Production method of humic acid

A production method, humic acid technology, applied in chemical instruments and methods, lignin derivatives, organic chemistry, etc., can solve the problems of serious pollution, large consumption of raw materials, poor product quality, etc., and achieve high humic acid content and high product quality. Good, large-scale production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

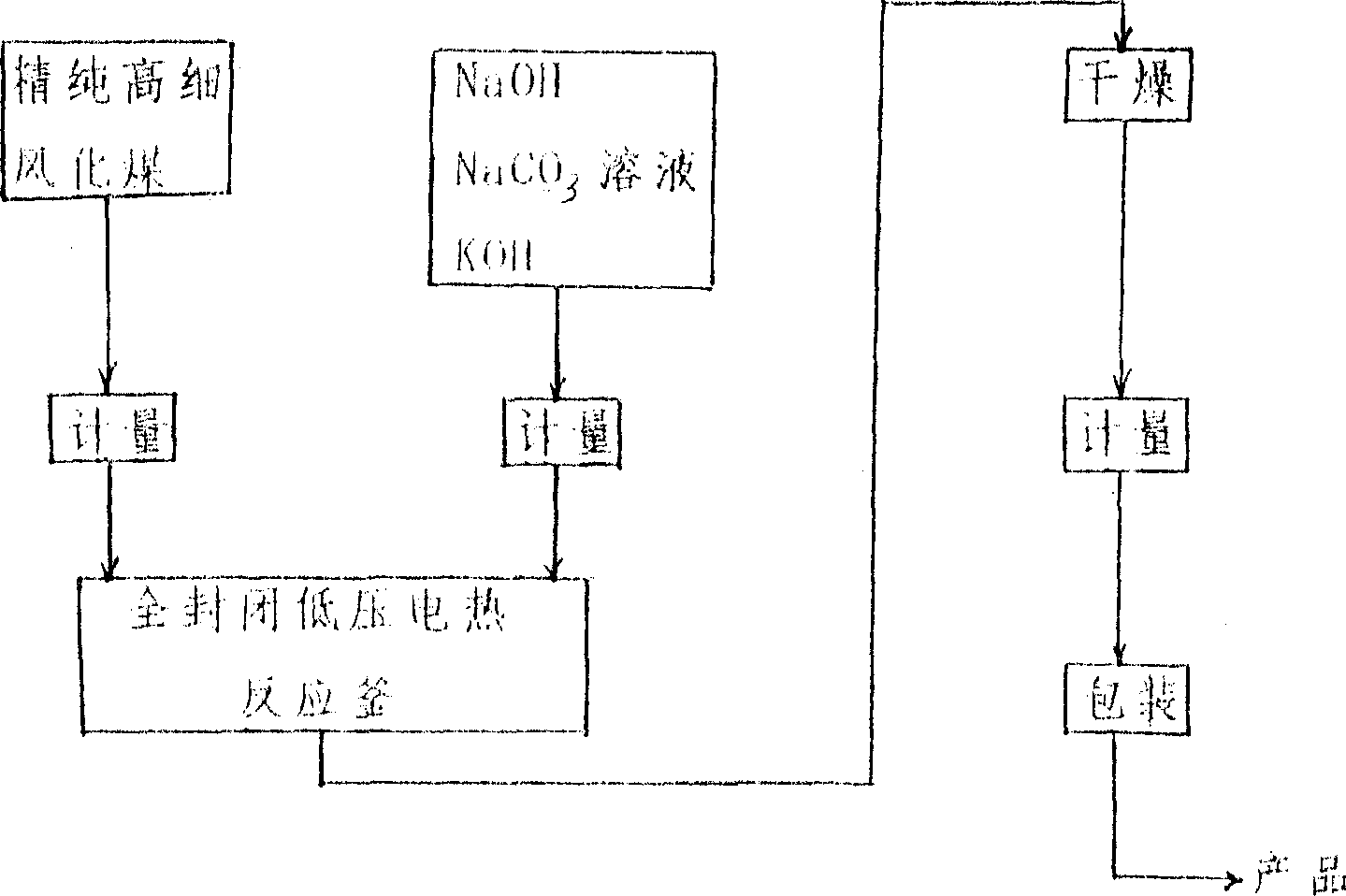

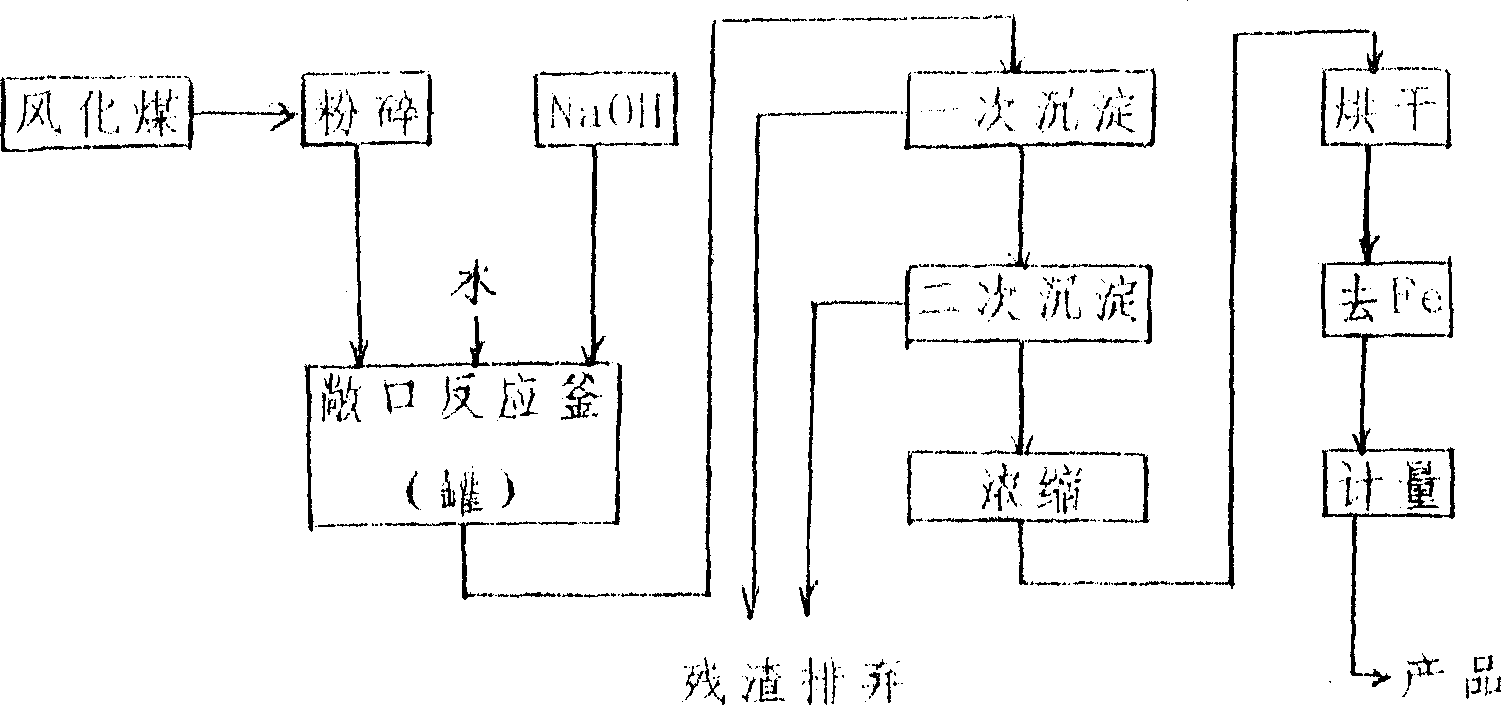

[0010] The production process of the present invention is described as follows in conjunction with the accompanying drawings:

[0011] attached figure 2 In the original wet process, the weathered coal is not purified by selection and purification. After being crushed, it directly enters the reactor to react with water and NaOH. The main material consumption (tons of product) is:

[0012] Weathered coal 2.5-3 tons

[0013] NaOH 0.22 tons

[0014] Water 25-30 tons

[0015] 5 tons of standard coal

[0016] Electricity 40KWh

[0017] According to the data, the discharge pollutants produced by wet process per ton of products are:

[0018] Coal-fired slag: 2 tons

[0019] Waste (sewage) water: 4 tons

[0020] SO: 160 kg

[0021] Weathered coal residue: 1.5-2 tons

[0022] Smoke (powder) dust: 400 kg

[0023] Exhaust, ONx (nitrogen oxides), carbon monoxide, carbon dioxide:

[0024] 2000 cubic meters

[0025] NaOH and Na root: 0.12 tons

[0026] Taking a 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com