Greenhouse heat preservation quilt and application thereof

A thermal insulation quilt and fabric layer technology, applied in the field of thermal insulation, can solve the problems of low service life, poor waterproofness, high cost, etc., and achieve the effects of reducing costs, ensuring thermal insulation effect, and increasing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

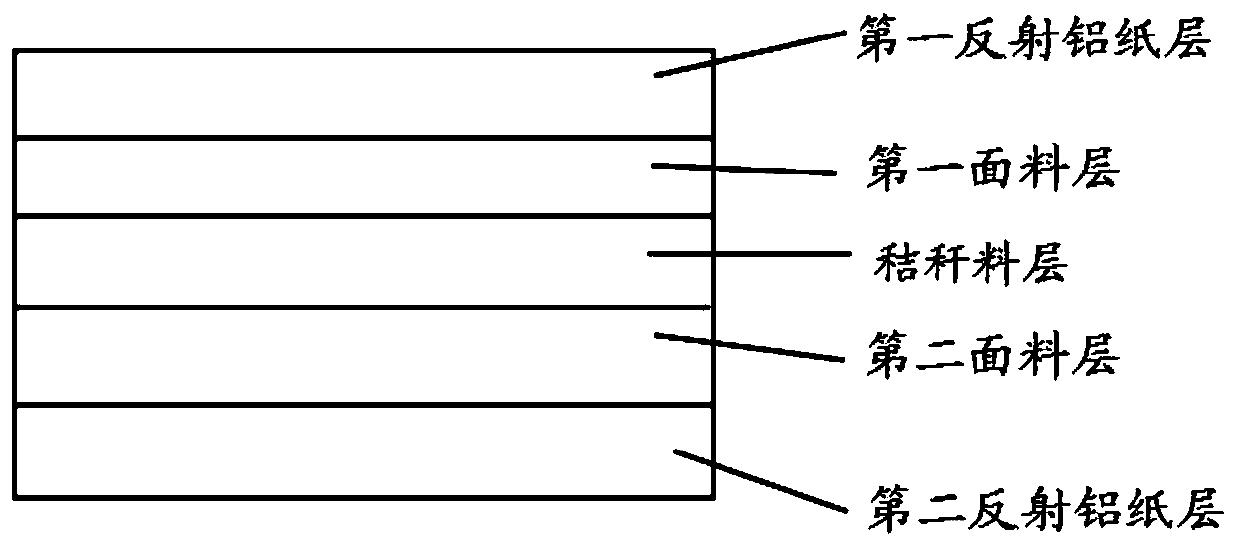

[0043] The present invention has no special requirements on the preparation method of the greenhouse insulation quilt, and it only needs to directly compound each layer. In the present invention, the preparation method of the greenhouse insulation quilt preferably includes the following steps:

[0044] Needling and sewing the edges of the first fabric layer and the second fabric layer to form a cavity, and filling the crushed straw into the cavity to obtain a straw composite layer;

[0045] The first reflective aluminum paper layer, the straw composite layer and the second reflective aluminum paper layer are sequentially stacked and compounded to obtain the greenhouse insulation quilt;

[0046] The first reflective aluminum paper layer is in contact with the first fabric layer of the straw composite layer, and the second reflective aluminum paper layer is in contact with the second fabric layer of the straw composite layer.

[0047] In the present invention, the preparation o...

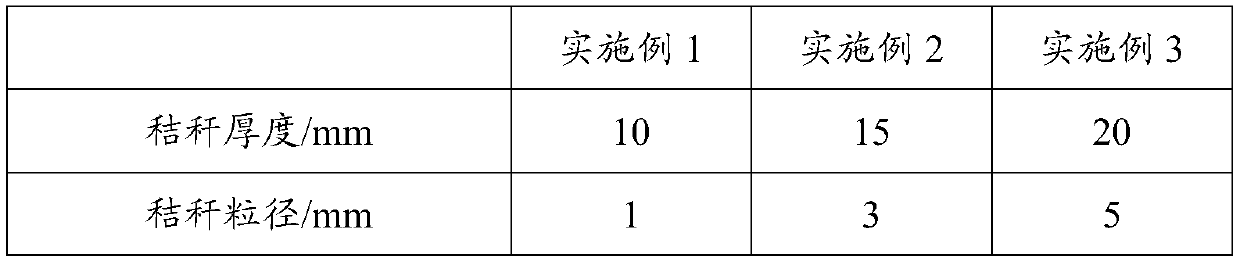

Embodiment 1

[0055] According to the size and parameters in Table 1, the edges of the first fabric layer and the second fabric layer were needle-punched to form a cavity, and the crushed straw was filled into the cavity to obtain a straw composite layer; needle-punched The straw composite layer is sewn into a net shape; the two sides of the straw composite layer are coated with adhesive, and then the first reflective aluminum paper layer, the straw composite layer and the second reflective aluminum paper layer are sequentially stacked and composited to obtain a greenhouse insulation quilt; The first reflective aluminum paper layer is in contact with the first fabric layer of the straw composite layer, and the second reflective aluminum paper layer is in contact with the second fabric layer of the straw composite layer.

Embodiment 2~3

[0057] The preparation steps are the same as in Example 1, except for the thickness of each layer and the particle size of the straw, see Table 1 for details.

[0058] The composition of table 1 embodiment 1~3 greenhouse insulation quilt

[0059]

[0060]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com