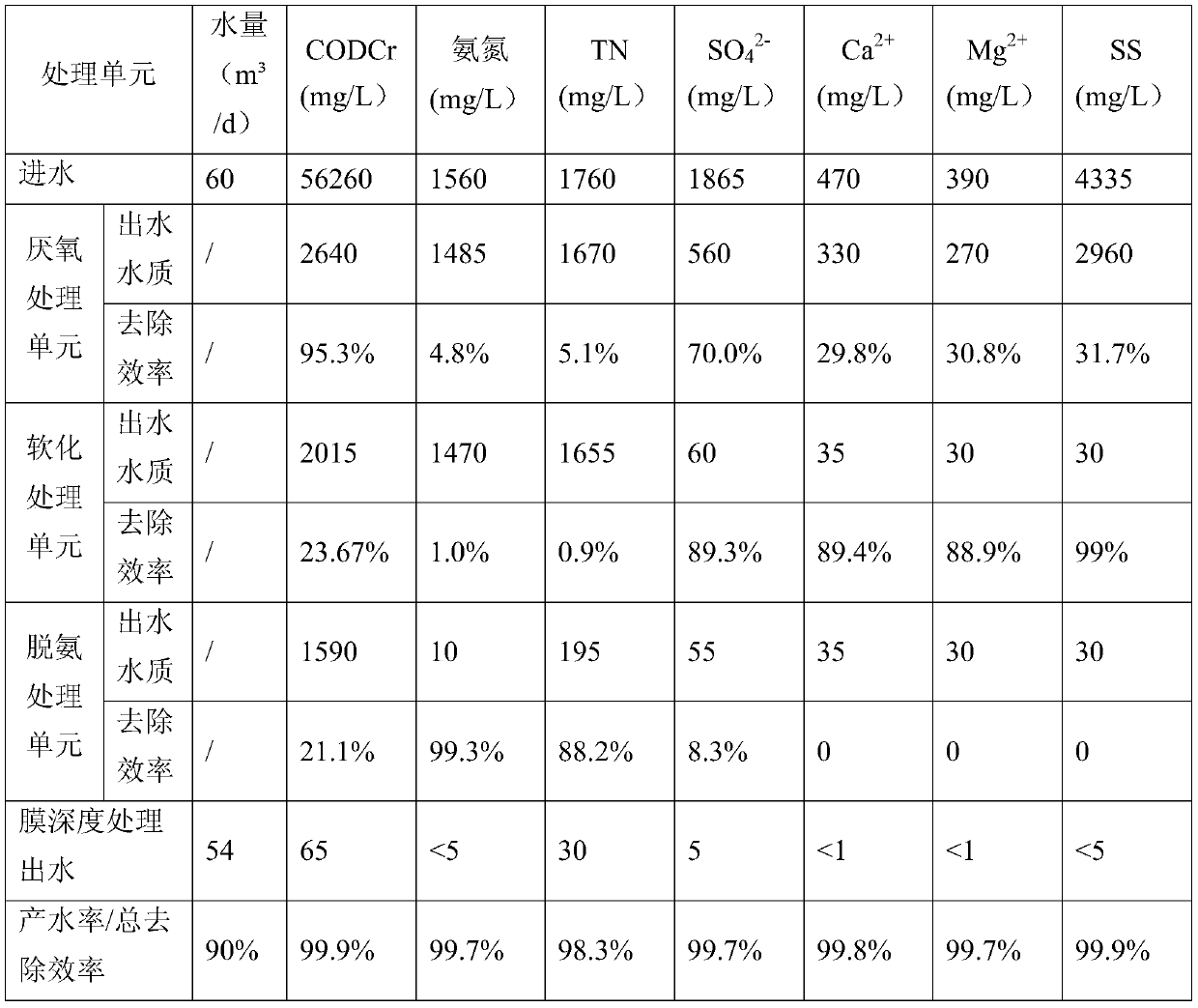

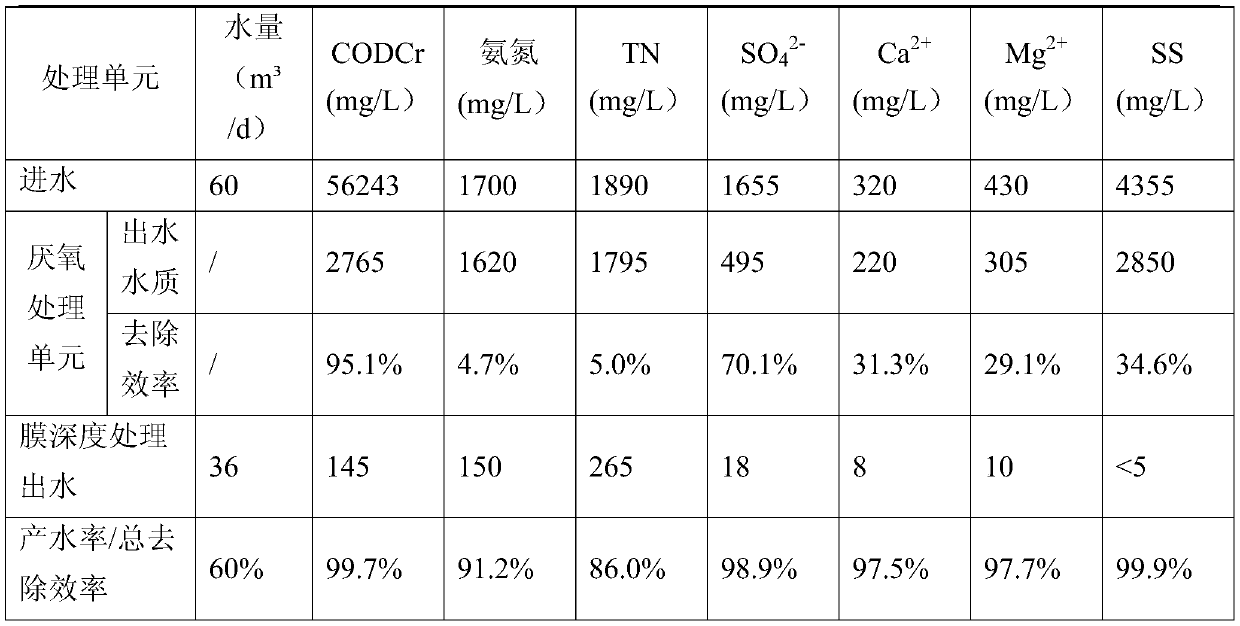

Method for treating leachate from waste incineration plants

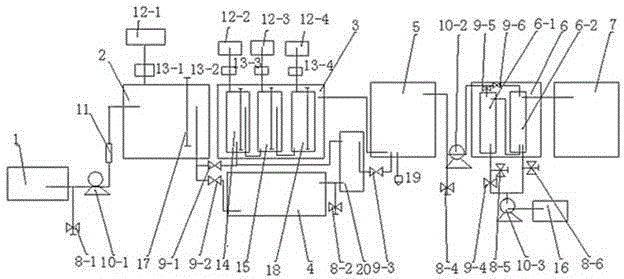

ActiveCN107840533AIncrease water production rateLow running costWater contaminantsWater softeningChemistryAnaerobic treatment

The invention discloses a method for treating leachate from waste incineration plants. The method comprises the following steps: (1) anaerobic treatment: carrying out anaerobic treatment on the leachate from the waste incineration plants by means of an upflow anaerobic sludge blanket (UASB) so as to obtain treated liquid I; (2) softening treatment: adding a softening agent into the treated liquidI, carrying out chemical softening treatment, and then filtering by using a tubular micro-filtration membrane (TMF) so as to obtain treated liquid II; (3) deamination treatment: pumping the treated liquid II into a negative pressure ammonia distillation tower, and introducing steam into the tower for carrying out deamination treatment so as to obtain treated liquid III; (4) membrane advanced treatment: cooling the treated liquid III to 35 DEG C or below, then adjusting the pH value to 6-7, and filtering by means of a disk tubular reverse osmosis (DTRO) membrane so as to obtain produced water.According to the method, the leachate from the waste incineration plants is treated by using a combined process of pretreatment, anaerobic treatment, TMF softening, deamination treatment and membraneadvanced treatment, so that ammonia nitrogen, total nitrogen and organic matters in the leachate can be effectively removed, and the produced water is enabled to meet requirement of up-to-standard discharge or to be recycled.

