Patents

Literature

101results about How to "Low pyrolysis temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing metal particle dispersion, conductive ink using metal particle dispersion produced by such method, and conductive coating film

InactiveCN101287566AEffective conductivityImprove performanceConductive layers on insulating-supportsInksDispersion stabilityLiquid medium

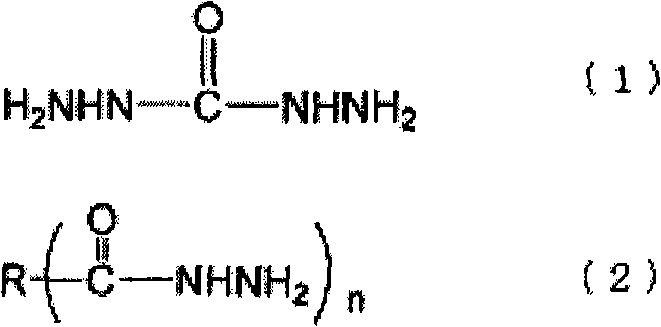

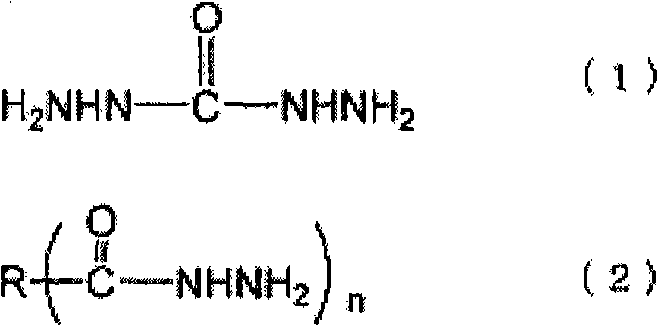

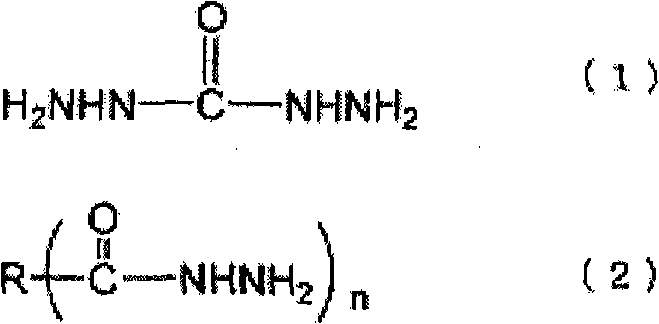

Disclosed is a method for producing a metal particle dispersion wherein a metal compound is reduced by using carbodihydrazide represented by the formula (1) below or a polybasic acid polyhydrazide represented by the formula (2) below (wherein R represents an n-valent polybasic acid residue) in a liquid medium. By reducing the metal compound in the presence of a compound having a function preventing discoloration of the metal, there can be obtained a metal particle dispersion having excellent discoloration preventing properties. Metal particles produced by such methods have a uniform particle diameter and are excellent in dispersion stability. By using a conductive resin composition or conductive ink containing a metal particle dispersion obtained by such production methods, there can be formed a conductive coating film, such as a conductive circuit or an electromagnetic shielding layer, having good characteristics.

Owner:TOYO INK SC HOLD CO LTD

Flame-proof nitrocellulose lacquer prepared by halogen-free flame retardant and preparation method thereof

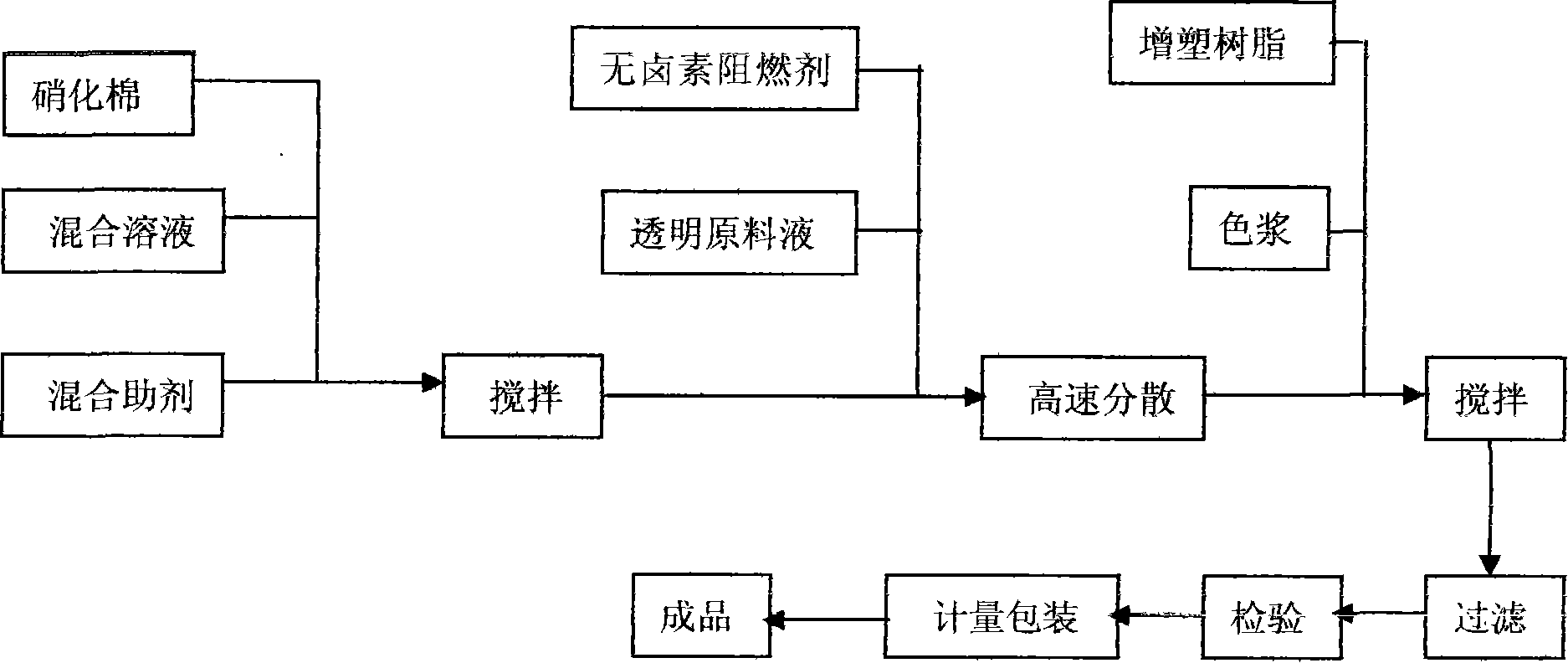

The invention discloses nitrocellulose lacquer which is prepared through utilizing free halogen flame retardant, and adding free halogen flame retardant on the basis of traditional nitrocellulose lacquer, whose proportion of components is that 13-18% nitrocellulose, 27-35% mixing solvent, 1-3% mixing auxiliary agent, 30-35% plasticizing agent, 7-10% transparent raw material liquid diluent and 10-15% color paste, which is characterized in that 7-10% free halogen flame retardant is added in the components. The invention further discloses a preparation process of nitrocellulose lacquer. The invention provides environment-friendly, no pollution nitrocellulose lacquer with excellent flame-retardant effect under the conditions of keeping basic property of original nitrocellulose lacquer and no changing functions.

Owner:刘春雨

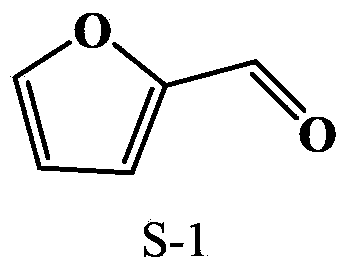

Method for preparation of furfural by biomass microwave mild pyrolysis

The invention discloses a method for preparation of furfural by biomass microwave mild pyrolysis. The method includes: 1) pretreating a biomass raw material by an inorganic acid catalyst or an inorganic salt catalyst; 2) taking microwave as a heat source, conducting mild pyrolysis on the biomass raw material pretreated in step 1), and subjecting the pyrolytic gas to condensation, thus obtaining furfural. The method provided in the invention has the advantages of simple process, high processing efficiency, short procedure and easy operation, short production cycle, and low cost.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI +1

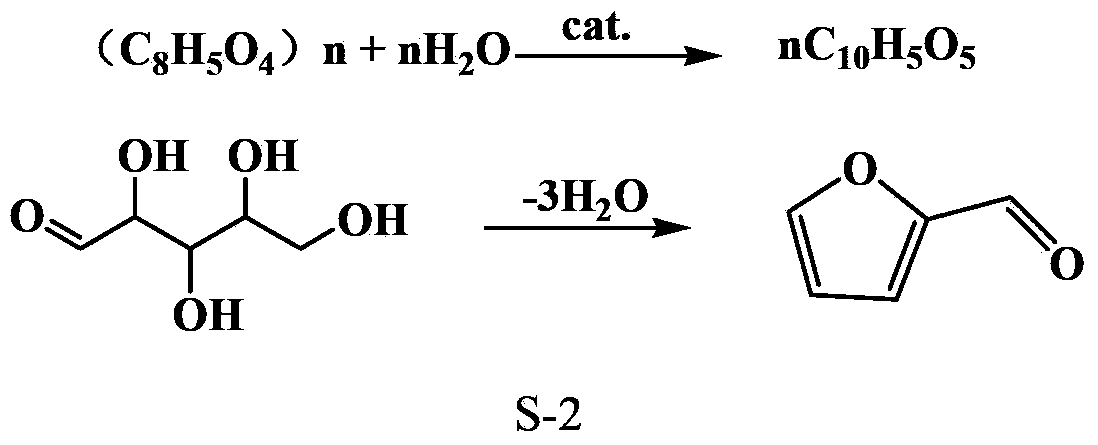

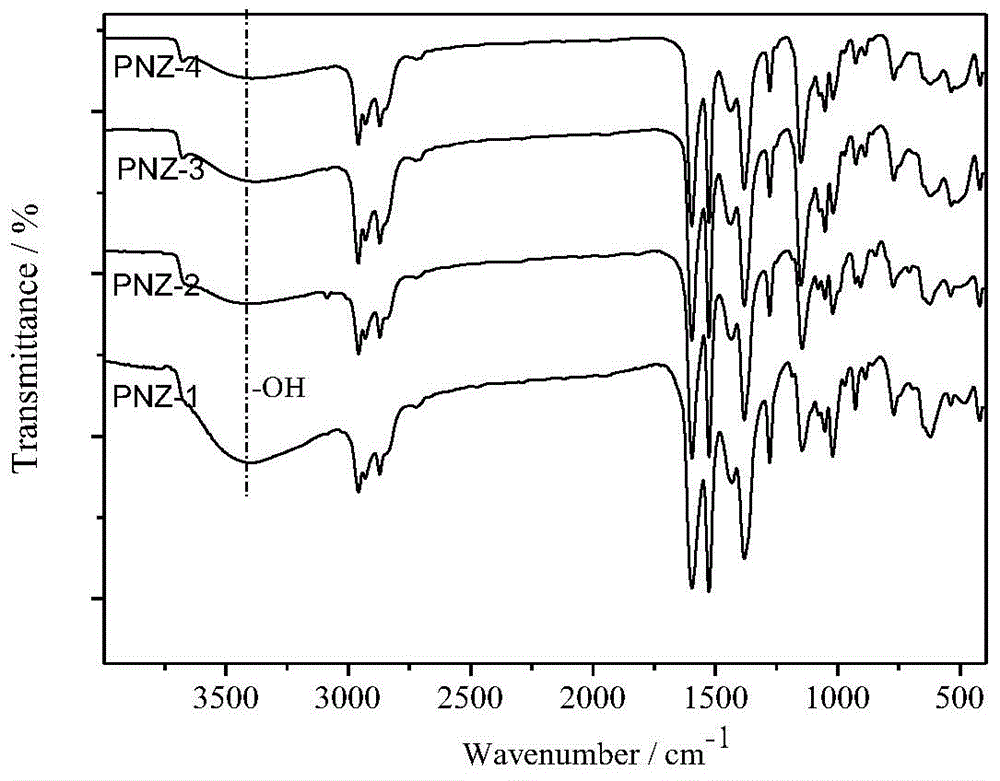

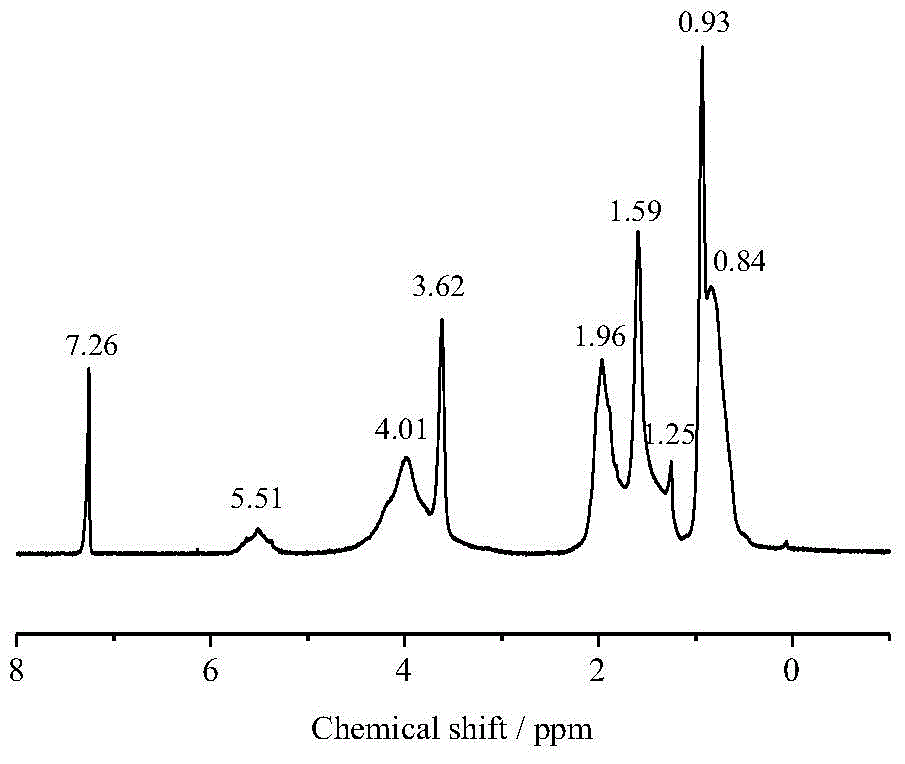

Nonpolar zirconium carbide liquid-phase ceramic precursor, preparation method therefor and application thereof

The invention relates to a nonpolar zirconium carbide liquid-phase ceramic precursor, a preparation method therefor and application thereof. The preparation method comprises: firstly preparing a nonpolar zirconium polymer-polyzircooxane through coordination protection of propyl zirconate and controllable hydrolysis condensation reaction; and by using the polyzircooxane as a zirconium source and divinyl benzene as a carbon source, compounding the components to obtain the nonpolar zirconium carbide liquid-phase ceramic precursor. The liquid-phase precursor prepared by the invention has the characteristics of polymer resin; the viscosity of the precursor can be controlled between 50 mpa.s and 500 mpa.s by adjusting the solid content, and the manufacturability is good. The zirconium carbide liquid-phase ceramic precursor which is cured and thermally treated can be converted into a pure-phase zirconium carbide ceramic at a relatively low temperature ( for example, 1500 DEG C). The liquid-phase ceramic precursor prepared by the invention is expected to be used as impregnating resin for a ceramic-based composite material and an antioxidant C / C and C / Si composite material so as to improve the ultra-high temperature antioxidant performance of the material and reduce the ablativity of the material.

