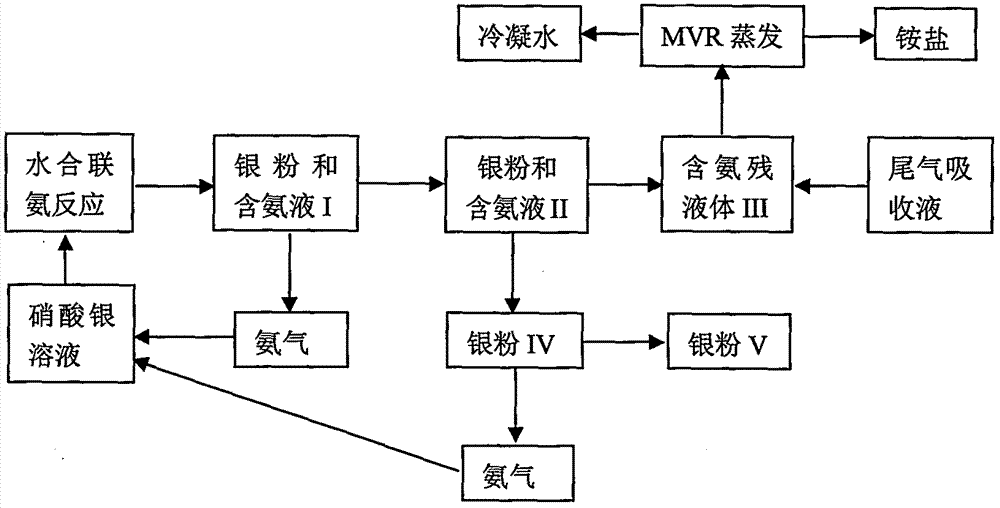

A kind of method that hydrazine hydrate reacts to prepare silver powder and ammonia recycles and utilizes

A hydrazine hydrate and ammonia recovery technology, applied in the field of environmental protection and energy saving, can solve problems such as undiscovered ammonia, and achieve the effects of reducing environmental risks and production risks, reducing acid usage, and reducing discharge capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

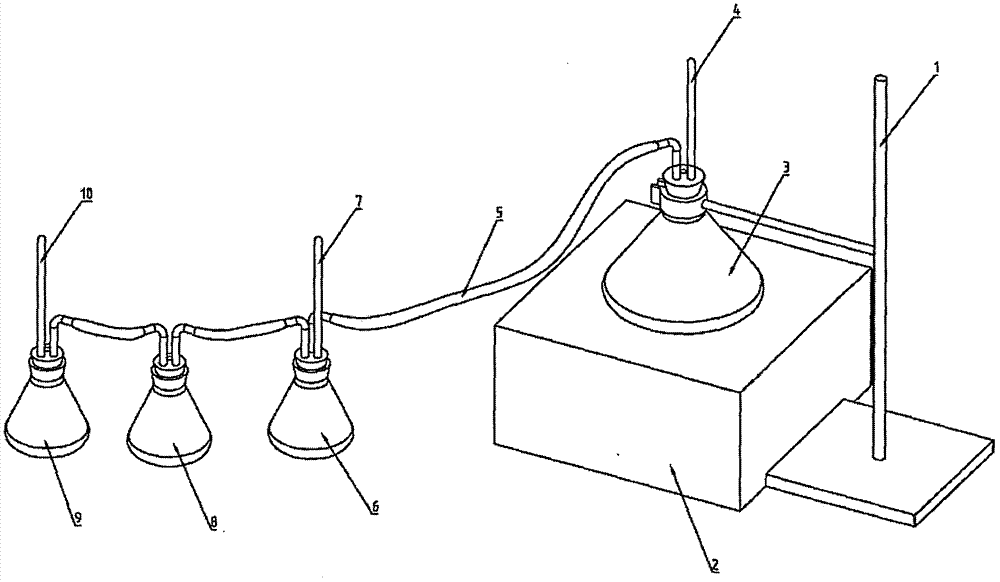

[0046] S1: After the reaction of hydrazine hydrate, the mixed solution I obtained by silver powder and ammonia-containing mother liquor was obtained, and 400ml mixed solution I was added to the round bottom flask of the above-mentioned experimental device of 1000ml. The volume ratio of silver powder accounted for about 50%, mixed solution I The temperature was 54°C.

[0047] The above round bottom flask is heated, and the generated ammonia gas enters into S2; when the temperature is lower than 80°C, only a small amount of gas inside the round bottom flask begins to escape, and when the temperature rises to 85°C, a large amount of gas escapes, and the constant temperature is 91°C 60min, stop heating, obtain the mixed solution II that silver powder and ammoniacal mother liquor are formed;

[0048] S2: Use silver nitrate solution to absorb the ammonia gas produced by S1 mixed solution I. The constant temperature time in S1 is the absorption time of silver nitrate. The absorbed si...

Embodiment 2

[0054] The steps are the same as in Example 1, and the result is that the initial concentration of ammonia is 0.72 mol / L, and after a constant temperature of 98° C. for 60 minutes, the residual concentration of ammonia is 0.049 mol / L, and the recovery rate of ammonia is 93.21%.

Embodiment 3

[0056] S1: After the reaction of hydrazine hydrate, a mixed solution I consisting of silver powder and ammonia-containing mother liquor is obtained. Take 400ml of the mixed solution and add it to a 1000ml round bottom flask. The volume ratio of the silver powder is about 50%, and the temperature of the mixed solution is 50°C.

[0057] Heating the round bottom flask, the generated ammonia gas enters into S2. When the temperature is lower than 80°C, only a small amount of gas inside the round bottom flask begins to escape. When the temperature rises to 85°C, a large amount of gas escapes. Keep the temperature at 95°C for 40 minutes. , stop heating to obtain mixed solution II composed of silver powder and ammonia-containing residual leaves;

[0058] S2: Use silver nitrate solution to absorb the ammonia gas produced by S1 mixed solution I, and the absorbed silver nitrate solution is used in the next hydrazine hydrate cycle reaction; the mixed solution II is left to stand for 40 min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com