Patents

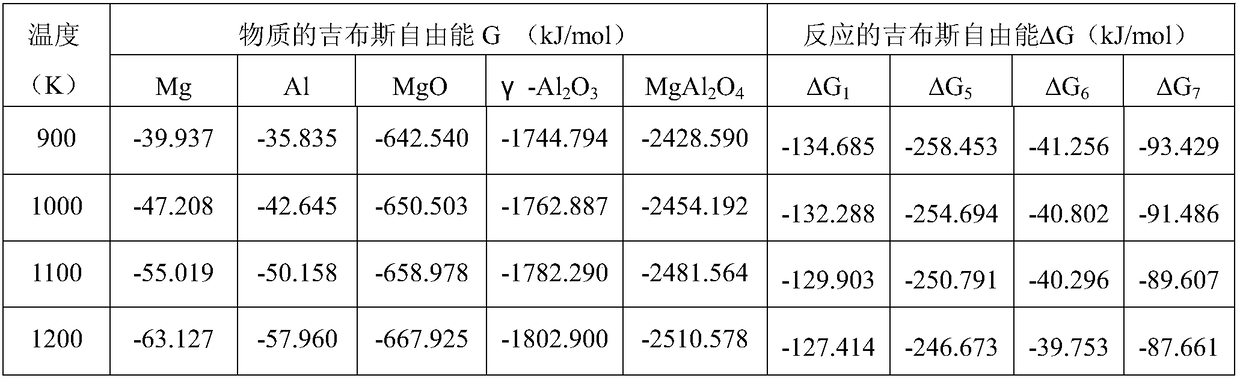

Literature

51results about How to "Good low temperature sintering performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fully-prealloyed powder and preparation method thereof

ActiveCN105463291AImprove control abilityImprove wear resistanceTransportation and packagingMetal-working apparatusUltimate tensile strengthImpurity

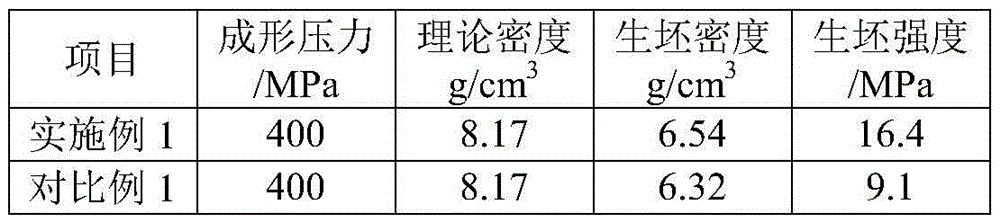

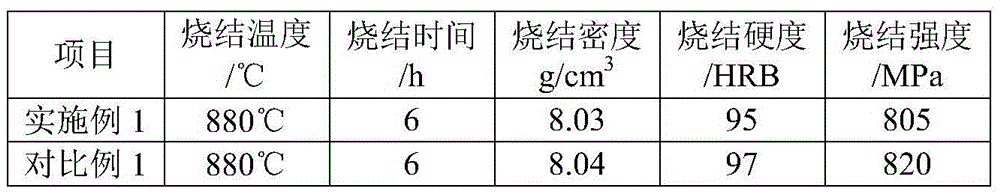

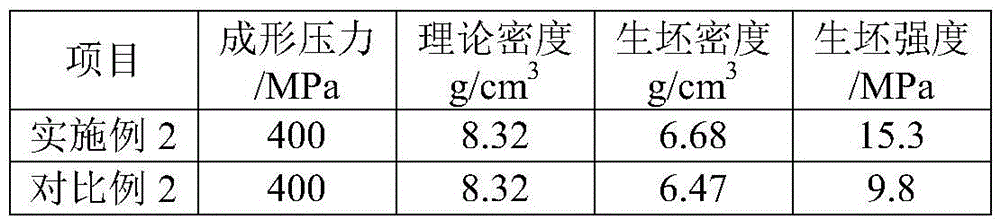

The invention discloses fully-prealloyed powder. The fully-prealloyed powder is prepared from, by weight percentage, 30%-65% of Fe, 15%-45% of Cu, 1%-15% of Sn, 0%-15% of Ni, 1%-30% of Co, 0%-5% of Qt and the balance inevitable impurities, wherein Qt is selected from one or more of Mn, Cr, Ti, P and W. The invention further discloses a preparation method of the fully-prealloyed powder. The formability and sintering strength of the fully-prealloyed powder are improved, and the sintering density of the fully-prealloyed power is increased; in the whole process, only the fully-prealloyed powder is used as a bonding agent in a diamond tool bit; and the advantages that the fully-prealloyed powder is low in sintering temperature, wide in process range and good in pullout strength on diamond are brought into full play.

Owner:BOSUN TOOLS CO LTD

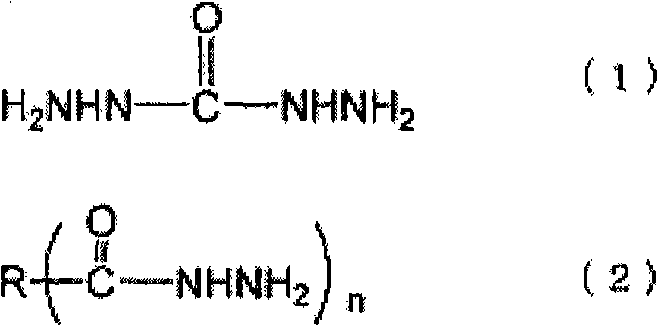

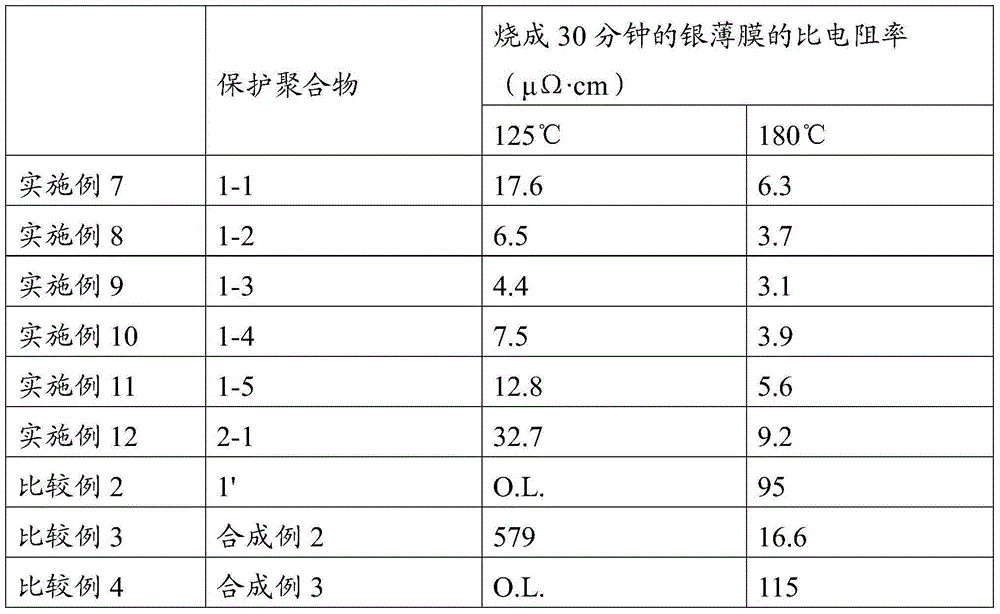

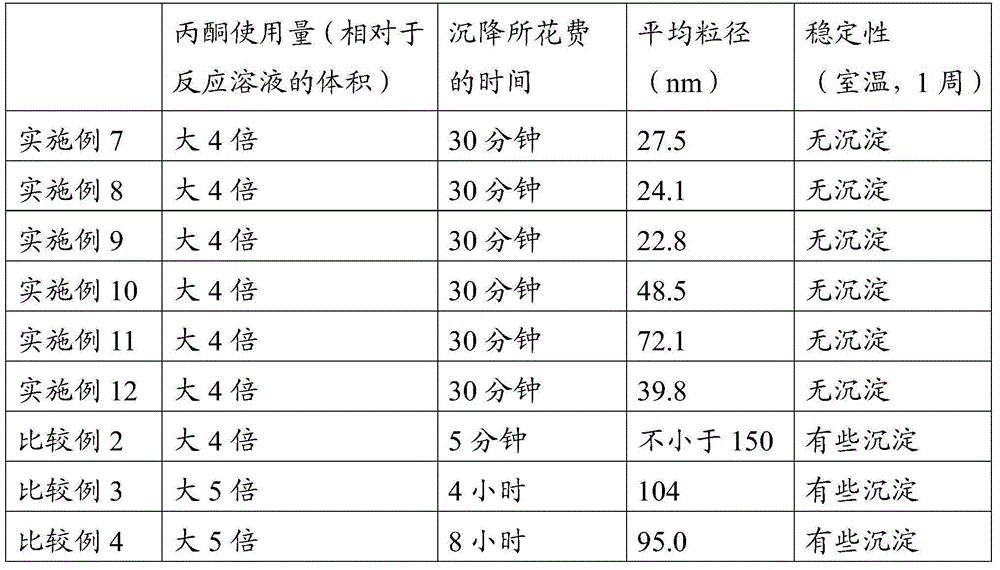

Method for producing metal particle dispersion, conductive ink using metal particle dispersion produced by such method, and conductive coating film

InactiveCN101287566AEffective conductivityImprove performanceConductive layers on insulating-supportsInksDispersion stabilityLiquid medium

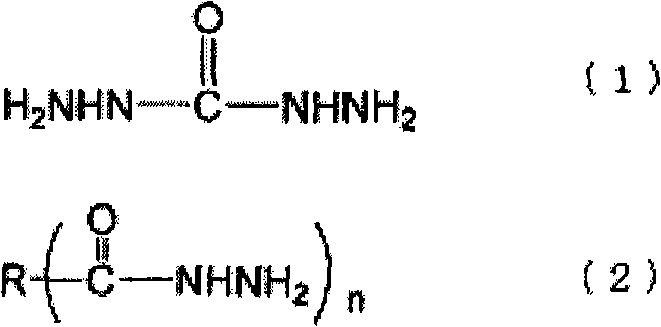

Disclosed is a method for producing a metal particle dispersion wherein a metal compound is reduced by using carbodihydrazide represented by the formula (1) below or a polybasic acid polyhydrazide represented by the formula (2) below (wherein R represents an n-valent polybasic acid residue) in a liquid medium. By reducing the metal compound in the presence of a compound having a function preventing discoloration of the metal, there can be obtained a metal particle dispersion having excellent discoloration preventing properties. Metal particles produced by such methods have a uniform particle diameter and are excellent in dispersion stability. By using a conductive resin composition or conductive ink containing a metal particle dispersion obtained by such production methods, there can be formed a conductive coating film, such as a conductive circuit or an electromagnetic shielding layer, having good characteristics.

Owner:TOYO INK SC HOLD CO LTD

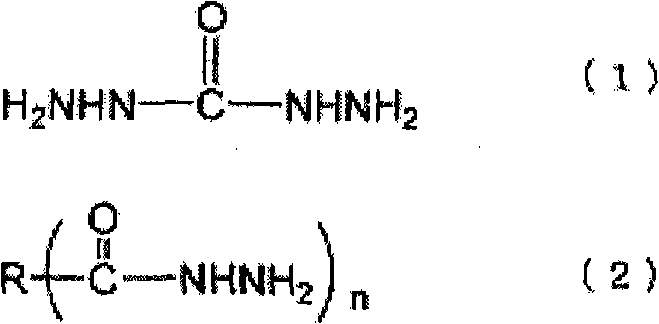

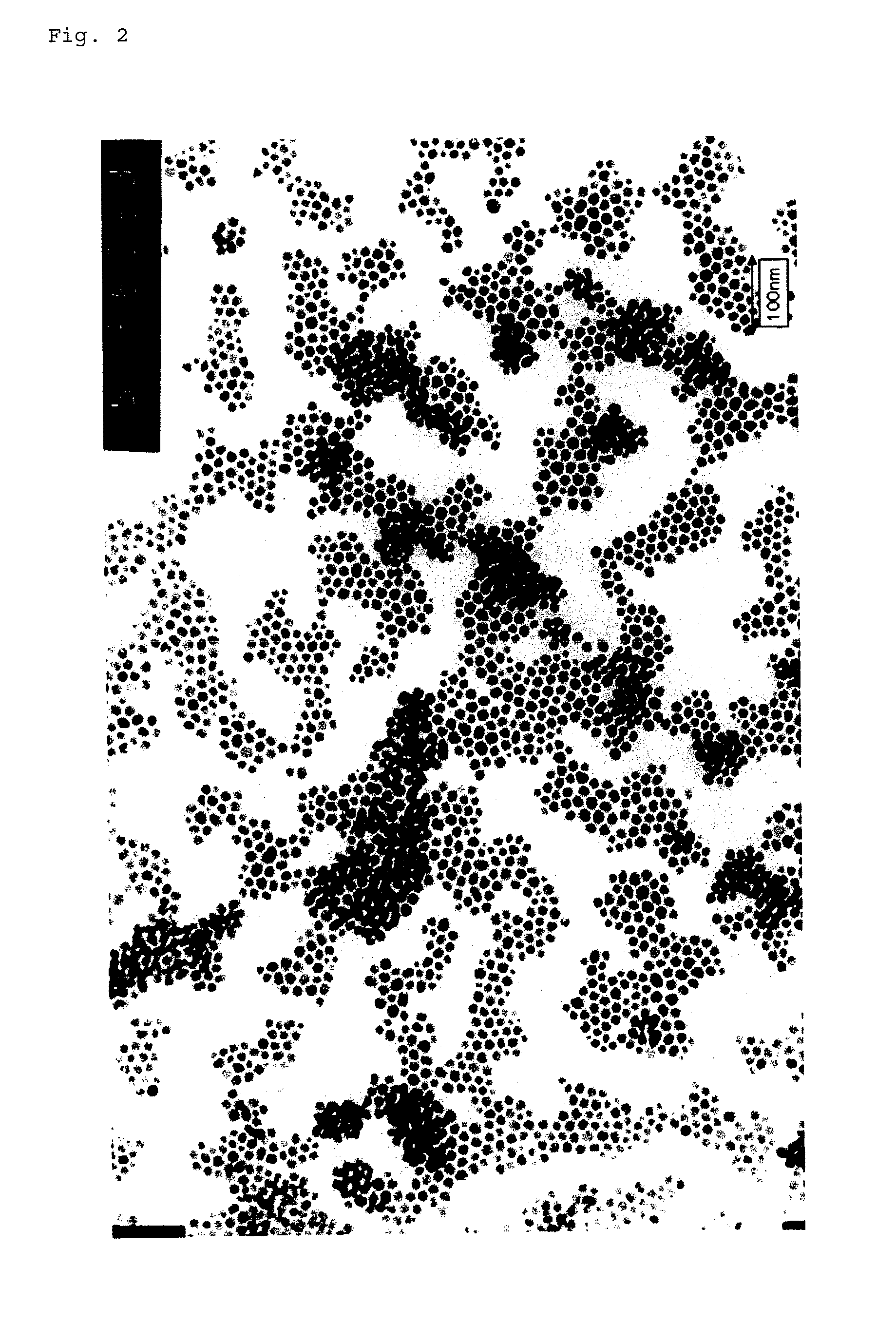

Fine silver particle powder, method for manufacturing the same, silver paste using the powder, and method of use of the paste

ActiveUS20110253949A1Good low temperature sintering performancePigmenting treatmentMaterial nanotechnologySilver pasteNanoparticle

A method suitable for mass production of nanoparticles with a uniform particle diameter is provided. It is an object to provide a powder of the nanoparticle obtained by this method, a dispersion containing the nanoparticles, and a paste containing the nanoparticles. There is provided a method for manufacturing silver particles including the step of reducing silver in a silver solution containing a protective agent composed of an organic material and a copper component in an amount of 1 to 1,000 ppm relative to the amount of silver to obtain particles having an average particle diameter (DTEM) of 5 to 100 nm as measured using a transmission electron microscope.

Owner:DOWA ELECTRONICS MATERIALS CO LTD

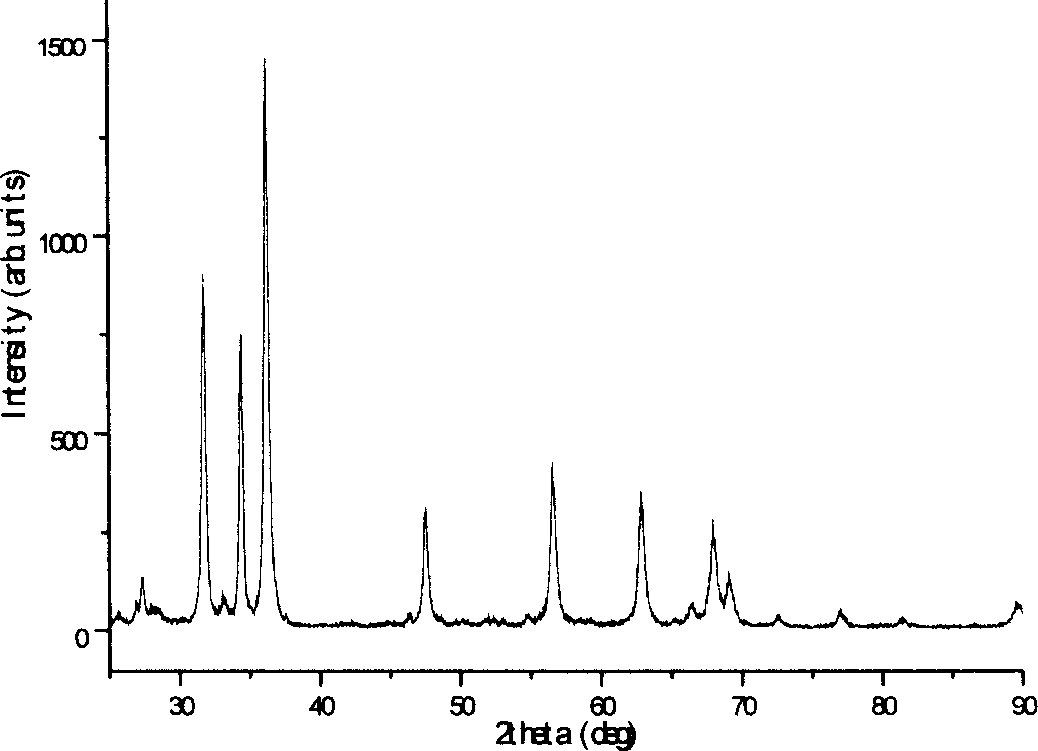

Preparation and application of high-potential gradient zinc oxide piezoresistor material

This invention relates to the preparation and application of a high potential gradient ZnO piezoresistive material including: mixing raw materials in the mol ratio of ZnO: Bi2O3:Sb2O3:Cr2O3:Co2O3:MnO2=96.5:0.7:1.0:0.5:0.8:0.5 to get the product by first and second time powerful fine grindings, low temperature sinter, which is taken as the raw material to be pressed to formation, sintered at low temperature, coated with electrode Ag pulp and welded with electrode lead to get the product of high potential gradient ZnO piezoresistors. This invention greatly refines the metal oxide mixed powder grain size by twice-powerful grindings, the sintered temperature is only 900deg.C and the grain is 1.5-3.5mum.

