Patents

Literature

407results about "Liquid/slurry treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

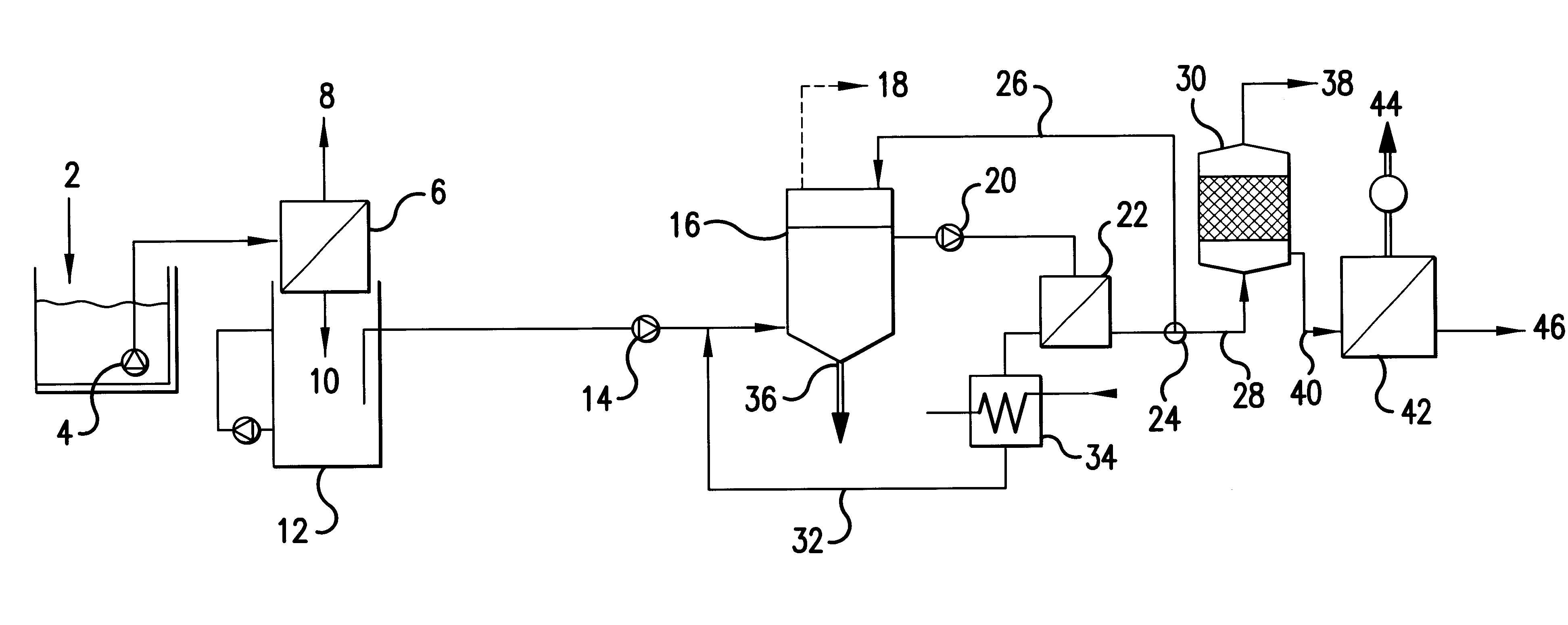

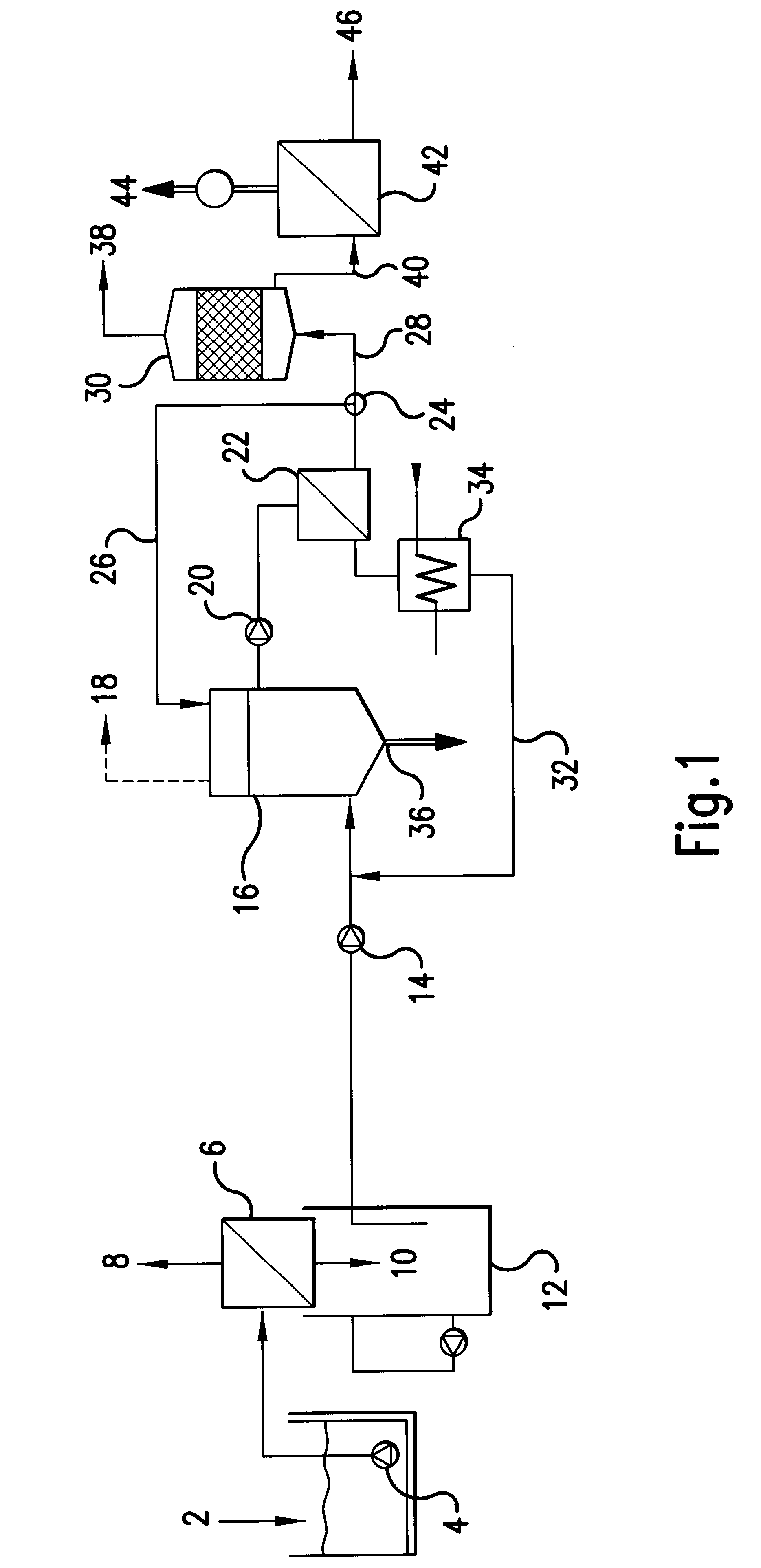

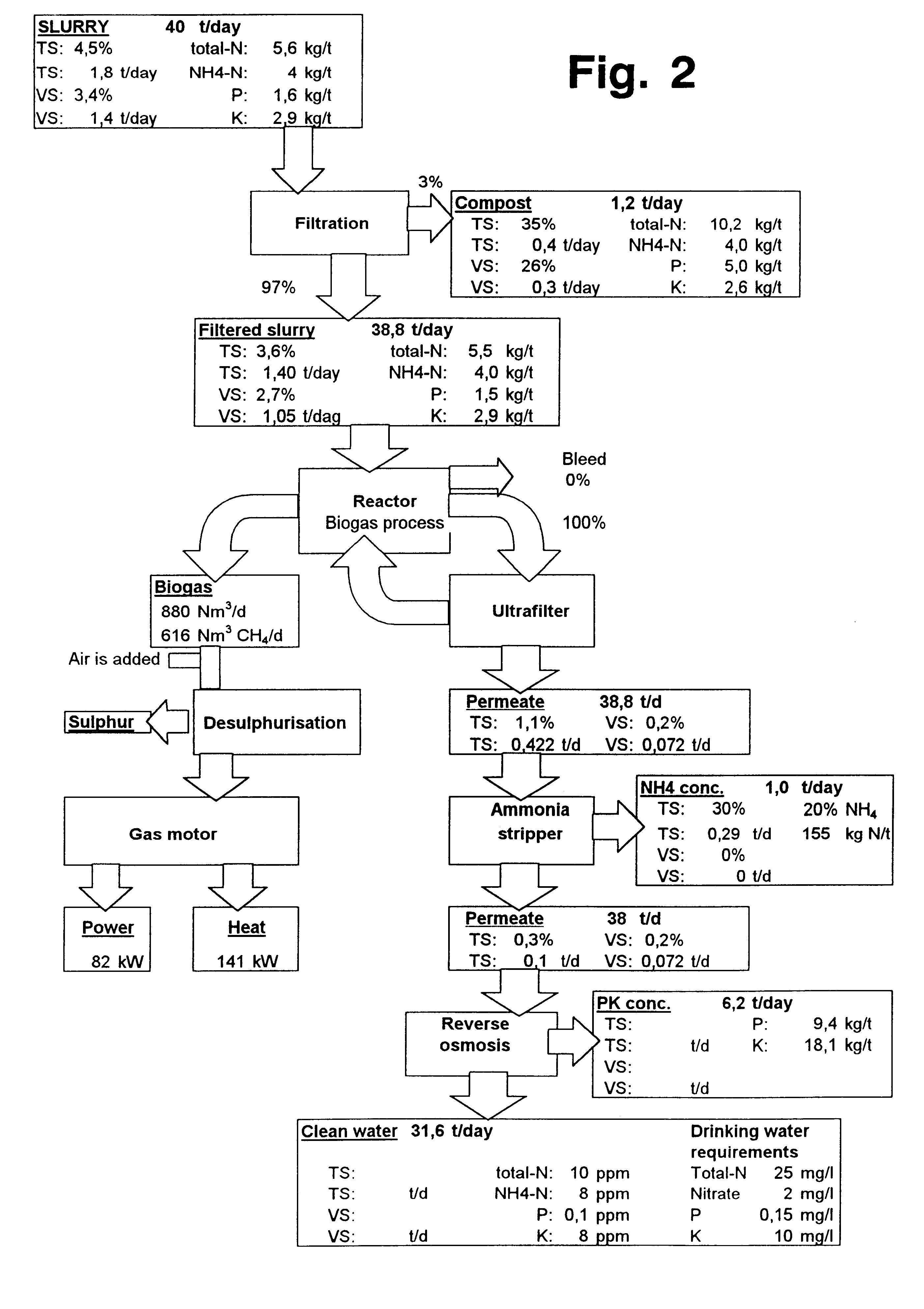

Method and plant for the treatment of liquid organic waste

InactiveUS6368849B1Increase profitReduce environmental impactBioreactor/fermenter combinationsBio-organic fraction processingFiberUltrafiltration

A method and plant for the treatment of an organic waste material in liquid form, e.g. liquid manure from livestock, the method comprising filtering fibres and particles from the liquid, subjecting the liquid to anaerobic fermentation in a biogas reactor, separating a substantially sterile and particle-free permeate stream from the biogas reactor, e.g. using ultrafiltration, subjecting the permeate stream to treatment with an ammonia stripper at an elevated temperature and preferably at reduced pressure to remove substantially all ammonia and carbon dioxide and to result in an ammonia fraction and a nutrient salt fraction, and separating the nutrient salt fraction into a fertiliser concentrate fraction and a water fraction, e.g. using reverse osmosis. The end products of the method are clean water, ammonia concentrate, fertiliser concentrate containing salts of P and K, compost and high-quality biogas with a high methane content.

Owner:GR BIOTECH

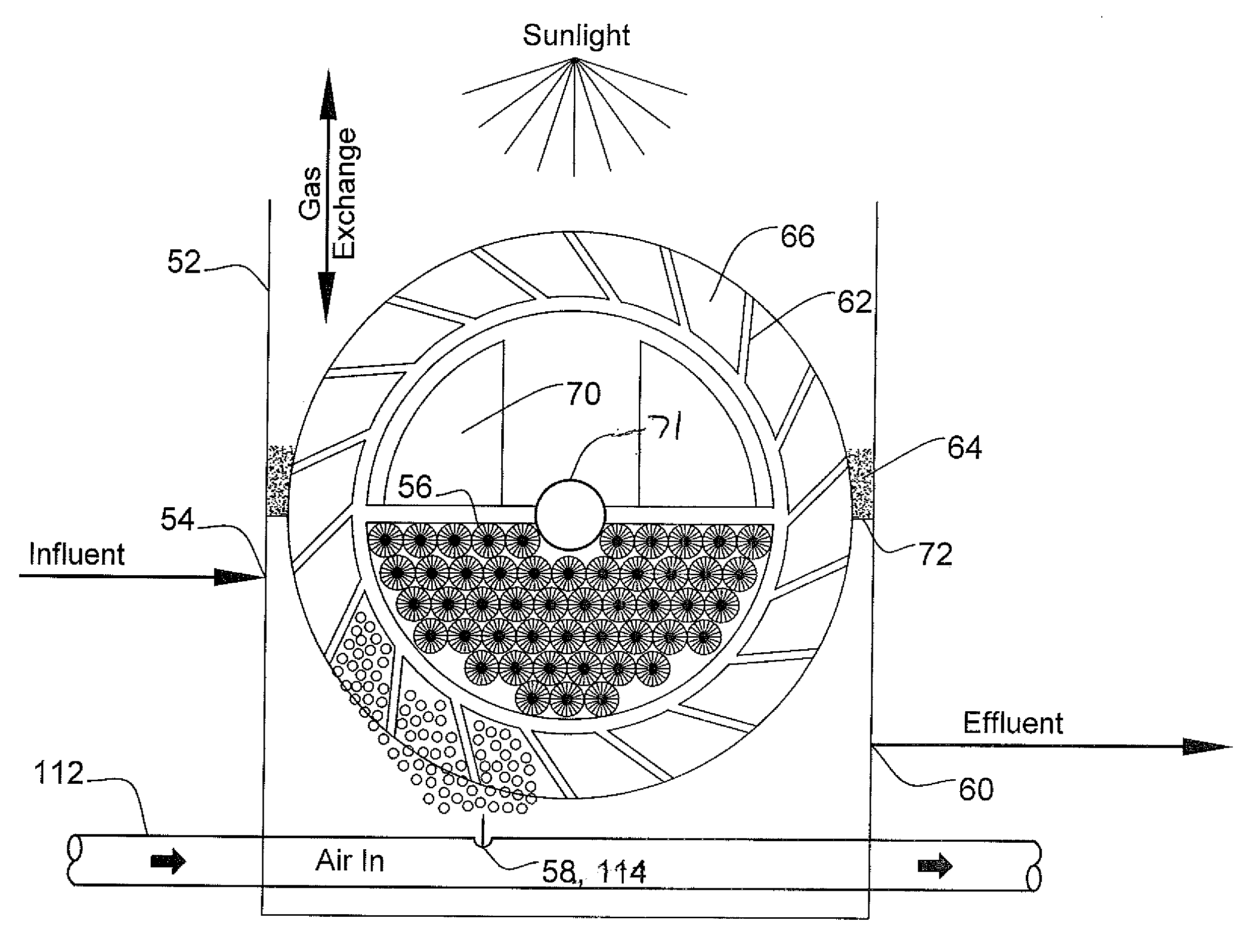

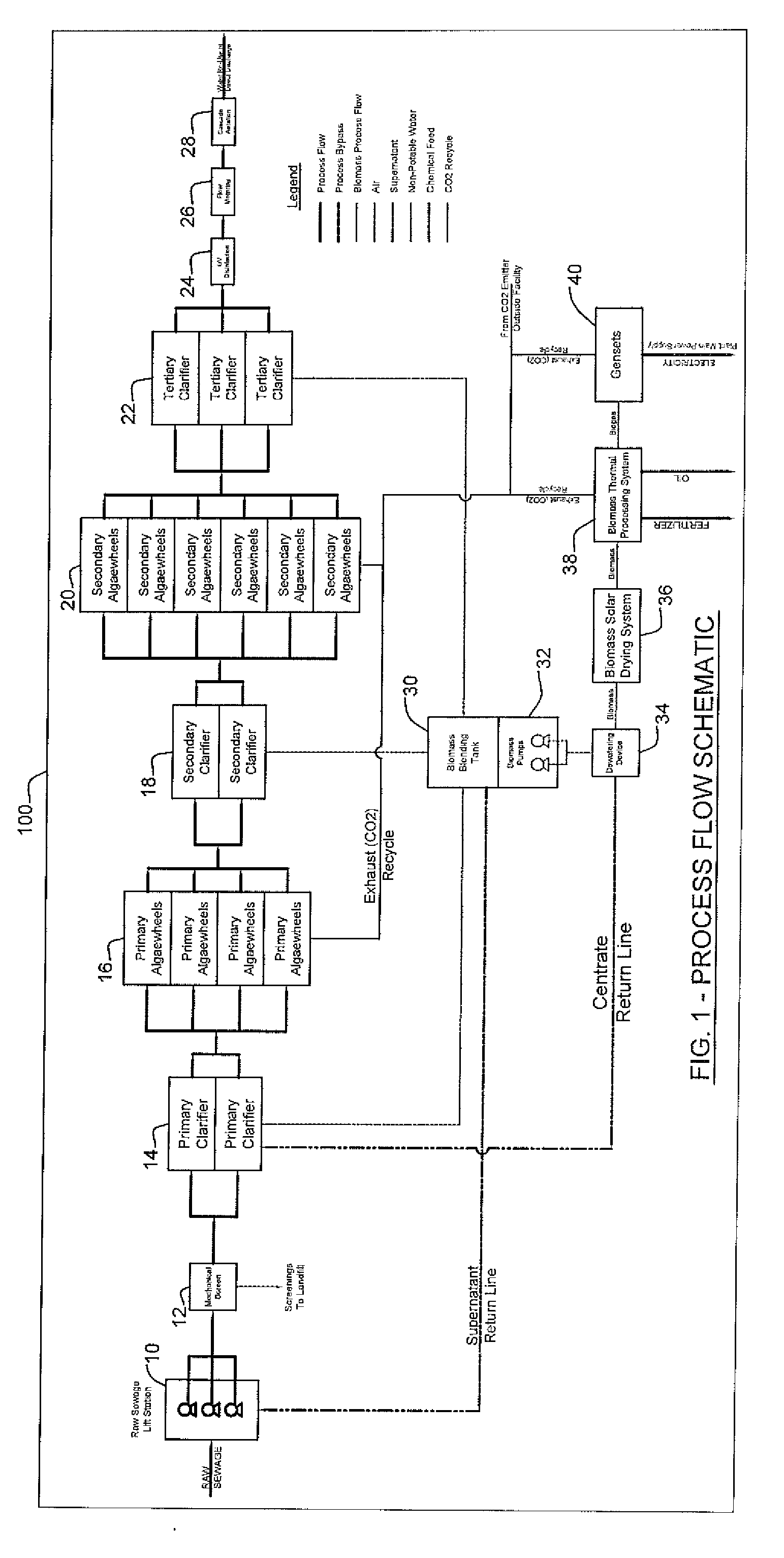

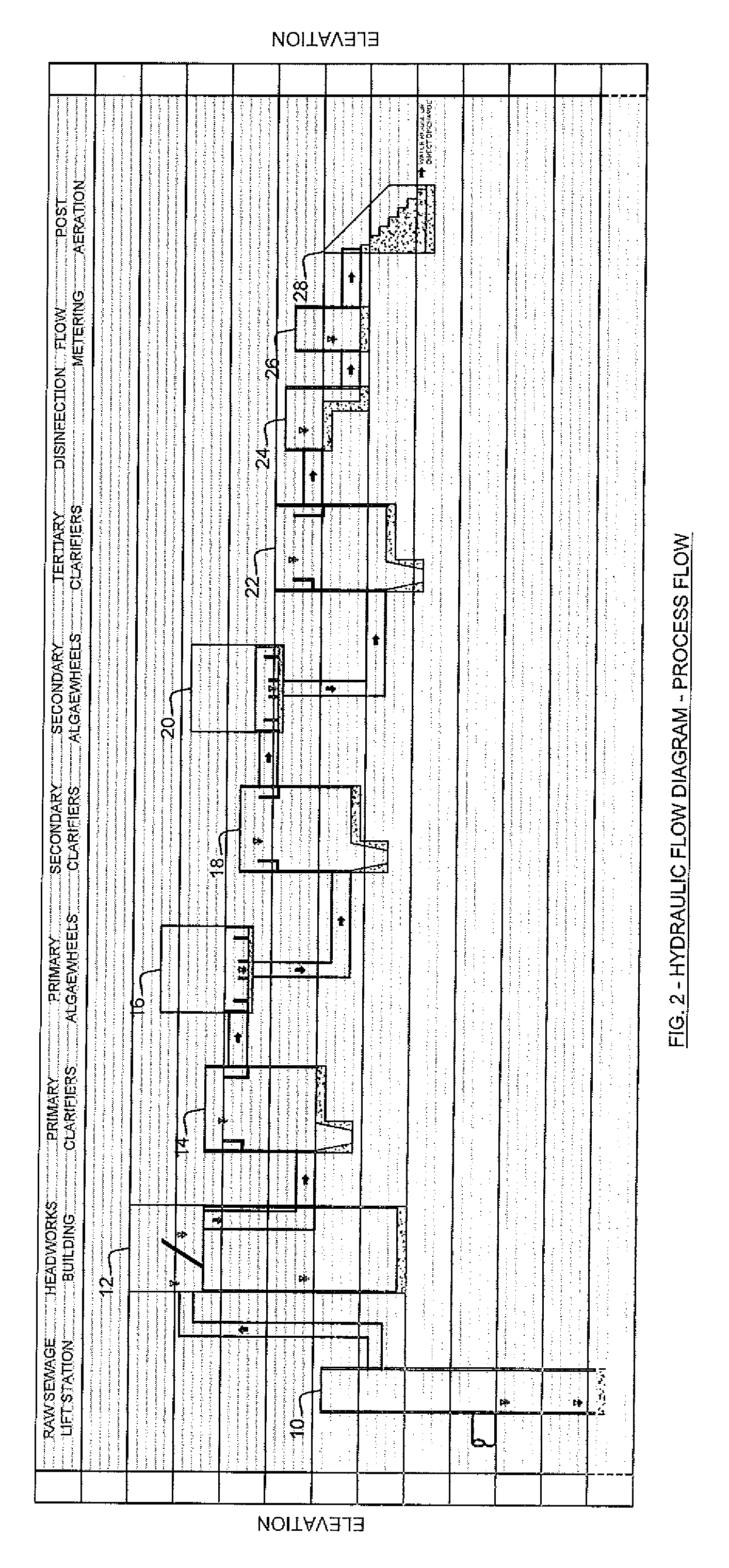

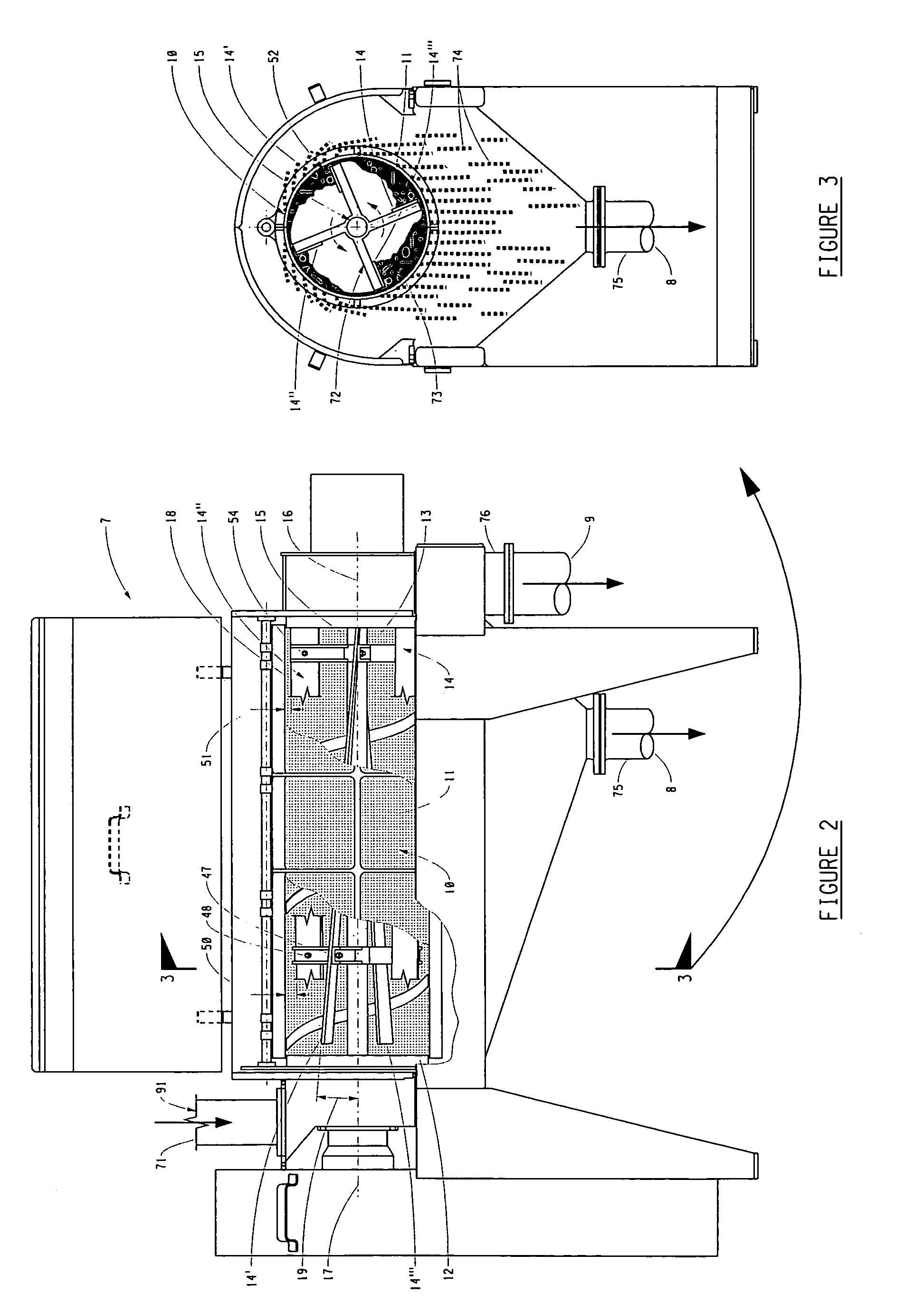

Apparatus and Process for Biological Wastewater Treatment

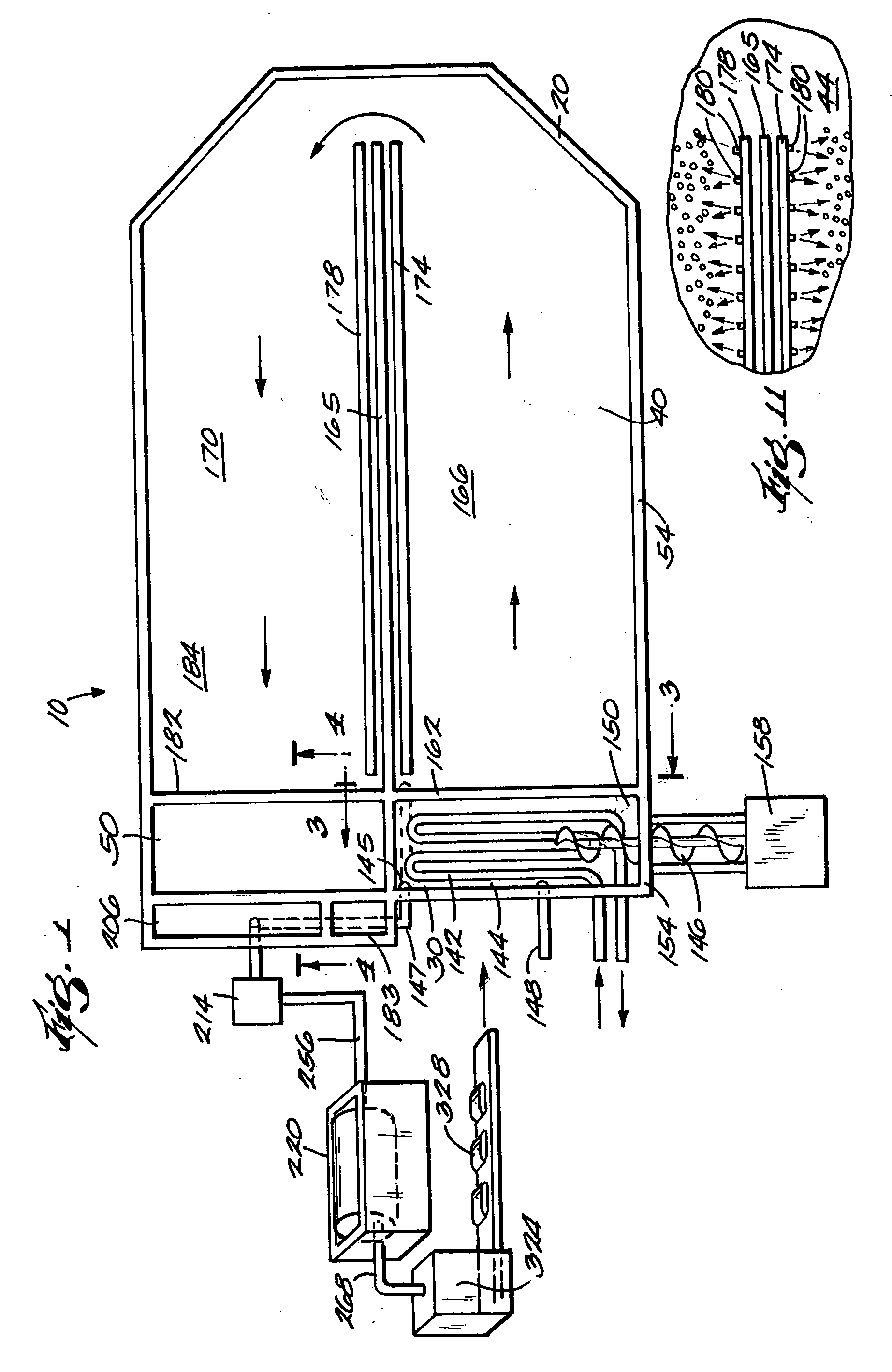

ActiveUS20090230040A1Bio-organic fraction processingTreatment using aerobic processesSustained growthBiofuel

A self-sustaining wastewater treatment facility abates greenhouse gas abatement, captures CO2 and produces biomass to address multiple critical environmental needs. The facility includes an array of rotating media wheels that create an optimum ordered mixing of algae for sustained growth. Biomass harvested from the rotating media wheels may be provided to other processing facilities to produce, for instance, bio-fuels. Waste CO2 from the processing facility may also be returned to the treatment system for enhanced algae growth. Bacteria are provided to form a symbiotic relationship with the algae, fueled by sunlight to effectively remove toxic materials from the wastewater. The multi-functional facility may also be integrated into a regenerative facility in which the biomass obtained from the algal and bacterial colonies is used in a separate facility and byproducts of the operation of the separate facility are used by the multi-functional facility to fuel further algal growth.

Owner:LIMCACO CHRISTOPHER A

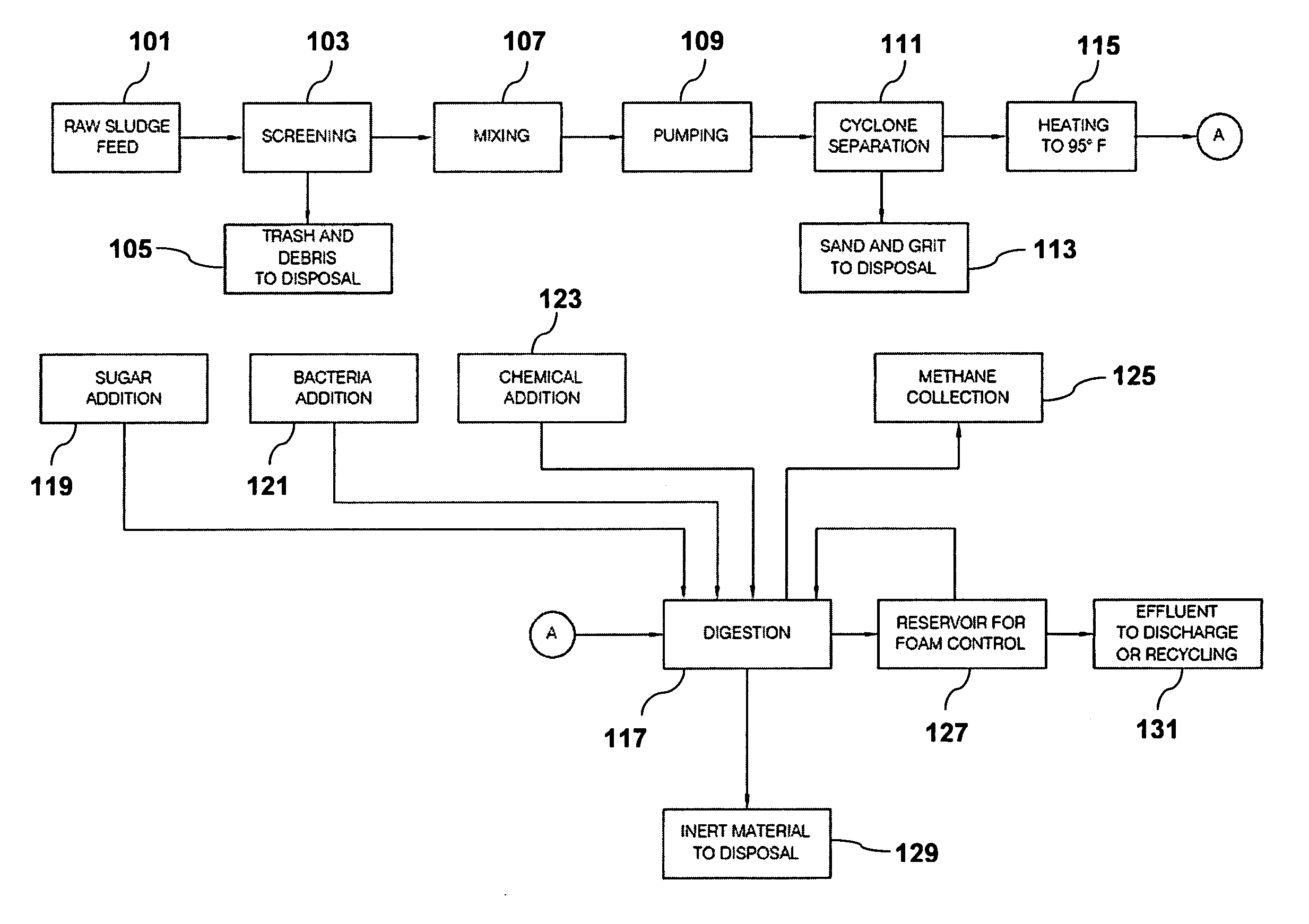

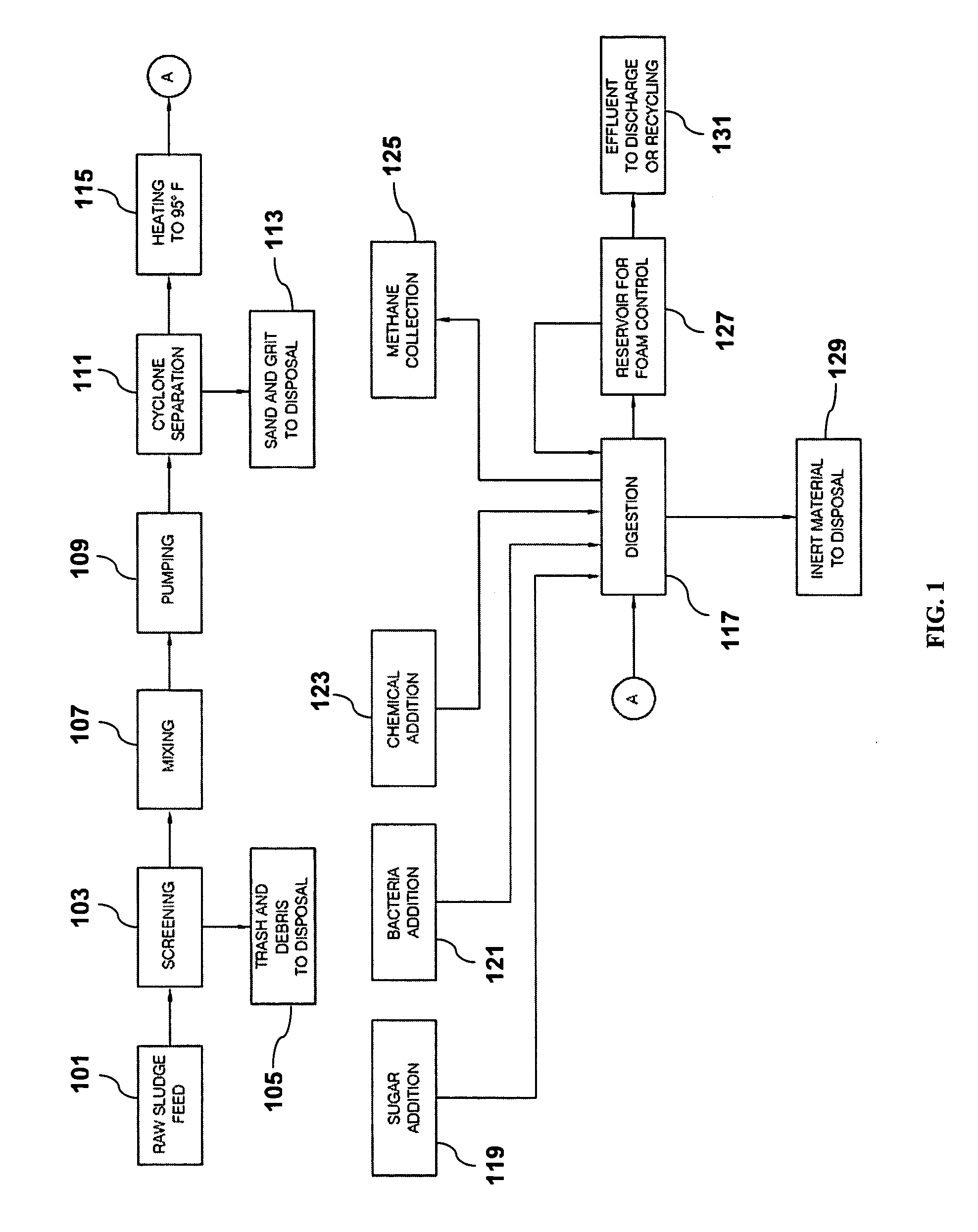

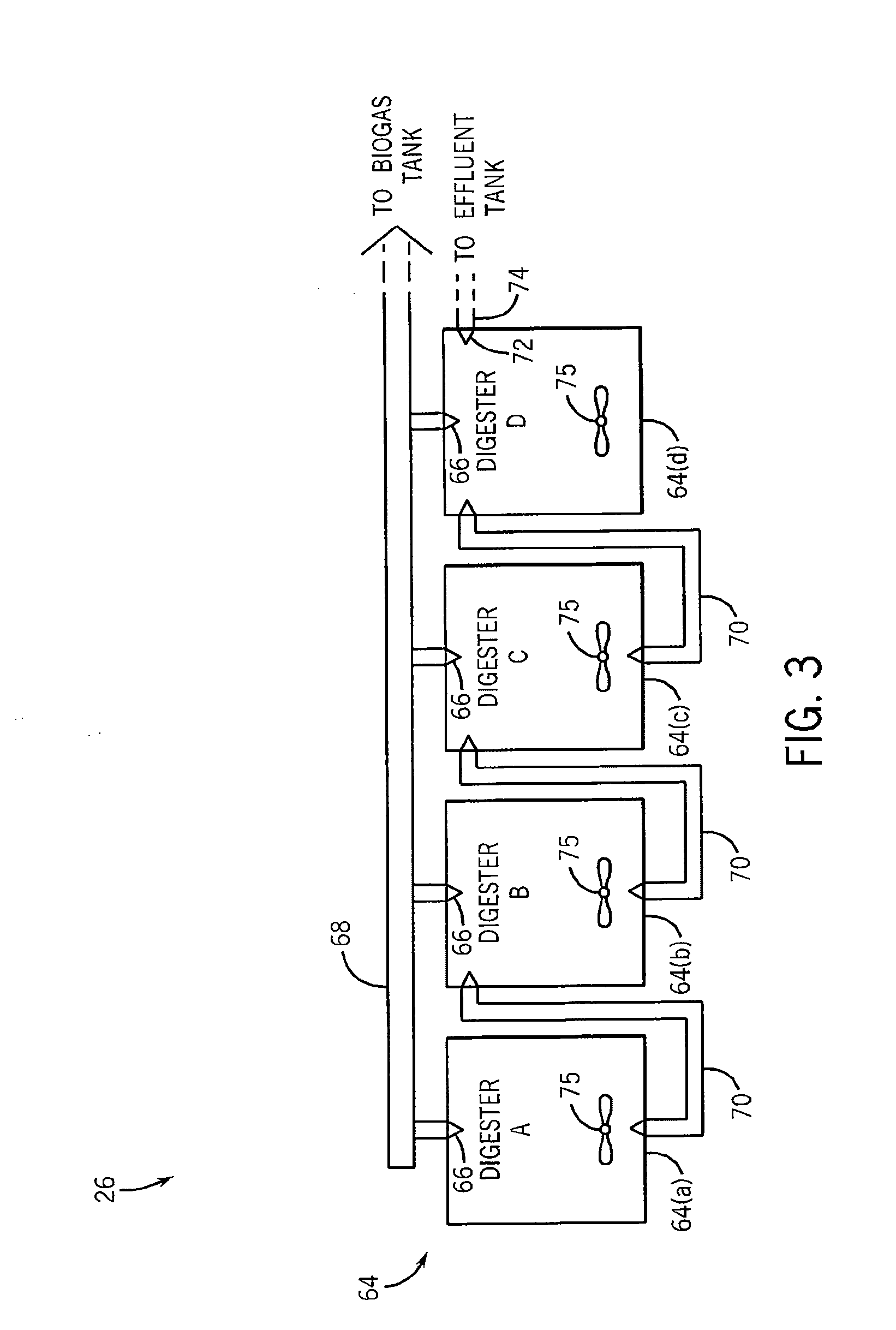

Digesters

Methods and devices are disclosed for converting predominantly organic waste materials, such as sludge, into useful byproducts.

