Patents

Literature

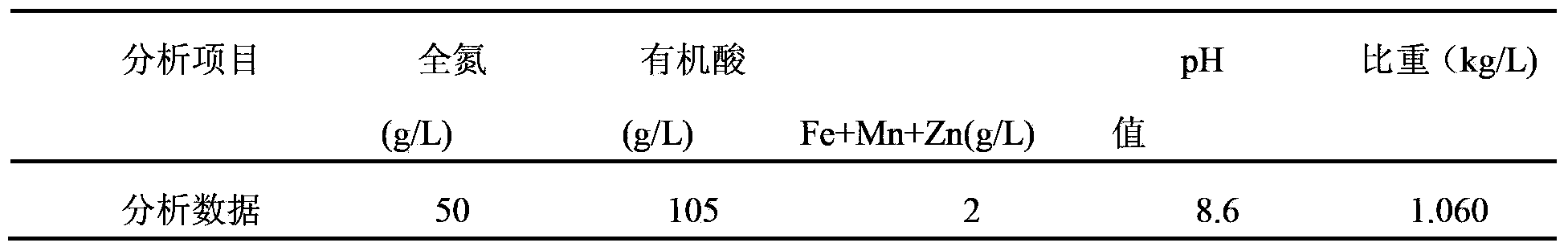

47 results about "Leonardite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Leonardite is a soft waxy, black or brown, shiny, vitreous mineraloid that is easily soluble in alkaline solutions. It is an oxidation product of lignite, associated with near-surface mining. It is a rich source of humic acid (up to 90%) and is used as a soil conditioner, as a stabilizer for ion-exchange resins in water treatment, in the remediation of polluted environments and as a drilling additive. It was named after A. G. Leonard, first director of the North Dakota Geological Survey, in recognition of his work on these deposits.

Humic acid complex fertilizer and its production method

InactiveCN1400197ANutritional diversityReduce manufacturing costOrganic fertilisersFertilizer mixturesNitrateTrace element

The present invention relates to a humic acid composite fertilizer and its production method. Its composition is composed of (wt%) 30-70% of leonardite containing 50-75% of human acid, 10-40% of urea, 3-15% of phosphoammonium, 0-30% of potassium chloride, 0-30% of potassium sulfate, 0-10% of potassium hydroxide, 0-12% of potassium carbojnate and 0-3% of trace element. Its production method includes the following steps: pulverizing leonardite, making activating agent, activating leonardite, pulverizing raw materials, mixing them uniformly so as to obtain the invented humic acid composite powerfertilizer product, granulating to obtain granular fertilizer product which can improve crop quantity, reduce nitrate content of agricultural product, raise saccharide content and vitamin content andimprove soil.

Owner:通辽绿阳科技开发有限公司

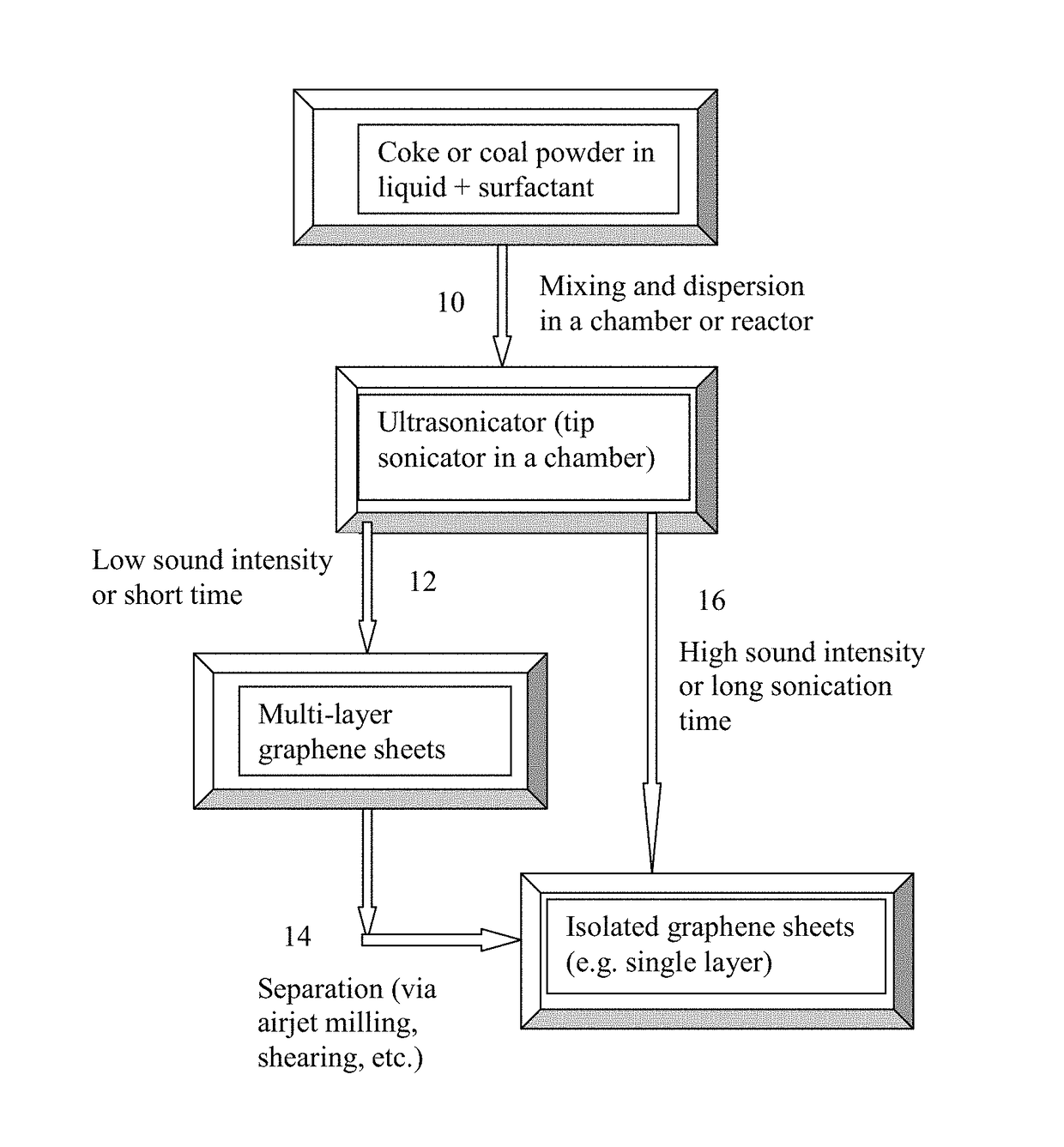

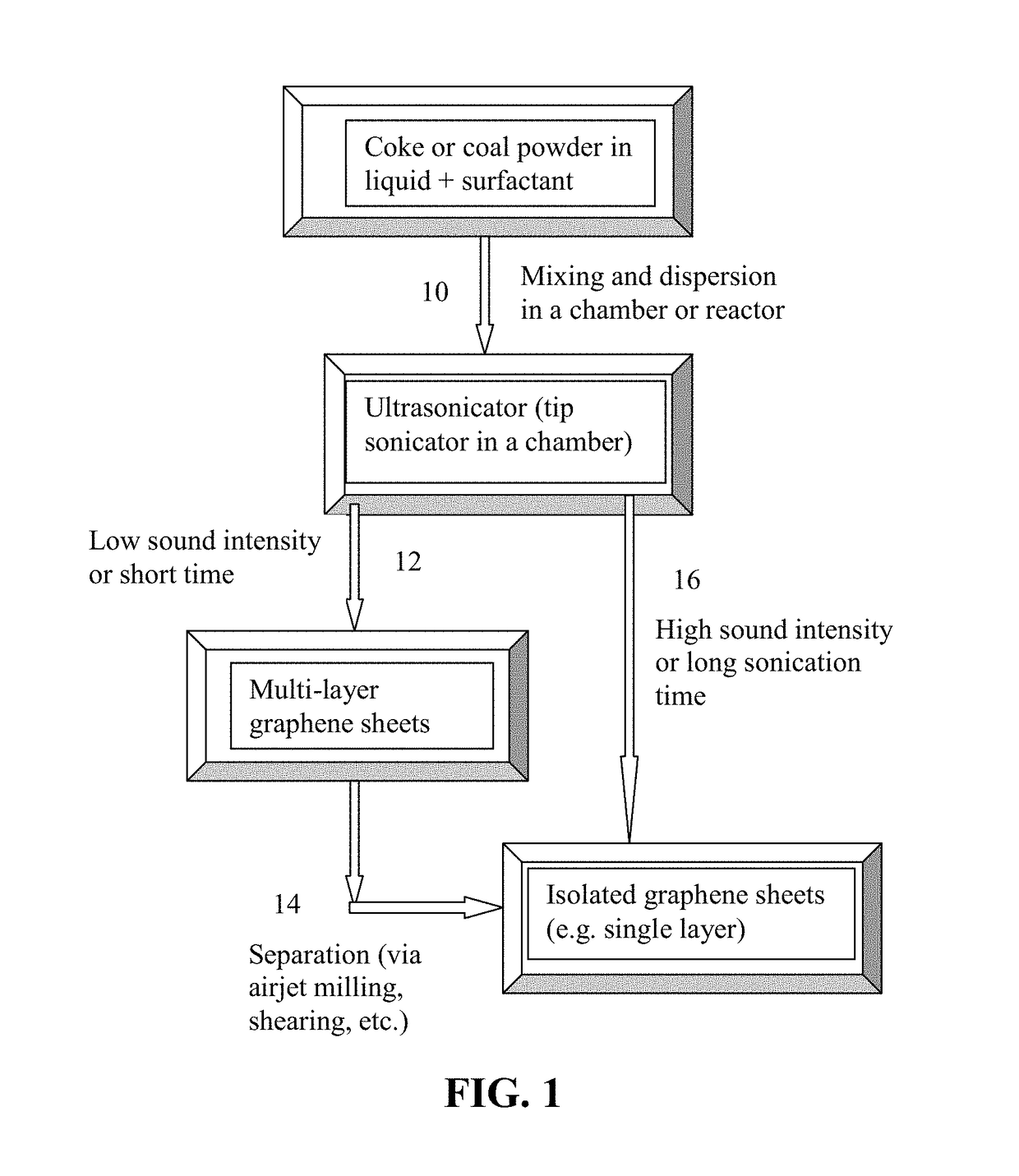

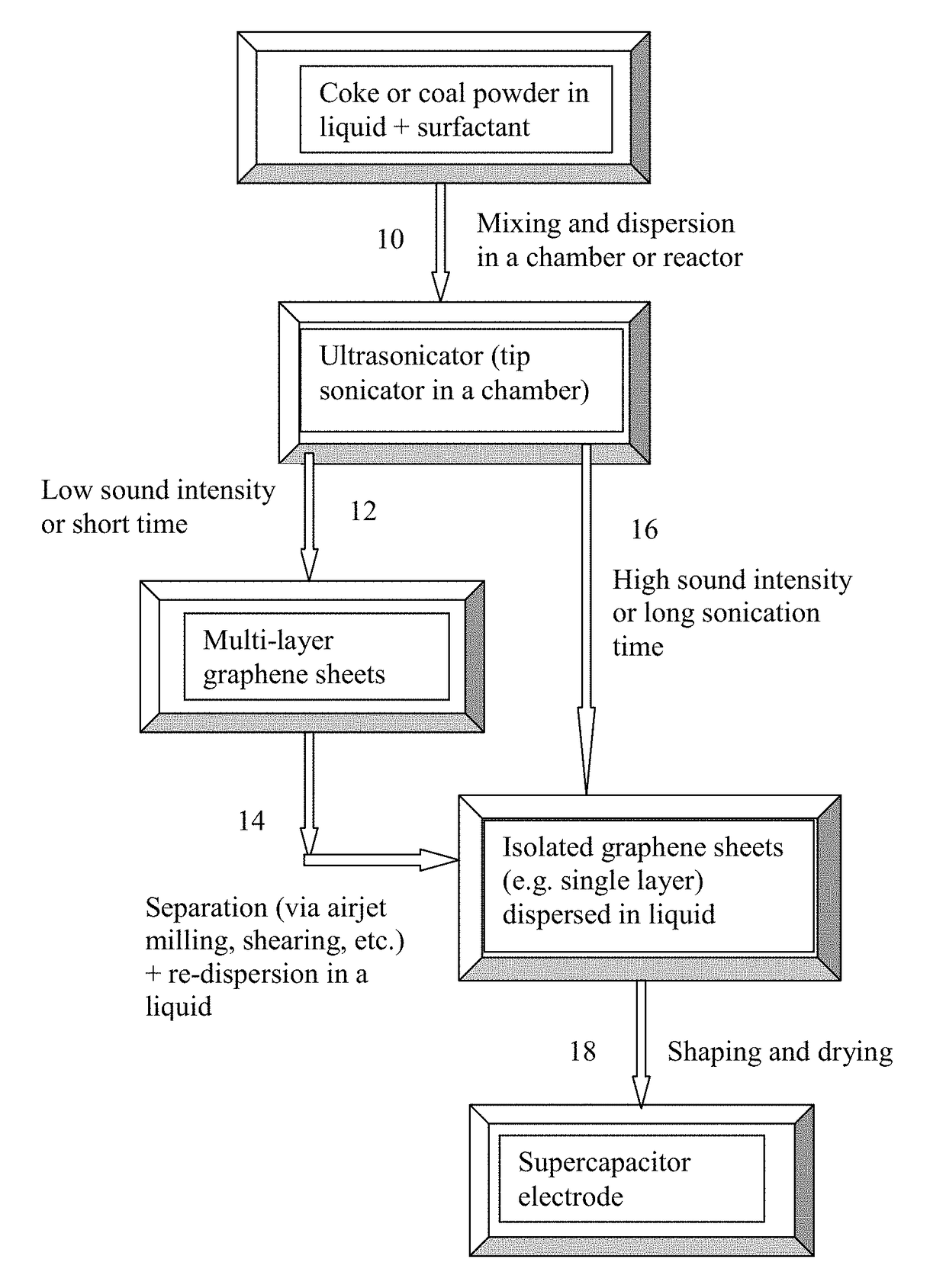

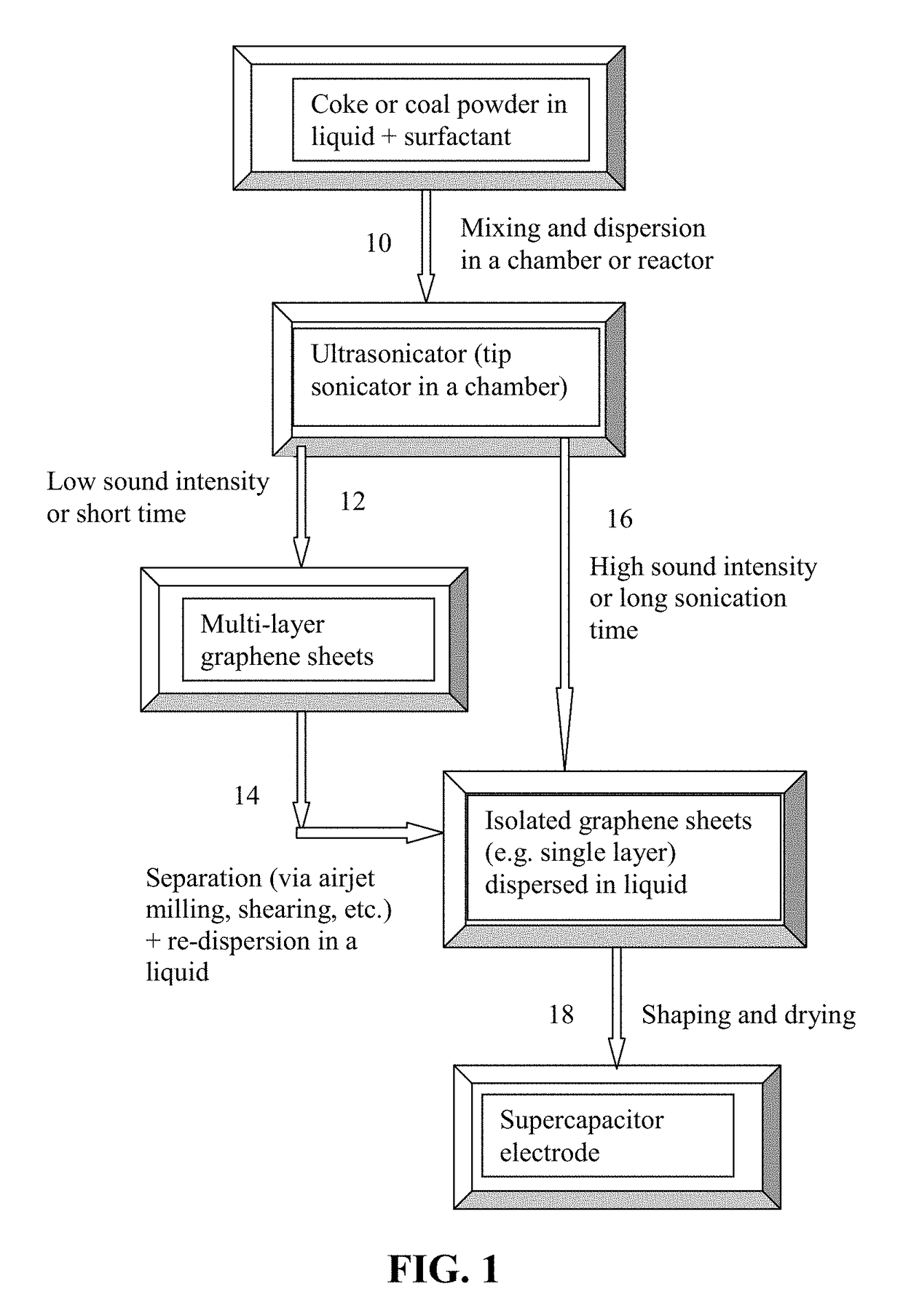

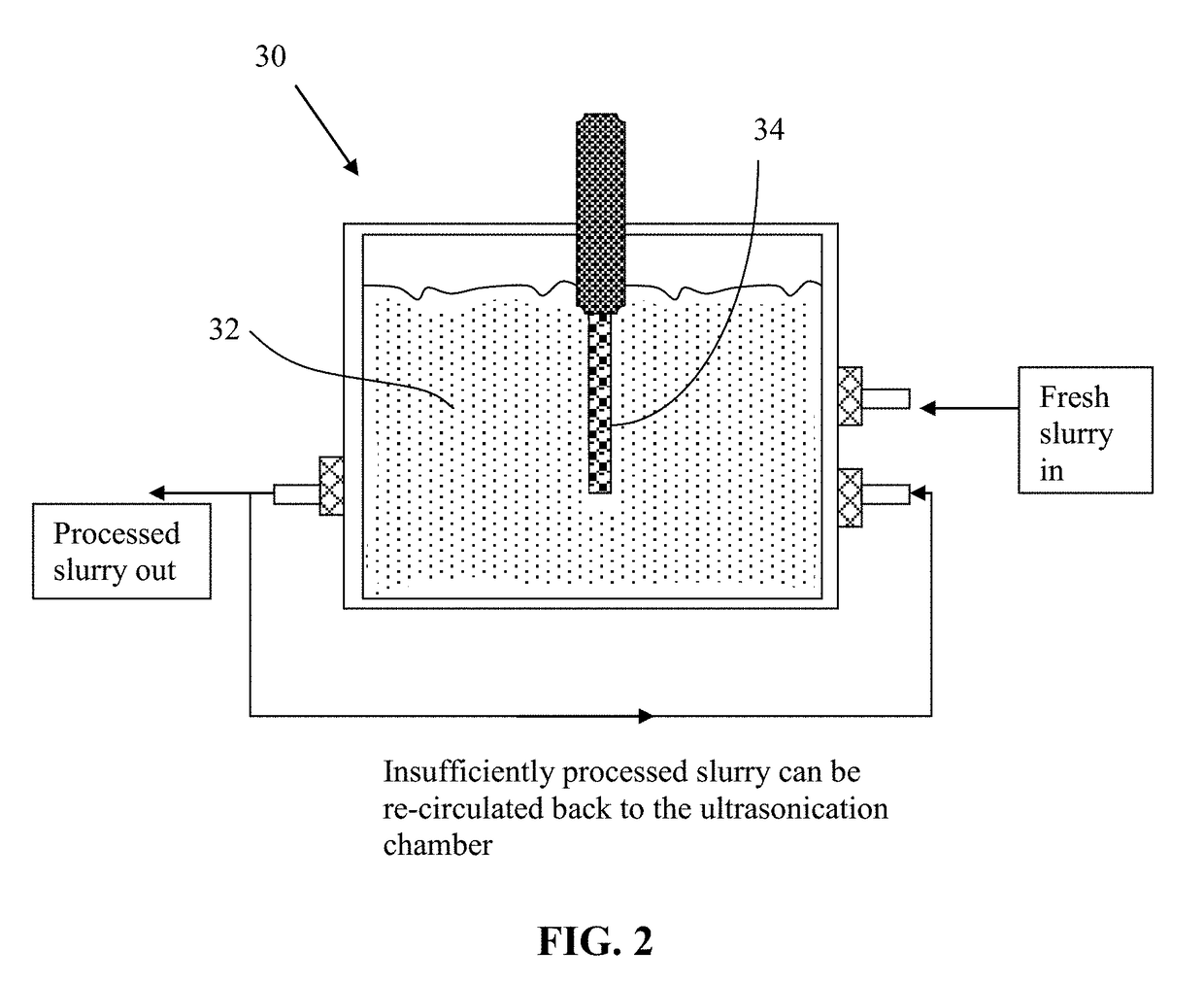

Direct Ultrasonication Production of Graphene Sheets from Coke or Coal

ActiveUS20170369320A1Prevent restackingGuaranteed normal transmissionGrapheneInksLiquid mediumAnthracite

Provided is a method of producing isolated graphene sheets from a supply of coke or coal powder containing therein domains of hexagonal carbon atoms and / or hexagonal carbon atomic interlayers. The method comprises: (a) dispersing particles of the coke or coal powder in a liquid medium containing therein an optional surfactant or dispersing agent to produce a suspension or slurry, wherein the coke or coal powder is selected from petroleum coke, coal-derived coke, meso-phase coke, synthetic coke, leonardite, anthracite, lignite coal, bituminous coal, or natural coal mineral powder, or a combination thereof; and (b) exposing the suspension or slurry to ultrasonication at an energy level for a sufficient length of time to produce the isolated graphene sheets.