Owner:EAST CHINA NORMAL UNIVERSITY

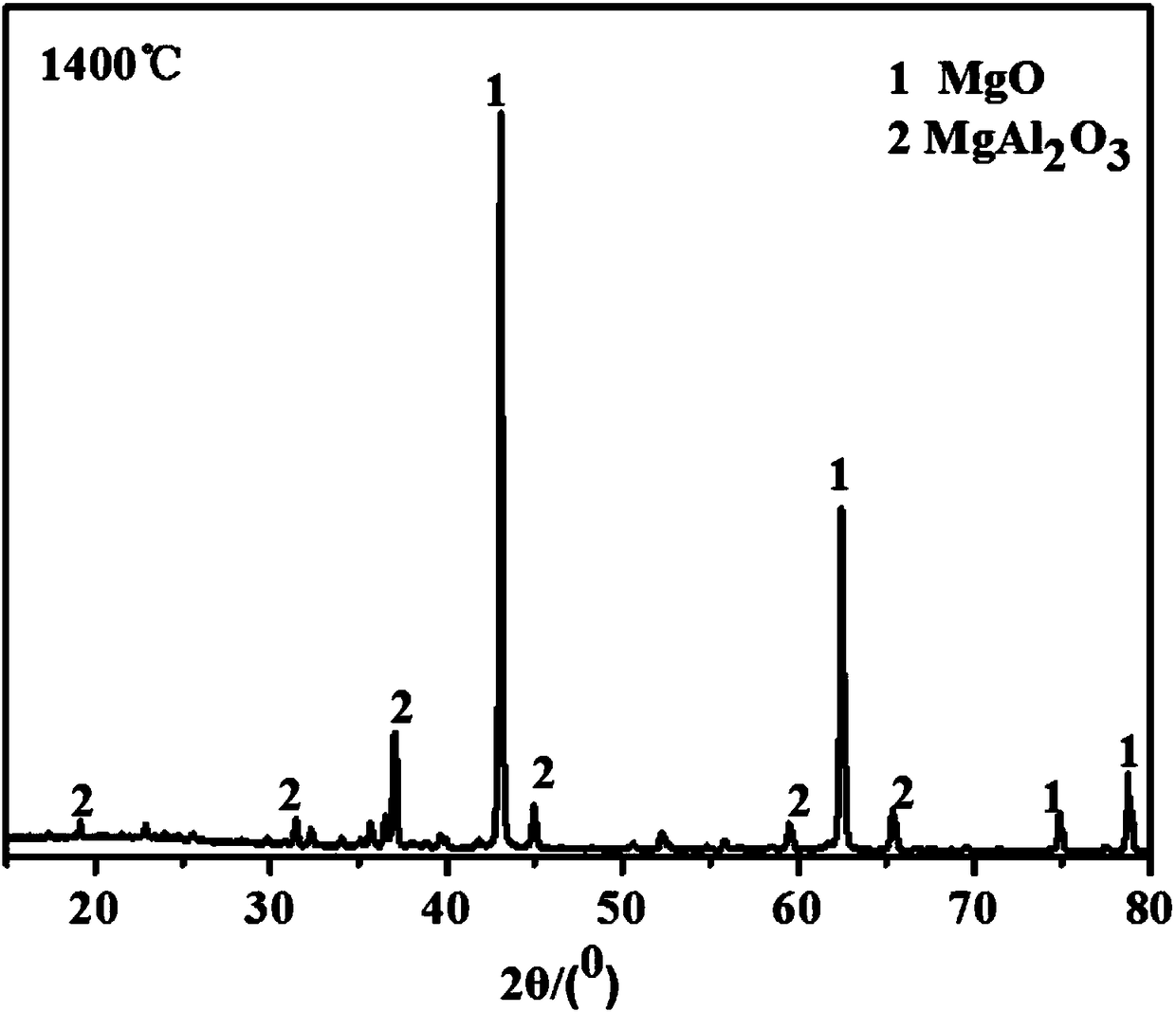

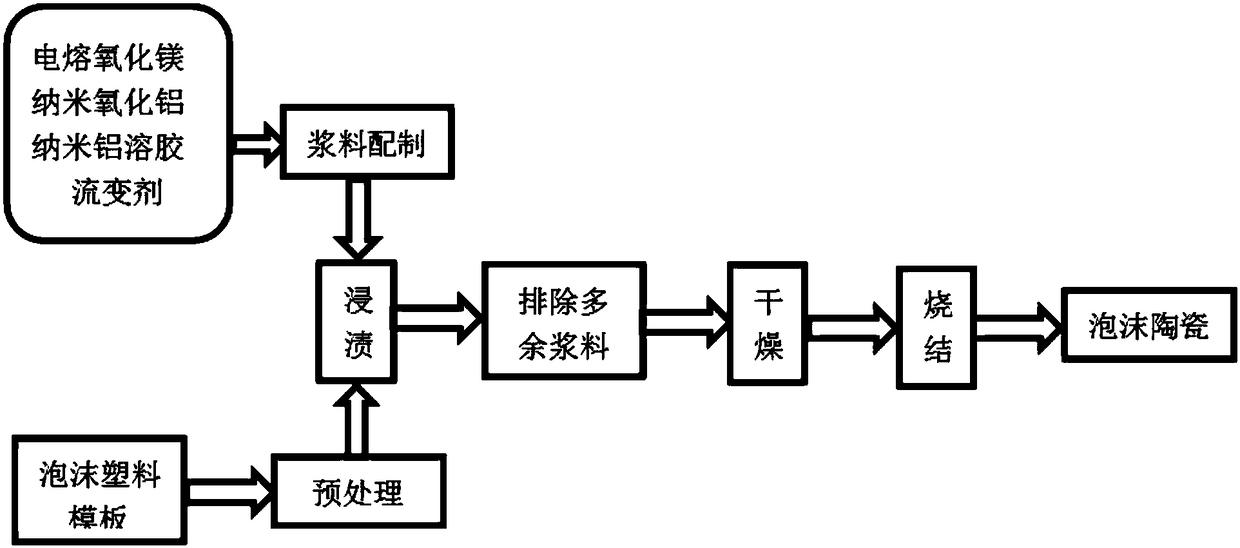

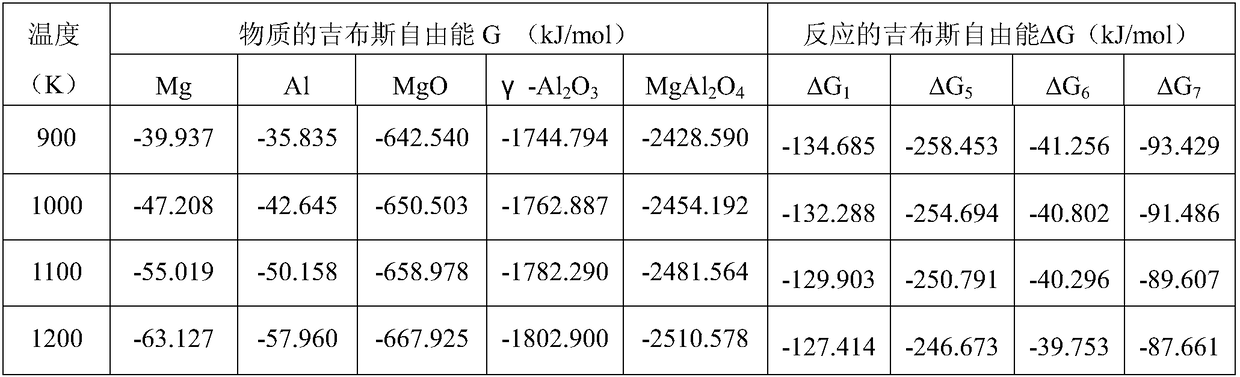

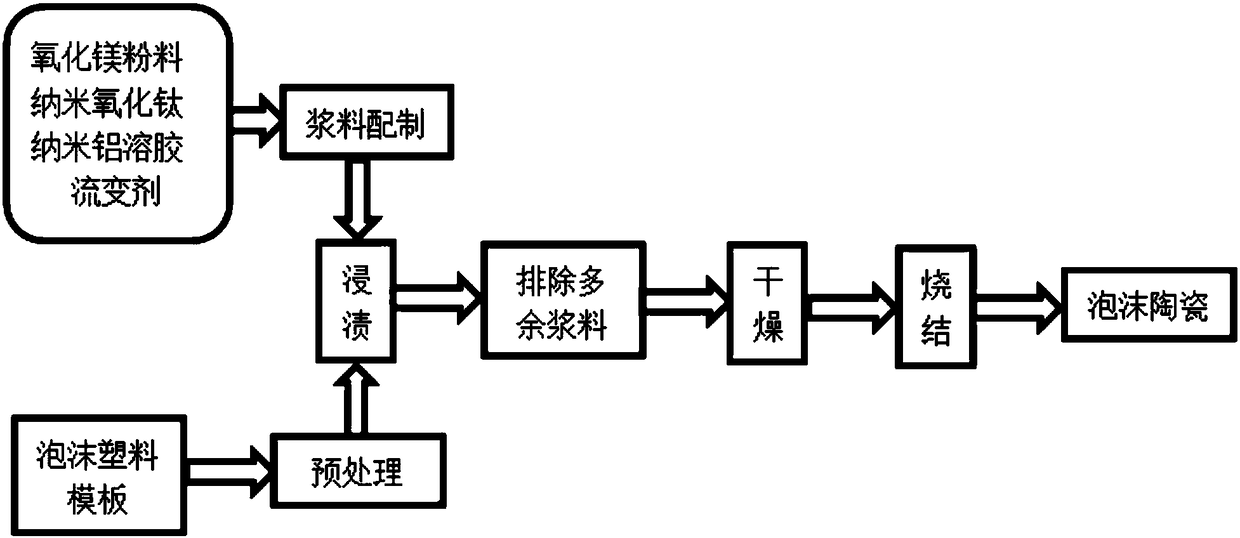

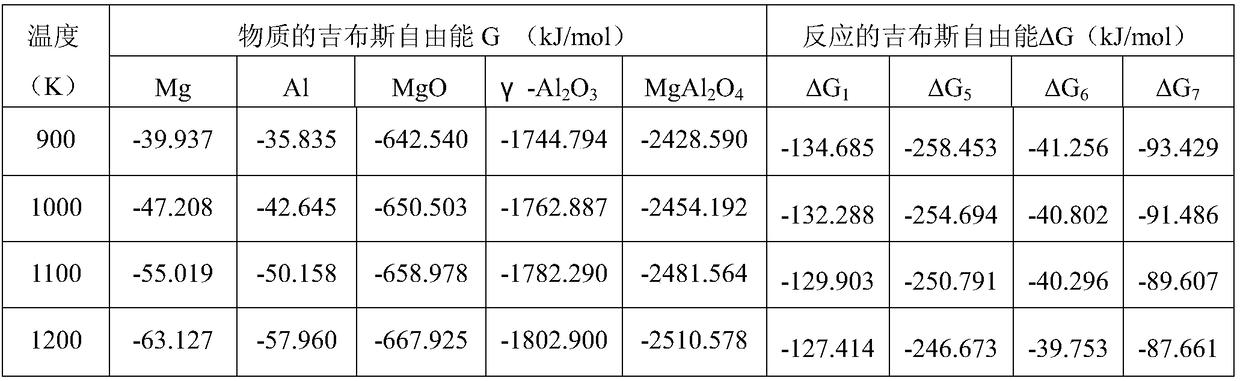

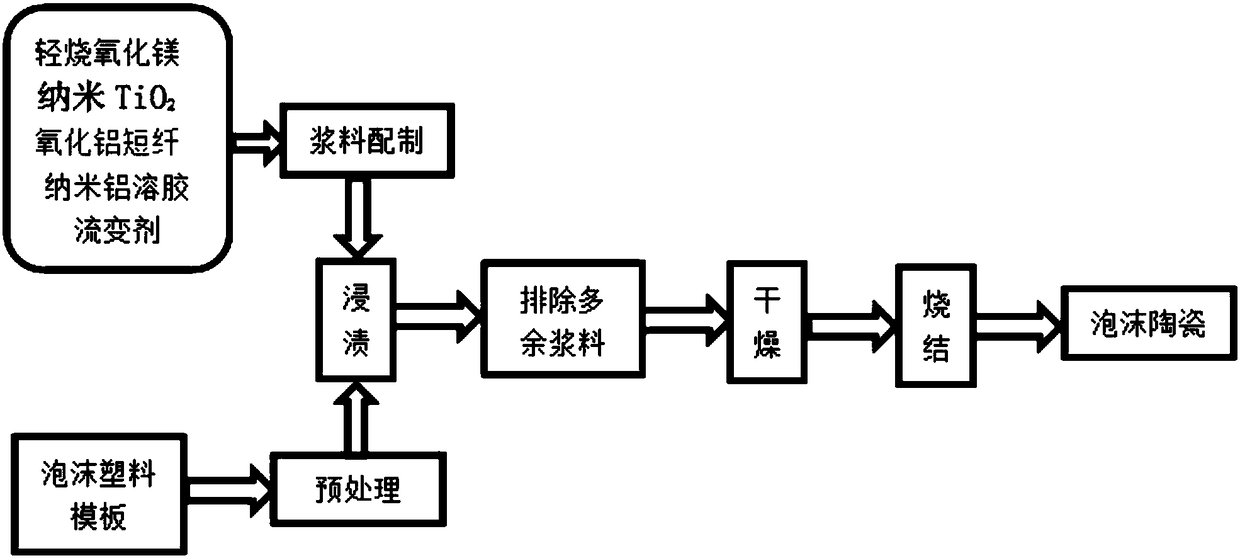

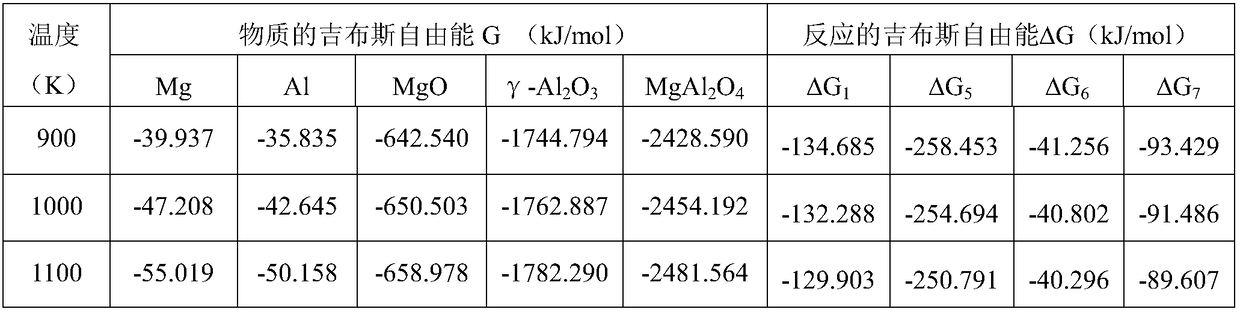

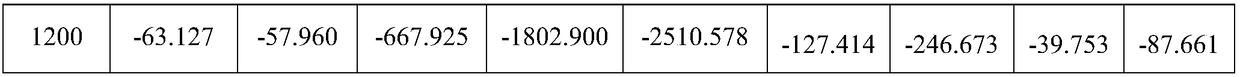

Magnesium aluminate spinel enhanced magnesia-based foamed ceramic filter and preparation method thereof

ActiveCN108516803AAct as a binderAvoid damageFiltration separationCeramicwareOxide ceramicNano al2o3