Owner:TOLBERT & ASSOCS

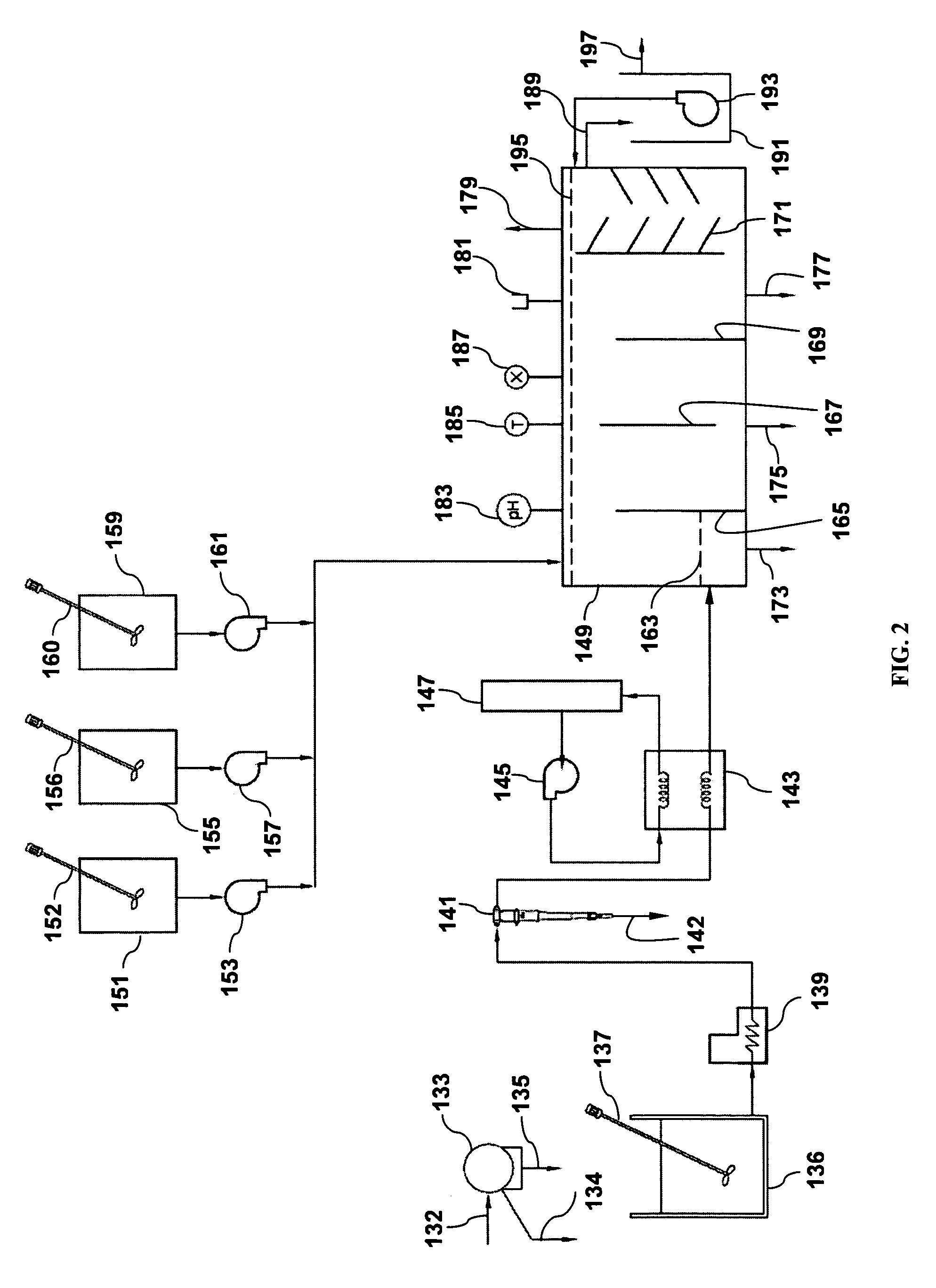

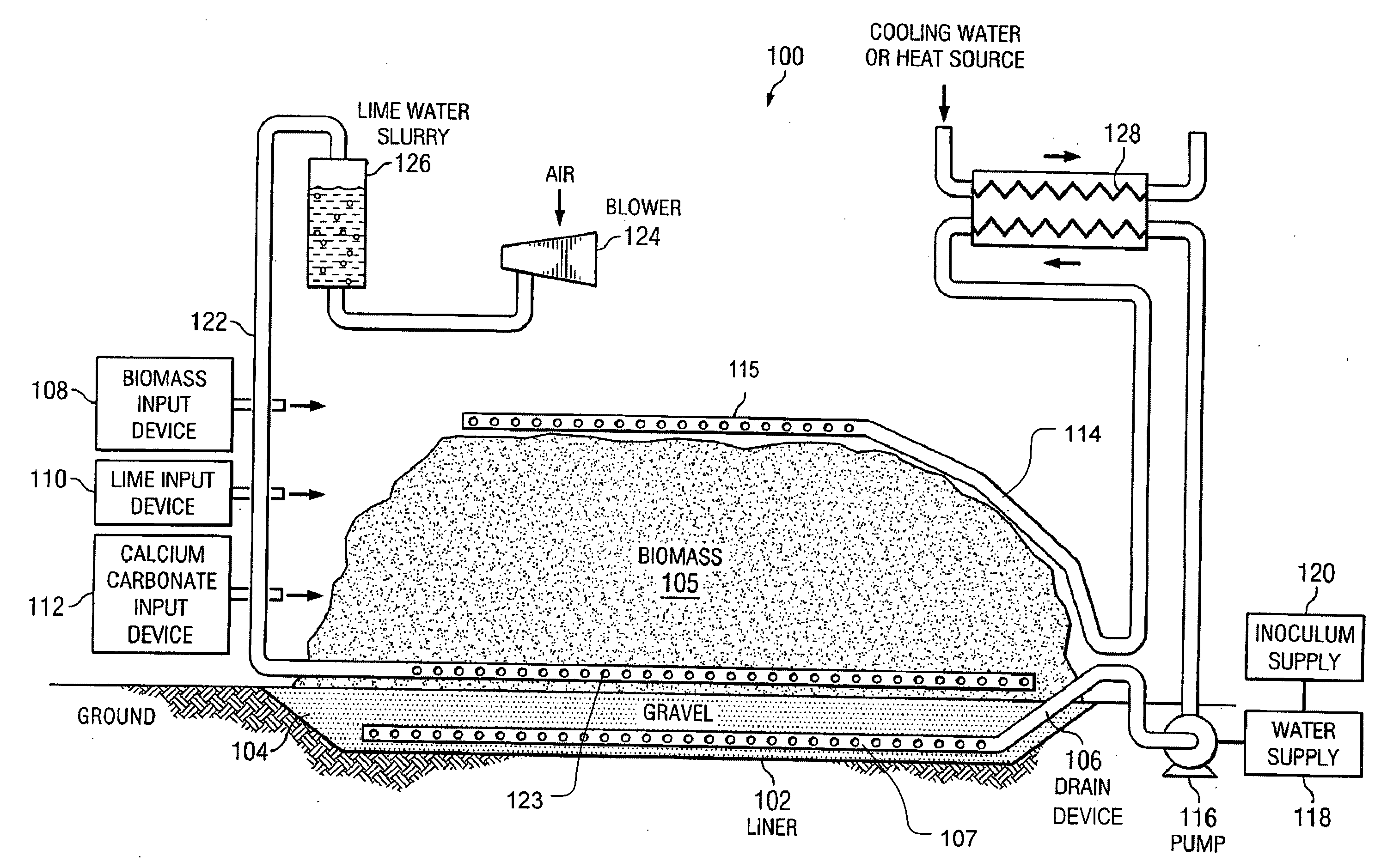

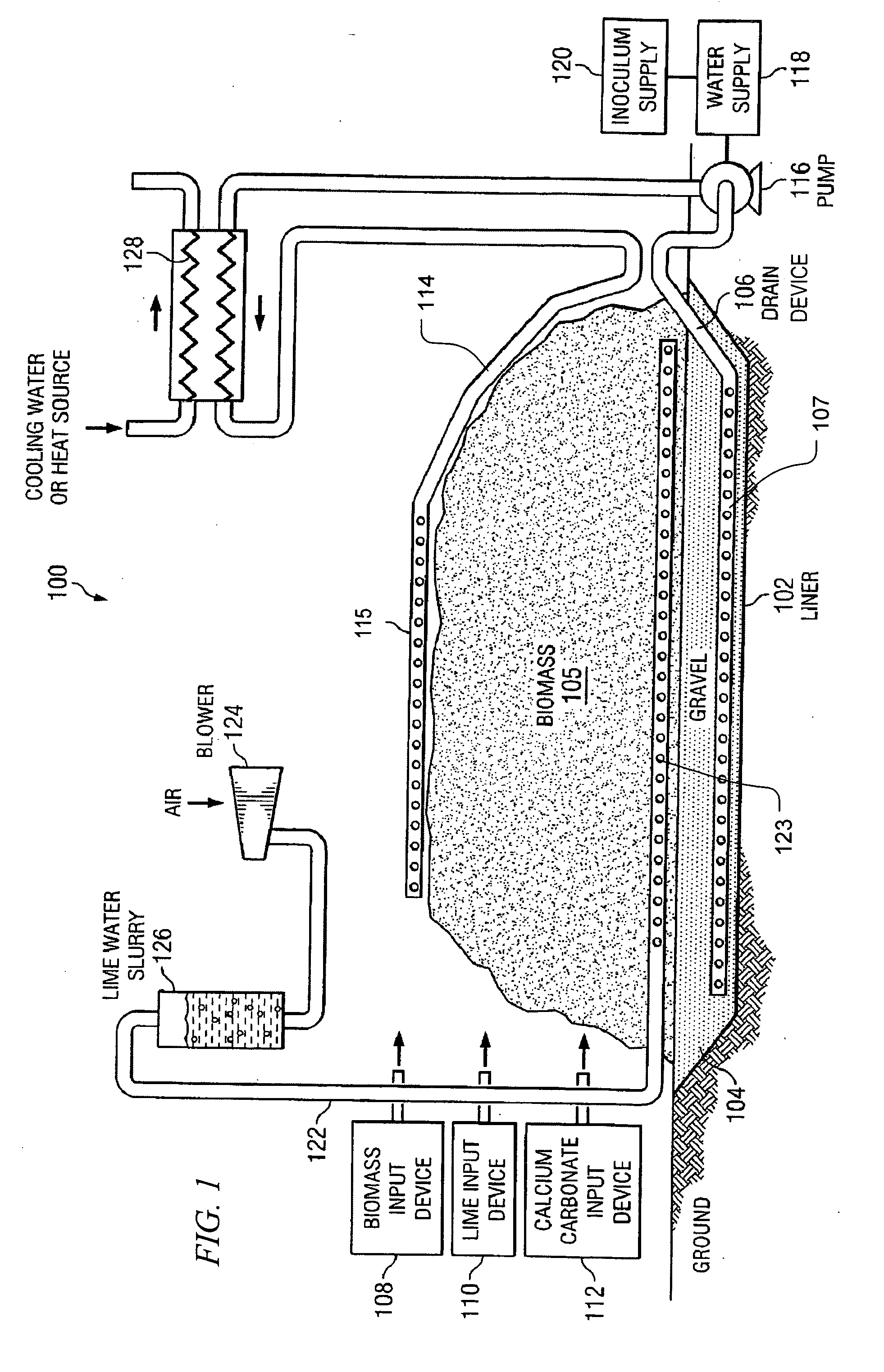

System and method for processing biomass

InactiveUS20060188980A1Low costBioreactor/fermenter combinationsBio-organic fraction processingEngineeringFluid input

According to one embodiment of the invention, a system for processing biomass comprises a chamber, a biomass input device, a fluid input device, and a retrieval device. The chamber is defined by at least a bottom, at least one wall, and a cover supported by the at least one wall. The biomass input device operable to deliver biomass into the chamber to form a biomass pile. The fluid input device is operable to deliver fluid into the chamber to the biomass pile. The retrieval device operable to receive fluid from the chamber.

Owner:TEXAS A&M UNIVERSITY

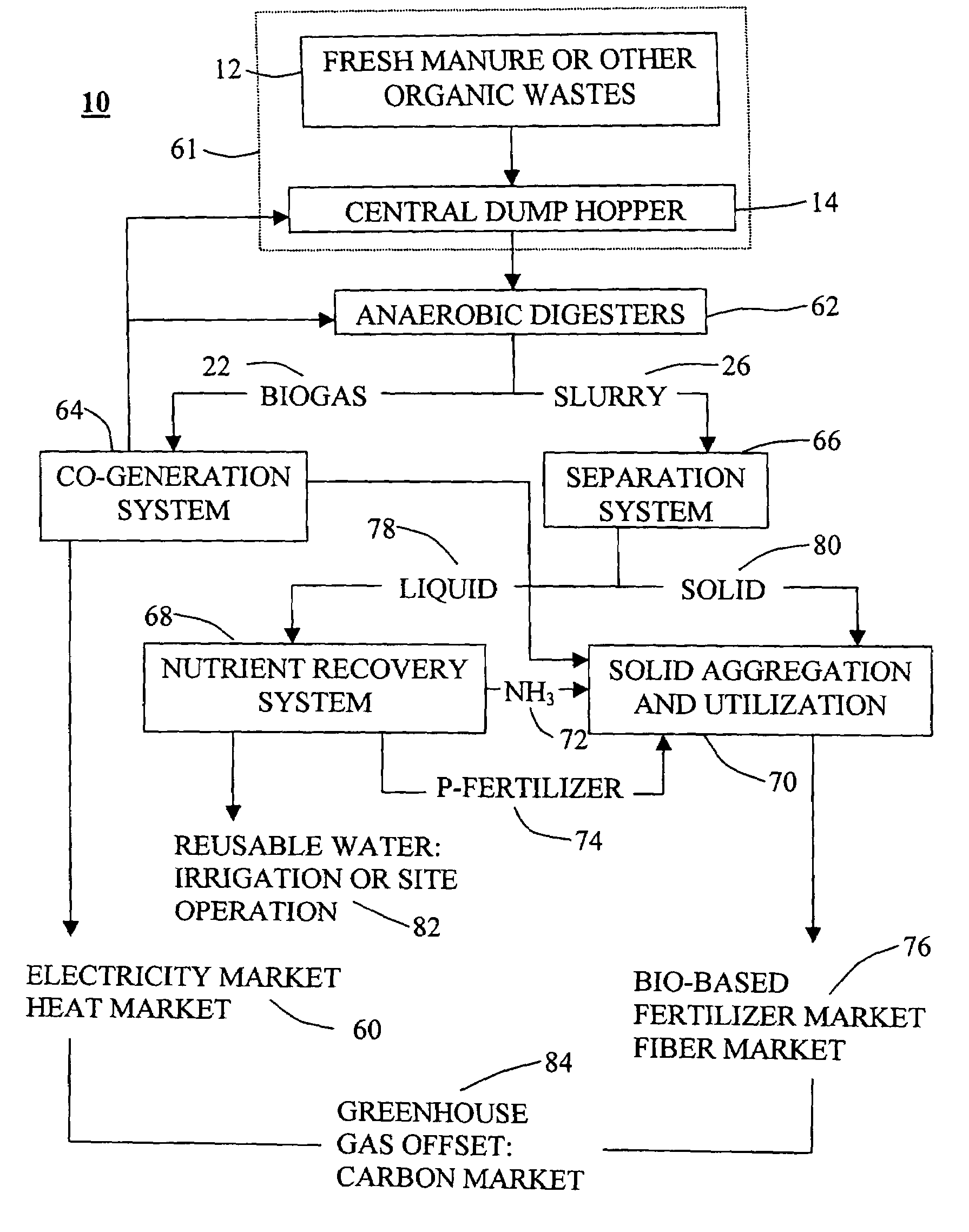

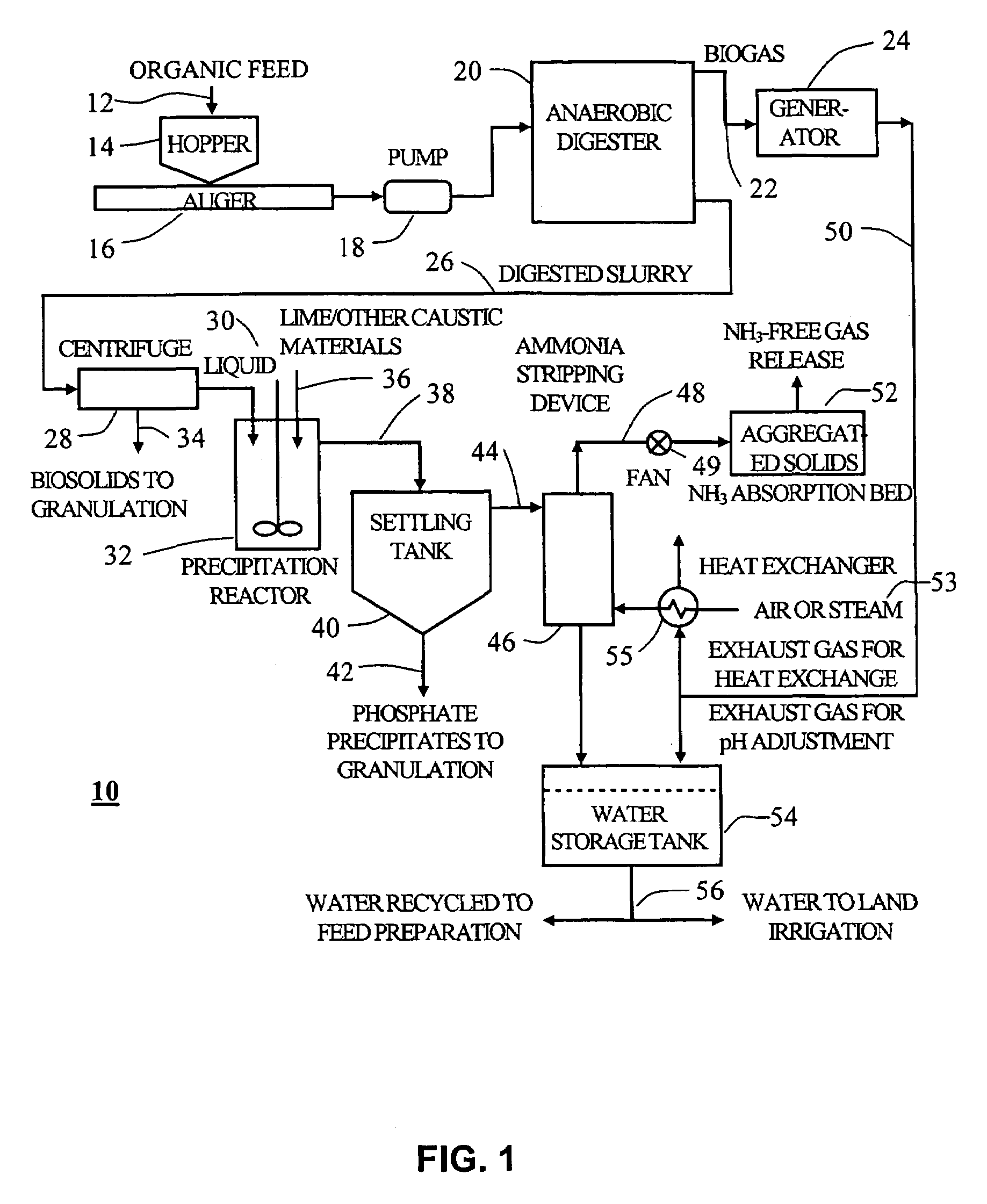

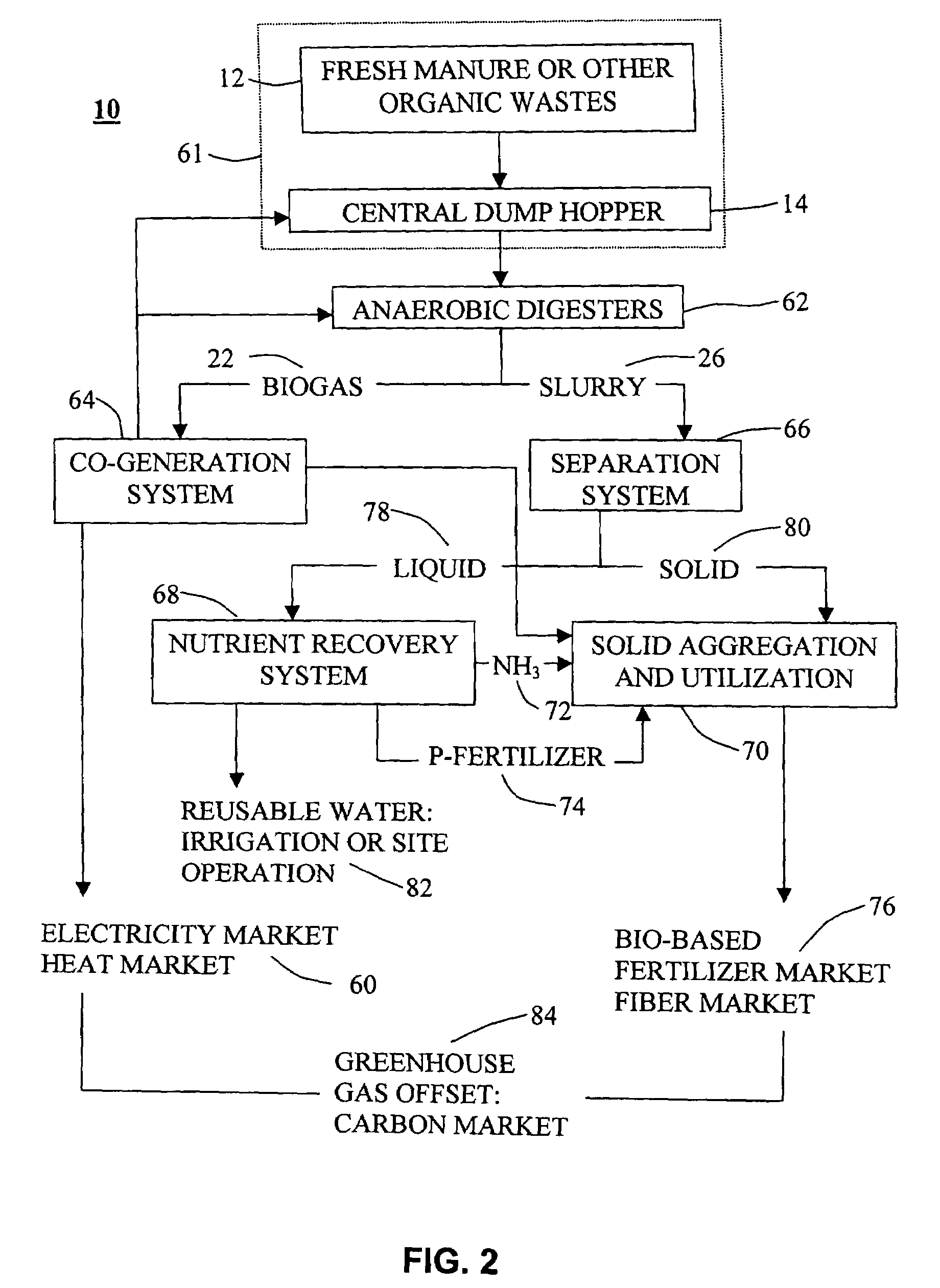

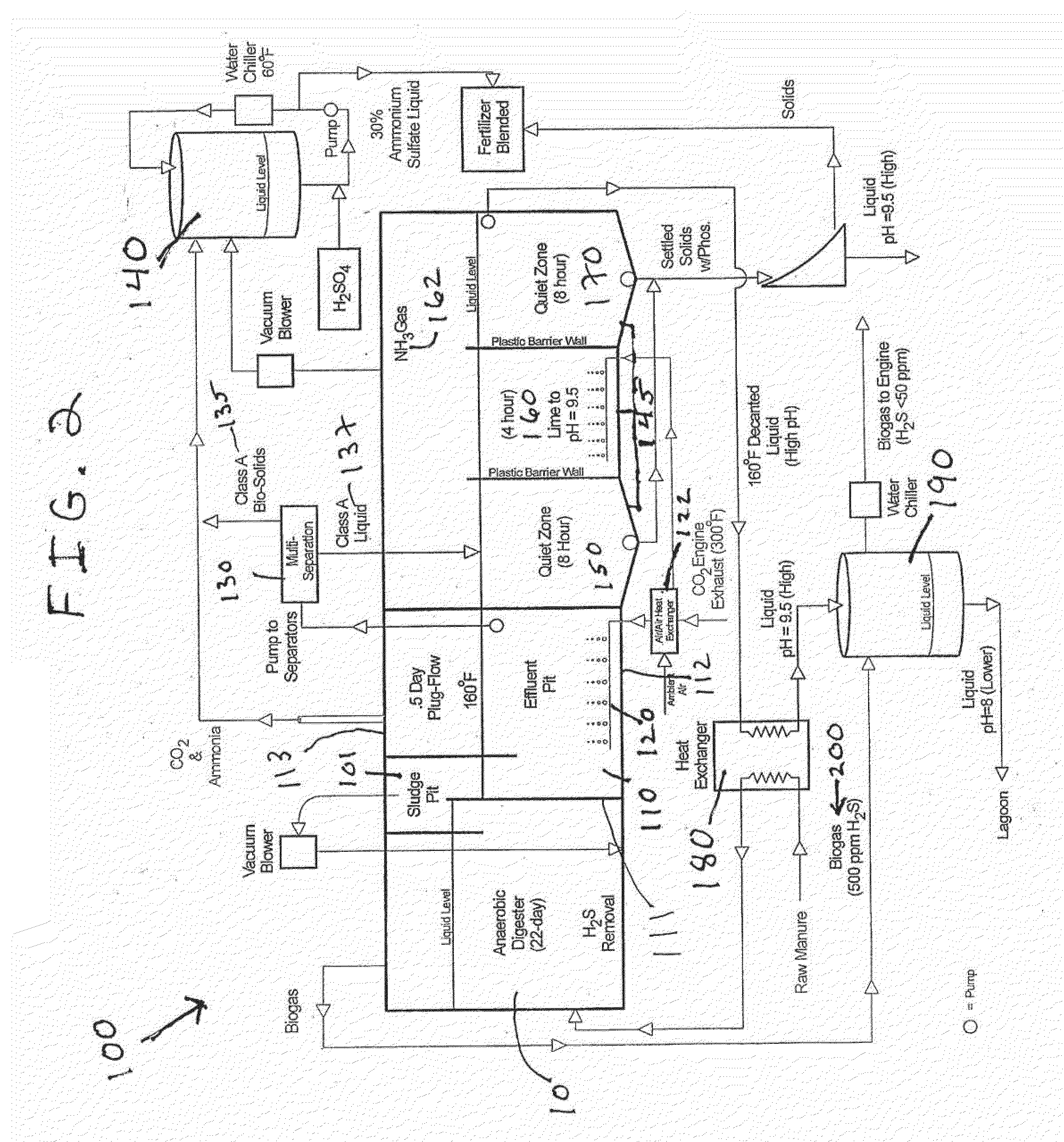

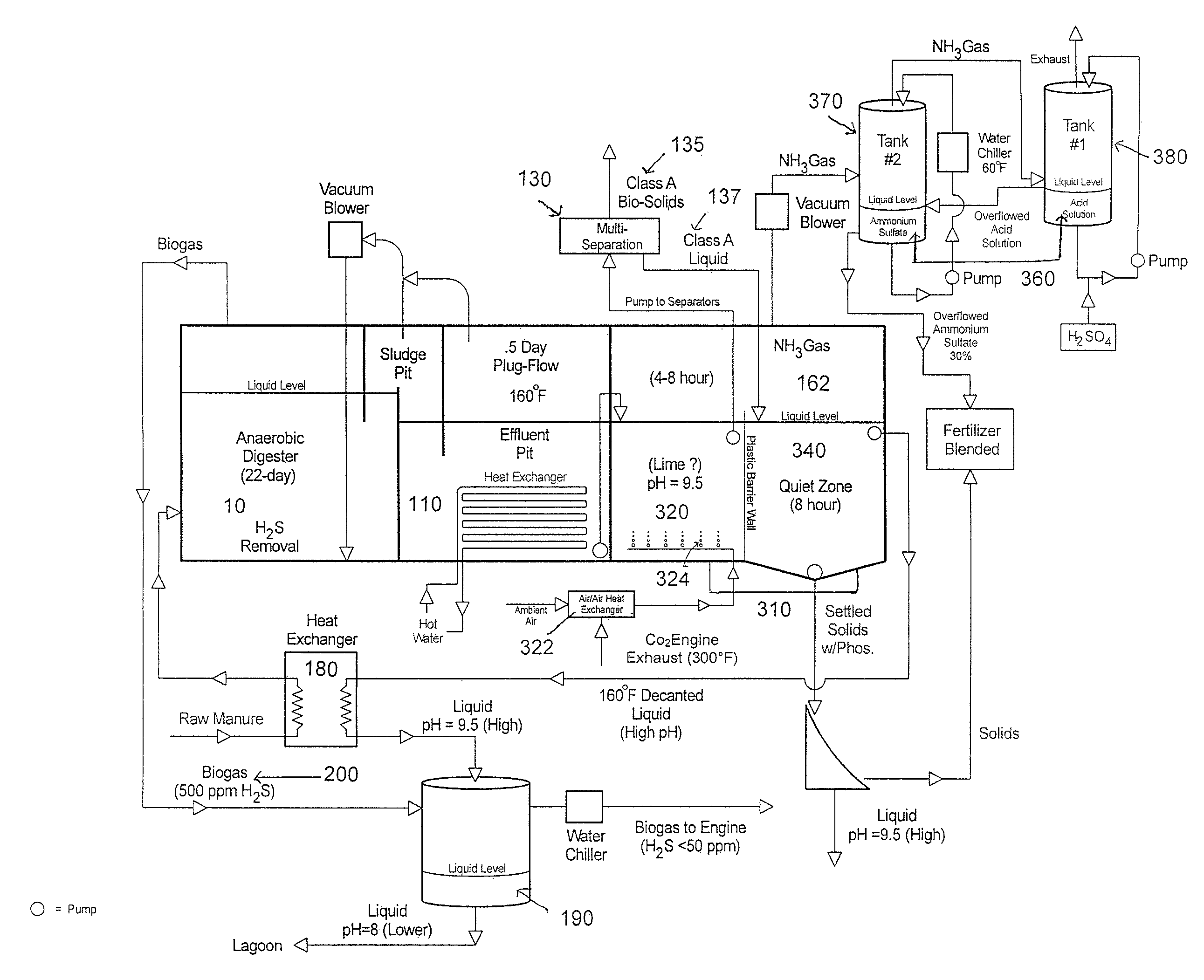

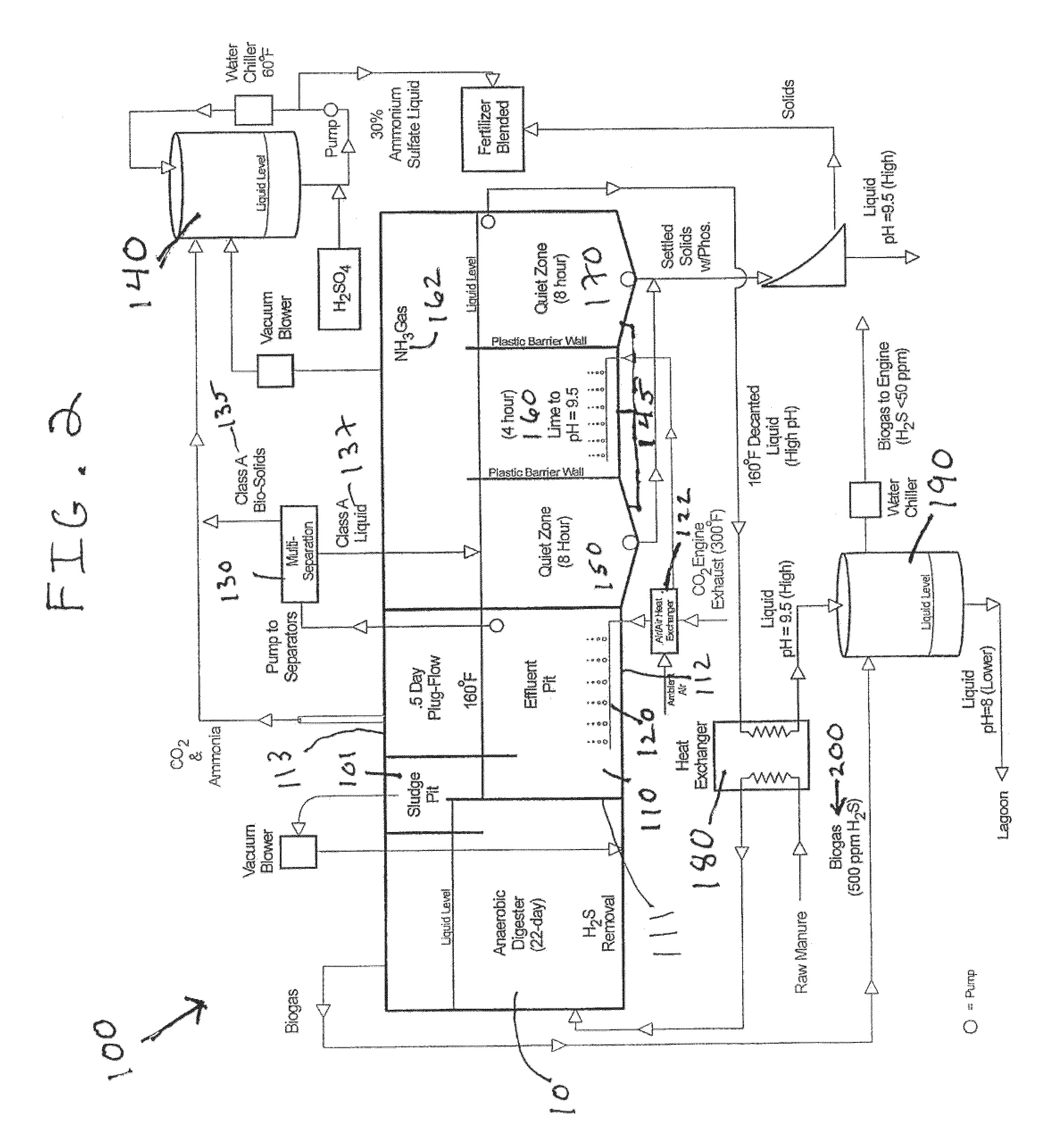

Process for removal and recovery of nutrients from digested manure or other organic wastes

InactiveUS7014768B2Eliminate the effects ofIncrease temperatureBioreactor/fermenter combinationsBio-organic fraction processingCogenerationNitrogen gas

A process for removal and recovery of nutrients and recycling of water from digested manure or other organic wastes. A first step involves separating waste from an anaerobic digester into digested liquids, digested solids, and biogas. A second step involves precipitating solids from the digested liquids. A third step involves stripping ammonia from the digested liquids. A fourth step involves injecting an exhaust stream of carbon dioxide drawn from the co-generator into the digested liquids to reduce the pH and raise the temperature of the digested liquid. A fifth step involves recycling the digested liquids back to the anaerobic digester for use in diluting in coming solid wastes. A sixth step involves passing the excess ammonia stripped from the digested liquid through the digested solids to recover nitrogen through aborption with the resultant digested solids being usable as a biofertilizer with a high nitrogen content. A seventh step involves capturing the biogas for use in a co-generation system.

