Single-membrane and double-chamber electrolytic copper and chlorine regeneration system and process for acidic chlorine salt waste etching solution

A technology of etching waste liquid and acid etching, which is applied in photography process, electrolysis process, electrolysis components, etc., can solve the problems of high risk, low efficiency of chlorine recycling, low efficiency of electrolysis, etc., so as to reduce production cost and power consumption , the effect of optimizing the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

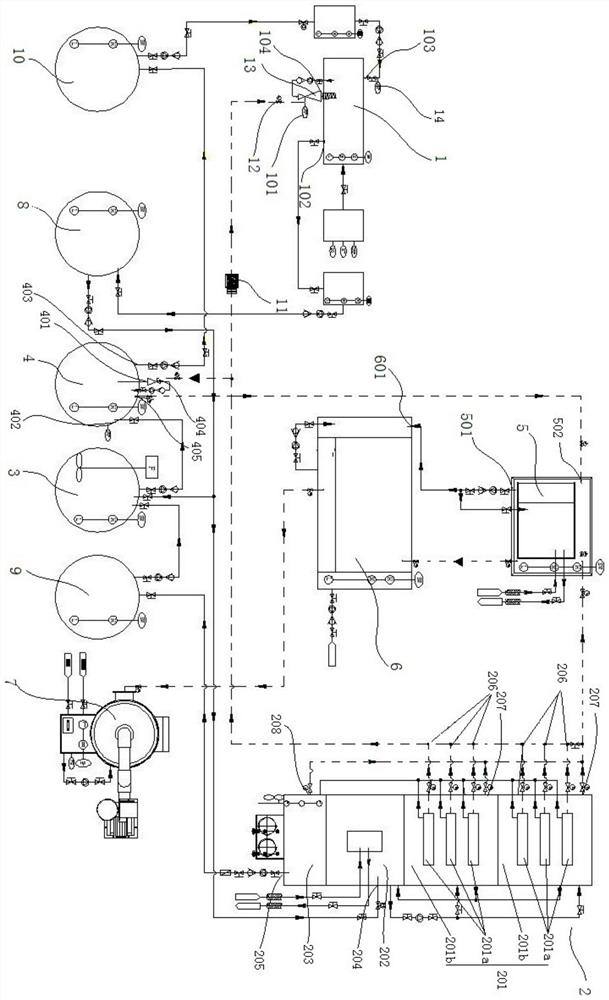

[0068] In order to be able to understand the technical means of the present invention more clearly and implement it according to the contents of the description, the specific implementation of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are used to illustrate the present invention, but not to limit the scope of the present invention.

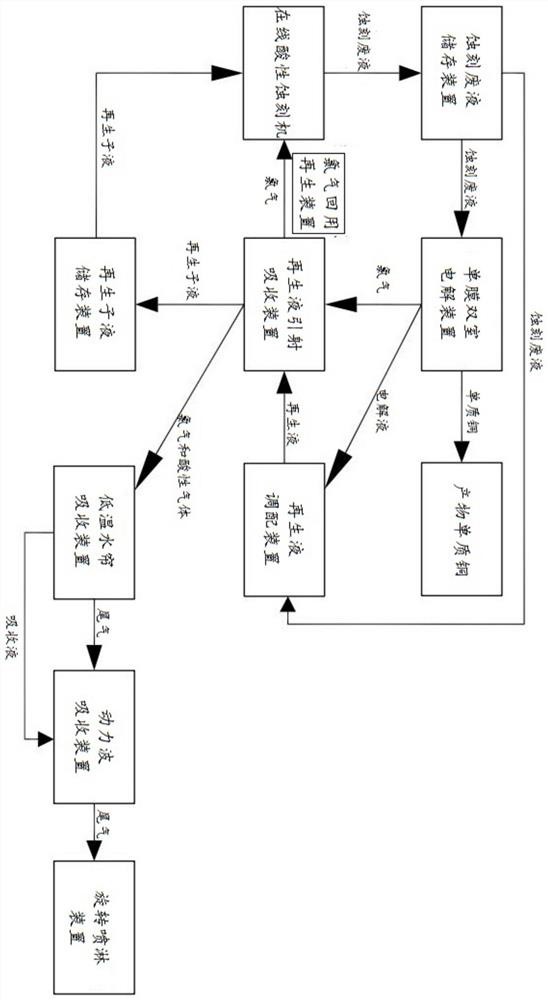

[0069] The following specific examples describe in detail a single-membrane double-chamber electrolytic copper and chlorine regeneration system for acid chloride salt etching waste liquid. , Regenerated liquid injection absorption device 4, chlorine gas reuse regeneration device, low temperature water curtain absorption device 5, dynamic wave absorption device 6 and swirl spray device 7.

[0070] The structure of the device for extracting copper from etching waste liquid in this system is as follows: the waste liquid outlet 102 of the online ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com