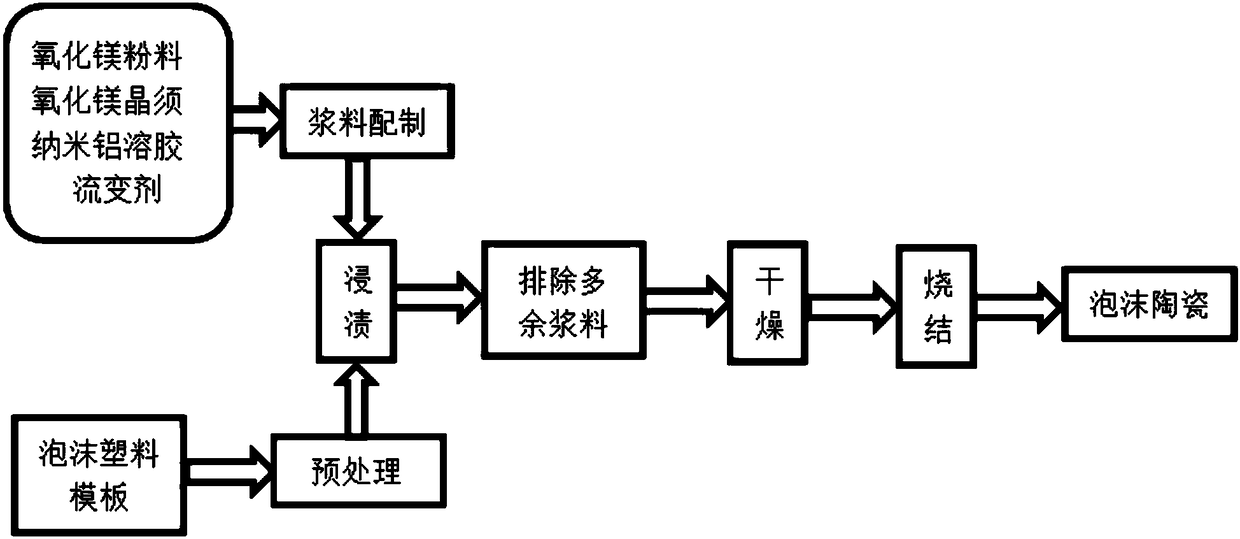

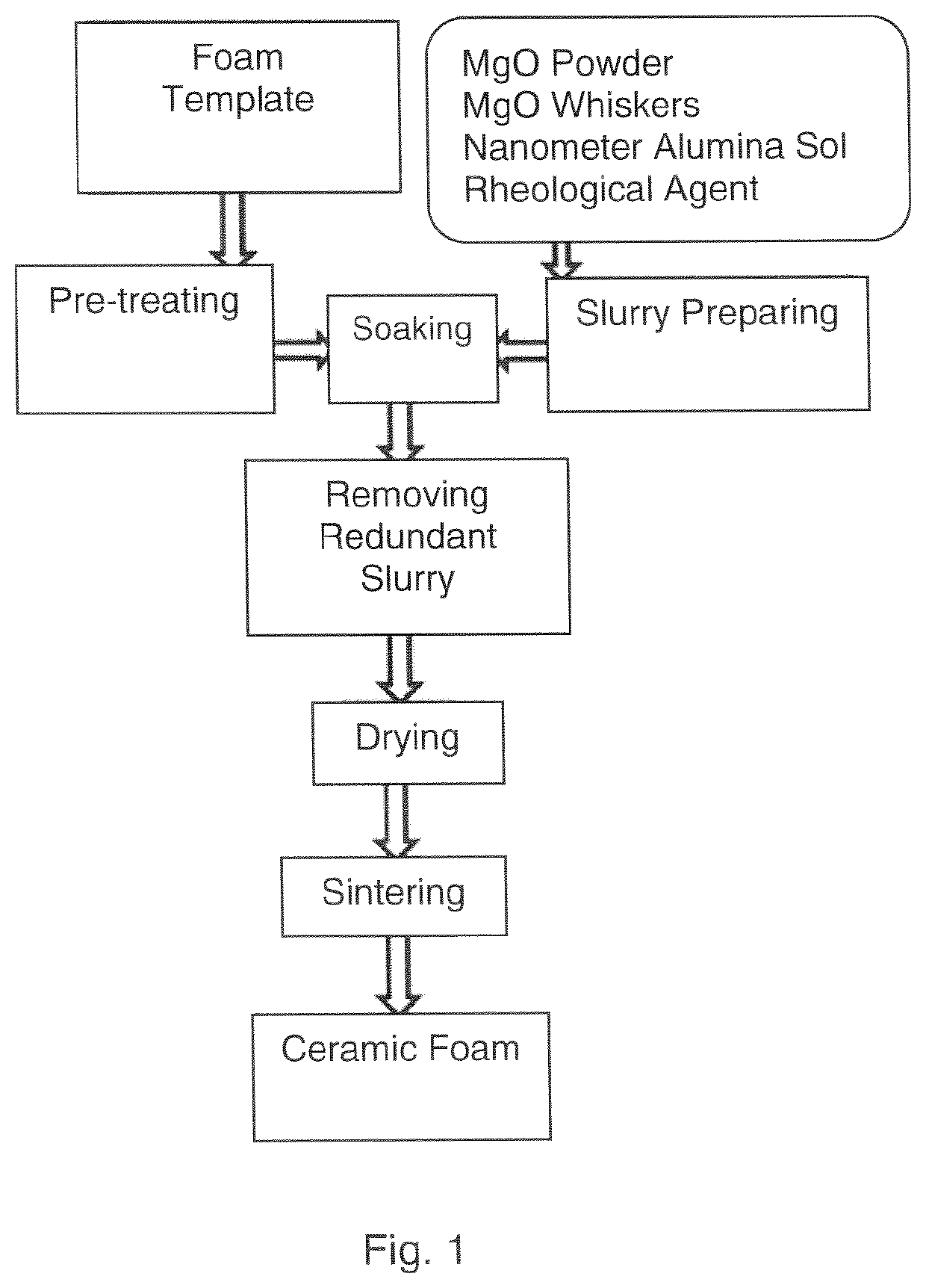

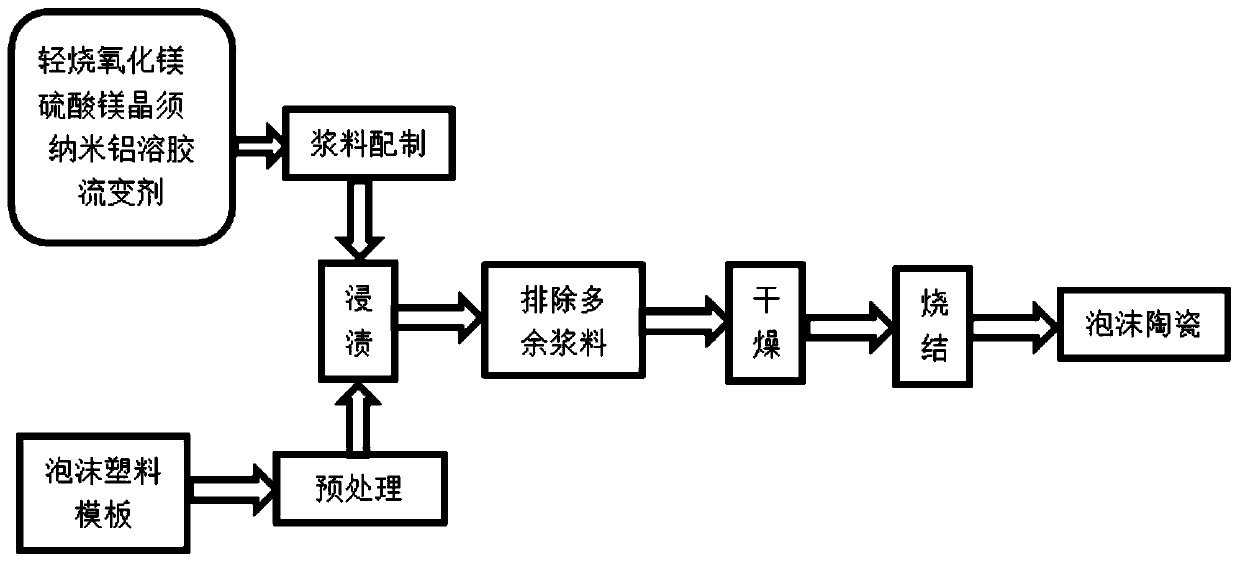

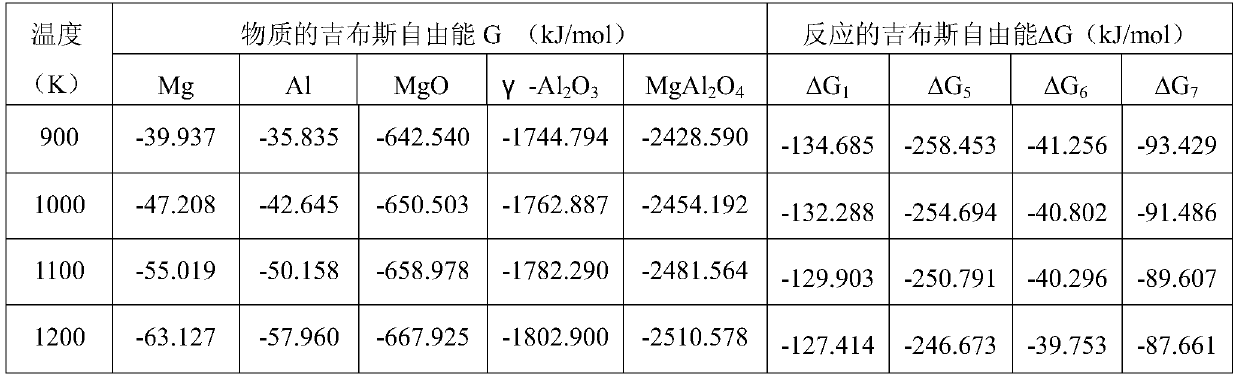

The invention discloses a magnesium aluminate spinel enhanced magnesia-based foamed ceramic filter with capability of realizing sintering at low temperature, excellent chemical stability and excellentthermal shock resistant performance, and a preparation method thereof. The preparation method comprises the following steps that (1) 10 to 20 percent of nanometer alumina sol, 0.8 to 1.5 percent of rheological agents and the balance of magnesium oxide ceramic powder containing a nanometer aluminum oxide sintering aid are proportioned; deionized water is added; ball milling and uniform mixing areperformed; then, through vacuum exhaust, ceramic slurry with the solid content being 60 to 70 percent is prepared; (2) a polyurethane foamed plastic template is soaked into the ceramic slurry; the polyurethane foamed plastic template is extruded through a roller press for removing the redundant leaching hanging slurry; then, biscuit is prepared; then, the biscuit is heated to 80 to 120 DEG C for drying; (3) the dried biscuit is put into a sintering furnace; the temperature is raised to 1400 to 1600 DEG C; high-temperature sintering is performed; cooling is performed along with the furnace to room temperature; the magnesia-based foamed ceramic filter is obtained.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

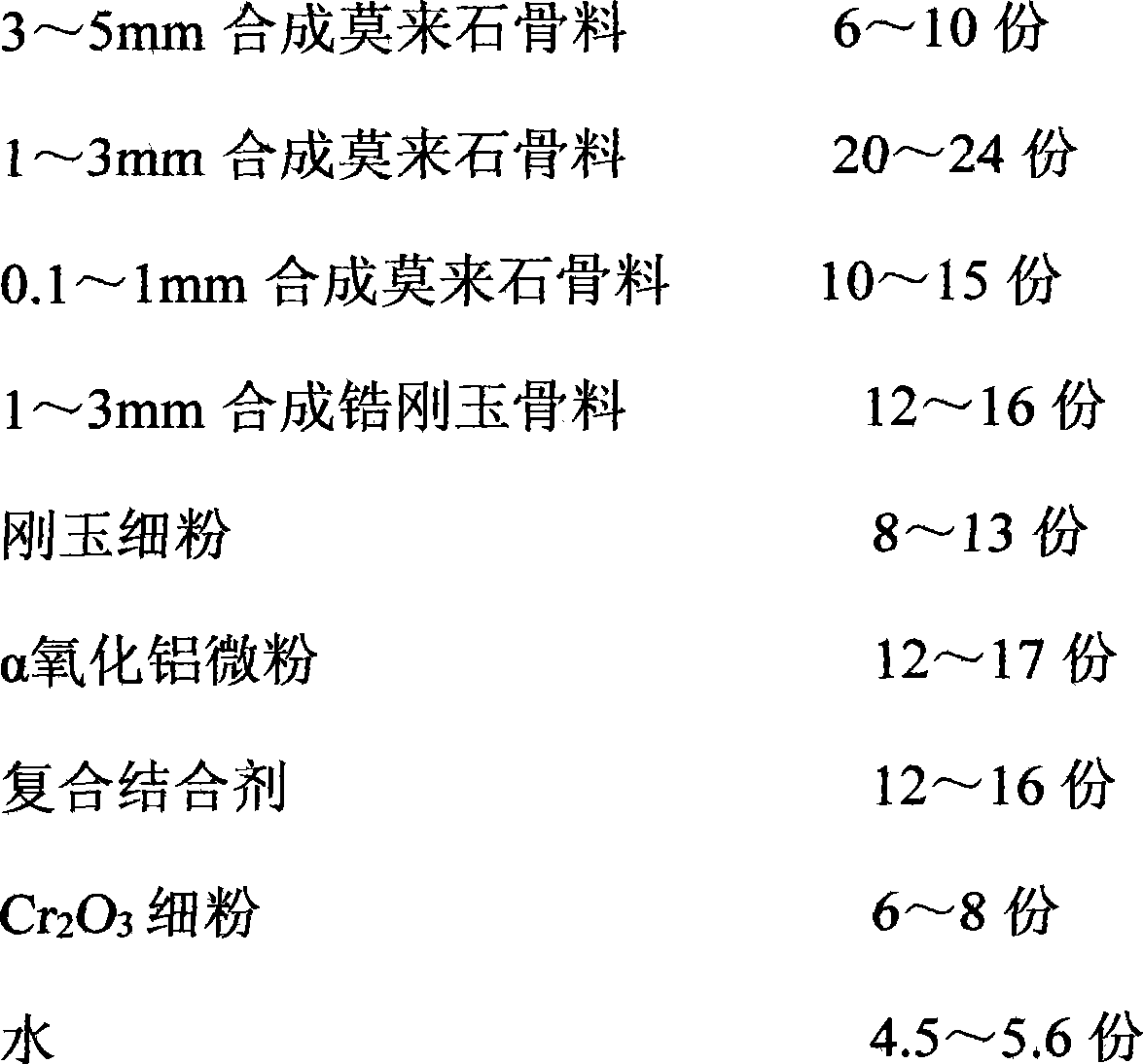

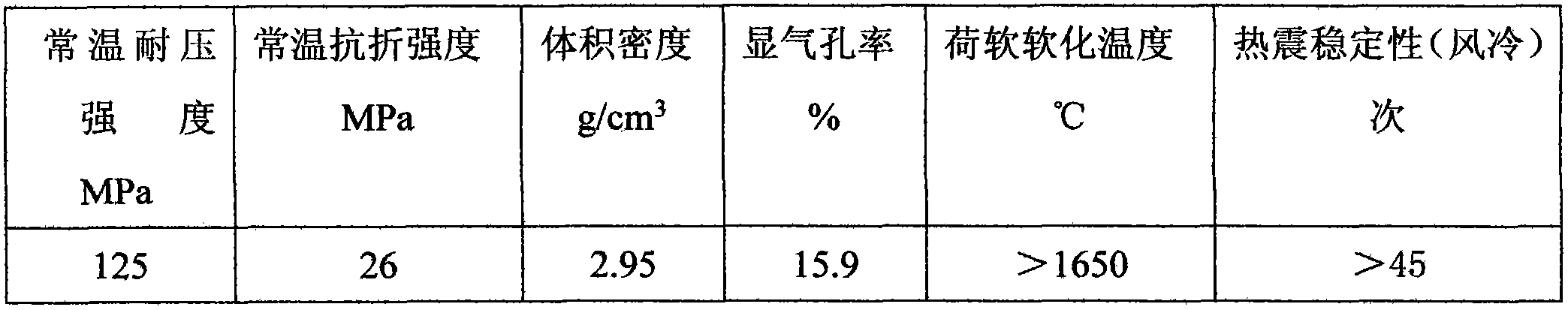

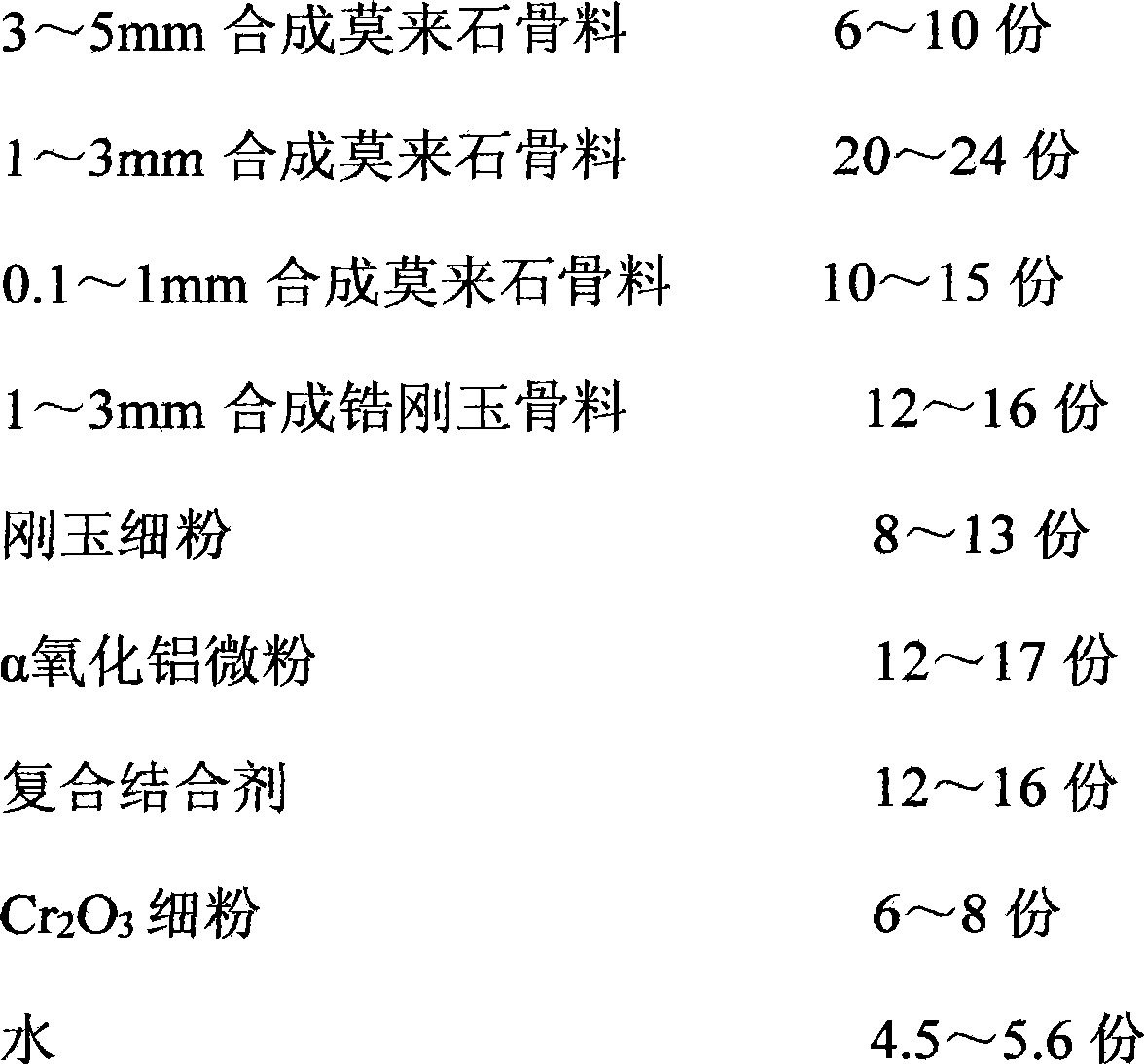

Chromium zirconium corundum mullite brick suitable for burning of waste liquid and wastes of petrochemical industry

The invention discloses a refractory material, especially a chromium zirconium corundum mullite brick suitable for burning of waste liquid and wastes of petrochemical industry. The mullite brick is characterized by comprising synthetic mullite aggregate, synthetic corundum aggregate, corundum fine powder, alpha-alumina micropowder, a composite binder, Cr2O3 fine powder and water. According to a formula amount, the materials is mixed by using a planetary mixer and molded by pressing, and the molded adobe is fired under 80-110 DEG C for 24-48 hours, and roasted under 1560-1610 DEG C for 3.5-4.5 hours. The invention further discloses a preparation method of the chromium zirconium corundum mullite brick. The invention is beneficial in that the chromium zirconium corundum mullite brick is relatively high in refractoriness and high-temperature intensity, and has excellent performances of erosion resistance, thermal shock resistance, stripping resistance, and low creep deformation. The brick is suitable for inner liners of a waste liquid incinerator of the petrochemical industry and a waste incinerator of a rotary kiln industry, and is simple in technology and easy to realize the manufacture.