Owner:SUZHOU TUNABLE MATERIALS TECH CO LTD

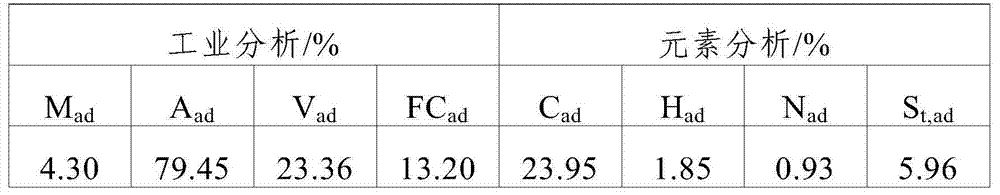

Method for preparing charcoal slow-release fertilizer by utilizing dioscorea zingiberensis saponin fiber waste residues

InactiveCN102701852ALow pyrolysis temperatureSimple processClimate change adaptationAgriculture gas emission reductionFiberCompression molding

The invention relates to a method for preparing a charcoal slow-release fertilizer by utilizing dioscorea zingiberensis saponin fiber waste residues. The method comprises the following steps of: (1) air drying the dioscorea zingiberensis saponin fiber waste residues, smashing and sieving; (2) putting in a reactor, rising temperature to be 300-600 DEG C, and carrying out pyrolytic carbonization under the condition of oxygen limited to obtain charcoal powder after cooling and grinding; and (3) spraying the charcoal powder onto binder solution, packaging a fertilizer for 2-5 times, air drying after mixing uniformly, or pelleting through a comminutor, or compression molding through a mould, so as to obtain the charcoal slow-release fertilizer. According to the method, the process is simple, the cost is low, and the time and the energy are saved; and charcoal and the fertilizer are packaged according to a certain proportion, and a complementary or synergistic effect which exists between the charcoal and the fertilizer is utilized, so that the nutrient efficiency is improved.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Preparation method of barium-calcium carbonate and potassium-sodium niobate alternative spin-coating lead-free piezoelectric thick film

The invention discloses a preparation method of a barium-calcium carbonate and potassium-sodium niobate alternative spin-coating lead-free piezoelectric thick film. The preparation method comprises the following steps of: based on a sol-gel process, preparing Bi0.5Ca0.5Ti03(BCT) precursor sol with concentration of 1mol / L by adopting barium acetate (Ba(CH3COO)2), calcium nitrate terahydrate (Ca(NO3)2.4H2O) and tetrabutyl titanate (C16H36O4Ti) as the materials, adopting ethylene glycol monomethyl ether (C3H8O2) and glacial acetic acid (CH3COOH) as solvent, and adopting acetylacetone (C5H8O2) as stabilizing agent; preparing K0.5Na0.5NbO3 (KNN) precursor sol with concentration of 0.6mol / L by adopting ethylene glycol (C2H6O2) as esterifying agent, adopting nitric acid as metal coordination agent and introducing polyvinylpyrrolidone (PVP) as modifying agent; coating the KNN sol on the (Pt / TiO2 / Ti / SiO2 / Si) substrate, and coating the BCT sol after the thermal treatment; repeating the steps by three times, i.e., carrying out spin-coating for six layers alternatively; and obtaining the KNN-BCT film through annealing treatment. The obtained film is uniform in crystalline grain, compact in arrangement, smooth in surface and free of cracks.

Owner:QIQIHAR UNIVERSITY

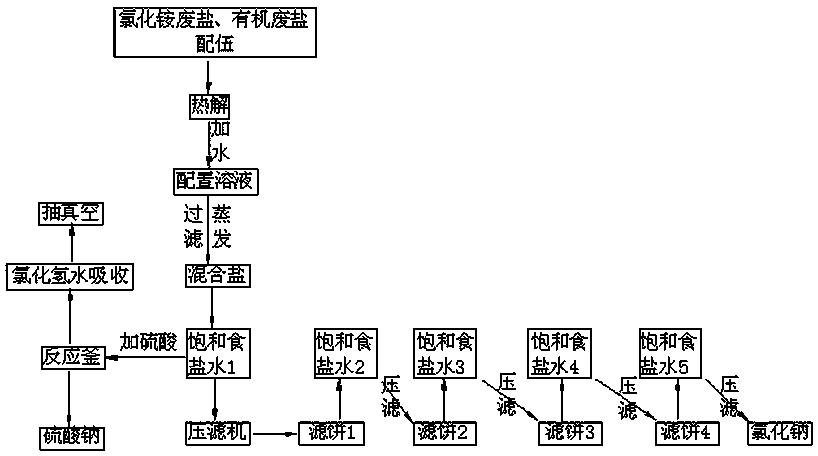

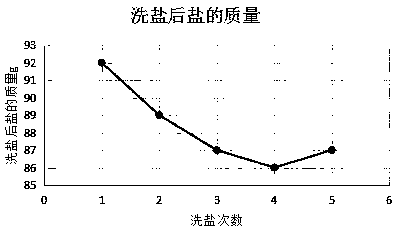

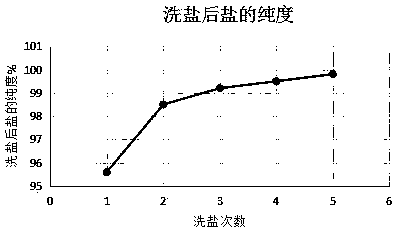

Method for recycling industrial waste salt

InactiveCN110711761AReduce corrosionLow pyrolysis temperatureWaste processingSolid waste disposalIndustrial wasteEnvironmental chemistry

The invention discloses a method for recycling industrial waste salt. The method comprises the following steps: taking waste salt containing relatively high ammonium chloride and organic waste salt for compatibility; heating and pyrolyzing the compatible waste salt to remove organic matters; cooling the pyrolyzed waste salt, and adding water for dissolving to prepare a solution; filtering the solution, and evaporating to obtain a mixed salt solid; preparing a plurality of tanks of saturated sodium chloride solutions, and performing salt washing on the mixed salt to obtain an industrial productsodium chloride; and adding sulfuric acid into the replaced saturated sodium chloride solution of sodium sulfate, absorbing hydrogen chloride gas in a reaction product by water to be converted into hydrochloric acid, filtering the sodium sulfate solution, and drying to prepare industrial sodium sulfate. The waste salt used in the method mainly contains ammonium chloride waste salt and organic waste salt, so that the problems that high-salt leachate is difficult to treat and the like after the waste salt is buried can be solved, meanwhile, sodium chloride and sodium sulfate are recycled, and resource recycling is achieved.

Owner:SHANGYU ZHONGLIAN ENVIRONMENTAL PROTECTION CO LTD

Harmless treatment method of household garbage

InactiveCN106838911AHigh calorific valueBurn completelyEmission preventionIncinerator apparatusSlagCarbonization

The invention provides a harmless treatment method of household garbage. The harmless treatment method of household garbage comprises the following steps of: performing carbonization and degradation on the pretreated household garbage under vacuum; after low-temperature vacuum carbonization treatment, stopping heating; turning off a pyrolysis exhaust gas treatment system and a vacuum pump; turning on an incineration flue gas treatment system and a fan; opening an air inlet in the bottom of a pyrolysis furnace; igniting the household garbage after being subjected to the low-temperature vacuum carbonization at the air inlet; the household garbage completely and spontaneously combusts under the condition of sufficient oxygen content; the incineration exhaust gas is sequentially introduced into a water washing tower and an alkaline washing tower; the incineration exhaust gas is purified by the water washing tower and then is exhausted into the atmosphere by the fan; performing landfill treatment on the slag produced by the combustion of the household garbage; obtaining pyrolytic oil, taking the pyrolytic oil out of a water cooling tower, and delivering the pyrolytic oil to a cement rotary kiln for high-temperature incineration. According to the harmless treatment method of household garbage disclosed by the invention, the household garbage is incinerated after vacuum carbonization treatment, and dioxin generation during the treatment process is effectively controlled by using two different exhaust gas treatment processes.

Owner:CHANGSHA HUIJU ENVIRONMENTAL TECH CO LTD

Catalyst for pyrolysis of oil shale as well as preparation method and use method of catalyst

InactiveCN103878031AIncrease lytic activityHigh cracking rateOrganic-compounds/hydrides/coordination-complexes catalystsSpecial form destructive distillationCatalytic pyrolysisMetallic sulfide

The invention discloses a catalyst for pyrolysis of oil shale. The catalyst is prepared from the following raw materials by weight percentage: 2-8% of a molecular sieve, 1-5% of activated clay, 10-60% of organic cobaltate, 5-20% of metal sulfide, 8-30% of glycerate, and 15-35% of paraffin; the organic cobaltate is one or more of cobalt acetate, cobalt oxalate, cobalt naphthenate and cobalt neocaprate; the metal sulfide is molybdenum sulfide and / or nickel sulfide. The invention further discloses a preparation method of the catalyst and a use method of the catalyst. According to the catalyst disclosed by the invention, the pyrolysis efficiency of the oil shale can be improved, the distribution of pyrolysis products of the oil shale is improved, more light products are produced, and components of gasoline and diesel oil can be separated through rectification. According to the preparation method and use method of the catalyst, which are disclosed by the invention, the catalytic pyrolysis and microwave heating are combined, so that the utilization efficiency of energy source can be improved, the composition and process performance of liquid fuel are improved, and the following processing difficulty is reduced.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

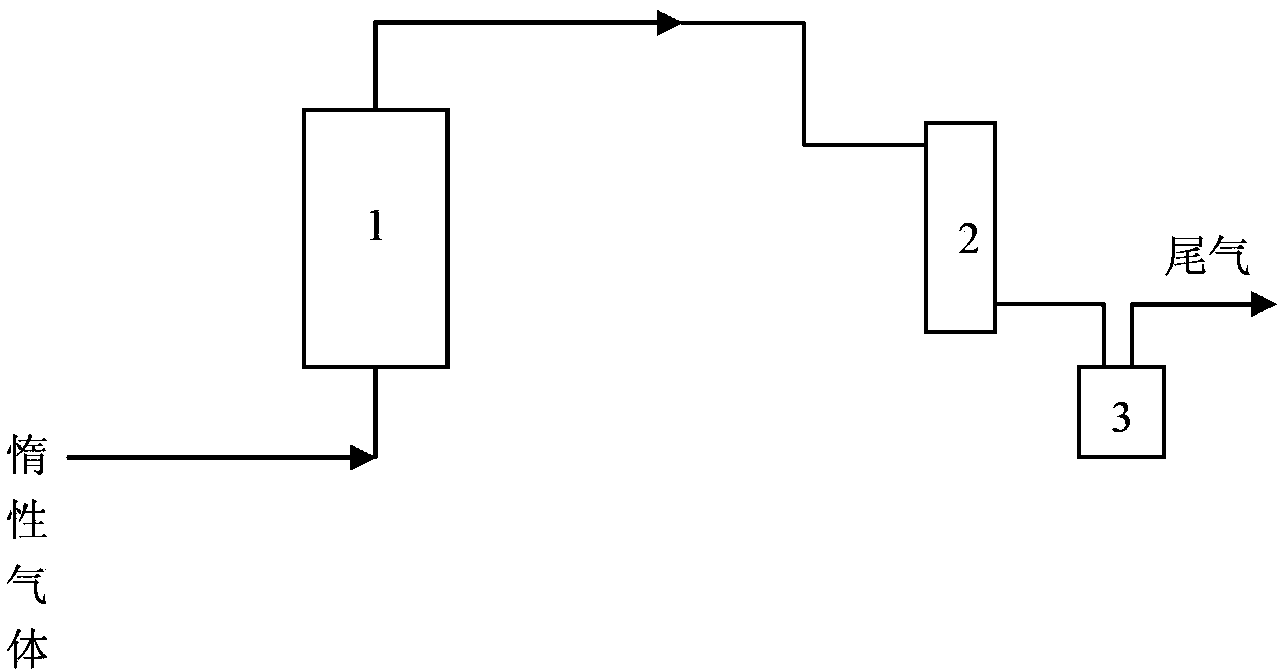

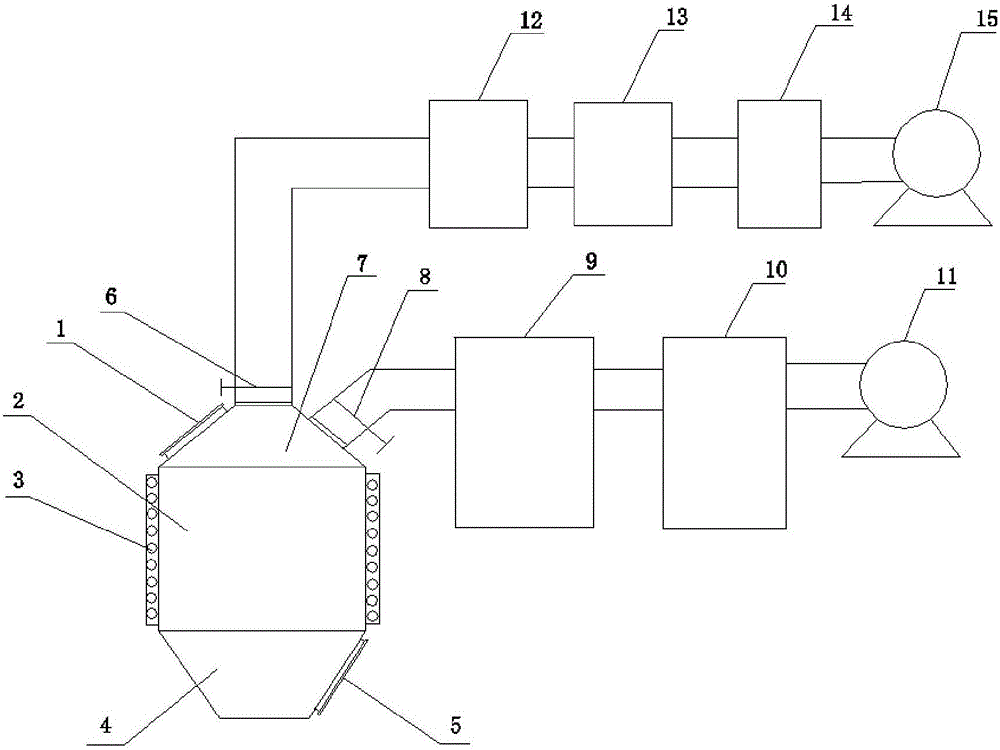

Fluidization heat accumulation type sludge low-temperature catalytic pyrolysis method and device thereof

InactiveCN102643001AAvoid pollutionEfficient use ofSludge treatment by pyrolysisByproduct vaporizationAir preheaterCatalytic pyrolysis

The invention discloses a fluidization heat accumulation type sludge low-temperature catalytic pyrolysis method. The method comprises the following steps: A, sludge is pyrolyzed to produce gas; B, pyrolysis gas is recycled; and C, the residual heat produced by waste gas combustion is utilized. The invention also discloses a fluidization heat accumulation type sludge low-temperature catalytic pyrolysis device. On one hand, the pyrolysis gas produced by the pyrolyzed sludge is enabled to pass through an air preheater, so that the heat is recycled, and then the pyrolysis gas is condensed by a condenser to obtain tar, and the pollution to the environment due to gas emission is avoided; on the other hand, the pyrolysis waste is directly discharged and collected, the structure is simple, the operation is convenient and the potential safety hazard is also reduced. According to the invention, the fluidization, the pyrolysis of heat accumulation particles and the residual heat produced by pyrolysis gas and waste gas combustion are comprehensively utilized, and tar is also prepared, so that the efficient utilization of energy and resource of sludge and the environmental protection are realized.