Owner:HIGHMARK RENEWABLES RES PARTNERSHIP

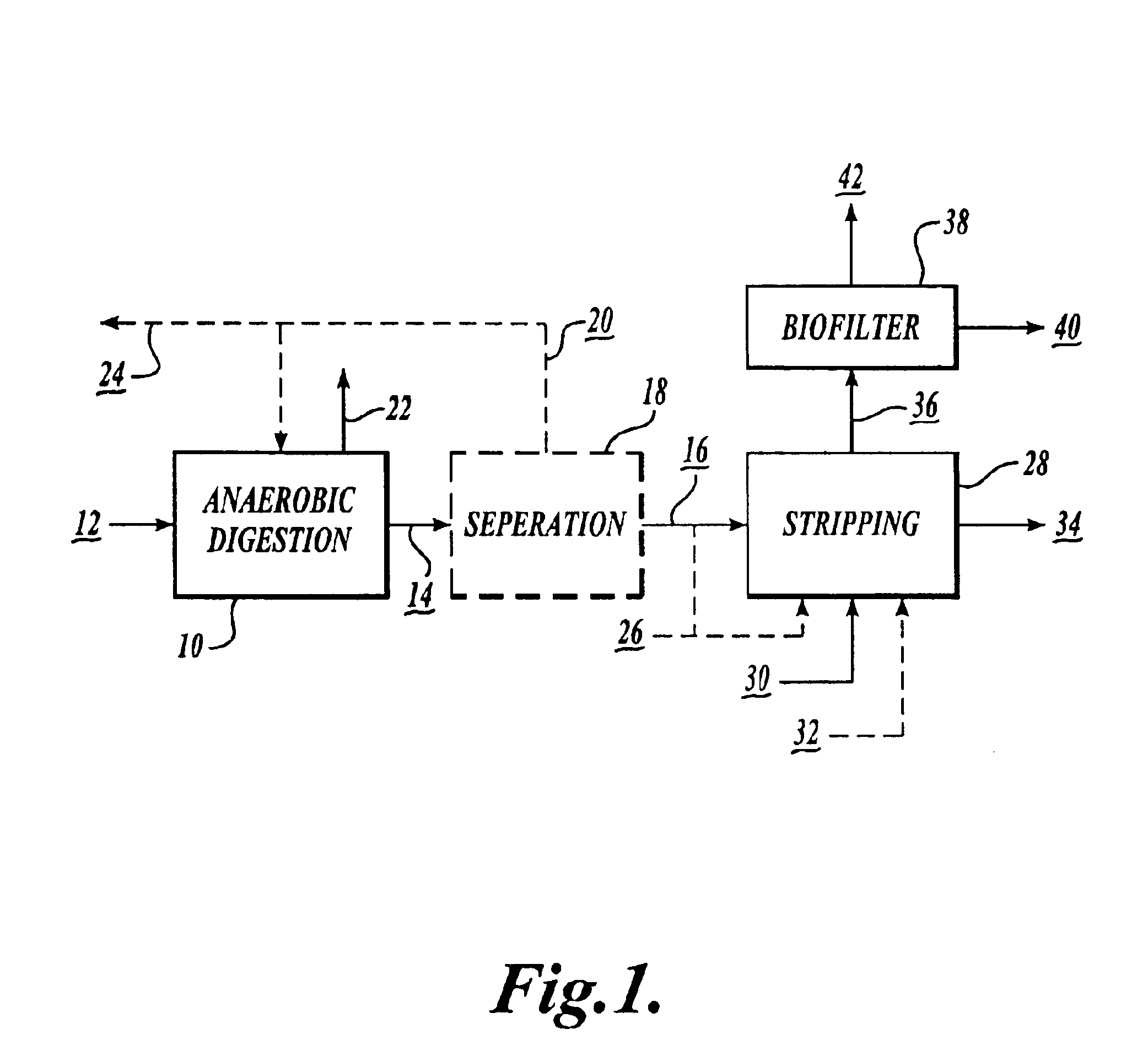

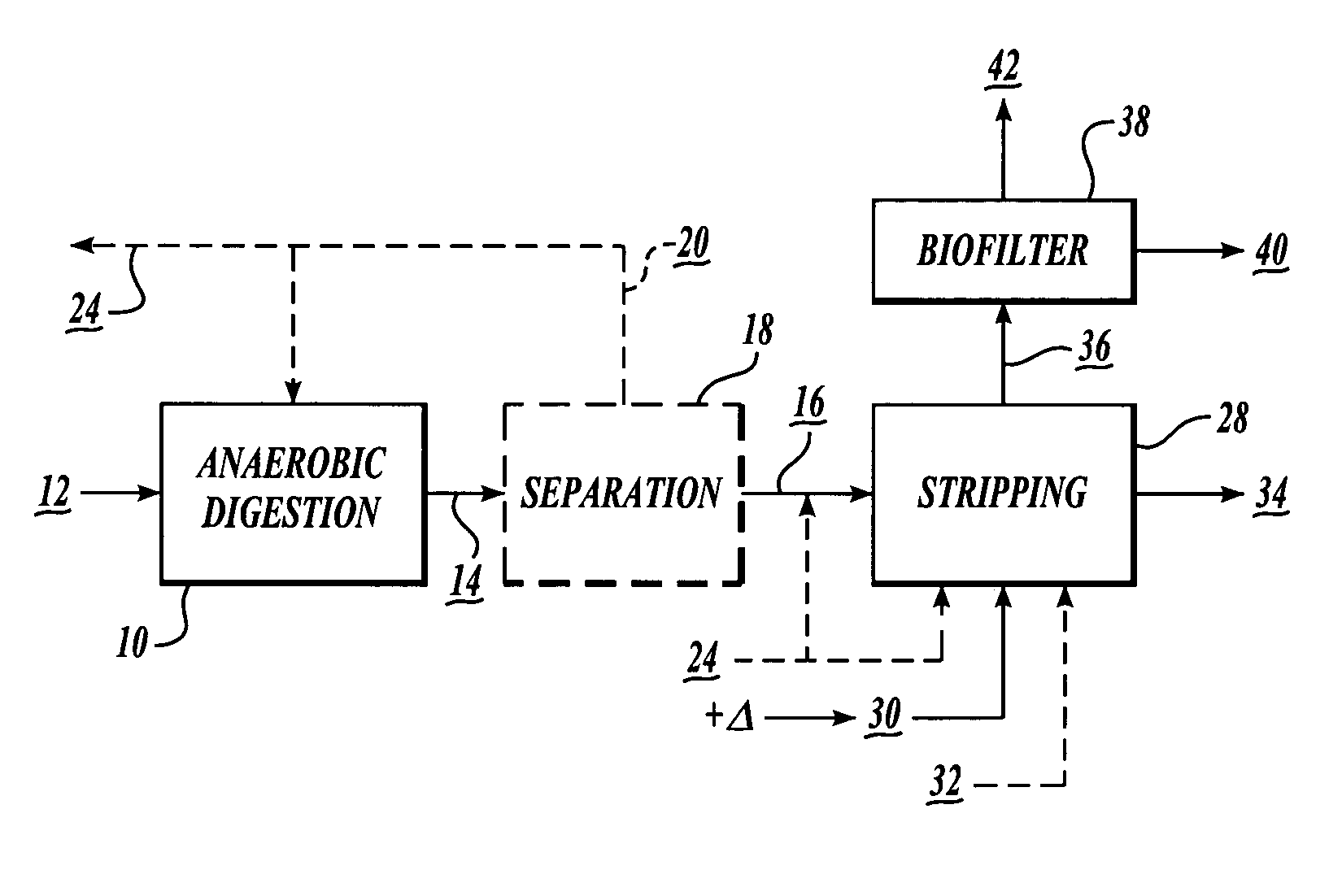

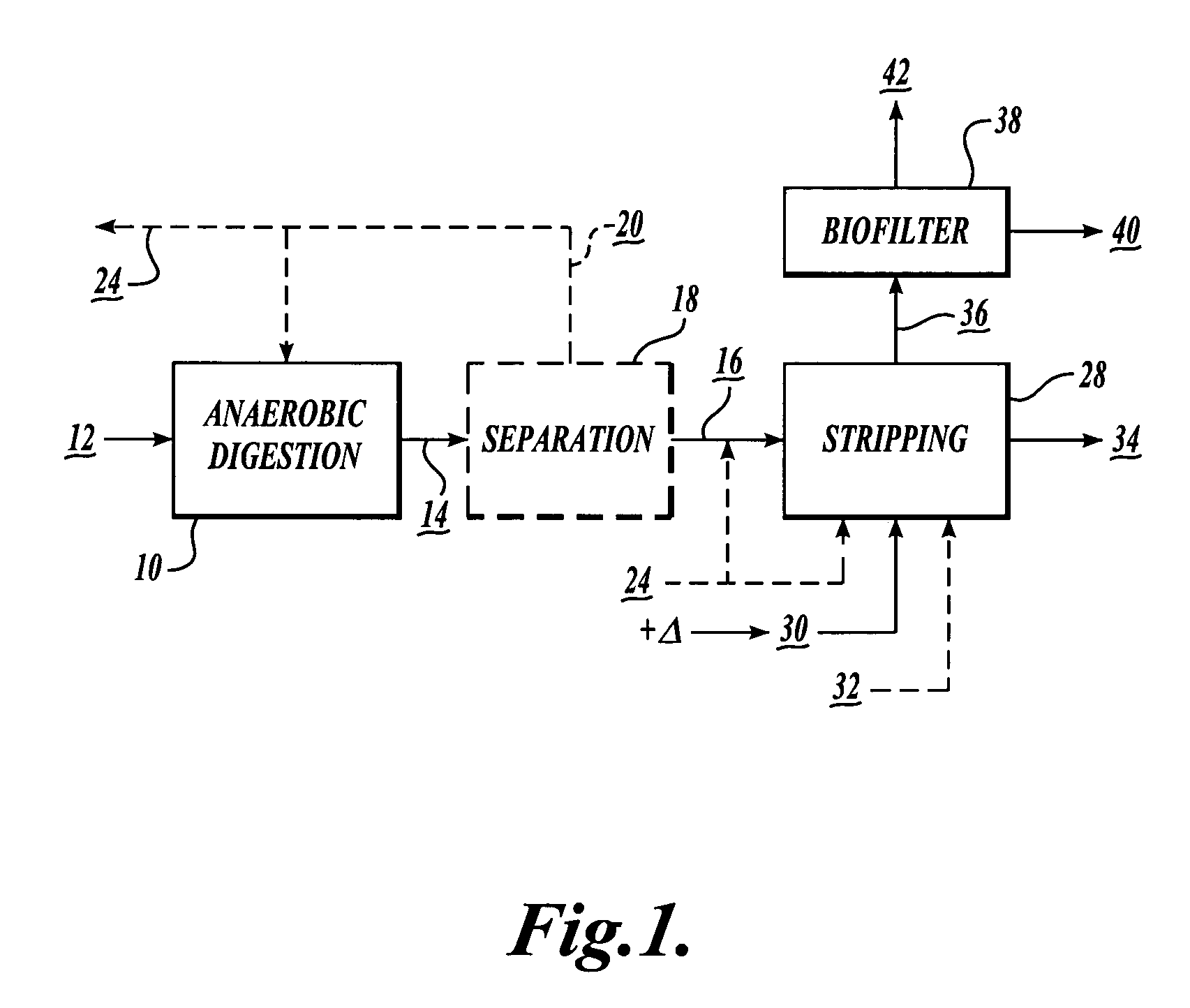

Nitrogen recovery system and method

InactiveUS6866779B1Less greenhouse gasGood health benefitsBio-organic fraction processingCyanogen compoundsLiquid wasteNitrate

A process for the recovery of nitrogen from anaerobically digested liquid waste and for the collection of the nitrogen as nitrate compounds that can be used to produce fertilizer and compost, includes stripping ammonia from anaerobically digested liquid waste, and converting the ammonia into nitrates via nitrification.