Owner:JILIN DESIGNING INST OF CNPC NORTHEAST REFINING & CHEM ENG

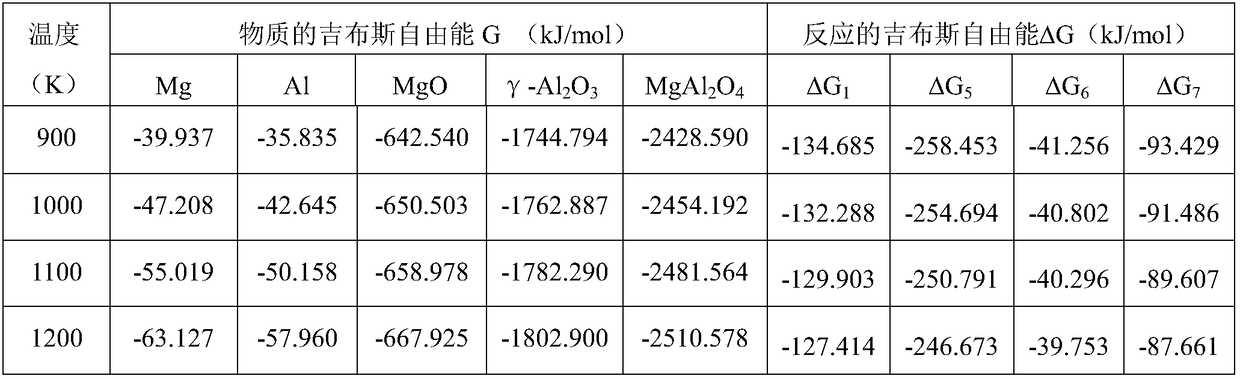

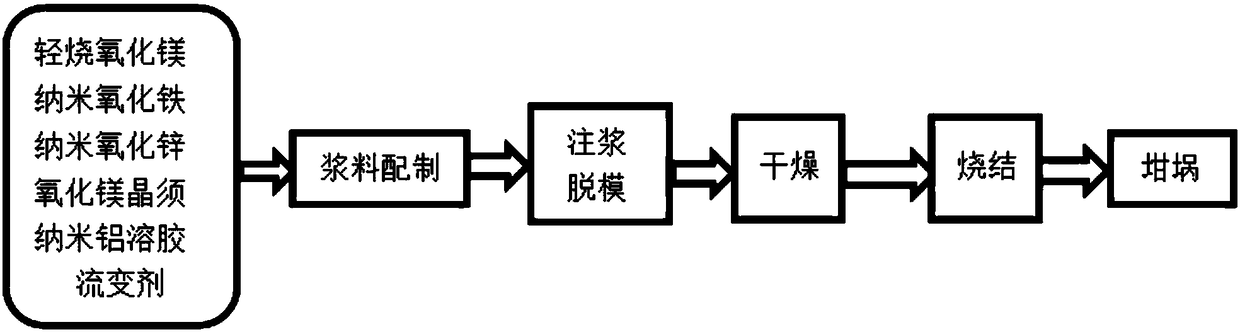

Magnesium oxide whisker in-situ synthesis magnesium aluminate spinel enhanced magnesium-oxide-based foam ceramic filter and preparation method thereof

ActiveCN108484182AAvoid obstructionAct as a binderFiltration separationCeramicwareRoom temperatureSlurry

The invention discloses a magnesium oxide whisker in-situ synthesis magnesium aluminate spinel enhanced magnesium-oxide-based foam ceramic filter with chemical stability and excellent thermal shock resistance capable of sintering in a low temperature and a preparation method thereof. The preparation method comprises the following steps: (1) according to a mass percent, compounding by 15%-25% of nano-aluminum sol, 0.8%-1.5% of rheological agent, and the balance of magnesia ceramics powder containing magnesium oxide whisker, adding deionized water, ball-milling, uniformly mixing, and preparing ceramic slurry of which the solid content is 60%-70% through vacuum exhaust; (2) immerging a polyurethane foamed plastic template in the ceramic slurry, extruding the polyurethane foamed plastic template through a roller press so as to remove redundant immerging slurry, preparing a biscuit, heating the biscuit to 80-120 DEG C, and drying; and (3) placing the dried biscuit in a sintering furnace, warming to 1400-1600 DEG C, and sintering in a high temperature, cooling to room temperature along with the furnace, to obtain the magnesium-oxide-based foam ceramic filter.

Owner:JIANGSU FAVOUR AUTOMOTIVE NEW STUFF SCI TECH +1

Magnesium aluminate spinel reinforced magnesium oxide-based foam ceramic filter synthesized in situ from magnesium oxide whisker, and preparation method therefor

ActiveUS20200316505A1Low chemical stabilityAvoid damageFiltration separationCeramicwareOxide ceramicNano al2o3

The present invention provides A magnesium oxide whisker in-situ formed MA spinel-reinforced magnesium oxide-based ceramic foam filter and a method for preparing the same. The method comprising: 1) preparing a ceramic slurry having a solid content of 60%-70% by dosing 15%-25% by mass of a nanometer alumina sol, 0.8%-1.5% by mass of a rheological agent, and the balance magnesium oxide ceramic powder comprising magnesium oxide whiskers, and then adding deionized water and ball milling to mix until uniform, and then vacuum degassing the mixture; 2) soaking a polyurethane foam template into the ceramic slurry, squeezing by a roller press the polyurethane foam template to remove redundant slurry therein to make a biscuit, and drying the biscuit by heating it to 80° C.-1200° C.; 3) putting the dried biscuit into a sintering furnace, elevating the temperature to 1400° C.-1600° C. and performing a high temperature sintering, cooling to the room temperature with the furnace to obtain the magnesium oxide-based ceramic foam filter.