Owner:GLOBAL GRAPHENE GRP INC

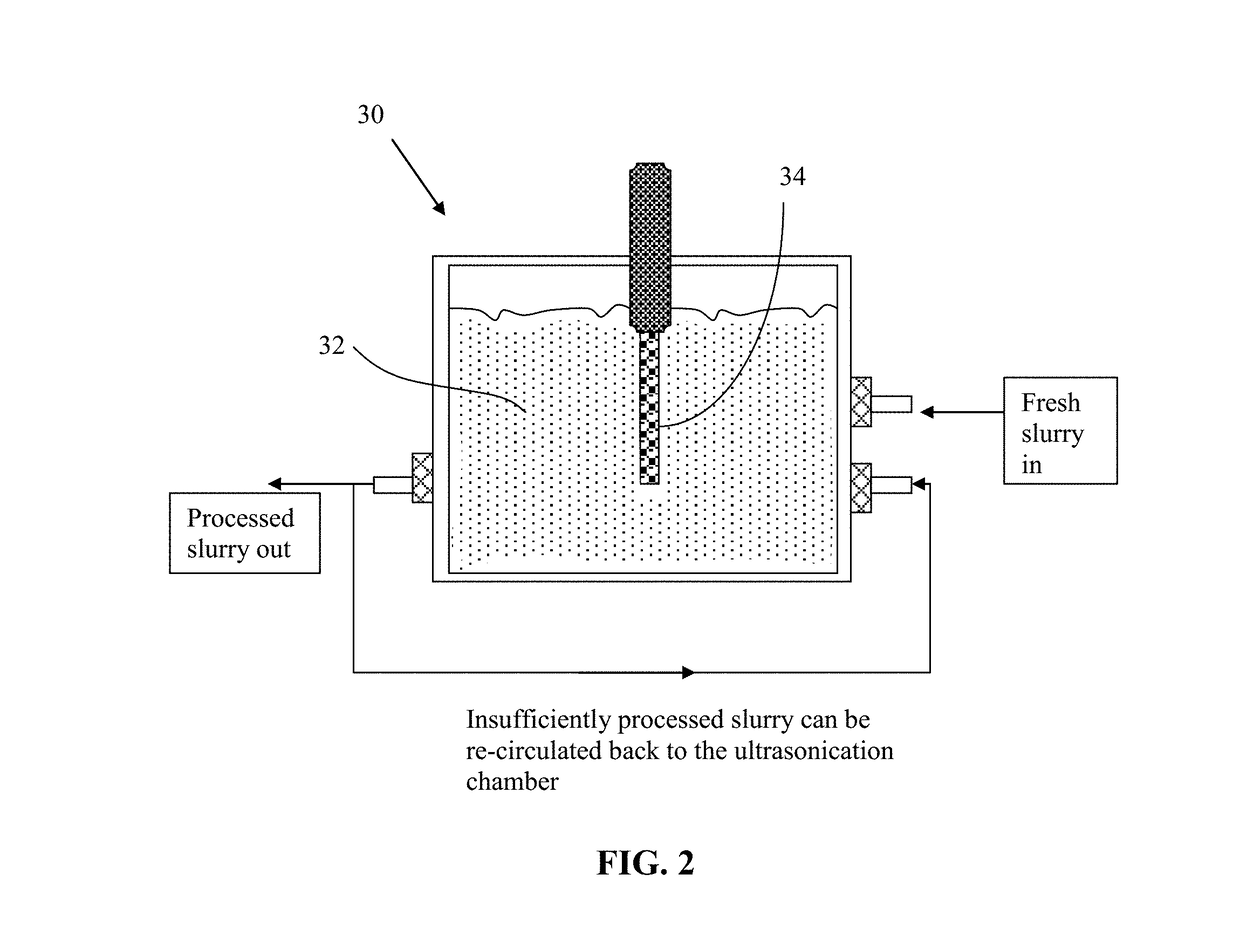

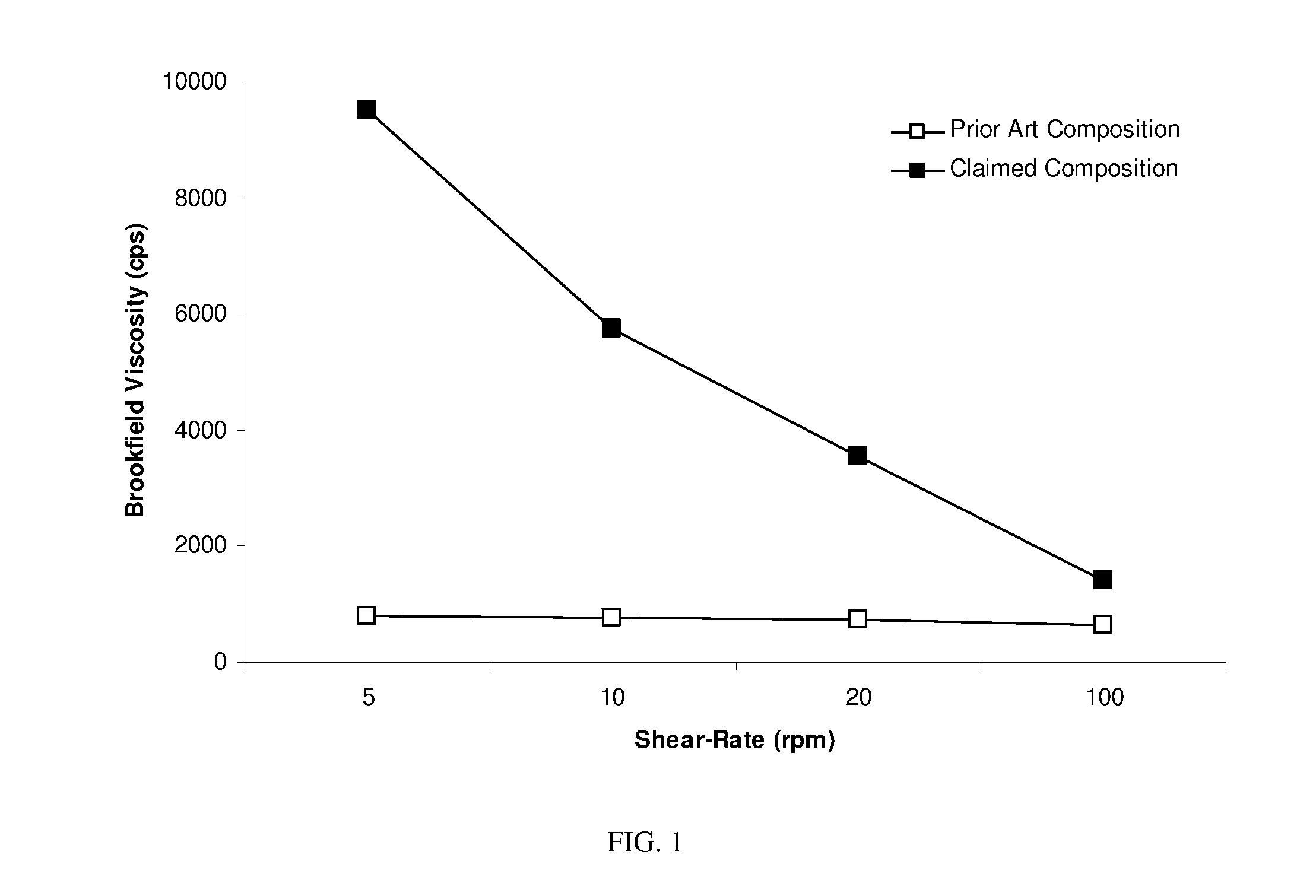

Lignite-based urethane resins with enhanced suspension properties and foundry sand binder performance

Described herein, in the preferred embodiment, is a leonardite-based polyurethane resin binder that may be used, among other applications, as a binder in combination with foundry aggregate, e.g., sand, for molding or casting metal parts. The binders described herein comprise a humic substance, preferably leonardite, combined with a polymerizable polyol, an isocyanate, and a polymerization catalyst to make a polyurethane resin binder in situ in a foundry aggregate, such as sand. The lignite is mixed with the polymerizable polyol, thickening and dispersing agents as additives to improve the suspension quality and binder performance of the lignite-containing part of the binder components.

Owner:AMCOL INTERNATIONAL CORPORATION

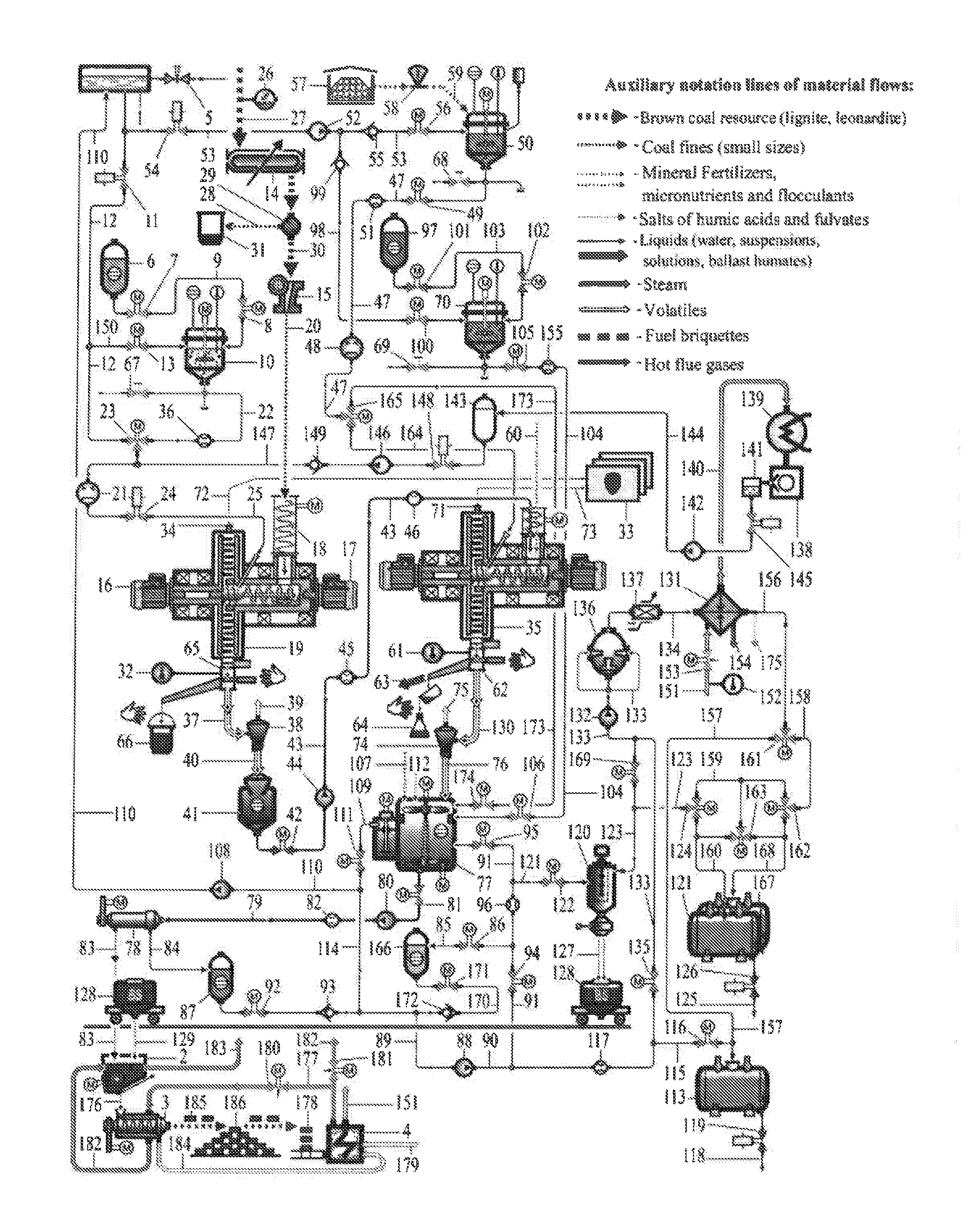

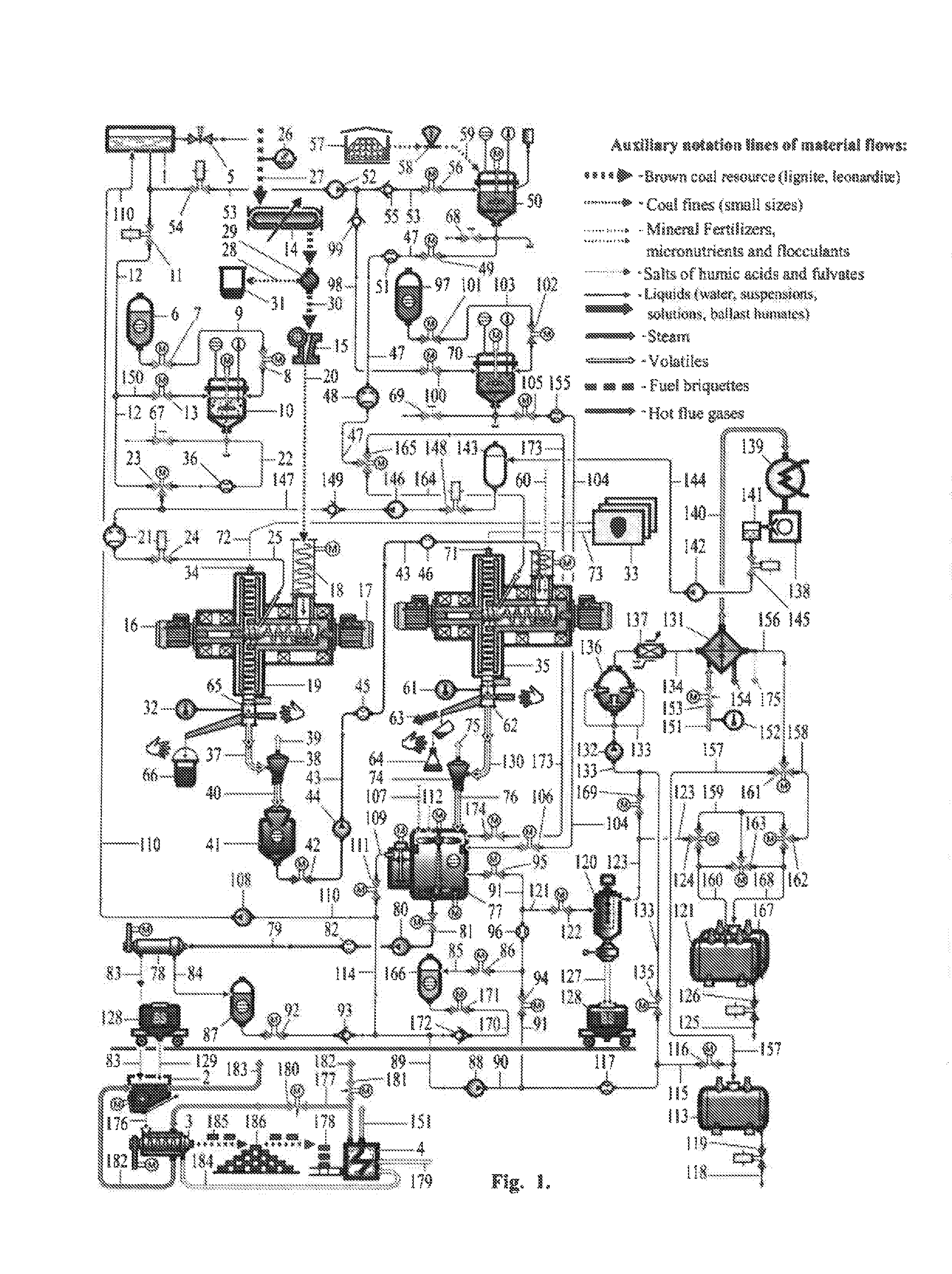

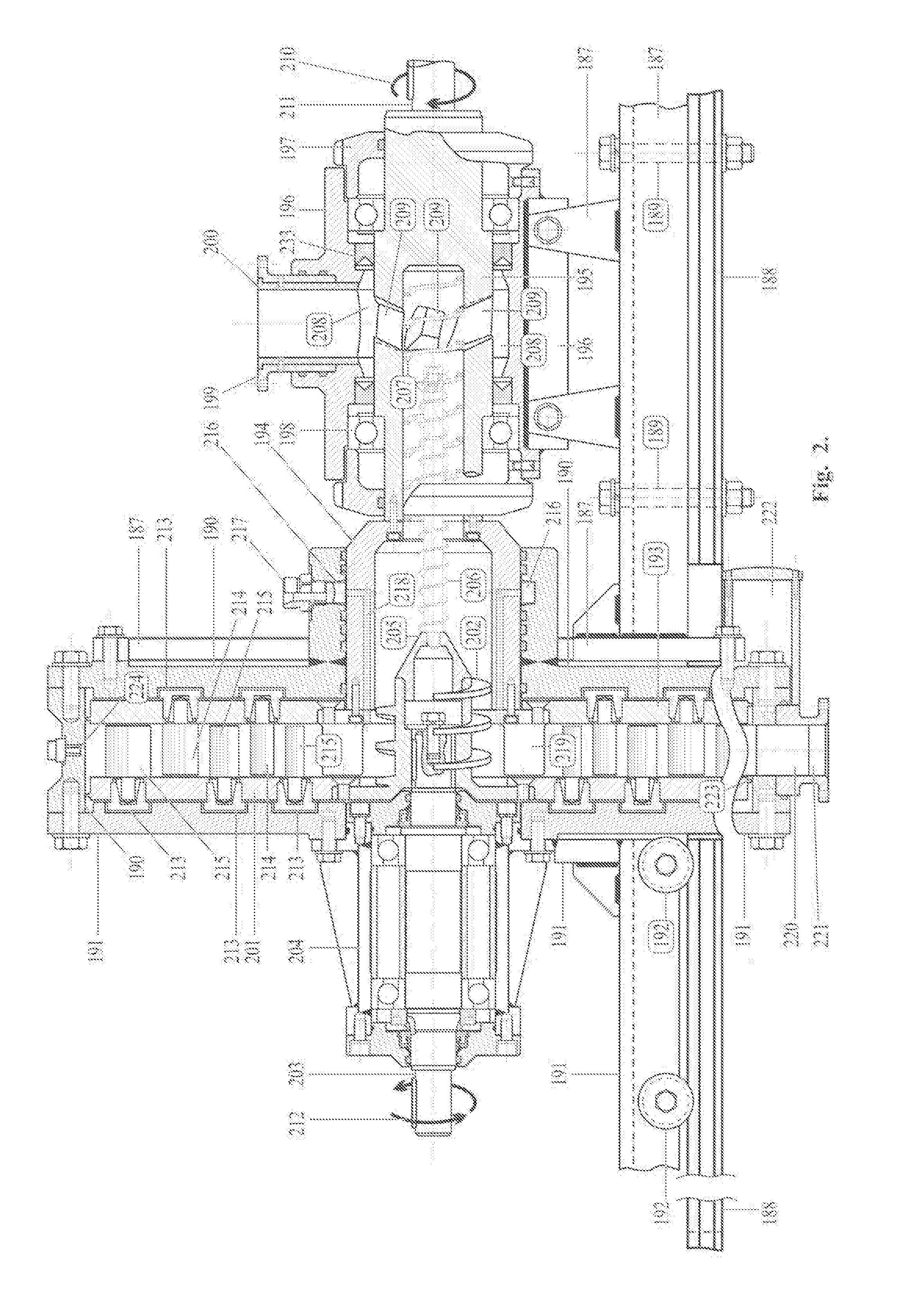

Method for comprehensively processing brown coal and leonardite into humic fertilizers and preparations and into fuel briquettes, and mechanochemical reactor for processing highly-viscous media

ActiveUS20170036967A1Improve soil structureMaintain stabilityBio-organic fraction processingEnergy inputRaw materialPhase separation process

A method for comprehensively processing coal-type caustobiolites, predominantly brown coal and leonardite, into humic organic and organomineral fertilizers and intor preparations producing fuel briquettes, including carrying out main processes in a continuous flow; carrying out leaching processes based on aqueous solutions with hydromodules of close to 2, carrying out acidification processes with the formation of humic acid released from a liquid phase into a heavy phase of a coagulated pulp, carrying out mechanical phase separation processes in a centrifugal field, carrying out liquid-phase mechanoactivation and the dispersion of reaction compositions via grinding, using residual “water” in recycling, and including the production of water-soluble humic acids and fuel briquettes and allowing for the production of a wide range of products; preliminarily grinding raw materials to a 03 mm class, and cleaning and electrochemically softening water in preparing reaction aqueous solutions; using a liquid-phase raw material oxidation process, and using liquid-phase mechanoactivation and / or mechanochemical activation, with the dispersion of reaction compositions by means of grinding and by means of dynamically shifting layers having statistical shift rate components, of a medium to be processed, which range from single-digit meters per second to tens of meters per second; accompanying said mechanoactivation with the dosed input into said medium of 1040 MJ of mechanical energy per cubic meter, with the stabilization of said dosing regardless of the drift of all other parameters in said medium to be processed; wherein, said grinding and shifting processes are formed by means of statistical and dynamic characteristics; in this way, a dynamic hydro-pulse effect on a medium to be processed is carried out within a range of frequencies floating between infrasound and frequencies bordering on ultrasound, wherein the processing is carried out beginning with higher frequencies; in addition, providing for automatically maintaining maximum parameters for inputting mechanical energy into the medium to be processed, while automatically restricting same within a sub-cavitation zone in order to prevent the transition of the mechanochemical reactors into cavitation modes.