Owner:浙江博世华环保科技有限公司

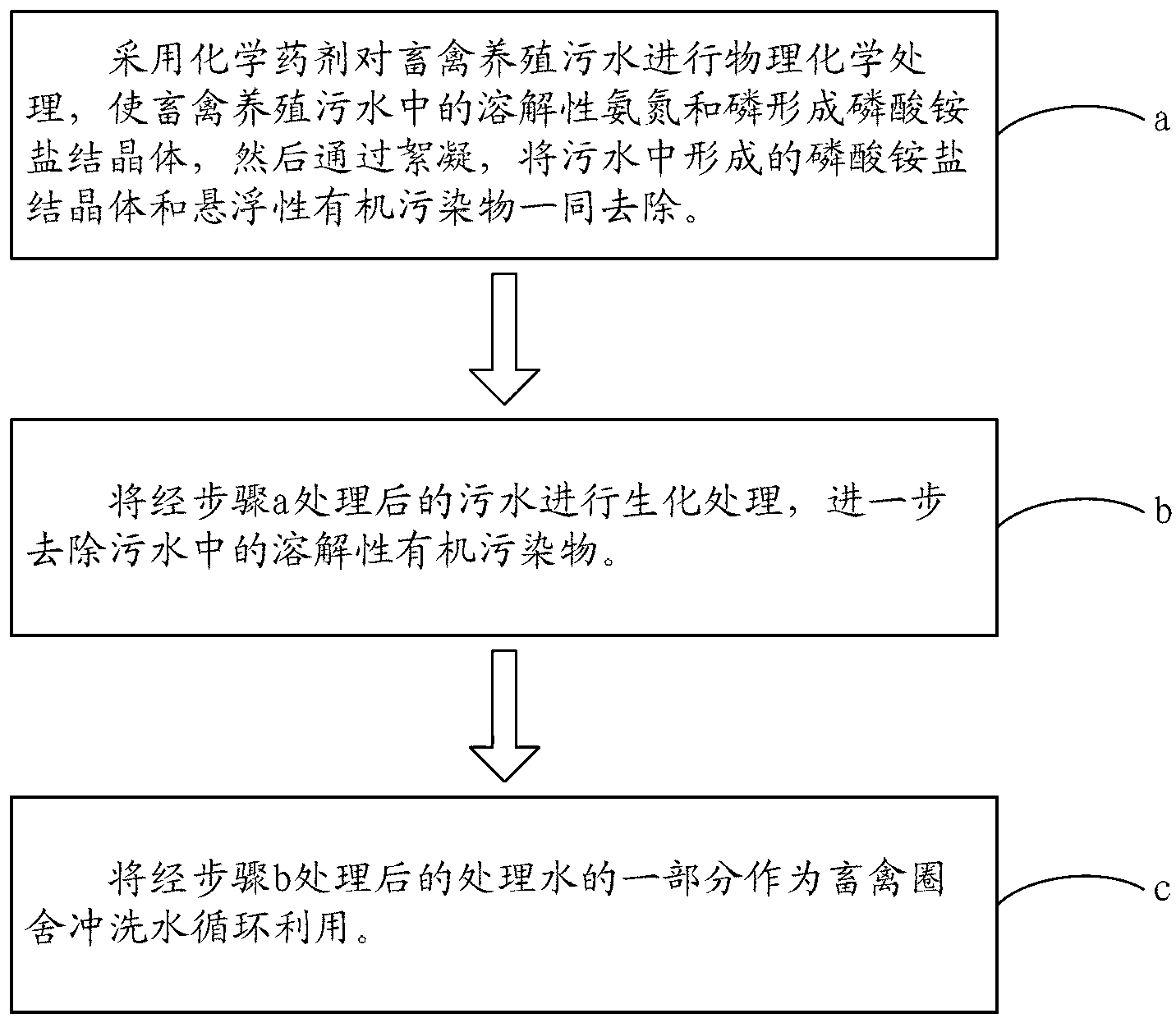

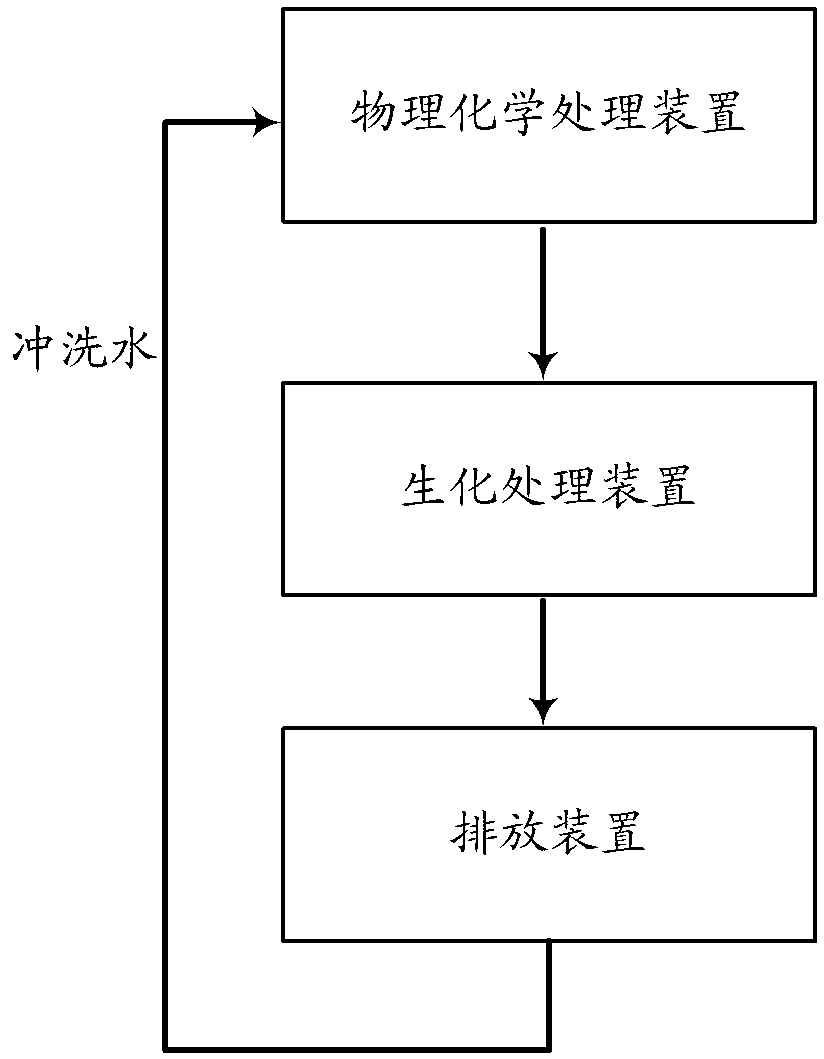

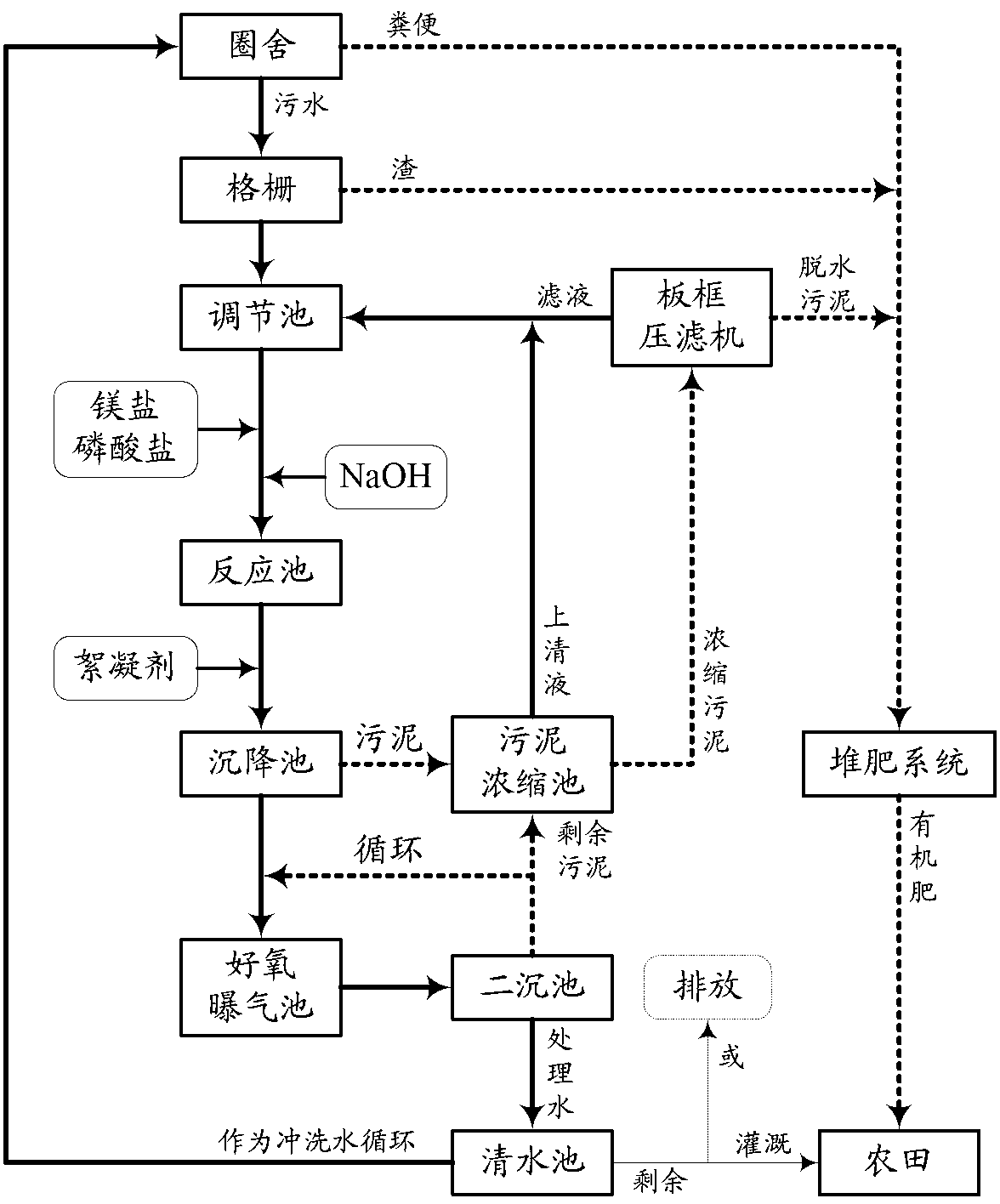

Large-scale livestock breeding sewage treatment method and equipment

InactiveCN103172217AEfficient use ofReduce pollutionSludge treatment by de-watering/drying/thickeningMultistage water/sewage treatmentPhosphoric acidBiology

The invention provides a large-scale livestock breeding sewage treatment method. The large-scale livestock breeding sewage treatment method comprises the following steps of: step a. carrying out physicochemical treatment on livestock breeding sewage by adopting a chemical agent, so that soluble ammonia nitrogen and phosphorus in the livestock breeding sewage form ammonium phosphate crystals, then removing the ammonium phosphate crystals formed in the sewage and suspended organic pollutants together through flocculation; step b. carrying out biochemical treatment on the sewage treated in the step a, and further removing soluble organic pollutants in the sewage; and step c. using a part of treating water treated in the step b as flushing water for colony houses of livestock, thus realizing the cyclic utilization of sewage. The invention also provides large-scale livestock breeding sewage treatment equipment. The large-scale livestock breeding sewage treatment equipment provided by the invention can be used for preventing pollution caused by livestock sewage breeding and realizing recycle processing and cyclic utilization of breeding sewage.