Owner:CHONGQING UNIV

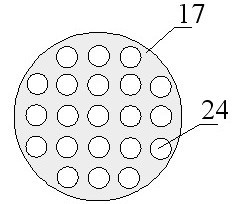

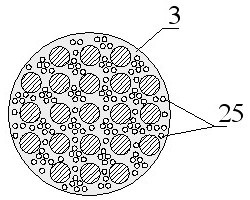

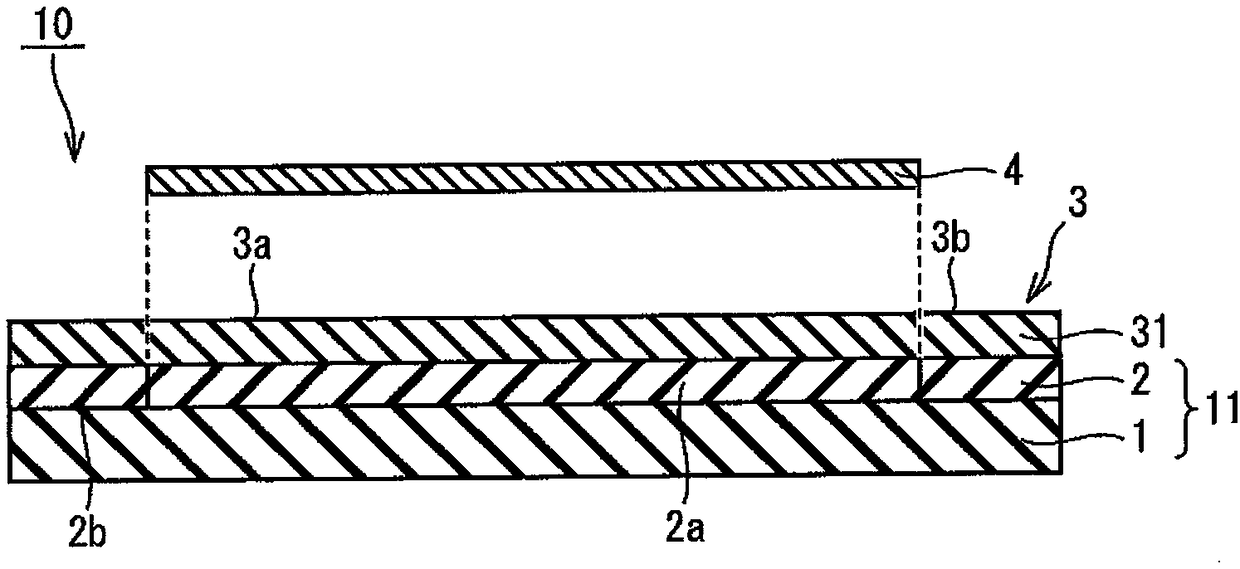

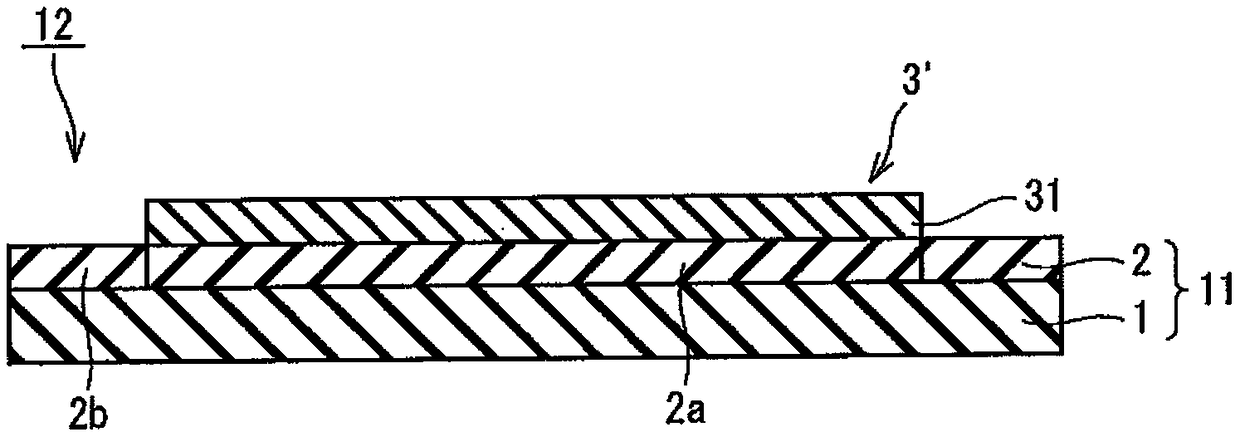

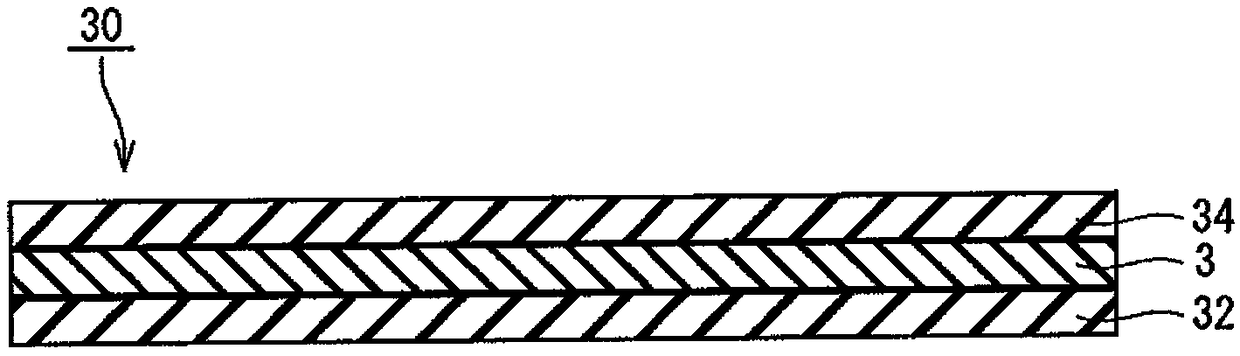

Thermal bonding sheet, thermal bonding sheet with dicing tape, bonded body production method, and power semiconductor device

PendingCN109070230ACheap manufacturingLow pyrolysis temperatureTransportation and packagingSolid-state devicesPower semiconductor deviceDicing tape

Owner:NITTO DENKO CORP

Preparation method of duckweed charcoal loaded nano zero-valent iron and method of repairing Pb pollutant soil

InactiveCN111054312AImprove stabilityGuaranteed stabilityOther chemical processesContaminated soil reclamationSoil sciencePotassium borohydride

The invention relates to a preparation method of duckweed charcoal loaded nano zero-valent iron and a method of repairing Pb pollutant soil. The preparation method comprises the steps: duckweed is pretreated and then placed in a pyrolytic reaction container, a muffle furnace is set to be in an oxygen limiting environment, the temperature and the pyrolytic time are set, natural cooling and sievingare conducted after the pyrolytic reaction is completed, and duckweed charcoal fine powder is prepared; ferric salt is dissolved into deionized water; a certain amount of absolute ethyl alcohol is added; the duckweed charcoal fine powder is added into the mixed solution; a magnetic stirrer is used for continuous and uniform stirring, dropwise adding of a certain amount of potassium borohydride solution at a constant speed under the protection of nitrogen is then carried out, aging is carried out for 1-2 hours after dropwise adding, washing with deoxygenated water and absolute ethyl alcohol formultiple times respectively is carried out under the protection of nitrogen, and after freeze-drying, storing in an oxygen-free environment in a sealed manner is carried out. When the soil polluted by Pb is repaired, the composite product of the duckweed charcoal and the nanometer zero-valent iron is injected into the soil polluted by the Pb, the bioavailability of the Pb in the soil can be obviously reduced, and the polluted soil is repaired.

Owner:曜昂环境技术(江苏)有限公司

Preparation method of high-purity aluminum oxide for growth of sapphire monocrystalline

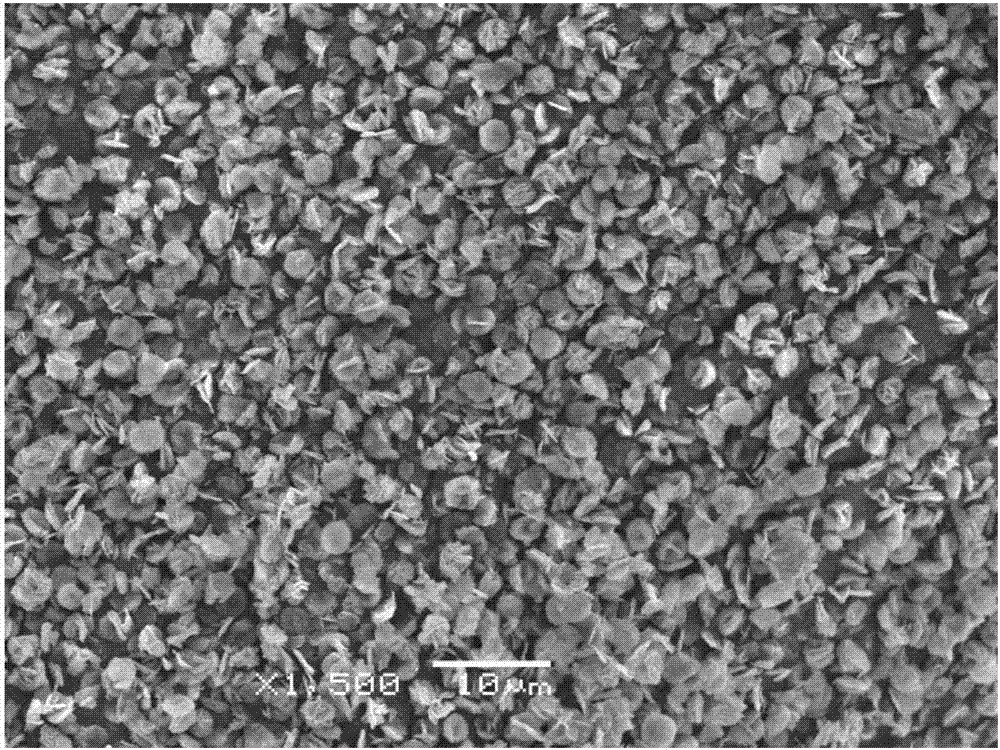

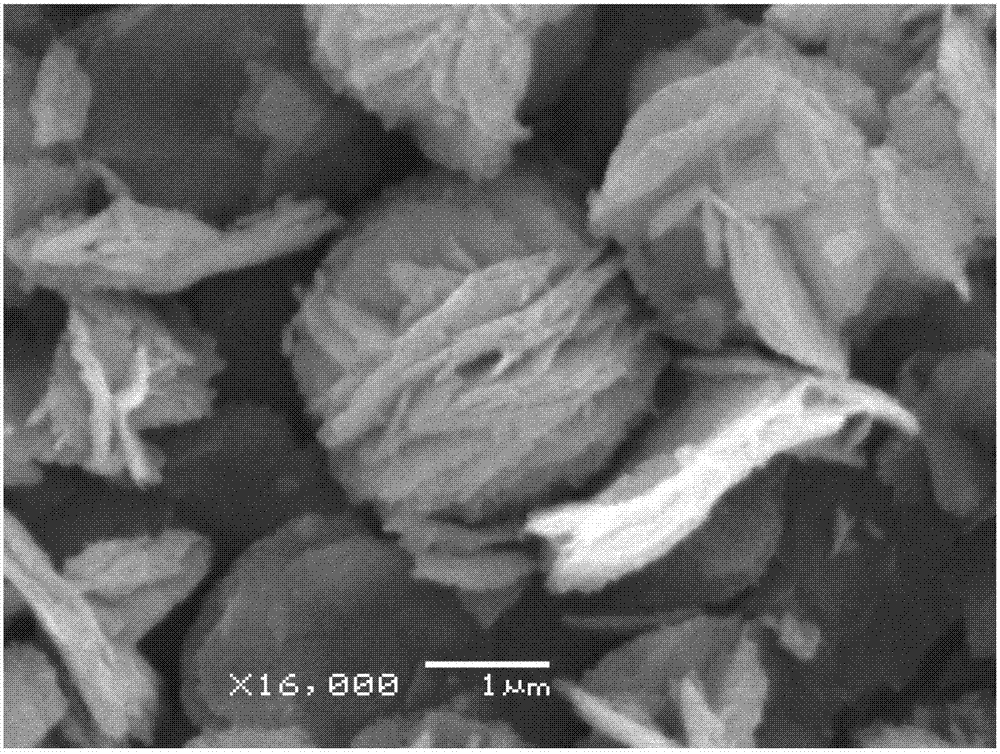

InactiveCN102863000ARaise the pyrolysis temperatureLow pyrolysis temperatureAluminium oxide/hydroxide preparationSingle crystalAmmonia gas

The invention relates to a preparation method of a high-purity aluminum oxide, in particular to a preparation method of high-purity aluminum oxide for growth of sapphire monocrystalline. The method includes: grinding high-purity ammonium aluminum sulfate to obtain ammonium aluminum sulfate precursor powder uniform in particle size, heating according to different temperature sections, pyrolyzing to remove by-products, and sintering to obtain high-purity aluminum oxide uniform in particle size. According to the method, the high-purity ammonium aluminum sulfate is ground to obtain ammonium aluminum sulfate raw material powder, dewatering is completed at a low temperature, ammonia gas is removed at a moderate temperature, the temperature is further increased to enable the raw materials to be decomposed completely, and the high-purity aluminum oxide is obtained by means of sintering at 1000-1050 DEG C. The aluminum oxide prepared by the method is low in pyrolysis temperature and high in purity, tail gases such as SO3 and NH3 can be recovered directly, and consequently environment pollution is reduced, by-products are used reasonably, and production cost is reduced.

Owner:ZHEJIANG ORIENT CRYSTAL OPTICS

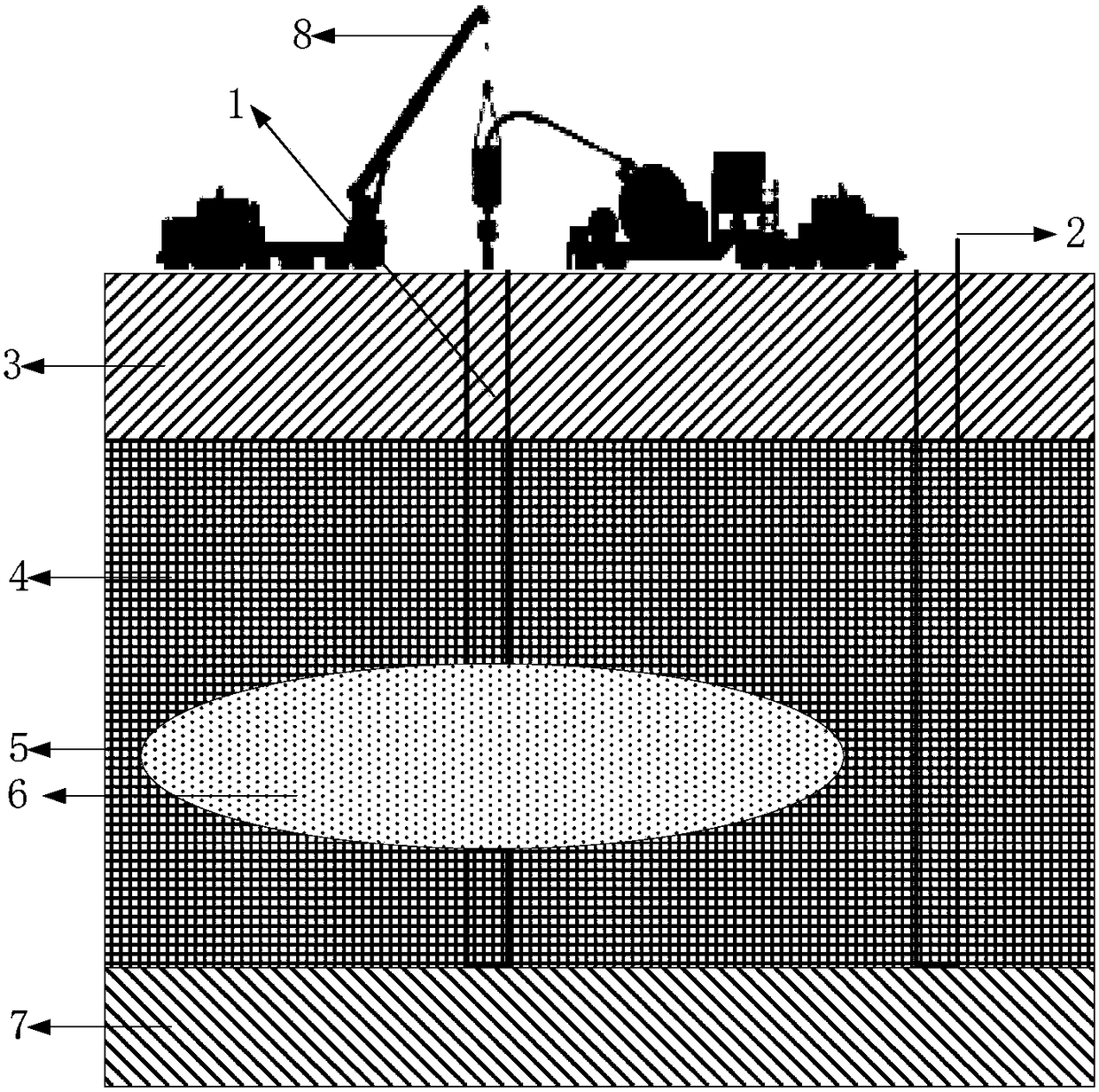

Method for in-situ exploitation of oil shale

ActiveCN109424345ALow pyrolysis temperatureLow viscosityFluid removalNano catalystOil shale reserves