Owner:SEVASTYANOV VLADIMIR PETROVICH +3

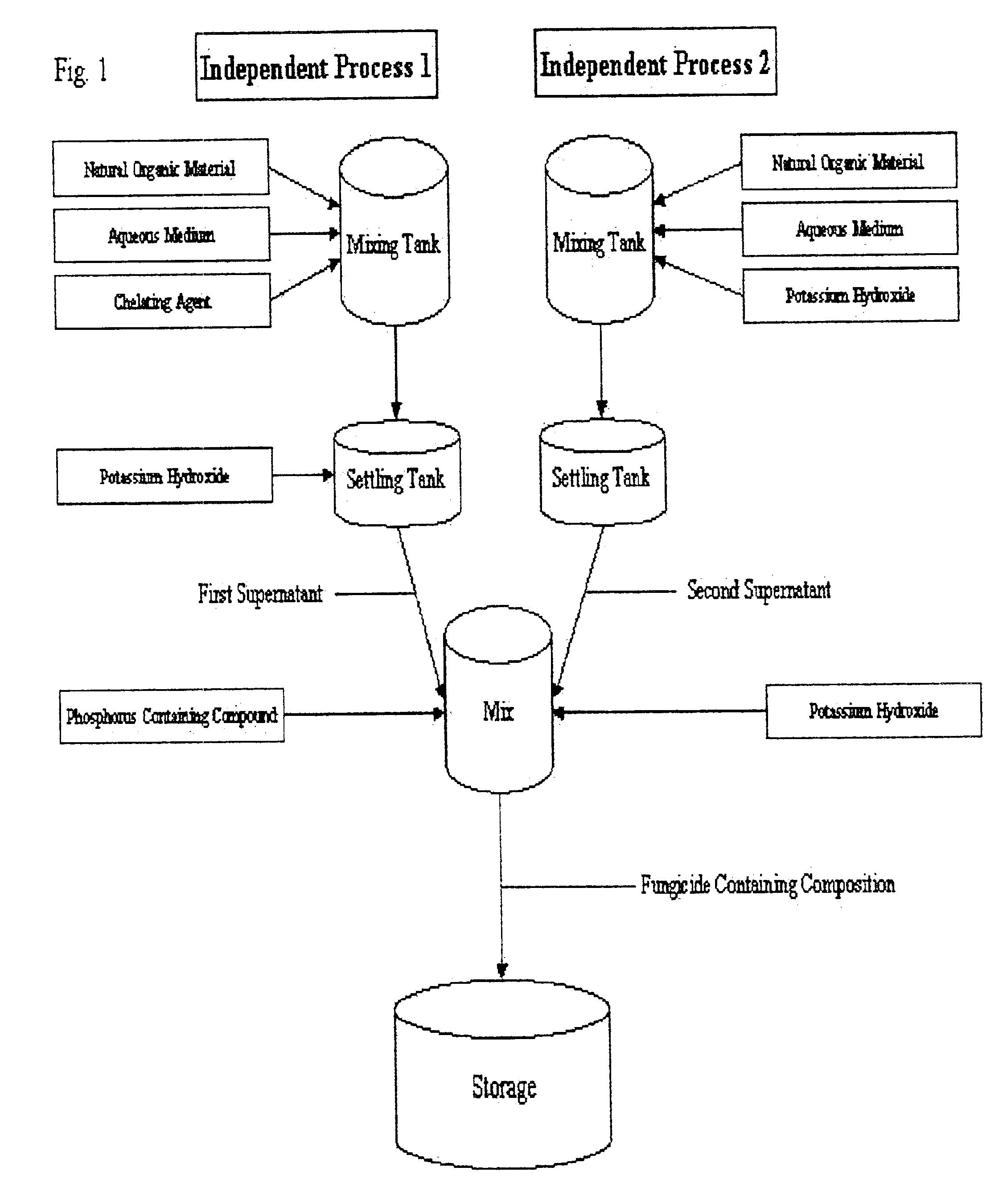

Fungicidal compositions containing organic compositions derived from natural organic materials, phosphorous acid, phosphite salts and phosphate salts, methods of making same and methods of applying same to plants

InactiveUS6911415B1Easy to controlAlleviates fungal diseaseBiocideDead animal preservationCompound organicPhosphorous acid

A fungicidal composition for controlling fungal diseases in plants, which includes a fungicide, and a complex organic composition derived from natural organic materials. The organic composition may comprise a humic acid composition, a fulvic acid composition, a humin component composition, mixtures thereof or other extracts from natural organic materials such as leonardite, lignite, peat, shale, sediments and soil. The fungicidal composition includes a phosphorus-containing compound such as phosphorous acid, a phosphite salt, and a phosphate salt or mixtures thereof. The preferred embodiments of the compositions provide enhanced control of select fungal diseases in plants as well as enhanced plant nutrient uptake abilities. The invention also includes processes for producing the fungicidal compositions and methods for applying the fungicidal compositions to plants.

Owner:ACTAGRO LLC A DELAWARE LLC

Organic soil modifier and production thereof

InactiveCN1778865ALow priceReduce manufacturing costOrganic fertilisersSoil conditioning compositionsAlkali soilOrganic farming

An organic soil ameliorant and its production are disclosed. The process is carried out by mixing leonardite 50í½70wt% and castor shell 20í½45wt% with ground phosphate rock 5í½10wt% and fermenting. It is simple and costs low. It can be used for the improvement of saline-alkali soil and low-yield filed.