Owner:吉林市环境保护科学研究院

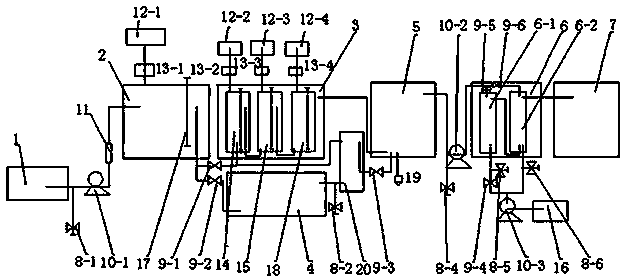

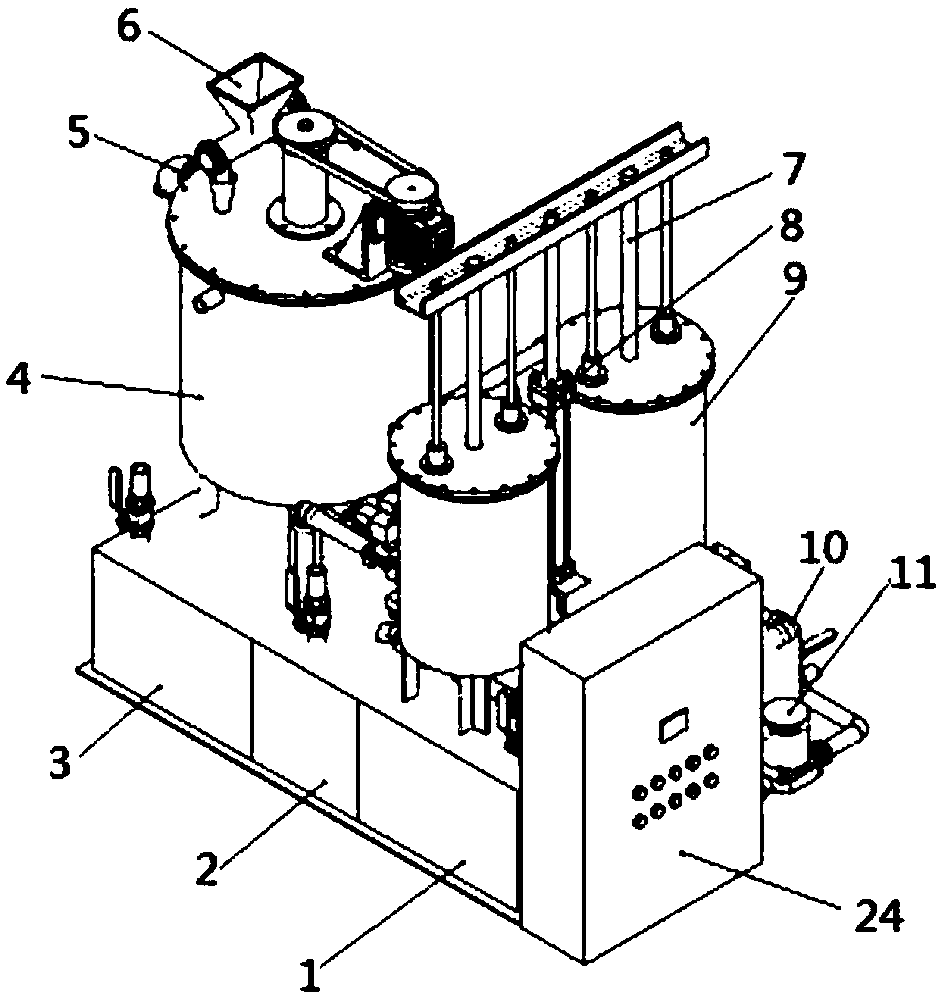

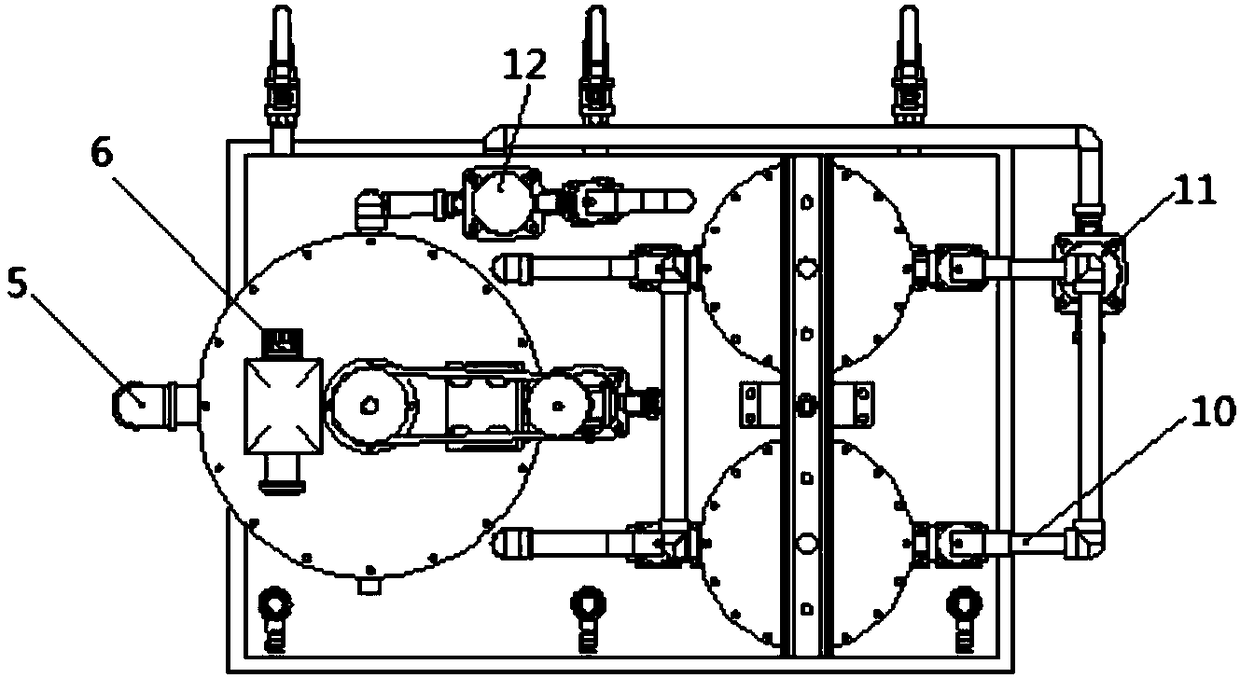

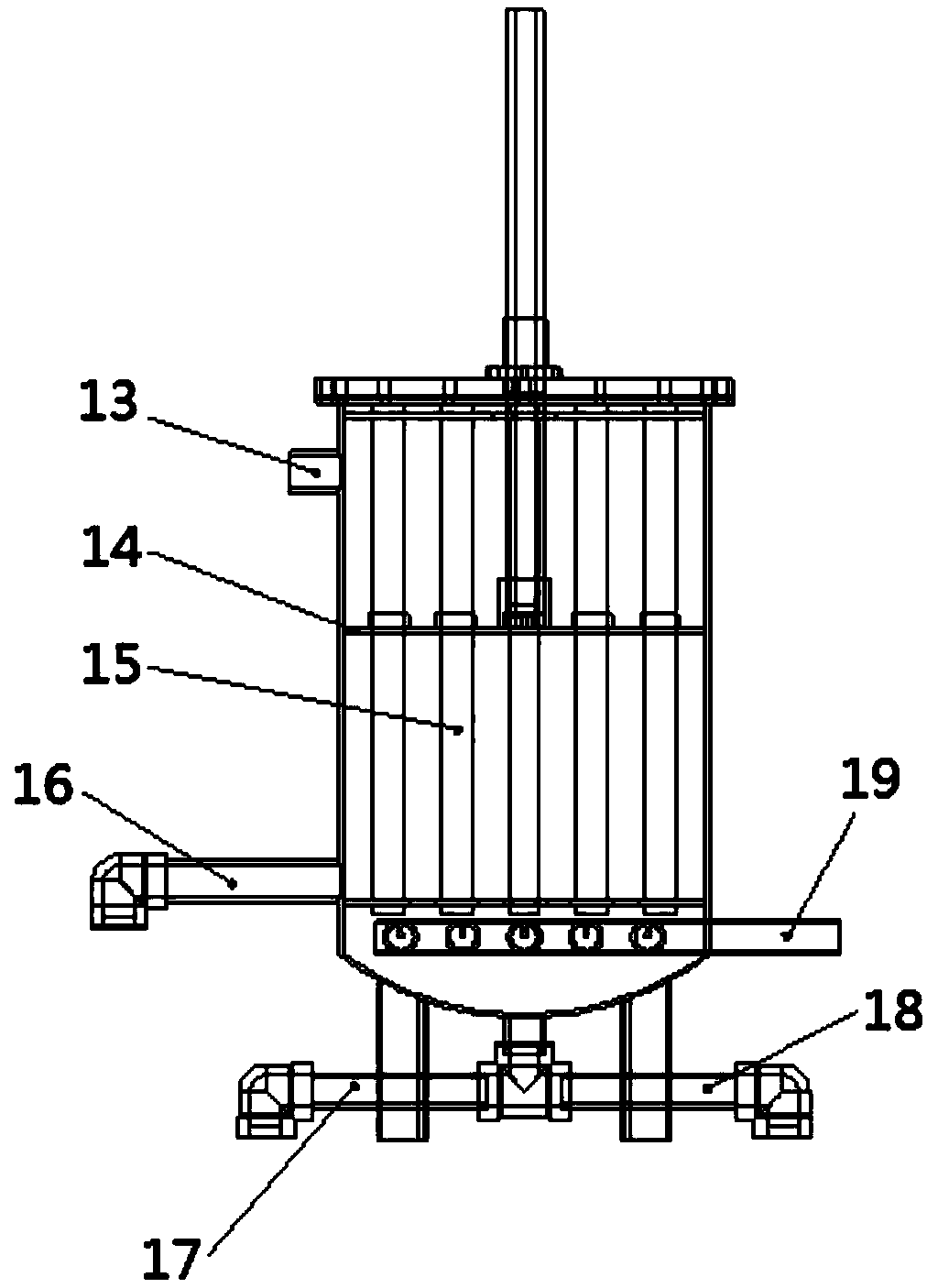

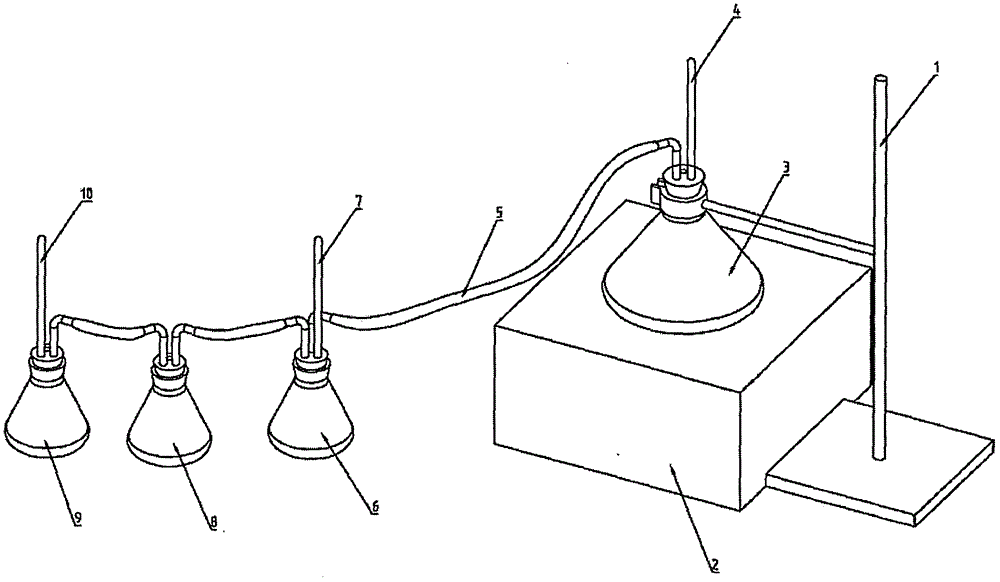

Recycling treating device for flowback pressure liquid in shale gas well fracturing operation

ActiveCN104261587AReduce contentAddressing water challengesWaste water treatment from quariesWater contaminantsThermodynamicsOxidation pond

The invention discloses a recycling treating device for flowback pressure liquid in shale gas well fracturing operation. The recycling treating device comprises a wastewater pool, a regulation pool, a composite coagulation reaction device, a settling pool, a solid-liquid separation device and a clean water pool which are sequentially connected to one another by virtue of a pipeline, wherein the composite coagulation reaction device consists of a rapid stirring pool, a slow stirring pool and an oxidation pool which are sequentially connected to one another by virtue of a pipeline, and the upper ends of the regulation pool, the rapid stirring pool, the slow stirring pool and the oxidation pool are all connected with a corresponding drug adding device by virtue of a constant-flow pump; the solid-liquid separation device consists of a crude filter and double-filtering equipment which are sequentially connected to one another by virtue of a pipeline, the crude filter is connected with a sludge pump by virtue of a fourth valve, the double-filtering equipment is also connected with the sludge pump, and the sludge pump is connected with a sludge dewatering machine. With the adoption of the recycling treating device, as the bottoms of the regulation pool, the rapid stirring pool, the slow stirring pool and the oxidation pool are all provided with stirrers, the problem of water resource challenge brought by shale gas development can be effectively solved, resource cyclic utilization is reached, and zero emission of flowback liquid caused by shale gas fracturing can be truly realized.

Owner:HAITIAN WATER GRP CO LTD

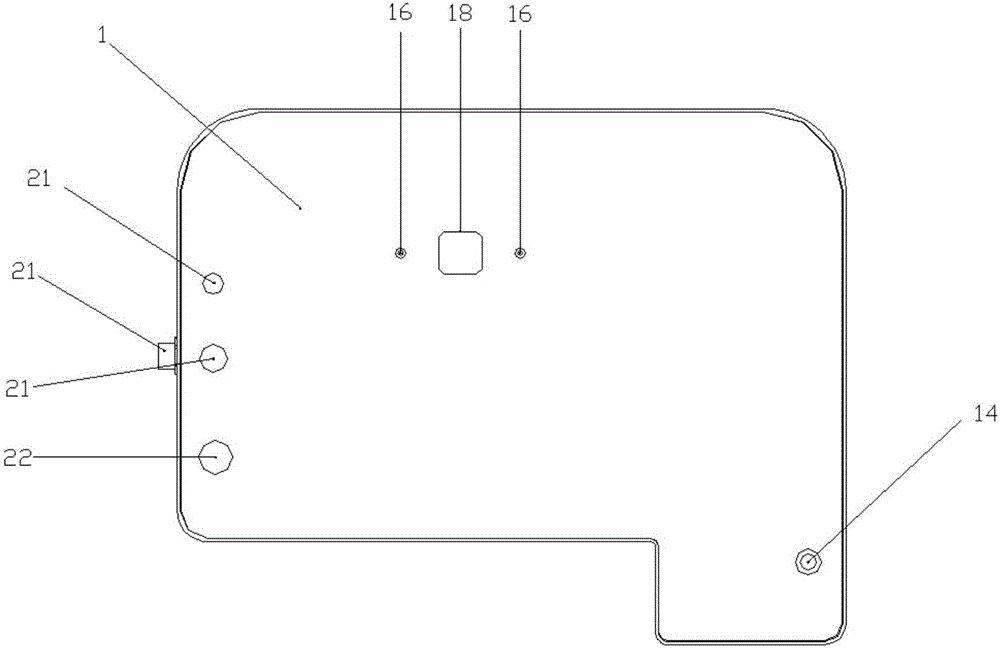

Intelligent oil-water separator

ActiveCN106673126ASimple structureSmall space volumeFatty/oily/floating substances removal devicesLiquid separationOil waterEngineering

The invention relates to an intelligent oil-water separator, in particular to an intelligent oil-water separator for foodservice industry. The intelligent oil-water separator comprises a main box body, wherein a liquid inlet, a drain outlet and an oil outlet are formed in the main box body; an oil-water separating cavity is formed in the main box body, and the liquid inlet is communicated with the inside of the oil-water separating cavity; an oil-separating funnel is arranged in the oil-water separating cavity, and the oil-separating funnel is located at the upper end of the oil-water separating cavity; the upper end of the oil-separating funnel is an oil inlet of the funnel and the lower end is an oil outlet of the funnel; the oil inlet of the funnel is communicated with the inside of the oil-water separating cavity, and the oil outlet of the funnel is communicated with the oil outlet through an oil outlet pipe; and a driving device is also arranged on the oil-water separator to drive the oil-separating funnel to move up and down. The oil-water separating device provided by the invention is simple in structure, small in spatial volume and low in cost, and can be directly arranged in a kitchen of a restaurant or a dinning hall.