Owner:ENVIRONMENTAL ENERGY & ENG

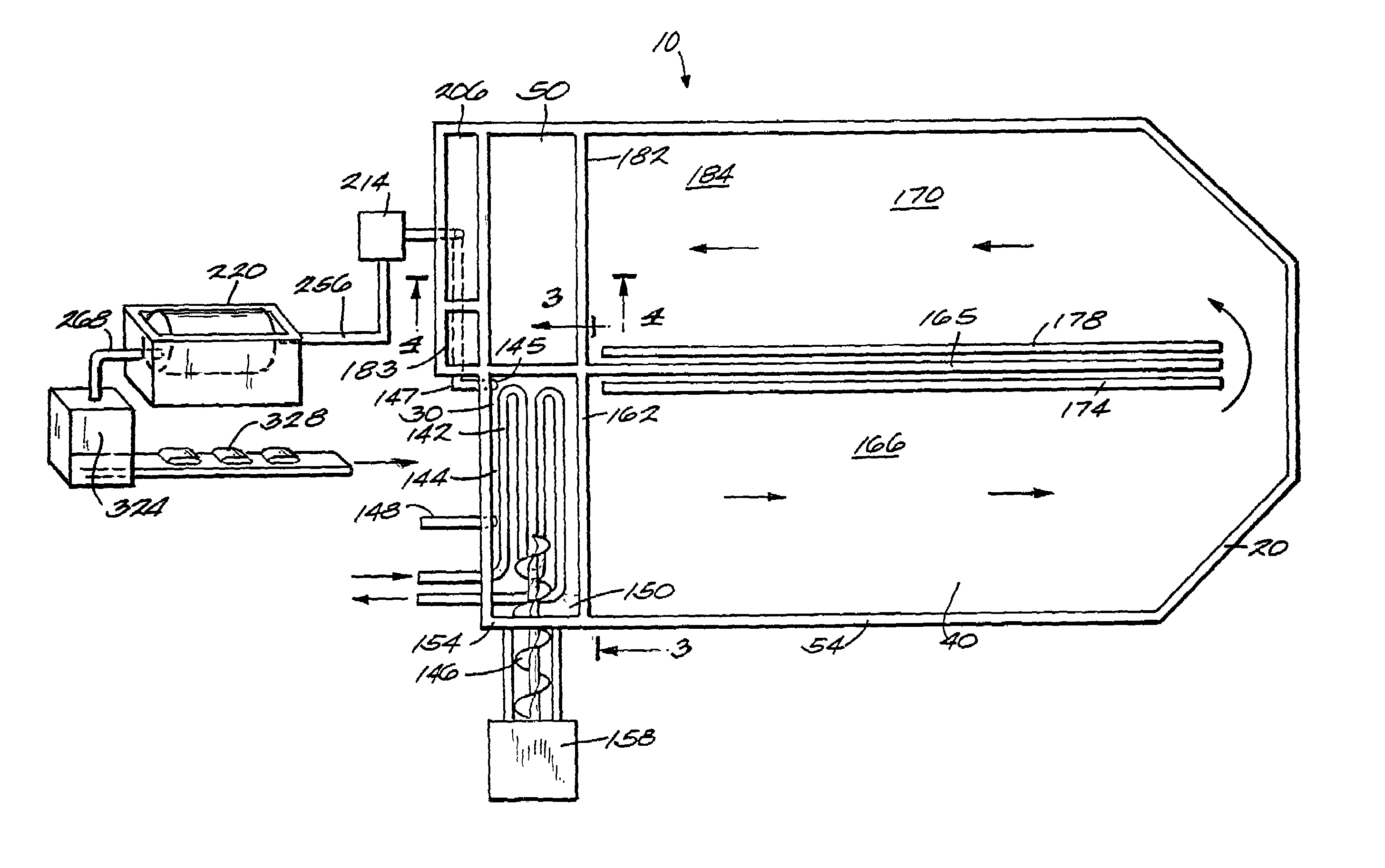

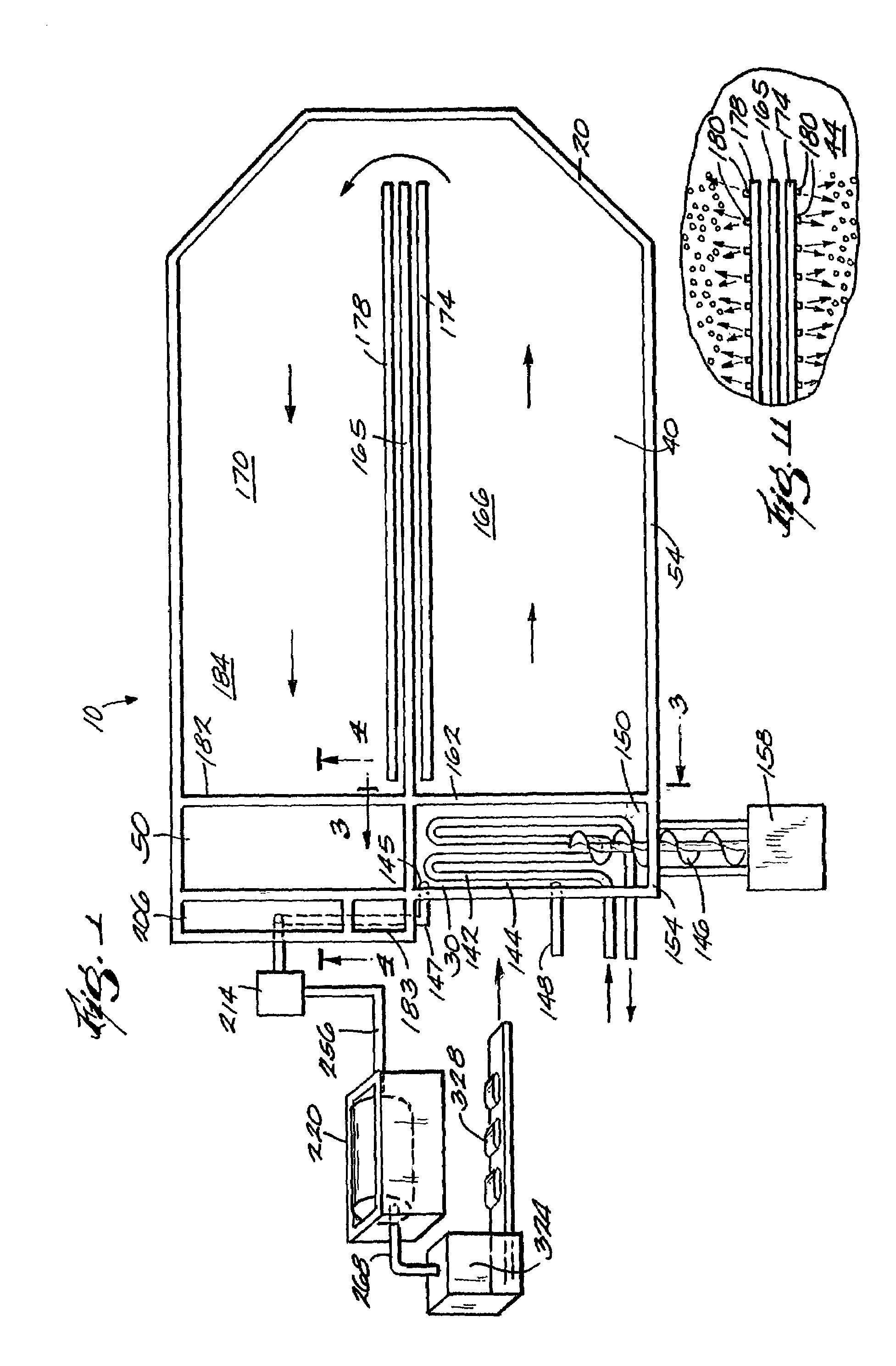

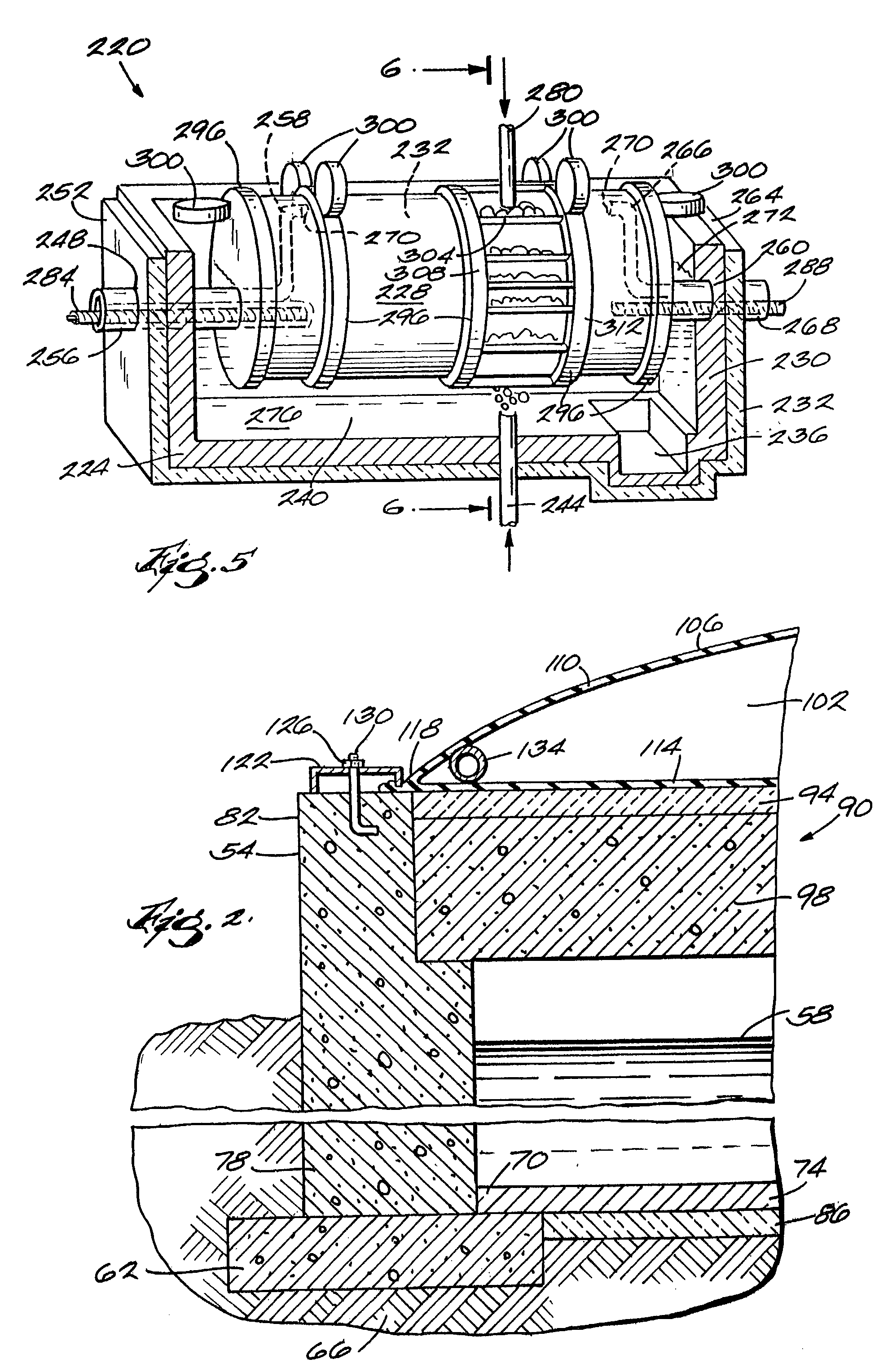

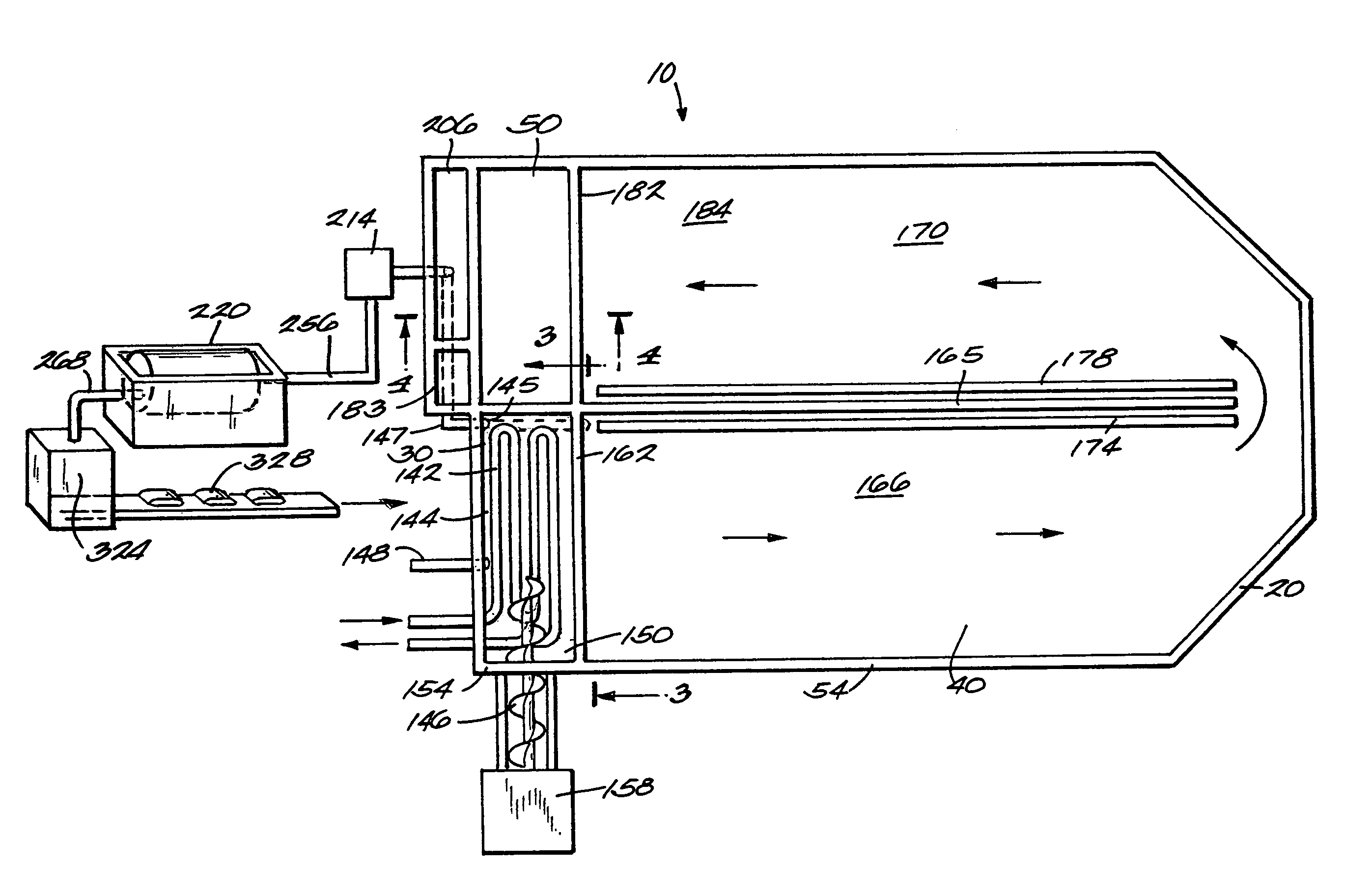

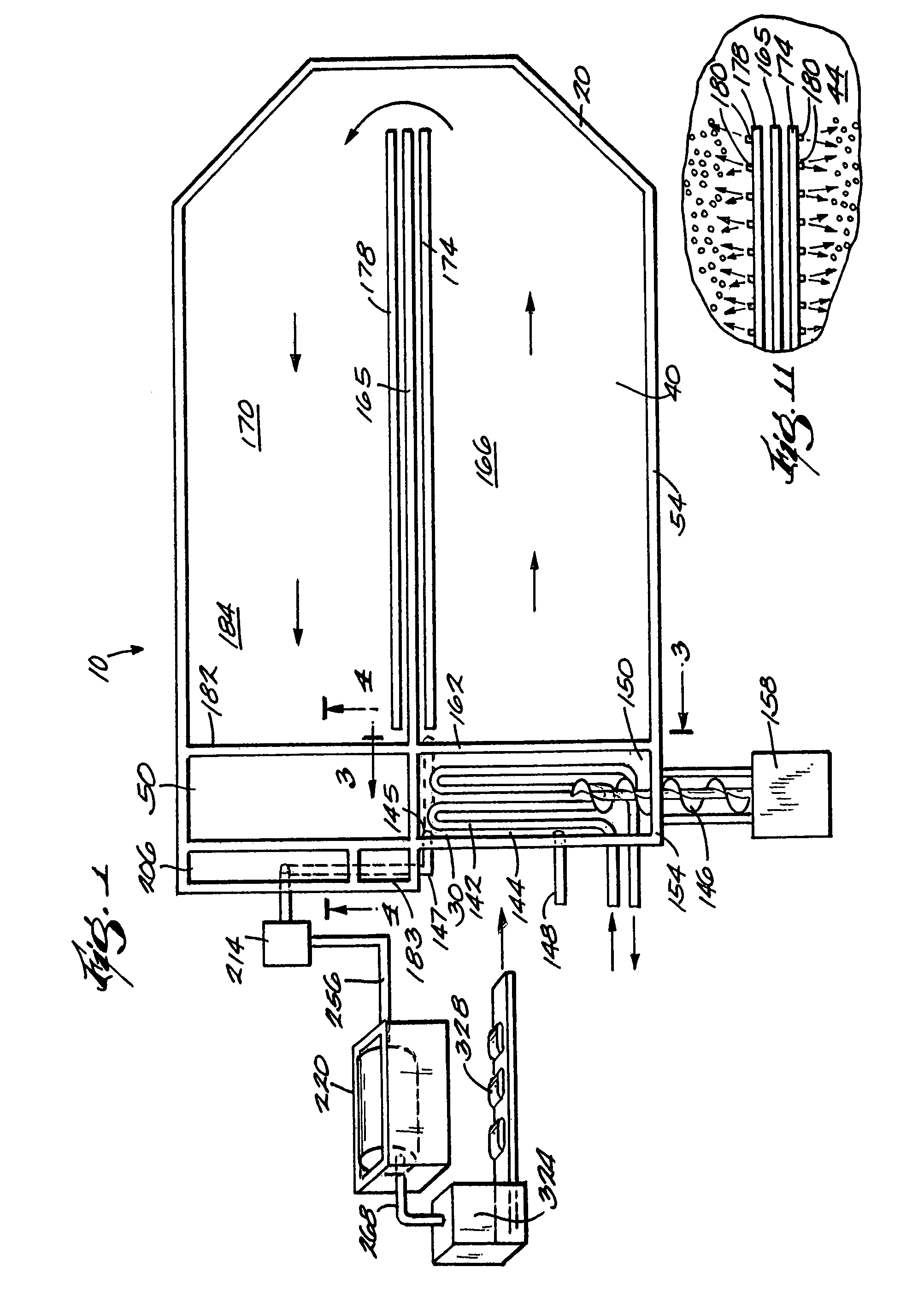

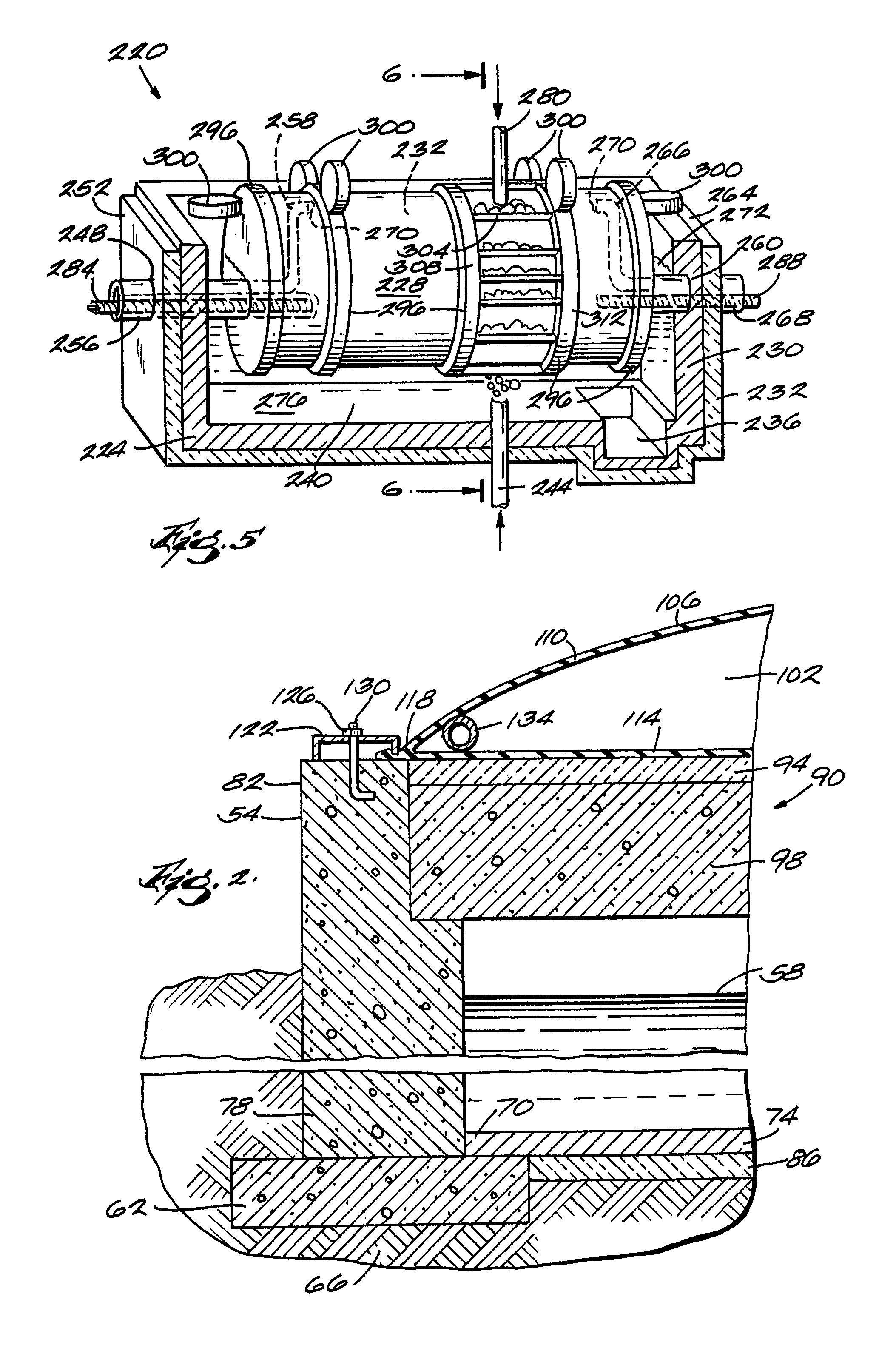

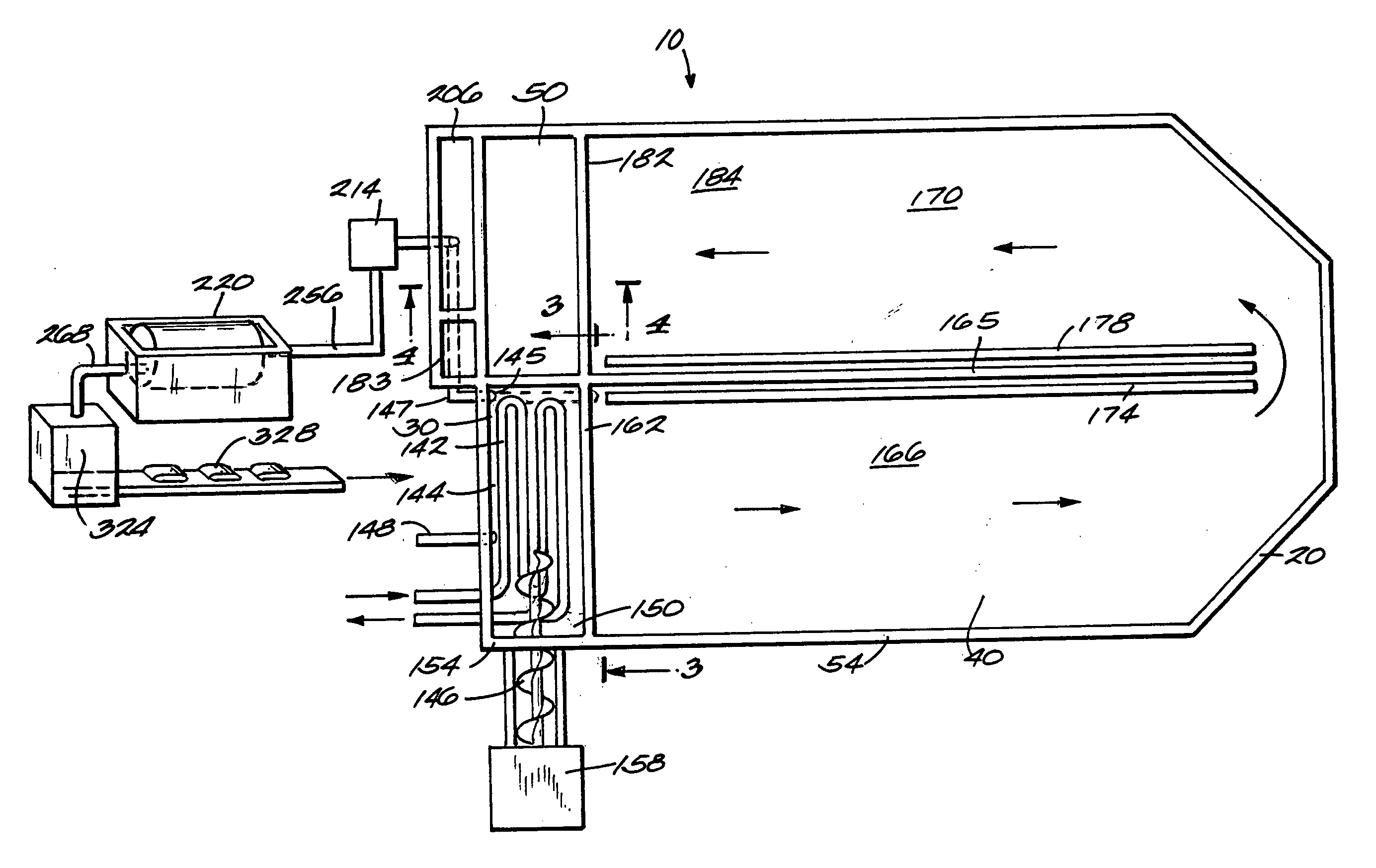

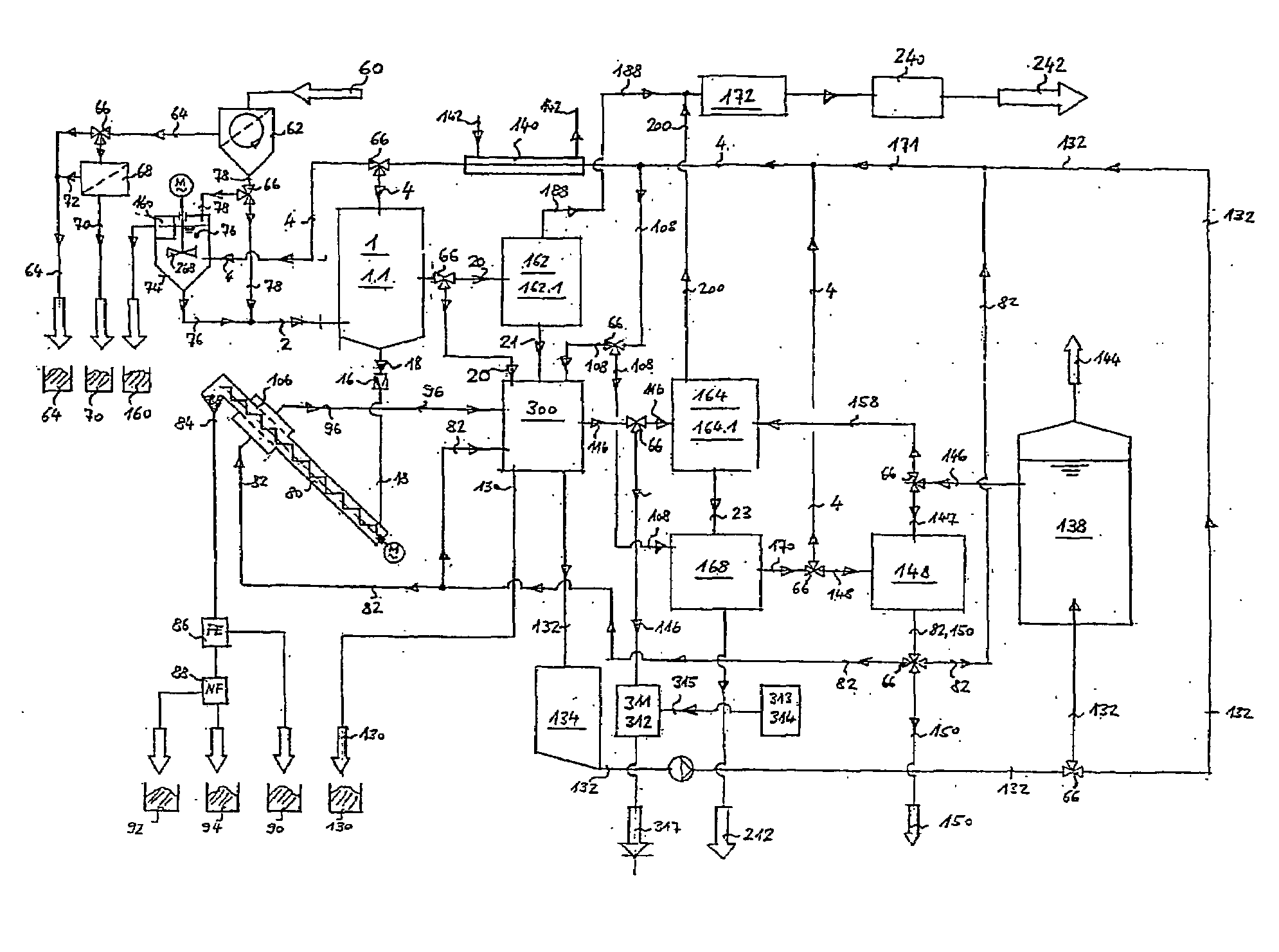

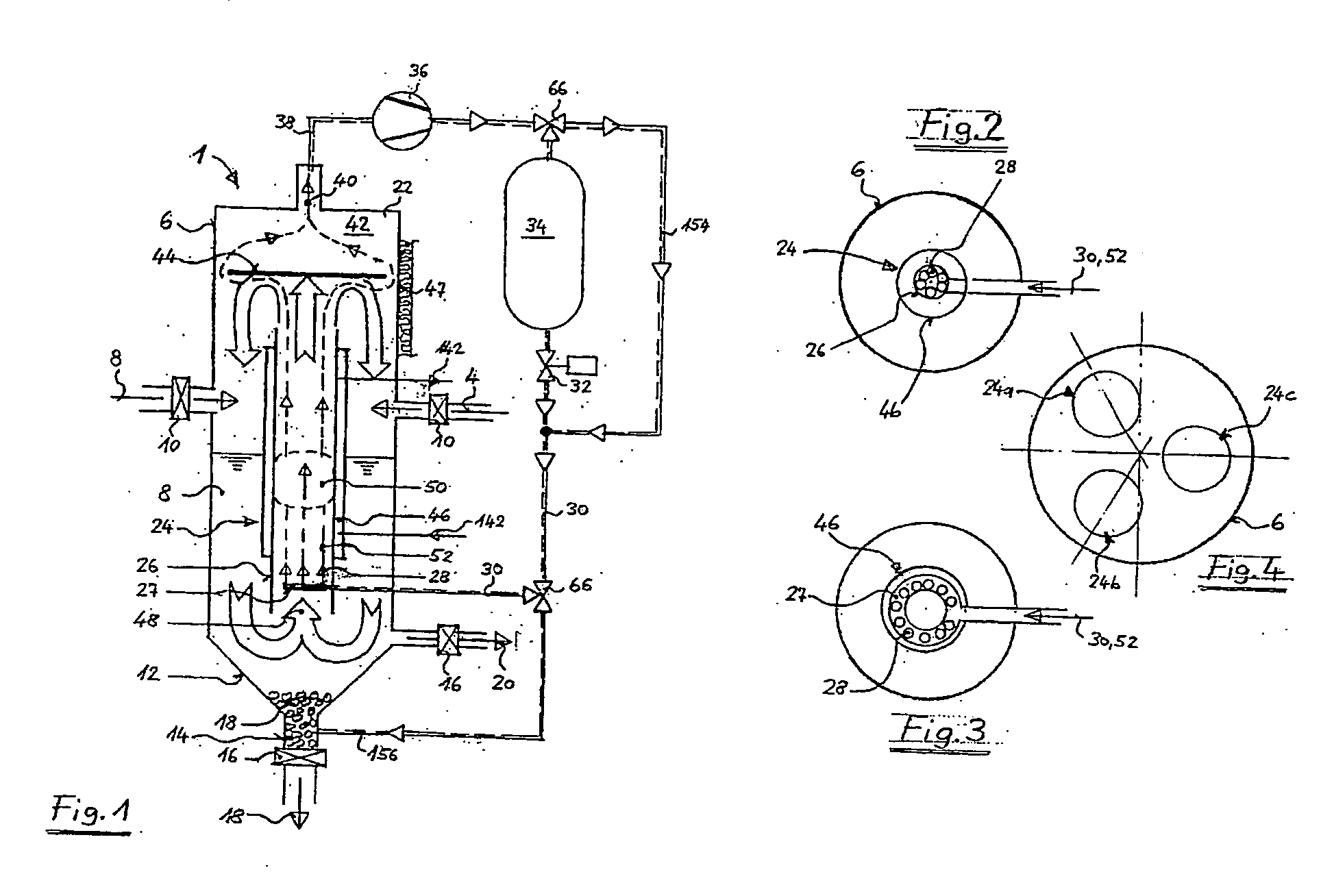

Method and apparatus for solids processing

InactiveUS7078229B2Minimize end waste productMaximize energy efficiencyBioreactor/fermenter combinationsBio-organic fraction processingWaste processingProcess engineering

This invention provides a waste-processing system capable of processing high-solids wastes such as manure. This invention provides a compact U-shaped digester that allows for recycling of activated sludge to improve the efficiency of the process. Efficiency is also improved through a sludge heating design that creates a current in the digester and efficiently heats the sludge. A composter is provided to further process the sludge through aerobic digestion to create usable fertilizer. Finally, one embodiment provides a turbine that is fueled by biological gases from the digester to generate heat and electricity to be used by the system.

Owner:DVO LICENSING

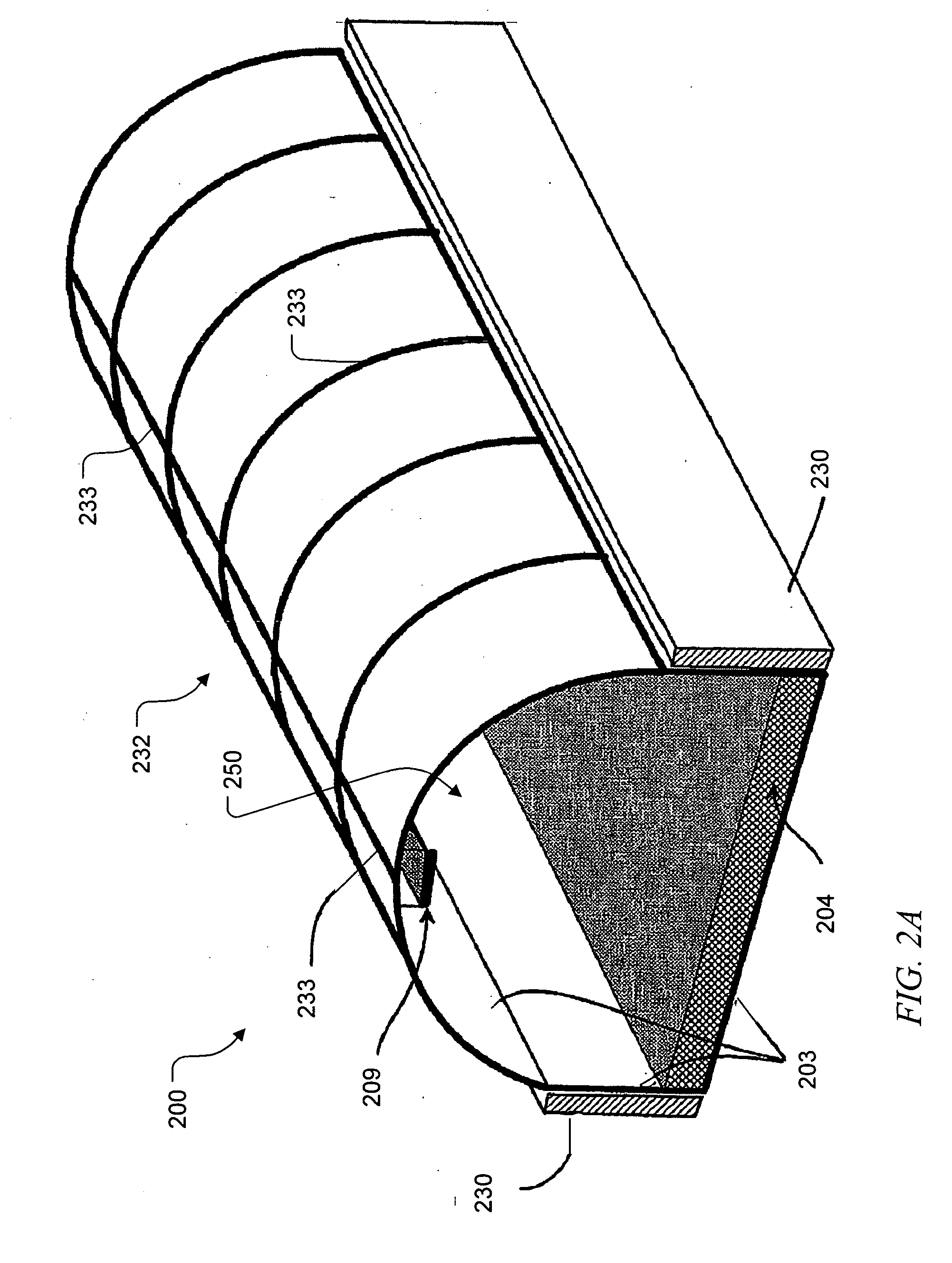

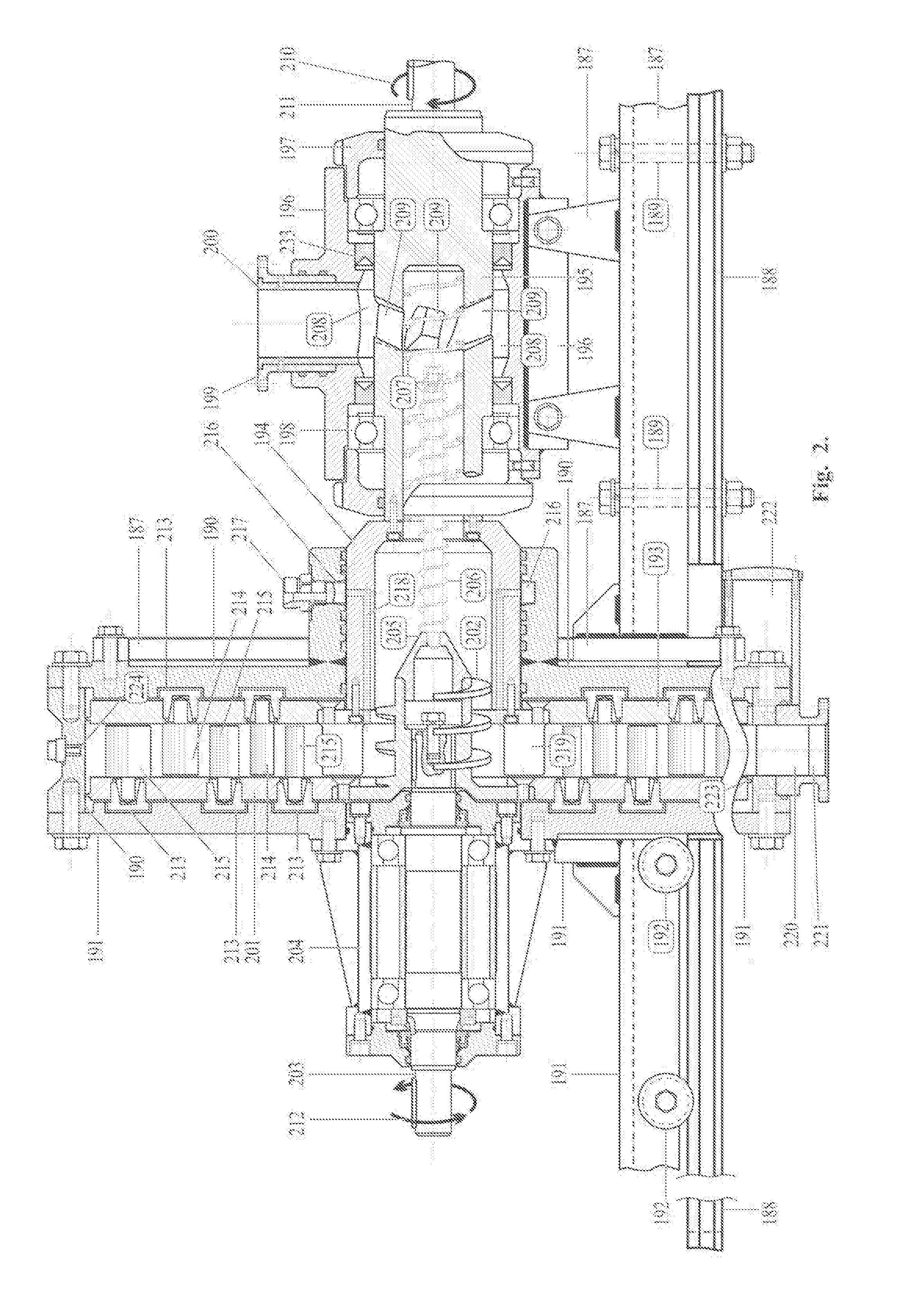

Method and apparatus for solids processing

InactiveUS7179642B2Bioreactor/fermenter combinationsBio-organic fraction processingAnaerobic digestionWaste management

Owner:DVO LICENSING

Method and apparatus for solids processing

InactiveUS20040087011A1Bioreactor/fermenter combinationsBio-organic fraction processingWaste managementAnaerobic digestion

Apparatuses and methods for anaerobic digestion of high-solids waste are provided. The methods may include and the apparatuses may be used for moving the solid waste in a corkscrew-like fashion through a closed container. The method may further include moving the high-solids waste into contact with a heating device to facilitate the corkscrew-like movement. Other methods and apparatuses may use at least one of a partition and a conduit from which liquid or gas is discharged.

Owner:DVO LICENSING

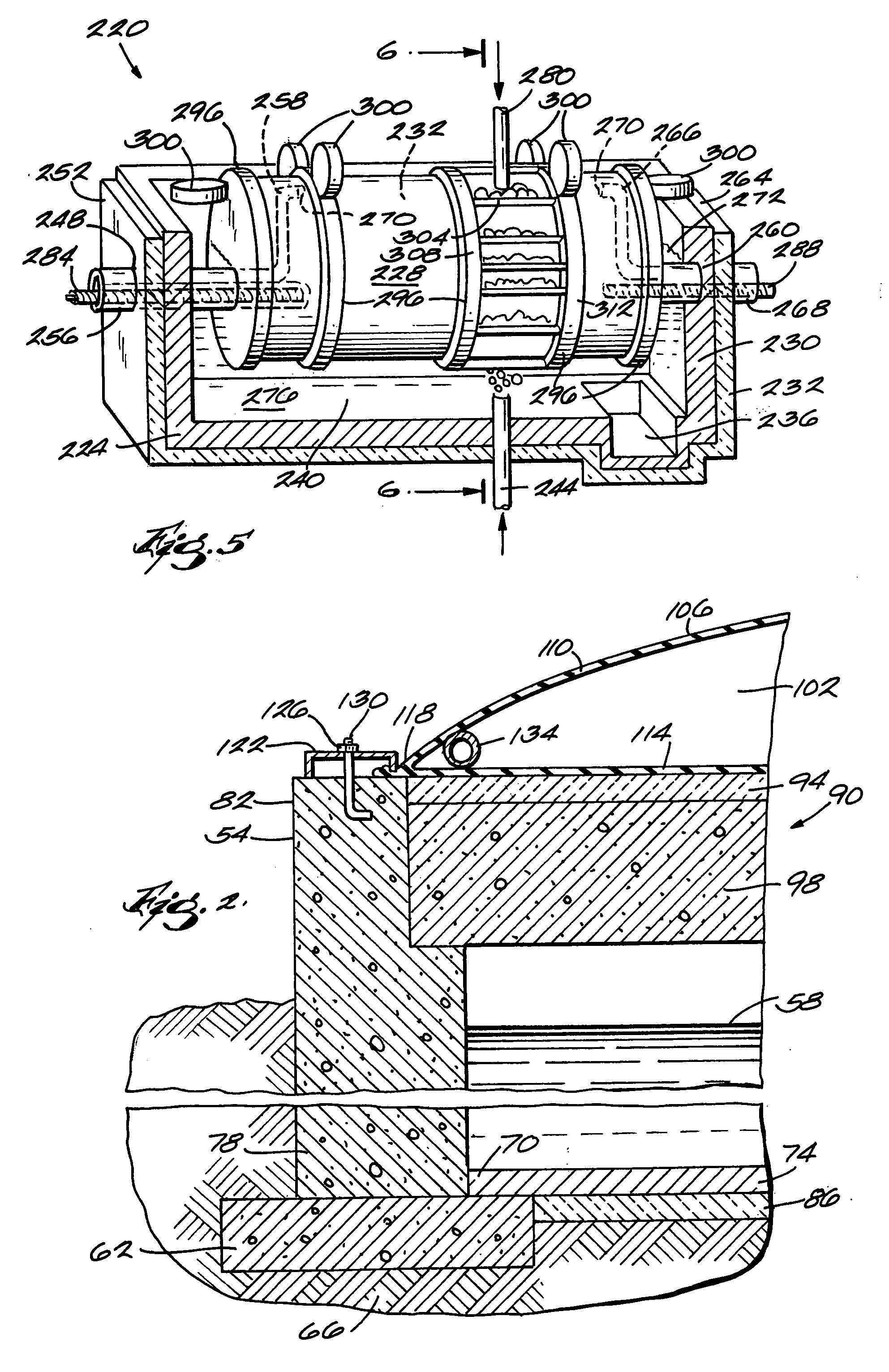

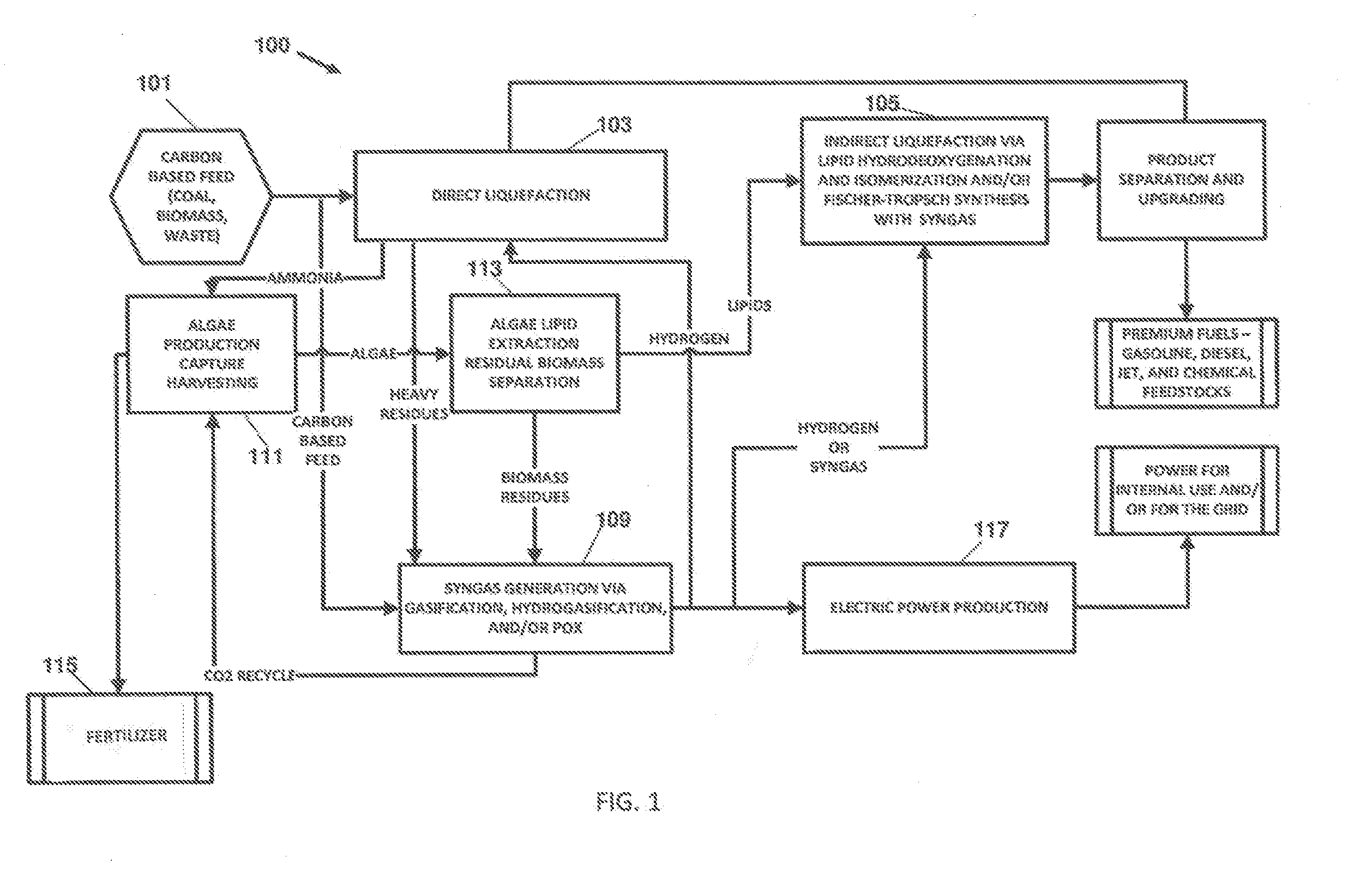

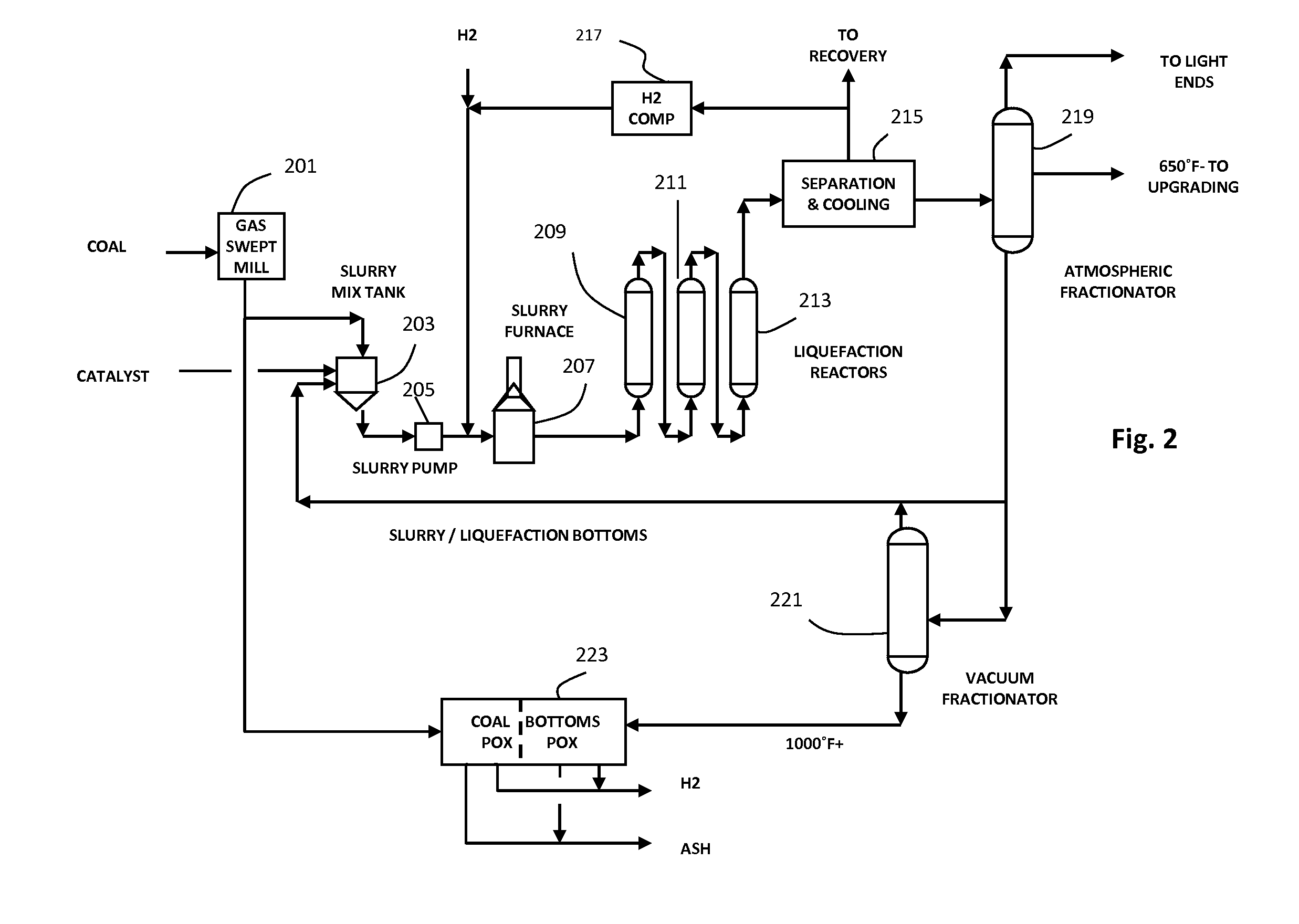

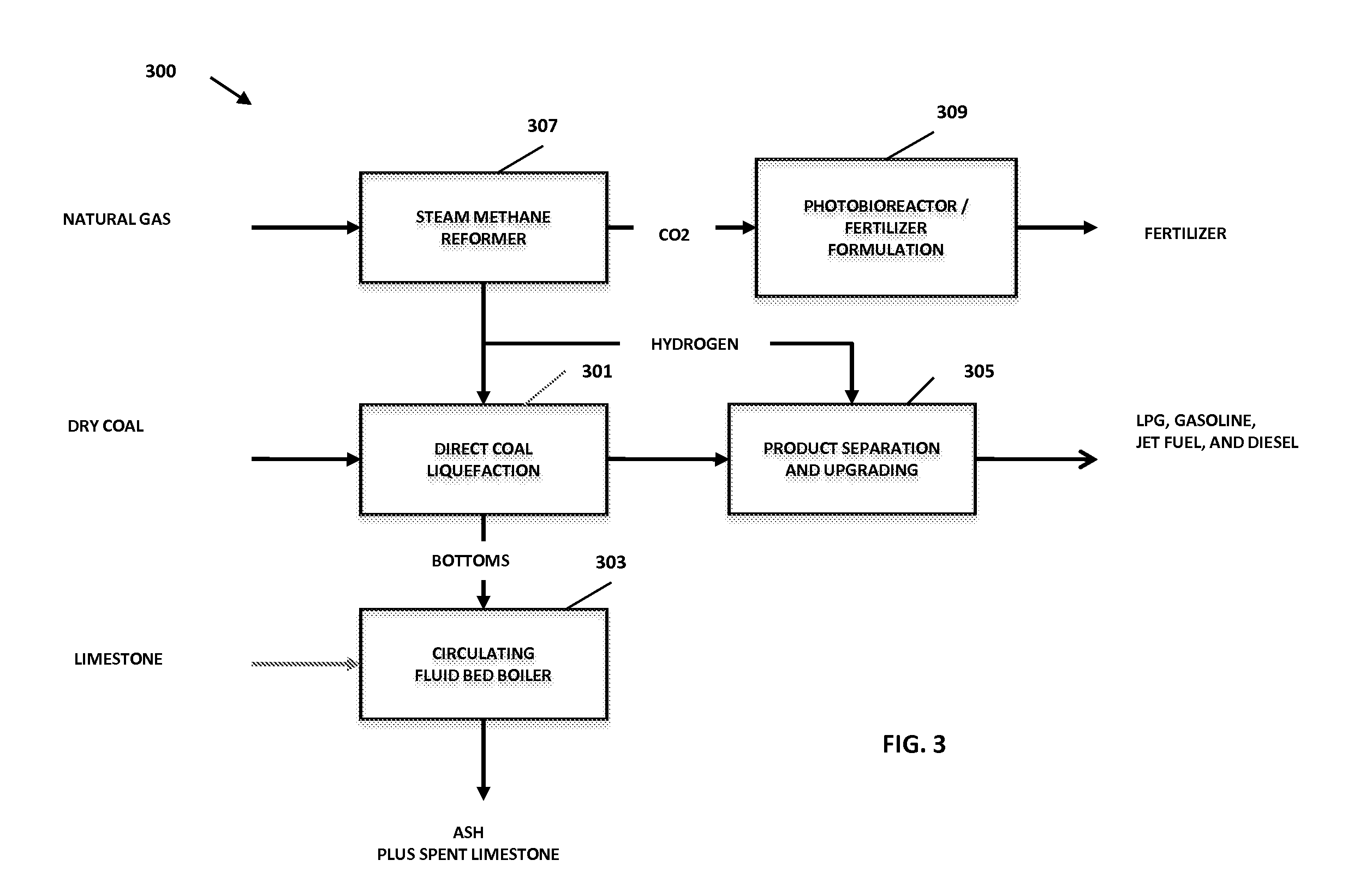

Integrated Coal To Liquids Process And System With Co2 Mitigation Using Algal Biomass

InactiveUS20120144887A1High thermal efficiencyReduced footprintBioreactor/fermenter combinationsBio-organic fraction processingMethane reformerSyngas

An ICBTL system having a low GHG footprint for converting coal or coal and biomass to liquid fuels in which a carbon-based feed is converted to liquids by direct liquefaction and optionally by indirect liquefaction and the liquids are upgraded to produce premium fuels. CO2 produced by the process is used to produce algal biomass and photosynthetic microorganisms in a photobioreactor. Optionally, lipids extracted from the some or all of the algal biomass is hydroprocessed to produce fuel components and biomass residues and the carbon-based feed our gasified to produce hydrogen and syngas for the direct and indirect liquefaction processes. Some or all of the algal biomass and photosynthetic microorganisms are used to produce a natural biofertilizer. CO2 may also be produced by a steam methane reformer for supplying CO2 to produce the algal biomass and photosynthetic microorganisms.

Owner:ACCELERGY CORP

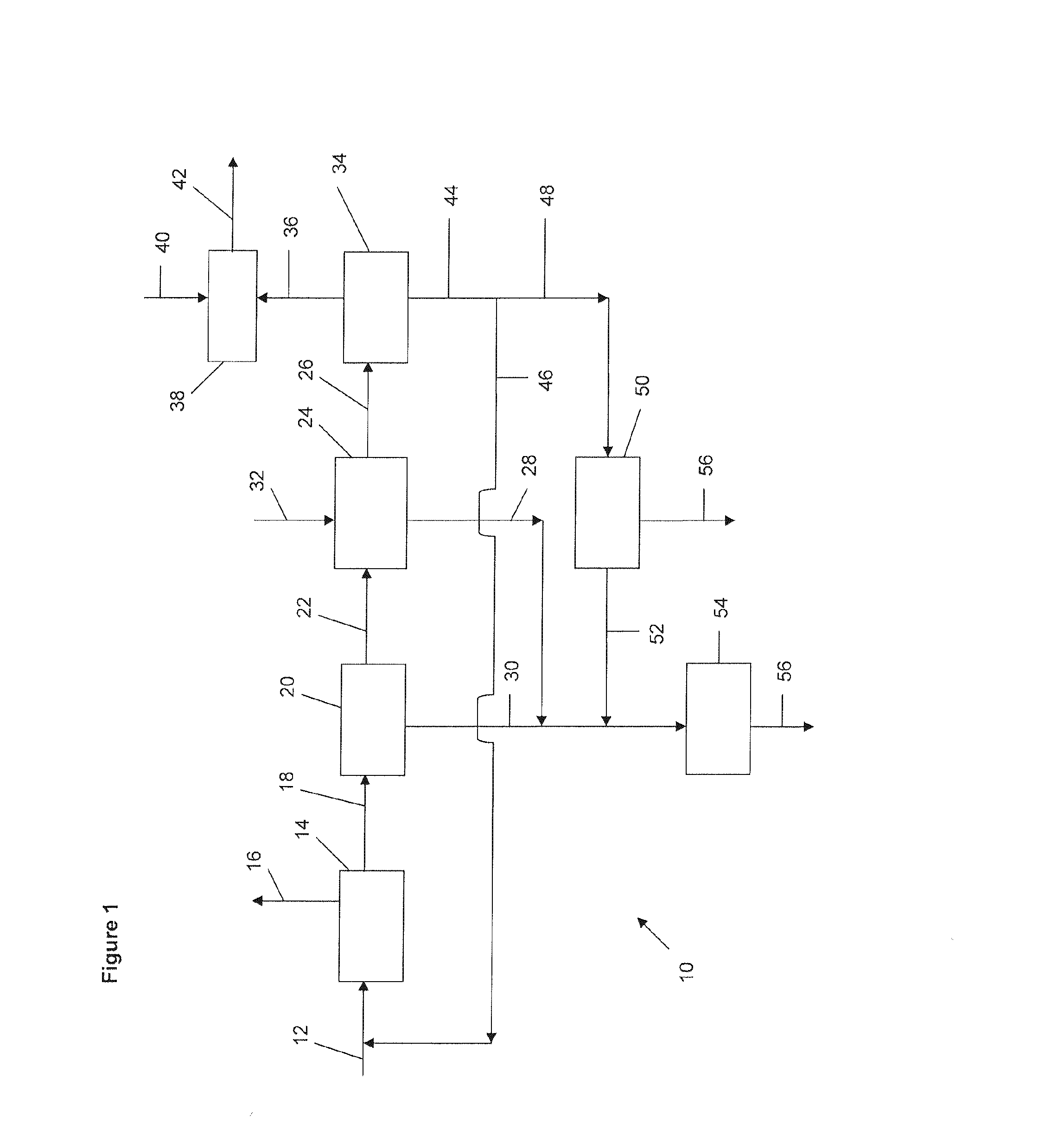

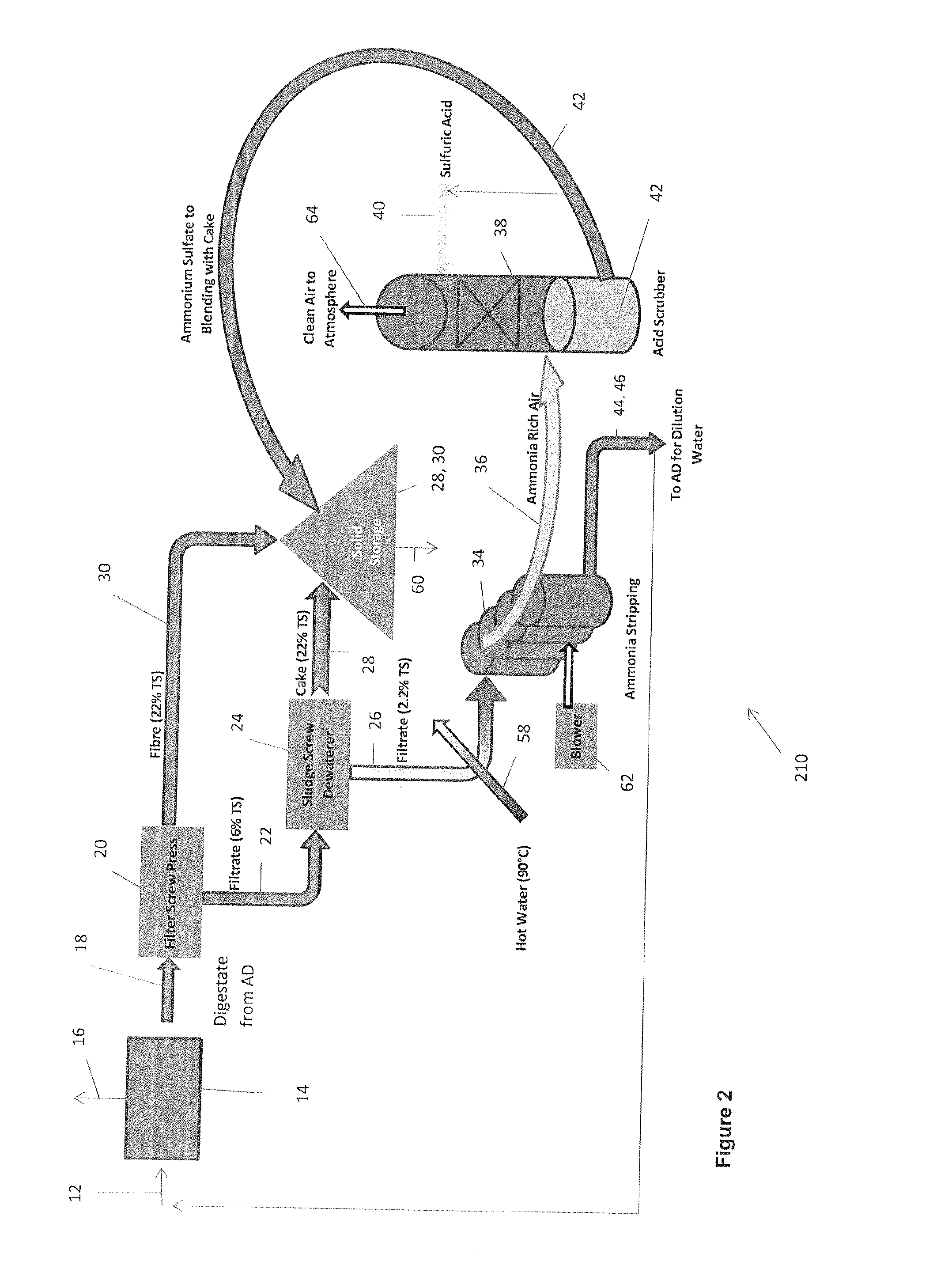

Organics and nutrient recovery from anaerobic digester residues

Sludge from an anaerobic digester is treated to recover one or more of fibers, or solids or liquids with a high nutrient content. The solids or liquids can be used as a fertilizer. The fibers can be used in a plant growing medium. Solids are separated from liquids in the sludge and dried. The solids may be dried to produce a flake or pellet. Ammonia in the liquids is recovered and used to produce a concentrated acidic ammonium salt solution. This solution may be mixed with the solids to produce a nitrogen enhanced solid. The fibers and solids or liquids can also be used in combination to produce an enhanced plant growing medium. A device and process for removing ammonia from a liquid can be used in the system or separately.

