A set of concrete production environmental protection equipment and concrete production process

A technology for production equipment and concrete, applied in the field of concrete production environmental protection equipment and concrete production technology, can solve the problems of high material handling cost, secondary dust, increase production cost of concrete production, etc., and achieve the effect of saving material handling costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

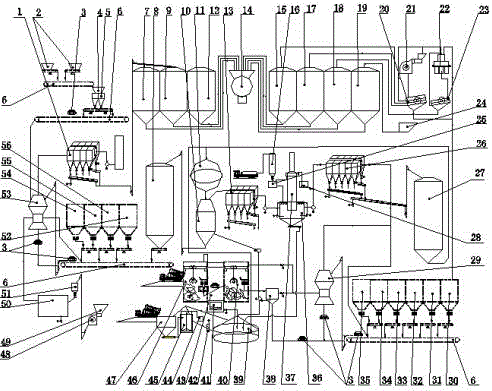

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

[0012]A set of concrete production equipment, including: a DCS central control system and a remote monitoring system. The DCS central control system controls the aggregate production line, cement mineral powder production line, cement kiln processing sludge equipment, and raw meal processing life through control signals. Garbage equipment and concrete mixing station equipment are used for concrete production, and the remote monitoring system monitors the aggregate production line, cement mineral powder production line, cement kiln sludge treatment equipment, raw material treatment domestic garbage equipment, and concrete mixing station equipment through electrical connections. Concrete production, the aggregate production line includes: limestone crusher 21, sand making machine 22, vibrating screen II 20, vibrating screen III 23, feeder installed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com