The invention relates to the technical field of oil shale exploitation, and provides a method for in-situ exploitation of oil shale. The method comprises the following steps that 1, at least two wellsare drill in the ground surface of the oil shale distribution region to an oil shale reservoir; 2, the oil shale reservoir is modified, and cracks are generated; 3, a popping agent containing magnetic nanometer catalysts is injected into the oil shale reservoir, and distributed into the cracks in the oil shale reservoir; 4, a heater is placed into a heating well, and the oil shale reservoir is heated; under the heating condition, under the effect of the magnetic nanometer catalyst, kerogen in the oil shale reservoir is split into products containing shale oil; 5, the products are output to the ground surface through a producing well, and separation and collection are performed. The pyrolysis temperature of the oil shale is lowered in the oil shale heating process, conversion of immaturedkerogen into oil gas resource is accelerated, the conversion rate is increased, the crude oil viscosity is lowered, and the crude oil quality is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing acetic acid activation sludge-based adsorbent

InactiveCN105817201ASimple manufacturing processEasy to operateOther chemical processesChemistryNitrogen atmosphere

The invention discloses a preparation method of an acetic acid-activated sludge-based adsorbent. The specific steps are as follows: taking an appropriate amount of sludge and glacial acetic acid to obtain a homogeneous acetic acid-activated sludge slurry; drying the homogeneous acetic acid-activated sludge slurry to obtain dry sewage Sludge and pulverize, and screen out sludge particles with a particle diameter of 1-2mm; add an activator solution compounded with zinc chloride and sulfuric acid, and perform pyrolysis reaction under nitrogen atmosphere to obtain sludge pyrolysis residue; wash with distilled water after grinding ,dry. The invention has simple manufacturing process and convenient operation. It adopts wet sludge to be directly pyrolyzed without drying treatment. The pyrolysis temperature is low, which belongs to low-temperature pyrolysis. While reducing the sludge drying process, it saves a lot of energy and is more energy-saving and environmentally friendly. The sludge adsorbent is prepared by the chemical activation method of the compound activator, and the carbon-containing compounds in the sludge are condensed into non-volatile polycondensation carbon through dehydration, condensation, moistening and expansion of chemical agents, so as to obtain adsorption with a well-developed porous structure. agent.

Owner:张能力

Method for marking active carbon by utilizing dyeing sludge

InactiveCN103318889ARealize resource utilizationSolve disposal problemsCarbon compoundsHigh carbonSludge

The invention discloses a method for making active carbon by utilizing dyeing sludge. The method comprises the following steps of: a, a pyrolyzing process: drying the sludge and pyrolyzing at the low temperature under the isolated air state; b, an oxidation pickling process; preparing a mixed aqueous solution mixture of potassium permanganate and sulfuric acid, wherein the potassium permanganate is 0.1mol / L-0.2mol / L, and the sulfuric acid is 1mol / L-1.8mol / L; soaking fixed carbon compound in a solid-liquid ratio of 1:(2-2.5), using the filtrate as aluminum ferric sulfate composite type purifying agent after removing heavy metal impurities; and drying the filter residue. According to the method for making active carbon by utilizing dyeing sludge disclosed by the invention, the sludge is used as the material to make the active carbon with low manufacturing cost and high carbon content through a pyrolyzing-oxidation pickling combination process. Moreover, the production process is almost free of pollution to the environment.

Owner:ZHEJIANG ZHUOJIA ENVIRONMENTAL ENG

Process for producing resistant dextrin

The invention relates to a process for producing resistant dextrin, and belongs to the technical field of food processing. The process comprises the steps of acid hydrolysis, pyrolysis, enzymolysis, alcohol precipitation, purification and the like. Based on a traditional production process, the production process combines with the step of hydrolysis in acid-alcohol medium, so that time and energy consumption in subsequent pyrolyzing step can be reduced; and surfactant is added in the enzymolysis step to achieve the synergizing effect, so that the whole production process is efficient and economical.

Owner:郑州国食科技有限公司

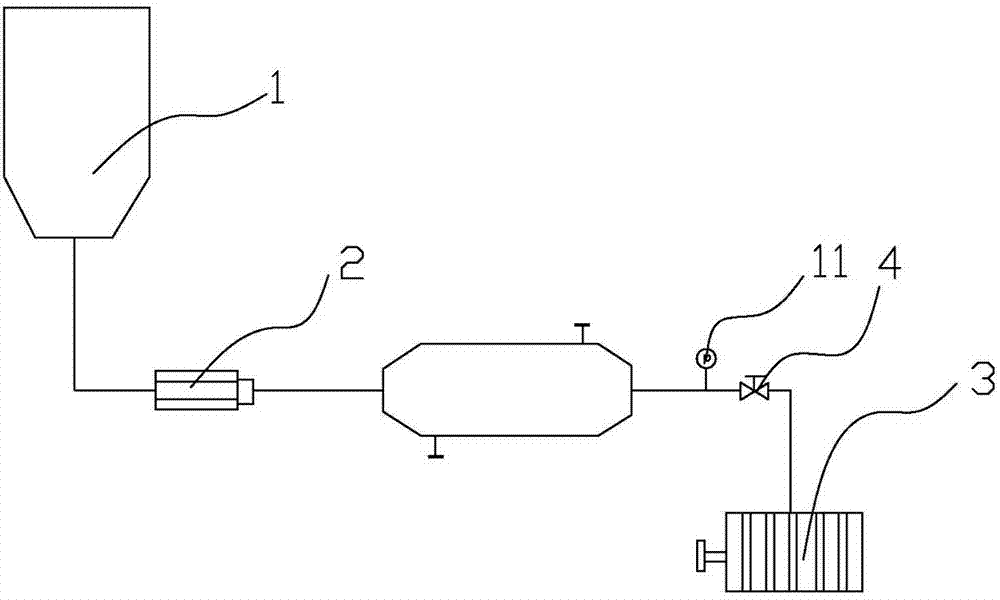

Sludge drying treatment system and process

ActiveCN103304124ANot easy to scaleFacilitated releaseSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisSludgeFilter press

The invention discloses a sludge drying treatment system, and solves the problems in the prior art that the continuous pyrolysis treatment on sludge can not be realized by using the sludge drying treatment system, the sludge feeding and taking process is complex, and the large-scale production and treatment are hard to realize. The sludge drying treatment system comprises a sludge storage tank, a high-pressure sludge pump, an internal spiral low-temperature pyrolysis device and a filter press which are connected through pipelines in sequence, wherein a pressure gauge and an adjusting valve are arranged on the pipeline between the internal spiral low-temperature pyrolysis device and the filter press; the pressure gauge is positioned in front of the adjusting valve. By utilizing the sludge drying treatment system, the continuous pyrolysis on the wet sludge is realized, the production efficiency is high, the energy consumption is low, and the operation is convenient and rapid. The invention further discloses a sludge drying treatment process. A dehydration prompting agent is added in the low-temperature high-pressure pyrolysis process, so that the process steps are simplified, the dehydration property of the sludge is greatly improved; when the sludge is mechanically hydrated by using the filter press, the water content of the sludge meets the requirements that the sludge can be fed into an incineration furnace, and the sludge does not need to be further dried.

Owner:NINGBO FUSHIDA ELECTRIC ENG

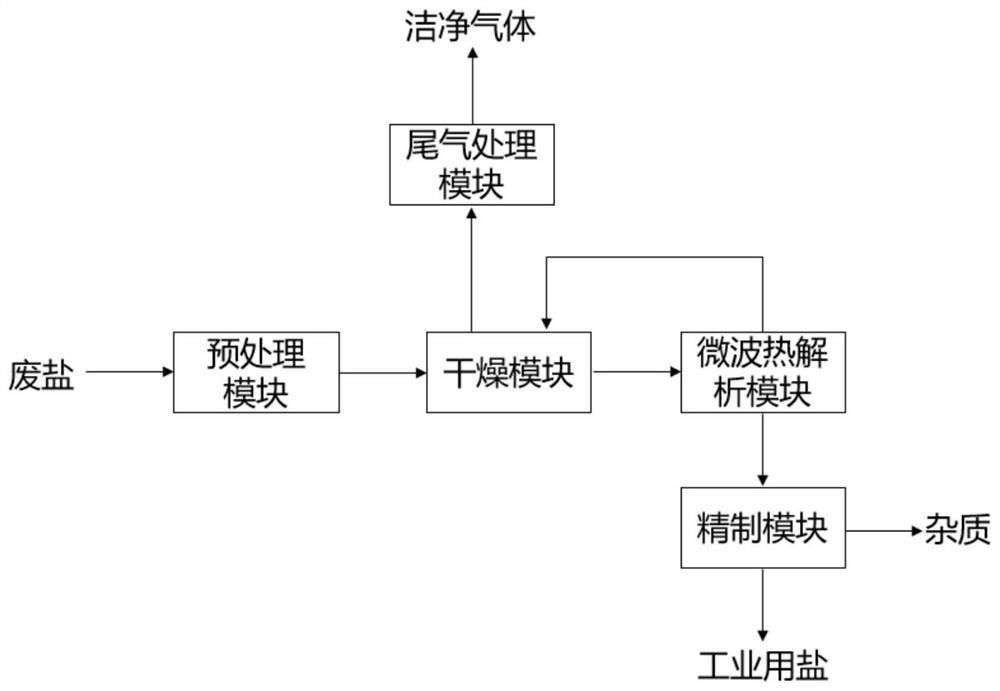

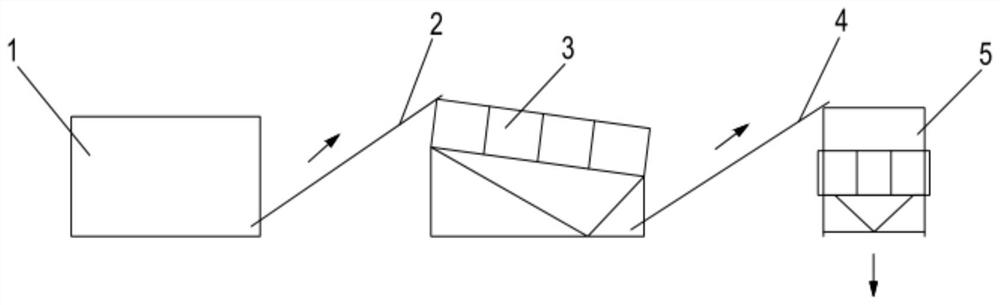

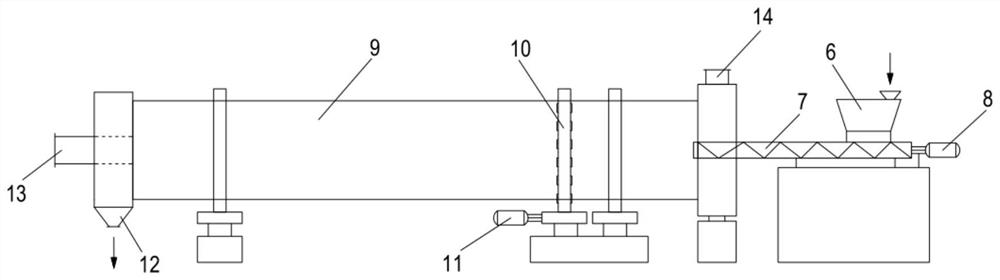

Industrial waste salt resource treatment system and method

PendingCN114472474ARealize Harmless GovernanceImplement resourcesTransportation and packagingSolid waste disposalThermal insulationHeat conservation

The invention discloses an industrial waste salt resource treatment system and method. The system comprises a pretreatment module, a drying module, a microwave thermal analysis module and a refining module which are connected in sequence, wherein a microwave thermal desorption reaction chamber is defined by a thermal insulation shell of the microwave thermal desorption module, and the outer wall of the thermal insulation shell is connected with a microwave magnetron through a waveguide; the material conveyor is arranged in the heat preservation shell and used for providing a material bearing and conveying working face. According to the method disclosed by the invention, microwave thermal desorption is taken as a core, and dissolution precipitation and inorganic substance adsorption precipitation are combined, so that the removal rate of organic matters in the waste salt is high, and TOC (Total Organic Carbon) in crystallized salt is reduced to below 5mg / L and meets the industrial salt standard; harmless treatment and resource treatment of the waste salt are achieved, and waste is turned into wealth.

Owner:山东绿满神州环境科技有限公司

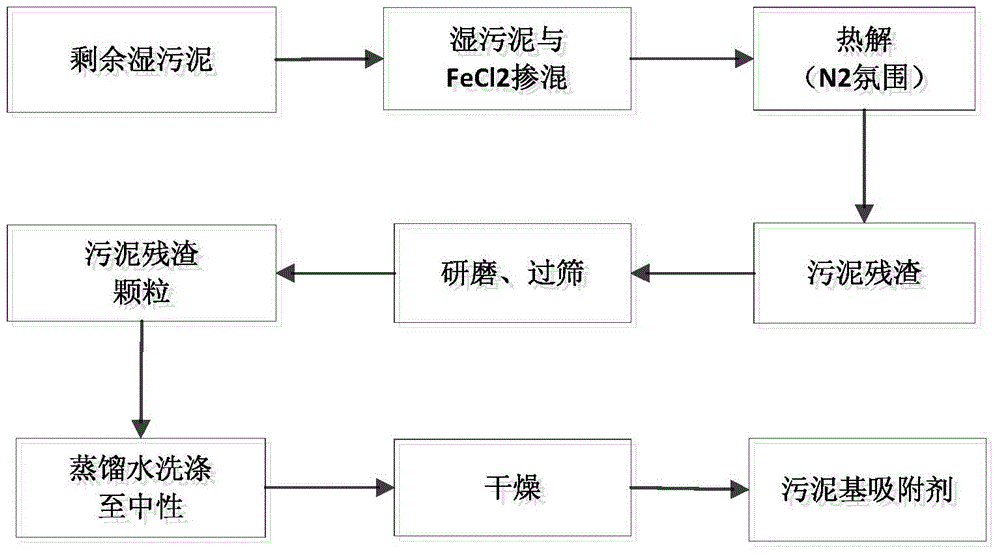

Preparation method of energy-saving sludge-based adsorbent

InactiveCN104874352AReduce drying processEmission reductionOther chemical processesSludge treatment by pyrolysisEnvironmental resistanceSludge

The invention discloses a preparation method of an energy-saving sludge-based adsorbent. The preparation method comprises the following steps: (1) placing residual wet sludge at a heating zone of a pyrolysis reactor of an external-heated tube furnace, wherein the residual wet sludge is doped with an activator FeCL2 and the content of moisture of the residual wet sludge is 60-90%, the mass part ratio of the FeCl2 to the residual wet sludge is 1 to (10-20), performing pyrolysis in a nitrogen atmosphere, wherein the temperature rising speed is 70-80 C degree per minute, the pyrolysis temperature is 550-560 C degree, the stay time is 10-15 minutes and the nitrogen blowing speed is 25-30ml per minute, switching off the tube furnace and a switch of a nitrogen tank after the reaction is completed and cooling to obtain pyrolyzed sludge residue; (2) collecting the pyrolyzed sludge residue, grinding, sieving with a 50-70 mesh screen to obtain sludge residue particles; and (3) washing the sludge residue particles with distilled water till a washing liquid is neutral and drying to obtain the sludge-based adsorbent. According to the preparation method, the energy consumption is effectively reduced and the environment friendliness is improved.