Owner:JIANGSU FAVOUR AUTOMOTIVE NEW STUFF SCI TECH +1

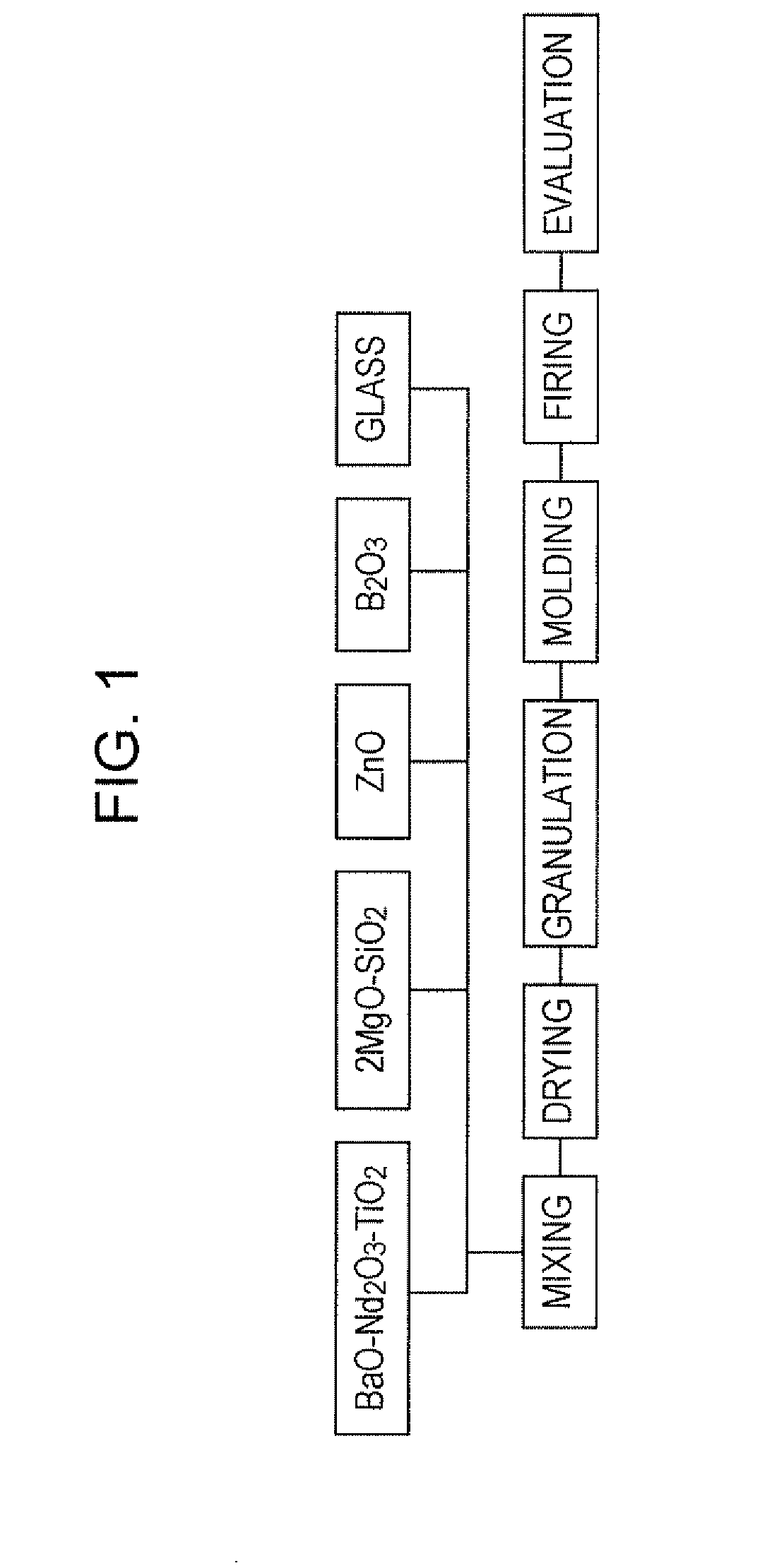

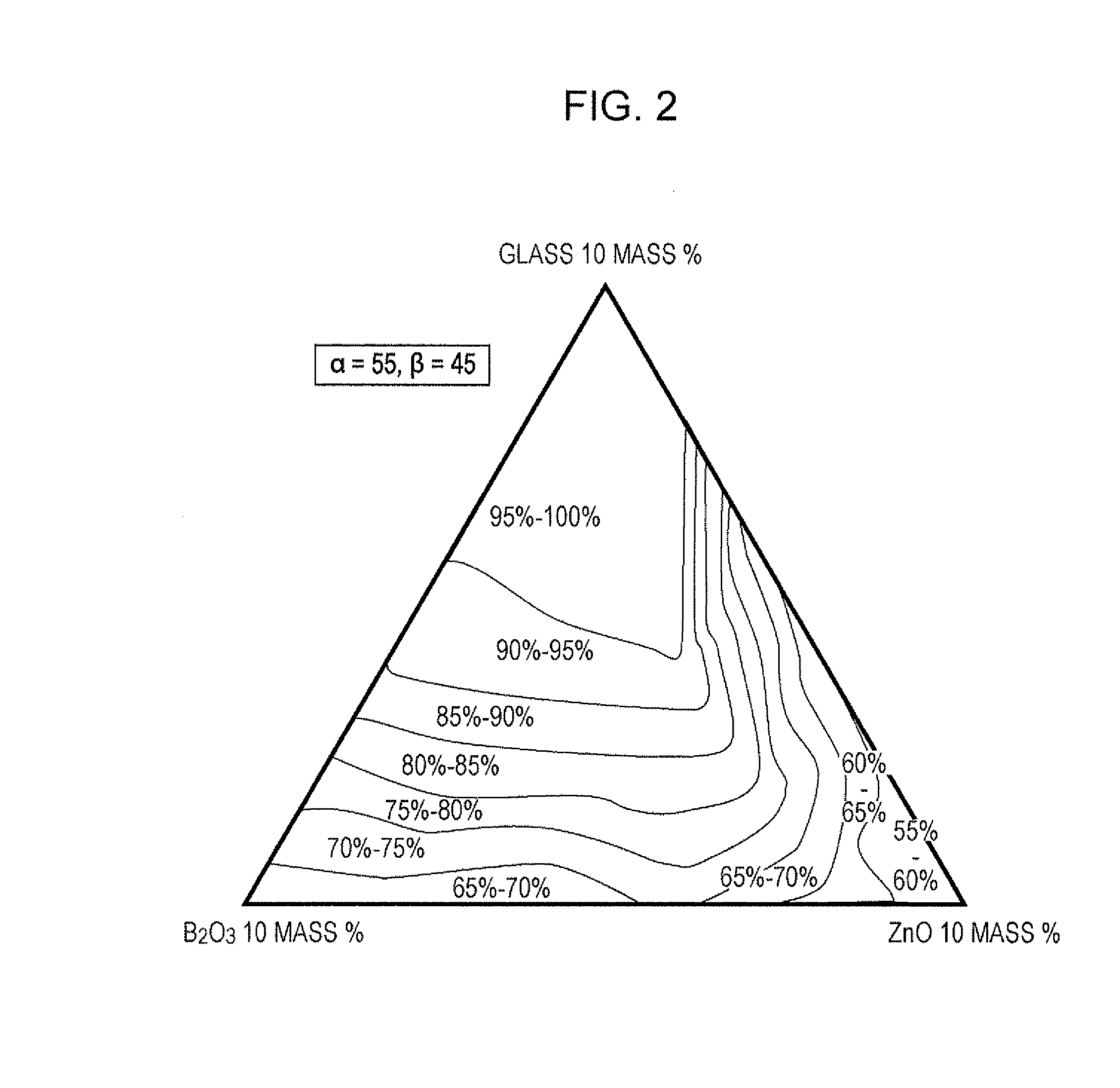

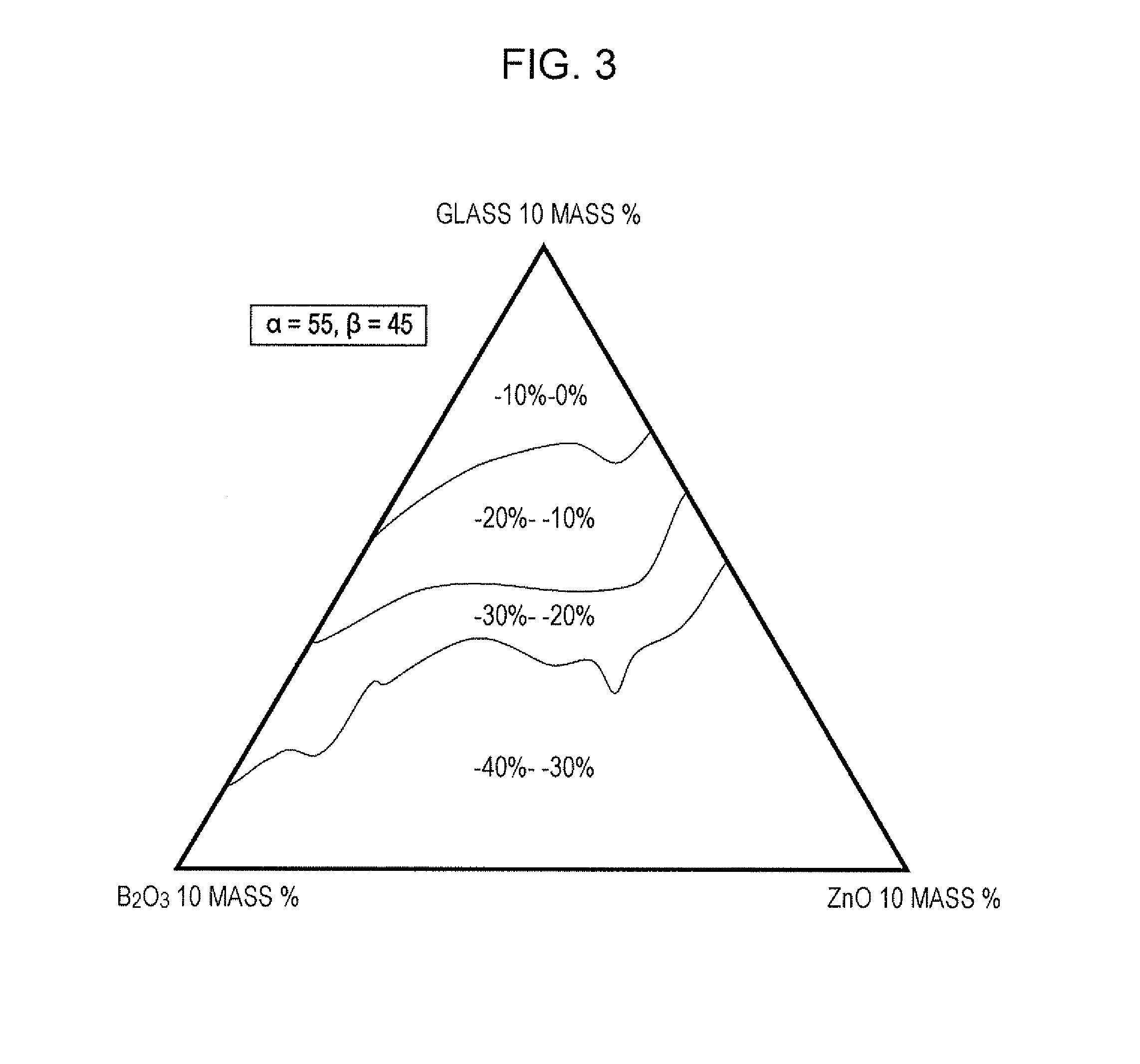

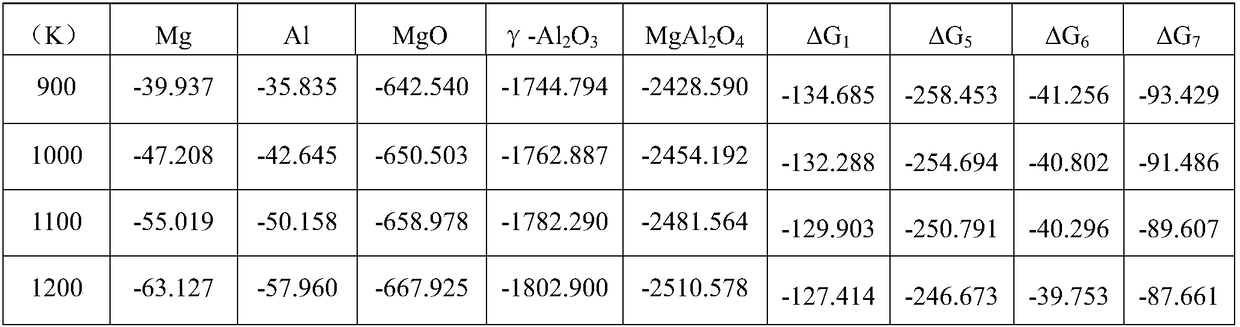

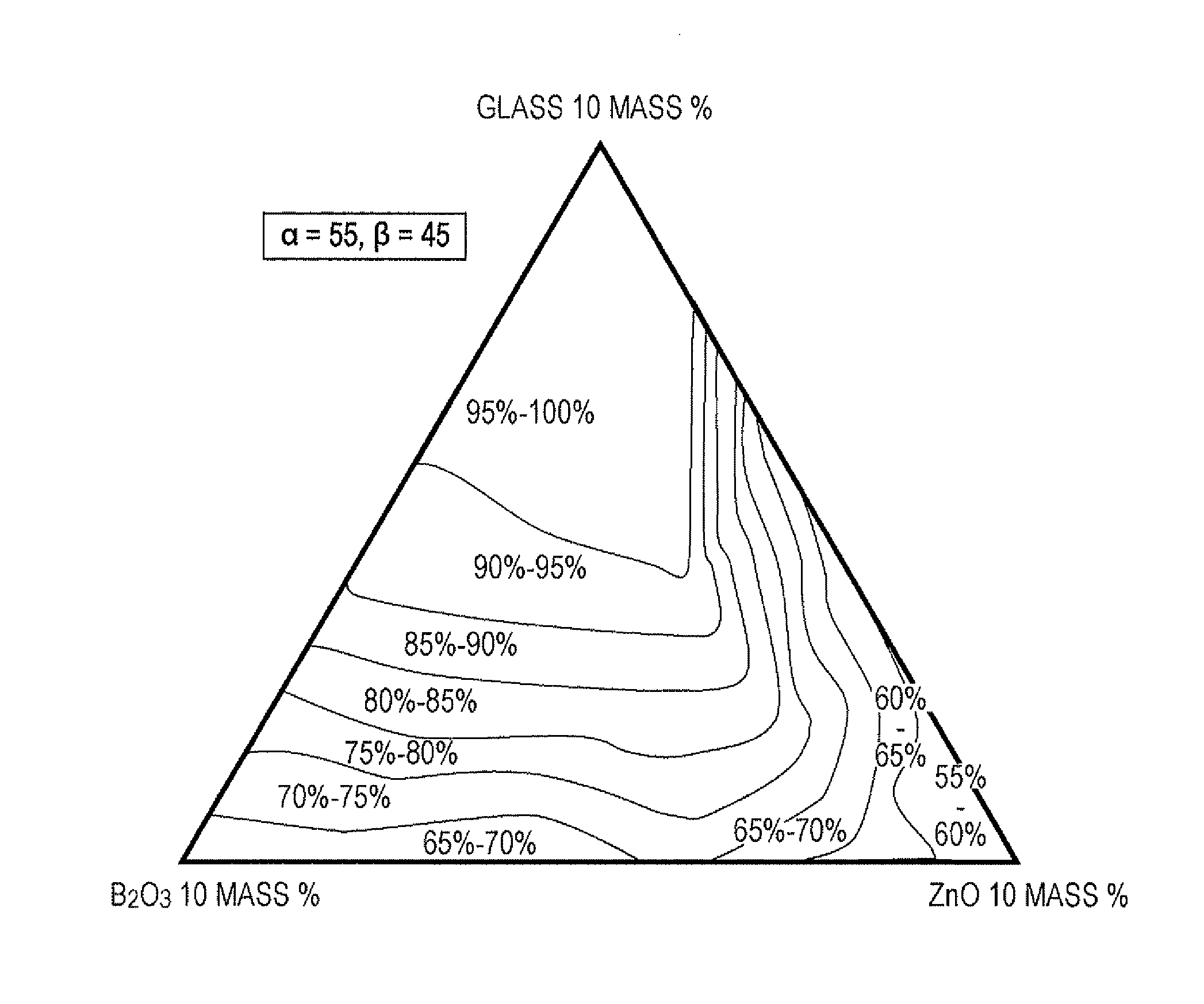

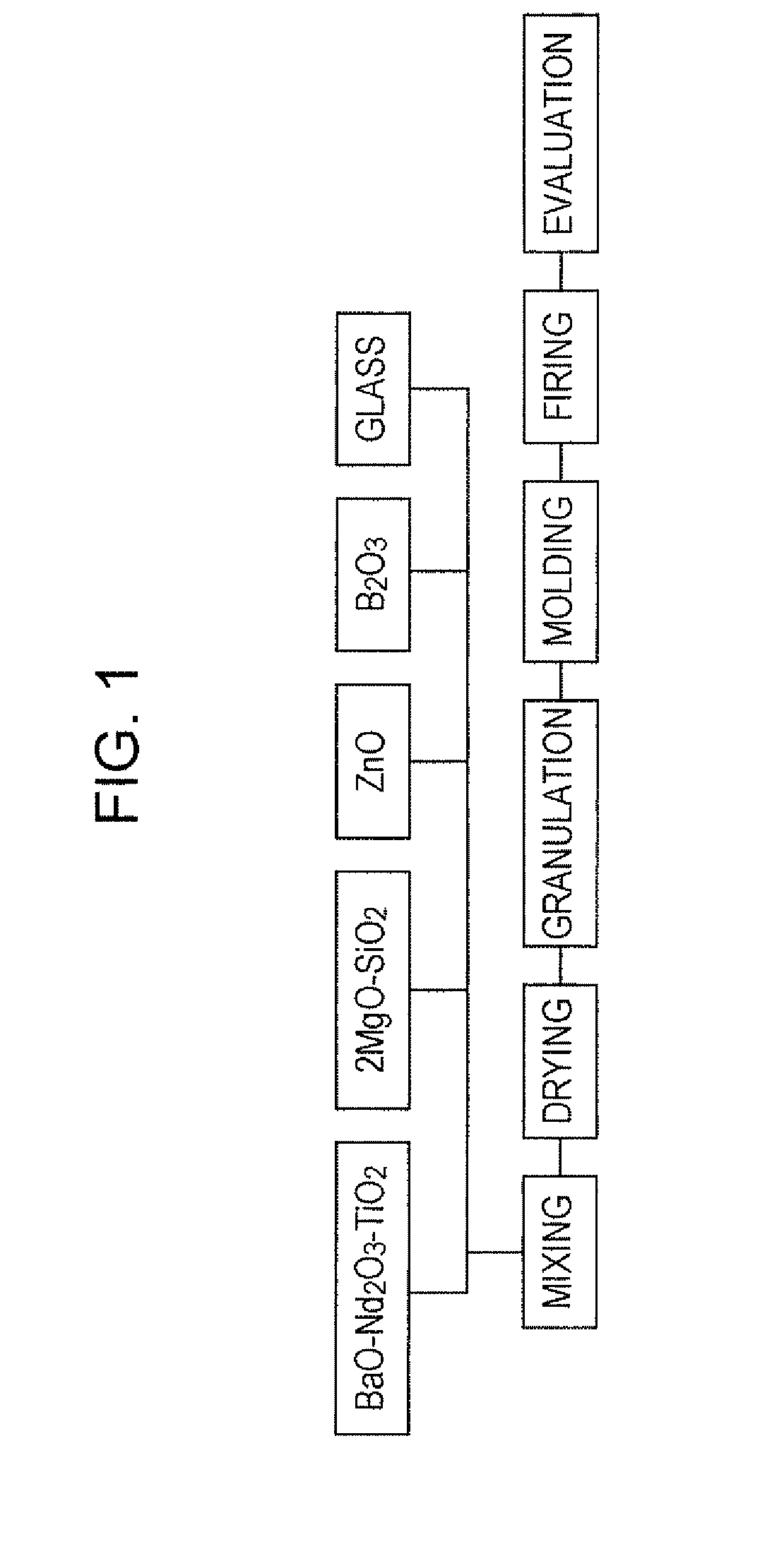

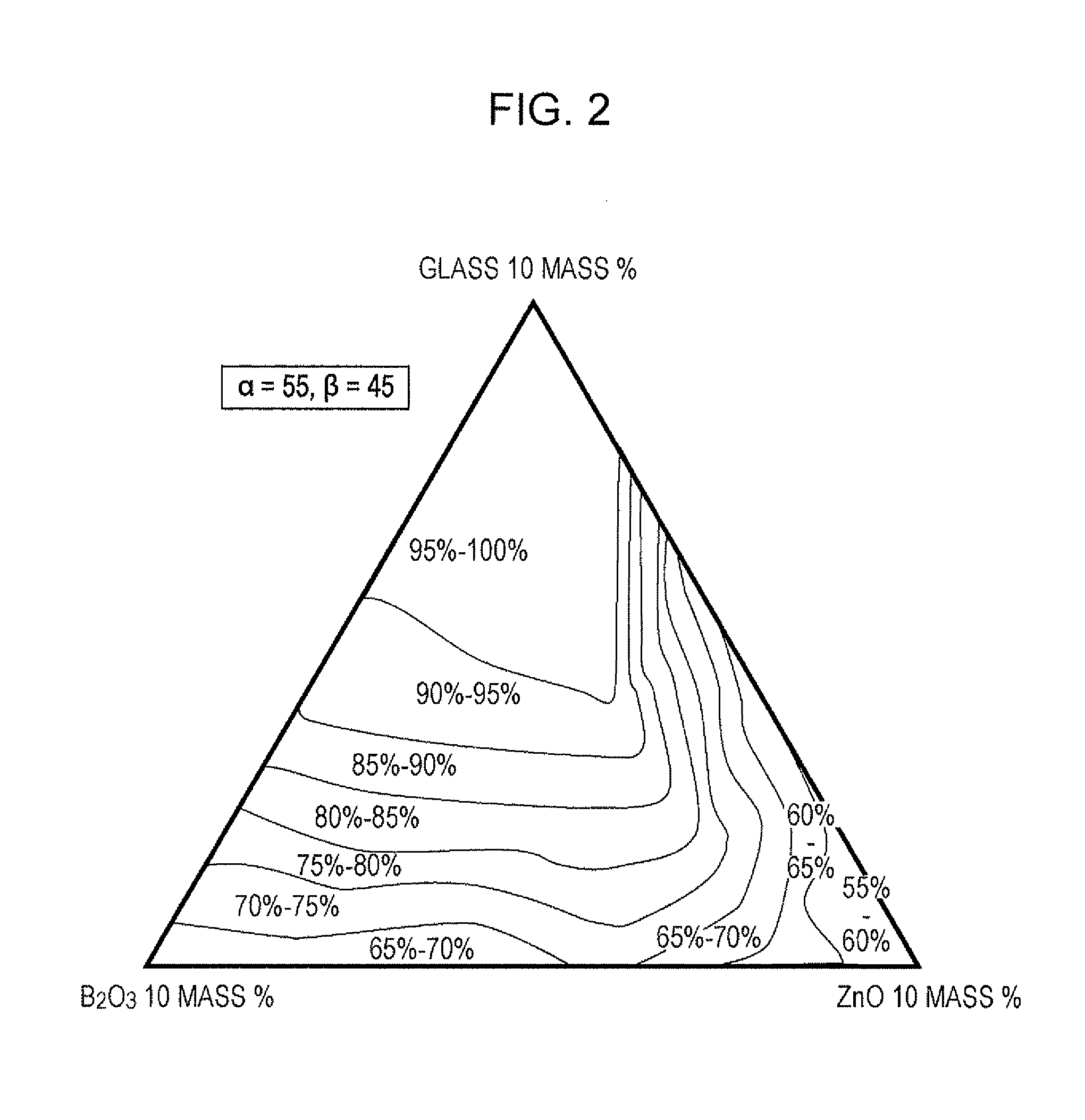

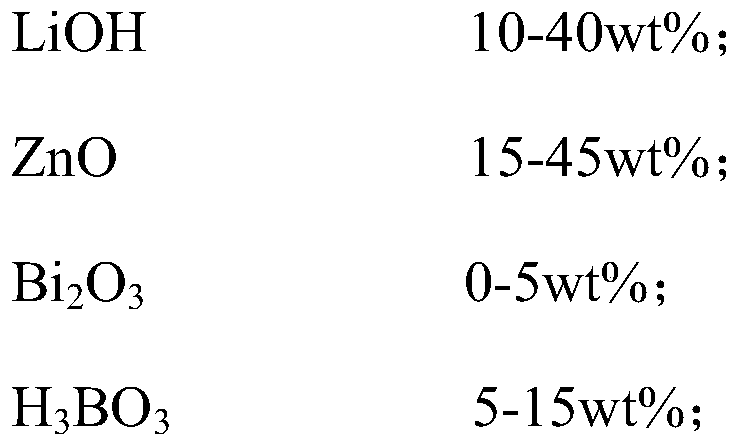

Dielectric ceramic composition

A dielectric ceramic composition includes a component represented by composition formula {α(xBaO.yNd2O3.zTiO2)+β(2MgO.SO2)} as a main component and zinc oxide, boron oxide, and a glass having a softening point equal to or lower than a certain temperature as minor components with respect to the main component. In the dielectric ceramic composition, x, y, and z that respectively represent molar ratios of BaO, Nd2O3, and TiO2 are in certain ranges and α and β that represent volume ratios of subcomponents (xBaO.yNd2O3.zTiO2 and 2MgO.SiO2) in the main component are in certain ranges. When the minor components are respectively represented by aZnO, bB2O3, and cglass, a, b, and c that represent mass ratios of the respective minor components to the main component are in certain ranges.

Owner:TDK CORPARATION

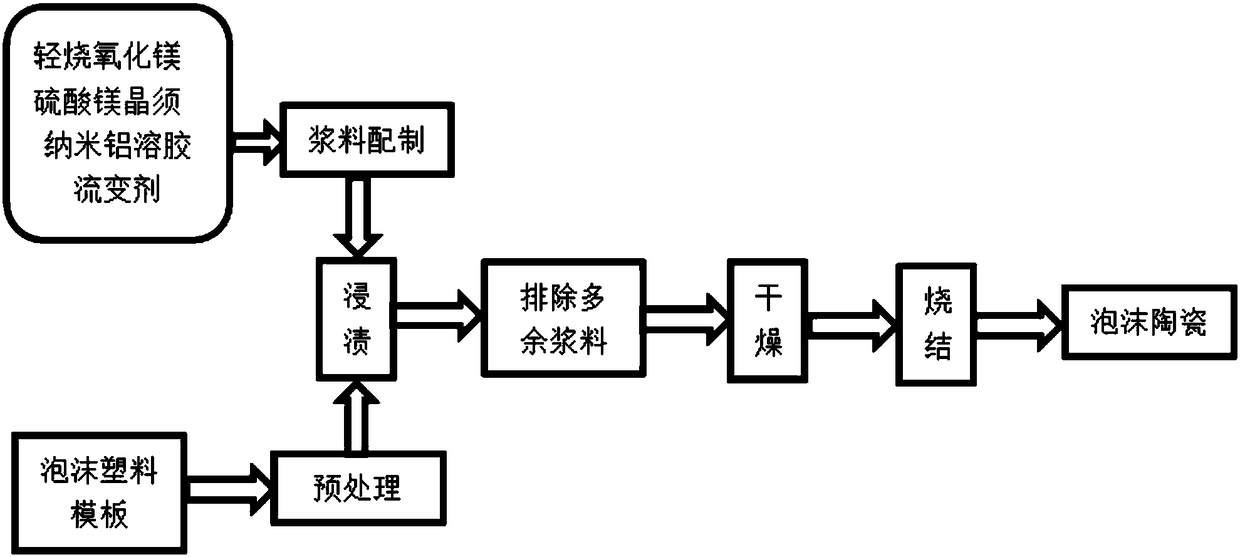

Basic magnesium sulfate whisker in-situ synthesized magnesium-aluminum spinel reinforced magnesium oxide based foamed ceramic filter and preparation method thereof

ActiveCN108530094ASimple processLow costProcess efficiency improvementCeramicwareOxide ceramicSlurry

The invention discloses a basic magnesium sulfate whisker in-situ synthesized magnesium-aluminum spinel reinforced magnesium oxide based foamed ceramic filter that can realize sintering at lower temperature and has excellent chemical stability and thermal shock resistance and a preparation method thereof. The preparation method comprises the steps of: (1) by mass percentage, blending 15%-25% of nano-aluminum sol, 0.8%-1.5% of a rheological agent, and the balance magnesium oxide ceramic powder containing basic magnesium sulfate whisker, adding anhydrous ethanol, performing ball-milling and uniform mixing to obtain a ceramic slurry with a solid content of 60%-70%; (2) immersing a polyurethane foam plastic template into the ceramic slurry, extruding the polyurethane foam plastic template by aroller press to remove redundant hung slurry for making a green body, then removing an ethanol solvent in a 40DEG C-50DEG C ventilation room, and drying the green body; and (3) putting the dried green body into a sintering furnace, performing heating to 1350DEG C-1550DEG C for high temperature sintering, and conducting furnace cooling to room temperature, thus obtaining the magnesium oxide basedfoamed ceramic filter.

Owner:FENGYANG L S NET FORMING CO LTD +1

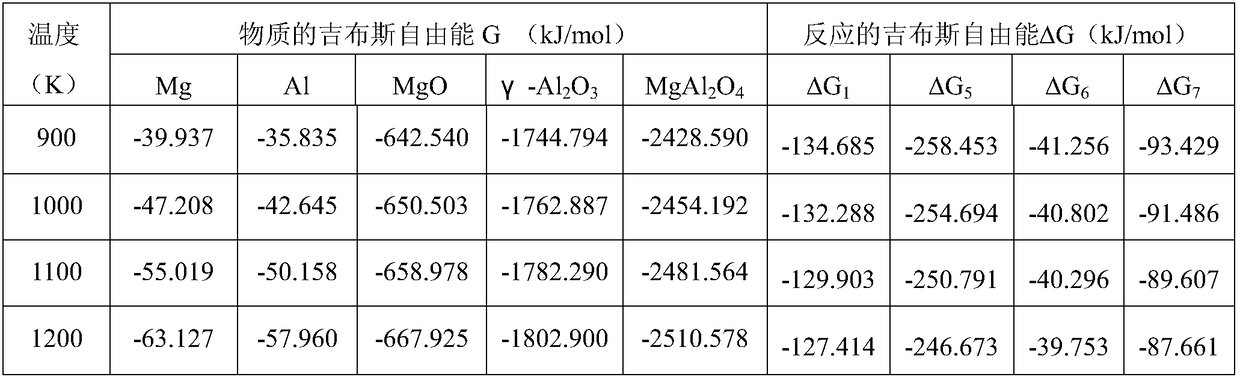

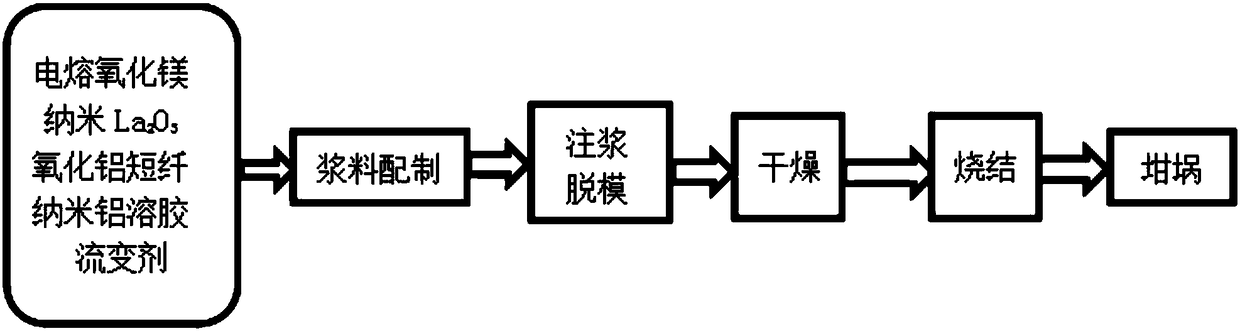

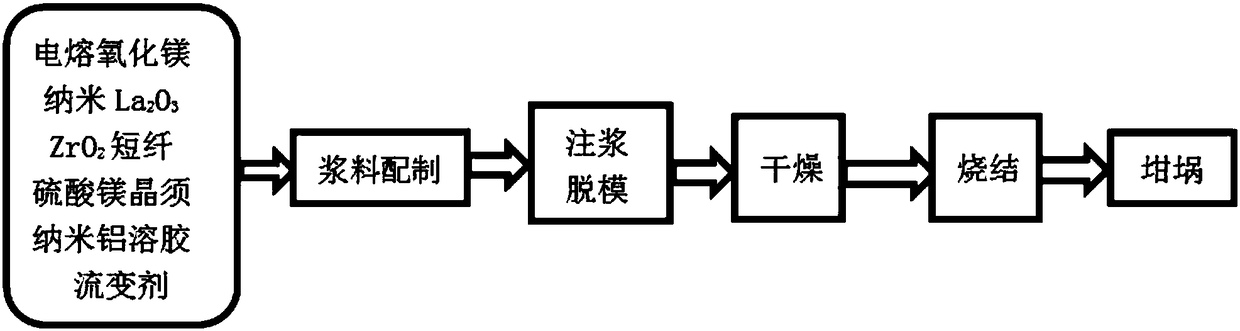

Alumina short fiber-reinforced magnesium oxide-based crucible and preparation method thereof

The invention discloses an alumina short fiber-reinforced magnesium oxide-based crucible which is excellent in chemical stability and thermal shock resistance, and can realize sintering at a low temperature and a preparation method thereof, the method comprises the following steps: (1) proportioning, by mass, 15% to 25% of nano-aluminum sol, 0.8% to 1.5% of a rheological agent, and balance of electro-fused magnesium oxide ceramic powder containing nano-lanthana and alumina short fiber, adding an appropriate amount of deionized water, uniformly mixing by ball milling, and vacuum degassing to obtain a ceramic slurry having a solid content of 70% to 80%; (2) preparing a crucible biscuit; (3) preparing a crucible blank; and (4) putting the magnesium oxide-based crucible blank in the aluminum sol for vacuum impregnation treatment, grinding the surface, drying, performing high-temperature secondary sintering at a temperature of 1400 to 1600 DEG C, and cooling in a furnace to room temperatureto obtain the magnesia-based crucible.