Owner:辽宁普乐科技发展有限公司

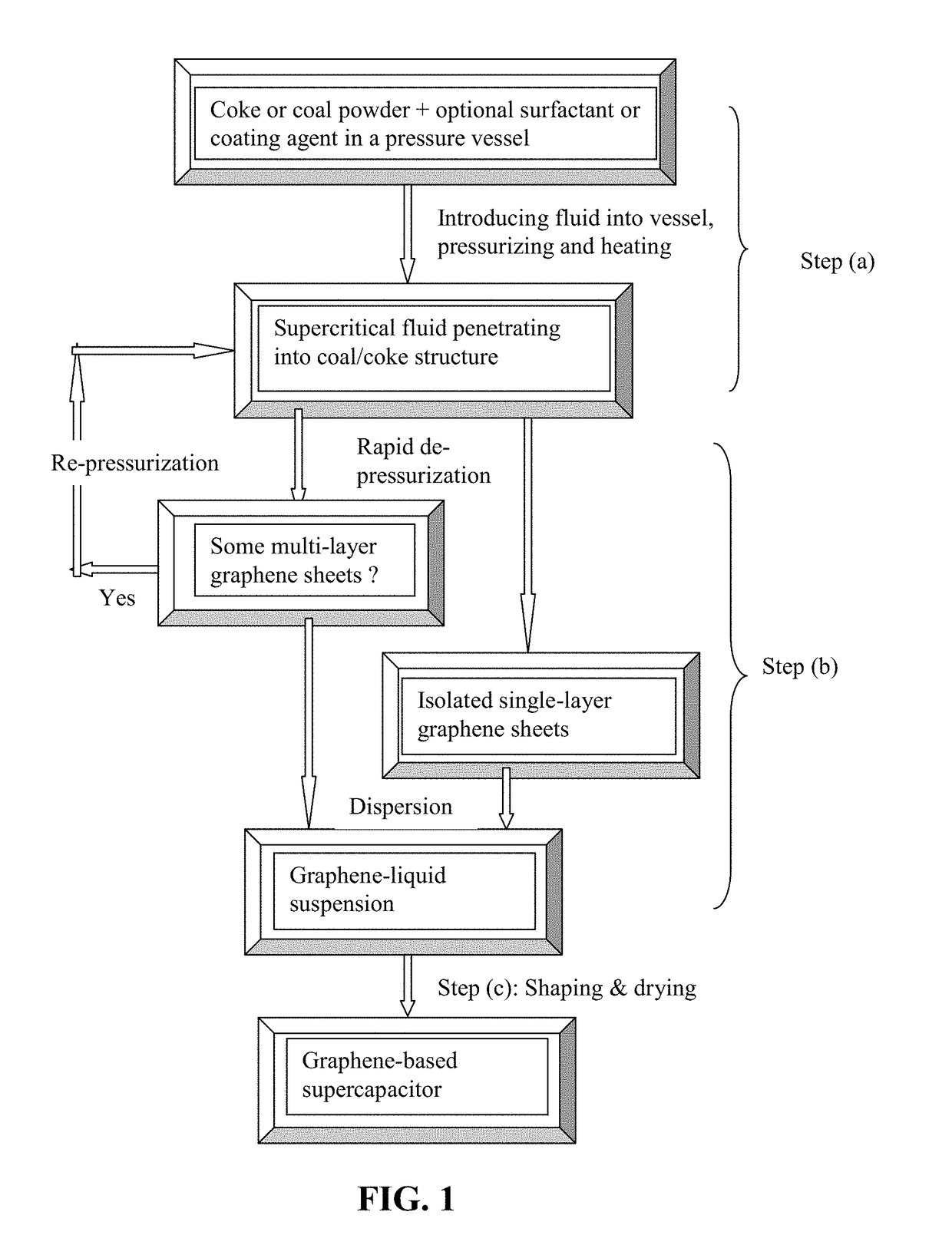

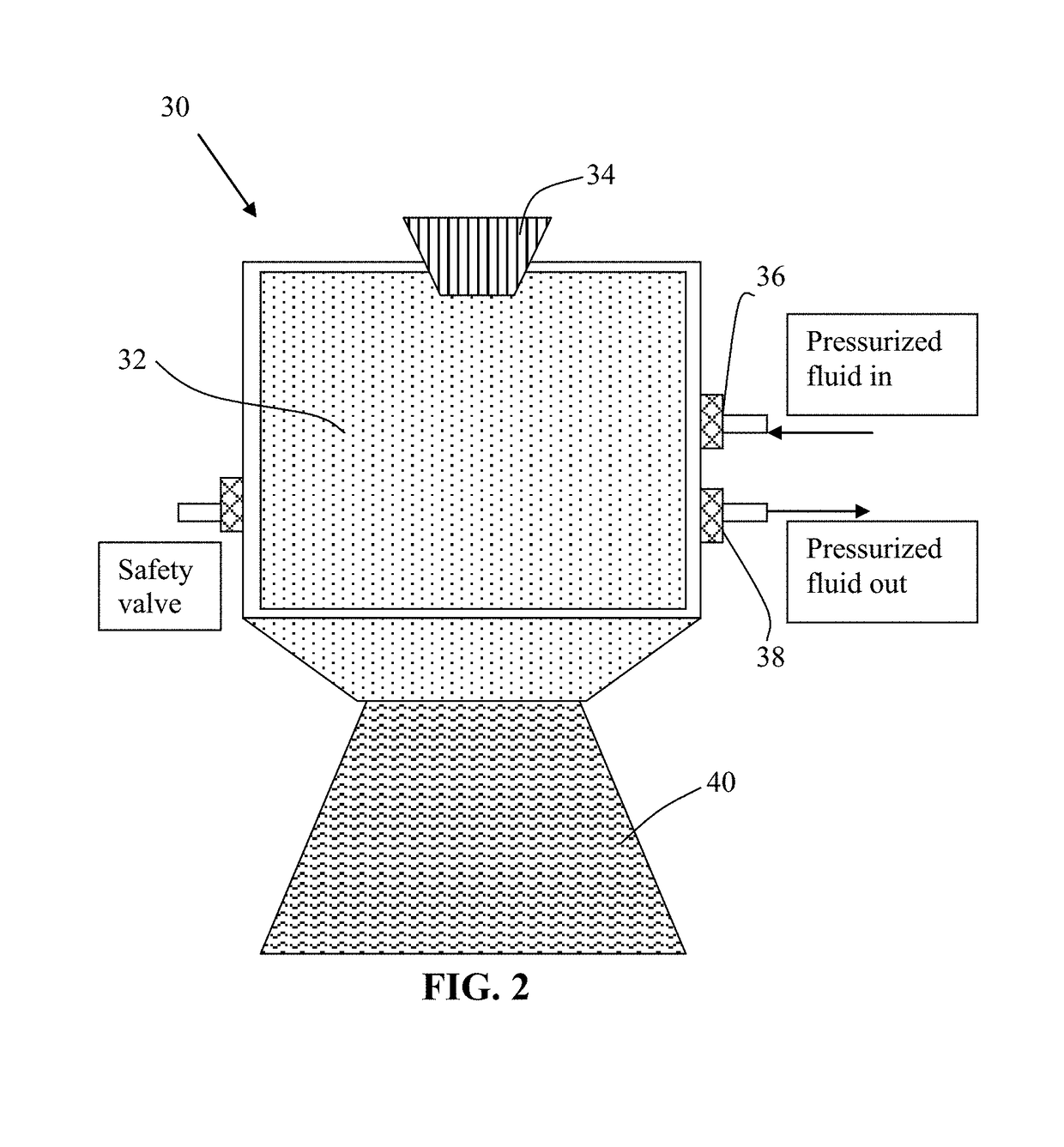

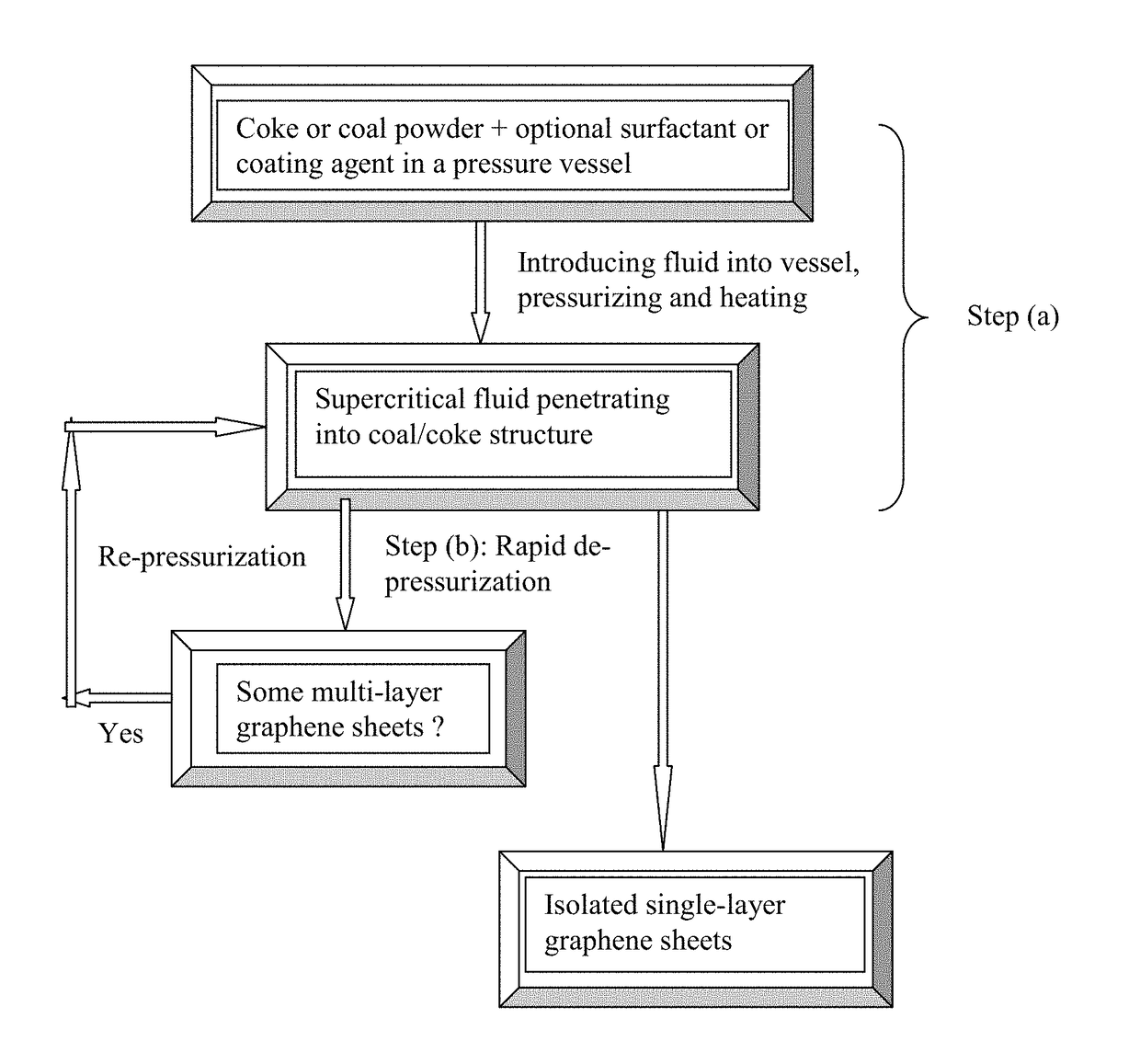

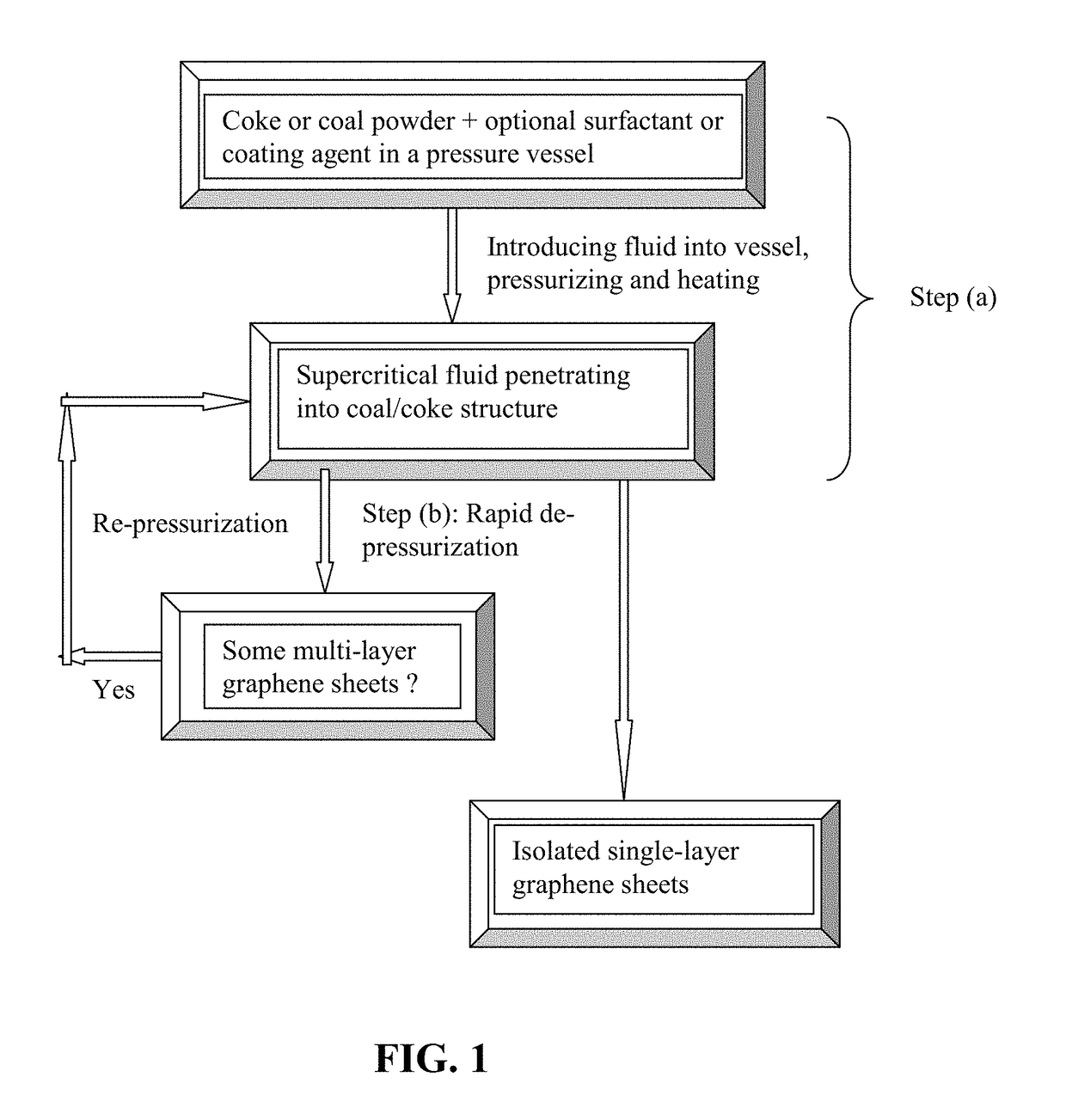

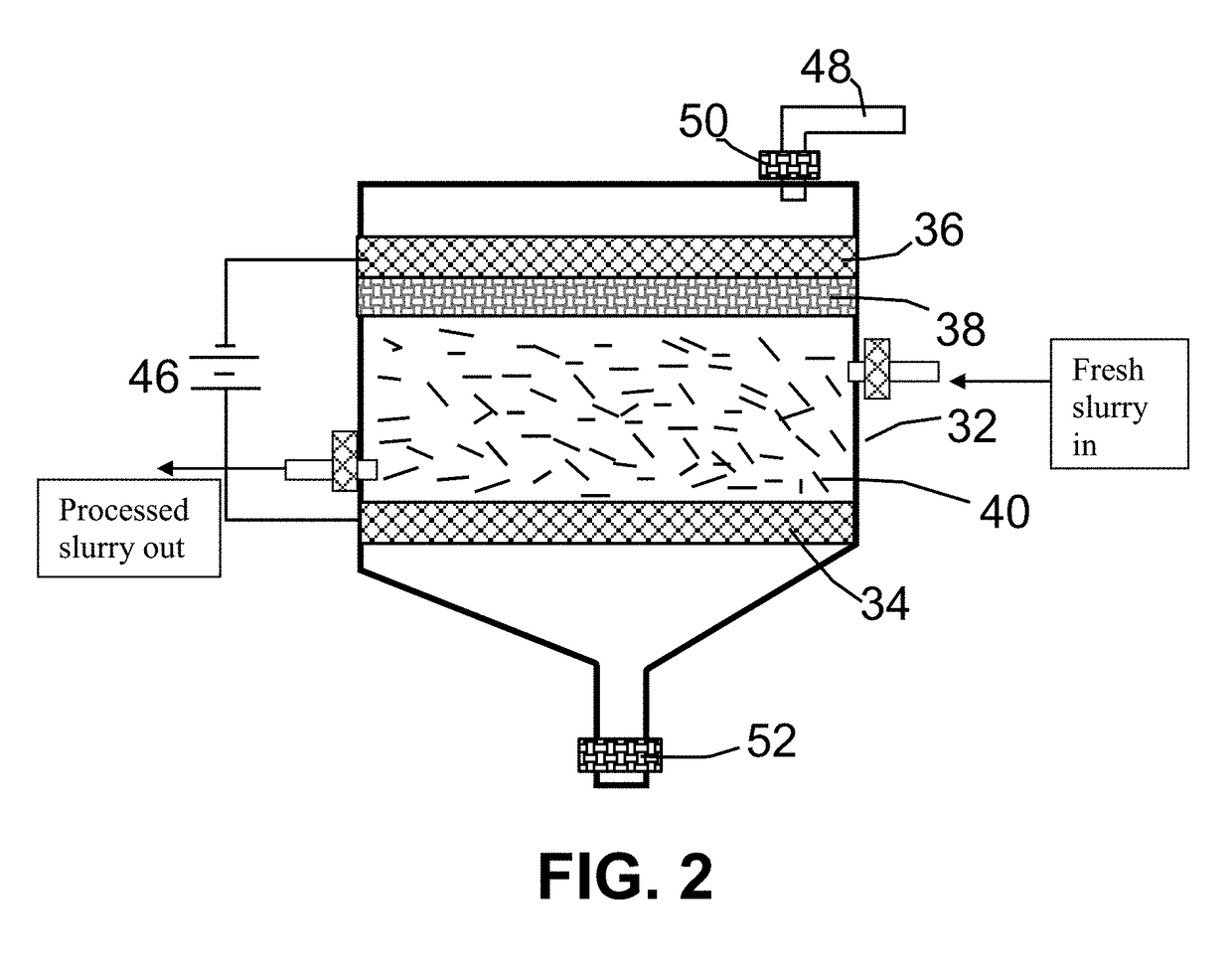

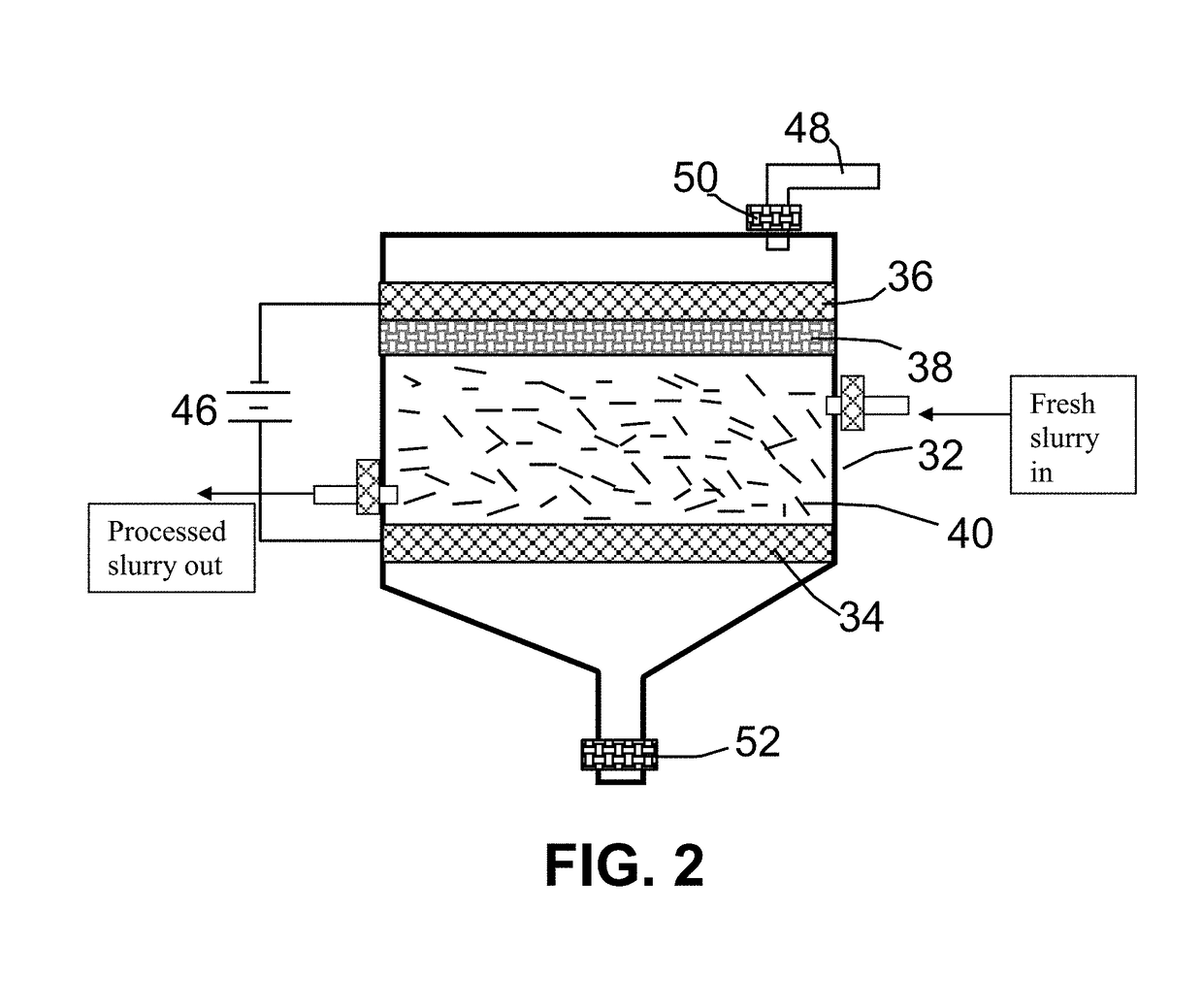

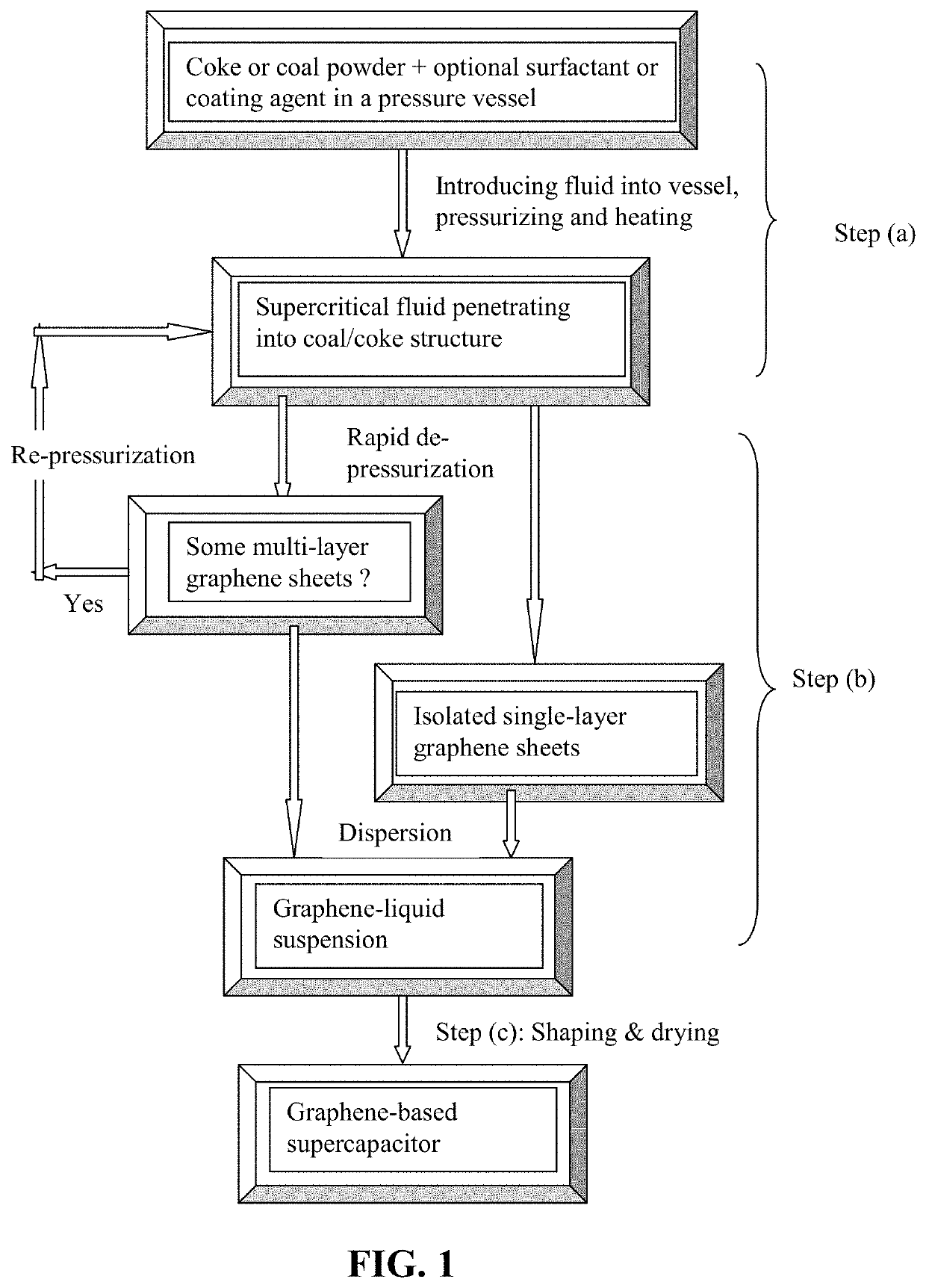

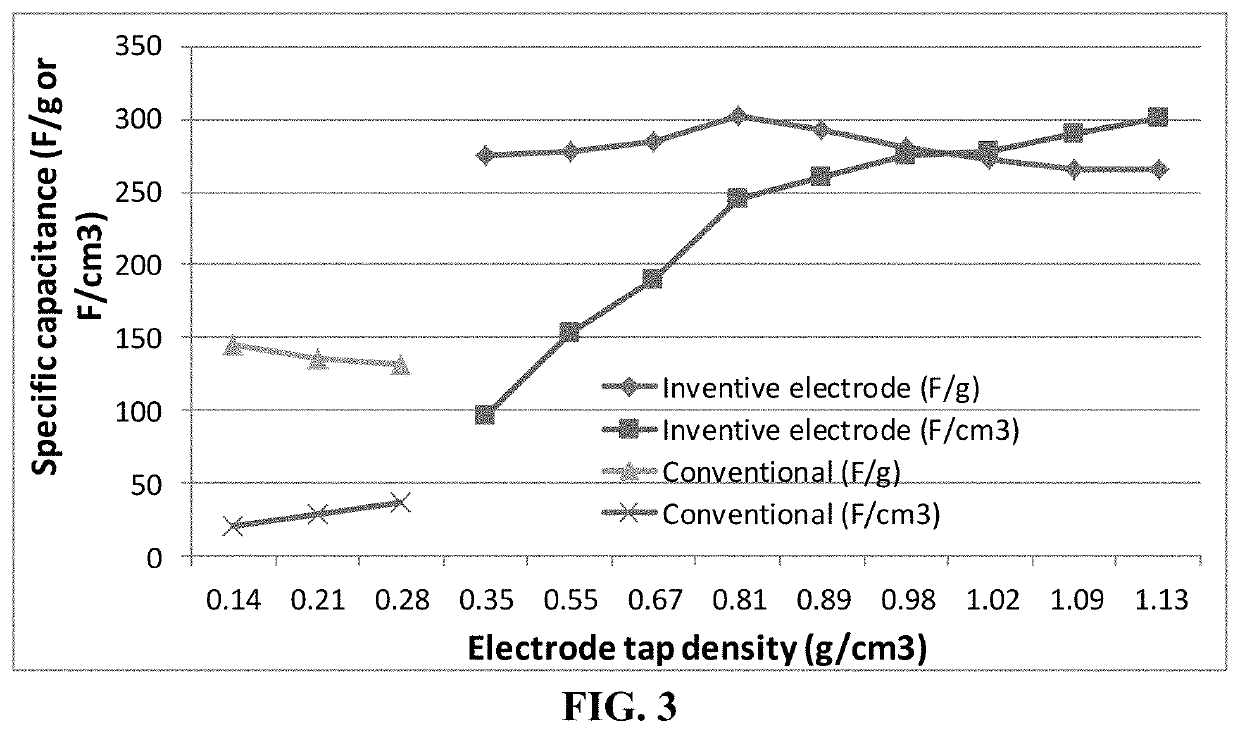

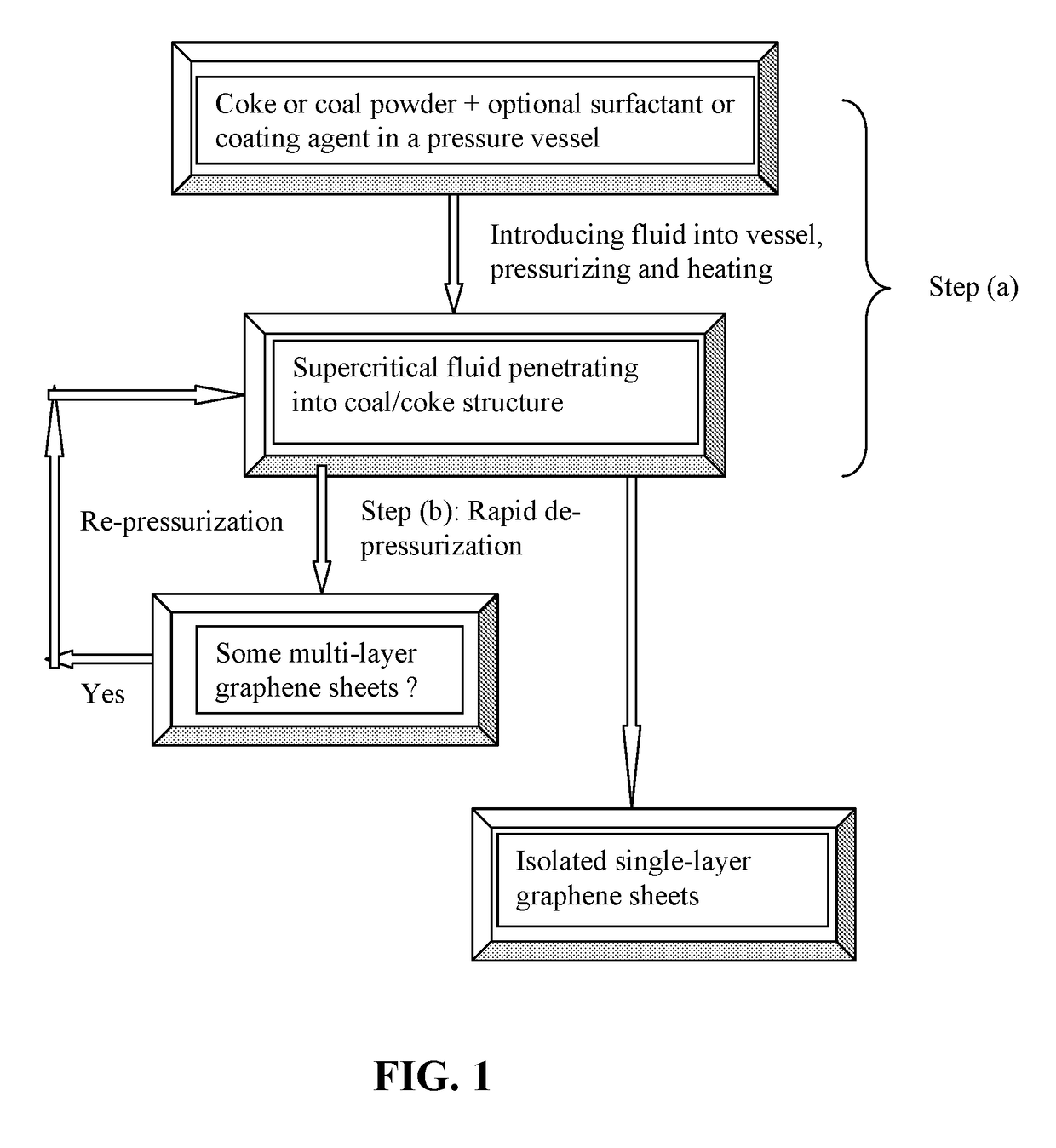

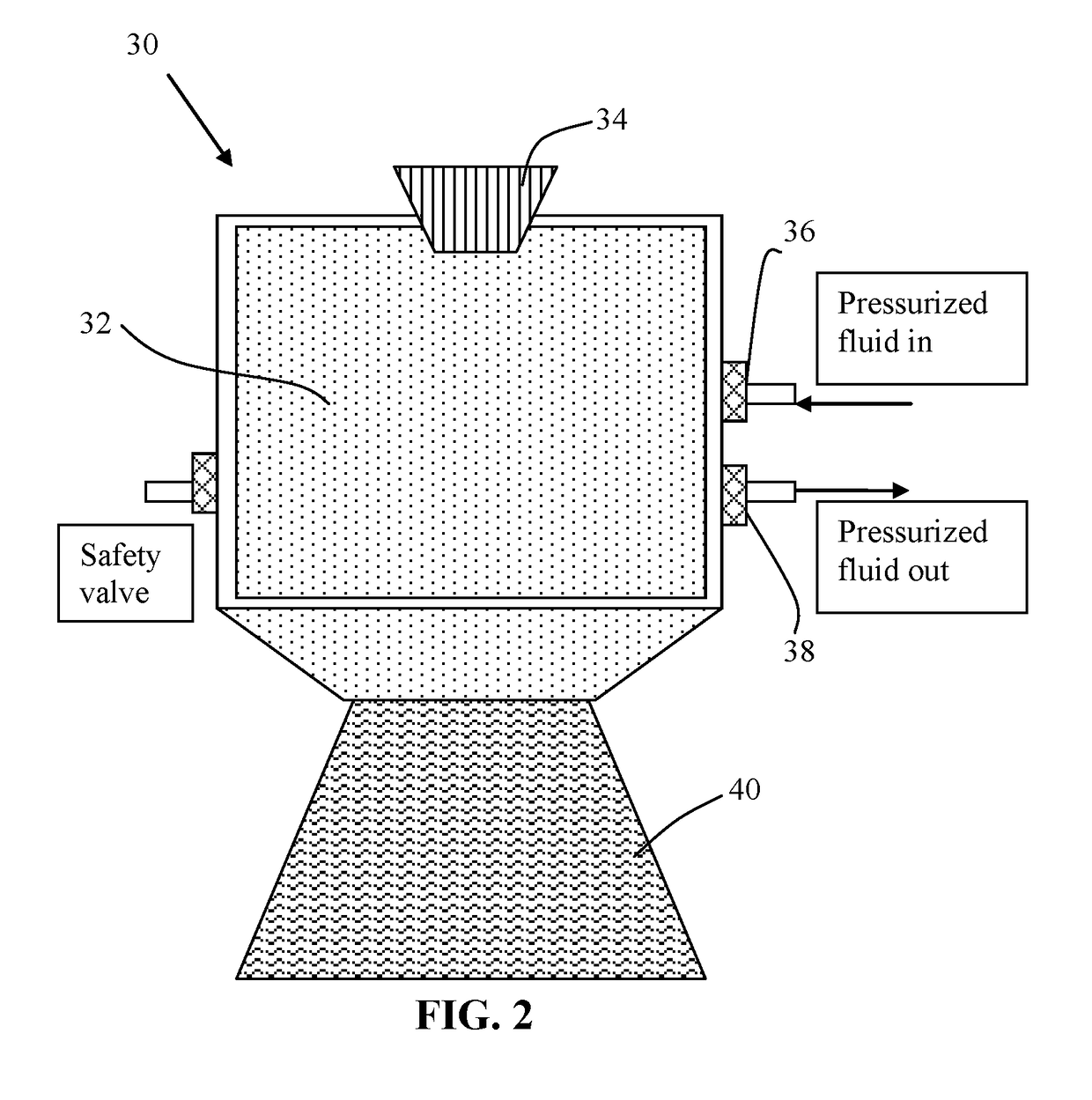

Supercritical Fluid Production of Graphene-Based Supercapacitor Electrode from Coke or Coal

ActiveUS20180019071A1Reduce thicknessHybrid capacitor electrodesCell electrodesLiquid mediumPetroleum

Provided is a process for producing a graphene-based supercapacitor electrode from a supply of coke or coal powder, comprising: (a) exposing this powder to a supercritical fluid for a period of time in a pressure vessel to enable penetration of the supercritical fluid into internal structure of the coke or coal; wherein the powder is selected from petroleum coke, coal-derived coke, meso-phase coke, synthetic coke, leonardite, anthracite, lignite coal, bituminous coal, or natural coal mineral powder, or a combination thereof; (b) rapidly depressurizing the supercritical fluid at a fluid release rate sufficient for effecting exfoliation and separation of the coke or coal powder to produce isolated graphene sheets, which are dispersed in a liquid medium to produce a graphene suspension; and (c) shaping and drying the graphene suspension to form the supercapacitor electrode having a specific surface area greater than 200 m2 / g.

Owner:NANOTEK INSTR GRP LLC

Production of Graphene-Based Supercapacitor Electrode from Coke or Coal Using Direct Ultrasonication

Provided is a method of producing graphene-based supercapacitor electrode from a supply of coke or coal powder. The method comprises: (a) dispersing particles of the coke or coal powder in a liquid medium containing therein an optional surfactant or dispersing agent to produce a suspension or slurry, wherein the coke or coal powder is selected from petroleum coke, coal-derived coke, meso-phase coke, synthetic coke, leonardite, anthracite, lignite coal, bituminous coal, or natural coal mineral powder, or a combination thereof; (b) exposing the suspension or slurry to ultrasonication at an energy level for a sufficient length of time to produce a graphene suspension having isolated graphene sheets dispersed in the liquid medium; and (c) shaping and drying the graphene suspension into the supercapacitor electrode in a film, filament, rod, or tube form that is porous and has a specific surface area greater than 200 m2 / g.

Owner:NANOTEK INSTR GRP LLC

Lignite-urethane based resins for enhanced foundry sand performance

Described herein, in a preferred embodiment, is a leonardite-based polyurethane resin binder that may be used, among other applications, as a binder in combination with foundry aggregate, e.g., sand, for molding or casting metal parts. The binders described herein comprise a humic substance, preferably leonardite, first mixed with a foundry aggregate and then the humic-aggregate mixture is combined with a polymerizable polyol, an isocyanate, and a polymerization catalyst to make a polyurethane resin binder in situ in a foundry aggregate, such as sand. The lignite is added as a solid to the foundry aggregate, and improves the binder performance of the lignite-containing part of the binder components.