Owner:ZHEJIANG UNIV OF TECH

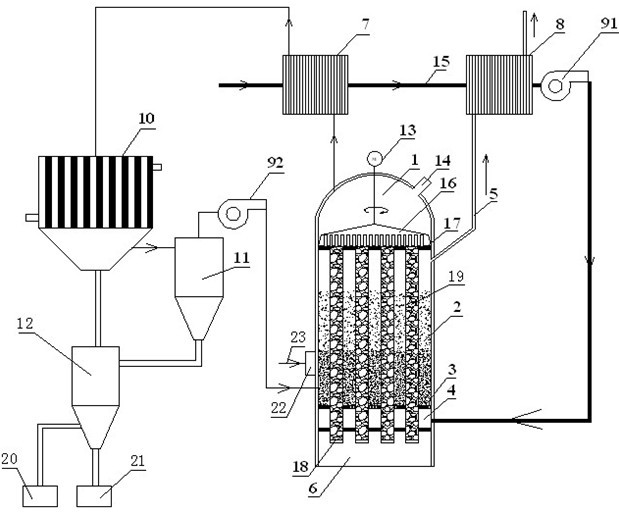

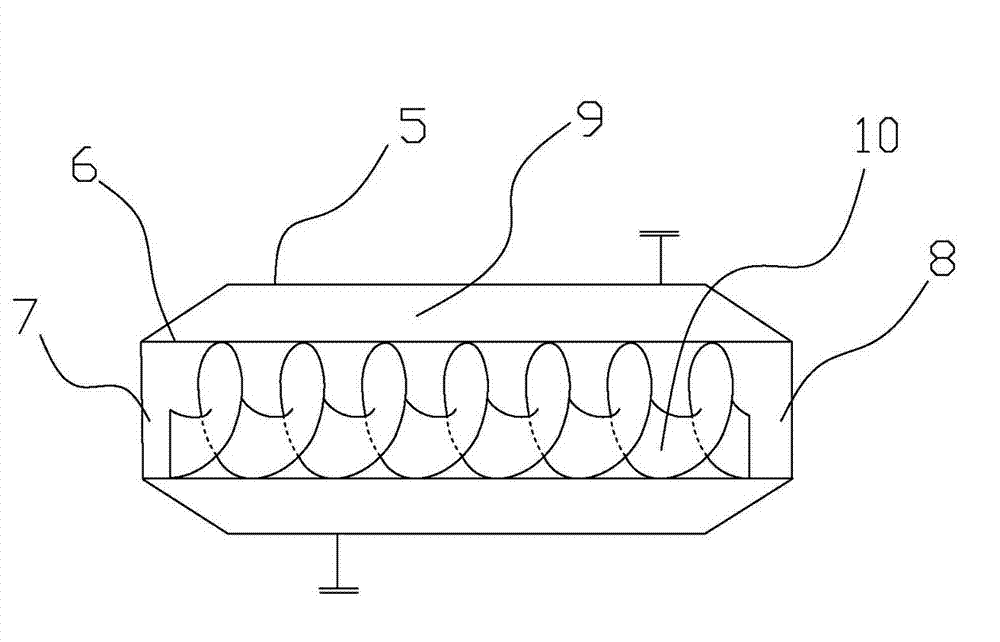

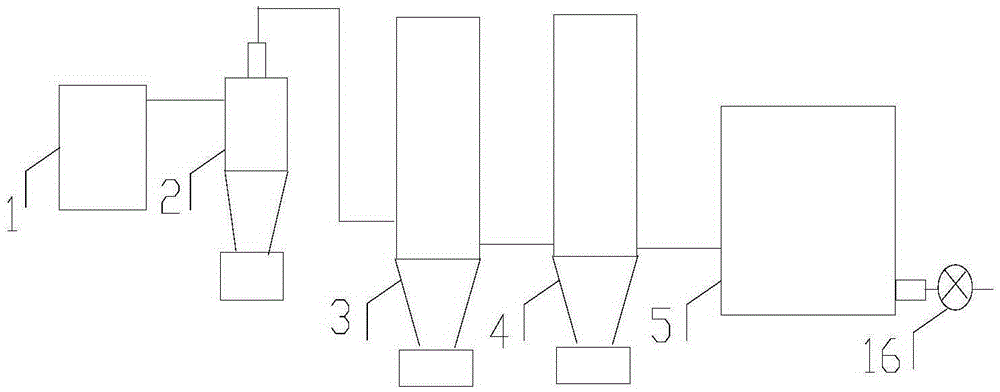

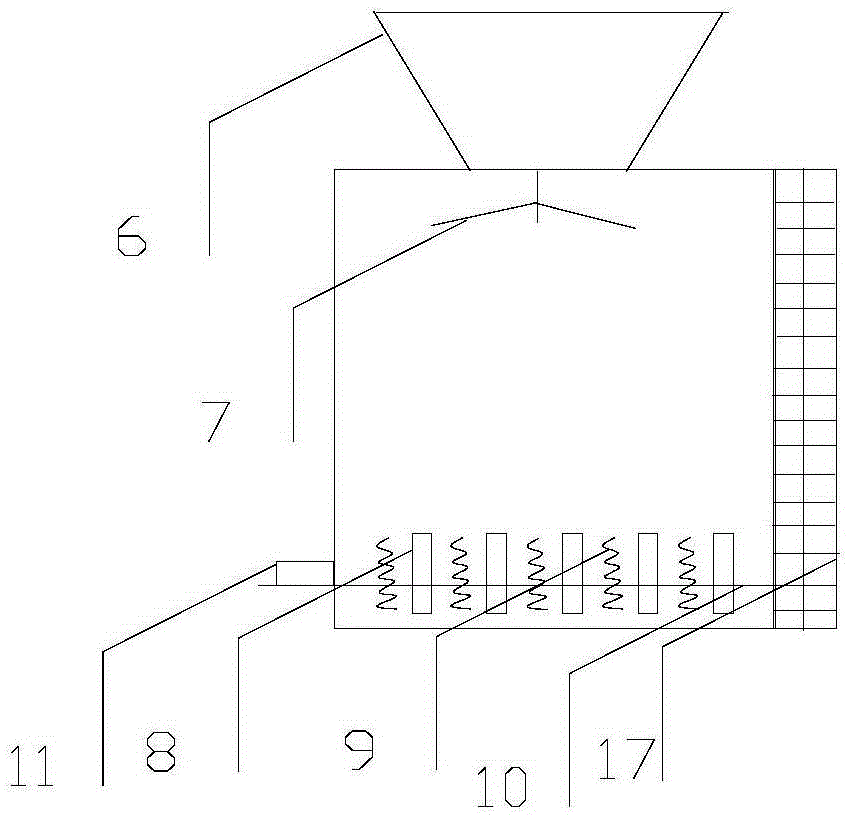

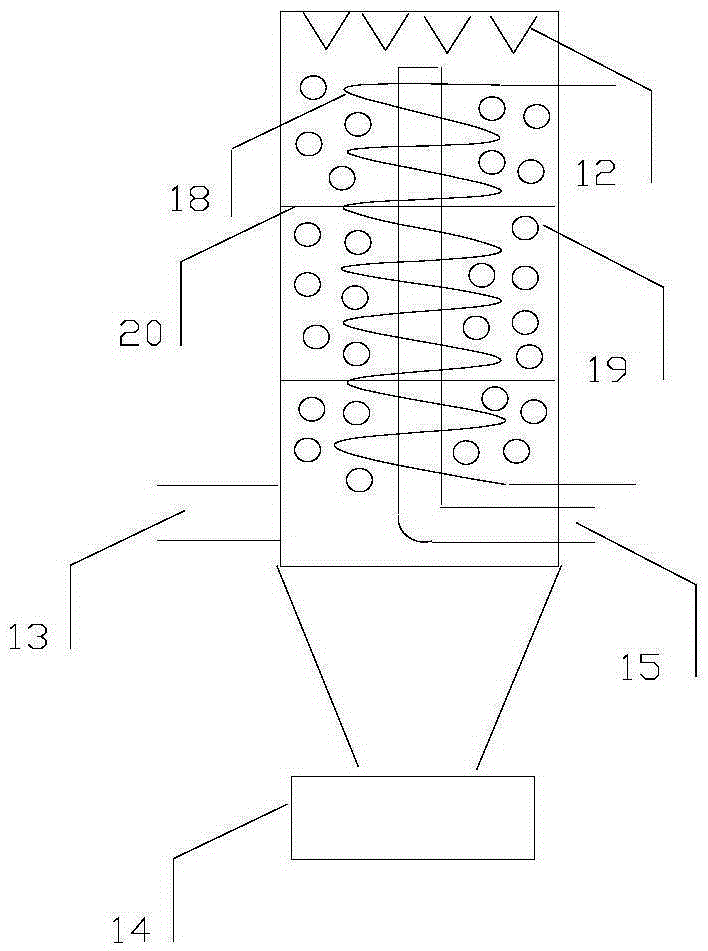

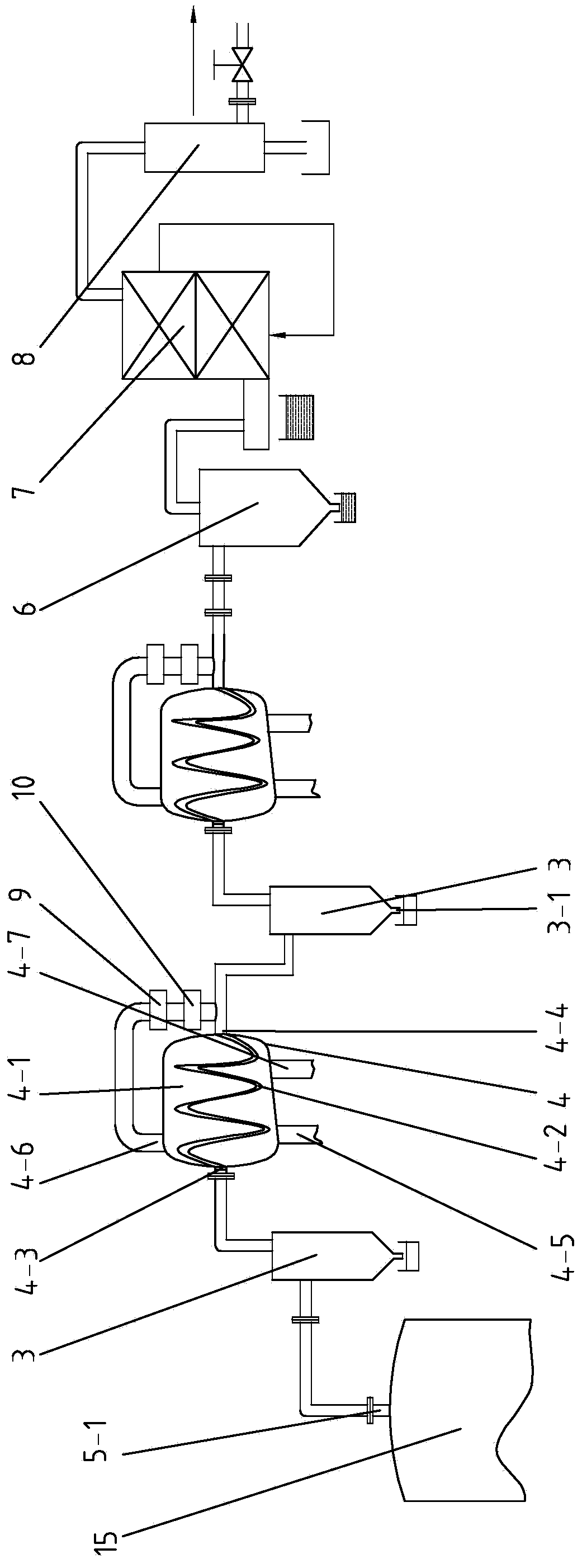

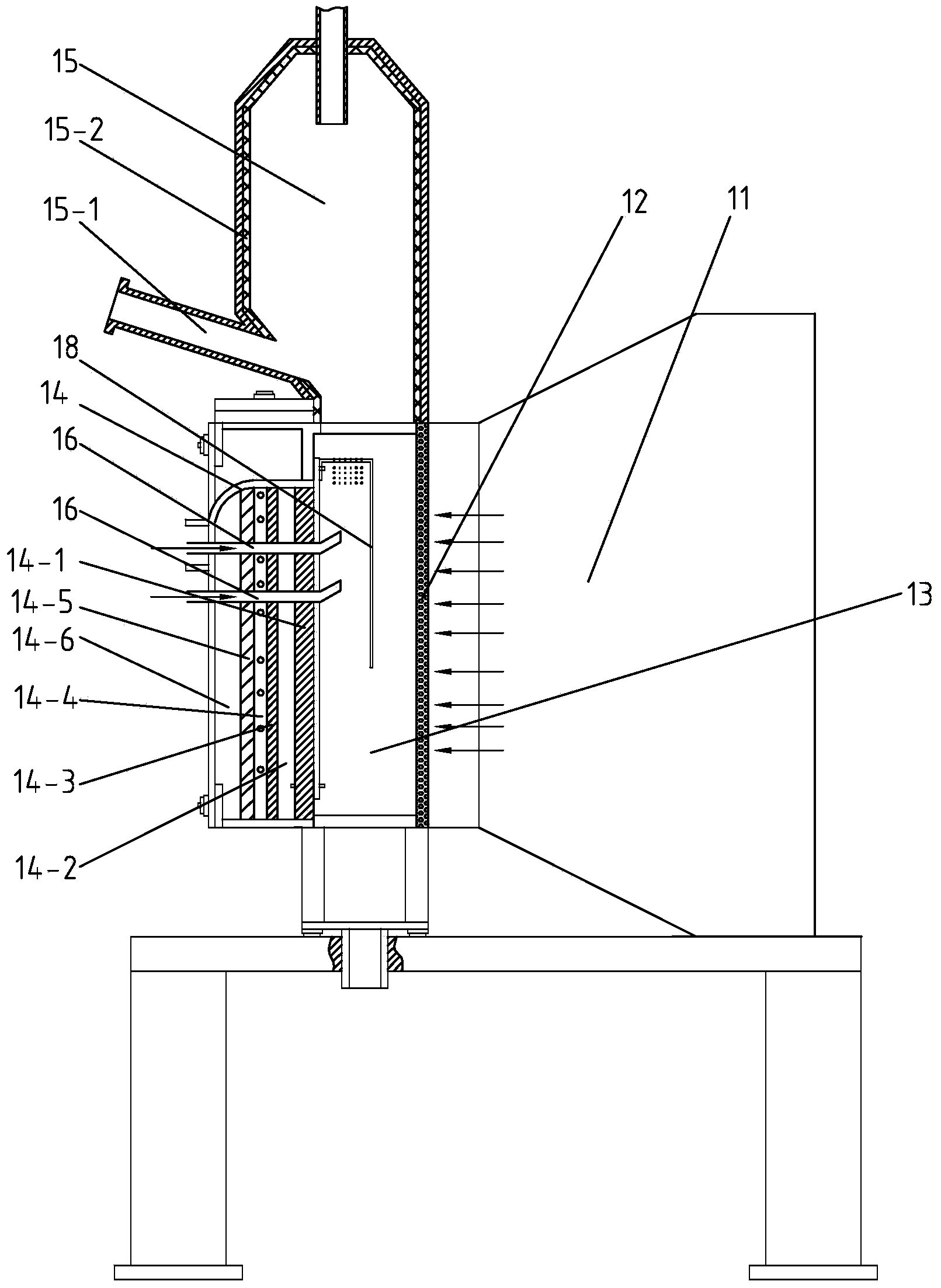

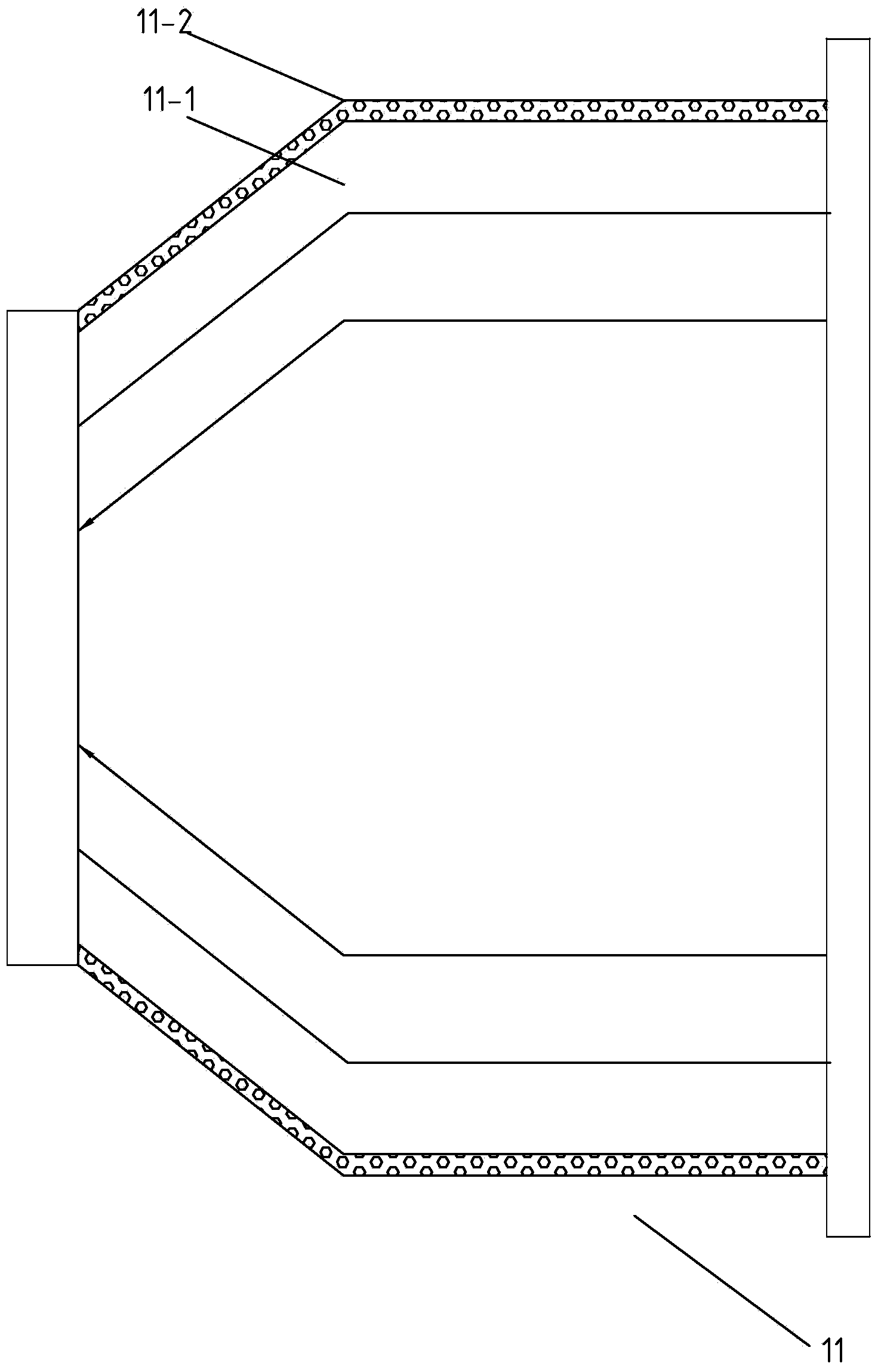

Device and method for improving tar yield by pyrolysis of low-rank coal

ActiveCN105295968APromote escapeHigh yieldSpecial form destructive distillationProcess engineeringEngineering

The invention provides a device and a method for improving tar yield by pyrolysis of low-rank coal. The device comprises a pyrolysis furnace, a cyclone separator, a first tar condensing tower, a second tar condensing tower and a vacuum pump which are sequentially connected from left to right, wherein the top of the pyrolysis furnace is provided with a coal hopper, a plurality of furnace walls are arranged in the pyrolysis furnace, a spiral tar remover is arranged between adjacent furnace walls, a pyrolysis gas inlet is formed in one side of the bottom of the first tar condensing tower, a tar collecting slot is formed right below the bottom of the first tar condensing tower, and a pyrolysis gas outlet is formed in the other side of the bottom of the first tar condensing tower. Under the conditions of negative pressure and pyrolysis of sweeping gas, along with the reducing of pressure in the pyrolysis process, the tar yield is increased, and the proportion of acid compounds (mainly phenolic compounds) in the components of coal tar is increased. The yield of the coal tar in the coal pyrolysis process can be obviously increased, and coal pyrolysis temperature is reduced. Meanwhile, the possibility of secondary reaction of the separated-out coal tar in the pyrolysis process is reduced.

Owner:NORTHWEST UNIV(CN)

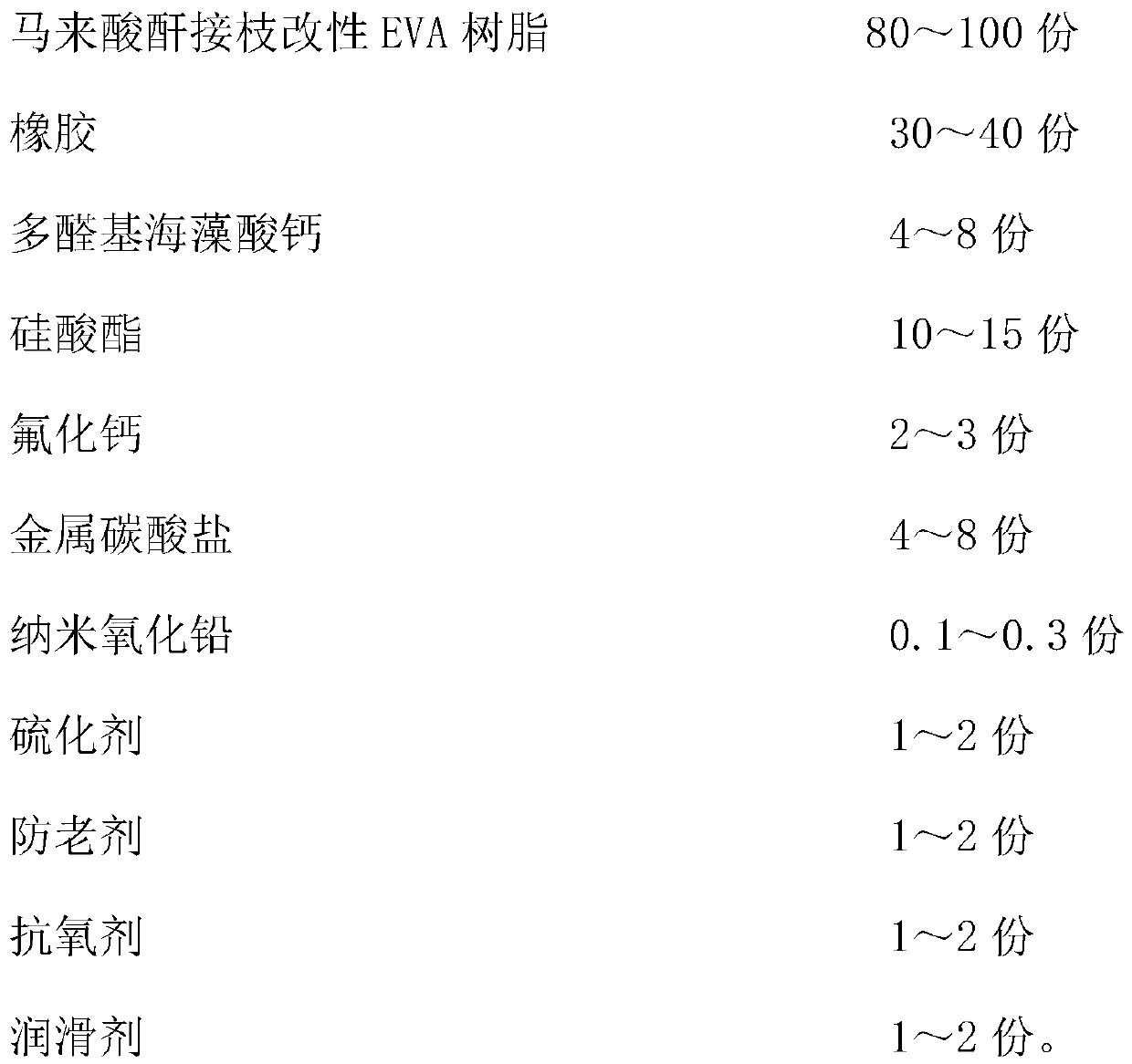

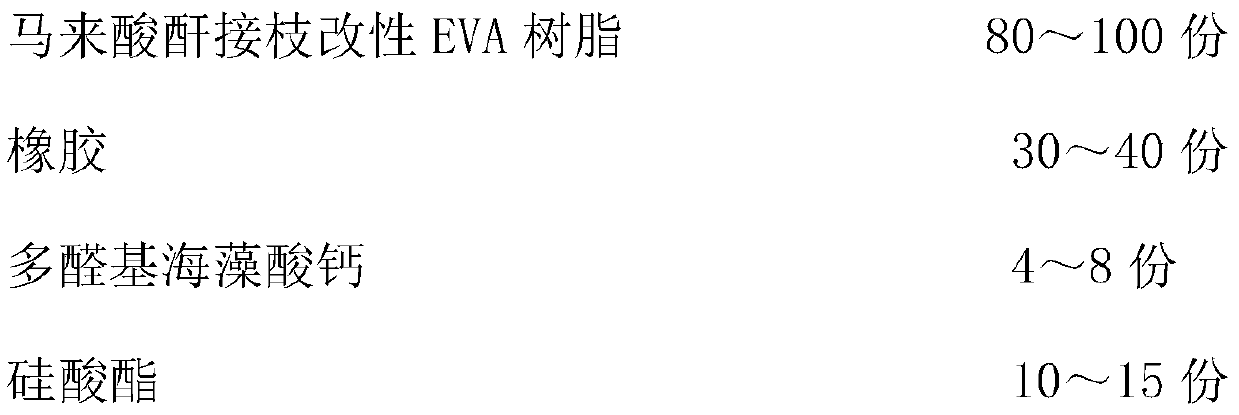

Flame-retardant sheath material for extra-high-voltage cable and preparation method of flame-retardant sheath material

ActiveCN110551356ALow pyrolysis temperatureIncrease polarityPlastic/resin/waxes insulatorsPolymer scienceAntioxidant