Owner:成都蔚蓝星生物科技有限公司

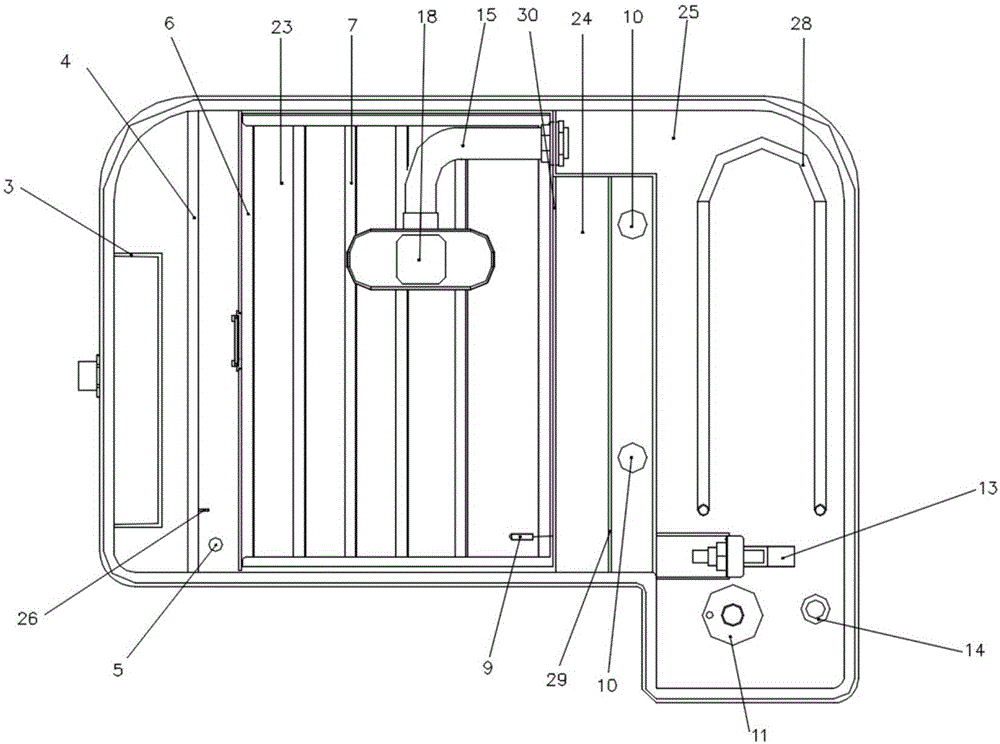

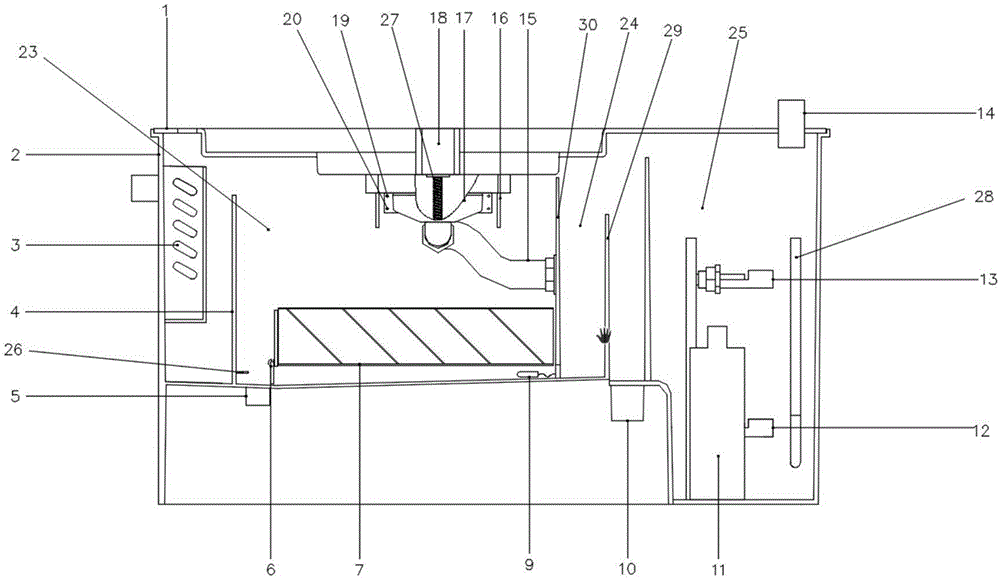

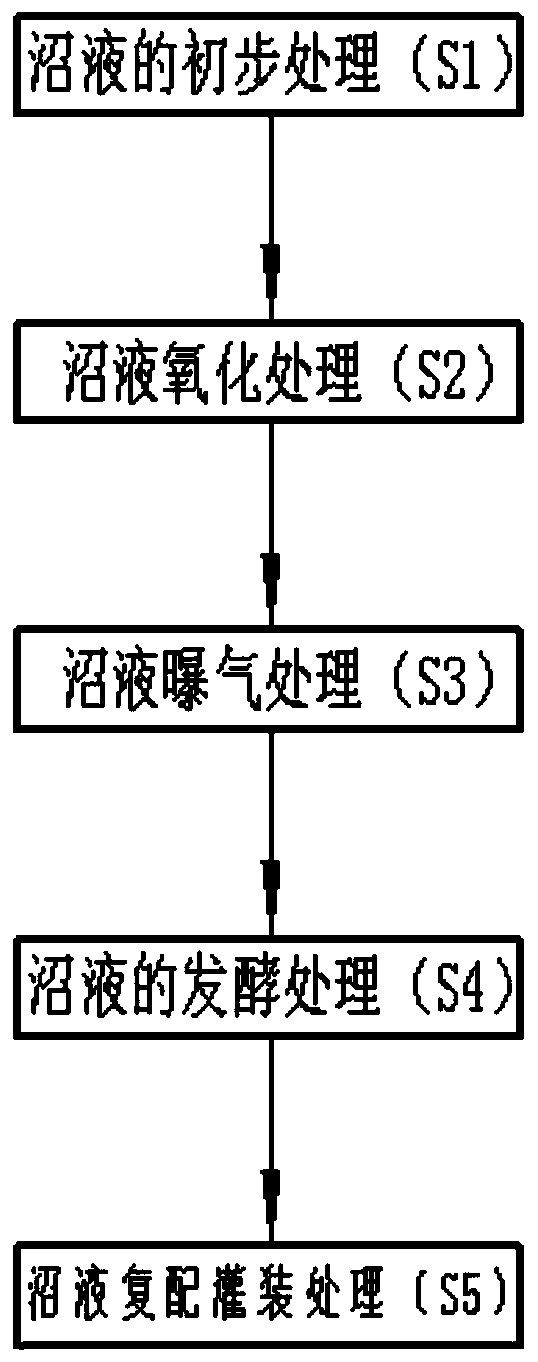

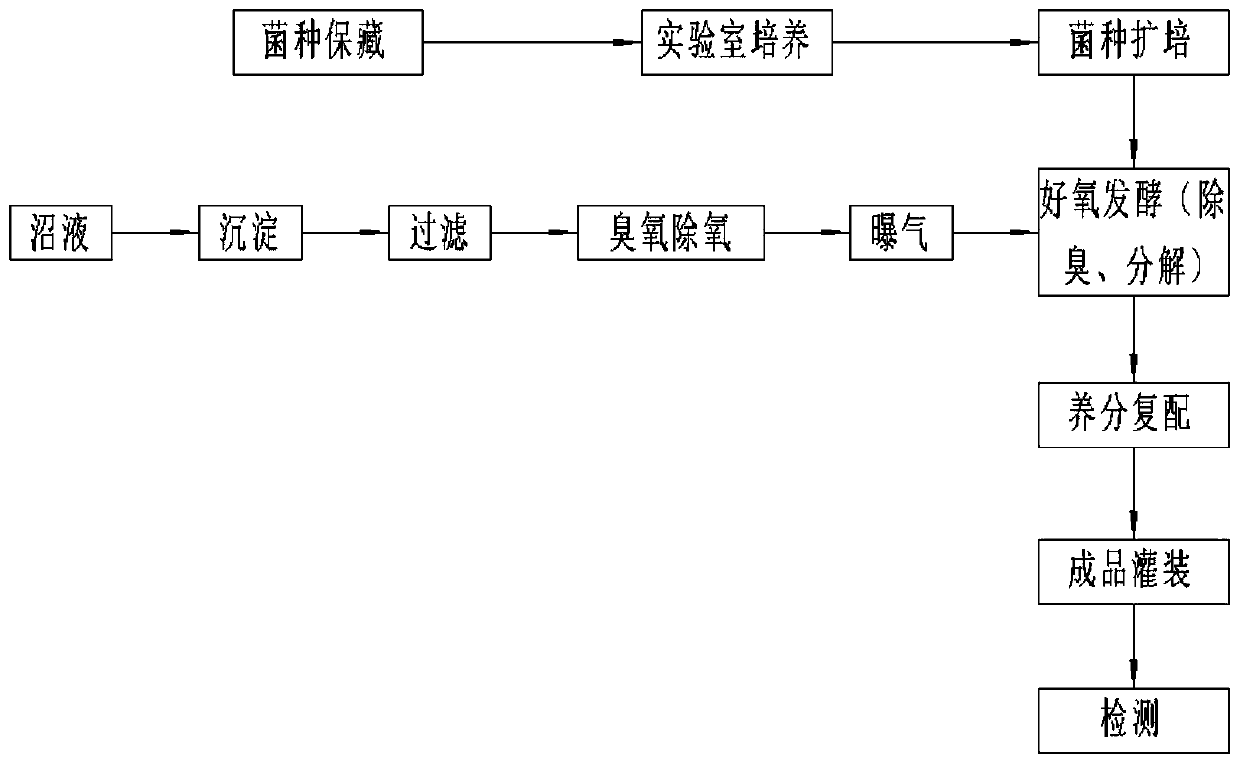

Preparation method for producing efficient water flush fertilizer by biogas slurry

InactiveCN110803947ASupplementary Nutrient ContentEasy to useBio-organic fraction processingMicroorganism based treatmentSoil scienceSlurry

The invention relates to a preparation method for producing an efficient water flush fertilizer by biogas slurry. An ozone deodorization technology and a biological aerobic fermentation technology areutilized, and peculiar smell factors and reducing substances in the biogas slurry are removed; meanwhile, through subsequent compounding and addition of macroelements, the problem of low nutrient content in the biogas slurry is solved. The prepared water flush fertilizer is small in dosage, high in fertilizer efficiency and capable of supplementing organic matters in soil; meanwhile, the biogas slurry contains many bacteriostatic factors and active substances, plant diseases can be effectively prevented and reduced, use of chemical fertilizers and pesticides is reduced, the crop yield is increased, the product quality is improved, the biogas slurry can be widely applied to agricultural planting, and resource recycling is achieved.

Owner:苏州腾康环保科技有限公司

Electronic control grease separation system

PendingCN108264960ASimple stable distinctionImprove qualityFatty-oils/fats refiningMagnetic separationOil and greaseResource recovery

The invention discloses an electronic control grease separation system, which consists of a stirring tank, an automatic powder feeding device and magnetic separation tanks. The stirring tank is provided with a liquid inlet and a magnetic powder inlet, and the magnetic powder inlet is communicated with the automatic powder feeding device, and the upper end and lower end of the stirring tank are communicated with the magnetic separation tanks through a conveying pipe. Compared with the prior art, the electronic control grease separation system provided by the invention has a simple structure, and integrates the mechanical structure, electric control and magnetic bar matrix. The adsorption of magnetic powder is utilized for simple and stable distinguishing of grease and moisture, the oil gathering efficiency is high, and the quality of discharged water is good. The oil-water separator has low manufacturing cost, and can greatly improve work efficiency. Through timely treatment of hogwashoil, the deterioration possibility of hogwash oil can be reduced, and grease in hogwash can be turned into treasure, thereby achieving resource recycling, and also reducing environmental pollution. Atthe same time, emission of waste grease can be reduced from the source.

Owner:深海华科(成都)环保科技有限公司

Semi-transparent paper preparation method

InactiveCN108978298ASave resourcesImprove product qualitySpecial paperPaper recyclingPapermakingSemi transparent

The invention relates to the technical field of papermaking, and provides a semi-transparent paper preparation method, solving the technical problem of how to use waste paper to replace a part of pulpto prepare semi-transparent paper. The semi-transparent paper preparation method includes the steps of (1), preparing pulp from waste paper; (2), removing sand and dregs; (3), preparing pulp from wood-pulp boards and deinked pulp; (4), blending the pulp and conditioning; (5), manufacturing paper with the pulp and calendering and shaping.

Owner:福建省晋江优兰发纸业有限公司

A method for removing fluoride and phosphorus from psry molecular sieve production wastewater

ActiveCN104556460BAvoid the influence of fluorine and phosphorus removal processSufficient supplyWater contaminantsMultistage water/sewage treatmentMolecular sieveWastewater

The invention relates to a defluorination and dephosphorization method of PSRY molecular sieve production wastewater. The method comprises the following steps: (1) solid waste residues generated during treatment process of PSRY molecular sieve production wastewater and other molecular sieve production wastewater are mixed, and aluminum in the solid waste residues is dissolved in the form of Al<3+> in the wastewater, wherein pH value of the mixed system during the dissolution process is less than 4.5; (2) pH value of the mixed system obtained from the step (1) is adjusted to more than 6 to make Al<3+> reacts with F<-> and PO4<3-> so as to fully precipitate F<-> and PO4<3->; and (3) a coagulant aid is added into the mixed system obtained from the step (2), and solid-liquid separation is carried out on the mixed system which has undergone coagulantion enhancement, wherein dosage and dissolution conditions of the solid waste residues in the step (1) enable Al<3+> in the step (2) to fully precipitate F<-> and PO4<3->. By the method, fluorine and phosphor in the PSRY molecular sieve production wastewater can be effectively removed.

Owner:CHINA PETROLEUM & CHEM CORP +1

High-quality pavement petroleum asphalt material and preparation method thereof

ActiveCN101629021BOptimize chemical compositionReasonable matchBuilding insulationsPavement engineeringRoad engineering

The invention discloses a high-quality pavement petroleum asphalt material and a preparation method thereof, belonging to the pavement engineering material technical field. The petroleum asphalt material is prepared from the raw materials according to the parts by weight: 80-95 parts of main asphalt, 5-20 parts of formulated asphalt, 0.01-2 parts of macromolecular crosslinking agent and 0.001-0.25 part of heat stabilizer. The invention adopts chemical crosslinking, heat stabilizer and the combination of cutting and milling to promote the matching of the four components of asphalt to be further optimized and develop in the direction of forming stable colloid structure, improving the pavement performance of the formulated asphalt material and increase the stability of the formulated asphaltproduct. The invention makes full use of the vacuum residue of residual oil and heavy crude which are treated through vacuum deep extraction and increases the use value so as to reach the effect of resource recycling and environmental protection.

