Regenerated sandy soil conditioner and preparation method thereof

A sandy soil and improver technology, applied in soil conditioning materials, chemical instruments and methods, organic fertilizers, etc., can solve problems such as unsatisfactory effects, low sludge fertilizer efficiency, and difficulty in retaining water, and is suitable for large-scale promotion and use. , low raw material and production cost, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0015] Regenerated sandy soil improver of the present invention, its preferred embodiment is:

[0016] It includes 90% by mass of urban sewage plant sludge and 10% by mass of sodium humate.

[0017] The sodium humate is sodium humate made from lignite.

[0018] The preparation method of above-mentioned regenerated sandy soil conditioner of the present invention, comprises steps:

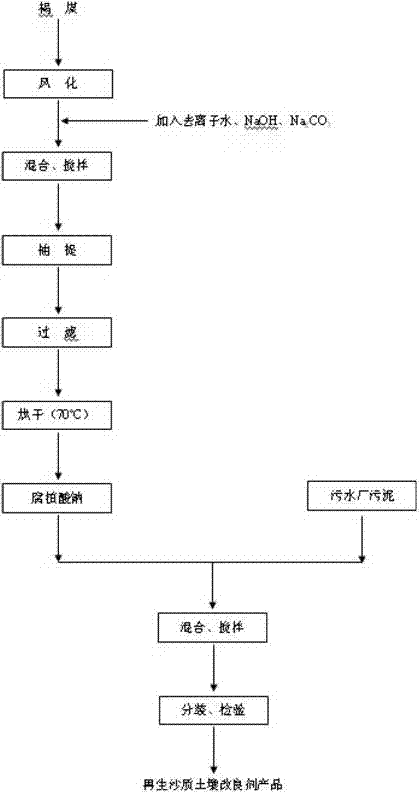

[0019] First, prepare sodium humate with weathered lignite;

[0020] Then, take 90 parts of urban sewage plant sludge and 10 parts of sodium humate by mass ratio and mix and stir for 30 minutes;

[0021] After that, subpackage and inspection processes are carried out.

[0022] The process for preparing sodium humate comprises:

[0023] First, put the weathered lignite into a beaker, add deionized water, NaOH and NaOH 2 CO 3 , stir evenly;

[0024] Afterwards, extract at room temperature for 2 hours, filter with a Buchner funnel, and dry the filtrate at 70°C to make a sodium humate product.

...

specific Embodiment

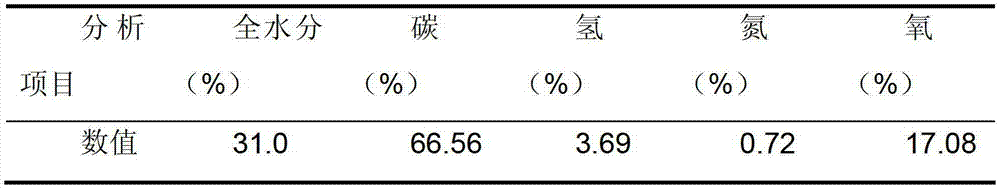

[0047] as attached figure 1 As shown, lignite is first made into sodium humate. The specific steps are as follows: take a certain amount of weathered lignite and put it into a beaker, add deionized water, NaOH and NaOH 2 CO 3 , stir well. Afterwards, extract at room temperature for 2 hours, filter with a Buchner funnel, and dry the filtrate at 70°C to obtain the sodium humate product. Under laboratory conditions, 630-690g sodium humate can be obtained from 1000g weathered lignite coal sample. Afterwards, 90 parts of urban sewage plant sludge and 10 parts of sodium humate were weighed according to the mass ratio, fully mixed and stirred for 30 minutes. Finally, the homogeneously mixed mixed material is sampled and inspected, and then measured and packaged after passing the inspection to obtain the finished product of the regenerated sandy soil improver.

[0048] Specific application examples:

[0049]Through the indoor pot experiment, Acorus calamus was planted in flowerp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com