Multifunction soil conditioner and preparation method thereof

A soil conditioner and multi-functional technology, applied in the field of agricultural chemistry, can solve the problems of poor improvement effect, short duration, large dosage, etc., to improve soil permeability, improve effectiveness, improve permeability and water retention. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

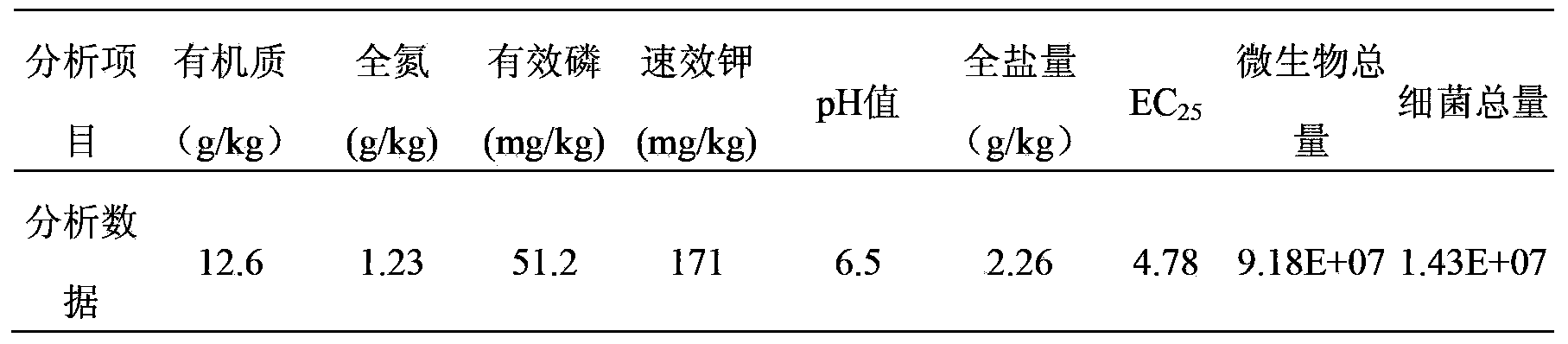

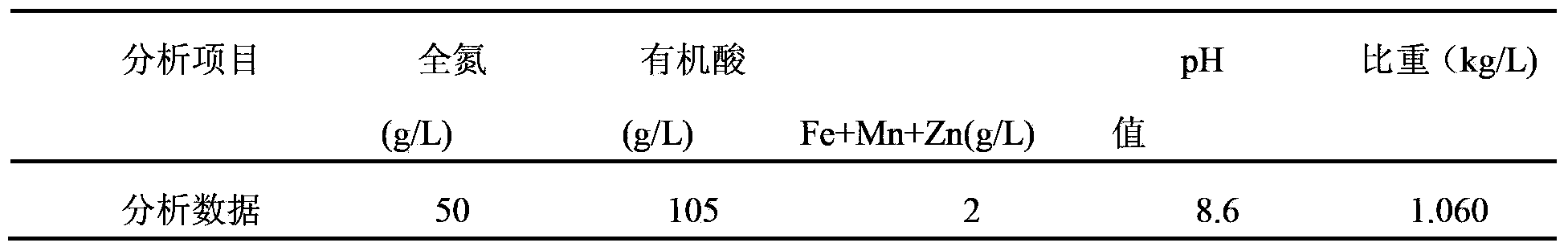

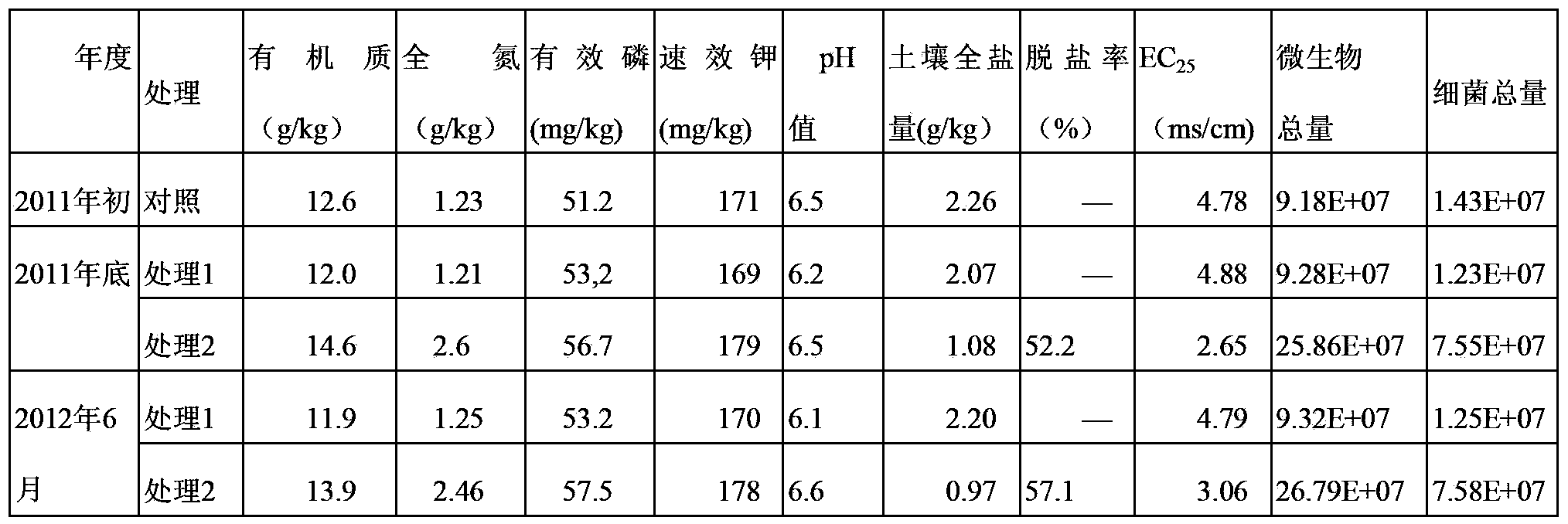

Image

Examples

Embodiment 1

[0040] The formula of this embodiment:

[0041] Urea: 10%;

[0042] Iron EDTA: 0.5%;

[0043] Zinc HEDTA: 11%;

[0044] Manganese EDTA: 4.0%;

[0045] Water-soluble polymer leachate: balance.

[0046] crafting process:

[0047] (1) Put 471kg of weathered lignite in a pool filled with 4239L of oxygen-enriched water, control dissolved oxygen and other parameters at 1.5mg / L-2.0mg / L, and place it for 20 days;

[0048] (2) Move the liquid obtained in step (1) to a stirrer, add 900 kg of weathered lignite, and stir for 90 days;

[0049] (3) Move the liquid in the agitator to another agitator, add citric acid to adjust the pH value to 6.0 while stirring at 400r / min, stop stirring, and let it stand for precipitation;

[0050] (4) Discard the precipitate, take the upper liquid, and add urea, EDTA iron, HEDTA zinc, and EDTA manganese according to the formula.

Embodiment 2

[0052] The formula of this embodiment:

[0053]Urea: 11%;

[0054] Iron EDTA: 0.75%;

[0055] Zinc HEDTA: 10%;

[0056] Manganese EDTA: 3.5%;

[0057] Water-soluble polymer leachate: balance.