Owner:FENGYANG L S NET FORMING CO LTD +1

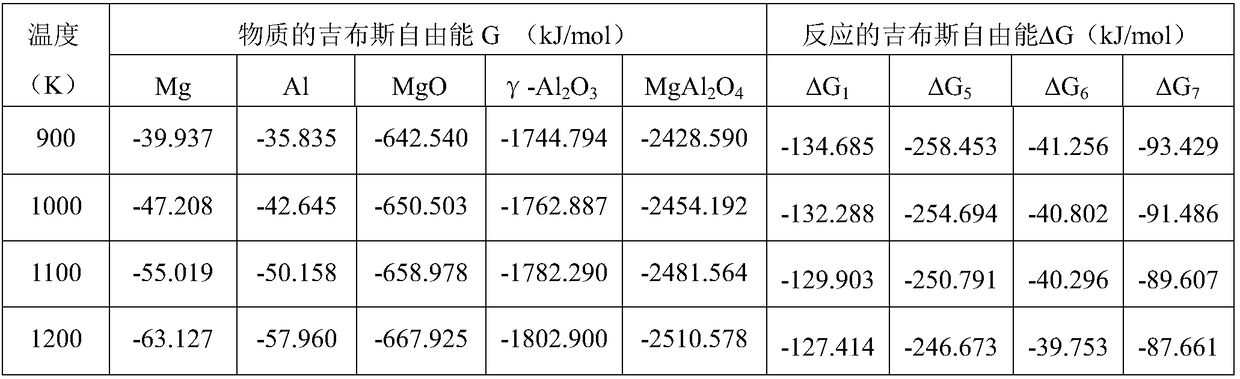

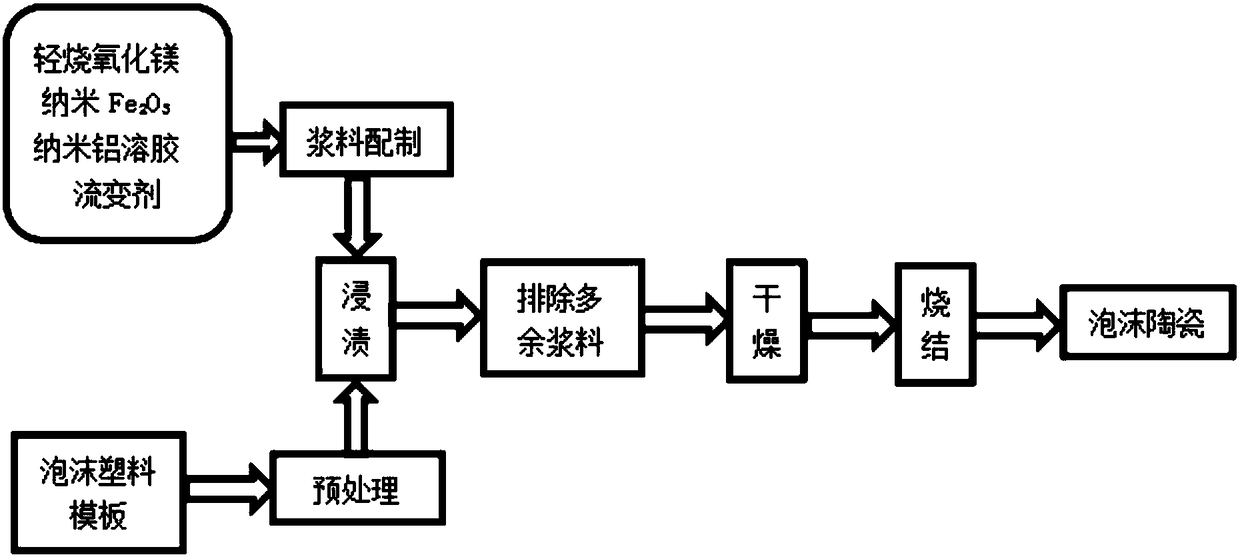

MA-MF composite spinel reinforced magnesium oxide based foam ceramic filter and preparation method thereof

The invention discloses a MA-MF composite spinel reinforced magnesium oxide based foam ceramic filter capable of realizing low temperature sintering and excellent chemical stability and thermal shockresistance and a preparation method thereof, the preparation method comprises the following steps: (1) proportioning 15% to 25% by mass of nano-aluminum sol, 0.8% to 1.5% by mass of a rheological agent, and balance of magnesium oxide ceramic powder containing a nano-ferric oxide sintering aid, and adding anhydrous ethanol for even mixing by ball milling to obtain ceramic slurry having a solid content of 60% to 70%; (2) immersing a polyurethane foam plastic template into the ceramic slurry, extruding the polyurethane foam plastic template by a roll press to remove excess immersing slurry to obtain a green body, and removing an ethanol solvent in a ventilating chamber at 40 DEG C to 50 DEG C to dry the green body; and (3) putting the dried green body in a sintering furnace, heating to 1350 to 1550 DEG C for high temperature sintering, and cooling in the furnace to room temperature to obtain the magnesium oxide based ceramic foam filter.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

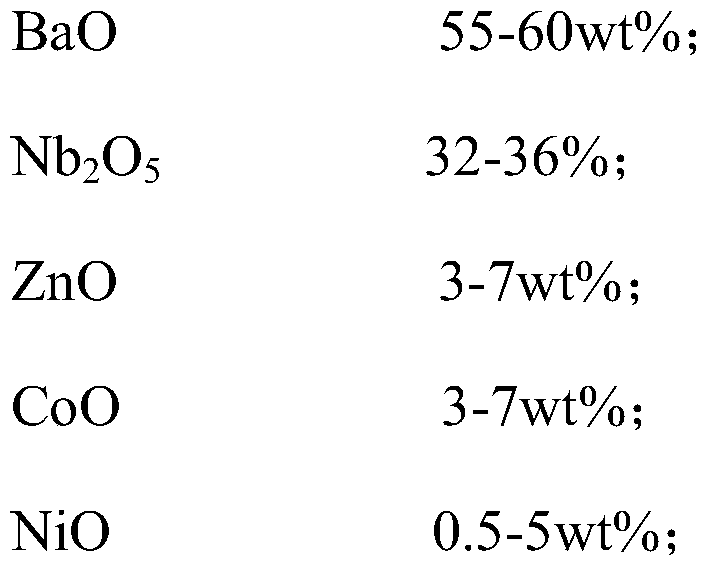

Barium niobate system microwave dielectric ceramic material and preparation method and application thereof

ActiveCN111116197ALower sintering temperatureImprove Microwave PerformanceResonatorsDielectricMicrowave

The invention belongs to the technical field of microwave dielectric ceramic materials, and particularly relates to a barium niobate system microwave dielectric ceramic material. BaCO3, Nb2O5, ZnO, CoO and NiO are used as raw materials to synthesize a main sintering block, SiO2, BaO, CaO, B2O3 and Li2O are used as raw materials to synthesize low-melting-point glass powder, and then the main sintering block and the low-melting-point glass powder are mixed and dispersed to obtain the required barium niobate system microwave dielectric ceramic material. The dielectric constant of the microwave dielectric ceramic material reaches 33-36, f*Q at 25 DEG C is larger than 80000, the frequency temperature coefficient calculated by testing the resonant frequencies f at -40 DEG C, 25 DEG C and 110 DEGC is low and is only -5 ppm / DEG C to 5 ppm / DEG C, and the performance of the microwave dielectric ceramic material meets the requirements of microwave dielectric ceramic devices. Meanwhile, the material also has relatively good dielectric properties in a millimeter wave frequency band, and the method can be used for producing ceramic devices such as filters and resonators.

Owner:SHANDONG SINOCERA FUNCTIONAL MATERIAL CO LTD

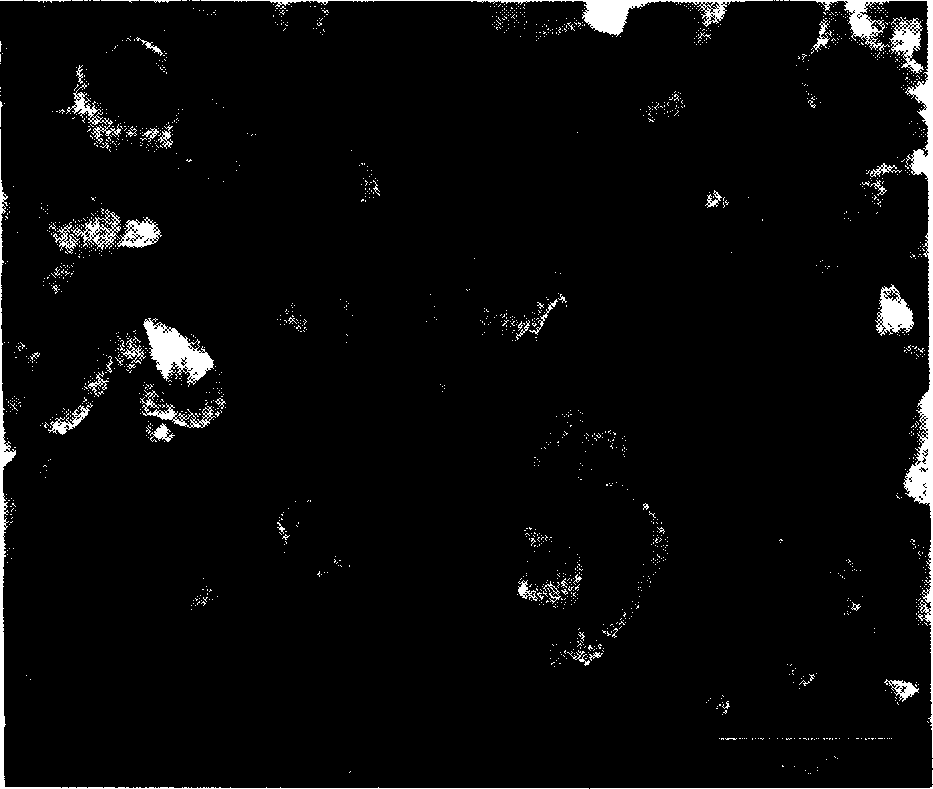

Metal nanoparticle-protecting polymer and metal colloidal solution, and method for producing same

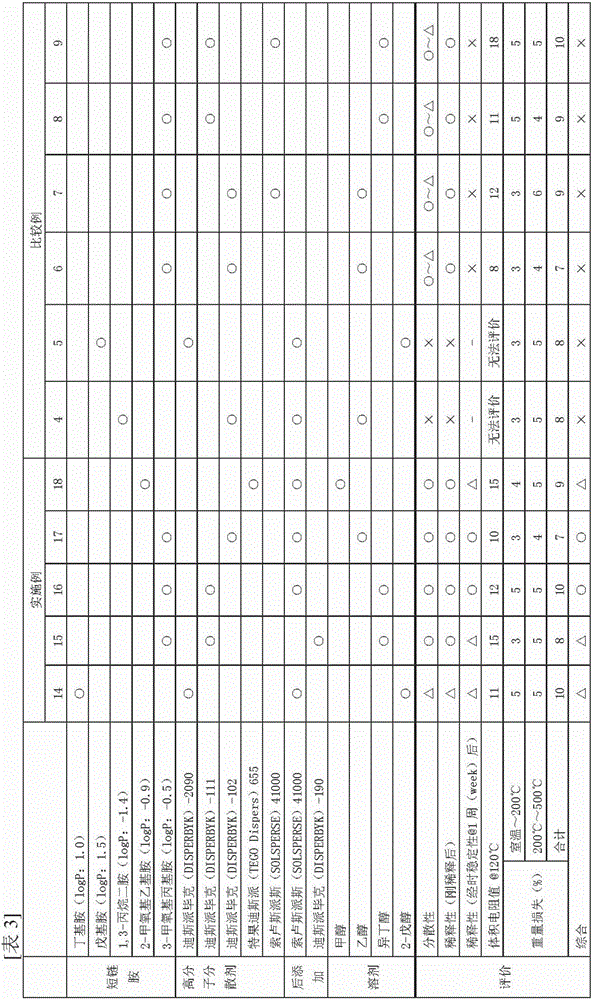

ActiveCN105164183AGood low temperature sintering performanceEasy to break awayMaterials sciencePolymer

A metal nanoparticle-protecting polymer includes a polyacetylalkylenimine segment (A) in which 5 to 100 mol% of primary amines in polyalkylenimine are acetylated and 0 to 50 mol% of secondary amines in polyalkylenimine are acetylated, and a hydrophilic segment (B) in a molecule. Also provided are a method for producing the metal nanoparticle-protecting polymer,a metal colloidal solution including a medium and composite bodies dispersed in the medium, each composite body containing a metal nanoparticle protected with the metal nanoparticle-protecting polymer, and a method for producing the metal colloidal solution.

