Moisture-conditioning paint and method for producing the same

A manufacturing method and coating technology, applied in the direction of coating, etc., can solve the problems of low recycling rate, inability to use incineration treatment, ecological environment impact, etc., and achieve the effect of high antibacterial rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

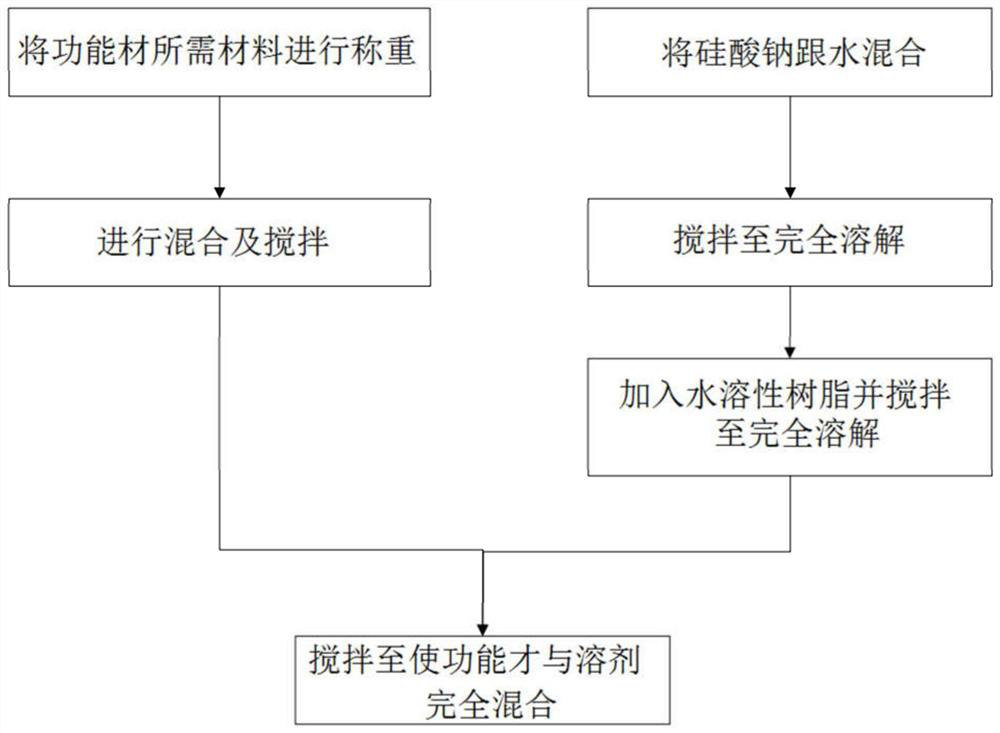

Method used

Image

Examples

Embodiment Construction

[0031] The above and other technical content, features and functions of the present invention will be clearly understood in the following detailed description of preferred embodiments with reference to the drawings.