Owner:AMCOL INTERNATIONAL CORPORATION

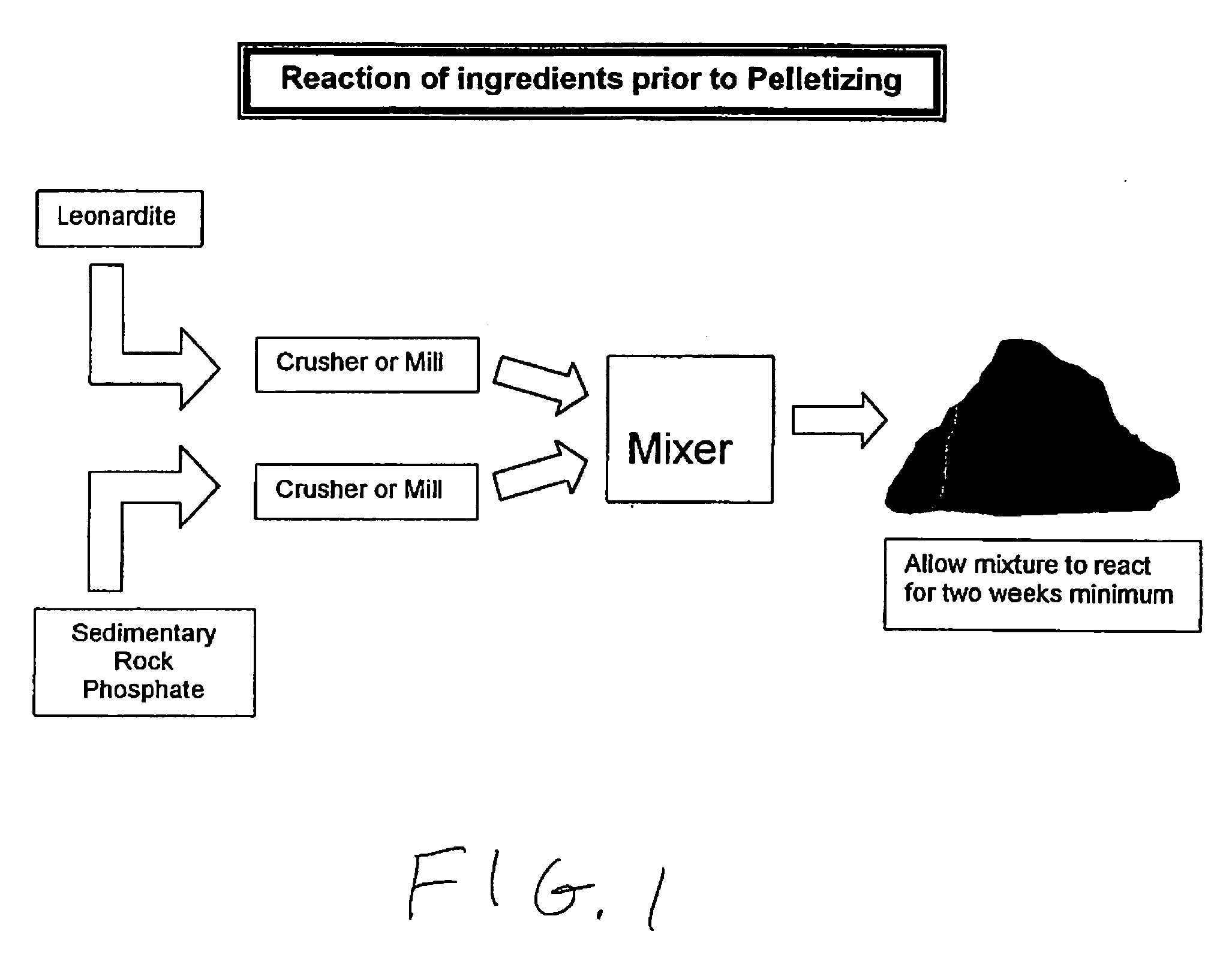

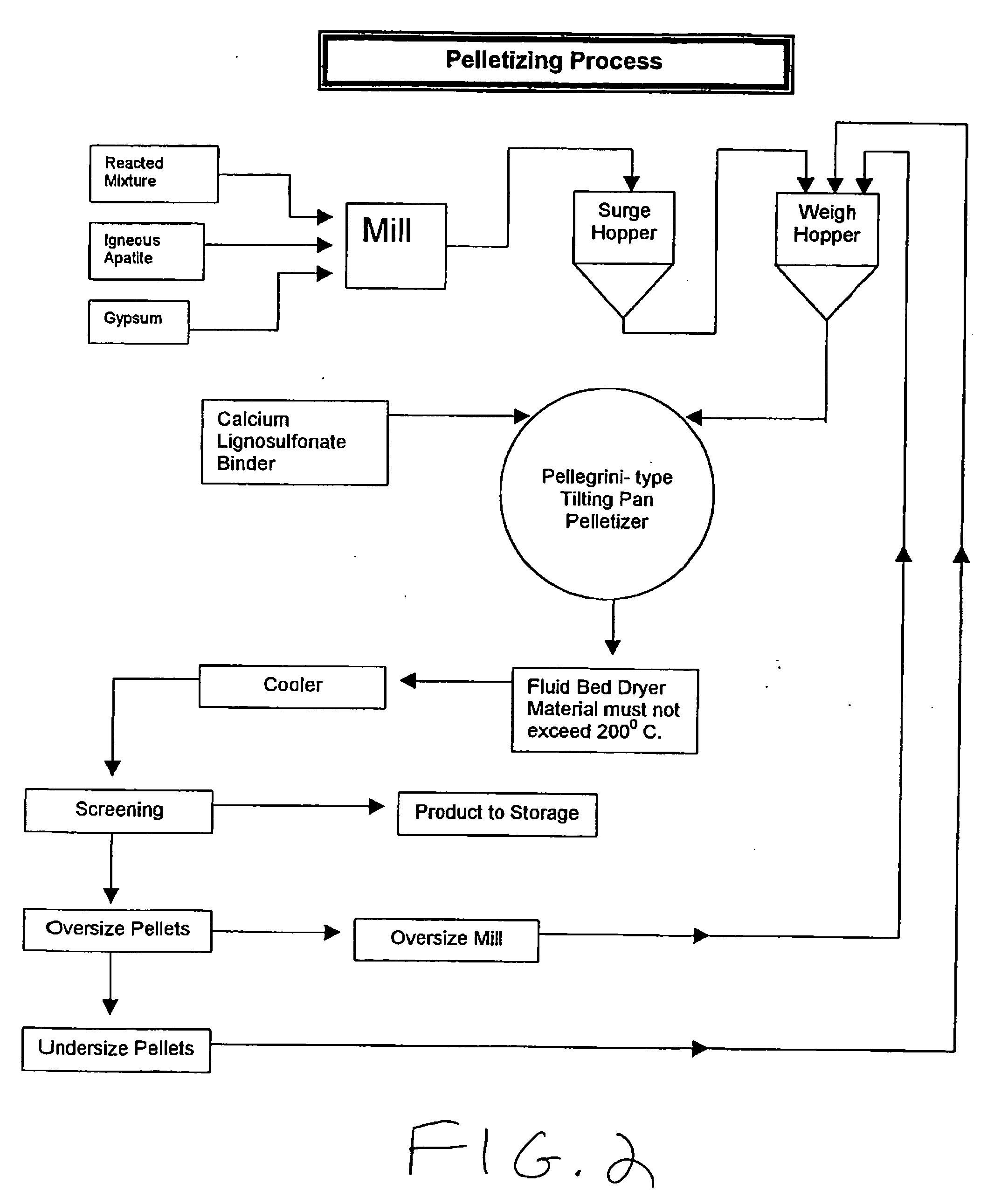

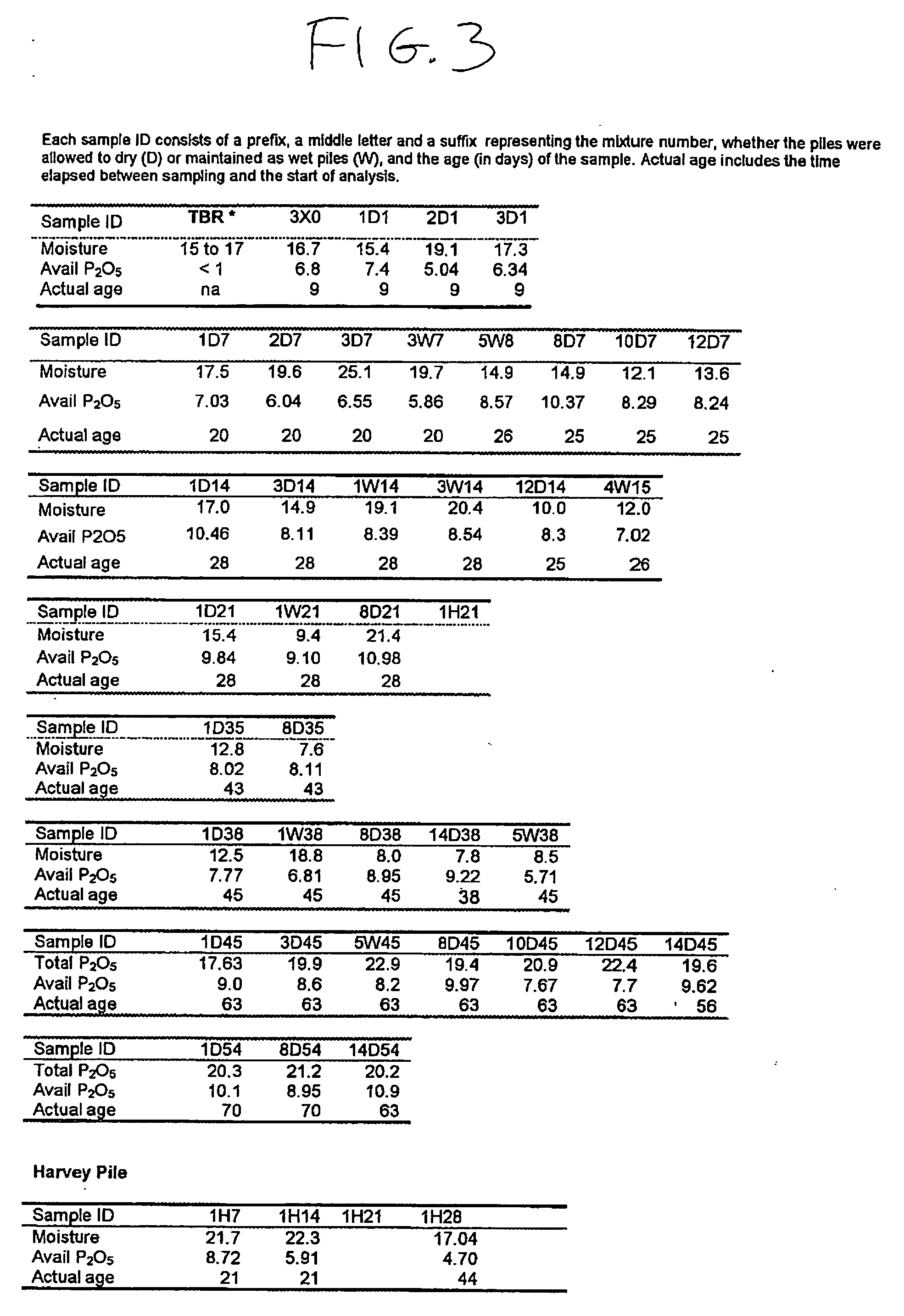

Pelleted organic calcium phosphate compositions

InactiveUS20060010946A1Di-calcium phosphate fertilisersOrganic fertilisersCalcium biphosphatePhosphorite

The present invention provides a method of producing a pelletized composition containing leonardite, sedimentary rock and gypsum. The method calls for pre-mixing the humic substance and the sedimentary rock for at least two weeks to yield a developed mixture prior to addition of other materials such as gypsum and pelletizing and drying the pellets to produce the final product. The invention also includes several pelleted compositions containing leonardite, rock phosphate and gypsum. In one aspect of the invention the rock phosphate comprises a mixture of sedimentary rock phosphate and igneous rock phosphate. In another aspect of the invention, the igneous rock phosphate comprises carbonatite and the sedimentary rock phosphate comprises phosphorite.

Owner:MIDWESTERN BIO PRODS & SERVICES

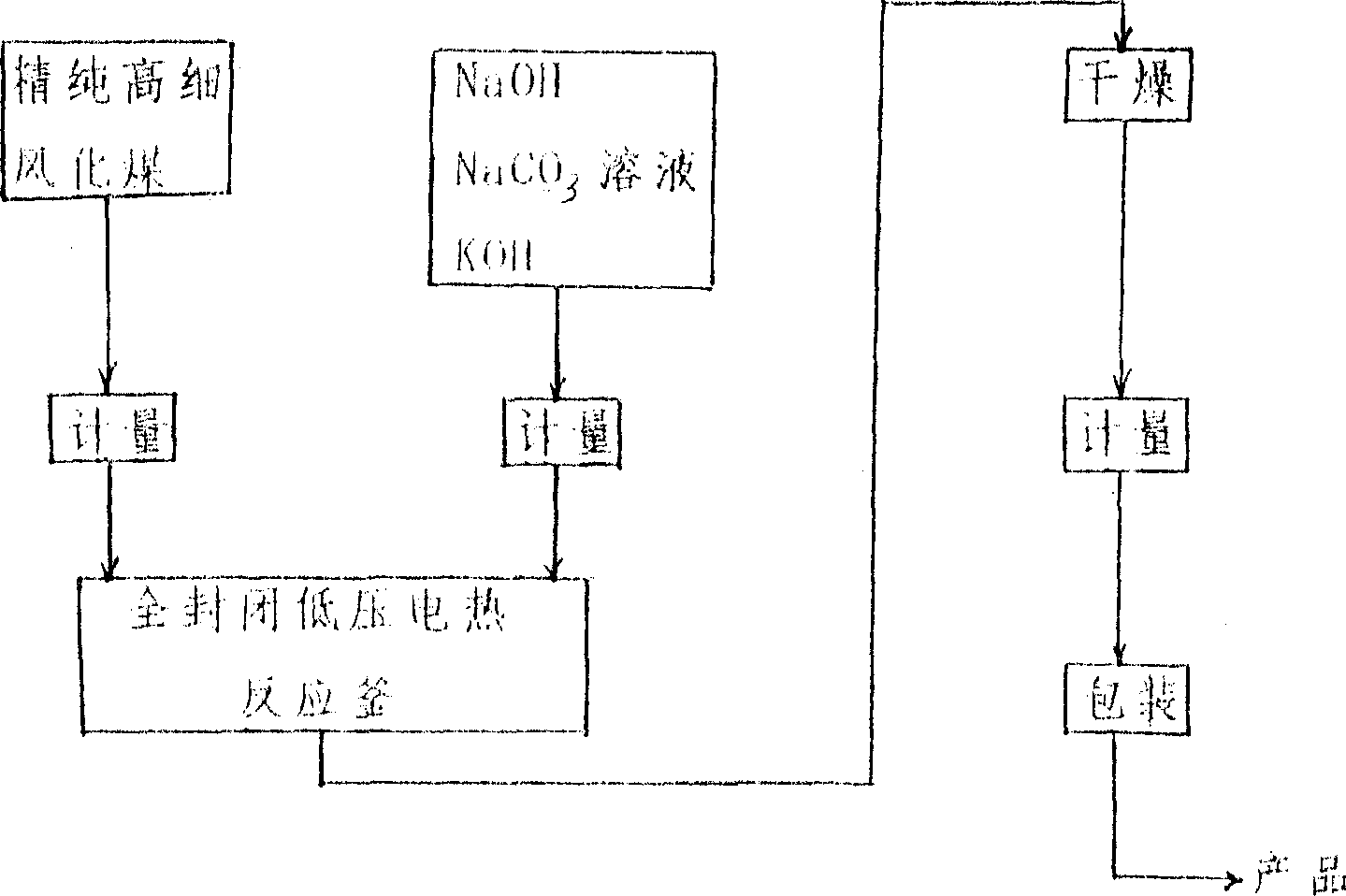

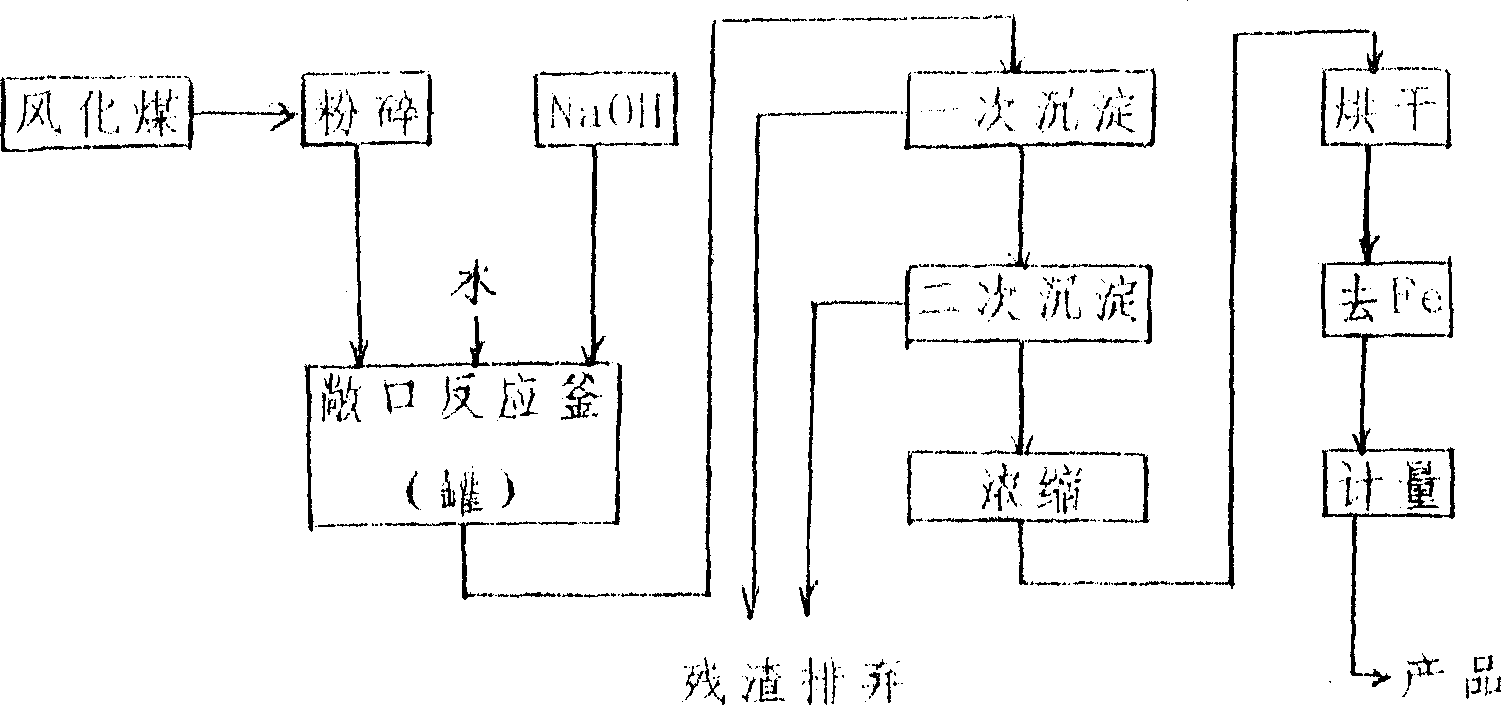

Production method of humic acid

InactiveCN1412223ANo pollution in the processNo "three wastes"Lignin derivativesHeat energyRaw material

On the basis of original wet production process said invention adopts full-sealed electric heat energy temp.-controlled reaction still and makes the leonardite undergo the processes of selection, purification, colloid milling and ultrasonic treatment, and adds the related chemical raw material to make reaction so as to obtain the invented product humic acid.