Owner:ANAERGIA

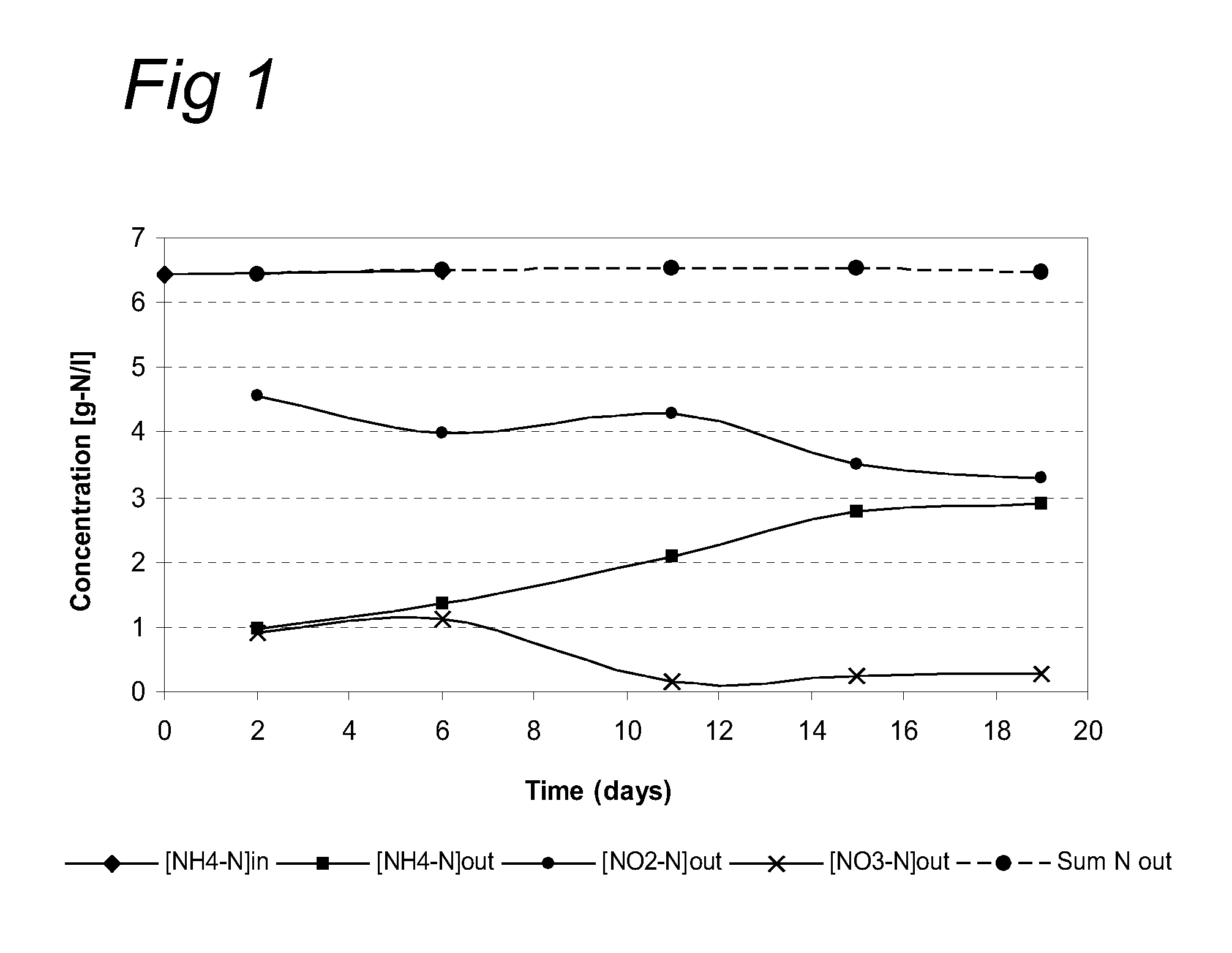

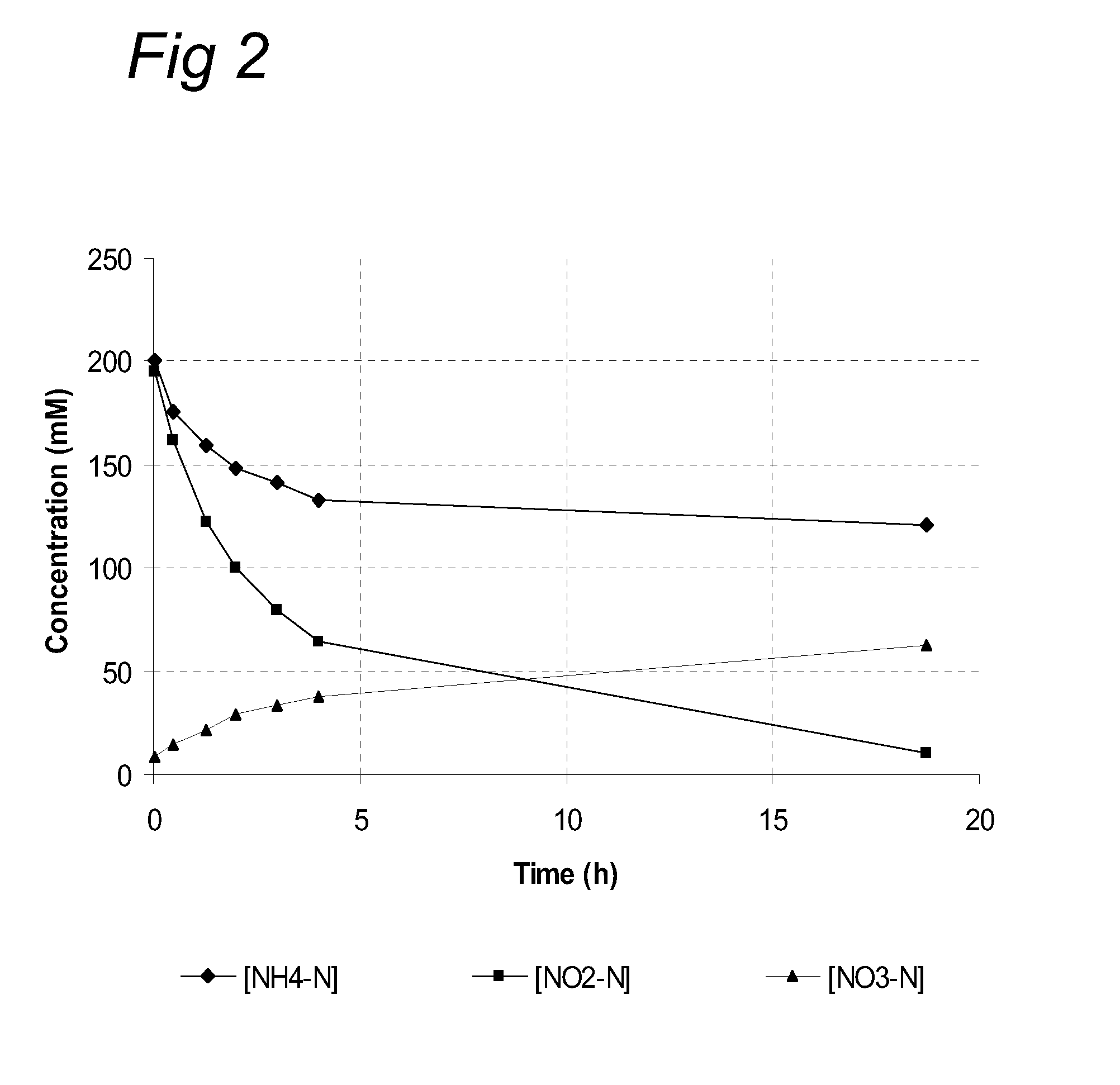

Process for the conversion of liquid waste biomass into a fertilizer product

InactiveUS20090282882A1Minimizing energyIncrease percentageBioreactor/fermenter combinationsBio-organic fraction processingLiquid wasteAmmonium nitrate

A process for the treatment of liquid waste biomass, especially liquid manure compositions, wherein the biomass is converted to a fertilizer product. The process at least includes a nitrification step including a first biological conversion stage wherein ammonium is converted to nitrite using nitritifying bacteria in an aerated reactor, and a subsequent chemical oxidation stage wherein nitrite is converted to nitrate by heating the liquid waste biomass in an aerated reactor under acidic conditions. The process is particularly suitable for treating liquid manure, because of the high ammonium nitrogen contents thereof, which render the process essentially self-regulatory. In addition a process for the treatment of liquid waste biomass wherein organic matters are converted to energy sources, referred to as biogas and green cokes, and wherein nitrogen is fixed in a fertilizer product in the form of ammonium nitrate, is provided, the process including the present nitrification process.

Owner:BEESTERZWAAG BEHEER

Preparation method of soluble fish protein ammonia acid fertilizer

InactiveCN104557339AReduce lossesSimple methodBio-organic fraction processingAnimal corpse fertilisersProduct processingNutrients substances

The invention relates to a preparation method of a soluble fish protein ammonia acid fertilizer, belongs to the field of biological technical processing, and particularly belongs to the field of fertilizer additive preparation. The preparation method comprises the following steps: crushing and pulping leftovers from fishery product processing or deep-sea low-value shrimp into fish pulp, mixing with water, adding lactic acid bacillus and protease, and fermenting for 3-8 days respectively through continuous ventilation and interval ventilation at a temperature of 40-45 DEG C to obtain the soluble fish protein ammonia acid fertilizer. The preparation method disclosed by the invention is simple, and short in heating treatment time, so that the heating cost is saved and the loss of nutrient substances is reduced. The fish protein ammonia acid soluble fertilizer prepared by adopting the preparation method has a good application effect, and particularly has remarkable effect on fruits and vegetables.

Owner:ZHOUSHAN YUANFENG MARINE BIOTECH

Nutrient recovery process

ActiveUS20150329399A1Reduce concentrationHigh pHBio-organic fraction processingSludge processingAmmoniaSalt solution

An apparatus for recovering nutrients or water from digestate comprises one or more solid-liquid separation units, an ammonia stripping device, and a gas scrubbing unit. In a process, digestate is separated into a solids portion and a liquid portion. Ammonia is stripped from the liquid portion and converted into an ammonium salt solution which may be sold or used as, or blended with, a fertilizer product. Optionally, at least part of the remaining liquid portion may be concentrated to produce brine. The brine is mixed with the solids portion. The mixture may be dried and used as, or blended with, a fertilizer product. Optionally, a least part of the remaining liquid portion may be re-used as dilution water in a digester. A solids portion of the digestate, and one or both of an ammonium salt solution and a brine, may be used as fertilizer without thermal drying.

Owner:ANAERGIA

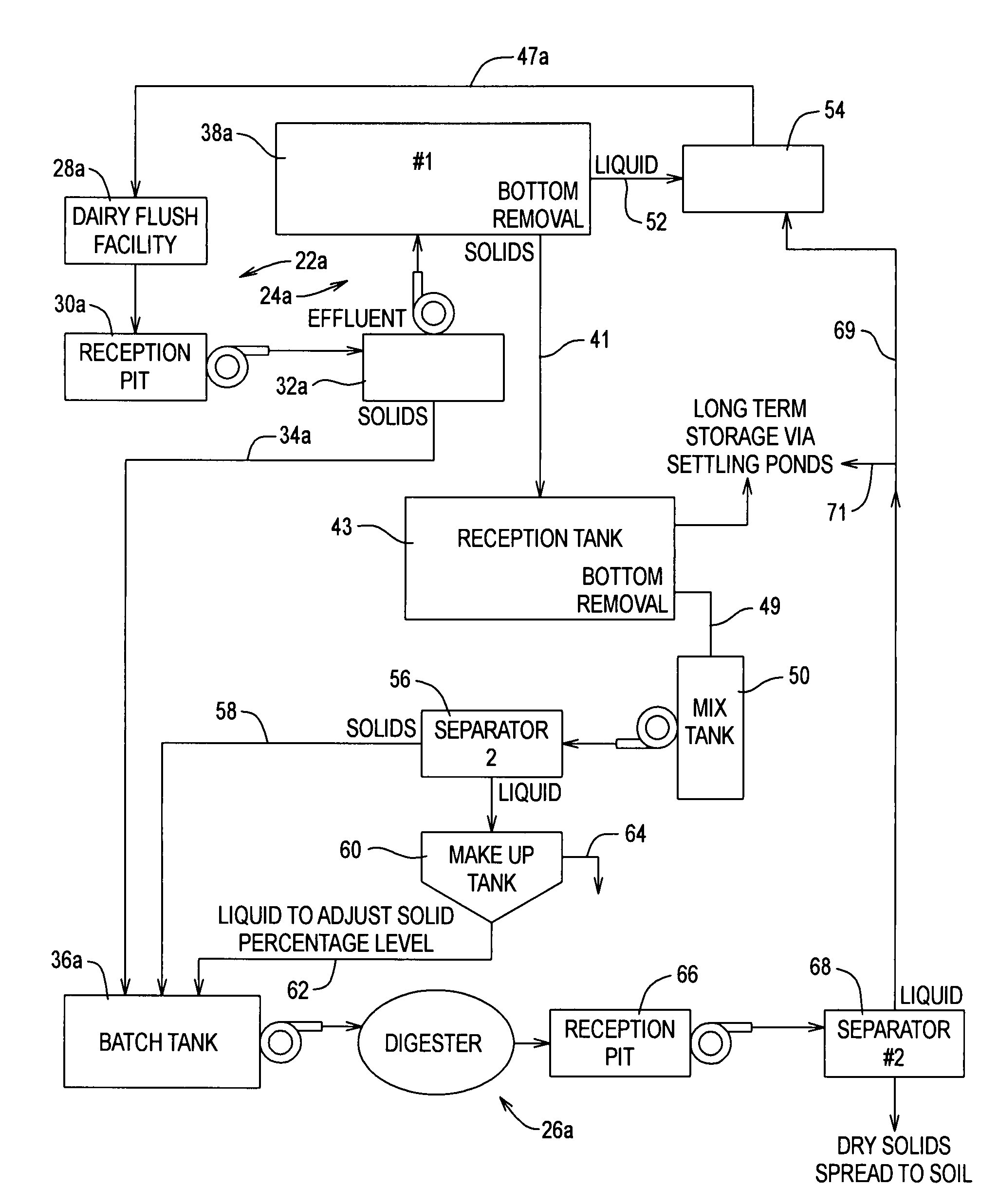

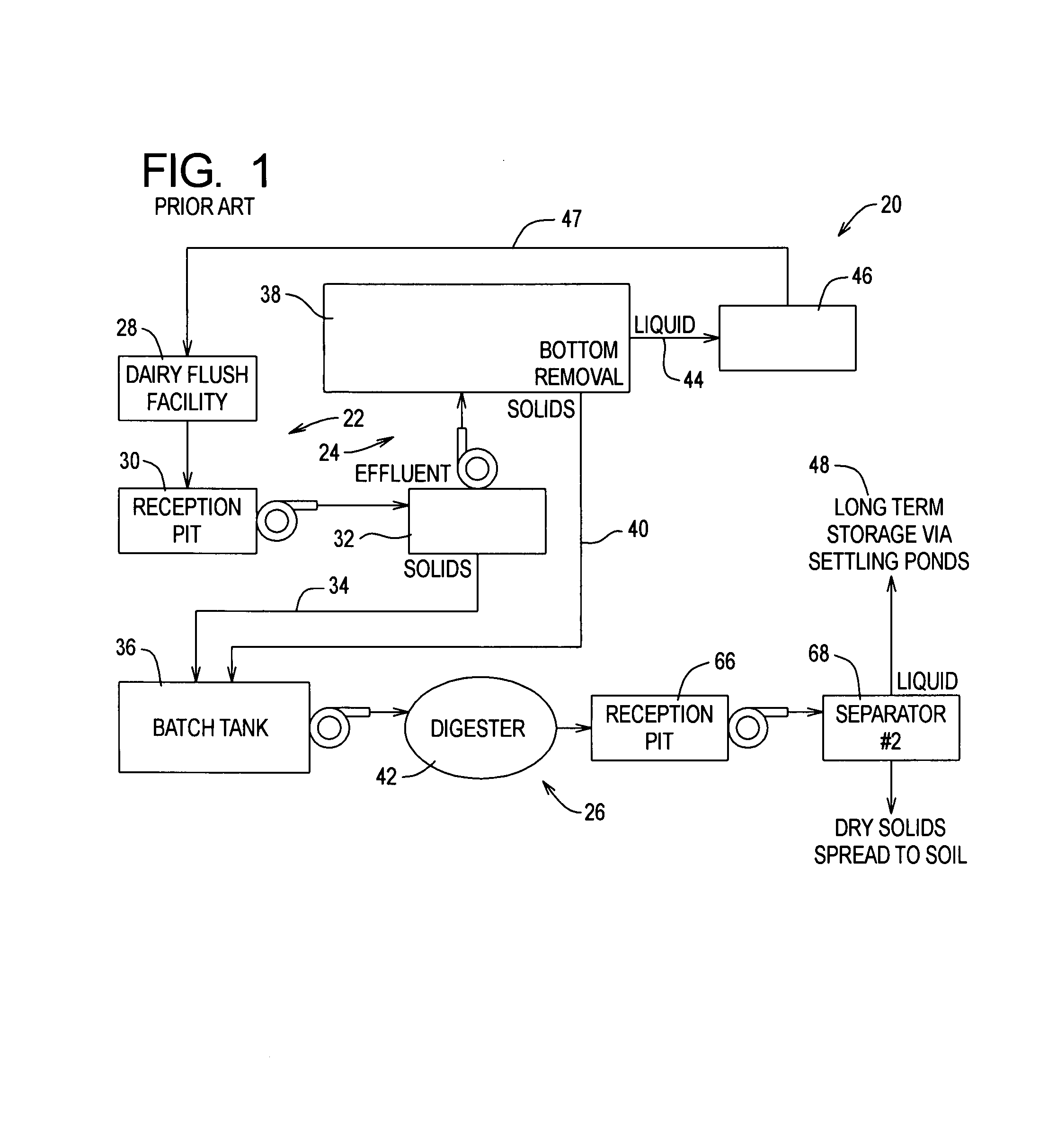

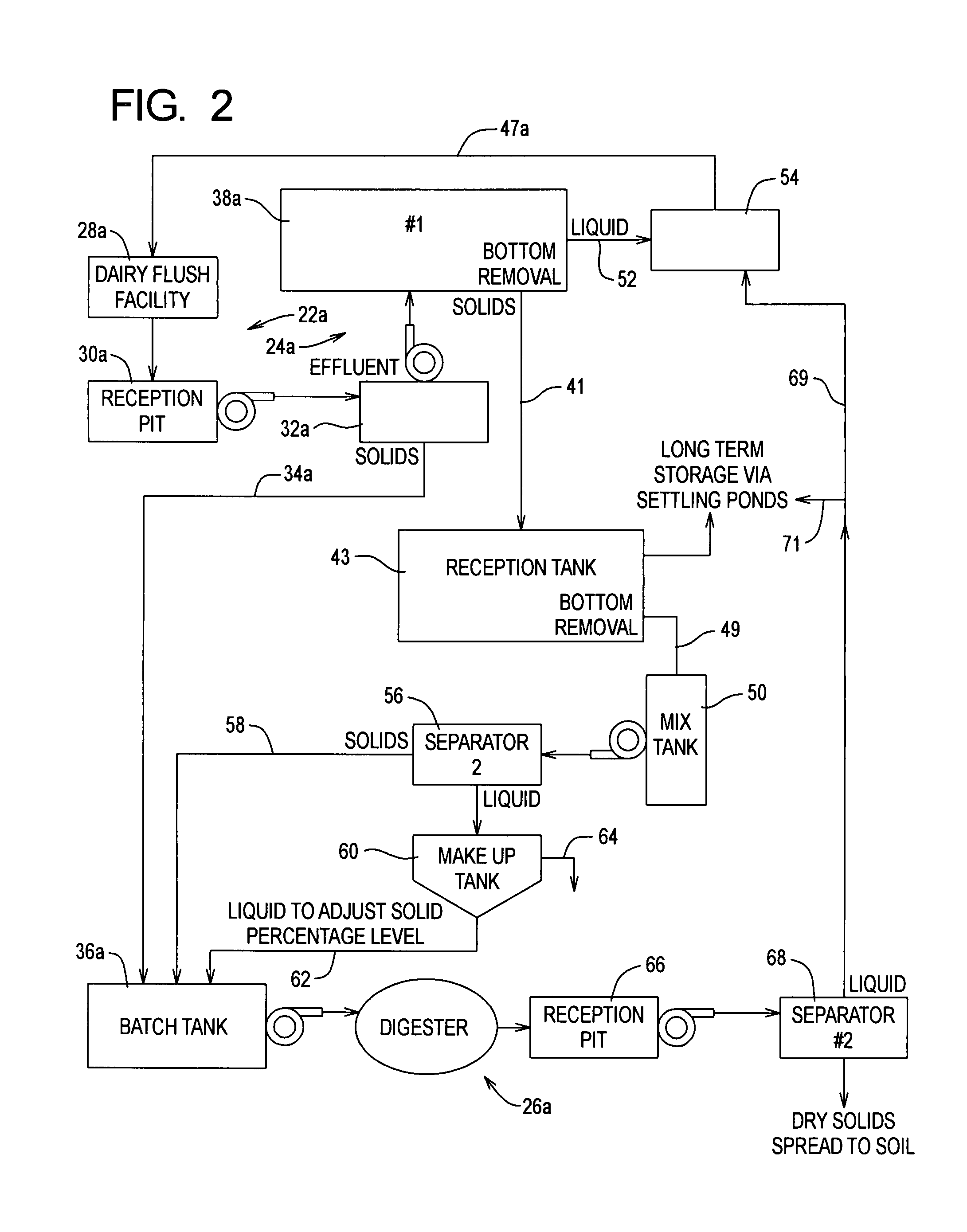

Manure separation for digester method and apparatus

ActiveUS7306731B1Liquid separation auxillary apparatusBio-organic fraction processingWaste managementSettling rate

A method and apparatus for removing settleable solids and unsettleable solids from a partially closed flush system in a diary milking operation whereby a first processing tank bottom removes settleable solids contained therein where the net current flow vertically in the process tank is less than the settling rate of the settleable solids contained therein. The process tank batch feeds a plurality of thickening tanks that are each allowed to settle for a period of time before transferring fluid is to a second separator. The method and apparatus is particularly conductive for feeding a digester.