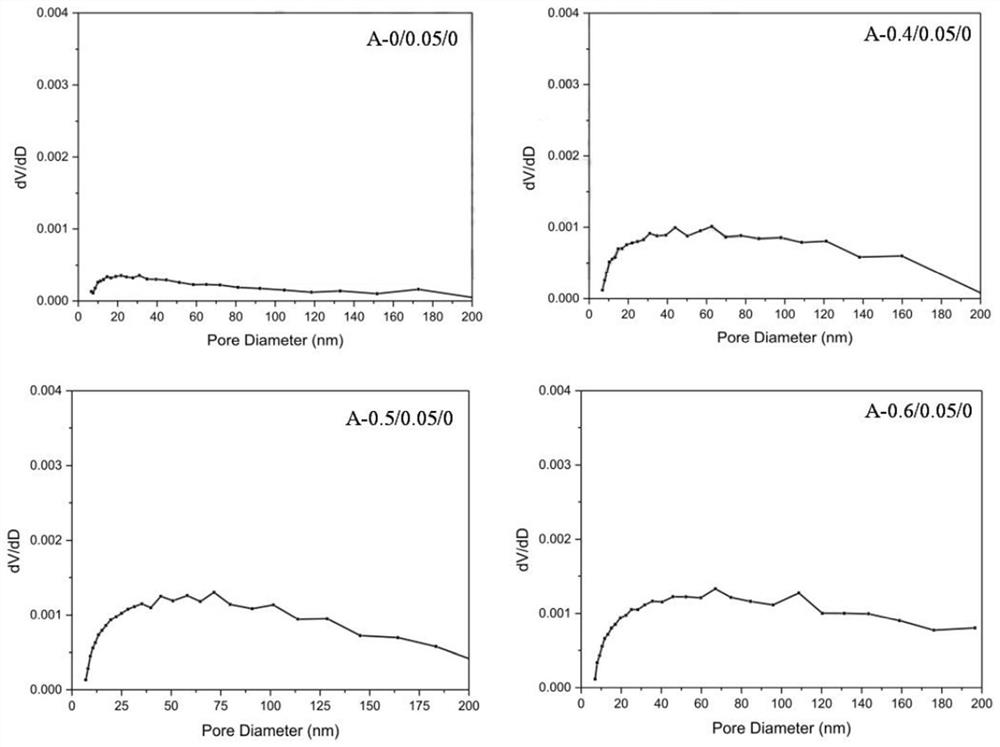

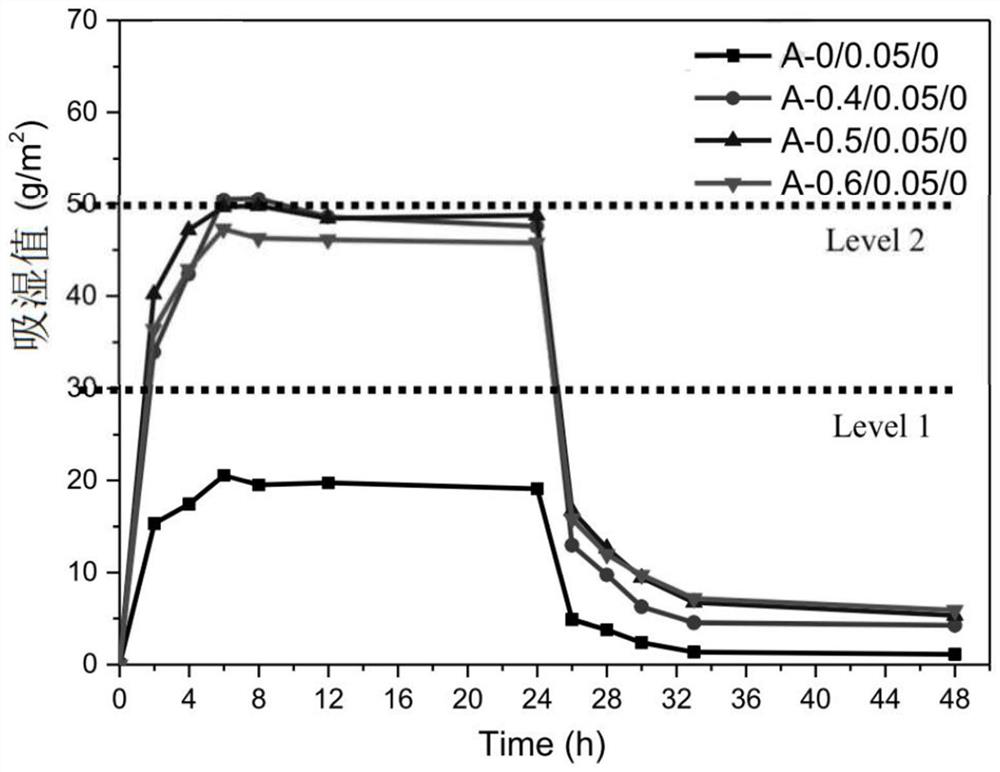

[0032] The first preferred embodiment of the present invention, the humidity-adjusting coating of this embodiment, which includes a functional material of 30% by weight, a mixture of 62.5% to 70% by weight, and a mixture of 2.5% to 7.5% by weight Sodium silicate; wherein, the functional material includes 20-60% by weight of inorganic sludge, 35-65% by weight of gypsum hemihydrate, and at least 5% by weight of inorganic minerals, and the above-mentioned inorganic The sludge contains at least 90% by weight of amorphous silicon dioxide; in addition, the mixture contains a water-soluble resin and water, and the mixing ratio of the water-soluble resin and the water is 1: (2-3), and The above-mentioned water-soluble resin (such as acrylic resin), or the water-soluble a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com