Owner:石历勤

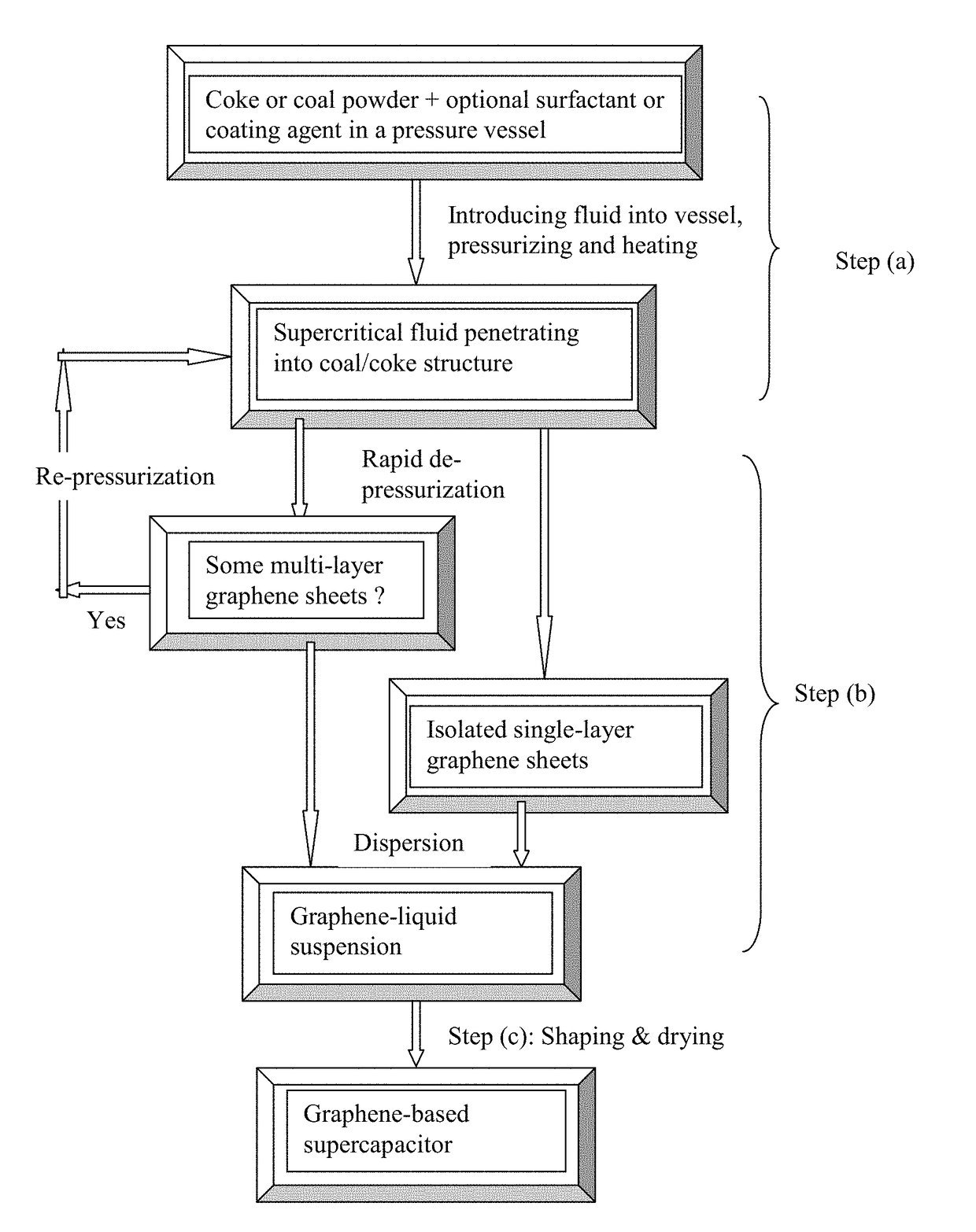

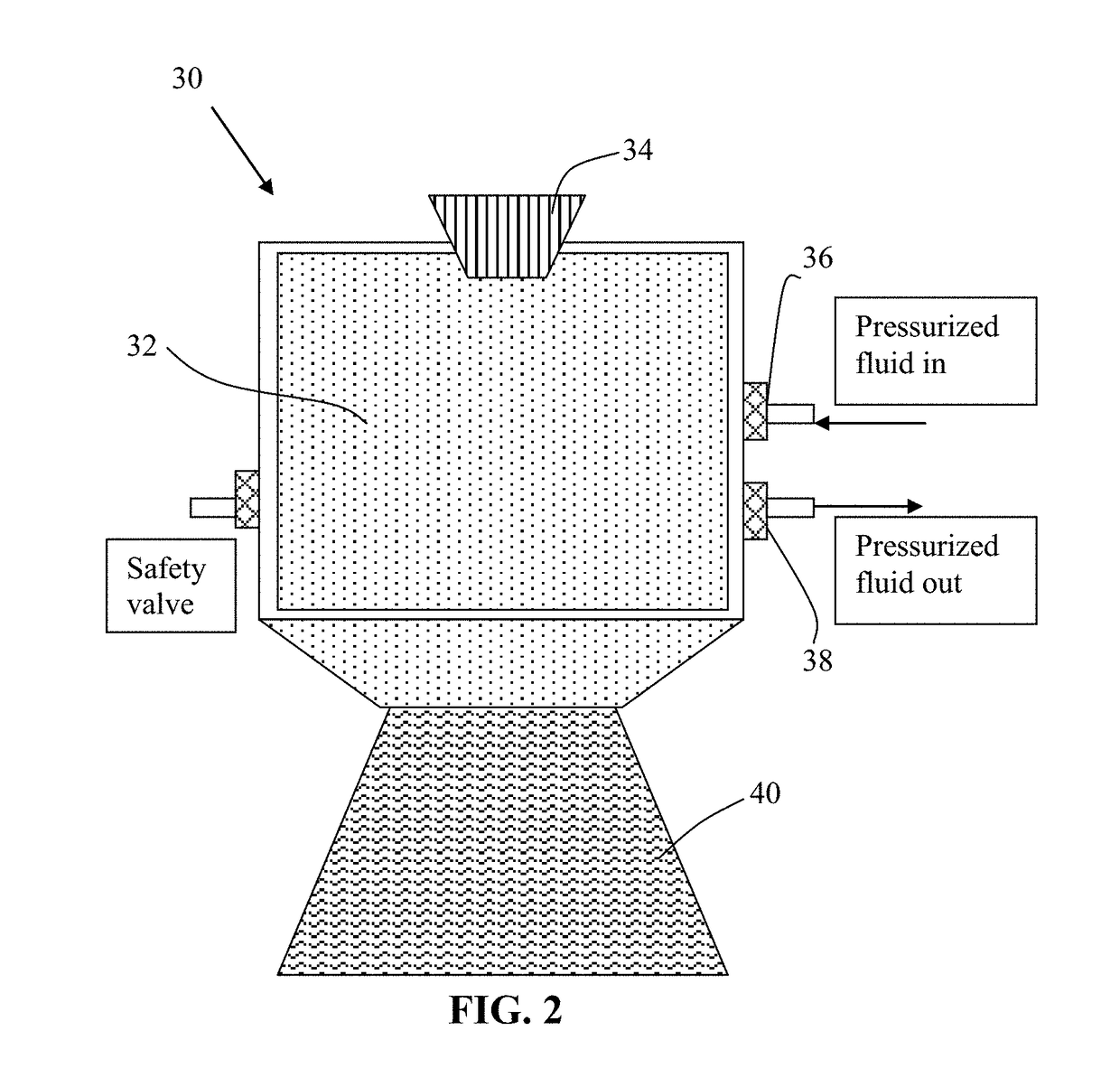

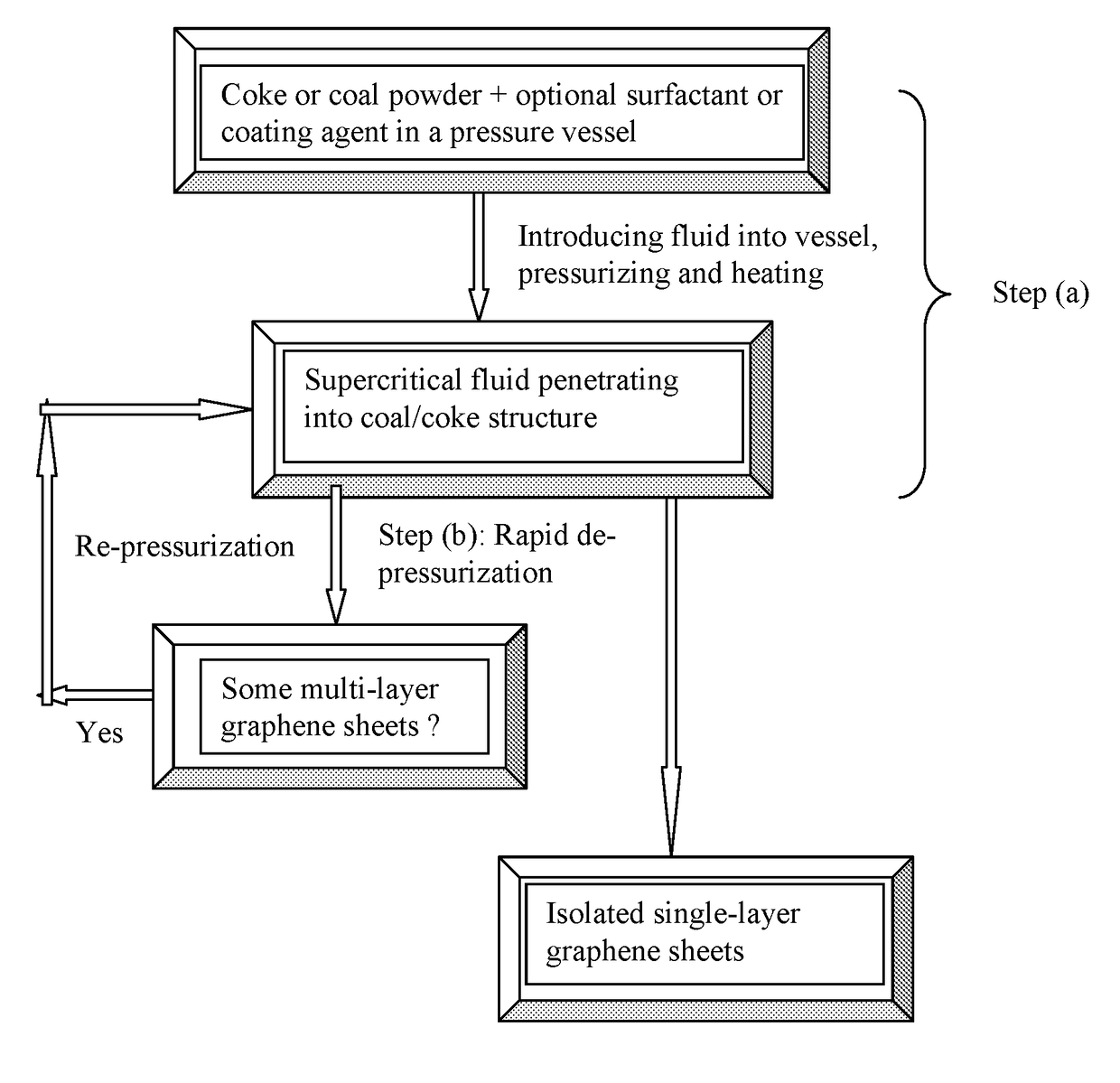

Supercritical Fluid Process for Producing Graphene from Coke or Coal

ActiveUS20180016149A1Reduce thicknessHybrid capacitor electrodesCell electrodesBrown coalGraphene flake

Provided is a process for producing isolated graphene sheets from a supply of coke or coal powder containing therein domains of hexagonal carbon atoms and / or hexagonal carbon atomic interlayers. The process comprises: (a) subjecting the supply of coke or coal powder to a supercritical fluid at a first temperature and a first pressure for a first period of time in a pressure vessel and then (b) rapidly depressurizing the supercritical fluid at a fluid release rate sufficient for effecting exfoliation and separation of the coke or coal powder to produce isolated graphene sheets, wherein the coke or coal powder is selected from petroleum coke, coal-derived coke, meso-phase coke, synthetic coke, leonardite, anthracite, lignite coal, bituminous coal, or natural coal mineral powder, or a combination thereof.

