Preparation method for producing efficient water flush fertilizer by biogas slurry

A production method and flushing fertilization technology, applied in fertilization devices, liquid fertilizers, applications, etc., can solve the problems of irritating odor that is difficult for growers to accept, difficult to apply biogas slurry on a large scale, and low nutrient in biogas slurry. The effect of preventing and plant diseases, reducing plant diseases, and improving the effect of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

[0031] The problem to be solved by the present invention is to provide a production method of using biogas slurry to produce high-efficiency fertilization, which can reduce the odor of biogas slurry and can be turned into fertilizer after biogas slurry treatment.

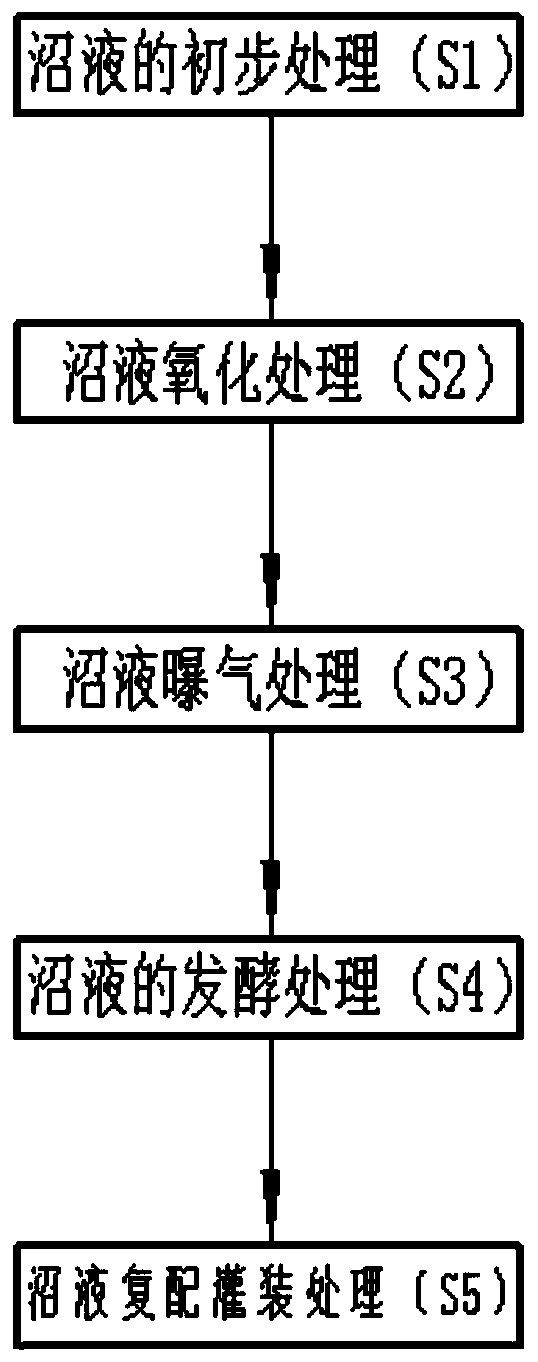

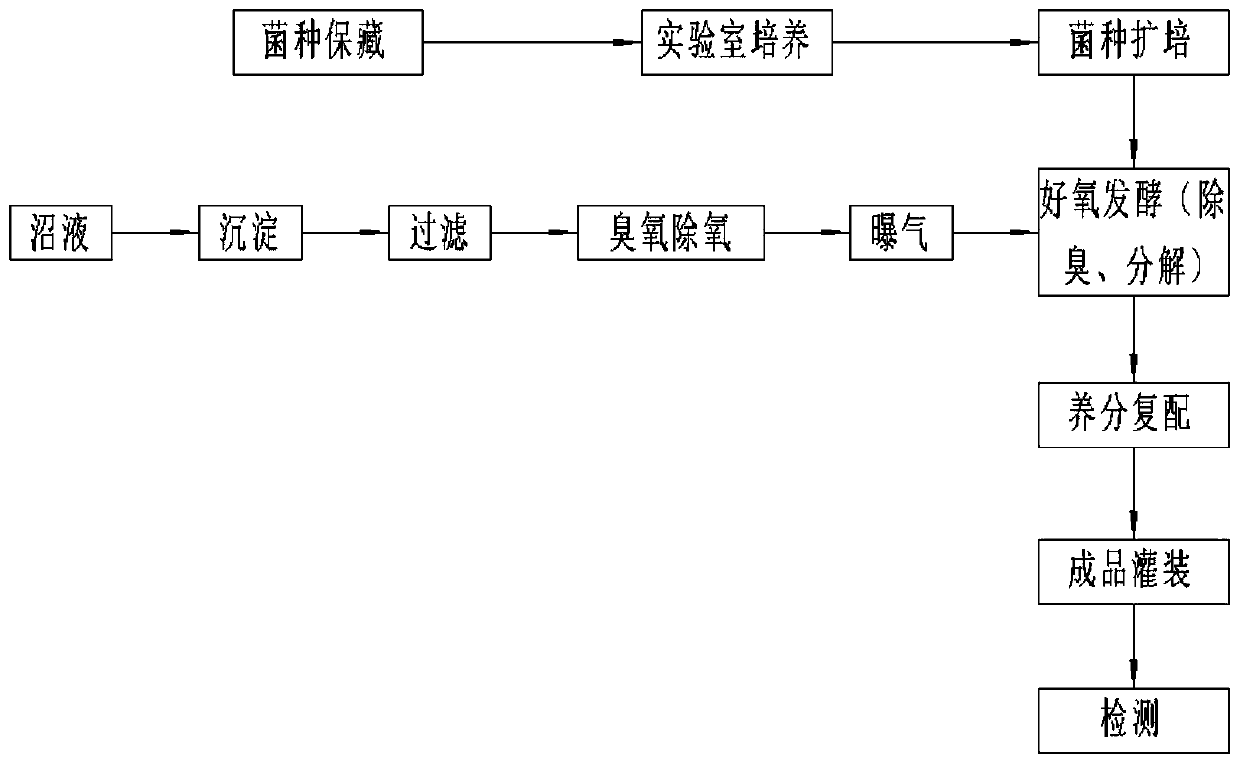

[0032] Such as figure 1 , figure 2 As shown, in order to achieve the technical purpose, the technical solution of the present invention is: a method for producing high-efficiency flushing fertilization using biogas slurry, which is characterized in that it includes the following steps:

[0033] S1: The biogas slurry is firstly subjected to preliminary treatment of extraction, sedimentation and filtration, and then passed into the pretreatment tank;

[0034] S2: Ozone is passed into the pretreatment tank again to oxidize the reducing substances to greatly reduce the odor concentration;

[0035]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com