Owner:XIAN ZHONGLI ASPHALT CO LTD

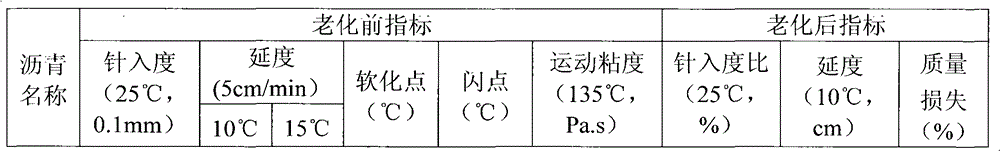

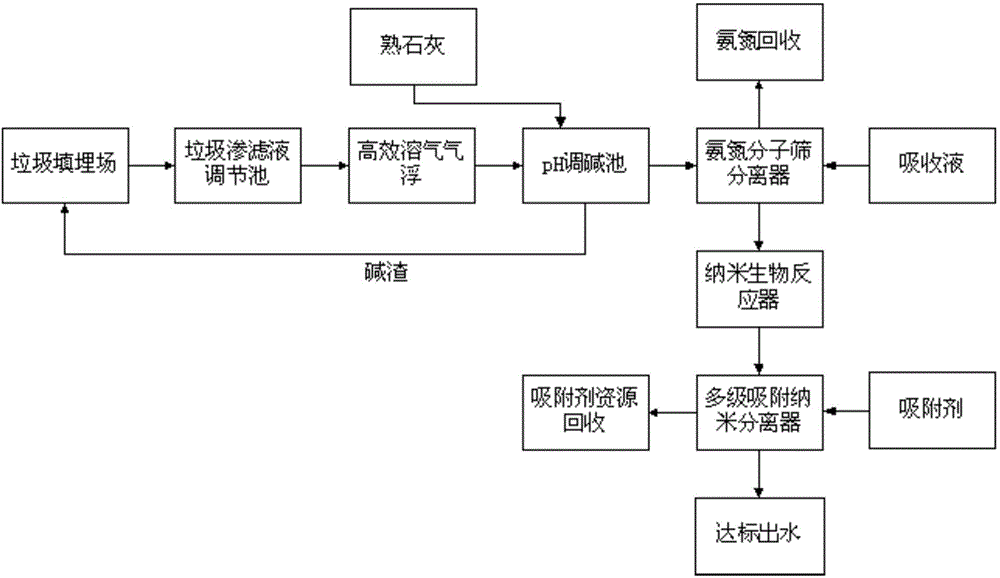

A treatment method for landfill leachate

ActiveCN103880245BAchieve emission standardsRealize recycling of resourcesMultistage water/sewage treatmentHazardous substanceChemistry

The invention relates to a method for processing landfill leachate. The method comprises the following steps: carrying out efficient dissolved air flotation after collecting landfill leachate; adding slaked lime to the landfill leachate after air flotation treatment to carry out alkali adjustment; carrying out ammonia-nitrogen molecular sieve separation on the landfill leachate after alkali adjustment, and adding an acid to form an ammonium salt to recover ammonia nitrogen; carrying out biochemical treatment on the landfill leachate after ammonia nitrogen recovery; removing an organic matter, nitrogen and phosphorus in the landfill leachate; discharging up to the standard after multi-stage reflux adsorption on the landfill leachate after biochemical treatment. The landfill leachate is processed by using the technique disclosed by the invention, toxic and harmful substances such as high-strength ammonia nitrogen, non-biodegradable organic pollutants, heavy metal and the like in the landfill leachate are thoroughly removed, recycling of ammonia nitrogen resources is achieved, and the landfill leachate is discharged up to the standard.

Owner:北京博力扬环保科技有限公司

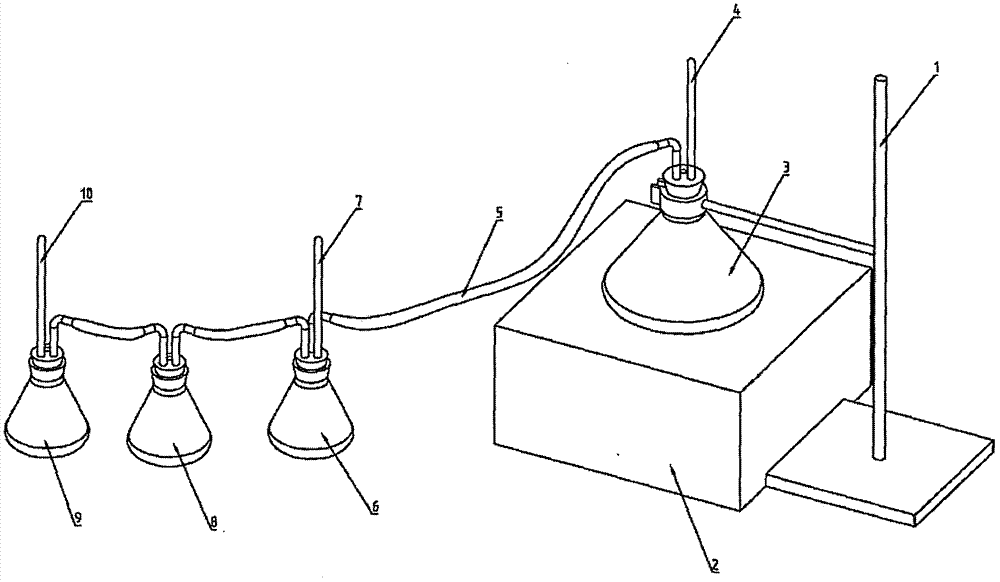

Nano-copper conductive slurry preparation method by utilizing printed circuit board alkaline etching waste liquid

ActiveCN102354571BRealistic emission reductionNo pollution in the processWater contaminantsMultistage water/sewage treatmentActive agentTurpentine

The invention relates to a method for utilizing alkaline etching waste liquid in a printed circuit board to prepare nano-copper which is made into nano-copper conductive slurry. The method comprises the following steps: filtering alkaline etching waste liquid, adding a nonionic surfactant of 0.43%-4.24% of alkaline etching waste liquid by weight and an aqueous antifoaming agent of 0.08%-1.61% of the alkaline etching waste liquid by weight, preparing a reaction solution A; preparing a reducing agent solution B which comprises a reducing agent of 1.70%-8.49% of the alkaline etching waste liquidby weight, a highly basic substance of 6.80%-10.20 % of the alkaline etching waste liquid by weight, and organic phase turpentine which is used for a phase-transfer agent and has a volume ratio of 1:1-1:2 to the alkaline etching waste liquid; carrying out heating and stirring, and adding the reaction solution A in to the reducing agent solution B drop by drop. The method has the characteristics of easy operation and small energy consumption, prepared nano-copper powder has good antioxidation performance, by utilizing the etching waste liquid, conductive slurry of a high added value is prepared, a high economic benefit is created, emission reduction and no pollution of waste water are realized, and resource recycling is achieved.

Owner:GUANGDONG CHENGDE ELECTRONICS TECH CO LTD +1

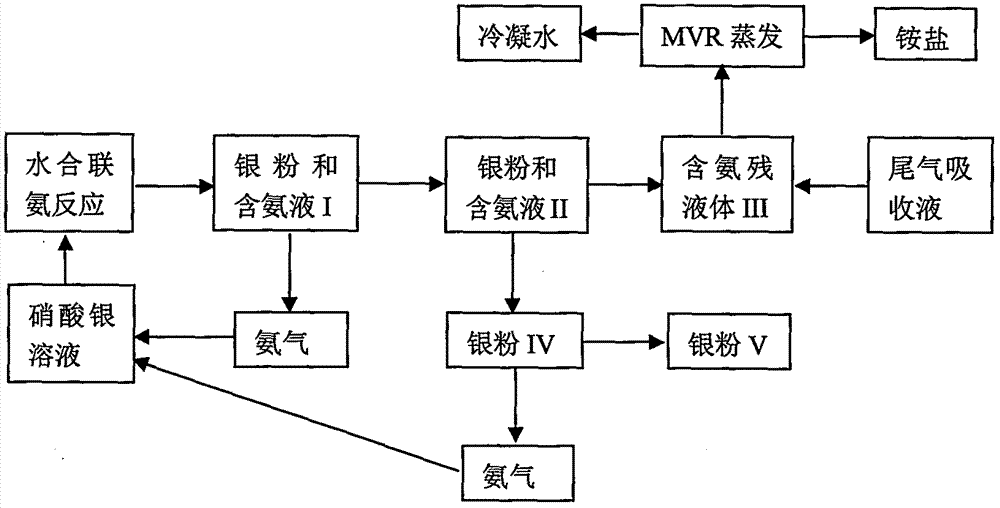

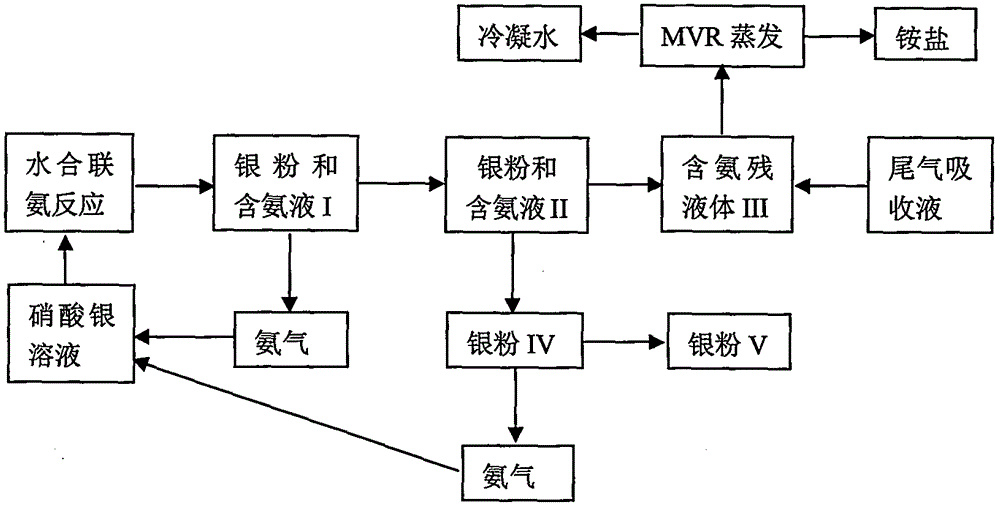

A kind of method that hydrazine hydrate reacts to prepare silver powder and ammonia recycles and utilizes

The invention relates to a method for recycling silver powder ammonia prepared by hydrazine hydrate reaction. The method comprises the following steps of: obtaining a mixed solution I of silver powder and ammonia-containing mother liquor after hydrazine hydrate reaction, and heating the mixed solution I to obtain mixed solution II of ammonia gas, silver powder and the ammonia-containing mother liquor; absorbing ammonia gas for recycling the mixed solution I by a silver nitrate solution, using the silver nitrate solution which absorbs the ammonia gas in next hydrazine hydrate circular reaction, and separating silver powder from ammonia-containing mother liquor for the mixed solution II to obtain silver powder IV and ammonia-containing residual liquor III; and carrying out steam stripping on silver powder IV to remove residual ammonia on the surface of silver powder to obtain sliver powder V, absorbing stripped ammonia gas by a silver nitrate solution, and using the silver nitrate solution which absorbs the stripped ammonia gas in next hydrazine hydrate circular reaction. According to the method, an environmental protection and control technology is combined with a chemical process technology, so that cyclic utilization of ammonia is directly realized, and reclamation, reduction and hazard-free treatment of ammonia in wastewater are achieved, and therefore, the environment is protected, and resources are saved.

Owner:WENZHOU HONGFENG ELECTRICAL ALLOY

A set of concrete production environmental protection equipment and concrete production process

ActiveCN105965699BSave on moving costsSave money on burningMixing operation control apparatusPretreatment controlEnvironmental resistanceControl signal

The invention discloses a set of concrete production environmental protection equipment and a concrete production process. The set of concrete production environmental protection equipment comprises a DCS central control system and a remote monitoring system, wherein the DCS central control system controls an aggregate production line, a cement and mineral powder production line, a cement kiln sludge processing equipment, raw material processing domestic garbage equipment and concrete mixing plant equipment to produce concrete through a control signal; and the remote monitoring system is connected with and monitors the aggregate production line, the cement and mineral powder production line, the cement kiln sludge processing equipment, the raw material processing domestic garbage equipment and the concrete mixing plant equipment through optical fibers. With adoption of the set of concrete production environmental protection equipment, the concrete production process can be carried out. The set of concrete production environmental protection equipment has the advantages that no dusts, not leakage and no secondary pollution and transportation are generated due to full-automation sealing production, the energy is saved, the environment is protected, environmental pollution of atmosphere and soils is reduced, toxic and harmful substances are prevented from damaging human health through processing, and the economic benefit in virtuous circle and the value-added effect of the building material industry are reached.