Owner:DARITECH

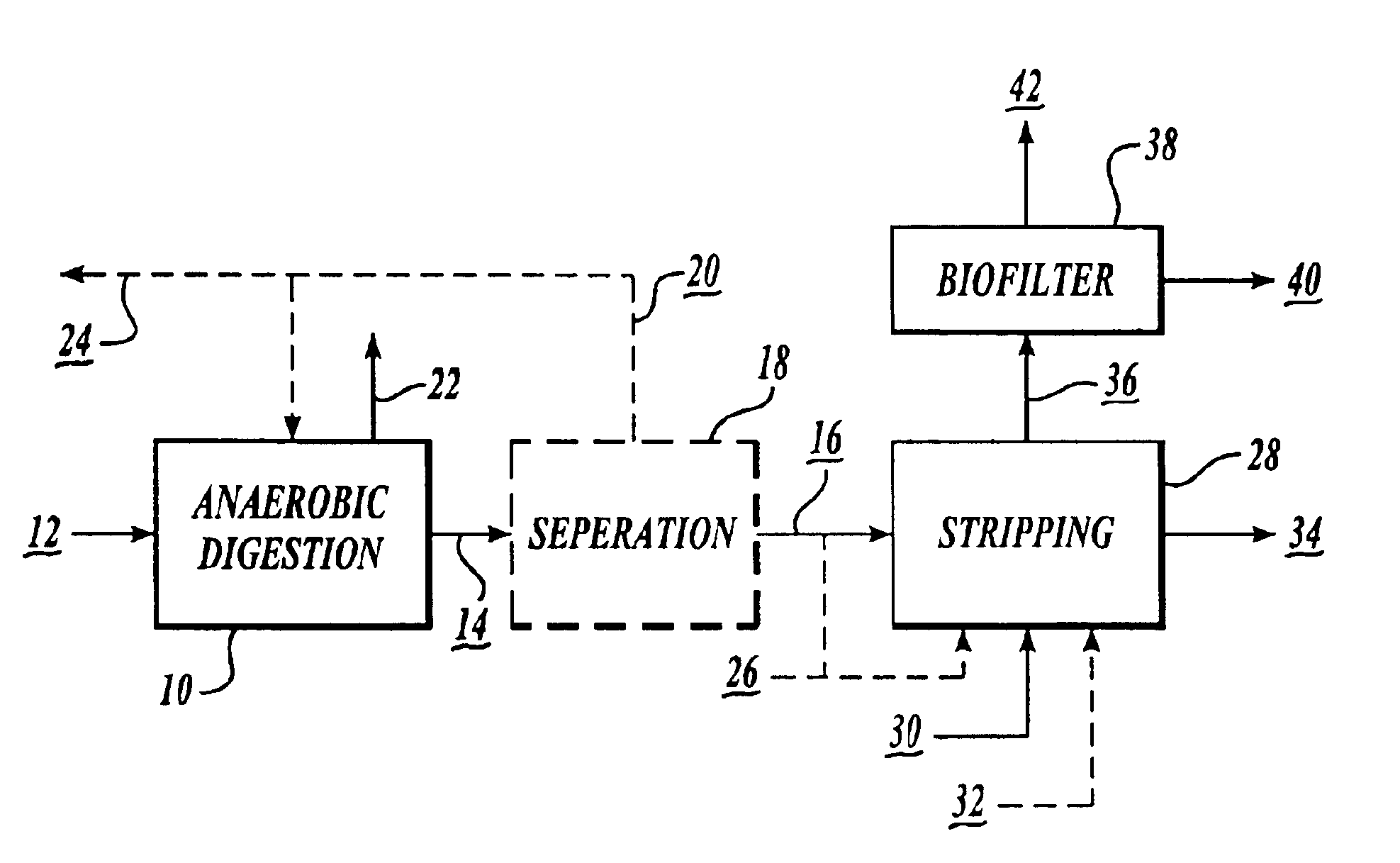

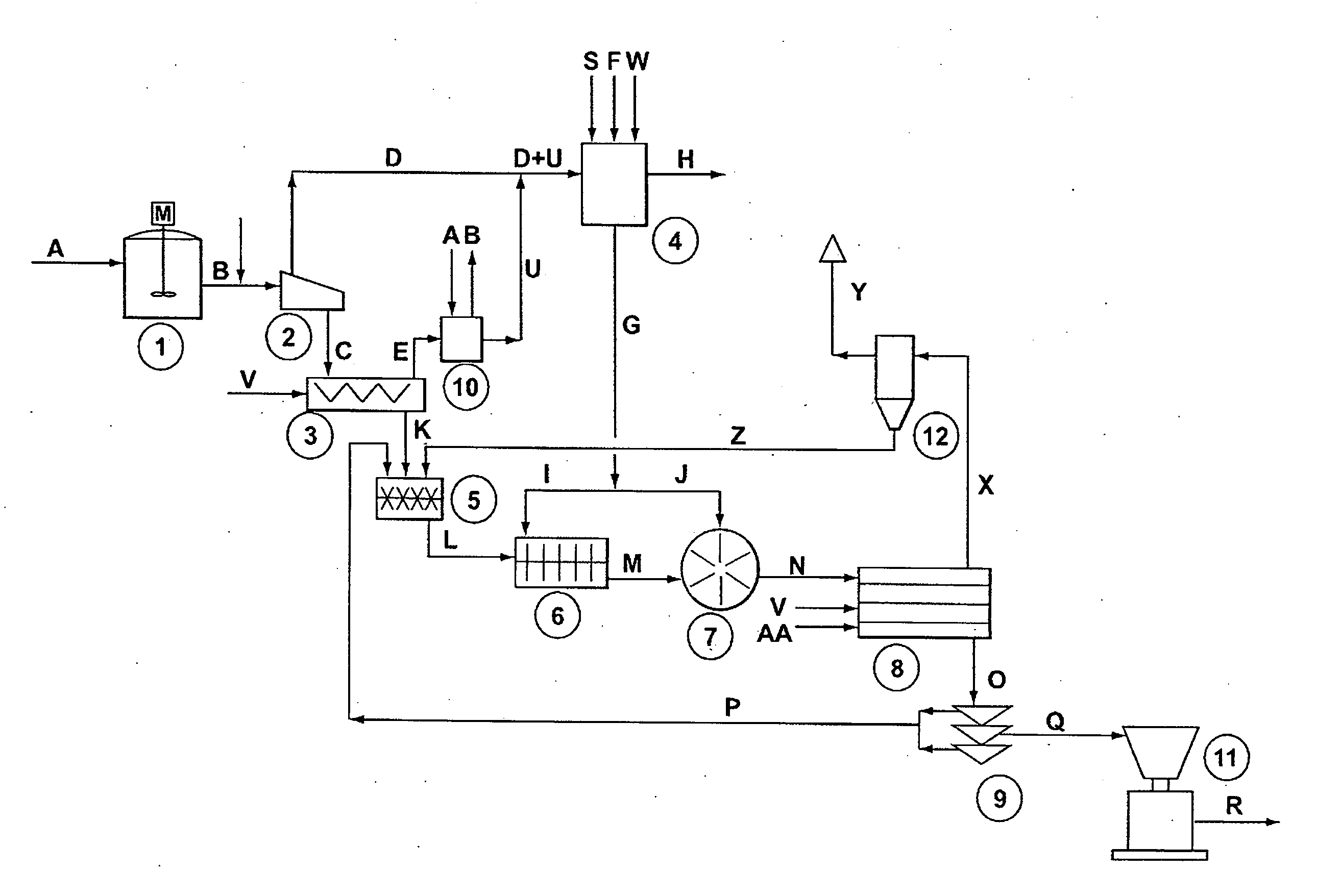

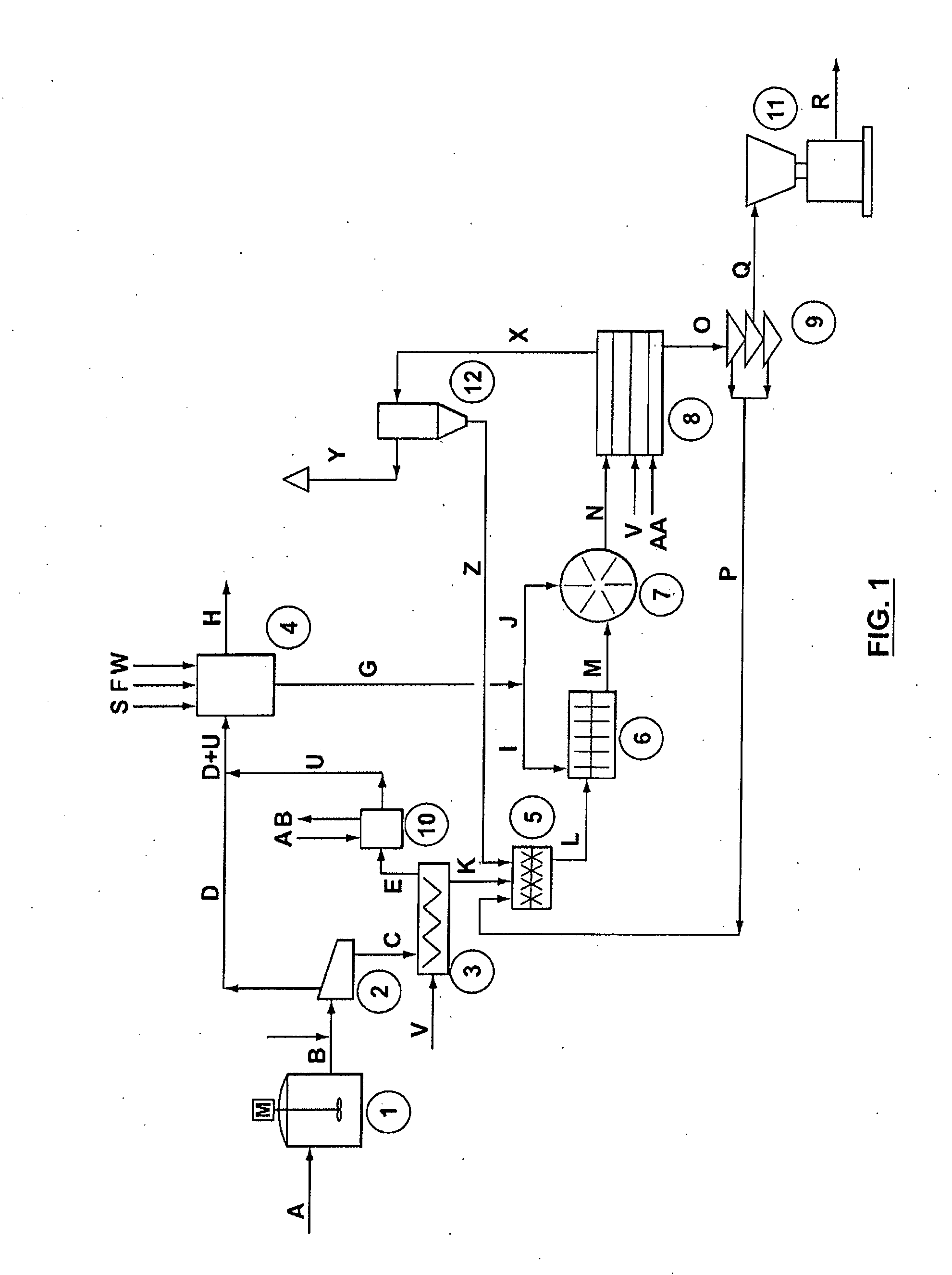

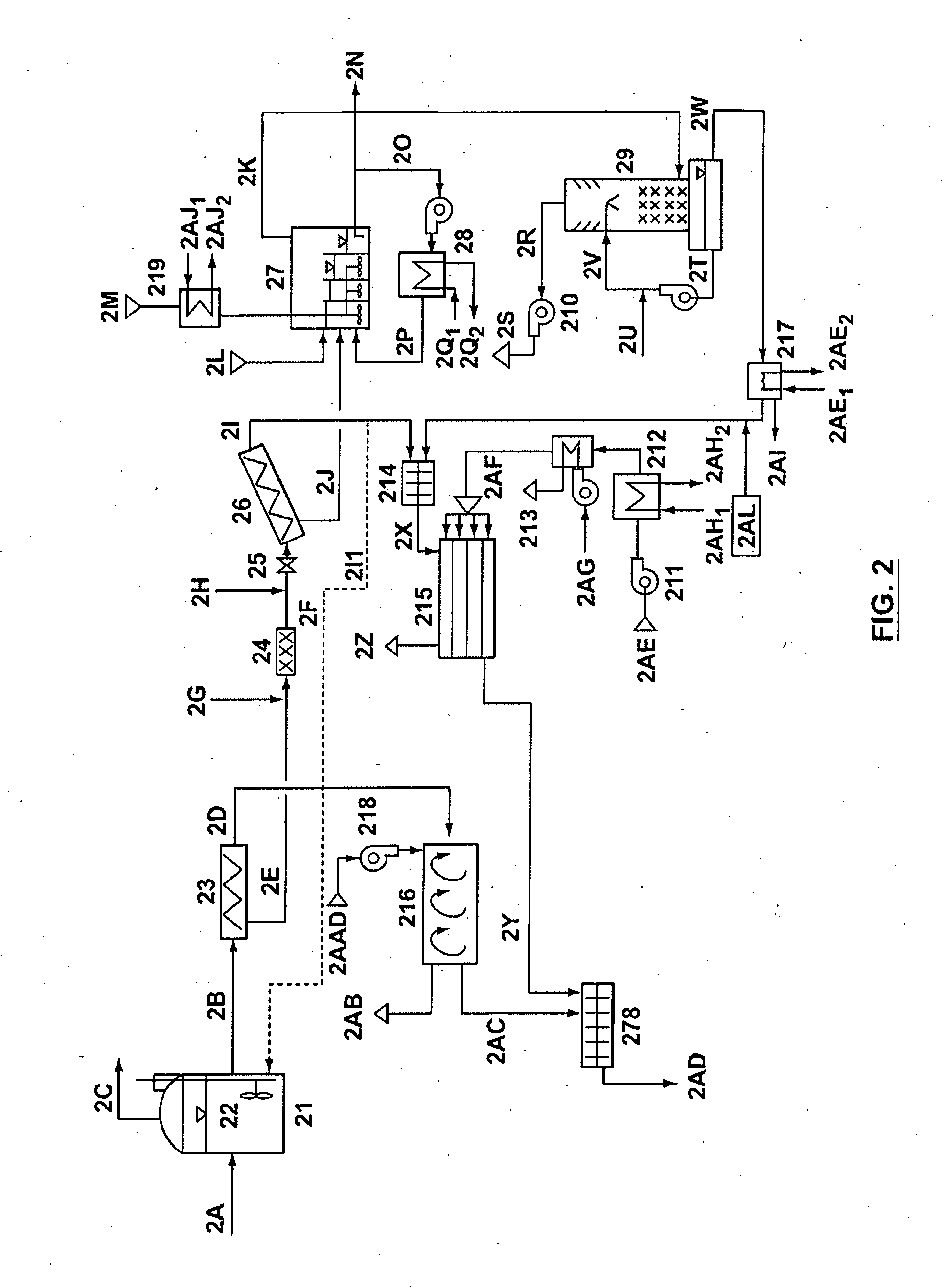

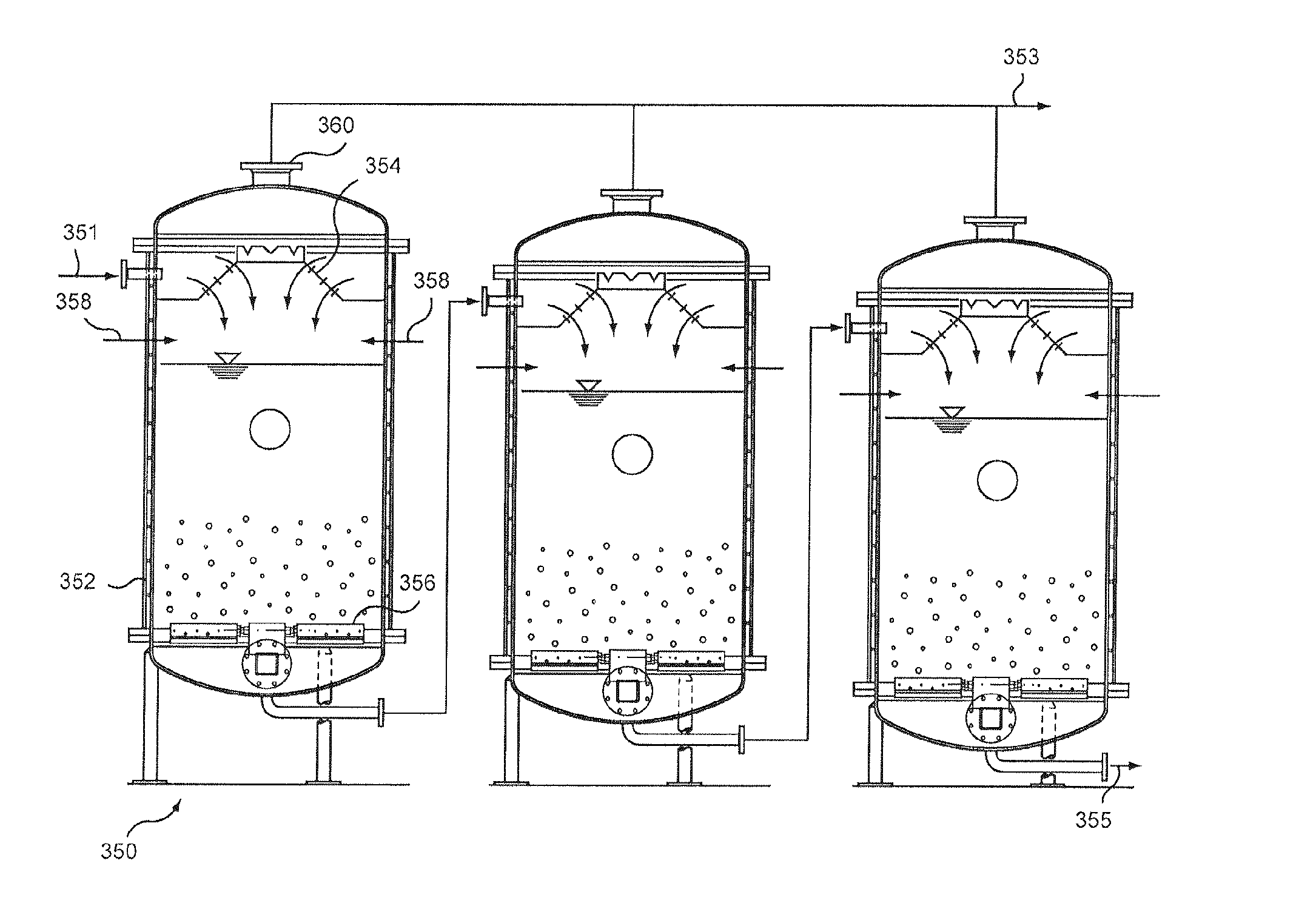

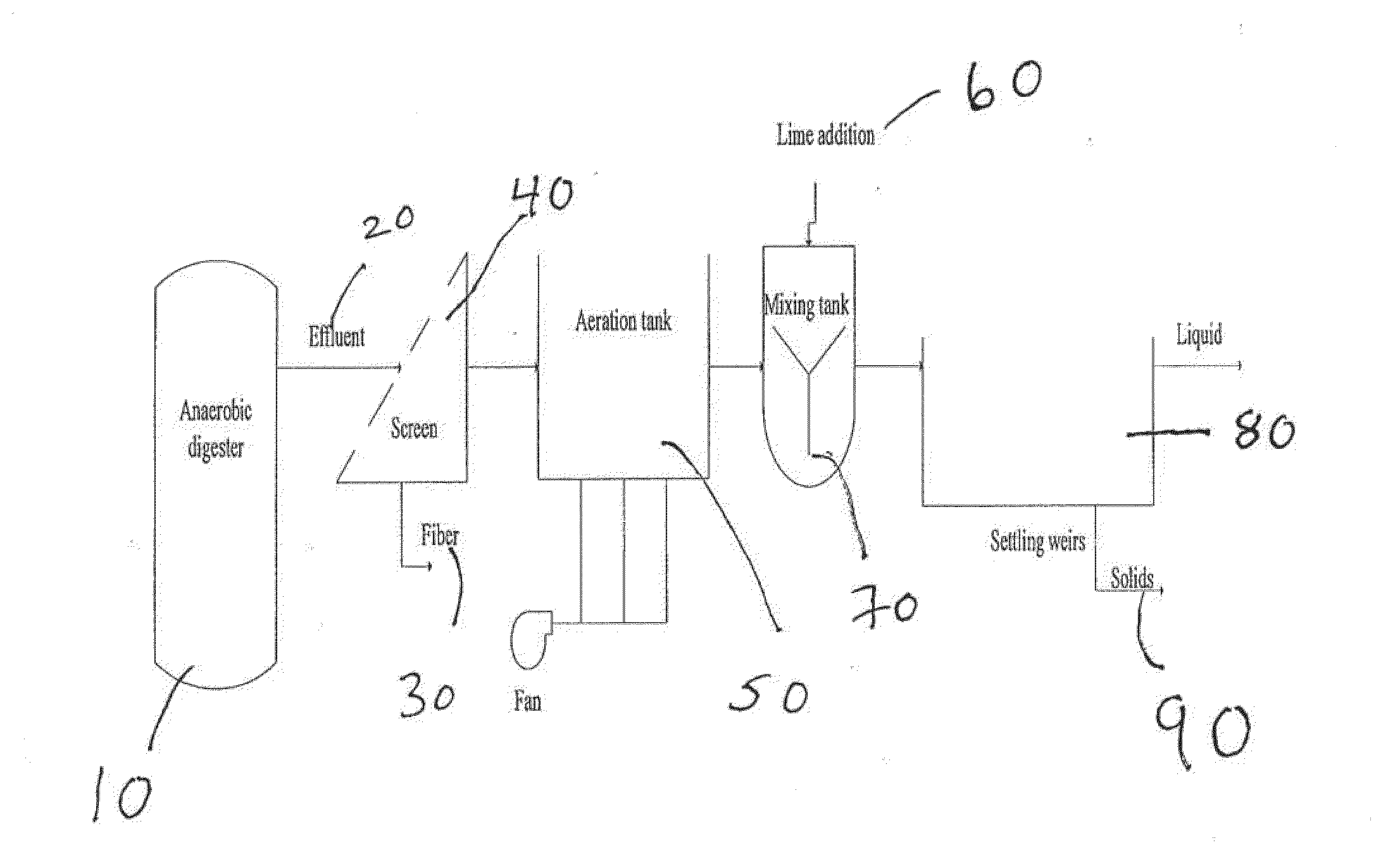

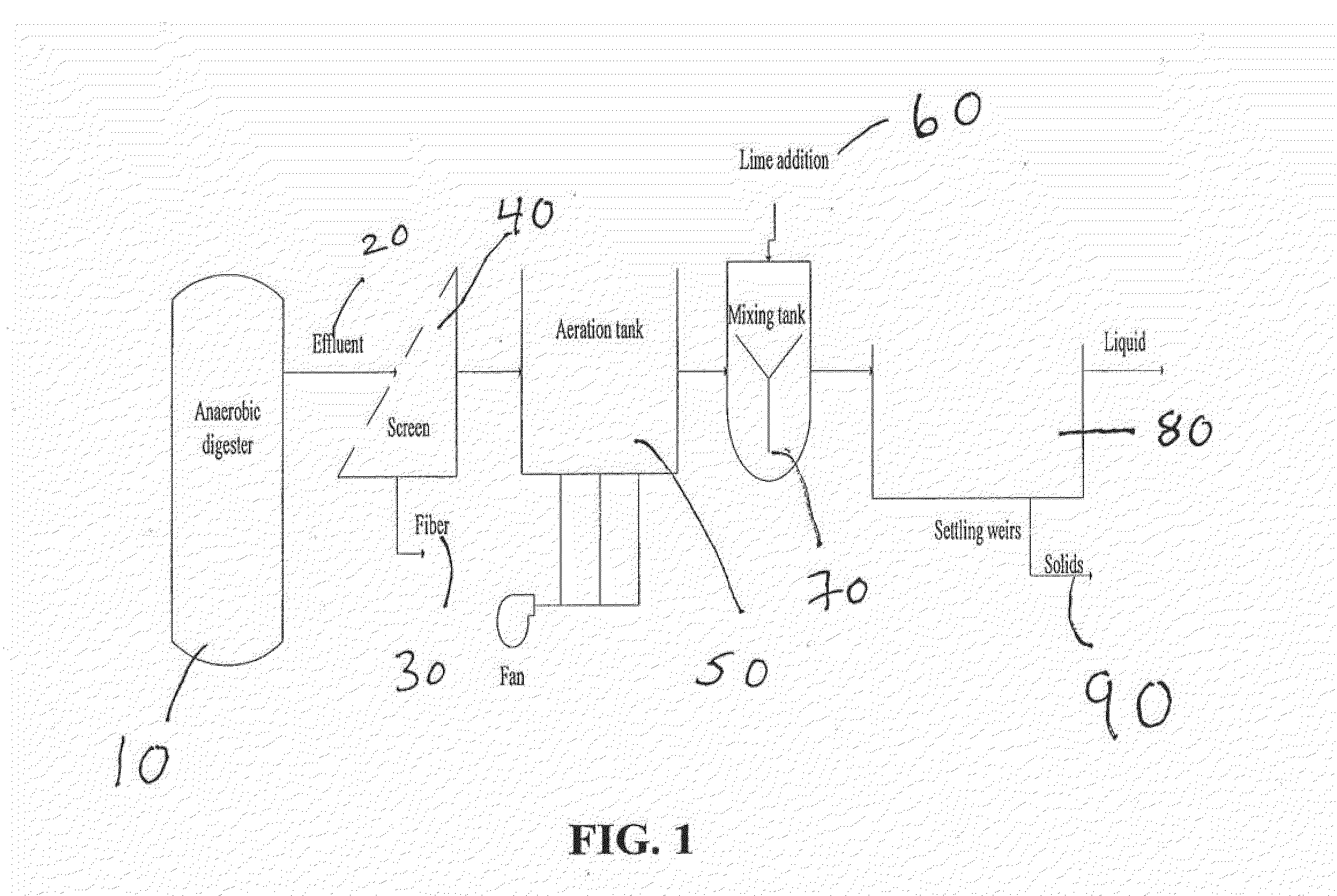

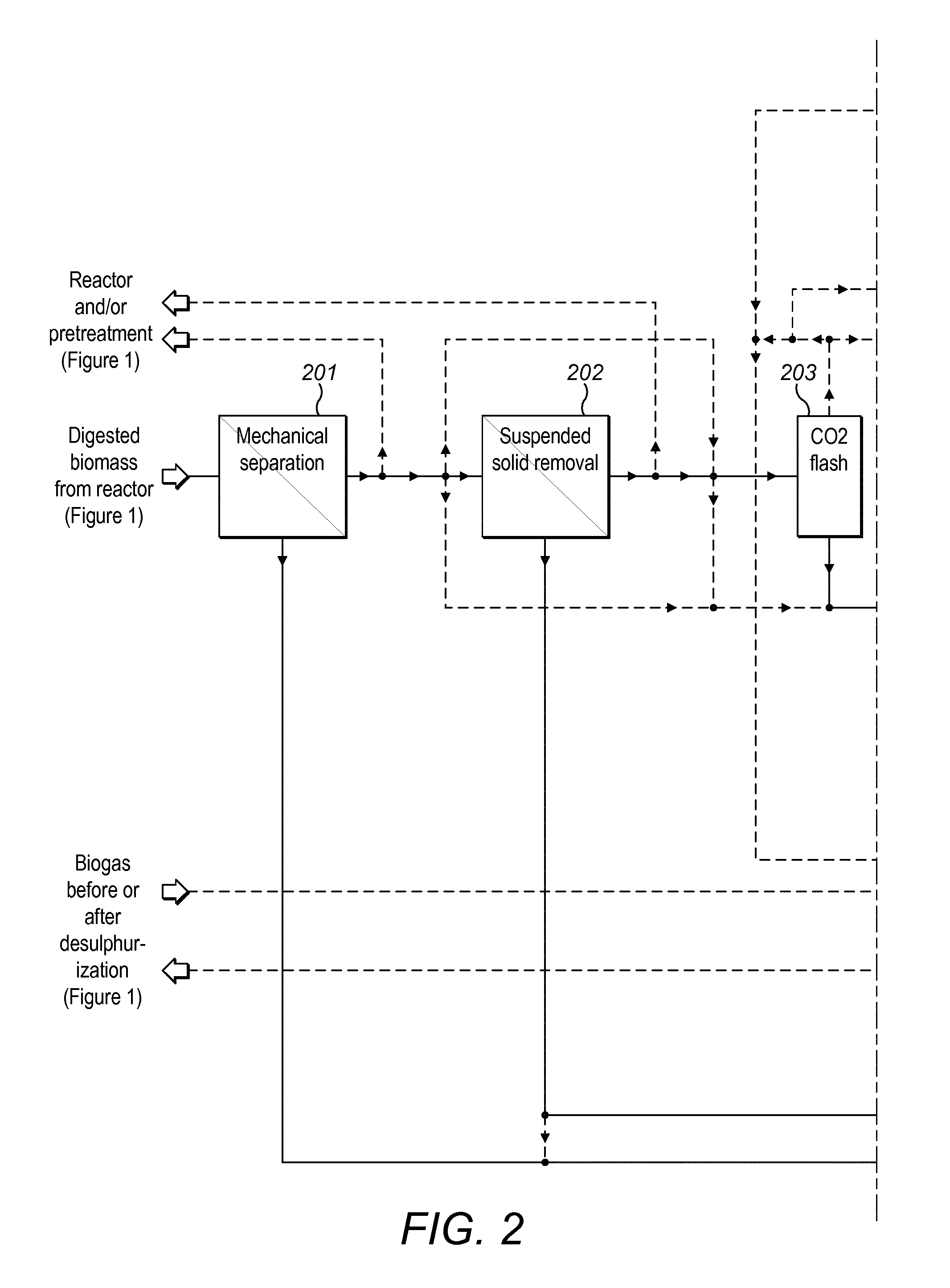

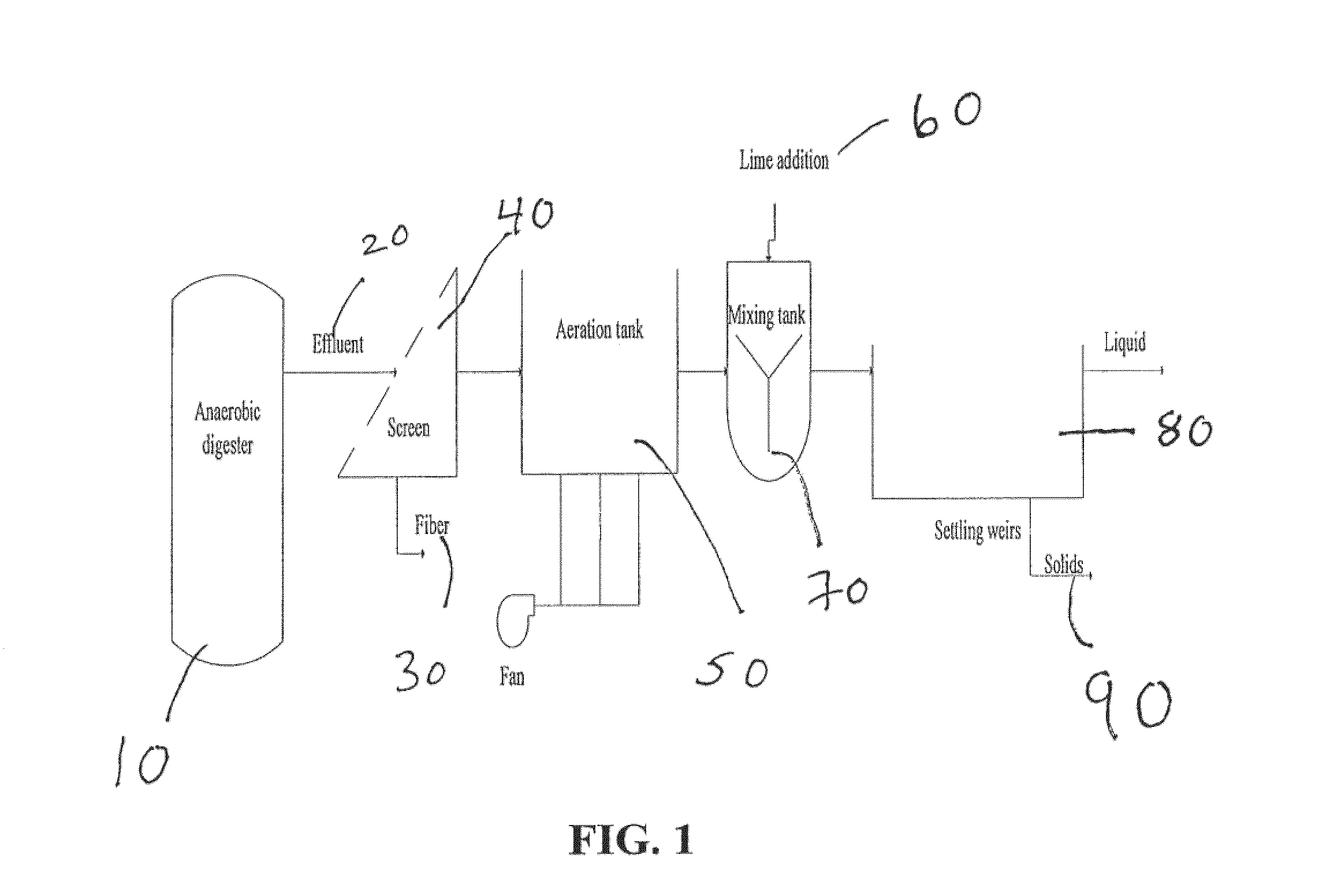

Nutrient recovery systems and methods

ActiveUS20120118035A1Large levelHigh recovery rateBio-organic fraction processingBioloigcal waste fertilisersAeration rateBiology

Methods, systems, and apparatuses for anaerobic digestion of waste fibrous material and the recovery of nutrients are provided. Methods, systems, and apparatuses disclosed herein provide mechanisms to release dissolved gases from anaerobic digester effluent. Methods, systems and apparatuses disclosed herein can recover one or more nutrients from anaerobic digested effluent using a range of temperatures, aeration rates, aeration times, pH ranges, and settling times.

Owner:DVO +2

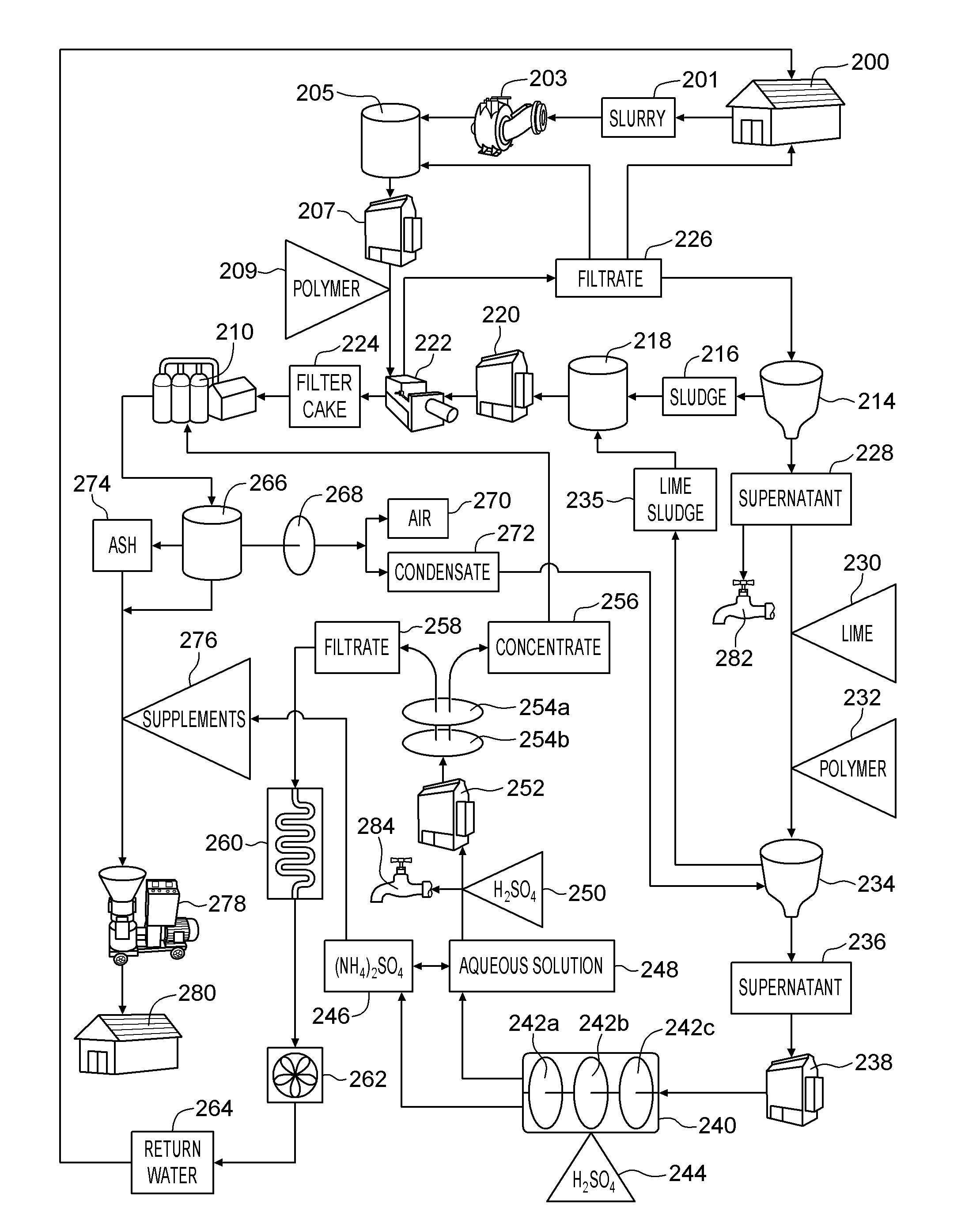

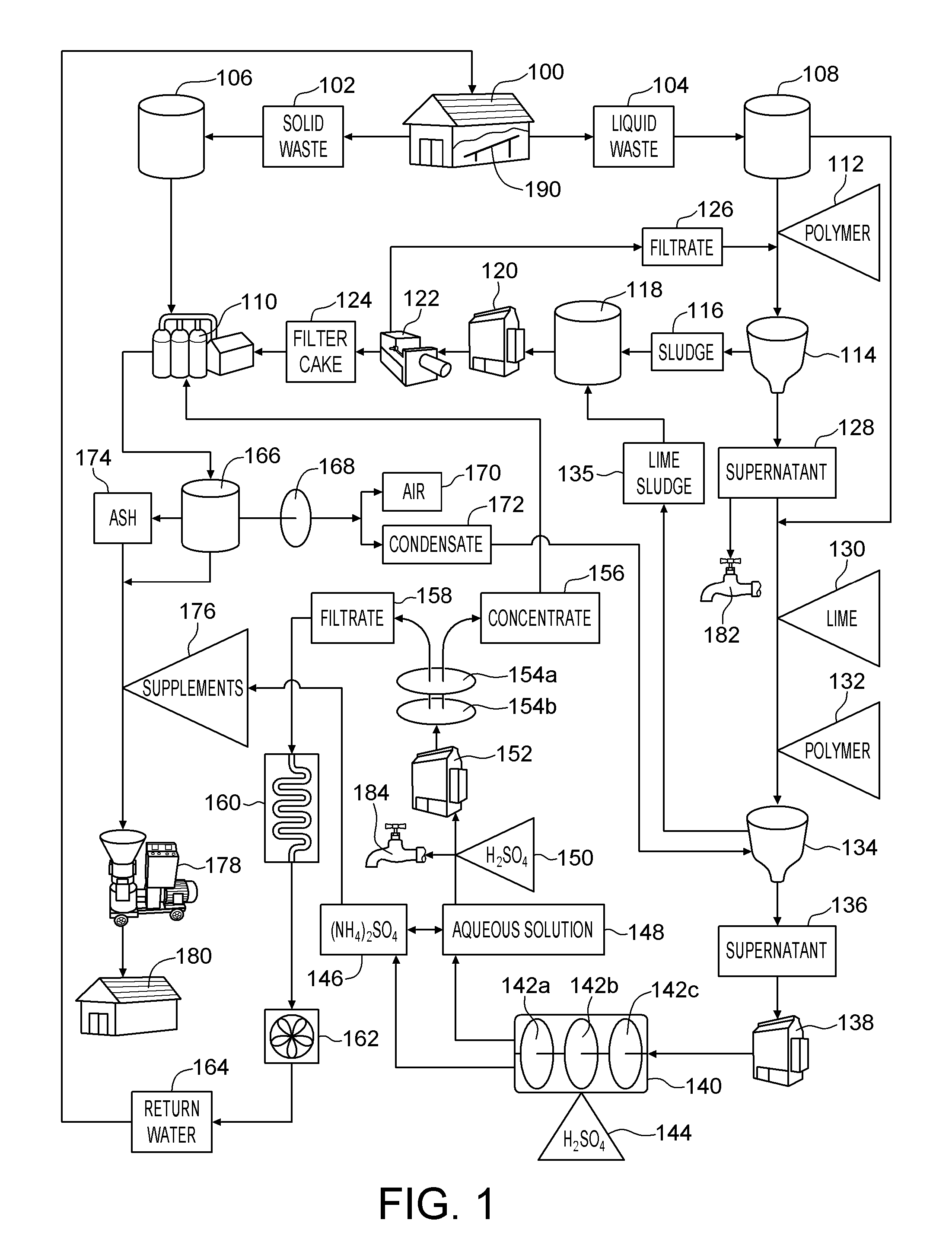

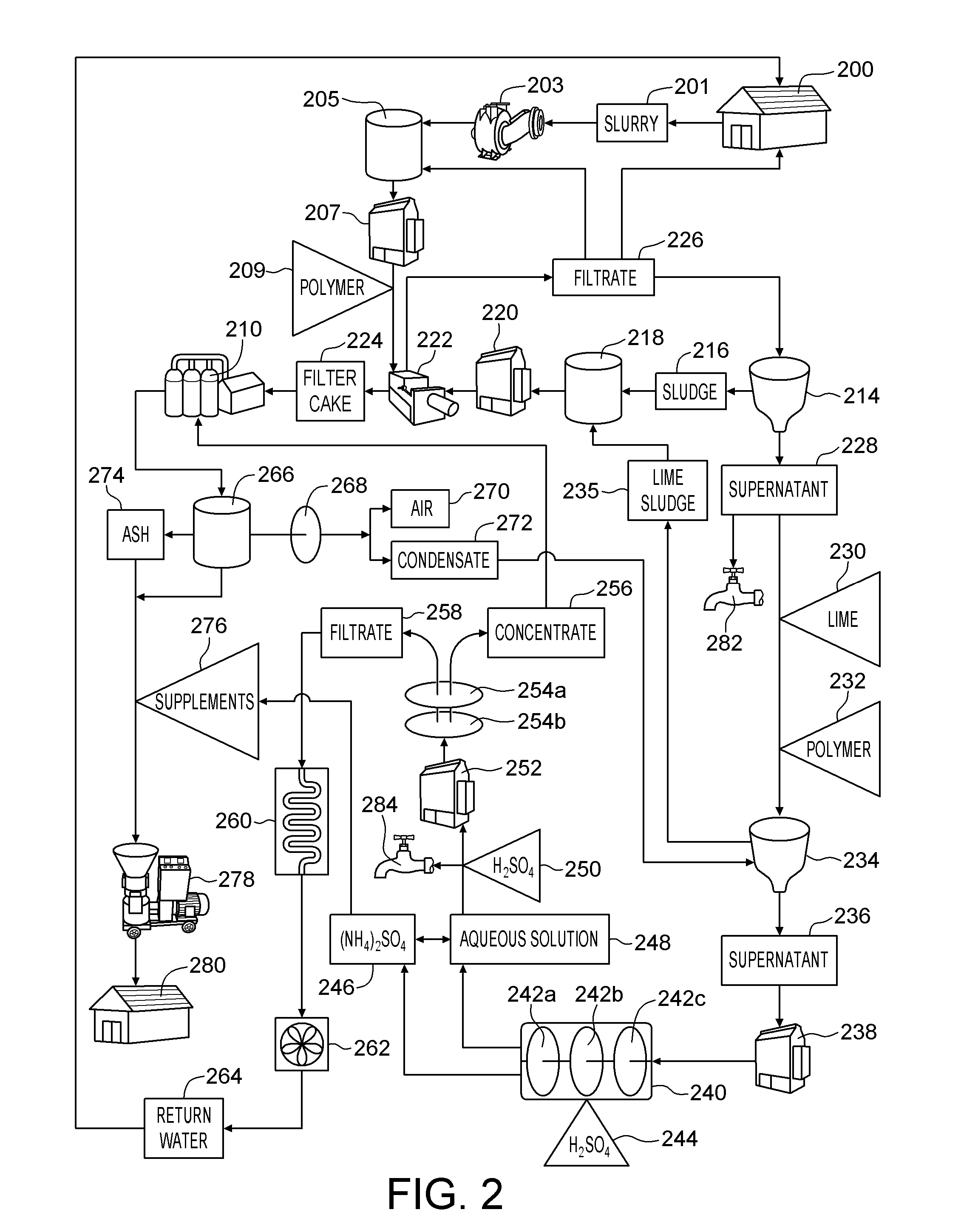

System and method for producing an organic based fertilizer and usable water from animal waste

InactiveUS20100218573A1Reduce water consumptionMinimize releaseCalcareous fertilisersBio-organic fraction processingLiquid wasteSludge

A method of producing an organic based fertilizer and usable water from animal waste includes the step of separating the animal waste into liquid waste and solid waste. The liquid waste is clarified to produce a supernatant and a sludge which is pressed into a filter cake. Ammonia is extracted from the supernatant to produce ammonium sulfate and an aqueous solution. The aqueous solution is filtered to produce a concentrate and water filtrate. The water filtrate may be used as drinking and washing water. The filter cake, ammonium sulfate, and concentrate may be used to supplement to the solid waste which is pelletized into the organic based fertilizer. In alternative embodiments a portion of the supernatant and aqueous solution may be used as a liquid fertilizer.

Owner:ATD WASTE SYST

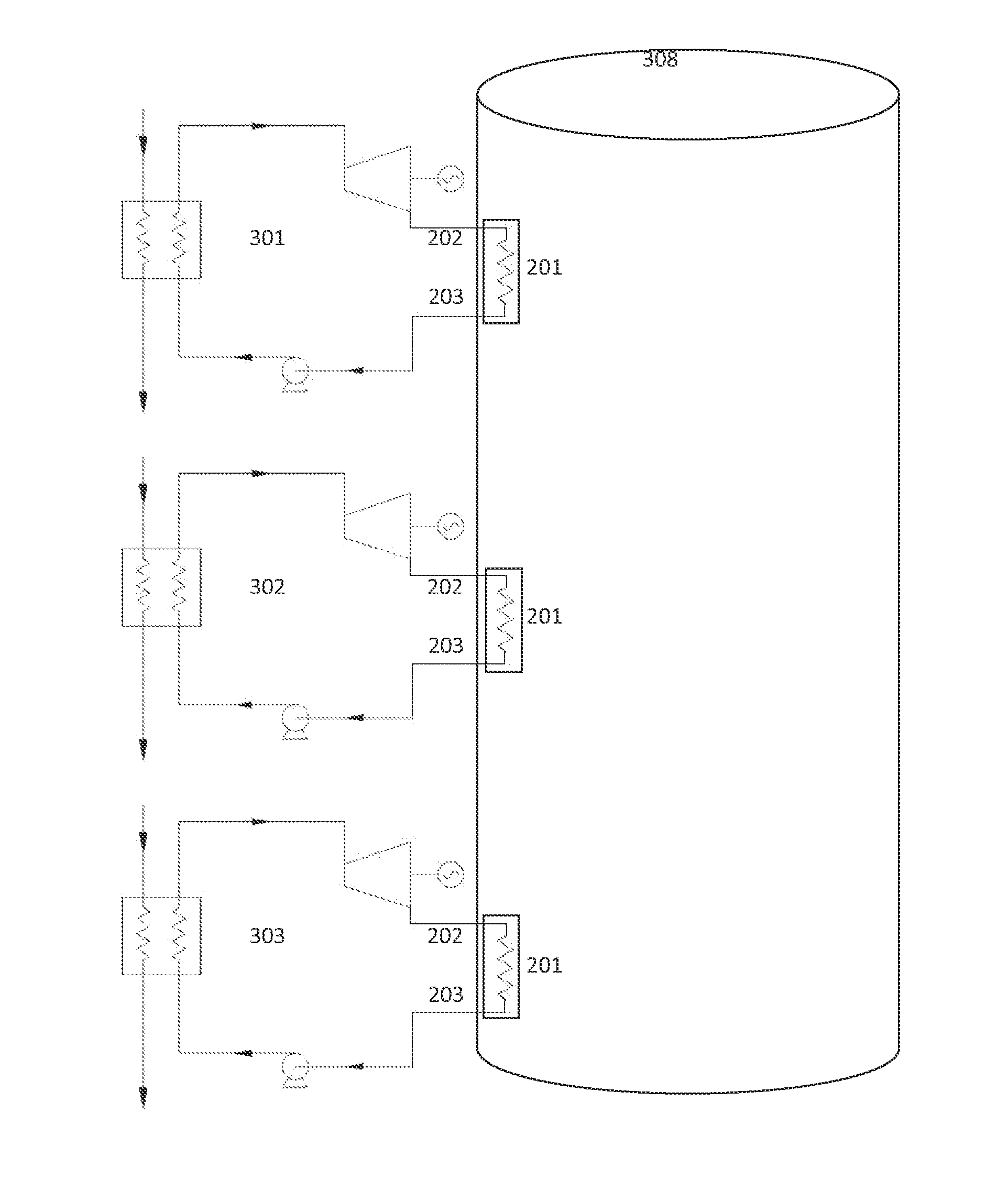

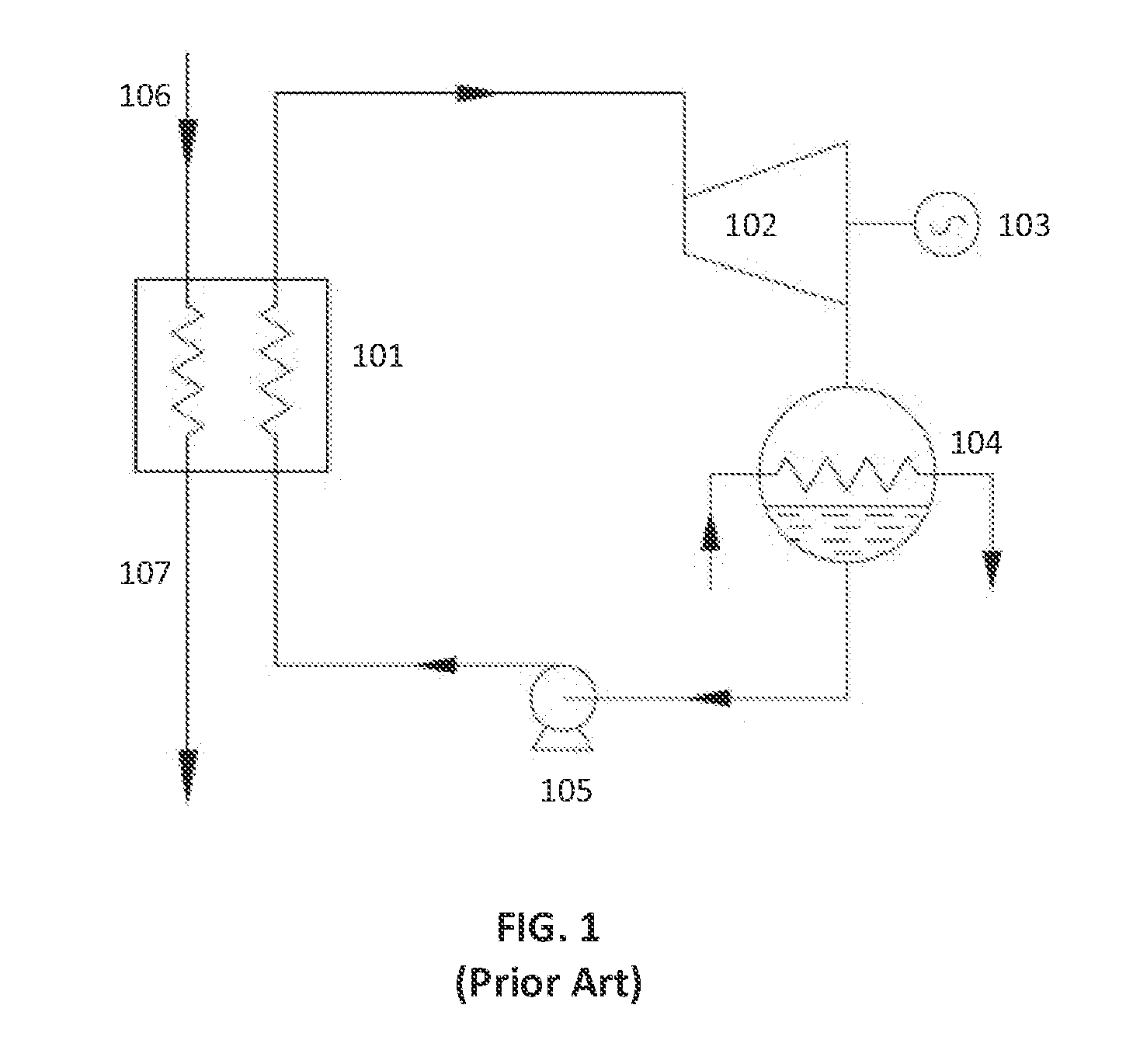

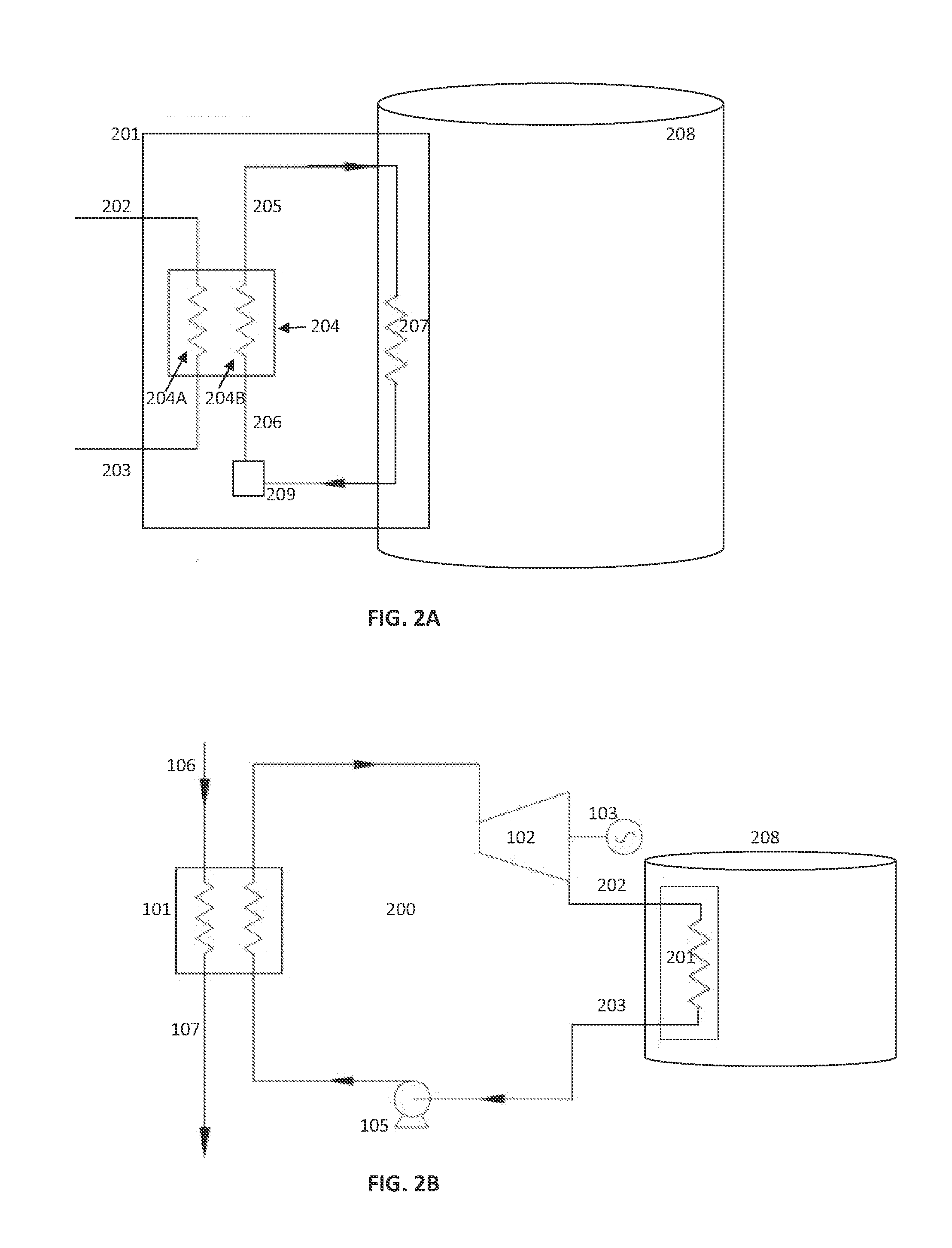

Improved Heat Utilization In ORC Systems

ActiveUS20130199185A1Cost efficiencyMeet cost performance requirementsBioreactor/fermenter combinationsBio-organic fraction processingWorking fluidOrganic Rankine cycle

Apparatus, systems and methods are provided for the improved use of waste heat recovery systems which utilize the organic Rankine cycle (ORC) to generate mechanical and / or electric power from waste heat of large industrial machines (prime movers) generating power from biofuel such as biogas produced during the anaerobic digestion process. Waste heat energy obtained from prime mover(s) is provided to one or more ORC system(s) which are operatively coupled to separate electrical generator(s). The ORC system includes a heat coupling subsystem which provides the requisite condensation of ORC working fluid by transferring heat from ORC working fluid to another process or system, such as anaerobic digester tank(s), to provide heat energy that enhances the production of fuel for the prime mover(s) without requiring the consumption of additional energy for that purpose.