The invention discloses a flame-retardant sheath material for an extra-high-voltage cable and a preparation method of the flame-retardant sheath material, and belongs to the technical field of composite polymer materials. The developed product is prepared from maleic anhydride graft modified EVA resin, rubber, polyaldehyde calcium alginate, silicate ester, calcium fluoride, metal carbonate, nanometer lead oxide, a vulcanizing agent, an anti-aging agent, an antioxidant and a lubricant. In the product preparation process, all components are weighed according to raw material compositions firstly;then all component raw materials are mixed, and then sequentially subjected to plastication and mixing, then extruding and granulating are conducted to obtain the flame-retardant sheath material forthe extra-high-voltage cable. By improving dispersion and compatibility of an inorganic flame retardant component in a system, the mechanical property and flame retardant performance of the product sheath material are significantly improved.

Owner:江苏枫润线缆材料有限公司

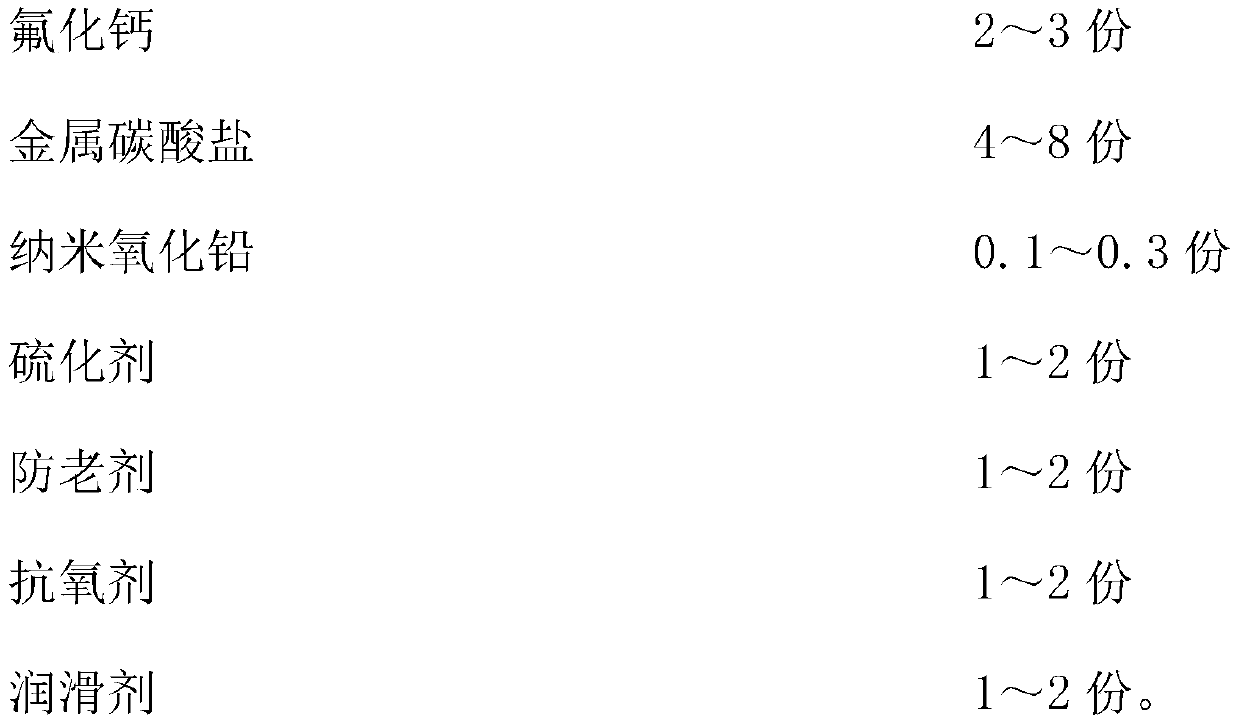

Efficient and energy-saving heavy-magnesium water pyrolysis method

ActiveCN104909394ANo "sticky wall" phenomenonSolve the phenomenon of easy scaling and cloggingMagnesium carbonatesWork cycleHot Temperature

The invention discloses an efficient and energy-saving heavy-magnesium water pyrolysis method. The efficient and energy-saving heavy-magnesium water pyrolysis method comprises the following steps: atomizing heavy-magnesium water by virtue of an atomizing device, enabling heavy-magnesium water to be in contact with high-temperature hot wind, mixing, heating and decomposing, wherein atomized heavy-magnesium water is in counter current trend with high-temperature hot wind; after adequate pyrolysis reaction, finishing gas-liquid separation in a separator, carrying out solid-liquid separation to obtain solid basic magnesium carbonate, and drying, so as to obtain pure-white high-bulkiness basic magnesium carbonate. The efficient and energy-saving heavy-magnesium water pyrolysis method has the advantages that the technical process is short, the production is continuous and smooth, cleaning is omitted, the working cycle is long, the production operation is easy, the production cost is low, equipment is simple, the fixed investment is low, an excellent operation effect is achieved in a pilot plant, and the method has industrial operation conditions.