Owner:GLOBAL GRAPHENE GRP INC

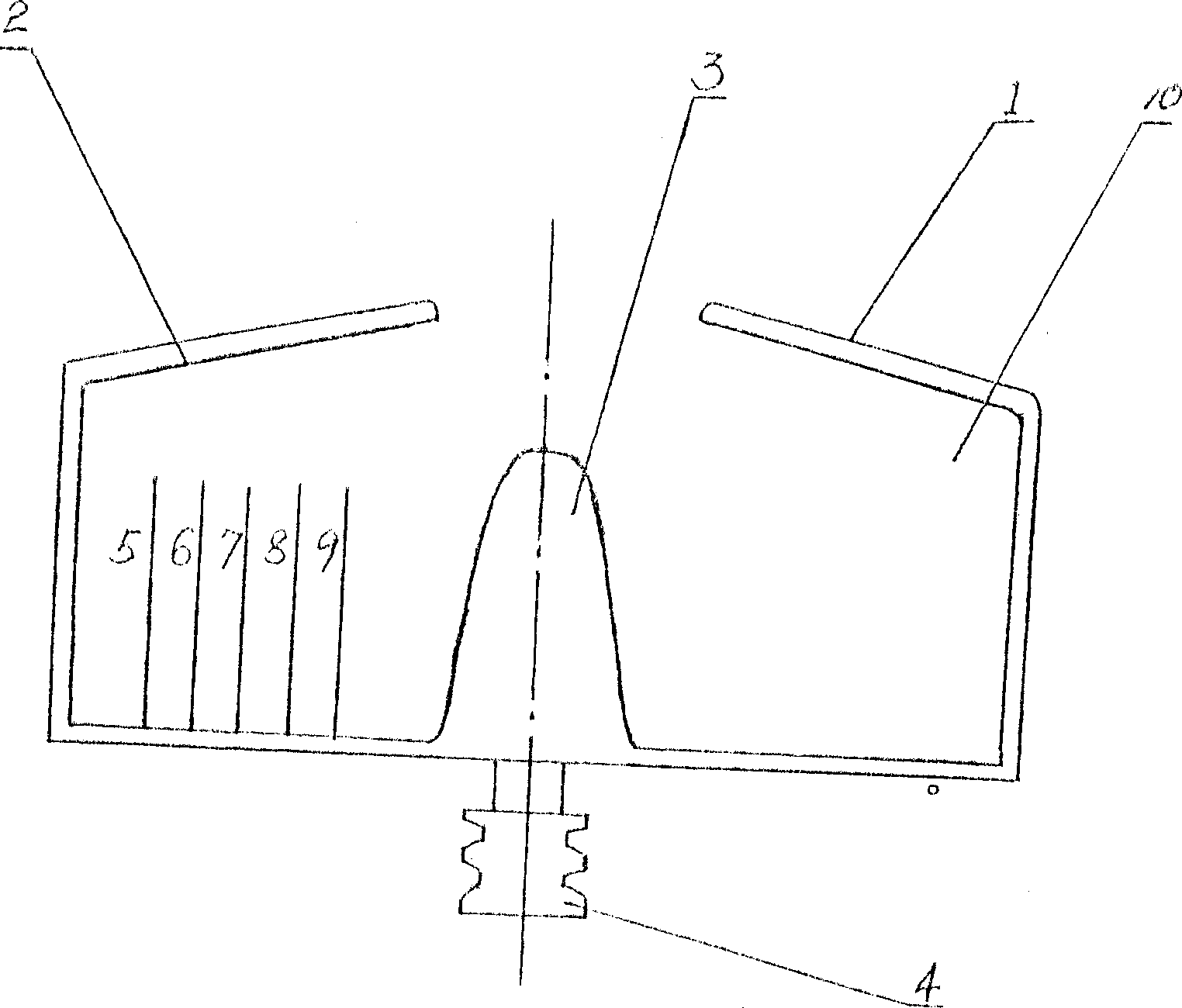

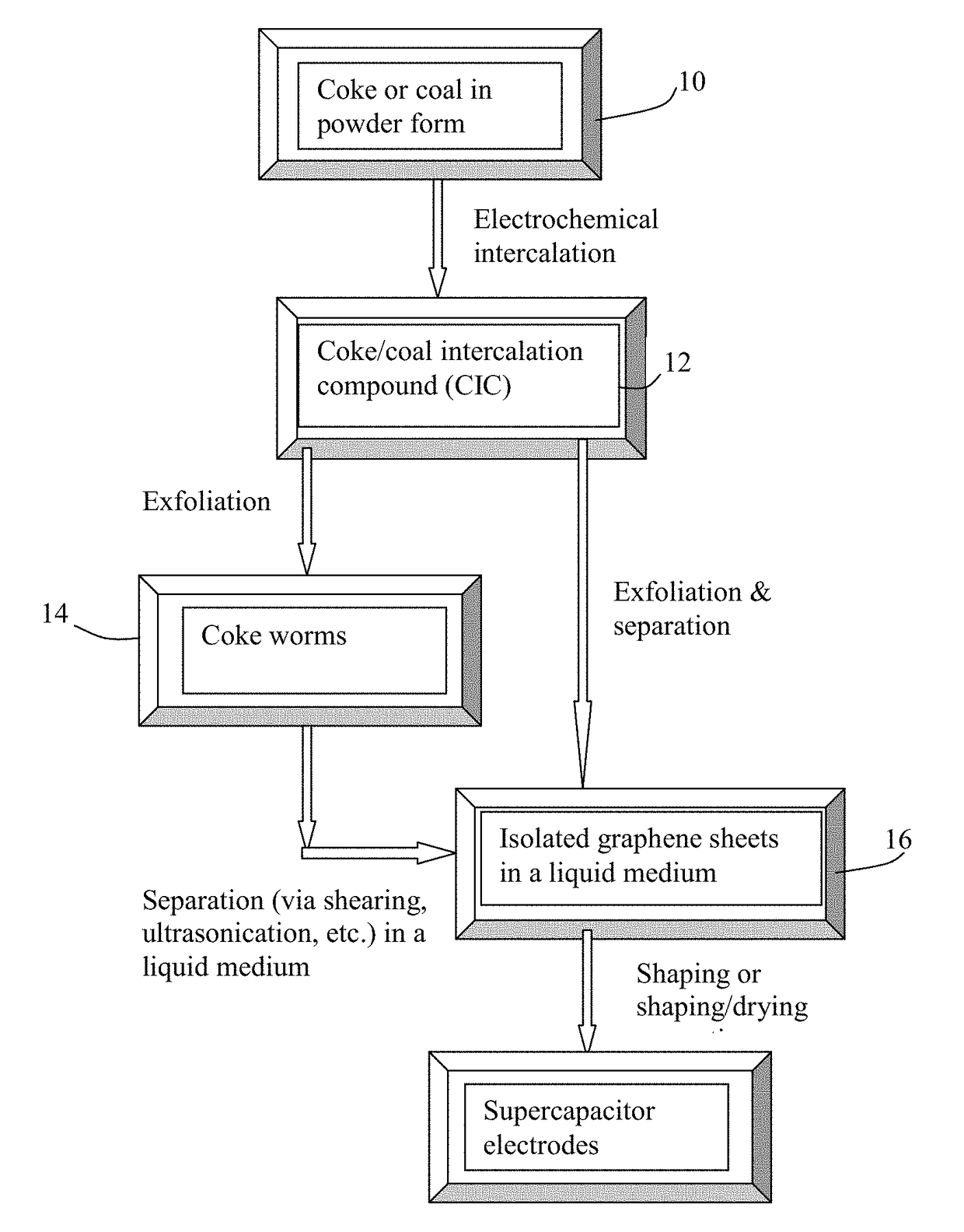

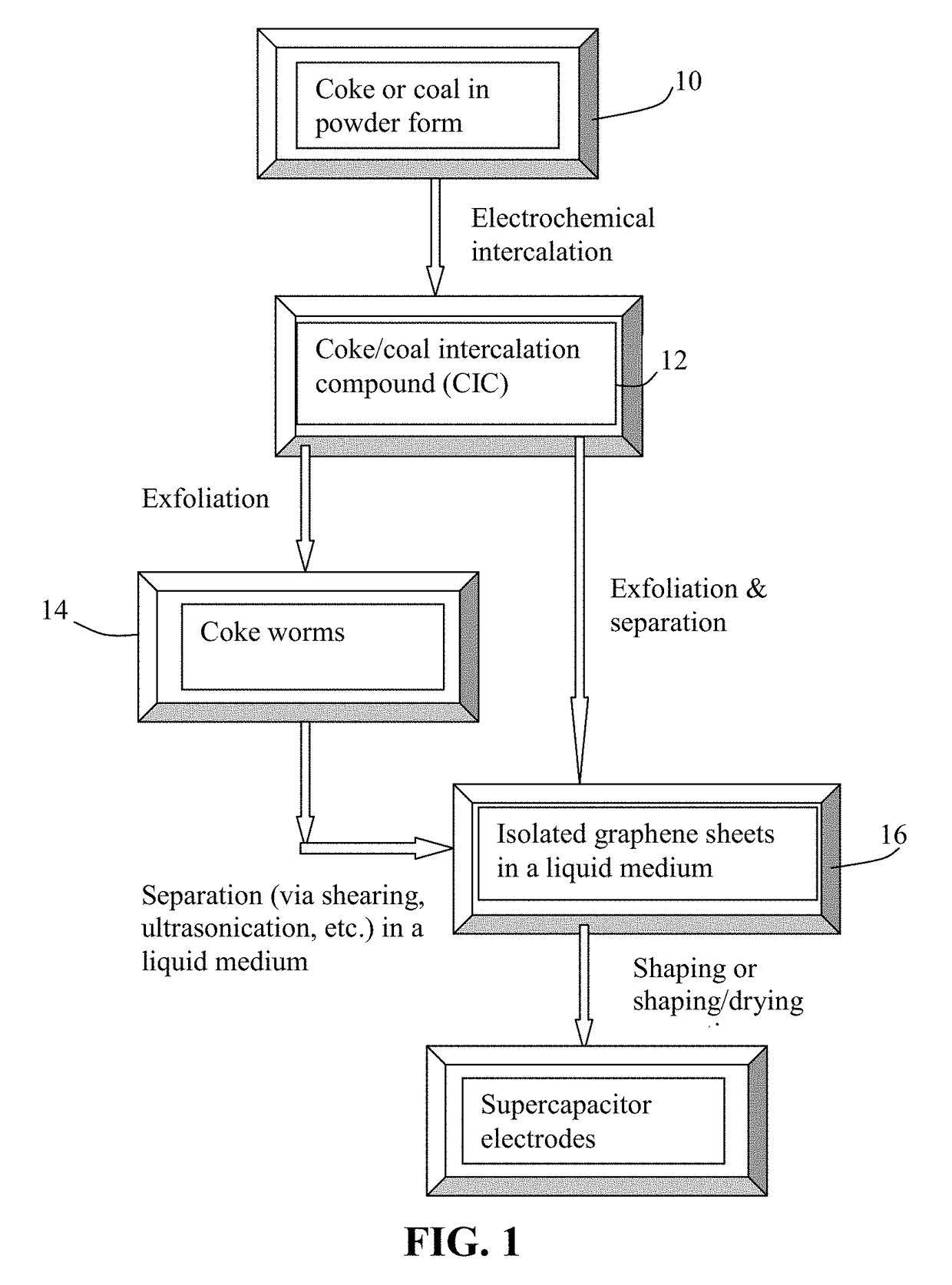

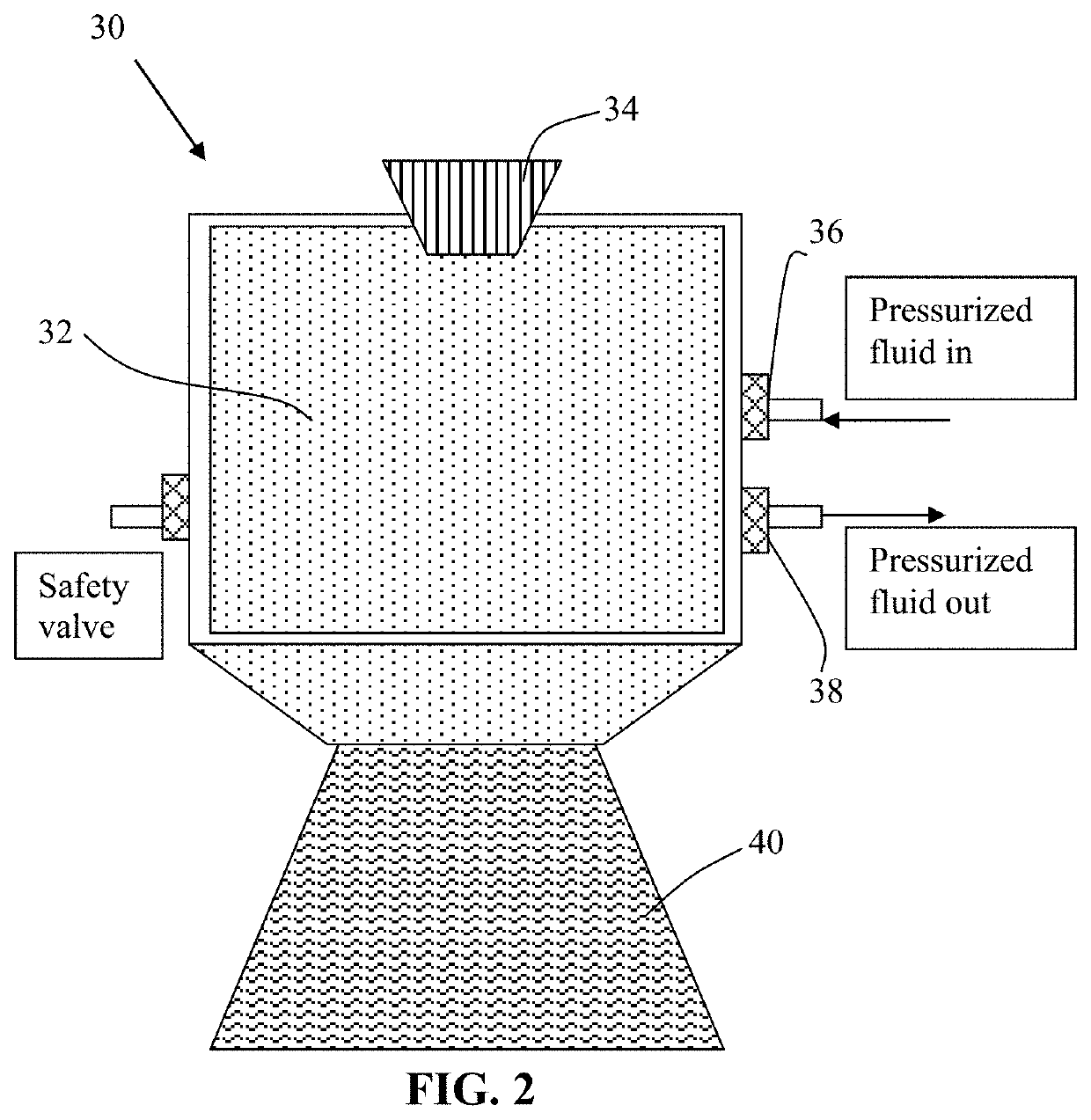

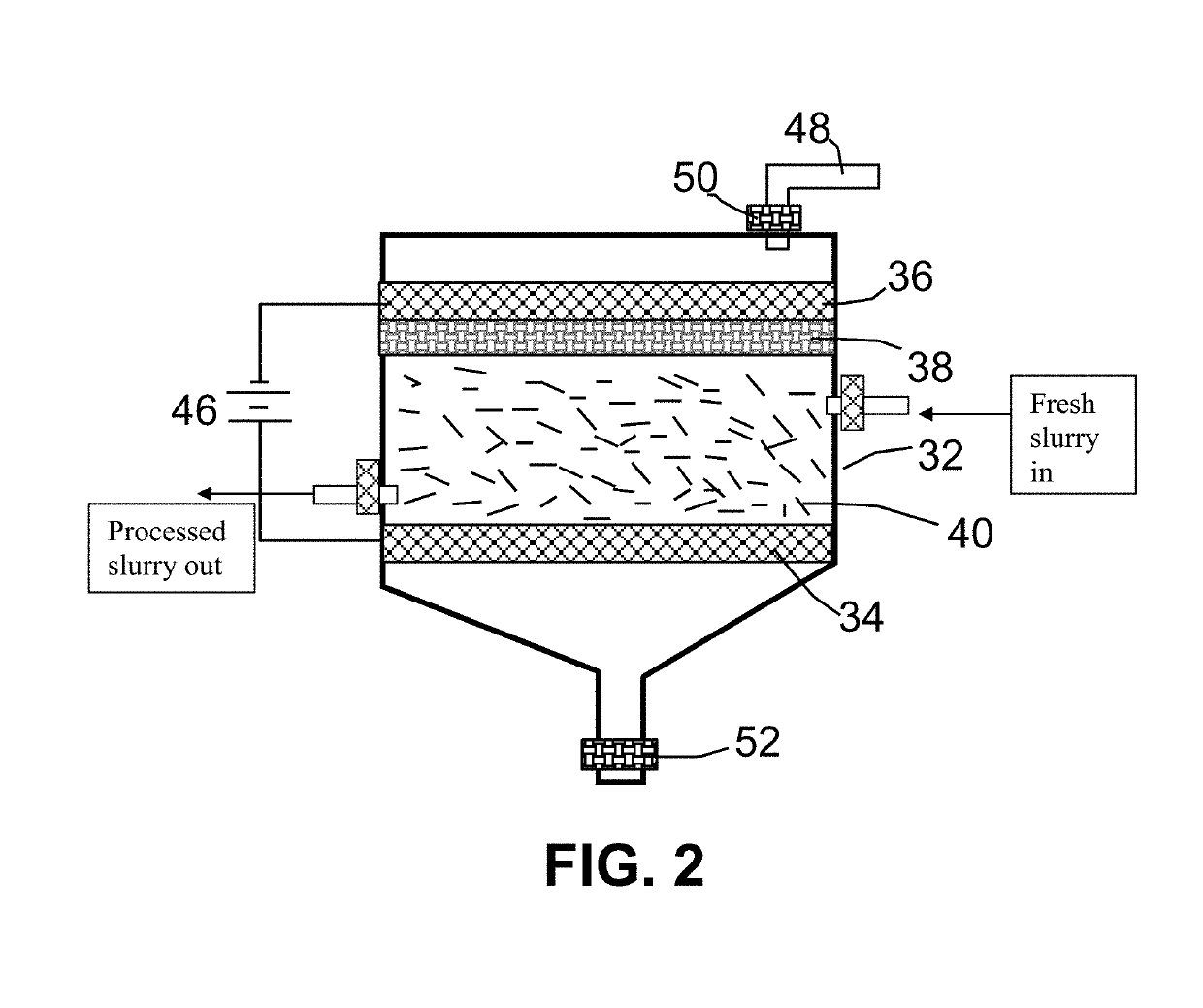

Electrochemical Method of Producing Graphene-Based Supercapacitor Electrode from Coke or Coal

PendingUS20180019072A1Reduce thin electrolyte layer thicknessImprove directionLiquid surface applicatorsElectrolysis componentsSupercapacitorCvd graphene

A method of producing graphene sheets from coke or coal powder, comprising: (a) forming an intercalated coke or coal compound by electrochemical intercalation conducted in an intercalation reactor, which contains (i) a liquid solution electrolyte comprising an intercalating agent; (ii) a working electrode that contains the powder in ionic contact with the liquid electrolyte, wherein the coke or coal powder is selected from petroleum coke, coal-derived coke, meso-phase coke, synthetic coke, leonardite, lignite coal, or natural coal mineral powder; and (iii) a counter electrode in ionic contact with the electrolyte, and wherein a current is imposed upon the working electrode and the counter electrode for effecting electrochemical intercalation of the intercalating agent into the powder; and (b) exfoliating and separating graphene planes from the intercalated coke or coal compound using an ultrasonication, thermal shock exposure, mechanical shearing treatment, or a combination thereof to produce isolated graphene sheets.

Owner:NANOTEK INSTR GRP LLC

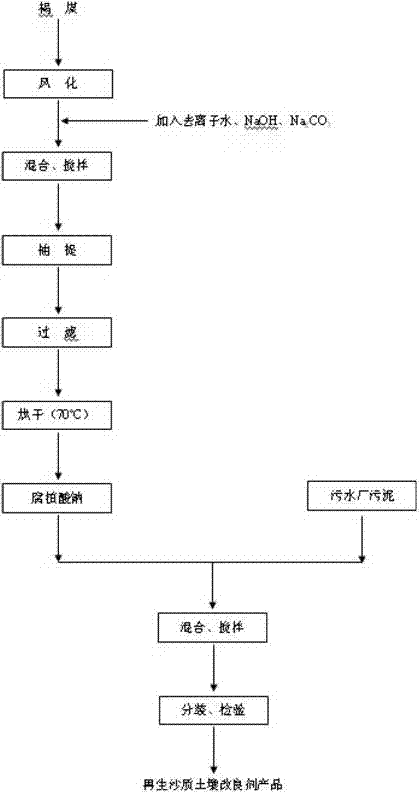

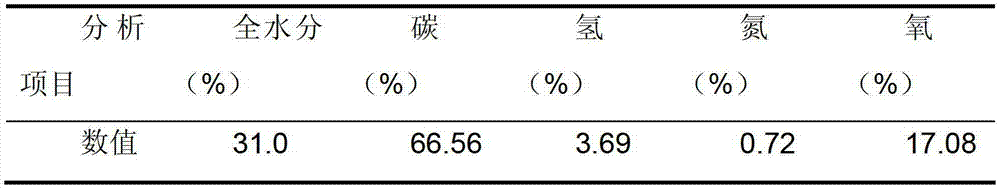

Regenerated sandy soil conditioner and preparation method thereof

InactiveCN103160284ASimple processLow raw material costOrganic fertilisersSoil conditioning compositionsSludgeEngineering

The invention discloses a regenerated sandy soil conditioner and a preparation method thereof. The preparation method of the regenerated sandy soil conditioner comprises the following steps of: taking abandoned sludge of an urban sewage plant and cheap lignite as raw materials, preparing sodium humate with leonardite, weighing 90 parts of abandoned sludge of the urban sewage plant and 10 parts of sodium humate according to the mass ratio to be mixed and stirred for 30 minutes, and carrying out split charging and checking processes. The prepared regenerated sandy soil conditioner has the advantages of being simple in production process and low in raw material and production cost. Moreover, the regenerated sandy soil conditioner is suitable for large-scale popularization and application.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Production and preparation process for fulvic acid

The invention relates to the field of chemical product production, in particular to a production and preparation process for fulvic acid. The production and preparation process is characterized in that a raw material lignite for preparing the fulvic acid is smashed into 80 mesh and added into warm water at the temperature of 49 DEG C to 51 DEG C, and the ratio of the dry weight of the lignite powder to the weight of the water is 1:(18-22), H2O2 is slowly added in a stirring state, the adding rate of H2O2 is limited by the reaction temperature lower than 65 DEG C, and the mass ratio of the lignite powder to H2O2 is 1:(0.68-0.72); after lignite is subjected to an oxydrolysis reaction, the mixture is subjected to solid-liquid separation and dried, and a fulvic acid product is obtained. The production and preparation process has the advantages that the leonardite is adopted as the raw material, so that the production cost is low; hydrogen peroxide is adopted as an oxidizing agent, so that environmental friendliness is achieved, and pollution is avoided; adopted equipment is simple, the production conditions are easy to control, the process route is feasible, the technical index is stable, the production and preparation process is suitable for large-scale industrial production, and the fulvic acid is high in yield and purity; compared with an imported product, the cost is greatly reduced, and conditions are created for full utilization of low-quality coal resources and substituting for imported goods.

Owner:王墨林

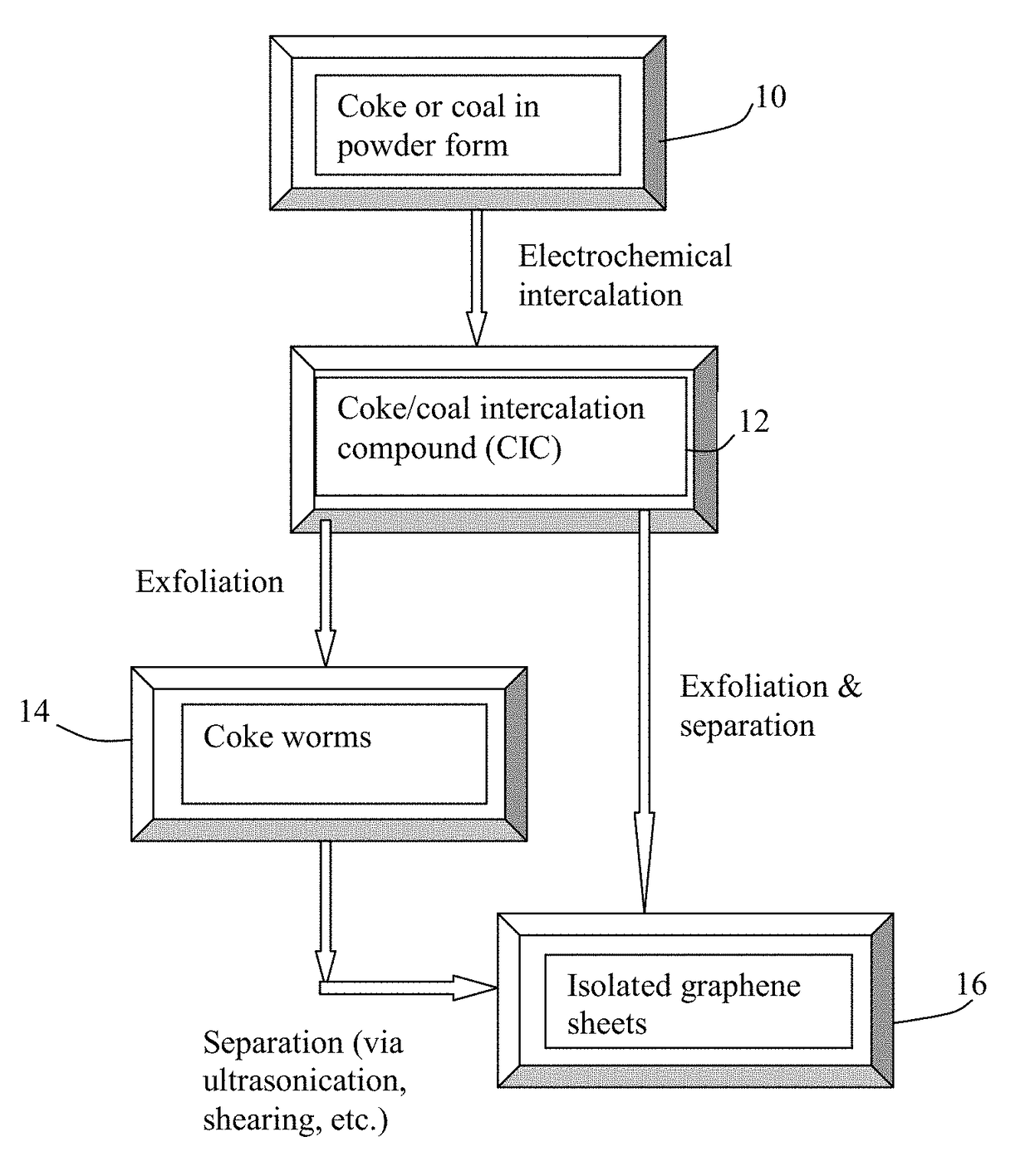

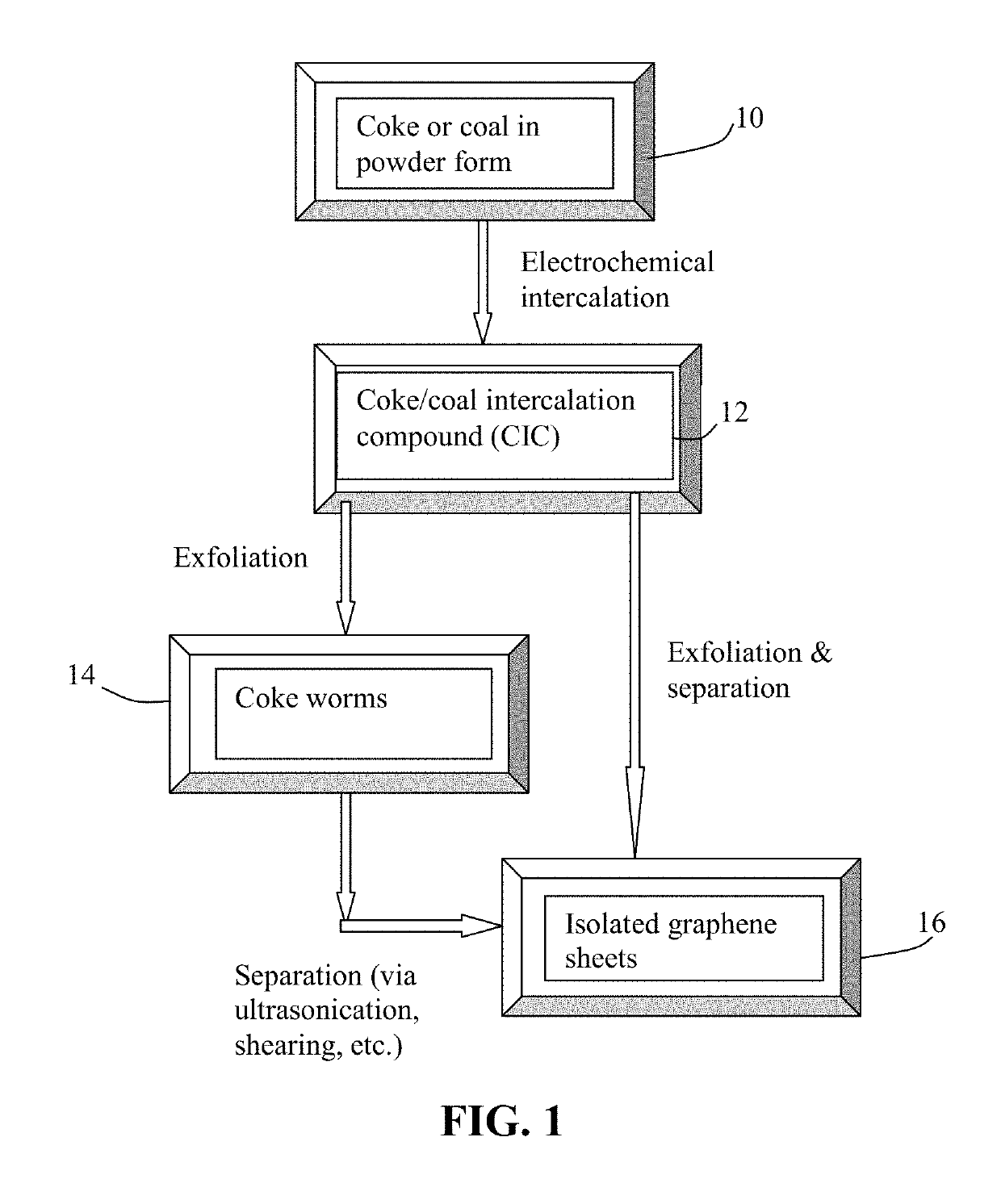

Electrochemical Production of Graphene Sheets from Coke or Coal

ActiveUS20170370009A1Promoting exfoliationPromoting intercalationCellsGrapheneGraphenePetroleum coke

A method of producing graphene sheets from coke or coal powder, comprising: (a) forming an intercalated coke or coal compound by electrochemical intercalation conducted in an intercalation reactor, which contains (i) a liquid solution electrolyte comprising an intercalating agent; (ii) a working electrode that contains the powder in ionic contact with the liquid electrolyte, wherein the coke or coal powder is selected from petroleum coke, coal-derived coke, meso-phase coke, synthetic coke, leonardite, lignite coal, or natural coal mineral powder; and (iii) a counter electrode in ionic contact with the electrolyte, and wherein a current is imposed upon the working electrode and the counter electrode for effecting electrochemical intercalation of the intercalating agent into the powder; and (b) exfoliating and separating graphene planes from the intercalated coke or coal compound using an ultrasonication, thermal shock exposure, mechanical shearing treatment, or a combination thereof to produce isolated graphene sheets.