[0058] crafting process:

[0059] (1) Put 471kg of weathered lignite in a pool filled with 4710L of oxygen-enriched water, control dissolved oxygen and other parameters at 1.5mg / L-2.0mg / L, and place it for 23 days;

[0060] (2) Move the liquid obtained in step (1) to a stirrer, add 500 kg of weathered lignite, and stir for 95 days;

[0061] (3) Move the liquid in the agitator to another agitator, add sodium bicarbonate to adjust the pH value to 6.5 while stirring at 500r / min, stop stirring, and let it stand for precipitation;

[0062] (4) Discard the precipitate, take the upper liquid, and add urea, EDTA iron, HEDTA zinc, and EDTA manganese according to the formula.

Embodiment 3

[0064] The formula of this embodiment:

[0065] Urea: 10.5%;

[0066] Iron EDTA: 1.0%;

[0067] Zinc HEDTA: 10.5%;

[0068] Manganese EDTA: 3.0%;

[0069] Water-soluble polymer leachate: balance.

[0070] crafting process:

[0071] (1) Put 471kg of weathered lignite in a pool filled with 5181L of oxygen-enriched water, control dissolved oxygen and other parameters at 1.5mg / L-2.0mg / L, and place it for 25 days;

[0072] (2) Move the liquid obtained in step (1) to a stirrer, add 550 kg of weathered lignite, and stir for 100 days;

[0073] (3) Move the liquid in the agitator to another agitator, add citric acid to adjust the pH value to 7.0 while stirring at 600r / min, stop stirring, and let it settle;

[0074] (4) Discard the precipitate, take the upper liquid, and add urea, EDTA iron, HEDTA zinc, and EDTA manganese according to the formula.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com