A kind of restoration method of ionic rare earth ore ammonium salt leaching site

An ionic rare earth and repair method technology, which is applied in the repair field of ionic rare earth ore ammonium salt leaching sites, can solve problems such as pollution, imbalance of calcium and magnesium nutrient elements, and achieve pollution avoidance, less leaching water, and barrier diffusion and the effect of migration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

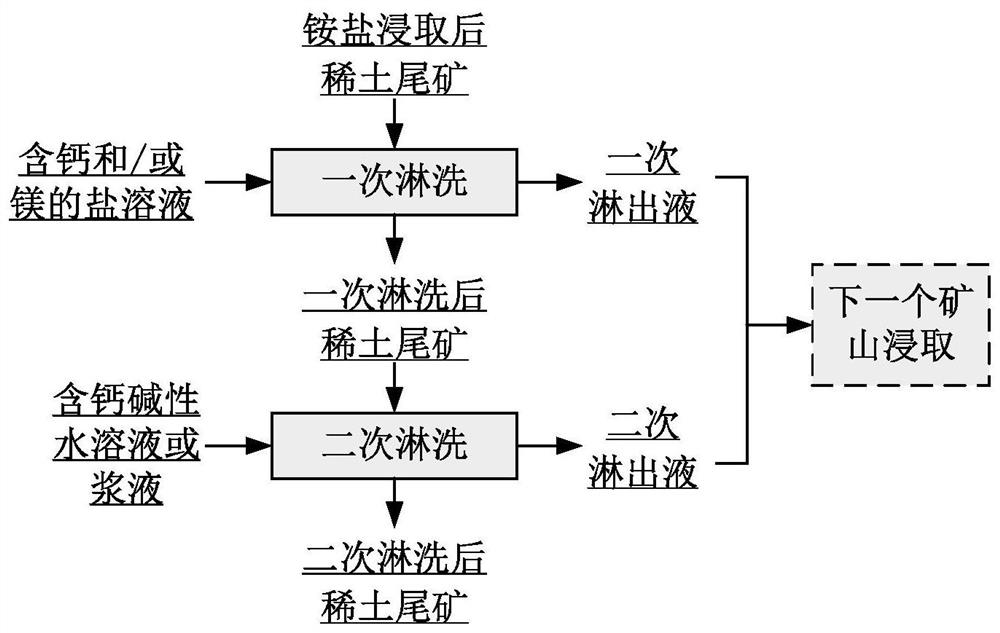

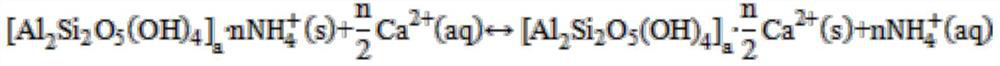

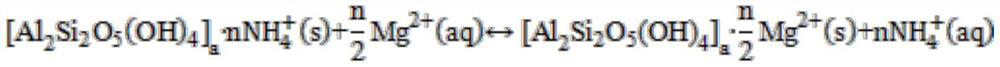

Method used

Image

Examples

Embodiment 1

[0055] After leaching with a certain ammonium salt, the pH value of the rare earth tailings is 3.39, the alkaline hydrolysis nitrogen is 1540mg / kg, the available calcium is 32.89mg / kg, the available magnesium is 17.98mg / kg, and the calcium-magnesium ratio is 1.83.

[0056] Use a salt solution containing calcium and / or magnesium to wash the rare earth tailings after ammonium salt leaching once. The concentration of cations in the salt solution containing calcium and / or magnesium is 0.05mol / L, and the salt containing calcium and / or magnesium The liquid-solid ratio of rare earth tailings after leaching solution and ammonium salt is 0.3m 3 / t; Calcium hydroxide solution is used for secondary leaching, and the liquid-solid ratio of the rare earth tailings after the first leaching is 0.4m 3 / t, the molar concentration of calcium hydroxide is 0.02mol / L, and the pH value is 12.53. The leachate obtained from the two washings is returned to the next ionic rare earth mine for leaching. ...

Embodiment 2

[0060] After leaching with a certain ammonium salt, the pH value of the rare earth tailings is 3.39, the alkaline hydrolysis nitrogen is 1540mg / kg, the available calcium is 32.89mg / kg, the available magnesium is 17.98mg / kg, and the calcium-magnesium ratio is 1.83.

[0061] A salt solution containing calcium and / or magnesium is used to wash the rare earth tailings after ammonium salt leaching. The change of cation concentration in the salt solution containing calcium and / or magnesium is shown in Table 2. Salt solution containing calcium and / or magnesium The liquid-solid ratio of rare earth tailings after leaching with ammonium salt is 0.4m 3 / t; Calcium hydroxide solution is used for secondary leaching, and the liquid-solid ratio of the rare earth tailings after the first leaching is 0.4m 3 / t, the molar concentration of calcium hydroxide is 0.02mol / L, and the pH value is 12.53. The leachate obtained from the two washings is returned to the next ionic rare earth mine for leach...

Embodiment 3

[0065] After leaching with a certain ammonium salt, the pH value of the rare earth tailings is 3.39, the alkaline hydrolysis nitrogen is 1540mg / kg, the available calcium is 32.89mg / kg, the available magnesium is 17.98mg / kg, and the calcium-magnesium ratio is 1.83.

[0066] Use a salt solution containing calcium and / or magnesium to wash the rare earth tailings after ammonium salt leaching once. The concentration of cations in the salt solution containing calcium and / or magnesium is 0.05mol / L, and the salt containing calcium and / or magnesium The change of the liquid-solid ratio of the rare earth tailings after the solution and ammonium salt leaching is shown in Table 3; the calcium hydroxide solution is used for secondary leaching, and the liquid-solid ratio of the rare earth tailings after the first leaching is 0.4m 3 / t, the molar concentration of calcium hydroxide is 0.02mol / L, and the pH value is 12.53. The leachate obtained from the two washings is returned to the next ionic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com