Owner:DIC CORP

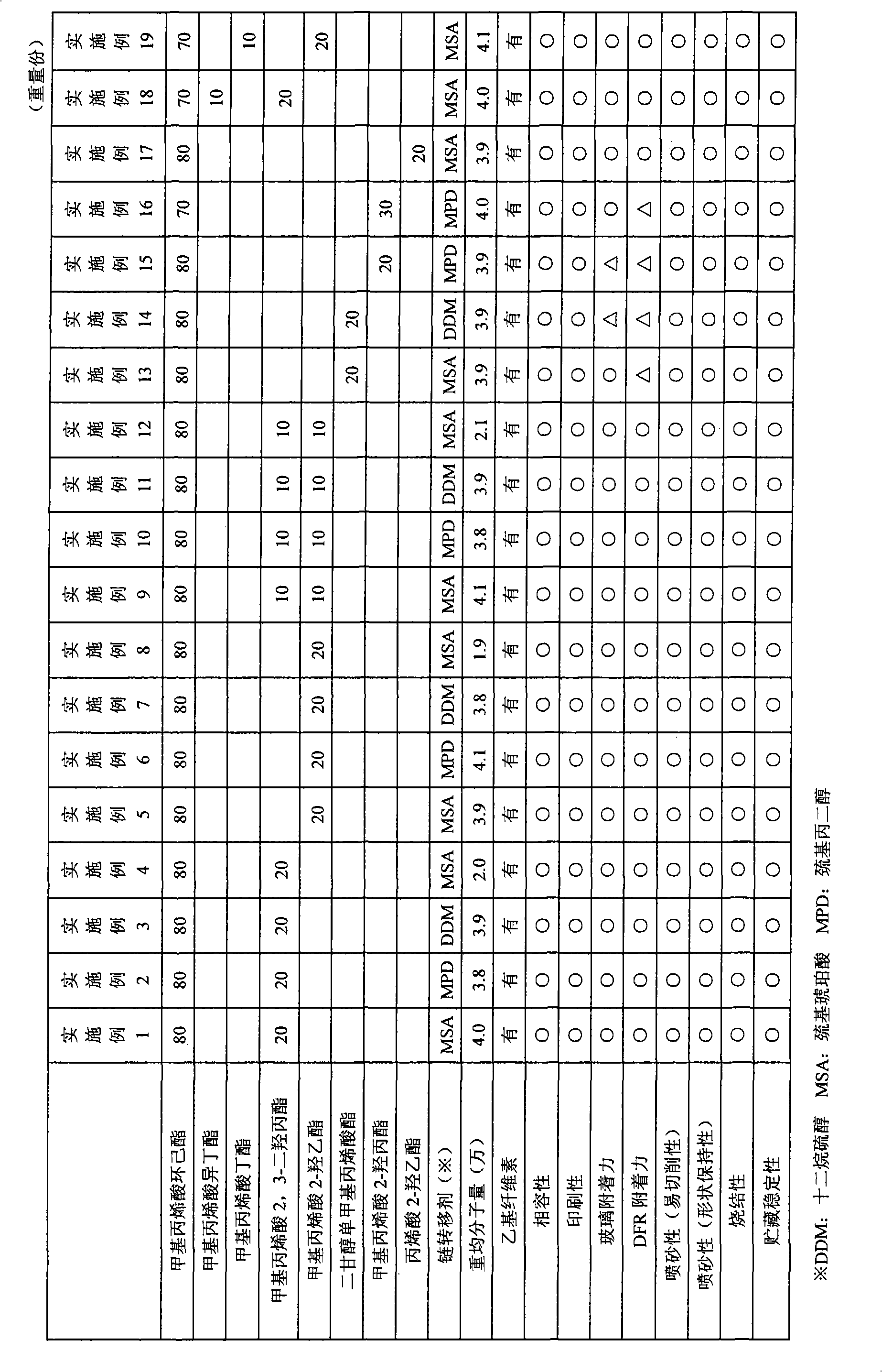

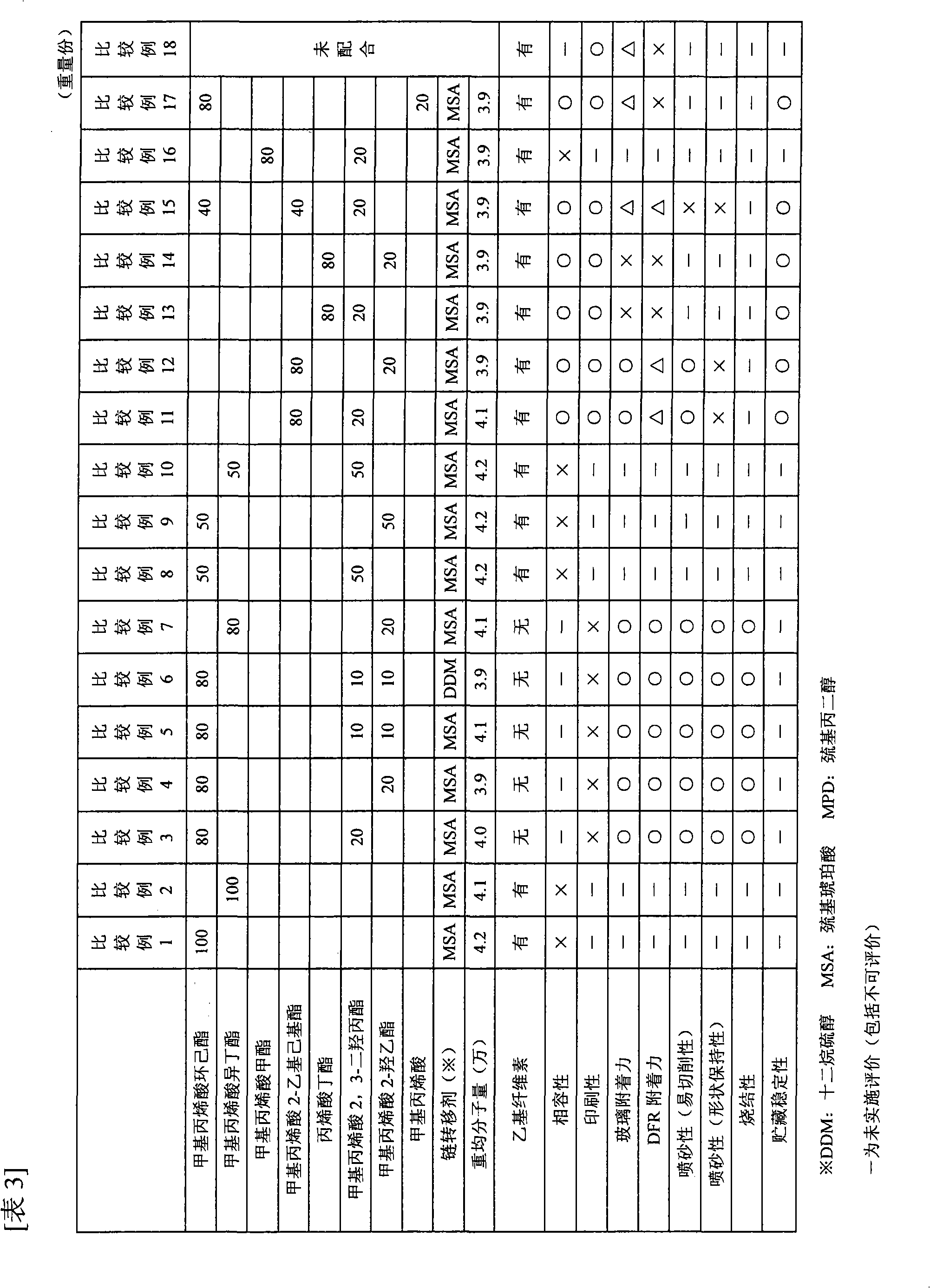

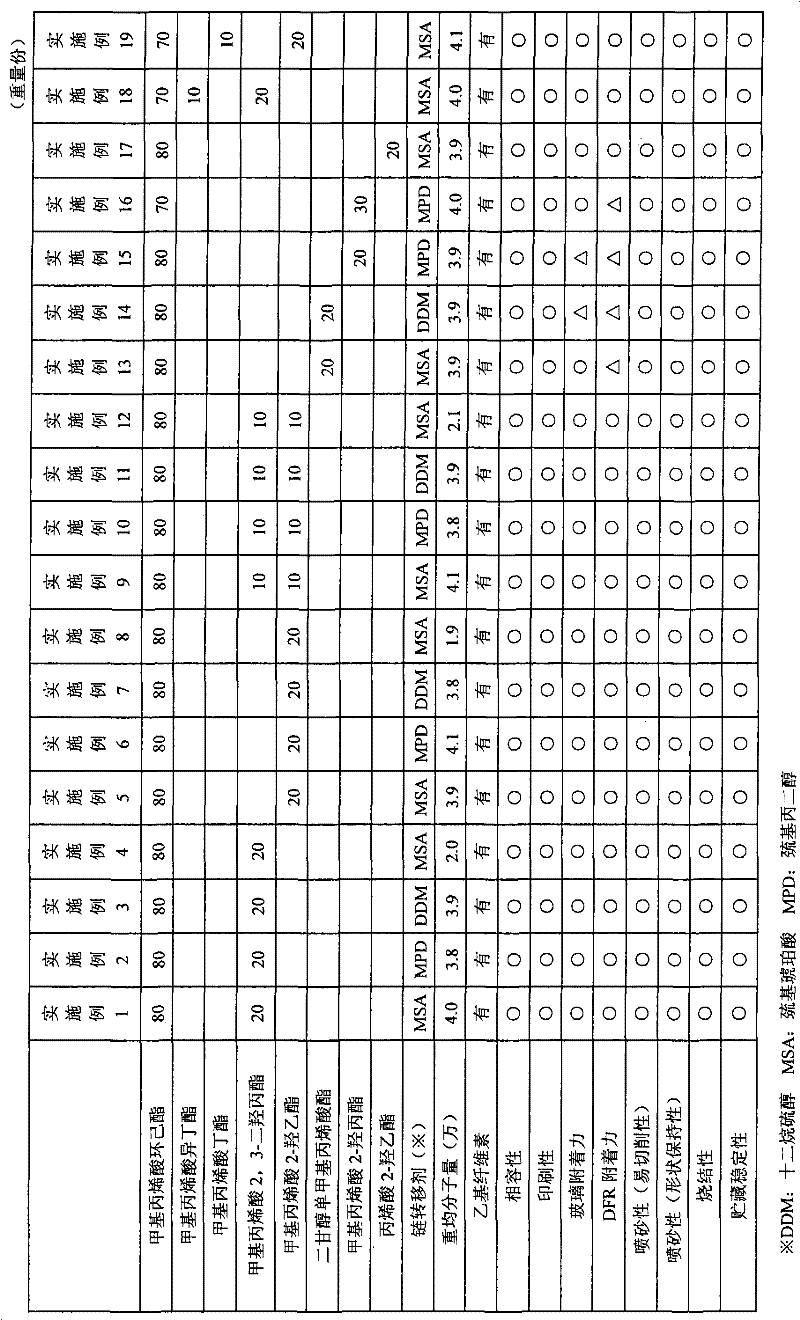

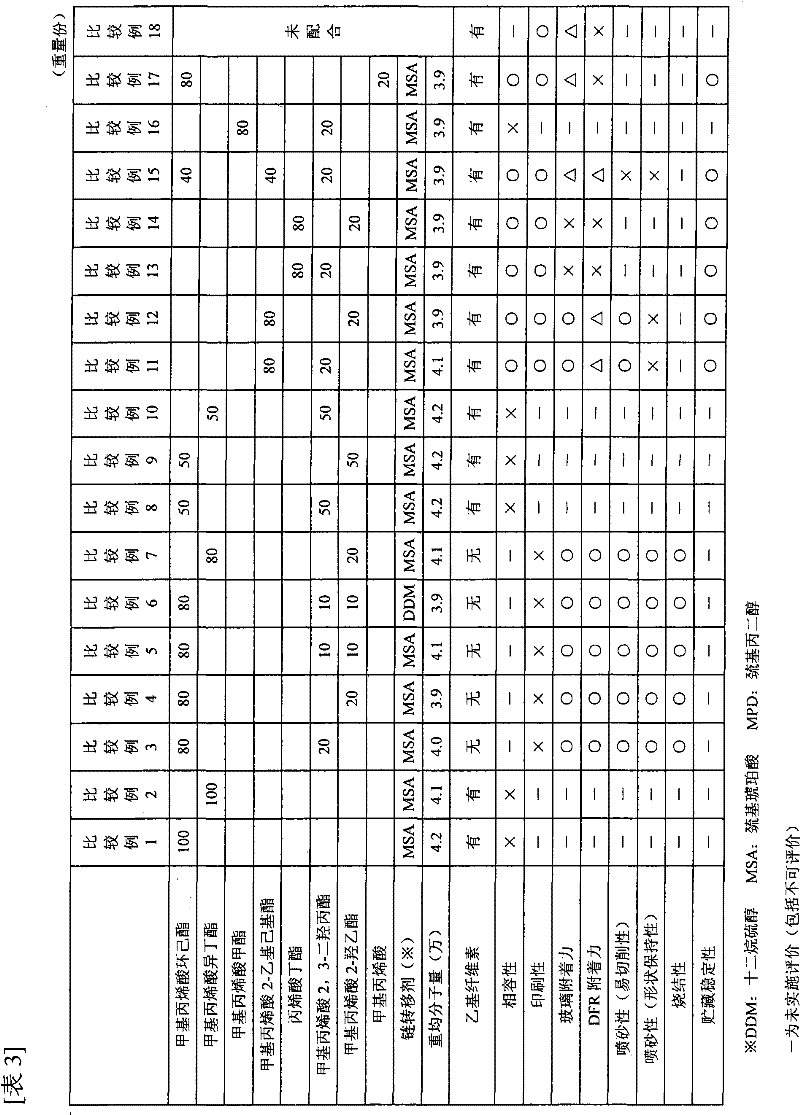

Glass paste

Disclosed is a glass paste which is excellent in compatibility of a binder resin component, adhesion to a substrate / dry film resist (DFR), and low-temperature sinterability. This glass paste can be easily ground by sandblasting without causing a breakdown of a partition wall since it has high dried film strength. Specifically disclosed is a glass paste containing a (meth)acrylate copolymer, a cellulose resin, a glass powder and an organic solvent. The (meth)acrylate copolymer is composed of at least one (meth)acrylate monomer A selected from the group consisting of cyclohexyl(meth)acrylate, isobutyl(meth)acrylate, isobornyl(meth)acrylate, ethyl methacrylate, n-propyl methacrylate and isopropyl methacrylate, and a (meth)acrylate monomer B having one or more hydroxy groups. The composition ratio of the (meth)acrylate monomer A in the (meth)acrylate copolymer is 60-99.9% by weight, while the composition ratio of the (meth)acrylate monomer B having one or more hydroxy groups is 0.1-40% by weight.

Owner:SEKISUI CHEM CO LTD

Magnesium oxide whisker in-situ synthesized spinel reinforced magnesium oxide-based crucible and preparation method of crucible

The invention discloses a magnesium oxide whisker in-situ synthesized spinel reinforced magnesium oxide-based crucible which can be sintered under low temperature and is outstanding in chemical stability and thermal shock resistance and a preparation method of the crucible. The method comprises the following steps: (1) mixing 15-25% by mass of nano alumina sol, 0.8-1.5% by mass of a rheological agent, and the balance of nanometer titania sintering additive containing magnesium oxide ceramic powder; adding absolute ethyl alcohol; performing ball milling; uniformly mixing to obtain ceramic sizing containing 65-75% of solid content; (2) preparing a crucible biscuit; (3) preparing a crucible blank; (4) preparing vacuum infiltration on the magnesium oxide-based crucible blank in the aluminum sol; polishing the surface; drying; then sintering for the second time under high temperature of 1350-1550 DEG C; then cooling along with the furnace until room temperature so as to obtain the magnesiumoxide-based crucible.

Owner:FENGYANG L S NET FORMING CO LTD +1

Dielectric ceramic composition

ActiveUS8841226B2Good low temperature sintering performanceGood chemical resistanceFixed capacitorsBoron oxideZinc

A dielectric ceramic composition includes a component represented by composition formula {α(xBaO.yNd2O3.zTiO2)+β(2MgO.SO2)} as a main component and zinc oxide, boron oxide, and a glass having a softening point equal to or lower than a certain temperature as minor components with respect to the main component. In the dielectric ceramic composition, x, y, and z that respectively represent molar ratios of BaO, Nd2O3, and TiO2 are in certain ranges and α and β that represent volume ratios of subcomponents (xBaO.yNd2O3.zTiO2 and 2MgO.SiO2) in the main component are in certain ranges. When the minor components are respectively represented by aZnO, bB2O3, and cglass, a, b, and c that represent mass ratios of the respective minor components to the main component are in certain ranges.

Owner:TDK CORPARATION

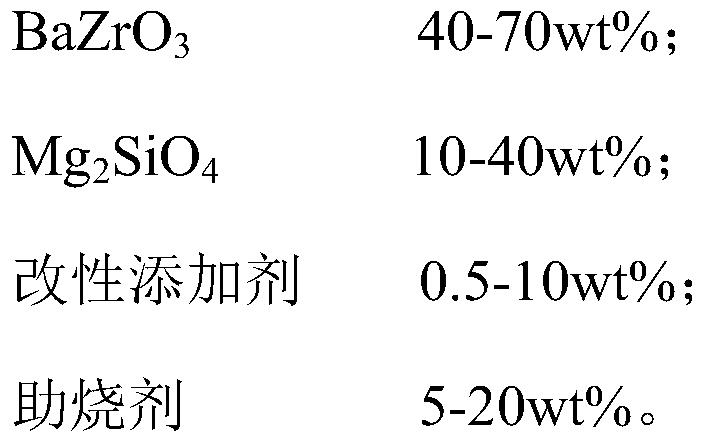

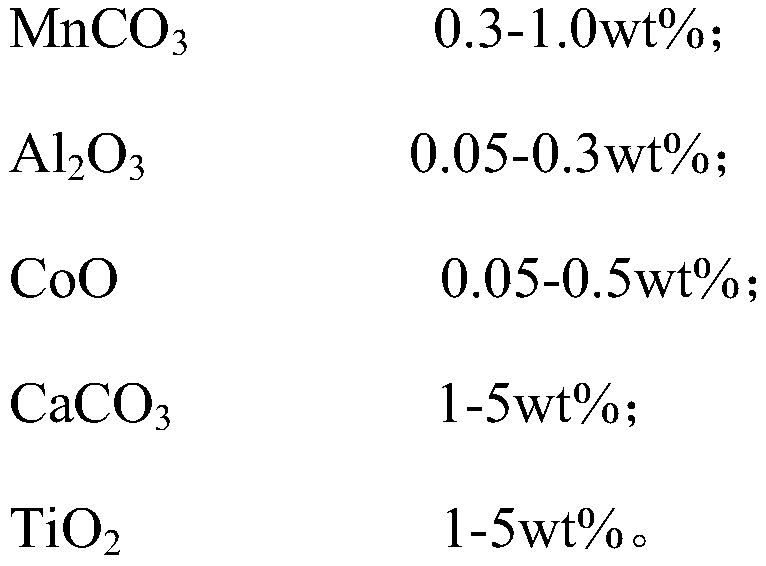

Low-sintering microwave dielectric ceramic material and preparation method thereof

ActiveCN111320473AGood low temperature sinterabilityGood low temperature sintering performanceLow-k dielectricMicrowave

The invention belongs to the technical field of microwave dielectric materials, and particularly relates to a BaZrO3 system low-temperature sintering low-dielectric-constant C0G microwave dielectric material and a preparation method thereof. The invention relates to the low-sintering microwave dielectric ceramic material, the material is prepared by doping a modifying additive and a sintering aidwith selected components and proportions, the dielectric constant of the obtained microwave dielectric ceramic material can reach 12-16, the Q*f value is 30000-50000, especially the sintering temperature of the material can reach 950 DEG C or below, TCC of the microwave dielectric ceramic material meets the C0G specification, and the microwave dielectric ceramic material has good low-temperature sintering performance and can be used for manufacturing microwave devices such as MLCC and microwave antennas.

