Chemical fertilizer for crops

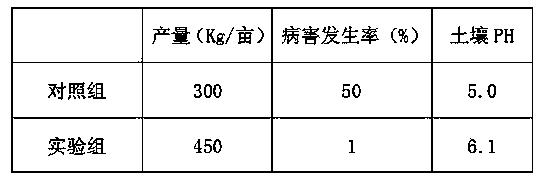

A technology for crops and chemical fertilizers, applied in agriculture, fertilization devices, fertilizer mixtures, etc., can solve problems such as soil acidification and hardening, damage to soil structure, and impact on human health. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A crop fertilizer made from raw materials of the following qualities:

[0018] Weathered lignite 100Kg, gluconic acid 12Kg, ammonium nitrohumate 80Kg, dicyandiamide 8Kg, urea 40Kg, trace elements 0.2Kg (including zinc 0.05Kg, iron 0.08Kg, boron 0.04Kg, copper 0.03Kg) and organic matter 120Kg ;

[0019] Its preparation method comprises the following steps:

[0020] A. Add 100Kg weathered lignite and 12Kg gluconic acid into a reactor equipped with 120Kg water, stir evenly, and react, and the reaction temperature is maintained at 25°C;

[0021] B. After the reaction time described in step A reaches 2 hours, add 80Kg of ammonium nitrohumate to it, stir evenly, and heat to 65°C, react for 30min, then add 8Kg of dicyandiamide, and continue to react at 65°C for 5min ;

[0022] C. After the reaction described in step B is finished, stop heating, then adjust the pH value to neutral with potassium hydroxide, then mix evenly with 40Kg urea, 0.2Kg trace elements, and 120Kg or...

Embodiment 2

[0024] A crop fertilizer made from raw materials of the following qualities:

[0025] Weathered lignite 100Kg, gluconic acid 12Kg, ammonium nitrohumate 80Kg, dicyandiamide 8Kg, urea 40Kg, trace elements 0.2Kg (of which, zinc 0.05Kg, iron 0.04Kg, boron 0.01Kg, molybdenum 0.02, cobalt 0.04, manganese 0.04) and organic matter 120Kg;

[0026] Its preparation method comprises the following steps:

[0027] A. Add 100Kg weathered lignite and 12Kg gluconic acid into a reactor equipped with 120Kg water, stir evenly, and react, and the reaction temperature is maintained at 25°C;

[0028] B. After the reaction time described in step A reaches 2 hours, add 80Kg of ammonium nitrohumate to it, stir evenly, and heat to 65°C, react for 30min, then add 8Kg of dicyandiamide, and continue to react at 65°C for 5min ;

[0029] C. After the reaction described in step B is finished, stop heating, then adjust the pH value to neutral with potassium hydroxide, then mix evenly with 40Kg urea, 0.2K...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com