Method for preparing EM bio-organic fertilizer by use of biogass slurry and bio-organic fertilizer

A technology of bio-organic fertilizer and EM bacteria, which is applied in the preparation of organic fertilizers, the treatment of bio-organic parts, organic fertilizers, etc., can solve the problems of environmental pollution, high-cost biogas slurry recovery, etc., achieve high content, promote microbial activities, and accelerate The effect of decomposition of organic matter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

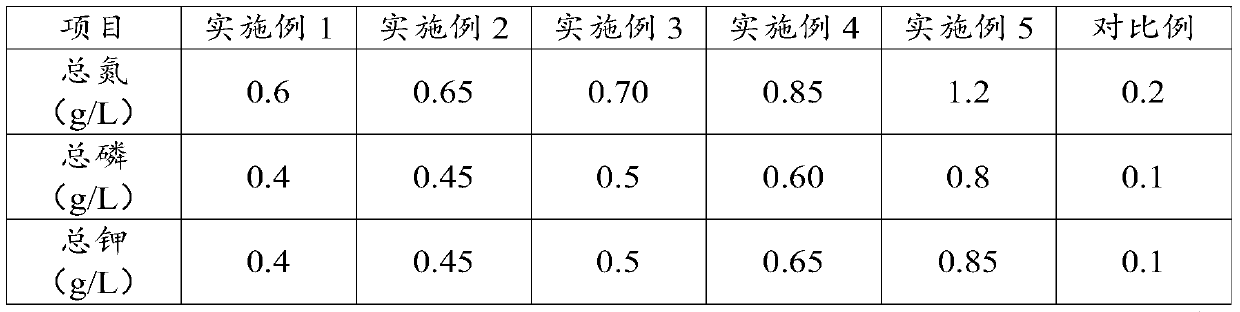

Examples

Embodiment 1

[0052] The method that utilizes biogas slurry to prepare EM bacterium bio-organic fertilizer provided by the invention comprises the following steps:

[0053] The EM bacteria stock solution and EM bacteria nutrient solution are added to the biogas slurry, and the bio-organic fertilizer is obtained after the biogas slurry is cultivated by EM bacteria.

[0054] Among them, the mass ratio of biogas slurry, EM bacteria stock solution and EM bacteria nutrient solution is 95:2:0.5.

Embodiment 2

[0056] The method that utilizes biogas slurry to prepare EM bacterium bio-organic fertilizer provided by the invention comprises the following steps:

[0057] The EM bacteria stock solution and EM bacteria nutrient solution are added to the biogas slurry, and the bio-organic fertilizer is obtained after the biogas slurry is cultivated by EM bacteria.

[0058] Among them, the mass ratio of biogas slurry, EM bacteria stock solution and EM bacteria nutrient solution is 105:6:1.5.

Embodiment 3

[0060] S31. Separating and concentrating the biogas slurry through an ultrafiltration membrane and a reverse osmosis membrane to obtain concentrated biogas slurry and water, and disinfecting the concentrated biogas slurry;

[0061] S32, add the EM bacteria stock solution containing photosynthetic bacteria group, lactic acid bacteria group, yeast group, Gram-positive actinomycetes group, filamentous bacteria group of fermentation system to the concentrated biogas slurry after disinfection in step S31, add brown sugar The EM bacteria nutrient solution in water was cultivated for 7 days at a temperature of 5°C, and refluxed and stirred with a submersible flowmaker. After the cultivation was completed, selenium, boron, zinc, and manganese were added, and 80 mesh The plate and frame filter press performs solid-liquid separation to obtain solid and liquid bio-organic fertilizers;

[0062] Among them, the mass ratio of biogas slurry, EM bacteria stock solution and EM bacteria nutrien...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com