Owner:BITZER US

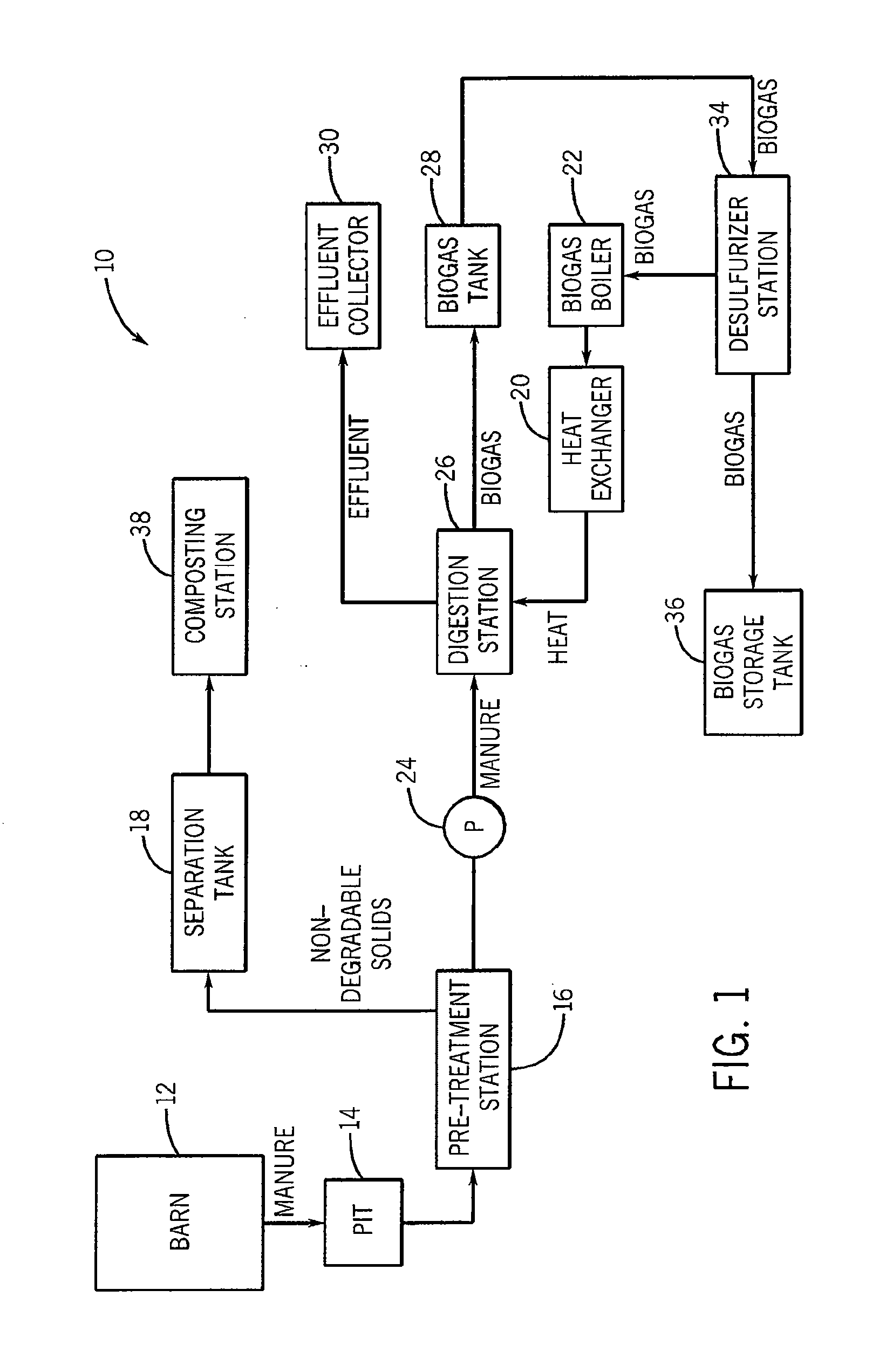

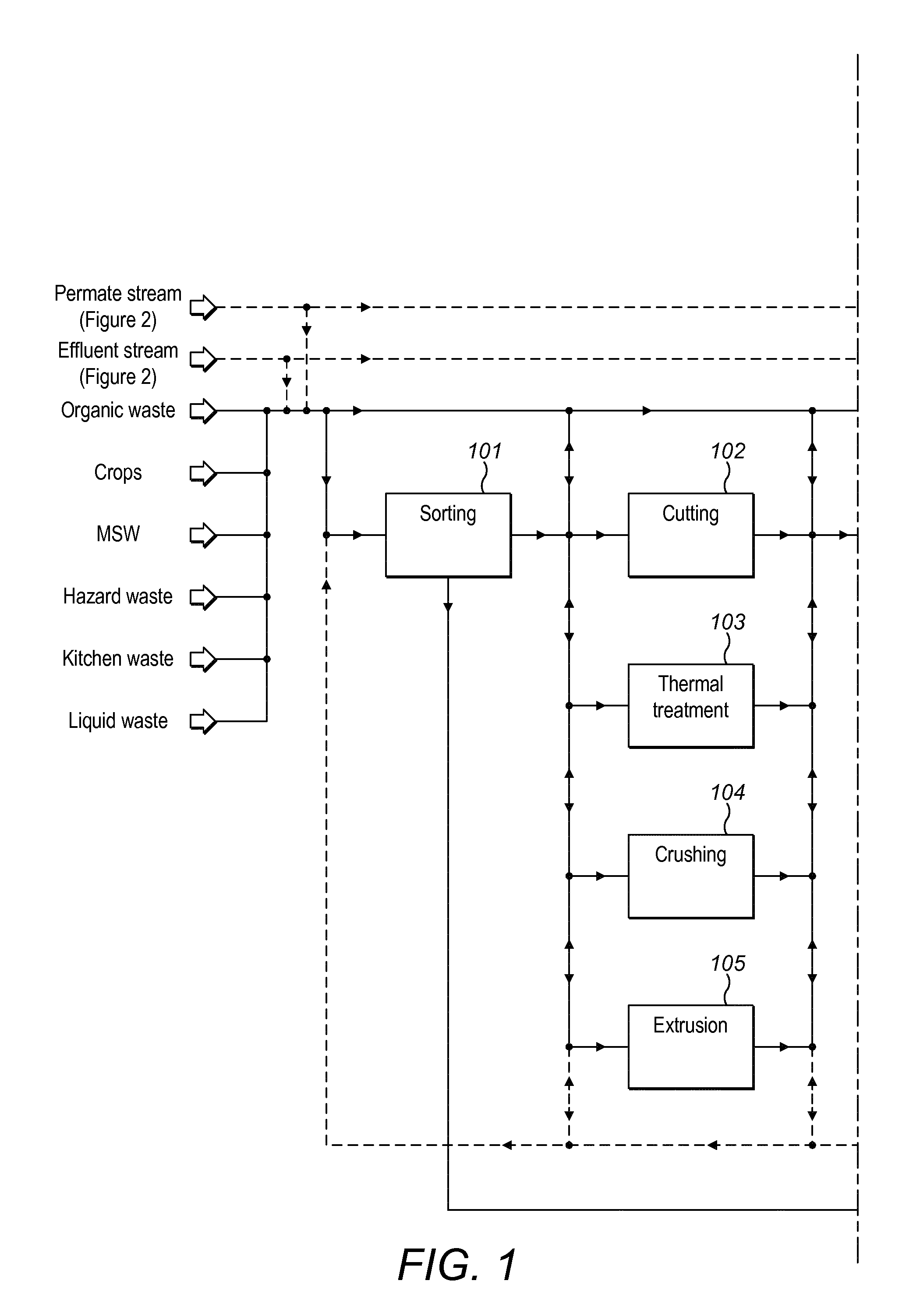

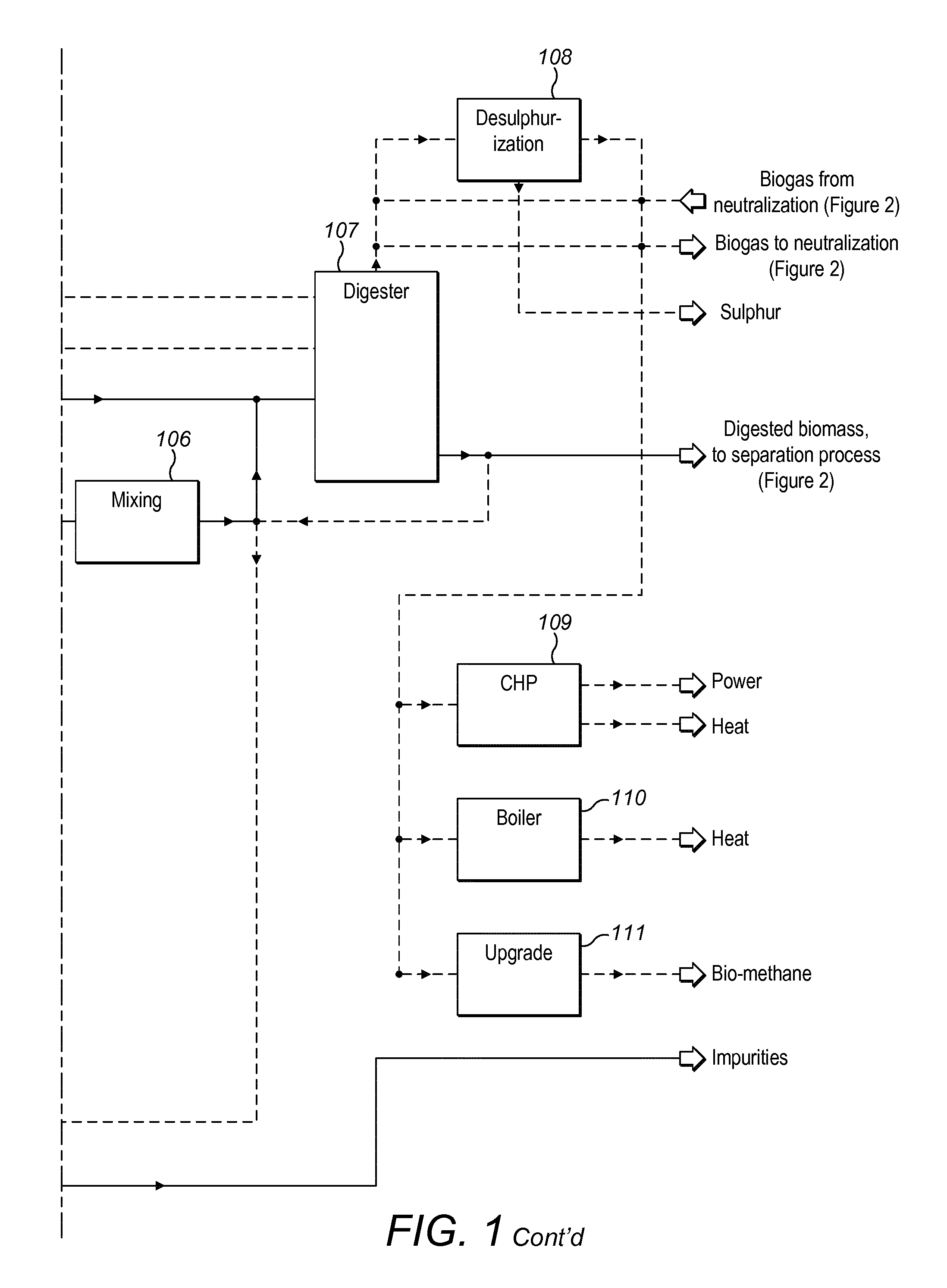

Organic Substrate Treatment System

InactiveUS20110318778A1Easy injectionPromote degradationBioreactor/fermenter combinationsBio-organic fraction processingBiogas productionDigestion

The present invention is directed to an organic substrate treatment system that converts organic substrate and other organic materials to nutrient rich effluent and biogas. Using sequential degradation of the organic materials, biogas and effluent is efficiently produced with relatively short digestion times. Additives are added to the organic materials prior to anaerobic digestion to enhance biogas production. A desulfurizer may be used to clean the raw biogas so that it is suitable for use with gas engines and boilers.

Owner:ICS RENEWABLES

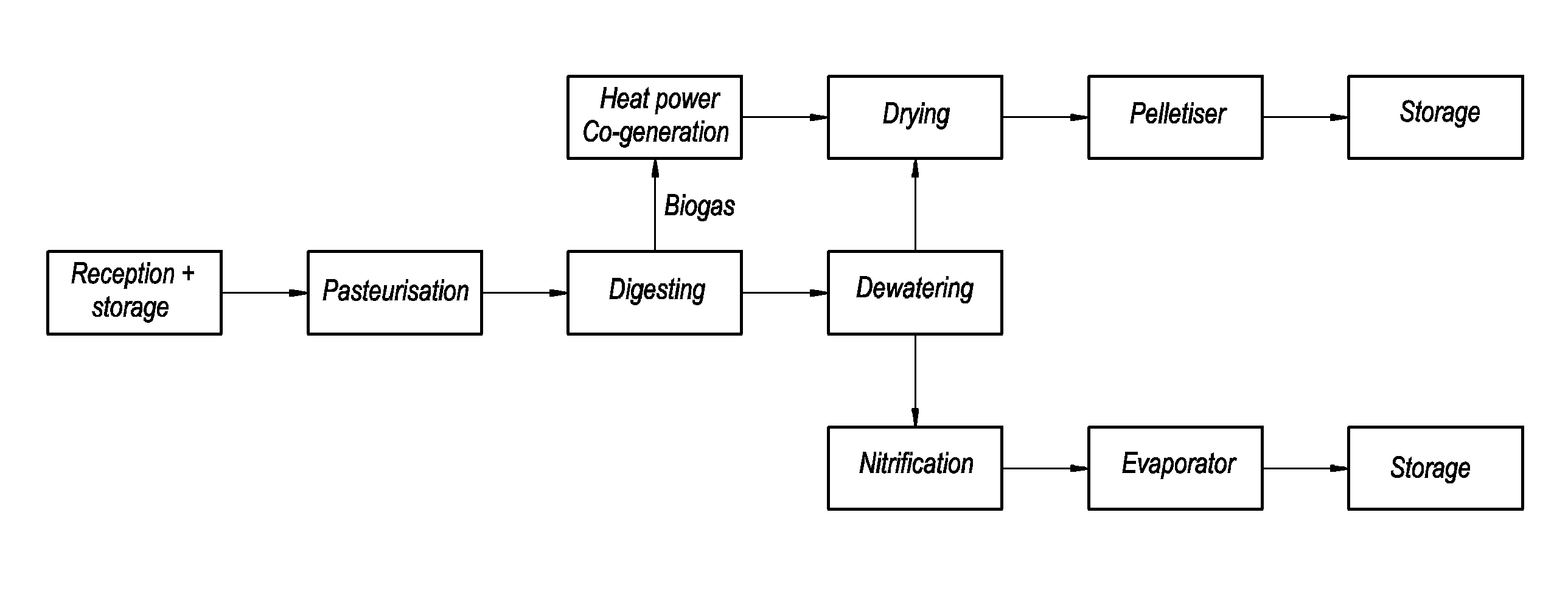

Method and plant for treatment of organic waste

ActiveUS20160176768A1Increasing biogasCost effectiveBioreactor/fermenter combinationsBio-organic fraction processingBoiling pointAmmonia

The present invention relates to methods and plants for the treatment of an organic waste material, wherein waste is subjected to anaerobic fermentation in a biogas digester; effluent is mechanically separated from the biogas digester into a concentrated fraction and a liquid fraction; the liquid fraction is heated to a high temperature below the boiling point of the liquid; the heated liquid is introduced to a flash column to partially remove volatile carbon dioxide, the pH of the liquid is elevated and ammonia is removed from the liquid.

Owner:RENEW ENERGY USA LLC +1

Nitrogen recovery system and method using heated air as stripping gas

InactiveUS7153427B2Less greenhouse gasesGood health benefitsBio-organic fraction processingTreatment using aerobic processesLiquid wasteNitrate

A process for the recovery of nitrogen from anaerobically digested liquid waste and for the collection of the nitrogen as nitrate compounds that can be used to produce fertilizer and compost, includes stripping ammonia from anaerobically digested liquid waste, and converting the ammonia into nitrates via nitrification. The stripping gas is heated above ambient atmospheric temperature to improve nitrogen recovery. The heat can be reclaimed by burning gases generated during the anaerobic digestion process.

Owner:ENVIRONMENTAL ENERGY & ENG

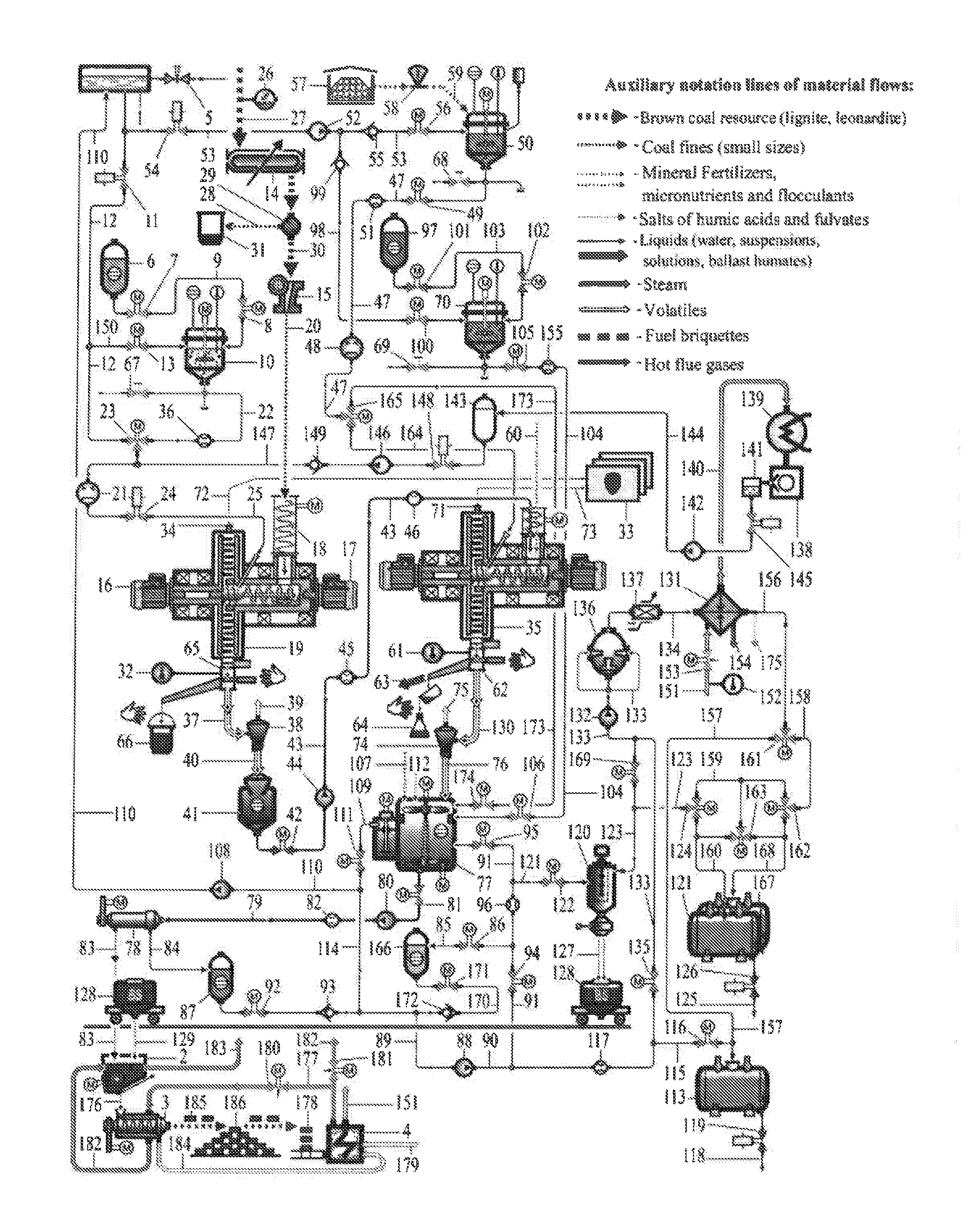

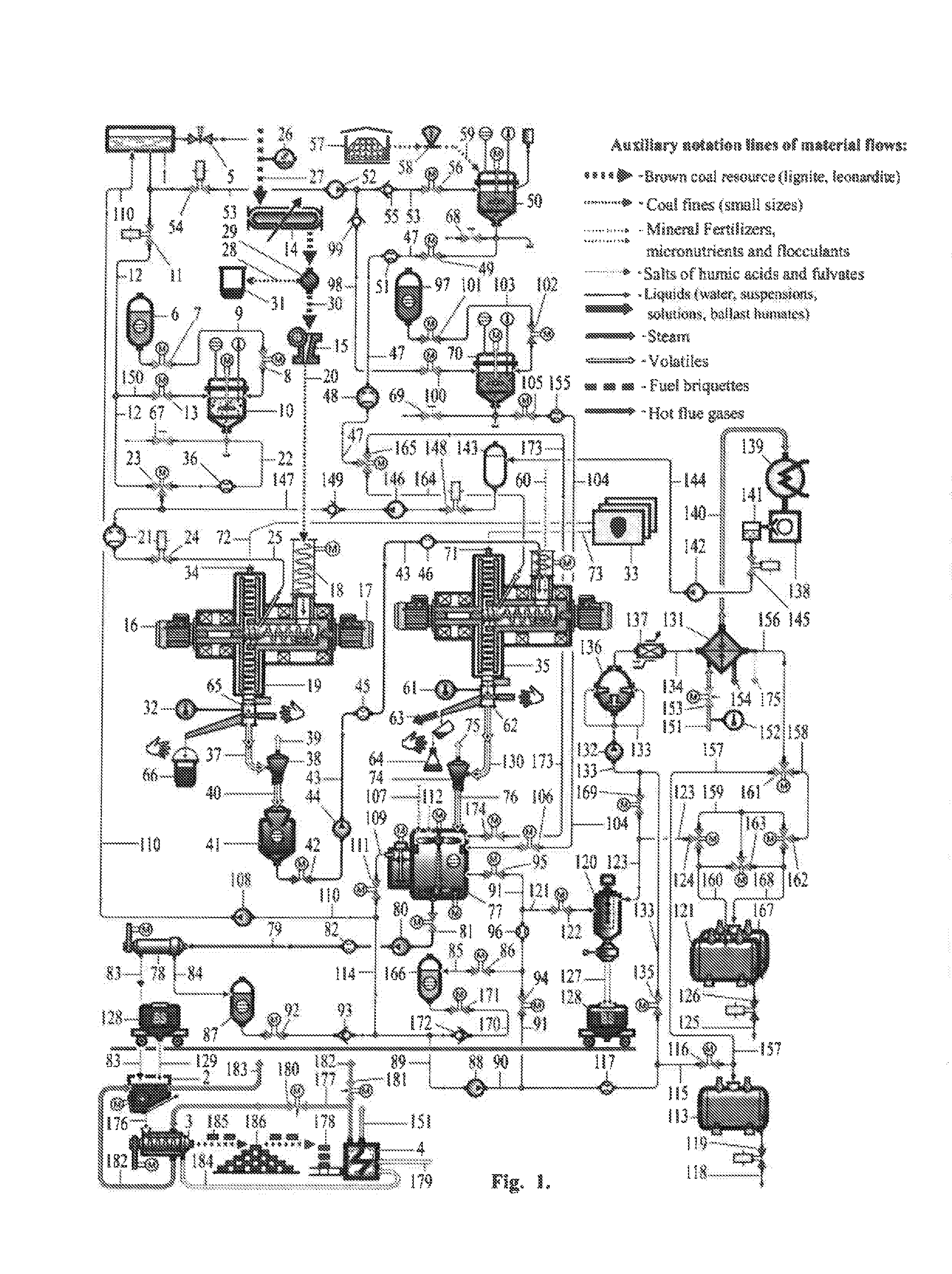

Method for comprehensively processing brown coal and leonardite into humic fertilizers and preparations and into fuel briquettes, and mechanochemical reactor for processing highly-viscous media

ActiveUS20170036967A1Improve soil structureMaintain stabilityBio-organic fraction processingEnergy inputRaw materialPhase separation process

A method for comprehensively processing coal-type caustobiolites, predominantly brown coal and leonardite, into humic organic and organomineral fertilizers and intor preparations producing fuel briquettes, including carrying out main processes in a continuous flow; carrying out leaching processes based on aqueous solutions with hydromodules of close to 2, carrying out acidification processes with the formation of humic acid released from a liquid phase into a heavy phase of a coagulated pulp, carrying out mechanical phase separation processes in a centrifugal field, carrying out liquid-phase mechanoactivation and the dispersion of reaction compositions via grinding, using residual “water” in recycling, and including the production of water-soluble humic acids and fuel briquettes and allowing for the production of a wide range of products; preliminarily grinding raw materials to a 03 mm class, and cleaning and electrochemically softening water in preparing reaction aqueous solutions; using a liquid-phase raw material oxidation process, and using liquid-phase mechanoactivation and / or mechanochemical activation, with the dispersion of reaction compositions by means of grinding and by means of dynamically shifting layers having statistical shift rate components, of a medium to be processed, which range from single-digit meters per second to tens of meters per second; accompanying said mechanoactivation with the dosed input into said medium of 1040 MJ of mechanical energy per cubic meter, with the stabilization of said dosing regardless of the drift of all other parameters in said medium to be processed; wherein, said grinding and shifting processes are formed by means of statistical and dynamic characteristics; in this way, a dynamic hydro-pulse effect on a medium to be processed is carried out within a range of frequencies floating between infrasound and frequencies bordering on ultrasound, wherein the processing is carried out beginning with higher frequencies; in addition, providing for automatically maintaining maximum parameters for inputting mechanical energy into the medium to be processed, while automatically restricting same within a sub-cavitation zone in order to prevent the transition of the mechanochemical reactors into cavitation modes.

Owner:SEVASTYANOV VLADIMIR PETROVICH +3

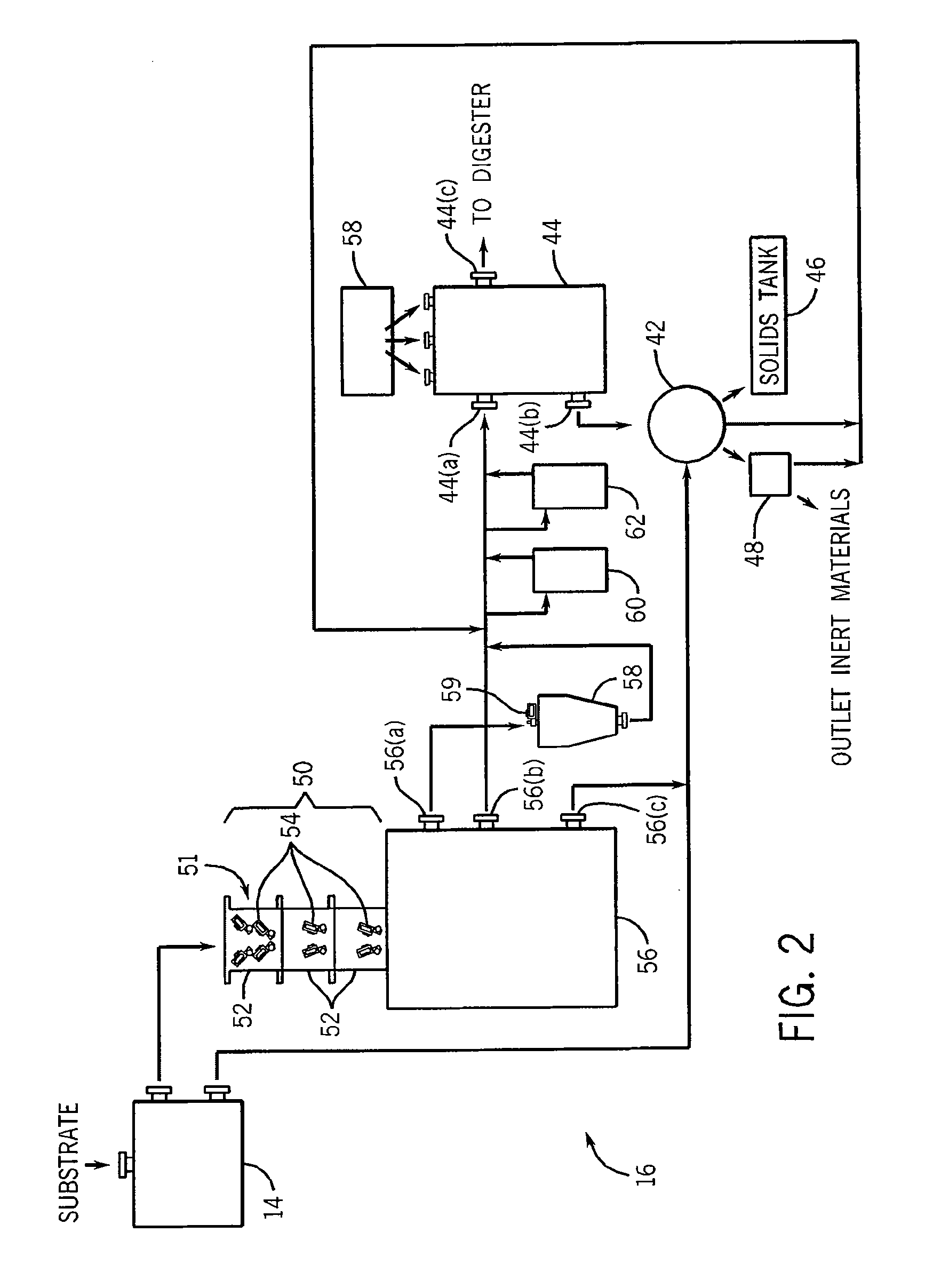

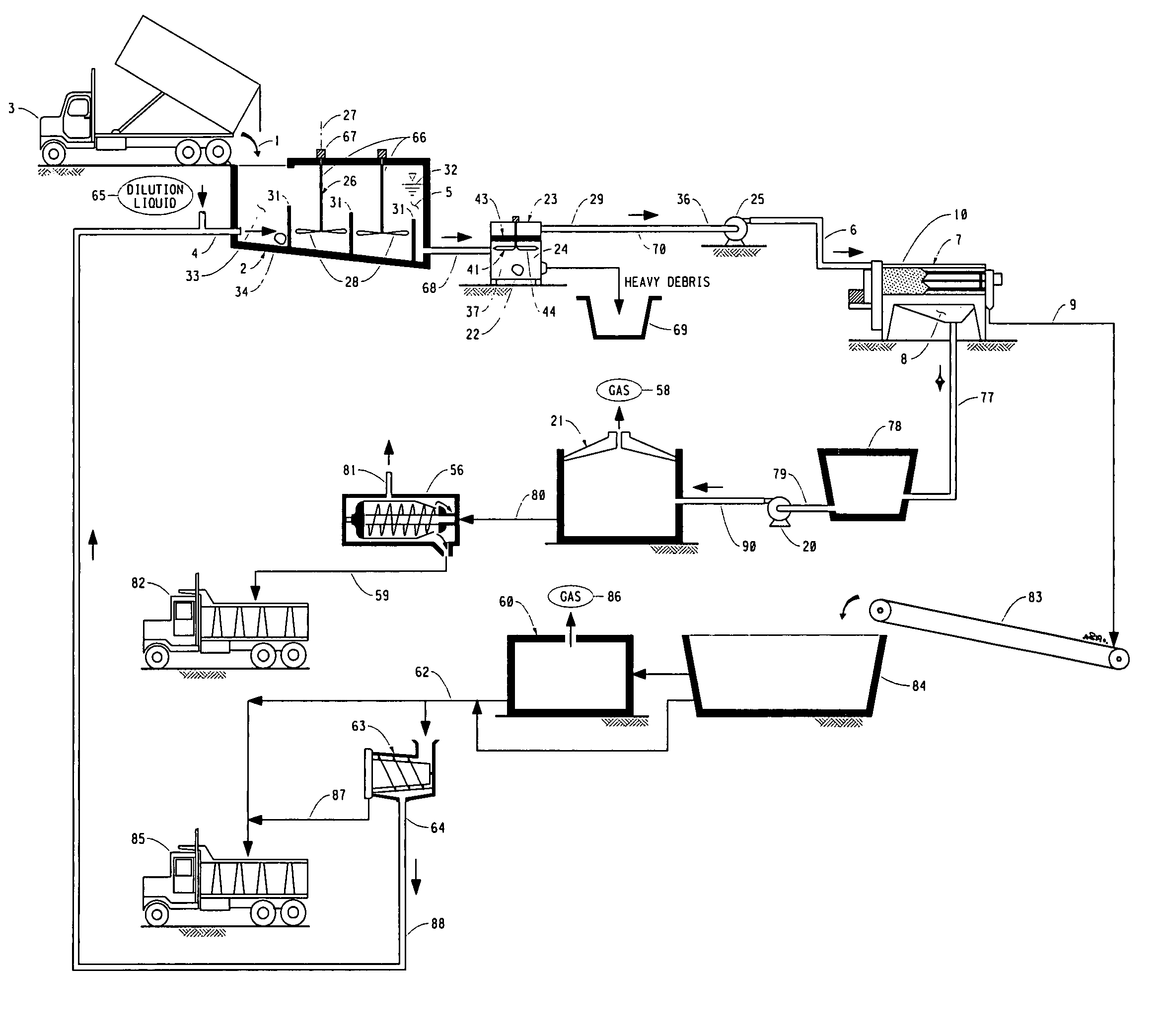

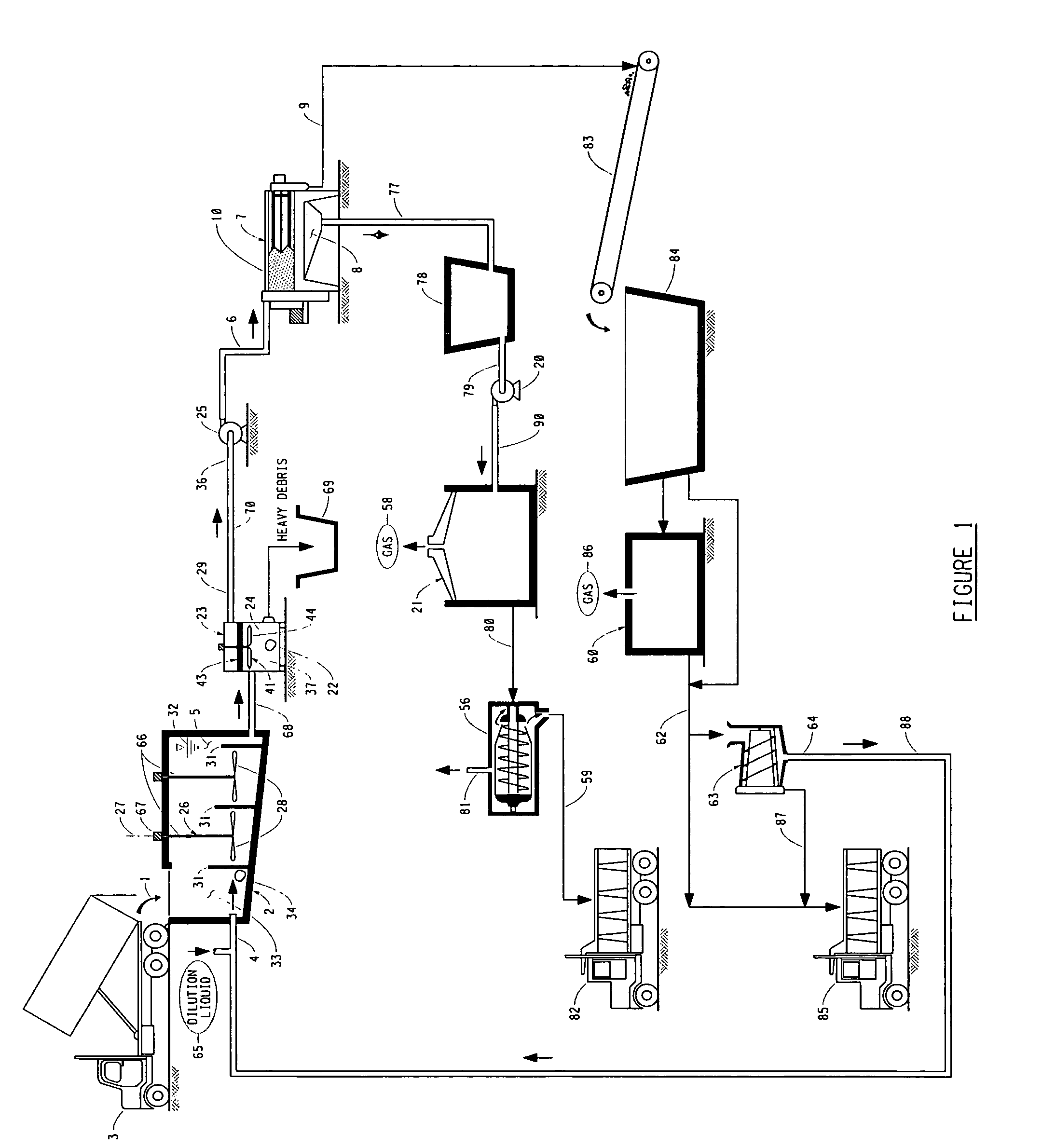

Process of treating organic waste for anaerobic digestion

InactiveUS7410583B2Generates bulkLow costBio-organic fraction processingBiological substance pretreatmentsAerobic digestionSoil conditioner

A process of treating organic waste such as food wastes for anaerobic digestion including preparing a waste-slurry from organic waste such as food wastes, transferring the organic waste-slurry to a paddle pulper / finisher, processing the waste-slurry in the paddle pulper / finisher which reduces the particle size of the solids in the waste slurry and separates the waste slurry into a pulp slurry and pomace, and processing the pulp slurry in an anaerobic digester for the production of methane gas fertilizer and soil amendments. In a further process, the organic waste is slurried by dumping the organic waste in a slurry tank, adding a liquid and mechanically mixing the organic waste and liquid until consistent slurry is attained. In a still further process, the slurry from the slurry tank is processed by forming a macerator-slurry in an inline macerator unit which removes heavy solids and cuts other solids into smaller sizes which can be transferred by a slurry pump.