Owner:GLOBAL GRAPHENE GRP INC

Coal water mixture

InactiveCN1814716AReduce manufacturing costLow calorific valueLiquid carbonaceous fuelsCoal waterLeonardite

This invention relates to a kind of coal-water slurry including the following weight percentages: slurry: 20-25% of the oil field extracted solution containing 75-85% water, raw coal with the average size: 30-60mum and water: 5-20%. This invention applies the slurry processed from the oil field extracted solution as the dispersion stabilizing agent of coal-water slurry to cost the wastes of waste water and said slurry can be used directly without dewater, the pollutant water process agent is the graft product of leonardite.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

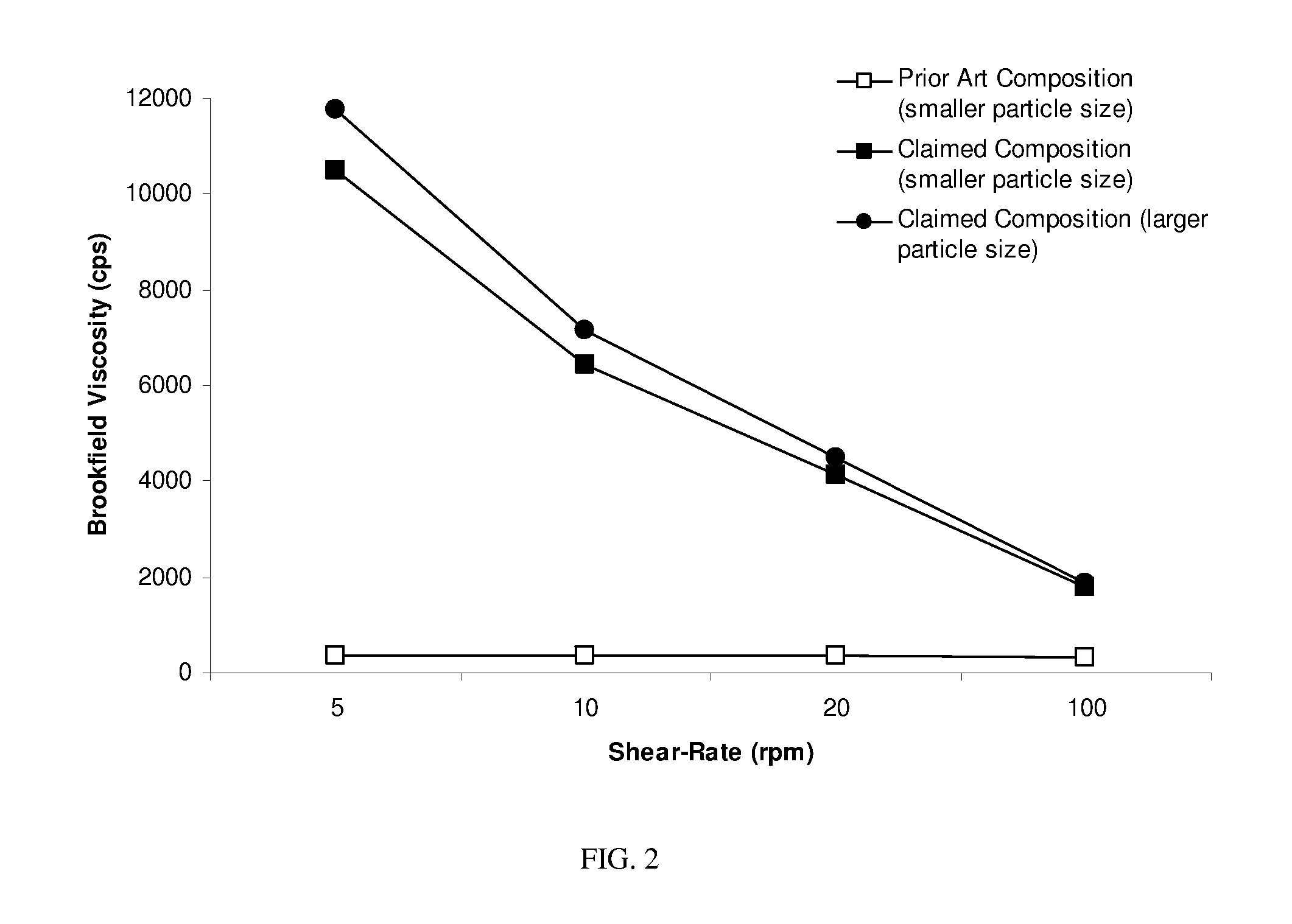

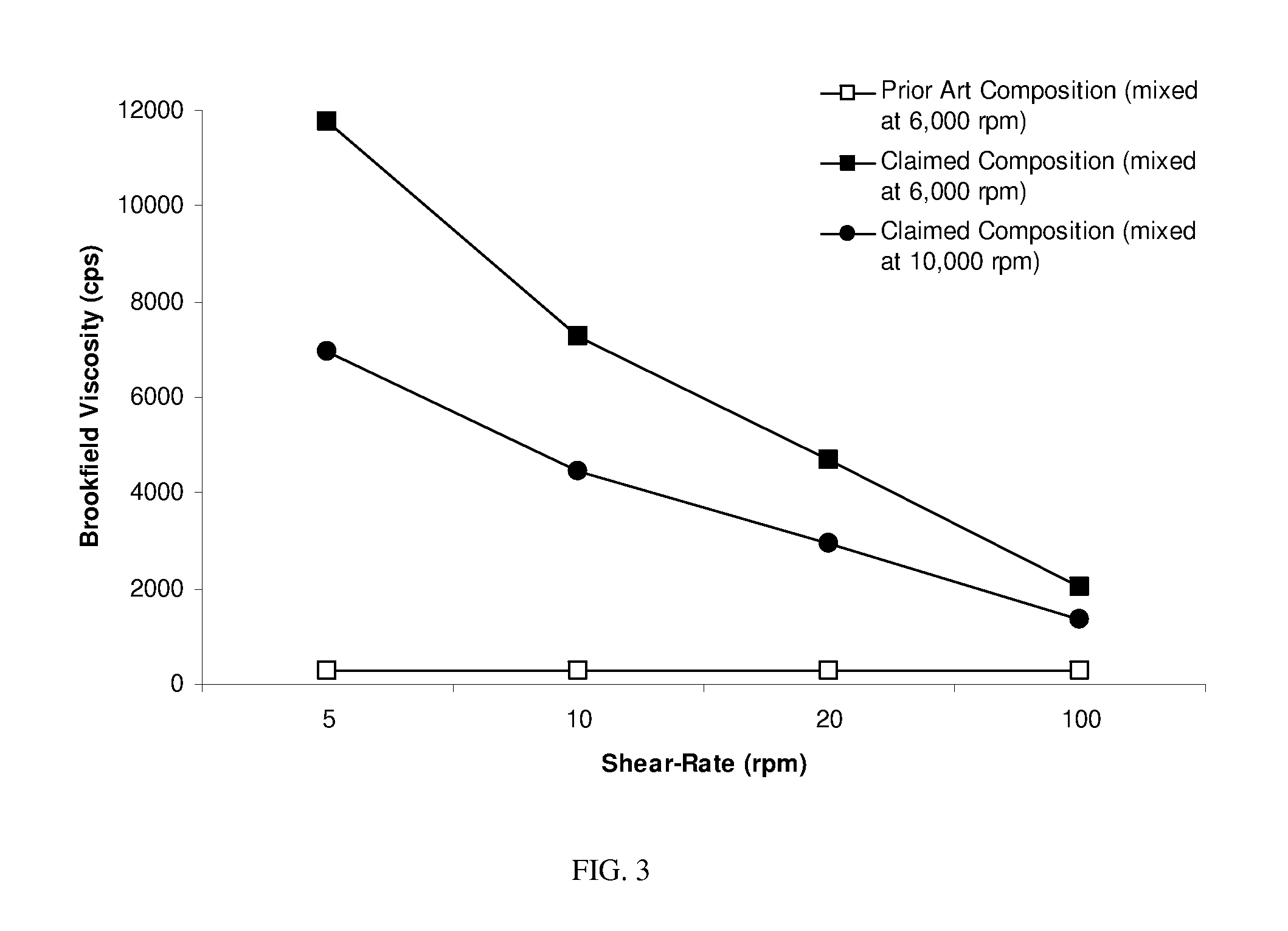

Lignite-based urethane resins with enhanced suspension properties and foundry sand binder performance

Described herein, in the preferred embodiment, is a leonardite-based polyurethane resin binder that may be used, among other applications, as a binder in combination with foundry aggregate, e.g., sand, for molding or casting metal parts. The binders described herein comprise a humic substance, preferably leonardite, combined with a polymerizable isocyanate, a polymerizable polyol, and a polymerization catalyst to make a polyurethane resin binder in situ in a foundry aggregate, such as sand.

Owner:AMCOL INTERNATIONAL CORPORATION

Lignite urethane based resins for enhanced foundry sand performance

Described herein, in a preferred embodiment, is a leonardite-based polyurethane resin binder that may be used, among other applications, as a binder in combination with foundry aggregate, e.g., sand, for molding or casting metal parts. The binders described herein comprise a humic substance, preferably leonardite, first mixed with a foundry aggregate and then the humic-aggregate mixture is combined with a polymerizable polyol, an isocyanate, and a polymerization catalyst to make a polyurethane resin binder in situ in a foundry aggregate, such as sand. The lignite is added as a solid to the foundry aggregate, and improves the binder performance of the lignite-containing part of the binder components.

Owner:AMCOL INTERNATIONAL CORPORATION

Toxin binding system

In some embodiments, a composition and / or method may include a toxin binding system formulated for safe and effective mixture into various feed rations which are fed to monogastric and ruminant animals such as poultry, swine, cows, cattle, and fish, among others. The toxin binding system includes novel combinations of one or more of an organoclay, an activated hydrated sodium calcium aluminosilicate clay, and a synthetic hectorite clay. In some embodiments, the binding composition may include organoclay, bentonite, hectorite, Leonardite, and / or any combination thereof. The toxin binding complex may effectively bind mycotoxins, endotoxins and some pesticides in the animal's digestive system, preventing their absorption and the consequent damages to the animal. This binding action includes the T-2 toxin, which can start their damaging action in the animal's mouth, hence, offering protection from oral lesions.

Owner:SPECIAL NUTRIENTS LLC

Supercritical fluid production of graphene-based supercapacitor electrode from coke or coal

ActiveUS11121360B2Reduce thicknessHybrid capacitor electrodesCell electrodesLiquid mediumGraphene flake

Provided is a process for producing a graphene-based supercapacitor electrode from a supply of coke or coal powder, comprising: (a) exposing this powder to a supercritical fluid for a period of time in a pressure vessel to enable penetration of the supercritical fluid into internal structure of the coke or coal; wherein the powder is selected from petroleum coke, coal-derived coke, meso-phase coke, synthetic coke, leonardite, anthracite, lignite coal, bituminous coal, or natural coal mineral powder, or a combination thereof; (b) rapidly depressurizing the supercritical fluid at a fluid release rate sufficient for effecting exfoliation and separation of the coke or coal powder to produce isolated graphene sheets, which are dispersed in a liquid medium to produce a graphene suspension; and (c) shaping and drying the graphene suspension to form the supercapacitor electrode having a specific surface area greater than 200 m2 / g.

Owner:NANOTEK INSTR GRP LLC

Humic acid complex fertilizer and its production method

InactiveCN1216833CNutritional diversityReduce manufacturing costOrganic fertilisersFertilizer mixturesNitrateTrace element

The present invention relates to a humic acid composite fertilizer and its production method. Its composition is composed of (wt%) 30-70% of leonardite containing 50-75% of human acid, 10-40% of urea, 3-15% of phosphoammonium, 0-30% of potassium chloride, 0-30% of potassium sulfate, 0-10% of potassium hydroxide, 0-12% of potassium carbojnate and 0-3% of trace element. Its production method includes the following steps: pulverizing leonardite, making activating agent, activating leonardite, pulverizing raw materials, mixing them uniformly so as to obtain the invented humic acid composite power fertilizer product, granulating to obtain granular fertilizer product which can improve crop quantity, reduce nitrate content of agricultural product, raise saccharide content and vitamin content and improve soil.

Owner:通辽绿阳科技开发有限公司

Supercritical fluid process for producing graphene from coke or coal

Owner:GLOBAL GRAPHENE GRP INC

Toxin binding system

ActiveUS10058568B2Safely and effectively mixed into animal feedInhibiting and ameliorating maladyBiocideInanimate material medical ingredientsSodium BentoniteOrganoclay

In some embodiments, a composition and / or method may include a toxin binding system formulated for safe and effective mixture into various feed rations which are fed to monogastric and ruminant animals such as poultry, swine, cows, cattle, and fish, among others. The toxin binding system includes novel combinations of one or more of an organoclay, an activated hydrated sodium calcium aluminosilicate clay, and a synthetic hectorite clay. In some embodiments, the binding composition may include organoclay, bentonite, hectorite, Leonardite, and / or any combination thereof. The toxin binding complex may effectively bind mycotoxins, endotoxins and some pesticides in the animal's digestive system, preventing their absorption and the consequent damages to the animal. This binding action includes the T-2 toxin, which can start their damaging action in the animal's mouth, hence, offering protection from oral lesions.

Owner:SPECIAL NUTRIENTS LLC

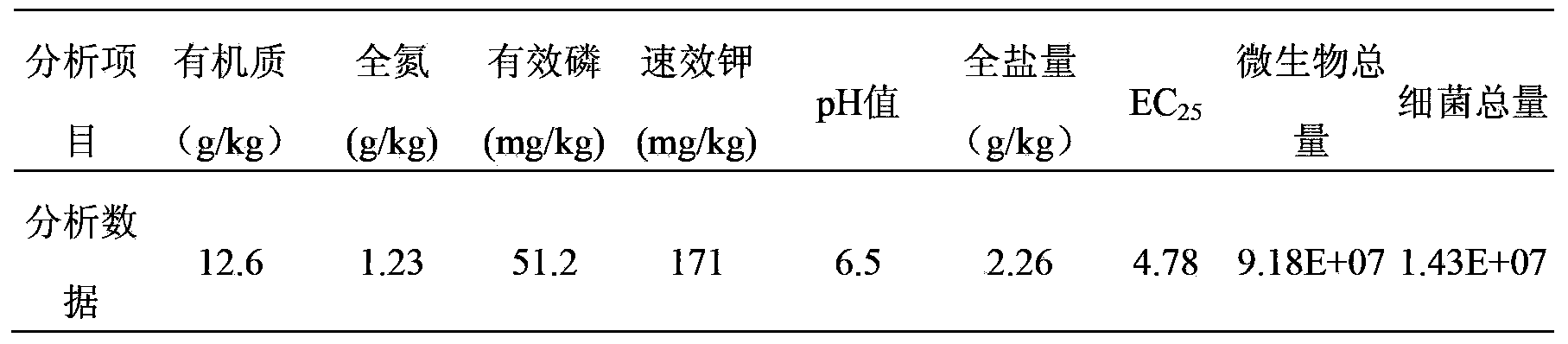

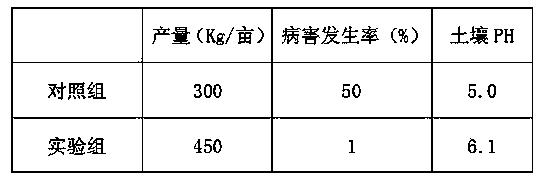

Multifunction soil conditioner and preparation method thereof

ActiveCN103382391AThe test effect is goodImprove breathabilityAgriculture tools and machinesOrganic fertilisersHigh sodiumAlkali soil

The invention discloses a multifunction soil conditioner and a preparation method thereof. The multifunction soil conditioner takes leonardite as a main raw material, and is produced by a biochemical extraction process of about 120 days. The soil conditioner provided in the invention can effectively improve the soil environment, help aerobiont growth, shield salt in high-alkali or high-sodium soil, improve the effectiveness of plant nutrition, and stimulate root growth and depth extension. The soil conditioner disclosed in the invention can improve saline-alkali soil, improve soil breathability and water retention, stimulate formation of organic matters, and increase the number of beneficial microorganisms in the soil. In addition, the soil conditioner has the advantages of low dosage and convenient use, thereby greatly saving labor force and reducing cost.

Owner:上海优马生物技术有限公司

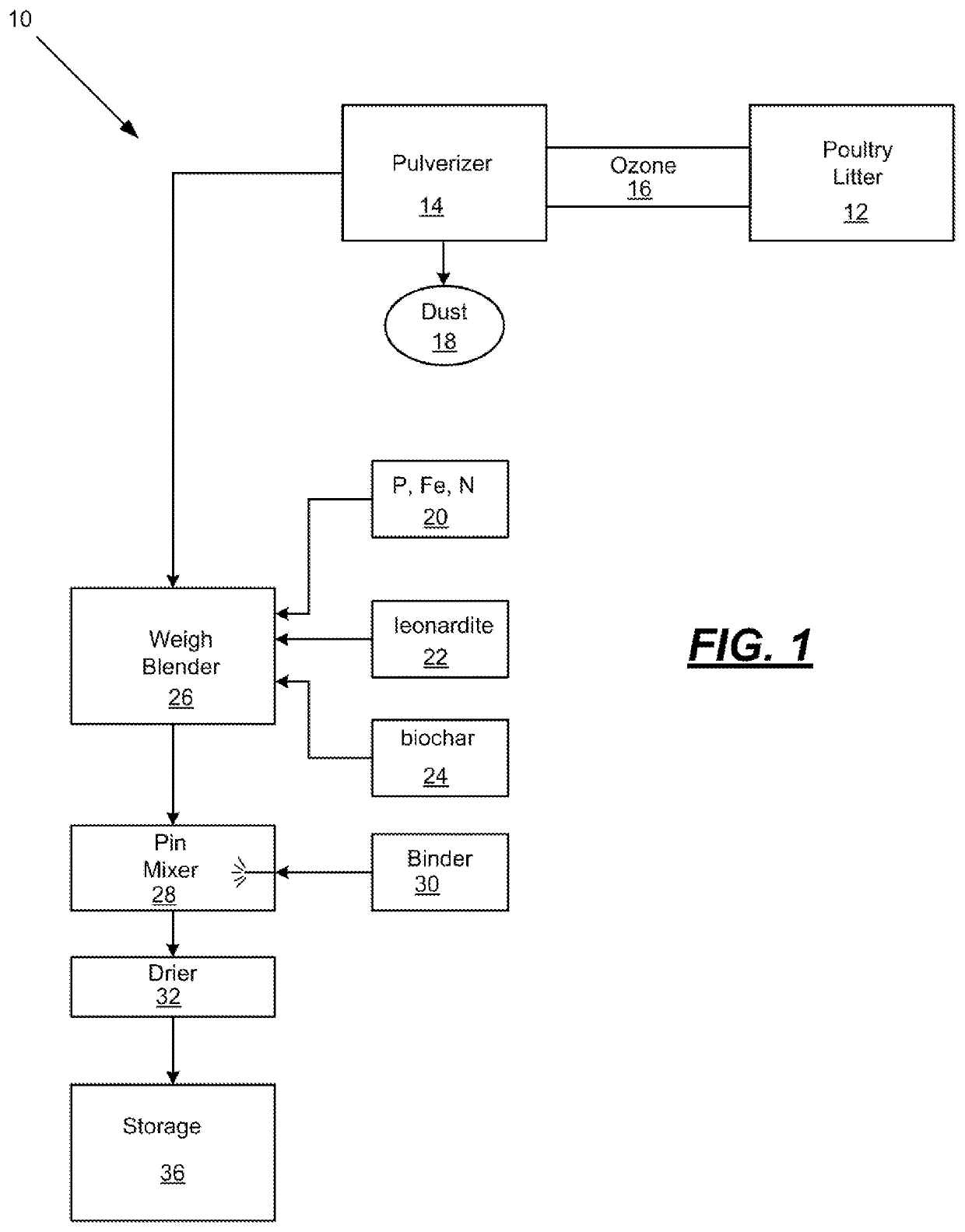

Biochar fertilizer

InactiveUS20200017418A1Aid flowabilityAid storageProductsReagentsFerrous sulfate ironAgricultural engineering

In view of the foregoing, an embodiment of the disclosure provides a process of producing a granulated fertilizer and a granulated fertilizer made by the process. The process includes the steps of:a) forming a dry mixture of:i) about 10% to about 45% by weight poultry litter;ii) about 20% to about 50% by weight ammonium sulfate;iii) about 0% to about 30% by weight leonardite;iv) about 0% to about 25% by weight biochar;v) about 5% to about 25% by weight potassium sulfate; andvi) about 0% to about 10% by weight ferrous sulfate;b) granulating the dry mixture in a granulator to form a granulated dry mixture;c) adding a binding agent to the granulated dry mixture to form a bound-granulated product; andd) drying the bound-granulated product to form the granulated fertilizer.

Owner:CARBON EARTH LLC

Lignite-Based Foundry Resins

Described herein, in the preferred embodiment, is a leonardite-based polyurethane resin binder that may be used, among other applications, as a binder in combination with foundry aggregate, e.g., sand, for molding or casting metal parts. The binders described herein comprise a humic substance, preferably leonardite, combined with a polymerizable polyol, an isocyanate, and a polymerization catalyst to make a polyurethane resin binder in situ in a foundry aggregate, such as sand. The lignite is mixed with the polymerizable polyol and dispersing agents as additives to improve the suspension quality and binder performance of the lignite-containing part of the binder components.

Owner:AMCOL INTERNATIONAL CORPORATION

Process for preparation of a humic substance based gel for targeted external application

ActiveUS9737560B1Prevent precipitationReduce particulates, excessive grindingSalicyclic acid active ingredientsInorganic non-active ingredientsHigh concentrationBiopolymer

A method of production and composition of a humic substances-based topical gel that contains a high concentration of polymerized humic substances in the form of polyelectrolyte-enhanced biopolymers, allowing for targeted application of gel to skin. A method of production consists of selection of humic substances containing material, extraction of humic substances from the material, polymerization of humic substances, and further processing for product preservation. Such humic substances based material may be derived from brown coal, such as leonardite or lignite, or peat. An extraction technique for extraction of the humic substances is an alkali extraction method. Such a resulting composition may contain sodium silicate as a gelling agent for ease of application, and in some embodiments a preservative or combination of preservatives for shelf life. Such a humic substances-based topic gel is water soluble, allowing for in-home application and ability to discard through washing down a household drain.

Owner:BLACKBALM LLC

Electrochemical production of graphene sheets from coke or coal

A method of producing graphene sheets from coke or coal powder, comprising: (a) forming an intercalated coke or coal compound by electrochemical intercalation conducted in an intercalation reactor, which contains (i) a liquid solution electrolyte comprising an intercalating agent; (ii) a working electrode that contains the powder in ionic contact with the liquid electrolyte, wherein the coke or coal powder is selected from petroleum coke, coal-derived coke, meso-phase coke, synthetic coke, leonardite, lignite coal, or natural coal mineral powder; and (iii) a counter electrode in ionic contact with the electrolyte, and wherein a current is imposed upon the working electrode and the counter electrode for effecting electrochemical intercalation of the intercalating agent into the powder; and (b) exfoliating and separating graphene planes from the intercalated coke or coal compound using an ultrasonication, thermal shock exposure, mechanical shearing treatment, or a combination thereof to produce isolated graphene sheets.

Owner:GLOBAL GRAPHENE GRP INC

Chemical fertilizer for crops

The invention discloses a chemical fertilizer for crops, and belongs to the field of chemical engineering. The chemical fertilizer for crops is prepared by taking 25 parts of leonardite, 3 parts of gluconic acid, 20 parts of ammonium nitro humate, 2 parts of dicyandiamide, 10 parts of urea, 0.05 part of trace elements and 30 parts of organic matters by weight as raw materials through the steps of reacting the leonardite and gluconic acid in water firstly; then, adding ammonium nitro humate into the obtained product to carry out a reaction under heating, adding dicyandiamide to react, and after the reacting is completed, adjusting the PH value to be neutral; finally, uniformly mixing the obtained product with urea, the trace elements and the organic matters. The chemical fertilizer for crops disclosed by the invention is mainly designed for crops, and has the effects of less application amount, high utilization rate, long fertilizer efficiency duration, and capability of improving the properties of soil, increasing the nutrition of crops, and increasing the yield of crops; the residues of the chemical fertilizer in crops are little, therefore, the chemical fertilizer does not cause damage to a human body.

Owner:柳州市汉森机械制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com