Owner:陈更

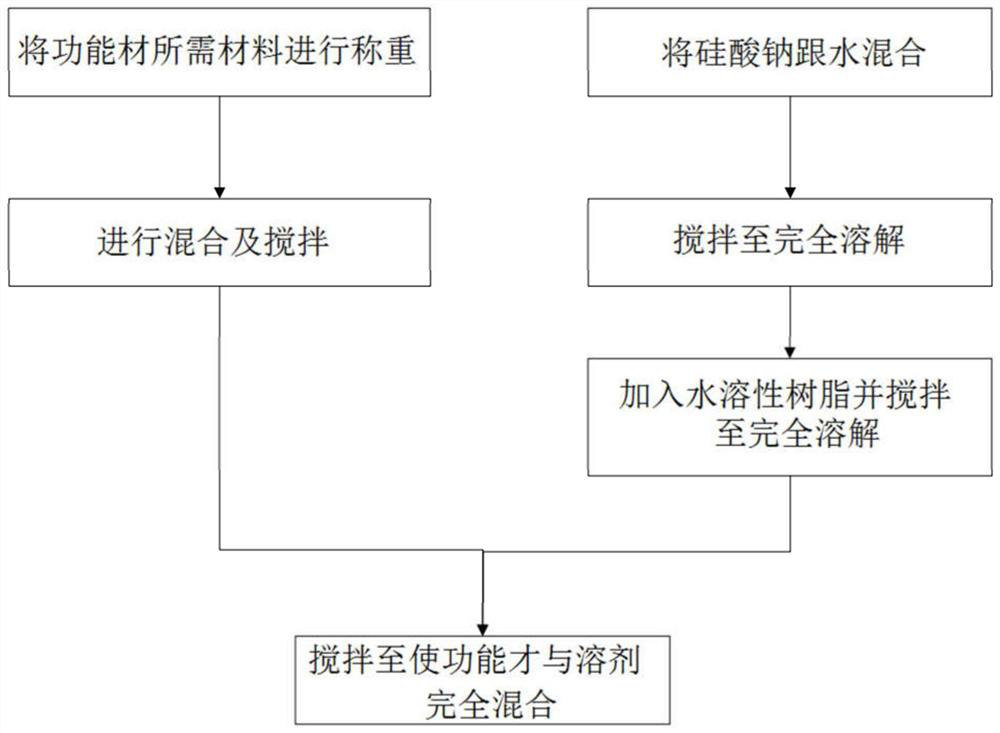

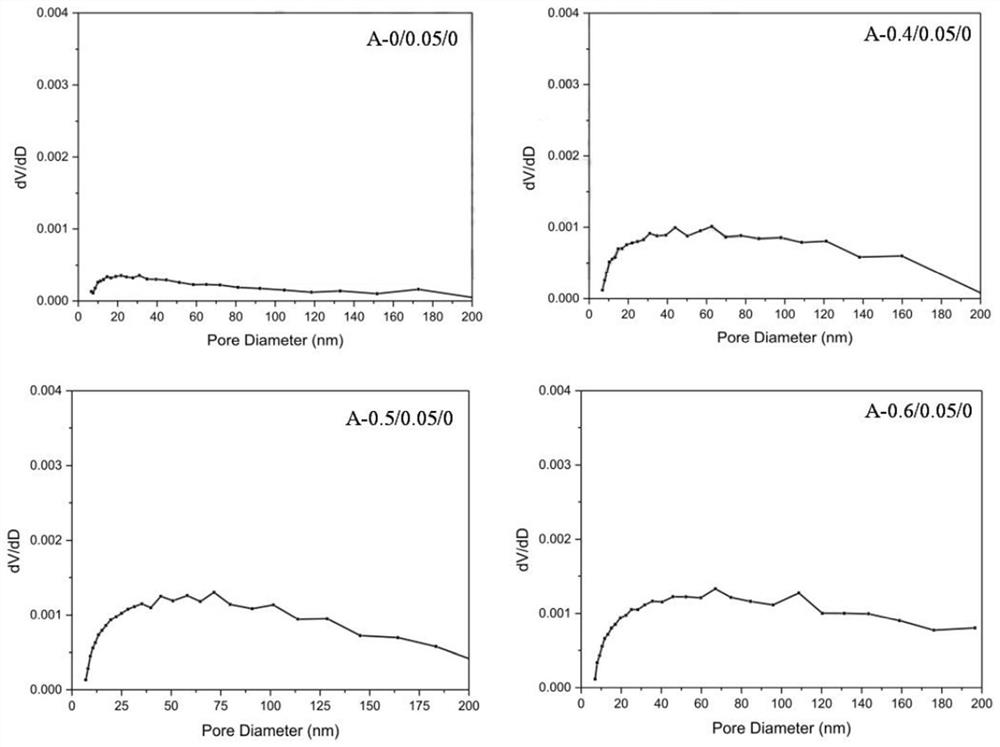

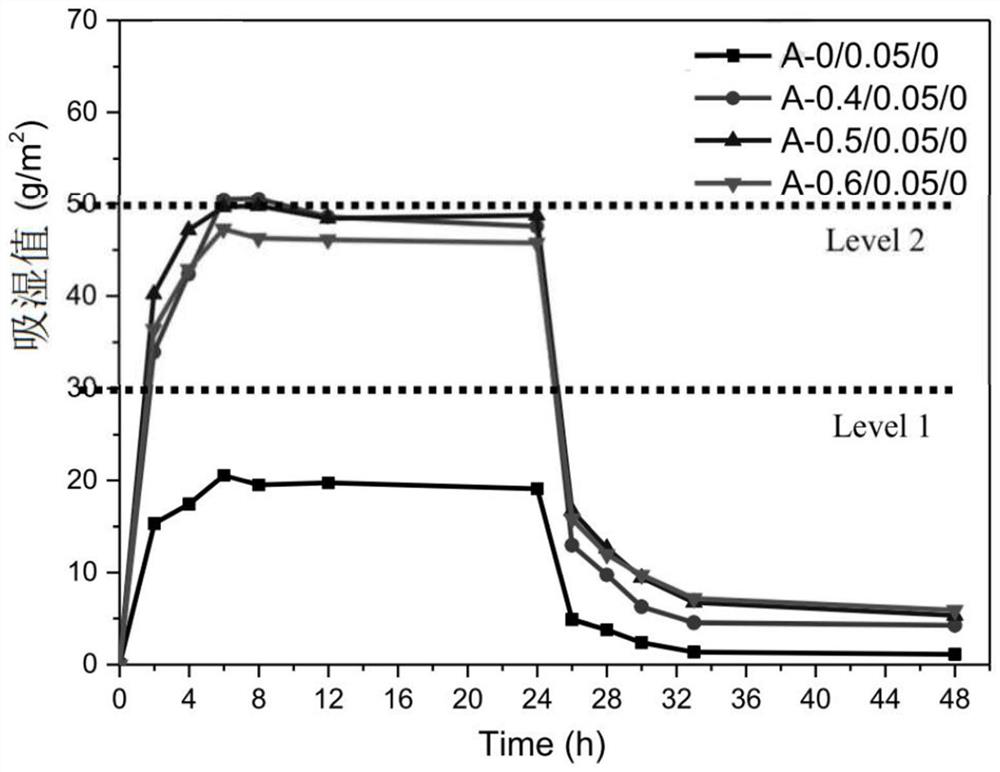

Moisture-conditioning paint and method for producing the same

ActiveCN111826034BSolve the problem of burialValid conversionCoatingsMoisture absorptionEnvironmental engineering

Owner:许人英

Method for recycling silver powder ammonia prepared by hydrazine hydrate reaction

The invention relates to a method for recycling silver powder ammonia prepared by hydrazine hydrate reaction. The method comprises the following steps of: obtaining a mixed solution I of silver powder and ammonia-containing mother liquor after hydrazine hydrate reaction, and heating the mixed solution I to obtain mixed solution II of ammonia gas, silver powder and the ammonia-containing mother liquor; absorbing ammonia gas for recycling the mixed solution I by a silver nitrate solution, using the silver nitrate solution which absorbs the ammonia gas in next hydrazine hydrate circular reaction, and separating silver powder from ammonia-containing mother liquor for the mixed solution II to obtain silver powder IV and ammonia-containing residual liquor III; and carrying out steam stripping on silver powder IV to remove residual ammonia on the surface of silver powder to obtain sliver powder V, absorbing stripped ammonia gas by a silver nitrate solution, and using the silver nitrate solution which absorbs the stripped ammonia gas in next hydrazine hydrate circular reaction. According to the method, an environmental protection and control technology is combined with a chemical process technology, so that cyclic utilization of ammonia is directly realized, and reclamation, reduction and hazard-free treatment of ammonia in wastewater are achieved, and therefore, the environment is protected, and resources are saved.

Owner:WENZHOU HONGFENG ELECTRICAL ALLOY

A treatment method for leachate of a waste incineration plant

ActiveCN107840533BEfficient removalIncrease water production rateWater contaminantsWater softeningAmmoniacal nitrogenDistillation

The invention discloses a method for treating leachate from waste incineration plants. The method comprises the following steps: (1) anaerobic treatment: carrying out anaerobic treatment on the leachate from the waste incineration plants by means of an upflow anaerobic sludge blanket (UASB) so as to obtain treated liquid I; (2) softening treatment: adding a softening agent into the treated liquidI, carrying out chemical softening treatment, and then filtering by using a tubular micro-filtration membrane (TMF) so as to obtain treated liquid II; (3) deamination treatment: pumping the treated liquid II into a negative pressure ammonia distillation tower, and introducing steam into the tower for carrying out deamination treatment so as to obtain treated liquid III; (4) membrane advanced treatment: cooling the treated liquid III to 35 DEG C or below, then adjusting the pH value to 6-7, and filtering by means of a disk tubular reverse osmosis (DTRO) membrane so as to obtain produced water.According to the method, the leachate from the waste incineration plants is treated by using a combined process of pretreatment, anaerobic treatment, TMF softening, deamination treatment and membraneadvanced treatment, so that ammonia nitrogen, total nitrogen and organic matters in the leachate can be effectively removed, and the produced water is enabled to meet requirement of up-to-standard discharge or to be recycled.