Owner:邳州世纪益圆家居有限公司

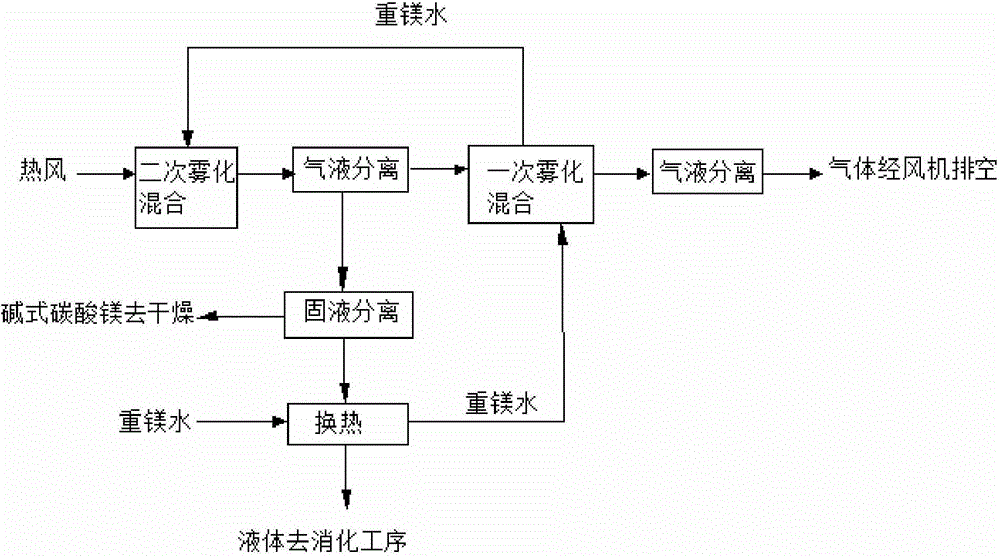

Method for low temperature preparation of basic magnesium carbonate crystal with assistance of absolute ethanol

ActiveCN107324361AWide variety of sourcesRich reservesPolycrystalline material growthFrom normal temperature solutionsSlurryDigestion

The invention provides a method for low temperature preparation of basic magnesium carbonate crystal with assistance of absolute ethanol, and belongs to the field of mineral processing. The method comprises the following steps: (1) magnesite is calcinated in order to obtain active magnesium oxide; (2) deionized water is added with fully stirring in order to prepare MgO initial slurry, and a Mg(OH)2 fluid suspension is prepared with digestion; (3) at 0-10 DEG C, CO2 gas is introduced, and a precursor solution Mg(HCO3)2 is prepared; (4) a NaOH solution is added, pH value is adjusted, absolute ethanol is added, at 40-65 DEG C, insulation is carried out for 60-120 minutes for pyrolysis of the precursor solution Mg(HCO3)2, and basic magnesium carbonate crystal is obtained. Magnesite is used as a raw material, magnesite is calcinated in order to obtain magnesium oxide of high activity, absolute ethanol is used as an auxiliary agent, and a hydration method is used at a normal pressure for low temperature preparation of the basic magnesium carbonate crystal. The products have high purity, complete crystal form, and uniform morphology.

Owner:SHENYANG LIGONG UNIV

Method for preparing 4-vinylphenol through catalytic pyrolysis of gramineous biomass

ActiveCN107043320AFacilitated response pathwayResponse pathway inhibitionOrganic chemistryOrganic compound preparationCatalytic pyrolysisLiquid product

The invention belongs to the field of utilization of biomass energy, and concretely relates to a method for preparing 4-vinylphenol through catalytic pyrolysis of gramineous biomass. The method comprises the following steps: loading an alkaline catalyst onto gramineous biomass used as a raw material in an impregnation manner, carrying out catalytic pyrolysis at 230-350 DEG C in an inert atmosphere, and condensing the obtained pyrolysis gas to obtain a liquid product rich in the 4-vinylphenol. The yield of the 4-vinylphenol and the selectivity of the 4-vinylphenol in the organic liquid product are high. The method for preparing the 4-vinylphenol overcomes the defects of low content of the 4-vinylphenol in obtained bio-oil, poor selectivity and high separation and extraction cost of existing gramineous biomass pyrolysis liquefaction technologies, and has a very good application prospect.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

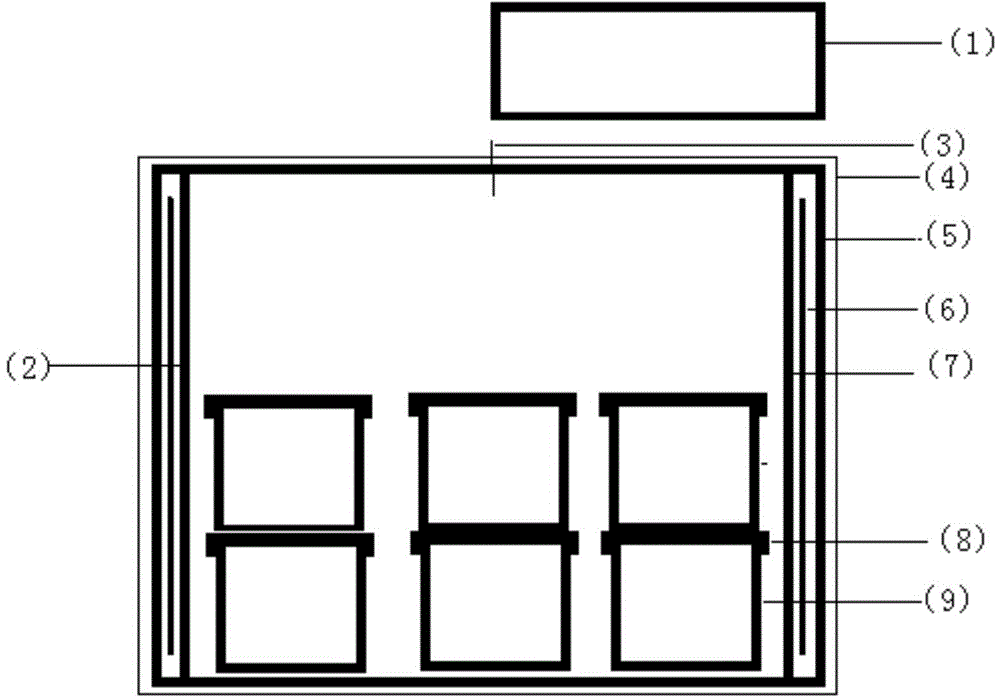

Closed charcoal preparation apparatus

InactiveCN104910932AImprove production efficiencyImprove productivityBiofuelsRetortsProduction rateRoom temperature

The invention relates to a charcoal preparation apparatus, and especially relates to a closed charcoal preparation apparatus. A technical scheme is characterized in that the apparatus comprises a temperature controller (1), a heater box (2) and a pyrolysis tank (9), and when charcoal is prepared, organic matters enter the pyrolysis tank (9), a lid (8) at the upper portion of the pyrolysis tank (9) is screwed up, the pyrolysis tank (9) is put in the heater box (2), and heating pyrolysis is carried out. The heater box is opened after the pyrolysis reaction, the pyrolysis tank (9) is cooled to room temperature, and then the prepared charcoal is taken out. The apparatus has the characteristics of ingenious conception, reasonable design, and realizes reduction of the pyrolysis temperature, shortening of the organic matter pyrolysis time and increase of the charcoal preparation efficiency by preparing charcoal through pyrolysis of organic substances in closed environment; and the apparatus can ensure anaerobic environment and improve the charcoal production rate through pyrolysis of the organic matters in a closed tank.

Owner:CHONGQING UNIV OF ARTS & SCI

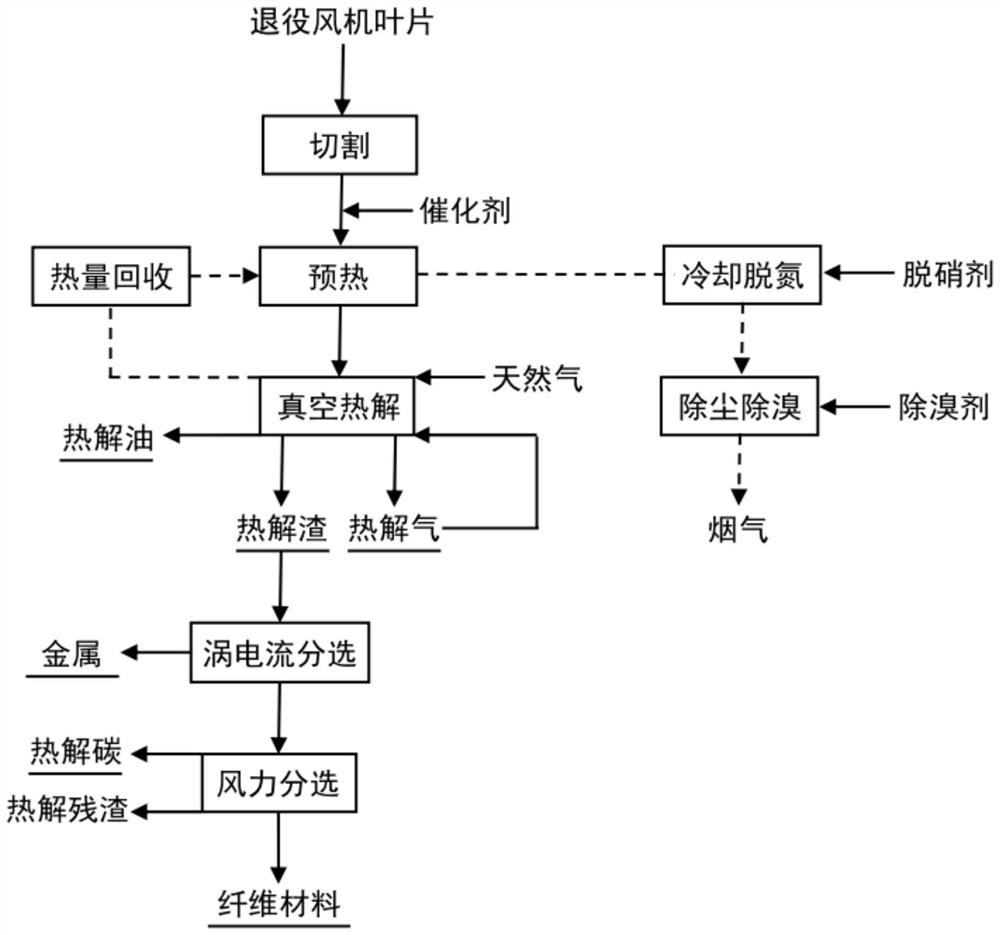

Vacuum pyrolysis treatment and recovery method for retired fan blades

ActiveCN114653729AAchieve dissociationAccurate temperature controlSolid waste disposalTransportation and packagingCatalytic pyrolysisFiber

The invention discloses a vacuum pyrolysis treatment and recovery method for retired fan blades, which comprises the following steps: (1) blade pretreatment: crushing the retired fan blades, adding a pyrolysis catalyst, and uniformly mixing; then, the combustion flue gas subjected to high-temperature treatment is introduced for preheating treatment; (2) vacuum pyrolysis: carrying out catalytic pyrolysis treatment on the pre-treated retired fan blade in a vacuum negative pressure state to obtain pyrolysis gas, pyrolysis oil and pyrolysis residues; (3) carrying out eddy current separation on the pyrolysis residues to obtain metal, and carrying out wind separation to obtain pyrolytic carbon, a fiber material and pyrolysis residues; (4) cooling and denitrifying the combustion flue gas generated in the step (1); and (5) removing dust and bromine from the cooled and denitrified combustion flue gas. According to the method, the retired fan blade can be efficiently treated, and resources such as fiber materials and metal in the retired fan blade can be recycled.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI +1

Hydrogen-rich gas production equipment as well as hydrogen-rich gas production process and solar condensation heat collecting coal gasifier

InactiveCN103965967ALow pyrolysis temperatureEnergy inputGranular/pulverulent flues gasificationWater vaporHydrogen content

The invention discloses hydrogen-rich gas production equipment as well as a hydrogen-rich gas production process and a solar condensation heat collecting coal gasifier. The hydrogen-rich gas production equipment comprises the solar condensation heat collecting coal gasifier, multistage hydrogen-rich gas production devices, a washing tower and a desulfurizer, wherein each hydrogen-rich gas production device comprises a cyclone separator and a spiral tube exchanger; the spiral tube exchanger is provided with a heat exchange cavity, a spiral tube assembly, a water gas inlet, a water gas outlet, a mixture outlet, a gas outlet and an inlet of a water pyrolysis product generated by introducing water or water vapor under the action of a water pyrolysis catalyst, the heat exchange cavity is positioned on the periphery of the spiral tube assembly, and the water gas inlet is connected with the spiral tube assembly and then communicated with the water gas outlet; the inlet, the mixture outlet and the gas outlet are all communicated with the heat exchange cavity; the output end of the cyclone separator is communicated with the water gas inlet of the spiral tube exchanger in the same stage of hydrogen-rich gas production device, and the water gas outlet is connected to the input end of the next stage of cyclone separator. By adopting the hydrogen-rich gas production equipment, the hydrogen-rich gas production process and the solar condensation heat collecting coal gasifier disclosed by the invention, clean gas with high hydrogen content can be produced, the heat conversion efficiency can be improved, and the pollution can be reduced.

Owner:巢建平

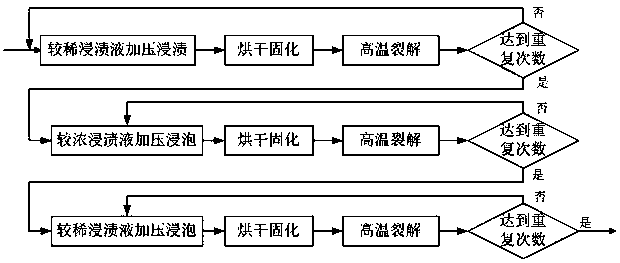

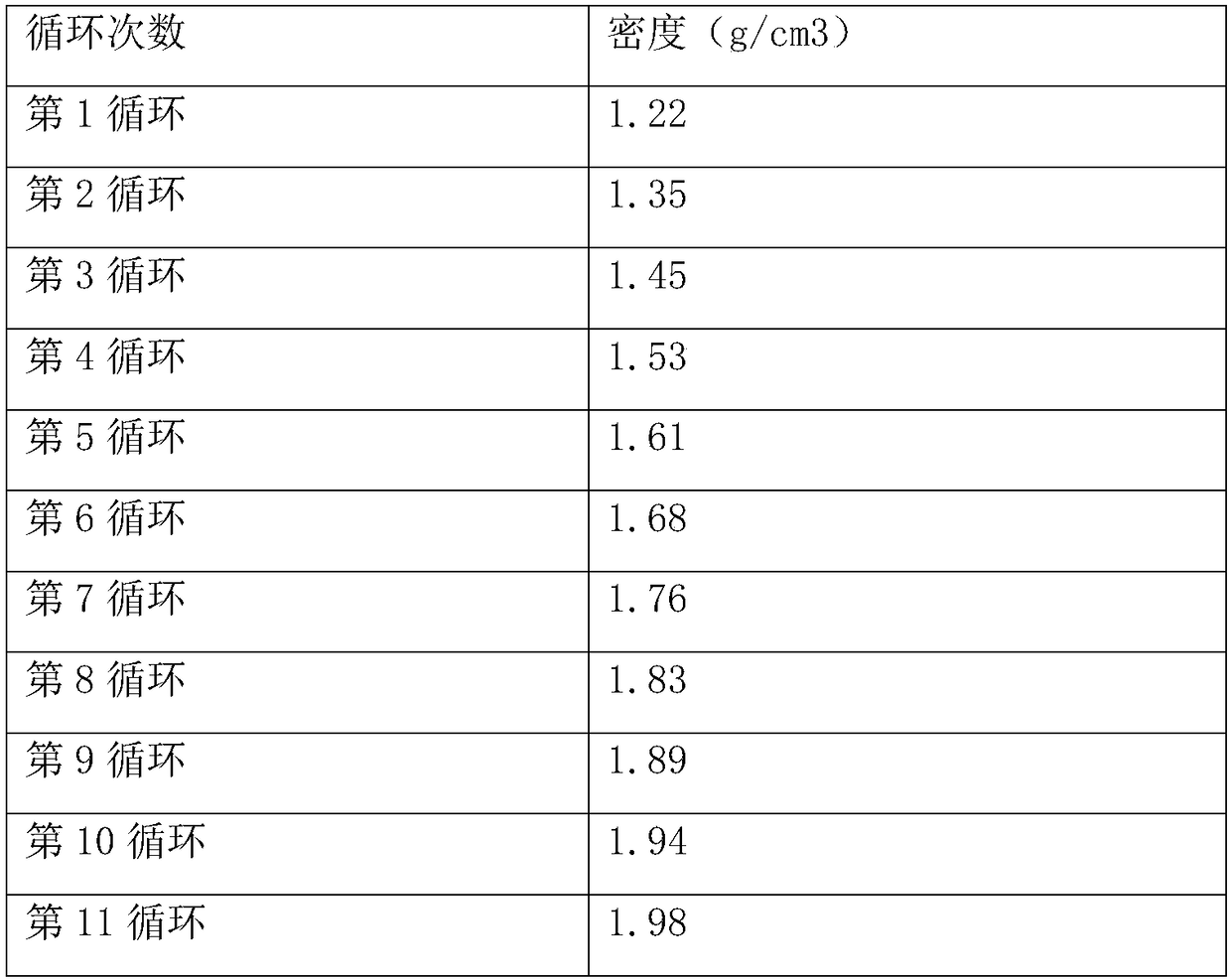

PIP (precursor infiltration and pyrolysis) rapid densification method of SiCf/SiC composite prefab

The invention discloses a PIP (precursor infiltration and pyrolysis) rapid densification method of a SiCf / SiC composite prefab. The method includes a step of impregnating the SiCf / SiC composite prefabinto impregnation liquid, wherein the impregnation liquid is made by uniform mixing of 200-mesh polycarbosilane and analytically pure xylene. In different stages of a densification process, impregnation liquids different in mass ratio of polycarbosilane to xylene are adopted; in a first stage of the densification process, the mass ratio of polycarbosilane to xylene in the adopted impregnation liquid is 1:5-1:4; in a second stage, the mass ratio of polycarbosilane to xylene in the adopted impregnation liquid is 3:5-2:3; in a third stage, the mass ratio of polycarbosilane to xylene in the adopted impregnation liquid is 2:5-1:2. By adoption of the method, density of the prefab reaches 2.3g / cm<3>, a preparation period is shortened by 25% or more as compared with that of a traditional PIP process, and various performance indexes of the prefab are increased.

