Long-term bearing test monitoring device for large-size cuboid coal and rock sample

A monitoring device and cuboid technology, which are applied in the direction of measuring device, measuring force, and testing the strength of materials by applying stable tension/pressure to achieve the effects of convenient disassembly and assembly, wide practicability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

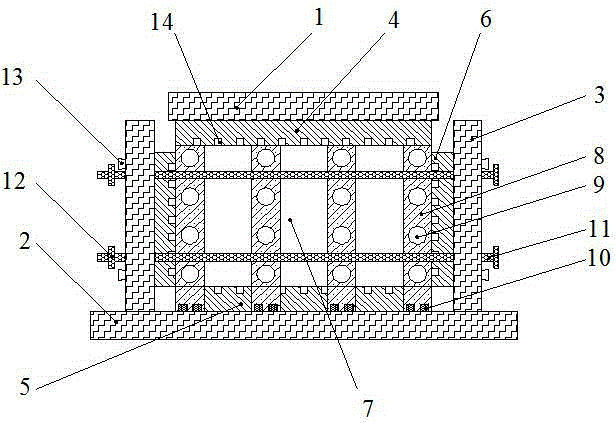

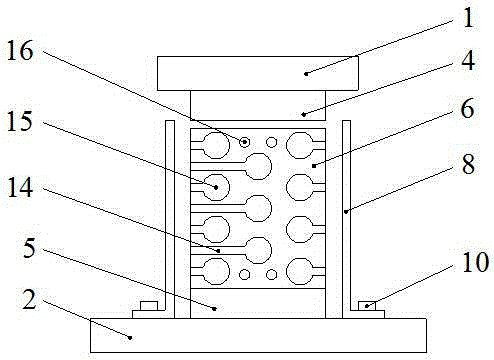

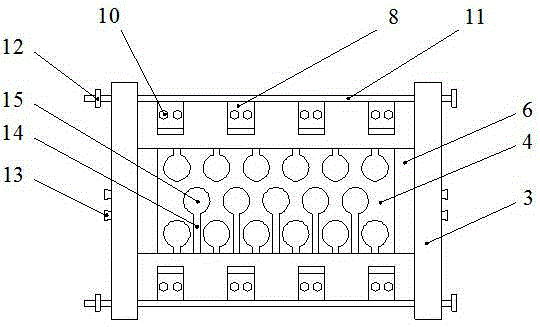

[0019] Such as figure 1 As shown, the monitoring device for the long-term bearing test of the large-size cuboid coal rock sample includes an upper platen 1, a bottom plate 2, a lateral restraint plate 3, an upper stress sensor positioning plate 4, a bottom stress sensor positioning plate 5, and a lateral stress sensor positioning plate. plate 6 and displacement sensor positioning plate 8, the upper platen 1 is arranged directly above the bottom plate 2, and the lateral limit restriction plate 3 is two pieces, which are arranged on the left and right sides of the bottom plate 2 and are fixed by fixing bolts 11. The lower surface of the upper platen 2, the inner surfaces of the two lateral restraint plates 3, and the upper surface of the bottom plate 2 are respectively provided with an upper stress sensor positioning plate 4, a side stress sensor position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com