Owner:浙江博世华环保科技有限公司

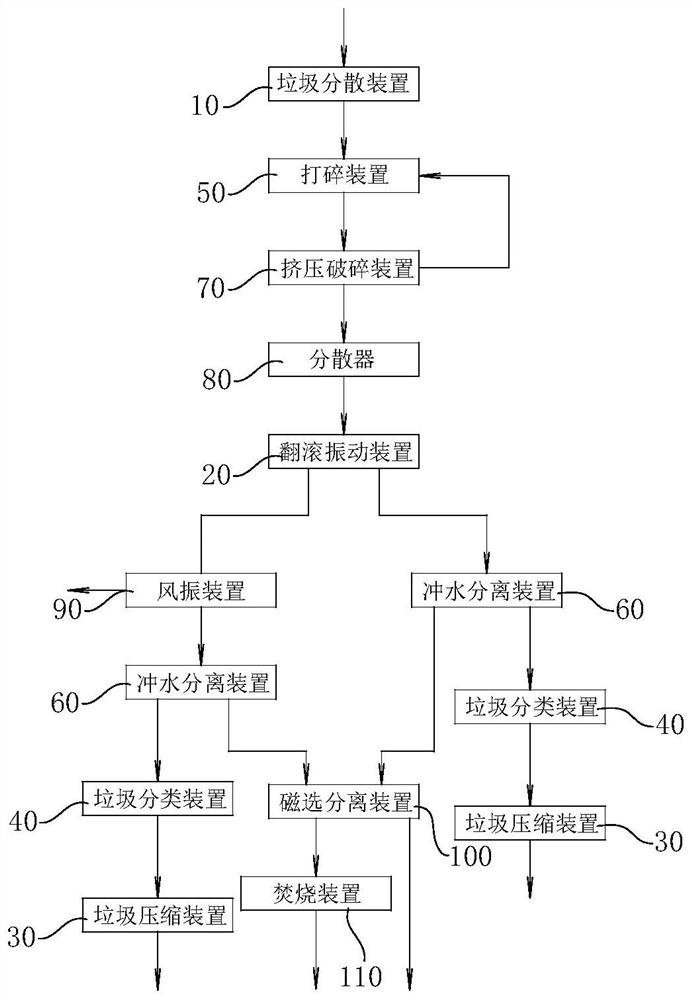

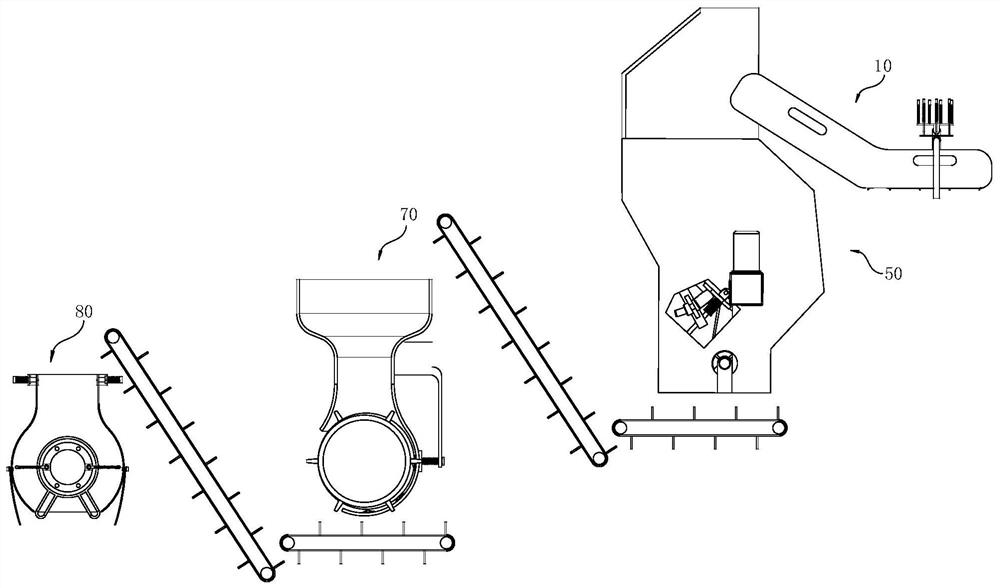

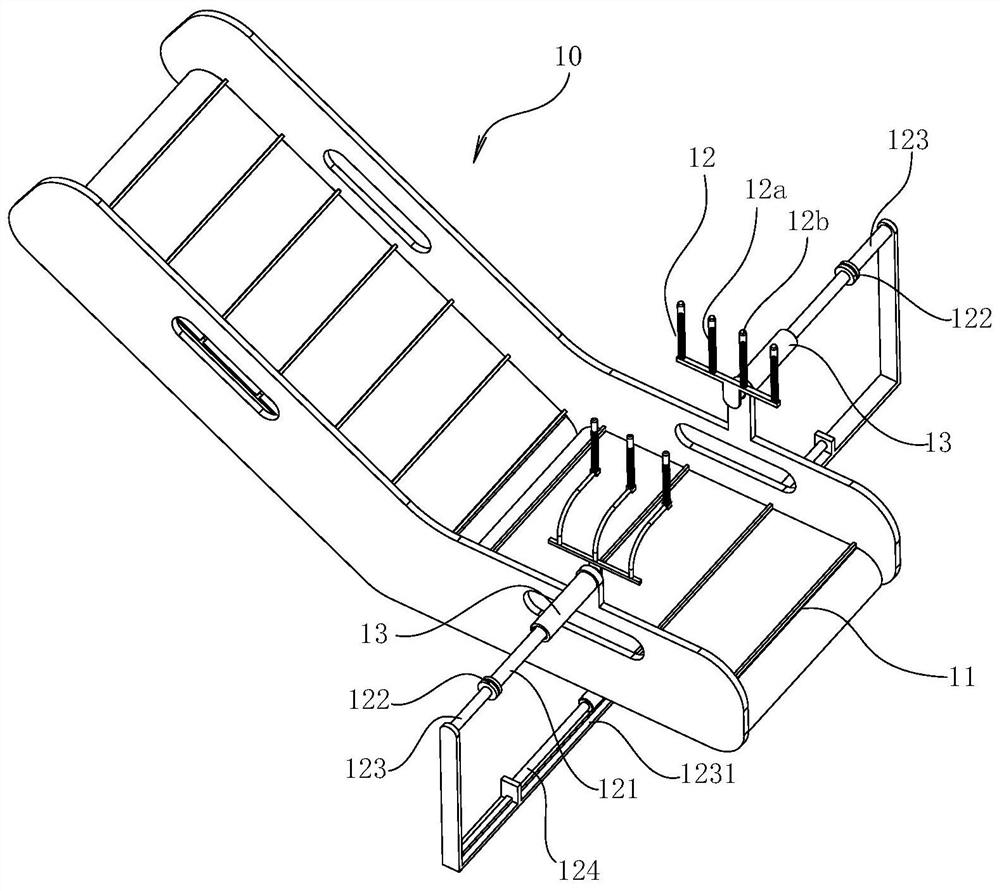

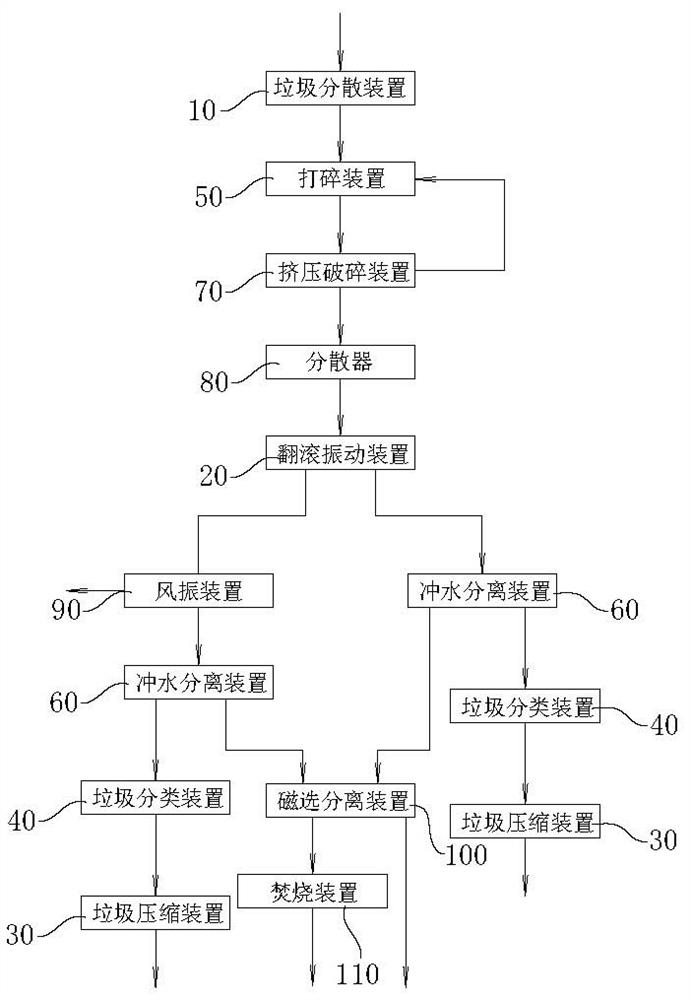

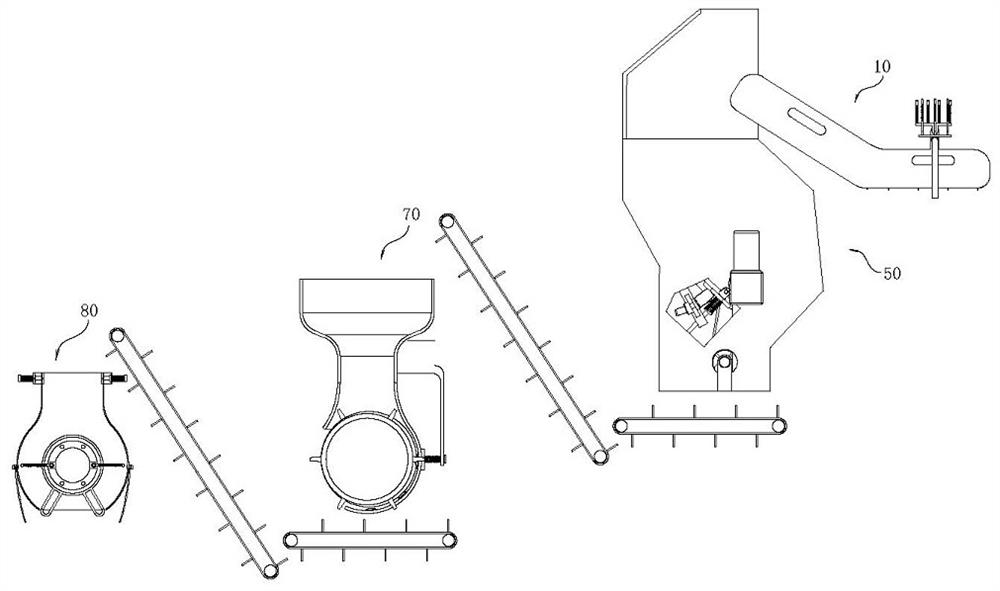

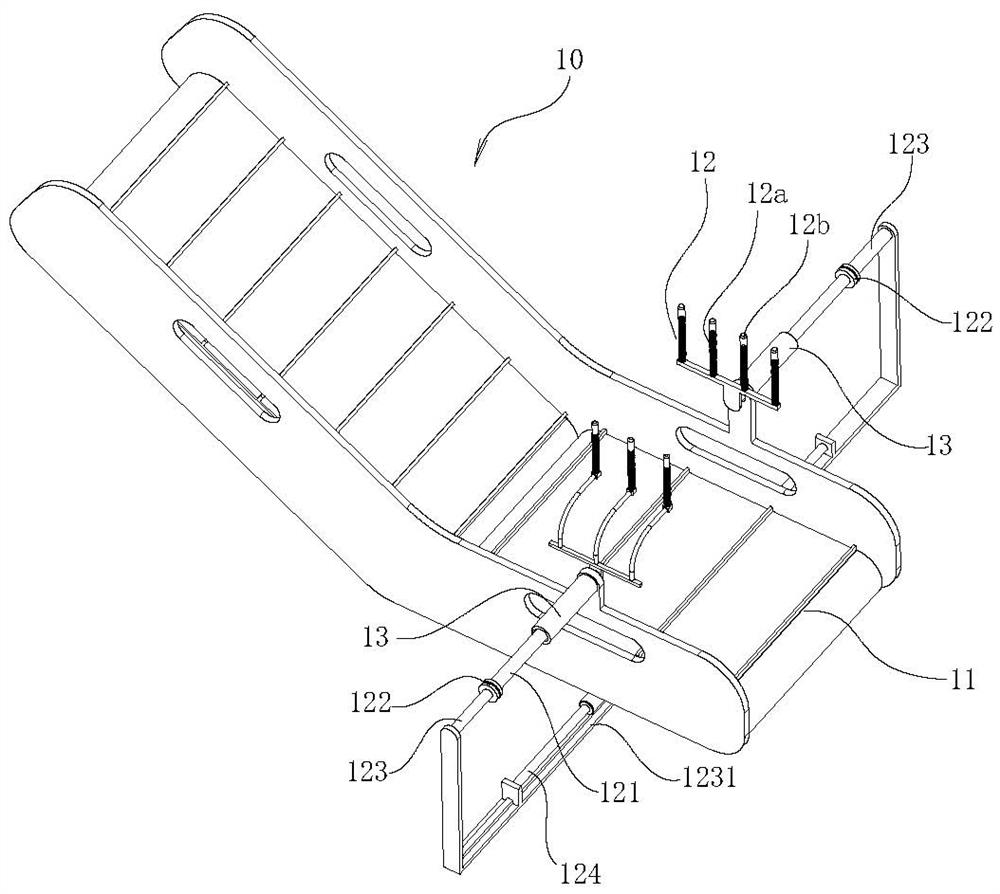

Rough garbage disposal method

ActiveCN110586629BEasy sorting operationImplement classification processingSolid waste disposalEnvironmental engineeringIndustrial engineering

The invention relates to a rubbish rough processing method. The rubbish rough processing method includes: guiding rubbish into a rubbish sorting device for dispersing the rubbish; and guiding the rubbish after being dispersed into a smashing device for smashing the rubbish, and guiding the rubbish after being dispersed by a disperser into a rolling vibration device. The rubbish rough processing method uses the rolling vibration device for separating light materials and heavy materials in the rubbish after being smashed, uses a flushing separation device for implementing sorting for rubbish chips, enables the flushing separation device to guide out the light rubbish and the heavy rubbish, and further sorts out large-density plastic and metal from the rubbish by classifying the rubbish, andtherefore the rough processing system can effectively realize sorting and clarification processing for the rubbish, reduces pollution, and realizes resource recycle to the utmost.