Owner:PLA NO 5719 FACTORY

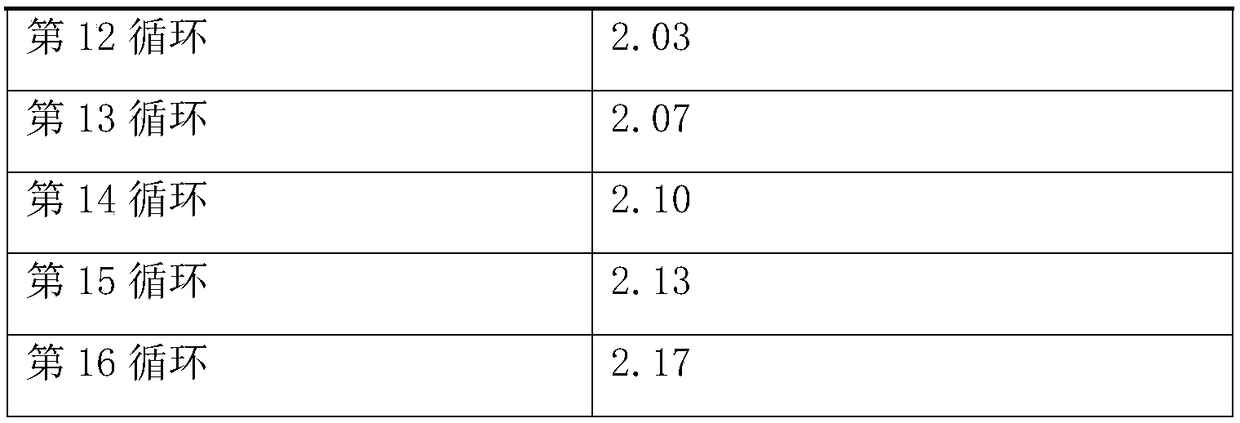

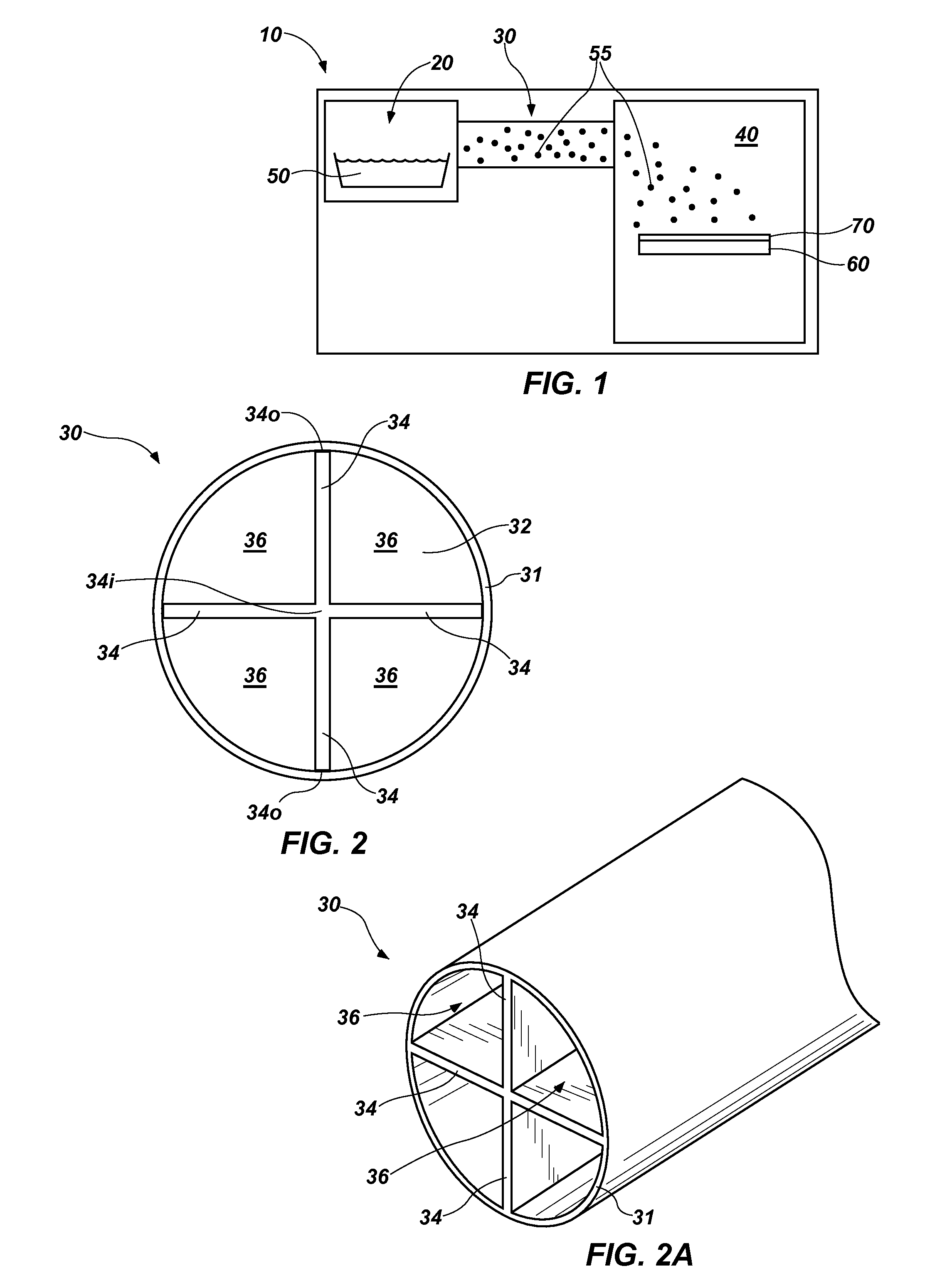

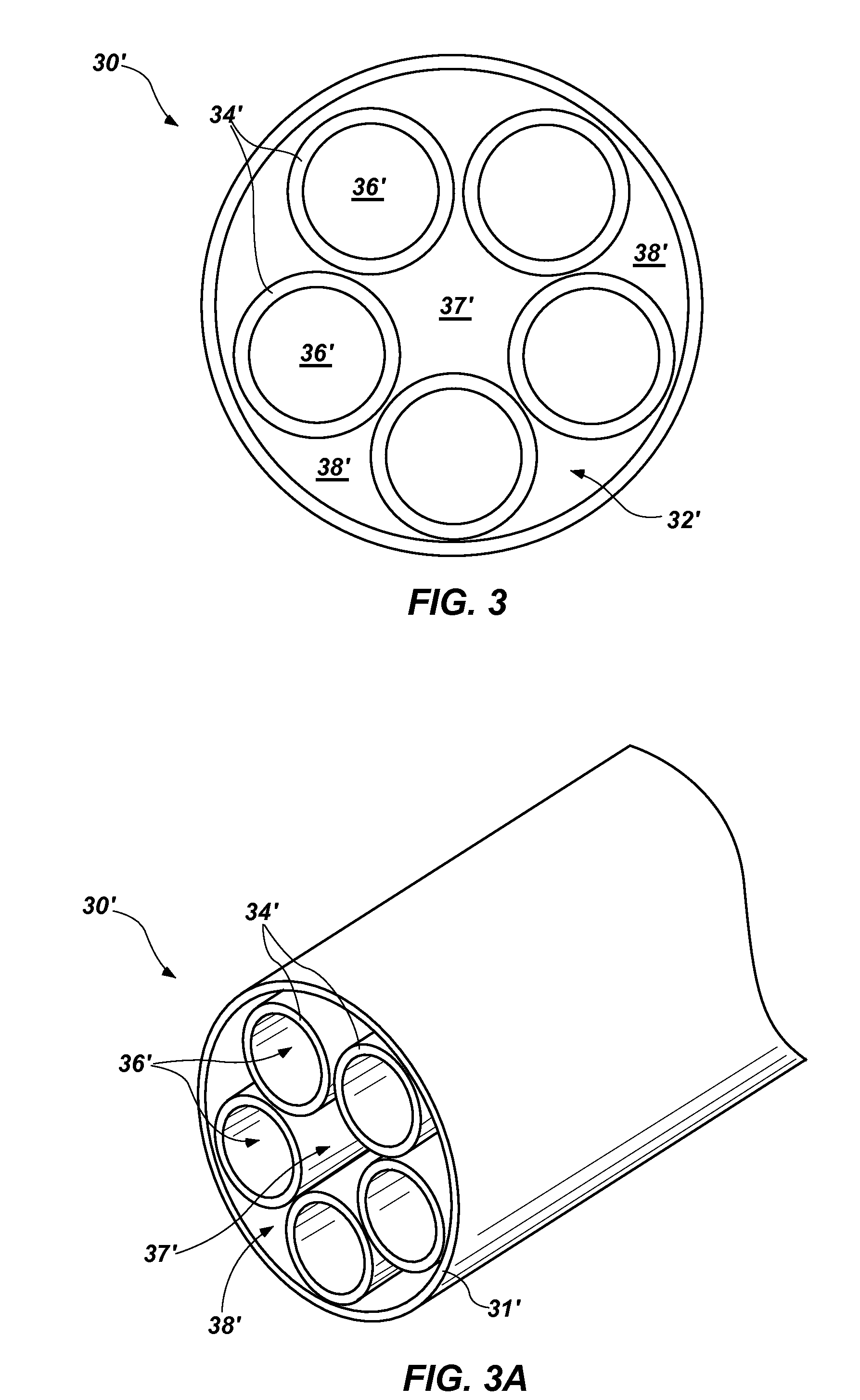

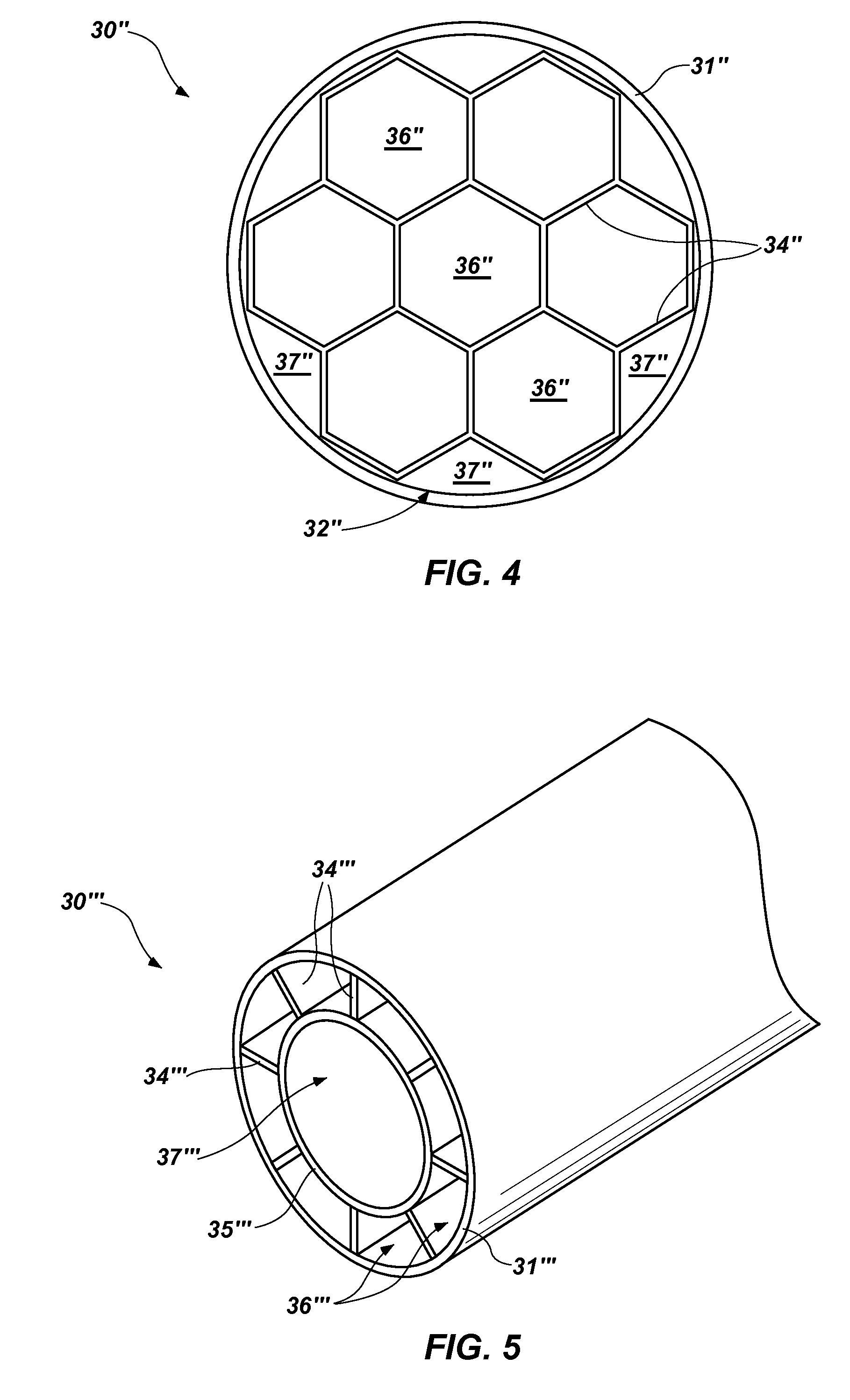

Multi-channel pyrolysis tubes, material deposition equipment including the same and associated methods

InactiveUS20150211115A1Easy to useShorten the timeHydrocarbon by isomerisationLiquid surface applicatorsEngineeringBiomedical engineering

A pyrolysis tube for use with a material deposition system includes a plurality of channels. The channels may be defined by internal elements of the pyrolysis tube, or by internal elements that form an insert for a conventionally configured pyrolysis tube. One or more of the channels may extend straight through the pyrolysis tube, providing a direct line of sight through the pyrolysis tube. Material deposition systems that include such an insert or pyrolysis tube are also disclosed, as are methods for efficiently pyrolyzing precursor materials at temperatures that are reduced relative to conventional pyrolysis temperatures and / or at rates that are increased relative to conventional pyrolysis rates.

Owner:HZO INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com