Owner:EAST BAY MUNICIPAL UTILITY DISTRICT

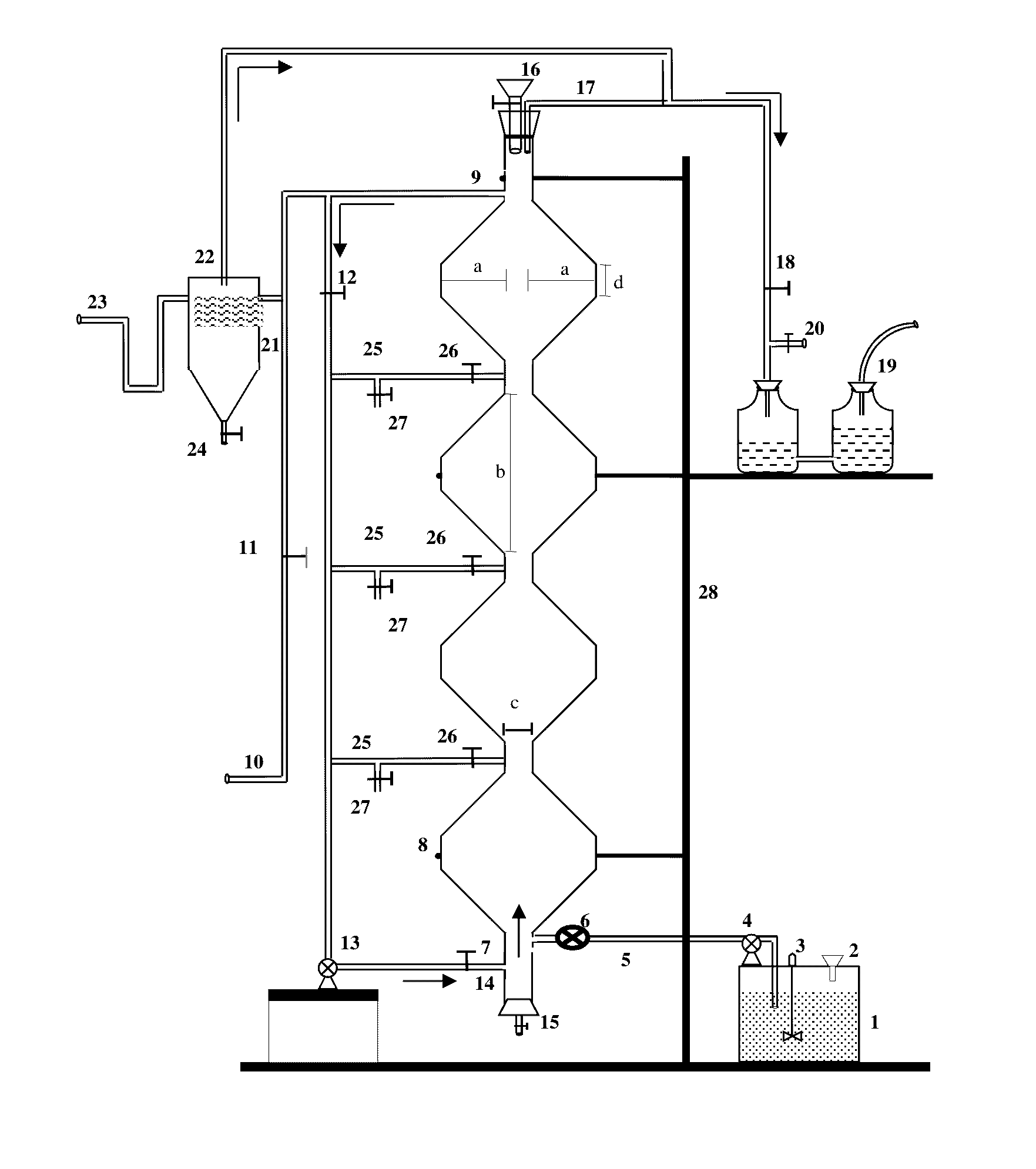

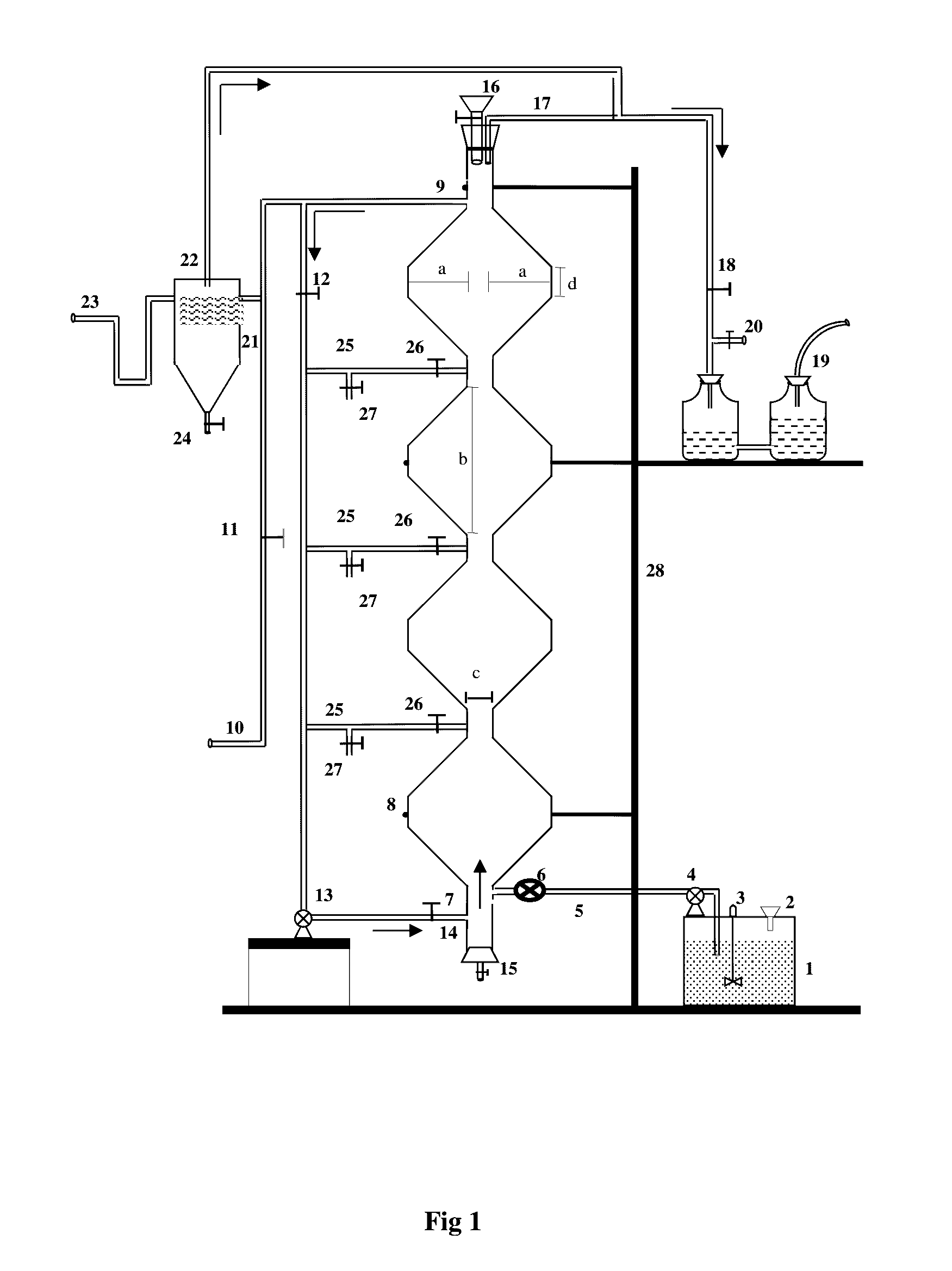

Anaerobic column reactor for biodegradation of wastes and the process thereof

ActiveUS20170050892A1Prevent escapeEnhances biomass substrate contactBioreactor/fermenter combinationsBio-organic fraction processingProcess engineeringAnaerobic reactor

The present invention relates to an anaerobic column reactor for biodegradation of wastes. Particularly the present invention relates to a process for conversion of biodegradable wastes to biogas and compost. More particularly, the present invention relates to an anaerobic reactor with unique arrangement of expanded and constricted portions alternatively placed vertically over each other which enhances the mixing pattern and thereby the mass transfer rates while controlling the biomass washout by regulating the upflow liquid velocity.

Owner:COUNCIL OF SCI & IND RES

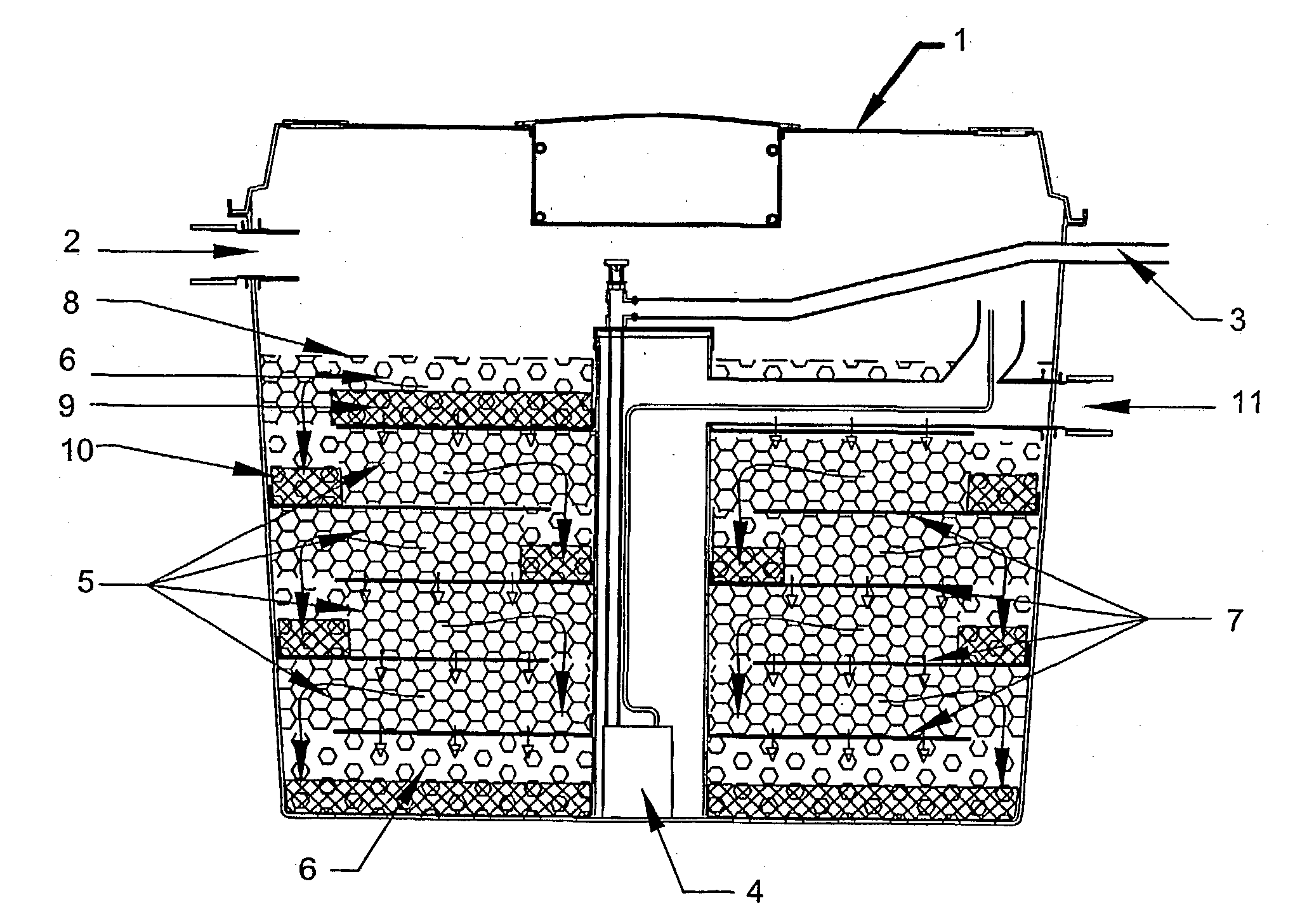

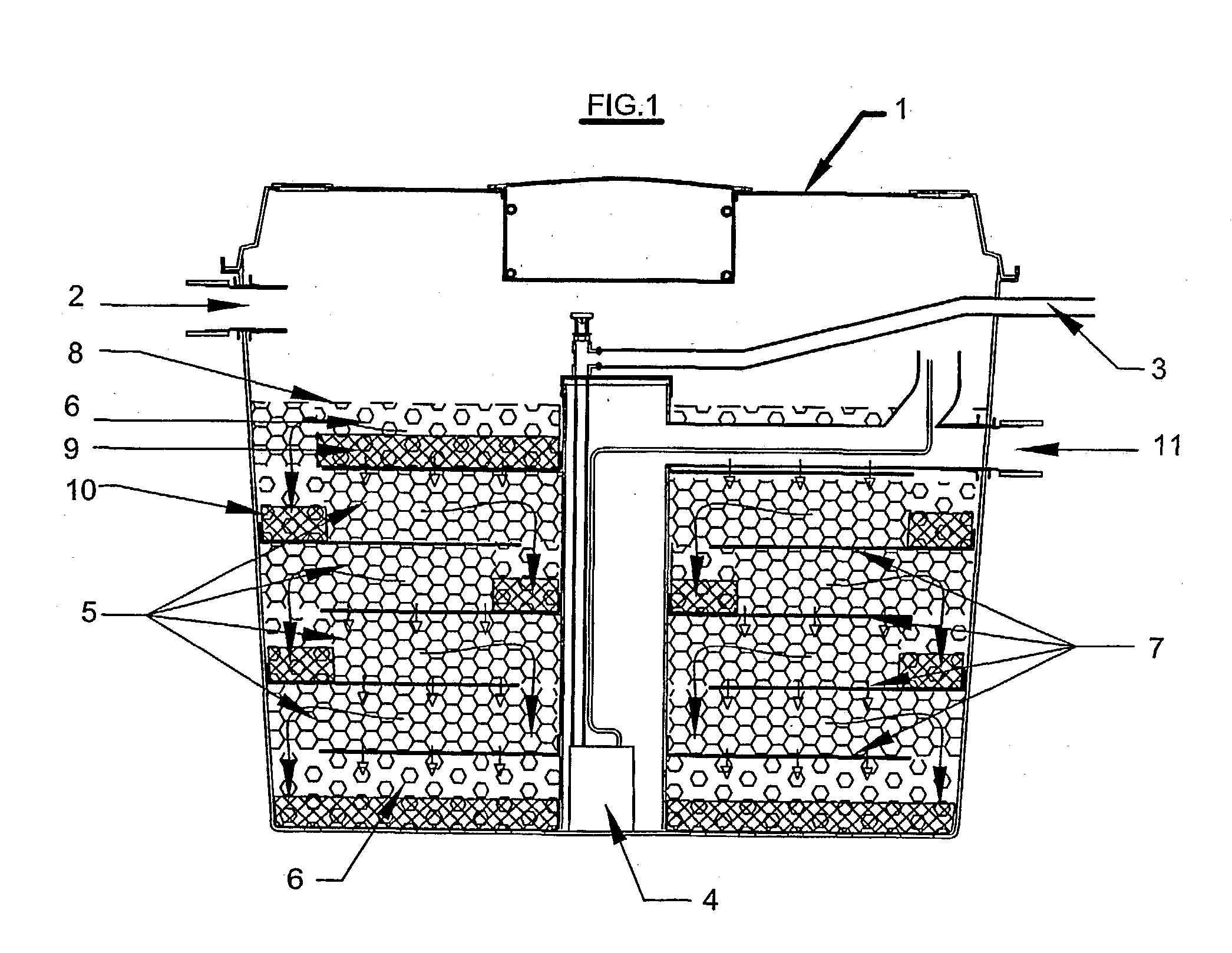

Biolytic filtration

InactiveUS20030116488A1Facilitate communicationAvoid erosionBio-organic fraction processingSludge treatment by de-watering/drying/thickeningBio filtrationFiltration

A filtration bed support for biolytic filtration wherein the filtration bed comprises a bed of solids in various stages of decomposition ranging from raw unprocessed organic material on the surface of the bed to fully decomposed humus which forms the bulk of the bed. The bed is kept from blocking by living organisms. The support comprises a three dimensional humus matrix lattice.

Owner:DOWMUS PTY LTD

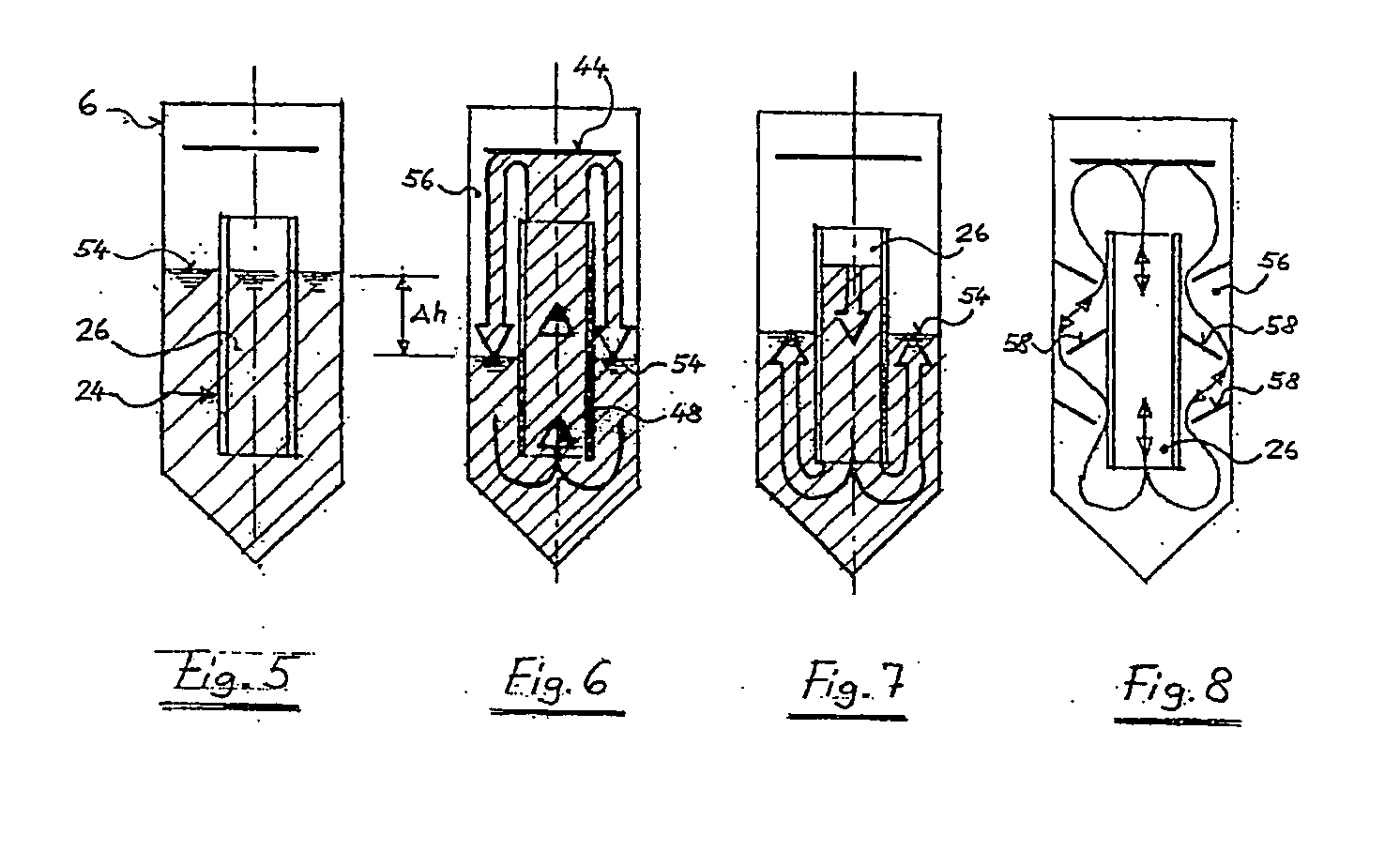

Method for preparing EM bio-organic fertilizer by use of biogass slurry and bio-organic fertilizer

InactiveCN105503288APromote absorptionHigh activityBio-organic fraction processingClimate change adaptationDecompositionOrganic manure

The invention provides a method for preparing an EM bio-organic fertilizer by use of biogass slurry. The method comprises the following steps: adding an EM stock solution and an EM nutrient fluid into biogass slurry, and cultivating the biogas slurry by EM to obtain a bio-organic fertilizer, wherein the mass ratio of biogas slurry, the EM stock solution and the EM nutrient fluid is (95-105): (2-6): (0.5-1.5). As the EM cultivation mode is adopted, the method for preparing the EM bio-organic fertilizer by use of biogass slurry has the advantages of being convenient, simple, easy to operate and the like. The bio-organic fertilizer contains rich organic matters and lots of beneficial bio-funguses, can play a soil improvement role, can accelerate decomposition of the organic matters, has the advantages of being rich in nutrition, being easy to be absorbed by plants, improving the yield and the quality of crops and the like, is a leaf fertilizer with comprehensive nutrients and can treat and control some plant diseases and insect pests of the crops.

Owner:湖北国源生物科技有限公司

Material Solubiliser Reactor For Hydrolysis and/or Wet Fermentation and Waste Treatment Plant With Such a Solubiliser and Reactor

InactiveUS20080199943A1Short timeReduce spendingBioreactor/fermenter combinationsBio-organic fraction processingSolventHydrolysis

The invention relates to a method for the treatment of waste with organic components, whereby in standardized method steps, various material solubilisers, for dissolving the organic material in a solvent and various reactors for carrying out a hydrolysis and / or a wet fermentation are used depending on the particle size and suitable solubilisers and reactors. A suitable waste treatment plant is also disclosed.

Owner:WIDMER CHRISTIAN

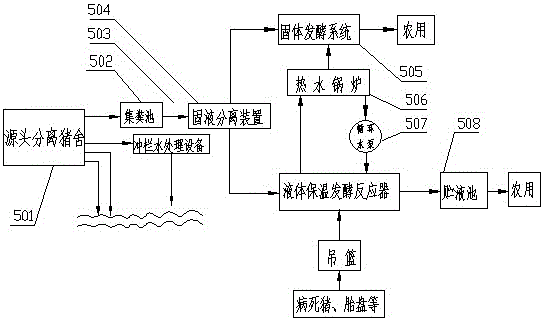

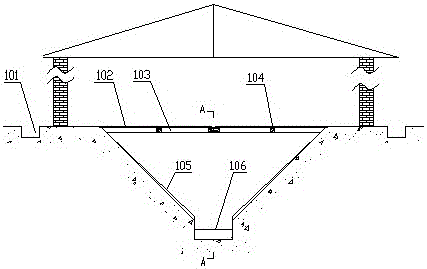

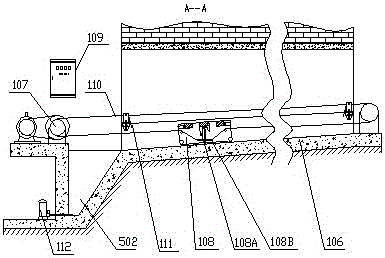

System and method for controlling excrement and urine of poultries and placentae of disease-caused dead poultries in large-scale farm

ActiveCN106116736AIn line with the cycleReduce the burden onBio-organic fraction processingAnimal corpse fertilisersSludgeThermal insulation

The invention relates to a system and method for controlling excrement and urine of poultries and placentae of disease-caused dead poultries in a large-scale farm. The system comprises a source separated poultry house, a solid-liquid separation system, a liquid high-temperature aerobic fermentation system, a solid fermentation system, a stink-flue gas treatment system, a circulating water system and a detection control system, wherein the source separated poultry house is a poultry house in which rainwater and sewage are separated, drinking water and sewage are separated, and fence flushing water and the excrement and urine of the poultries are separated; the solid-liquid separation system comprises a excrement collecting pool, a sludge pump and a solid-liquid separation device; the liquid high-temperature aerobic fermentation system comprises a liquid thermal-insulation fermentation reactor; the stink-flue gas treatment system comprises a stink heat exchange condenser, a flue gas heat exchange condenser, a biological deodorization filter tower, an aeration fan, an air blower and an induced draft fan; and the detection control system comprises a material temperature sensor, a material level sensor, a pressure sensor, a water temperature sensor and a controller. According to the system, the harmless treatment, the reduction and the recycling are realized, the environment is protected, and the energy is saved.

Owner:HUNAN SAKAL ENVIRONMENTAL SCI & TECH CO LTD +1

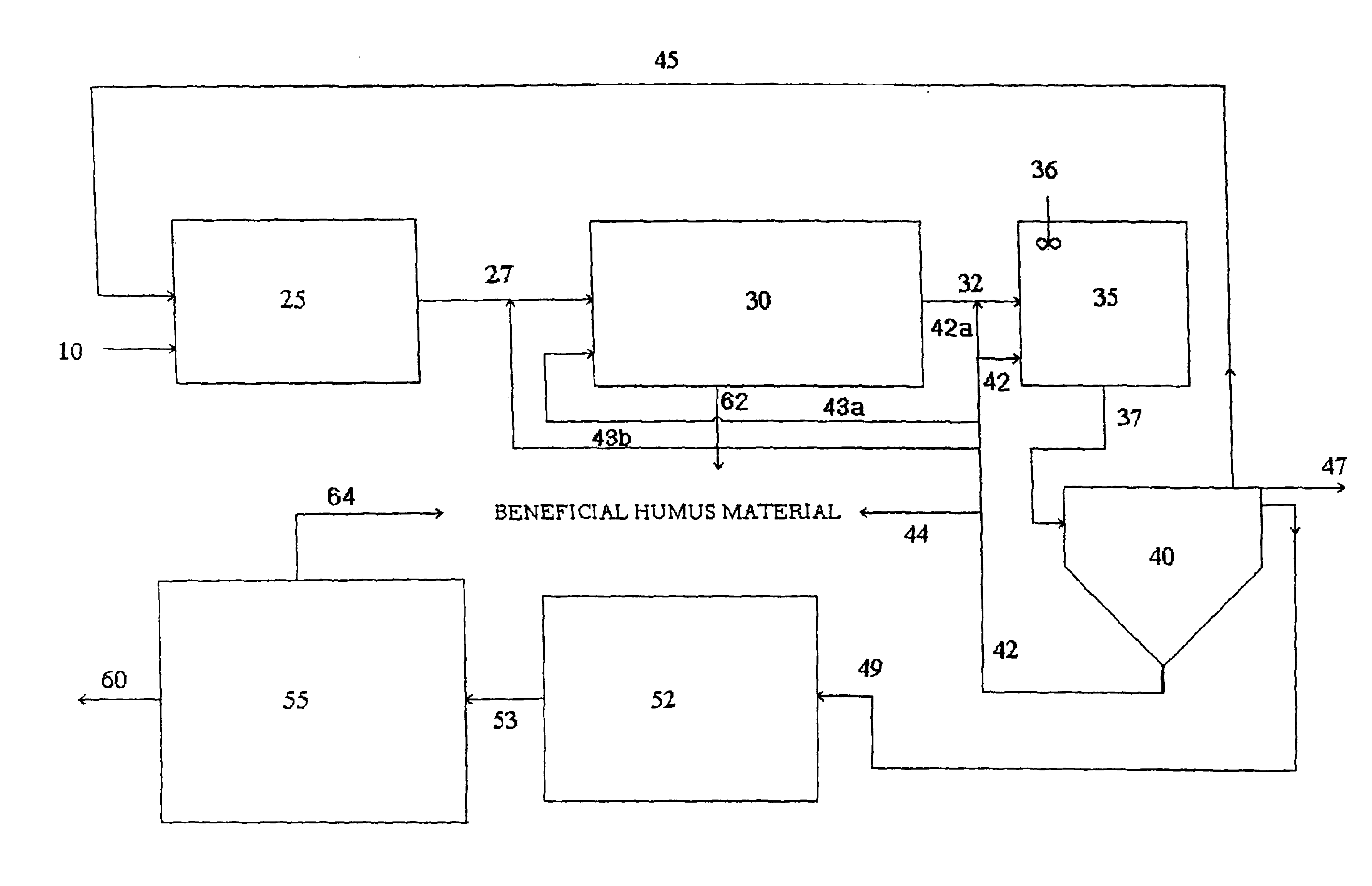

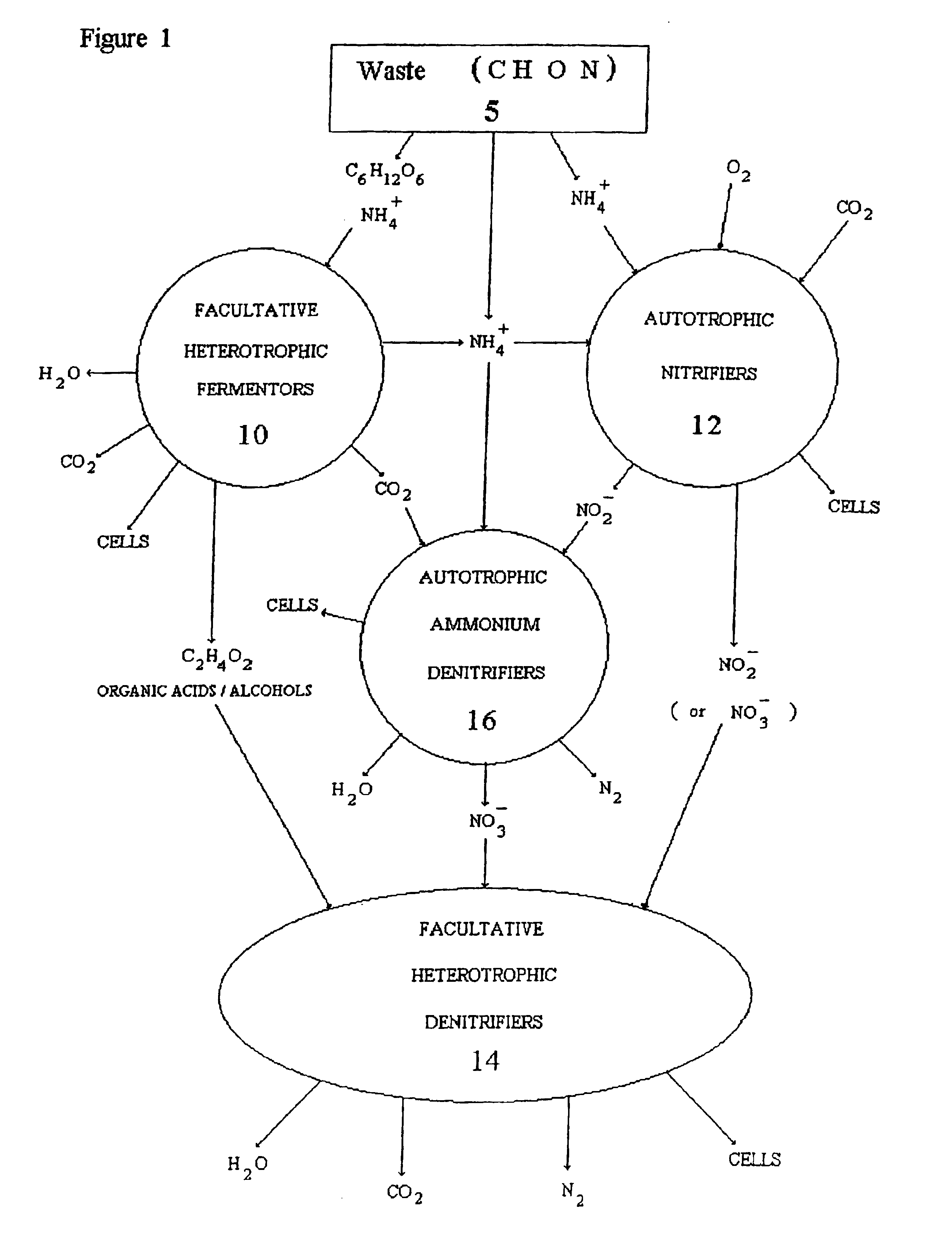

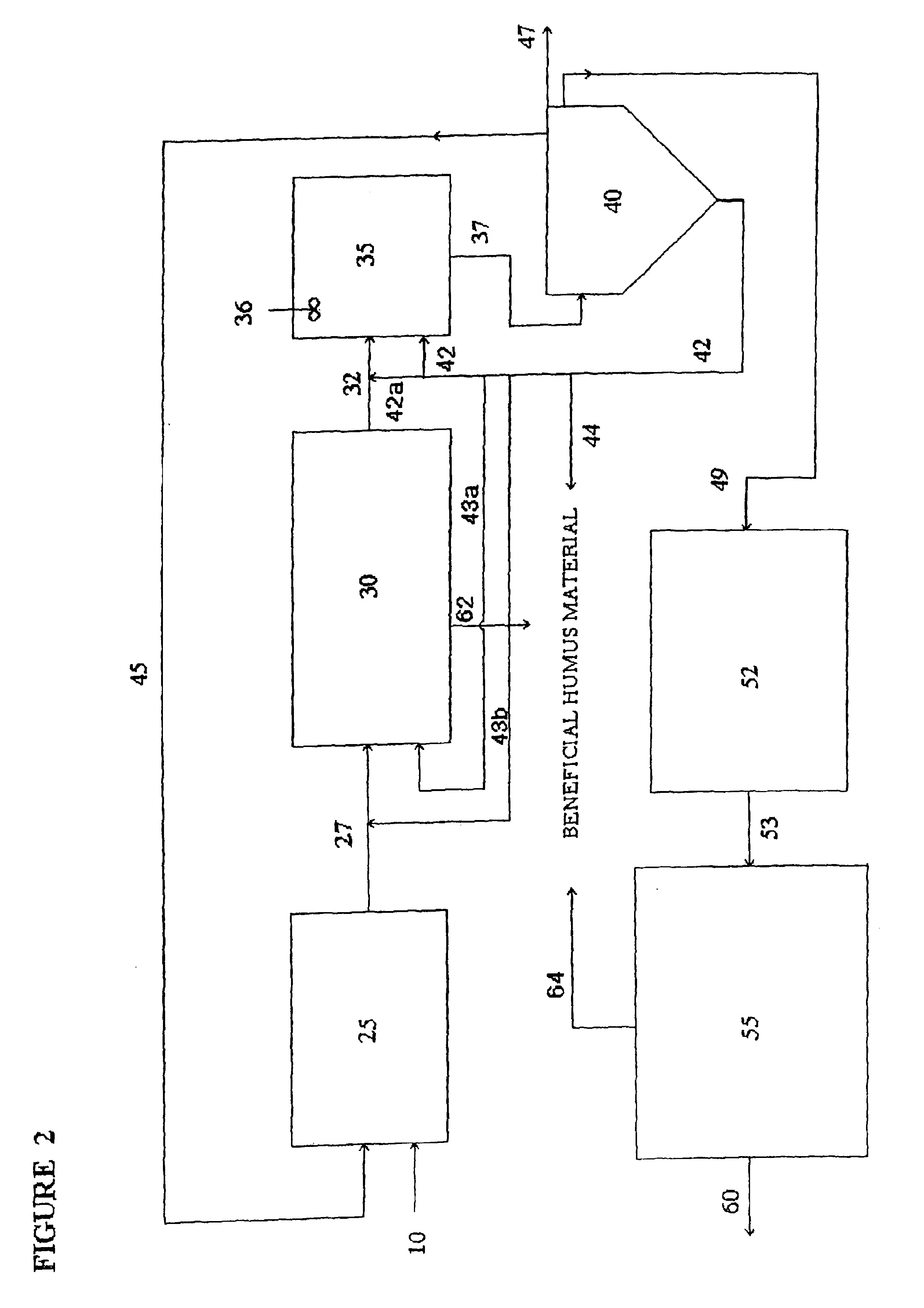

Low oxygen organic waste bioconversion system

InactiveUS6908495B2Pleasant odorMaintain securityBio-organic fraction processingExcrement fertilisersHumusBioconversion

The present invention is directed to a substantially odorless biological treatment process for solid and liquid organic wastes. The present invention also provides for a novel nutrient rich humus material produced from the biological treatment process. The bioconversion process of the present invention results from low oxygen concentrations and high quantities of microorganisms in a diverse microbial community.

Owner:BION TECH INC

Nutrient recovery systems and methods

ActiveUS8613894B2High recovery rateLow costBio-organic fraction processingBioloigcal waste fertilisersAeration rateBiology

Methods, systems, and apparatuses for anaerobic digestion of waste fibrous material and the recovery of nutrients are provided. Methods, systems, and apparatuses disclosed herein provide mechanisms to release dissolved gases from anaerobic digester effluent. Methods, systems and apparatuses disclosed herein can recover one or more nutrients from anaerobic digested effluent using a range of temperatures, aeration rates, aeration times, pH ranges, and settling times.

Owner:DVO +2

Popular searches

Biochemistry cleaning apparatus Gas production bioreactors Ultrafiltration Treatment with anaerobic digestion processes Biomass after-treatment Sewage/sludge fertilisers Enzymology/microbiology apparatus Tissue/virus culture apparatus Sustainable biological treatment Specific use bioreactors/fermenters

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com