Owner:胡刘满

High-modulus modifier composite of bituminous mixture and preparation method thereof

ActiveCN101921419BHigh modulus of elasticityImprove adhesionBuilding insulationsRoad surfacePolypropylene

The invention discloses a high-modulus modifier composite of a bituminous mixture and a preparation method thereof. The high-modulus modifier composite of the bituminous mixture comprises the following components in parts by weight: silica powder, thermoplastic butadiene styrene rubber, modified polyethylene, polyethylene, modified polypropylene, polypropylene, ethylene-vinyl acetate polymers, antiagers and bitumen. The preparation method of the high-modulus modifier composite of the bituminous mixture comprises the following steps of: weighing the components in the parts by weight according to a proportion; stirring the components, and raising temperature at the same time; then adding the silica powder, the antiagers and the bitumen to a molten mass, and stirring for uniformly mixing at 160-200 DEG C and under certain rotating speed; extruding through a screw extruder, cooling with normal temperature water, and cutting so as to obtain granular finished products. The invention enhances the elastic modulus, improves the adhesive property, enhances the high-temperature anti-rutting property, the water stable property and the ageing-resistant performance, obviously reduces the damages, i.e. rutting, process, bumps, cracks, pits, looseness, and the like, of bituminous pavements, has the advantages of simple processing process, prolonged service life and convenient use, omits a process link of modifying the bitumen and can be widely used for paving the bituminous pavements of roads.

Owner:XIAN ZHONGLI ASPHALT CO LTD

A treatment method for fluorine-containing wastewater

ActiveCN104512972BAvoid the impact of the defluoridation processEffective in removing fluorideWater contaminantsMultistage water/sewage treatmentSludgeTreated water

A treating method of fluorine-containing waste water is disclosed. The fluorine-containing waste water comprises F-, SO4<2-> and Al<3+>. The method includes: adjusting the pH value of the fluorine-containing waste water to be not lower than 5 so as to subject the F- to neutralization and sedimentation reactions; bringing the fluorine-containing waste water after the neutralization and sedimentation reactions and coagulant aids into contact; separating solid and liquid to obtain first sludge and a first liquid phase; bringing the obtained first liquid phase and an aluminum-containing compound capable of adsorbing the F- in the waste water into contact to perform coagulating sedimentation; separating liquid and solid to obtain second sludge and a second liquid phase; bringing the obtained second liquid phase and coagulant aids into contact; and performing liquid-solid separation to obtain third sludge and discharged treated water. The method can perform effective fluorine removal treatment for the fluorine-containing waste water having high contents of the F-, the SO4<2-> and the Al<3+>.

Owner:CHINA PETROLEUM & CHEM CORP +1

Single-membrane and double-chamber electrolytic copper and chlorine regeneration system and process for acidic chlorine salt waste etching solution

PendingCN111748826ALow purityHigh replacement frequencyCellsPhotography auxillary processesEtchingProcess engineering

The invention discloses a single-membrane and double-chamber electrolytic copper and chlorine regeneration system and process for an acidic chlorine salt waste etching solution and belongs to the technical field of recycling equipment for an acidic etching solution, a hardware etching acidic waste solution and a mine acidic chlorine salt copper-containing waste solution of a printed circuit board.The system comprises an online acidic etching machine, a single-membrane and double-chamber electrolyzing device, a regenerated liquid blending device, a regenerated liquid injecting and absorbing device, a chlorine recycling device, a low-temperature water curtain absorbing device, a power wave absorbing device and a rotational flow spraying device. By adopting a process of electrolyzing copperby the single-membrane and double-chamber electrolyzing device and recycling chlorine by the chlorine recycling device for the acidic etching waste solution generated by the acidic etching machine, problems in the processes such as a substitution method, an ion member electrolytic process, a sulfuric acid distillation method and a diaphragm electrolytic process in the prior art are improved, low cost acidic chlorine salt etching waste solution regeneration and circulation can be realized truly, and targets of clean production and improvement of economical benefits of a PCB enterprise are achieved.

Owner:昆山科之源环保科技有限公司

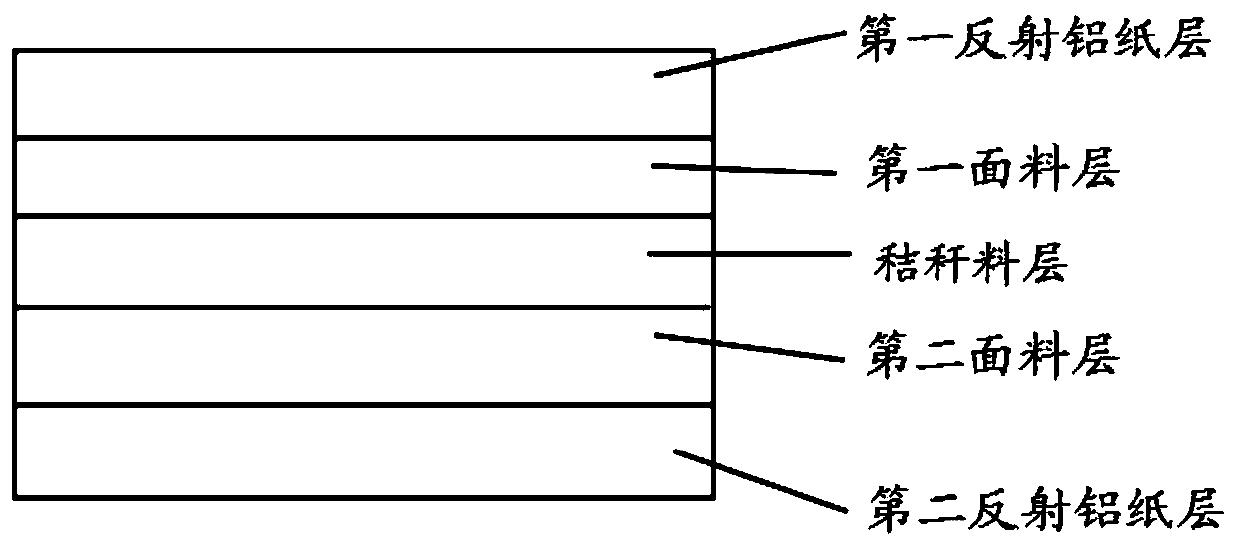

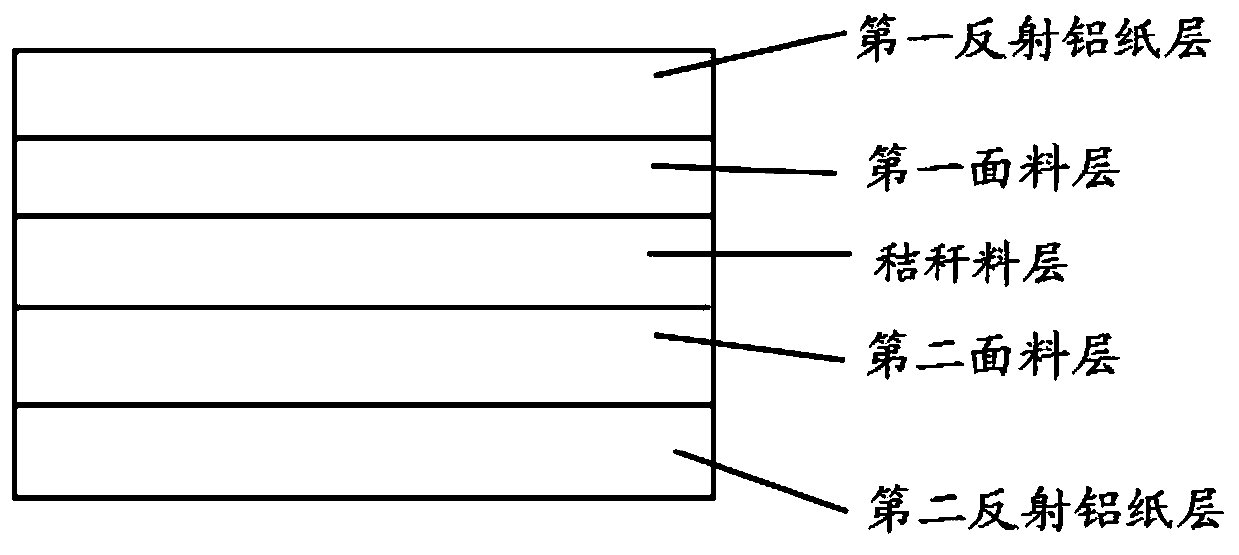

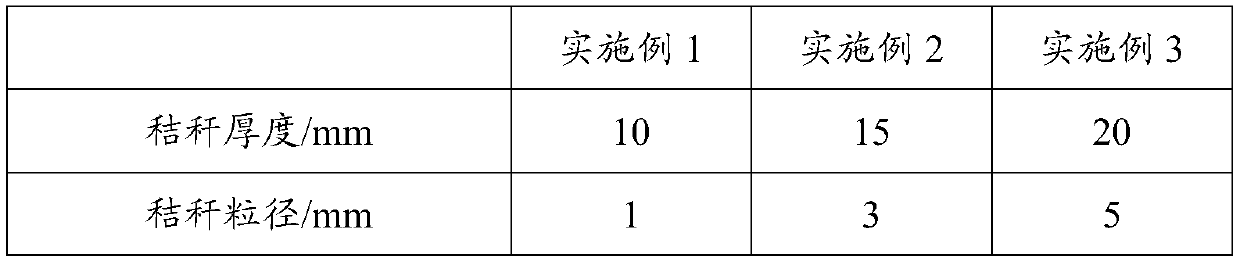

Greenhouse heat preservation quilt and application thereof

PendingCN109964705AGood heat insulationGuaranteed insulation effectClimate change adaptationSynthetic resin layered productsGreenhouseCompound (substance)

The invention provides a greenhouse heat preservation quilt and application thereof and belongs to the technical field of heat insulation and preservation. The greenhouse heat preservation quilt comprises a first reflective aluminum paper layer, a first fabric layer, a straw material layer, a second fabric layer and a second reflective aluminum paper layer which are sequentially stacked. The reflective aluminum paper layer can reflect back heat in a greenhouse and plays a good heat insulation effect. A straw material is adopted for replacing cotton felts, synthetic resin foam and synthetic fiber cotton and serves as a heat preservation medium, so that the cost is greatly reduced while the heat preservation effect is guaranteed, and resource recycling and the reduction of environmental pollution are achieved. The result of the embodiment shows that the temperature in the greenhouse obviously rises after the greenhouse heat preservation quilt is adopted, and the heat preservation effectof the greenhouse quilt is not inferior to the heat preservation effect of a greenhouse quilt made of an expensive thick chemical fiber velvet and is obviously superior to the heat preservation effectof a common regenerated cotton greenhouse quilt.

Owner:阳谷信民耐火材料有限公司

Garbage Rough Treatment System

ActiveCN110586630BHigh densityEasy to reuseSolid waste disposalProcess engineeringMechanical engineering

The invention relates to a garbage coarse processing system. The system involves a garbage dispersing device, wherein the garbage dispersing device is used for dispersing garbage, and an outlet of thegarbage dispersing device is connected with a rolling vibration device; the rolling vibration device is used for dividing the garbage into two types of garbage, the rolling vibration device is provided with two falling ports, and the two falling ports are used for exporting the two types of garbage correspondingly; the first falling port of the rolling vibration device is connected with a feedingport of a garbage compression device in an engagement mode, and the garbage compression device is used for compressing and pressing the first type of garbage; and the second falling port of the rolling vibration device is connected with a garbage classification device, and the garbage classification device is used for further sorting recyclable plastic and metal garbage in the second type of garbage, so that the coarse processing system can effectively realize sorting and classification processing on the garbage, reduce pollution, and achieve resource recycling as much as possible.

Owner:安徽智汇和科技服务有限公司

A reuse treatment device for flowback pressure fluid in shale gas well fracturing operations

ActiveCN104261587BReduce contentAddressing water challengesWaste water treatment from quariesWater contaminantsWater resourcesFracturing fluid

The invention discloses a recycling treating device for flowback pressure liquid in shale gas well fracturing operation. The recycling treating device comprises a wastewater pool, a regulation pool, a composite coagulation reaction device, a settling pool, a solid-liquid separation device and a clean water pool which are sequentially connected to one another by virtue of a pipeline, wherein the composite coagulation reaction device consists of a rapid stirring pool, a slow stirring pool and an oxidation pool which are sequentially connected to one another by virtue of a pipeline, and the upper ends of the regulation pool, the rapid stirring pool, the slow stirring pool and the oxidation pool are all connected with a corresponding drug adding device by virtue of a constant-flow pump; the solid-liquid separation device consists of a crude filter and double-filtering equipment which are sequentially connected to one another by virtue of a pipeline, the crude filter is connected with a sludge pump by virtue of a fourth valve, the double-filtering equipment is also connected with the sludge pump, and the sludge pump is connected with a sludge dewatering machine. With the adoption of the recycling treating device, as the bottoms of the regulation pool, the rapid stirring pool, the slow stirring pool and the oxidation pool are all provided with stirrers, the problem of water resource challenge brought by shale gas development can be effectively solved, resource cyclic utilization is reached, and zero emission of flowback liquid caused by shale gas fracturing can be truly realized.

Owner:HAITIAN WATER GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com