Owner:SHANDONG SINOCERA FUNCTIONAL MATERIAL CO LTD

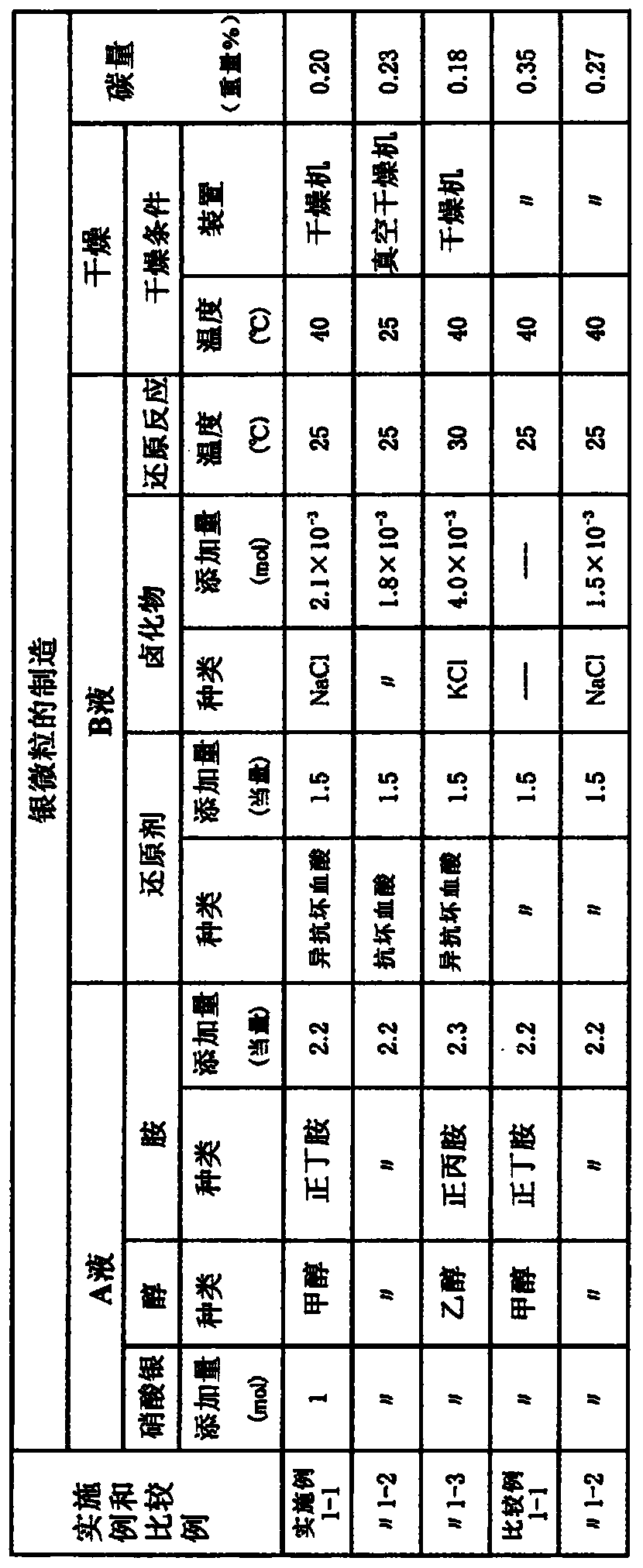

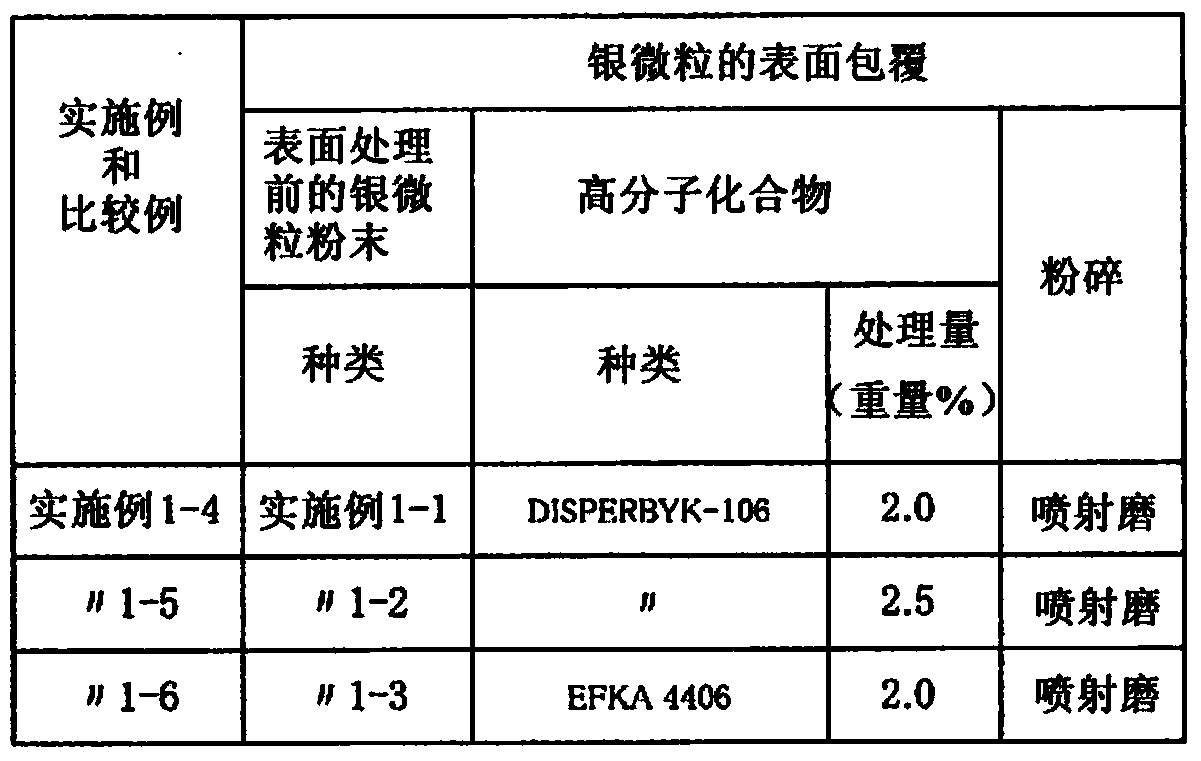

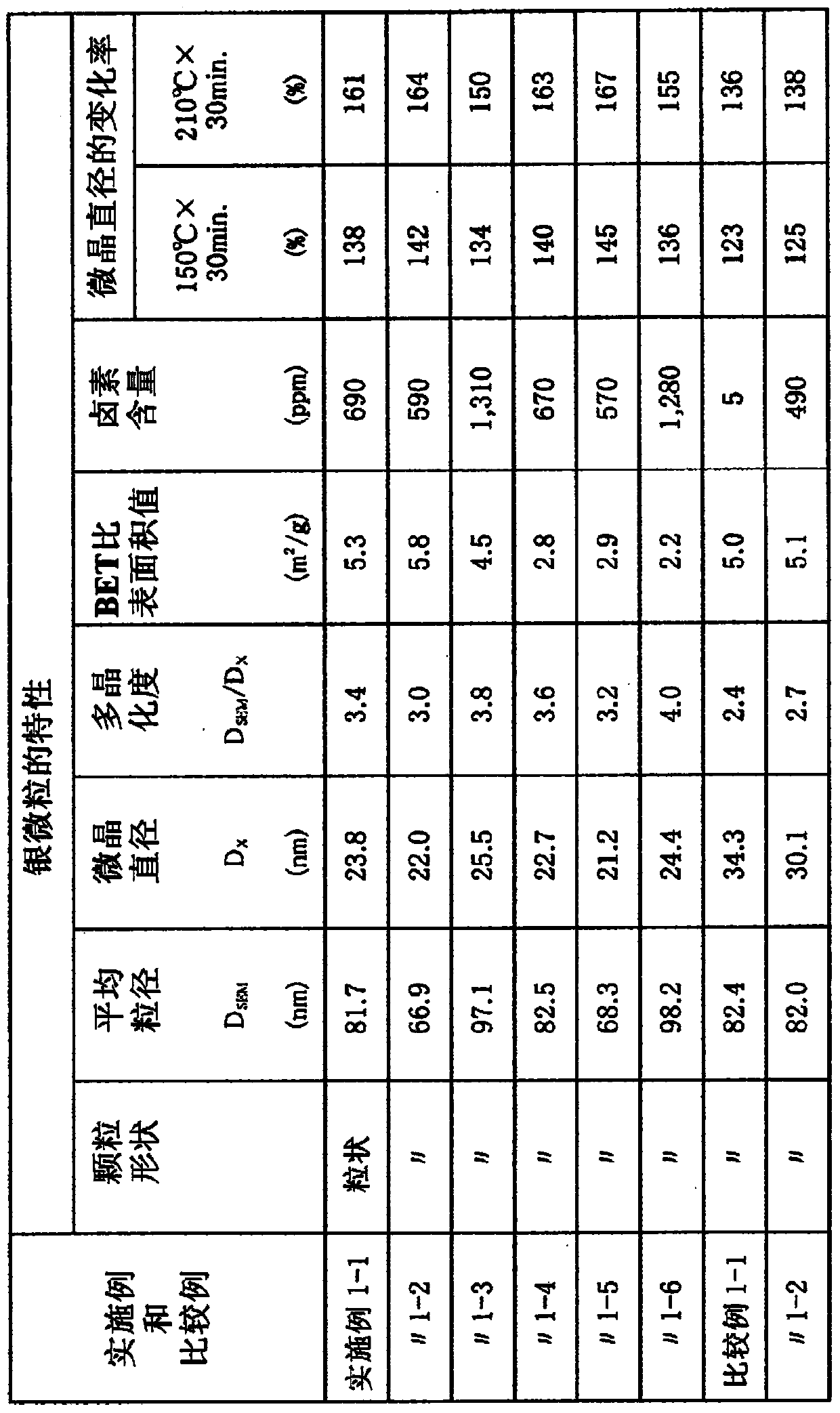

Silver fine particles, production process therefor, conductive paste, conductive membrane and electronic device, containing said silver fine particles

InactiveCN104010752AReduce carbon contentHigh yieldMaterial nanotechnologyConductive layers on insulating-supportsWater solubleConductive membrane

The present invention pertains to: silver fine particles with excellent low-temperature sinterability; a production process therefor; and a conductive paste, a conductive membrane and an electronic device, containing the silver fine particles. In a process for producing silver fine particles which comprises preparing an alcoholic solution (A) of a silver nitrate-amine complex prepared using silver nitrate and at least one water-soluble C2-4 aliphatic amine, preparing, separately from the solution (A), an aqueous solution (B) in which either ascorbic acid or erythorbic acid and a halide are dissolved, adding a mixture of the solution (A) with the solution (B) into a vessel in which water has been put, stirring the resulting mixture, and then subjecting the thus obtained silver fine particles to washing and drying, at least 1.6*10<-3> mol of a halide per mol of silver nitrate is added to the solution (B), whereby an aggregate silver fine particle slurry can be obtained to facilitate the subsequent washing. Thus, silver fine particles which have a carbon content of 0.25wt% or less and thus exhibit excellent low-temperature sinterability can be obtained.

Owner:TODA IND

Silver particle dispersion and process for producing the same

InactiveCN101584010AGood dispersionGood low temperature sintering performanceMaterial nanotechnologyConductive materialPolyolAlcohol

A silver particle dispersion which is a dispersion of silver particles in a liquid organic medium which has a boiling point of 60-300 DEG C and is nonpolar or lowly polar, the surface of the particles being coated with an organic protective material and the particles having an average particle diameter (DTEM) of 50 nm or smaller. It is characterized in that the organic protective material is an amine compound having one or more unsaturated bonds per molecule. This silver particle dispersion can be produced by reducing a silver compound in a liquid comprising one or more alcohols or polyols which function as a reducing agent, the reduction reaction being conducted in the presence of an amine compound having one or more unsaturated bonds per molecule and having a molecular weight of 100-1,000.

Owner:DOWA ELECTRONICS MATERIALS CO LTD

Zirconium dioxide short fiber and basic magnesium sulfate whisker composite enhanced magnesia-based crucible and preparation method thereof

The invention discloses a preparation method of a zirconium dioxide short fiber and basic magnesium sulfate whisker composite enhanced magnesia-based crucible which can be sintered at the low temperature and has excellent chemical stability and thermal shock resistance. The method comprises steps as follows: (1) 15%-25% of nano aluminum sol, 0.8%-1.5% of a rheological agent and the balance of fused magnesia ceramic powder containing nano lanthanum oxide, zirconium dioxide short fiber and basic magnesium sulfate whisker are prepared in percentage by mass, deionized water is added, the mixture is subjected to ball milling and mixed uniformly, then, vacuum exhausting is performed, and ceramic slurry with the solid content of 70%-80% is prepared; (2) a crucible biscuit is prepared; (3) the dried biscuit is put in a sintering furnace to be sintered at the high temperature and then cooled with the furnace, and a magnesia-based crucible blank is obtained; (4) the magnesia-based crucible blankis subjected to vacuum impregnation treatment in aluminum sol, then, surface polishing treatment is performed, high-temperature secondary sintering is performed after drying, a product is cooled withthe furnace to the room temperature, and the magnesia-based crucible is obtained.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Preparation and application of high-potential gradient zinc oxide piezoresistor material

Owner:EAST CHINA NORMAL UNIV

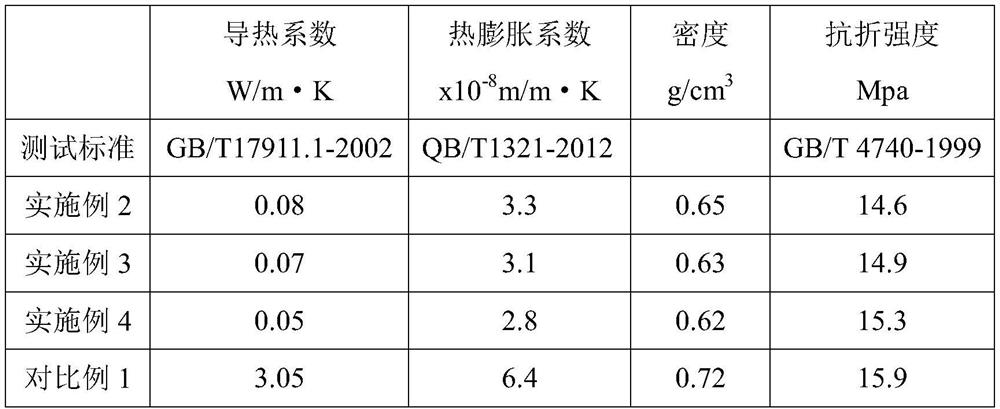

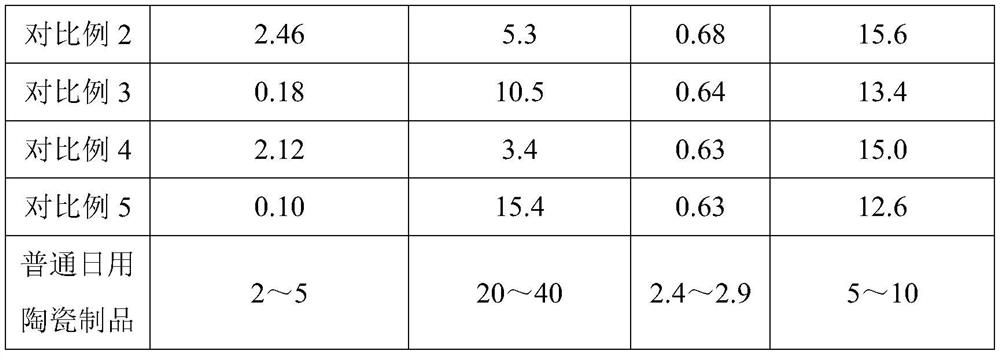

A kind of daily-use ceramic product with good thermal insulation performance and preparation method thereof

ActiveCN111548126BImprove high temperature resistanceImprove mechanical propertiesClaywaresThermal dilatationFiber

The invention discloses a daily-use ceramic product with good thermal insulation performance and a preparation method thereof. The daily-use ceramic product with good thermal insulation performance is made from the following raw materials by weight: 20-26 parts of albite, anorthite 15-19 parts, 30-40 parts of calcite, 25-32 parts of attapulgite, 10-14 parts of sodium bentonite, 5-7 parts of monetite, 10-14 parts of quartz, 8-8 parts of aluminum silicate fiber tube 11 parts, 4-5.5 parts of sodium silicate, 2.2-3 parts of foaming agent, 0.9-1.3 parts of foam stabilizer, and 0.8-1.1 parts of water reducing agent. The daily-use ceramic product with good thermal insulation performance of the invention has low thermal conductivity and good thermal insulation performance; small thermal expansion coefficient, small thermal expansion, good high temperature resistance; , the overall performance is good.

Owner:FUJIAN PROVINCE DEHUA COUNTY GRANGTOP CERAMICS CO LTD

LED plant growth warm white fluorescent powder and preparation method thereof

PendingCN112175619AImprove luminous performanceGood low temperature sintering performanceSaving energy measuresEnergy efficient lightingTungstenHydrothermal synthesis

The invention discloses a LED plant growth warm white fluorescent powder and a preparation method thereof. The chemical formula of the fluorescent powder is RM<x>Y<y> (WO<4>)<3y / 2> (PO<4>)< (1 + 2X) / 3>: aEu<3+>, bMn<4+>, wherein R is one of Li, Rb, Cs or In, M is one of Ca, Sr, Ba or Mg, 0.1 < = x < = 0.75, 0.2 < = y < = 0.55, and 0.1 < = a < 0.8, 0.3<=b<2. The method comprises steps: grinding ina mortar, mixing R2CO3 and M3(PO3)2, dropwise adding a mixed solution of R2CO3 and M3(PO3)2, adding RMnO4, stirring, taking an obtained precipitate for hydrothermal reaction, and mixing with Eu2O3 toobtain a precursor powder; carrying out high-temperature firing in a reducing atmosphere, adopting an alkaline-earth metal and Y co-doped mixed tungsten phosphate system as a matrix material, codopingEu < 3 + > and Mn < 4 + > to serve as activated light-emitting particles, transferring excitation energy from R3 to sensitized Mn < 4 + >, carrying out gradient temperature control firing treatment after a precursor is prepared through a hydrothermal synthesis method, so that activity and light-emitting efficiency are improved, and concentration quenching effect is overcome. The problems of insufficient stability and deliquescence pollution are avoided, and the requirements of red fluorescent powder for growth of warm white LED plants are met.

Owner:DONGTAI TIANYUAN FLUORESCENT MATERIALS CO LTD

MA-M2T spinel solid liquor enhanced magnesium oxide based foam ceramic filter and preparation method thereof

ActiveCN108439957AAvoid damageIncrease vacanciesSemi-permeable membranesMembrane filtersOxide ceramicSlurry

The invention discloses an MA-M2T spinel solid liquor enhanced magnesium oxide based foam ceramic filter which can realize sintering at the low temperature and has excellent chemical stability and thermal shock resistance and a preparation method of the foam ceramic filter. The preparation method comprises steps as follows: (1) 15%-25% of nano aluminum sol, 0.8%-1.5% of a rheological agent and thebalance of magnesium oxide ceramic powder containing a nano titania sintering aid are prepared in percentage by mass, deionized water is added, the mixture is subjected to ball milling and uniform mixing, and ceramic slurry with the solid content of 60%-70% is prepared through vacuum exhausting; (2) a polyurethane foam plastic template is soaked in the ceramic slurry and is extruded by a roller press to remove redundant soaked hanging slurry, a biscuit is prepared, and the biscuit is heated to 80-120 DEG C and dried; (3) the dried biscuit is put in a sintering furnace, heated to 1,400-1,600 DEG C for high-temperature sintering and cooled to the room temperature with the furnace, and the magnesium oxide based foam ceramic filter is obtained.

Owner:FENGYANG L S NET FORMING CO LTD +2

Aluminum oxide short-fiber enhanced magnesium-oxide-based foam ceramic filter and preparation method thereof

The invention discloses an aluminum oxide short-fiber enhanced magnesium-oxide-based foam ceramic filter with chemical stability and excellent thermal shock resistance capable of sintering in a low temperature and a preparation method thereof. The preparation method comprises the following steps: (1) according to a mass percent, compounding by 15%-25% of nano-aluminum sol, 0.8%-1.5% of rheologicalagent, and the balance of magnesia ceramics powder containing aluminum oxide short-fiber and nano-titania, adding absolute ethyl alcohol, ball-milling, and uniformly mixing to prepare ceramic slurryof which the solid content is 60%-70%; (2) immerging a polyurethane foamed plastic template in the ceramic slurry, extruding the polyurethane foamed plastic template through a roller press so as to remove redundant immerging slurry, preparing a biscuit, and removing an ethyl alcohol solvent in a ventilating chamber in 40-50 DEG C, and drying the biscuit; and (3) placing the dried biscuit in a sintering furnace, warming to 1350-1550 DEG C, and sintering in a high temperature, cooling to room temperature along with the furnace, to obtain the magnesium-oxide-based foam ceramic filter.

Owner:JIANGSU FAVOUR AUTOMOTIVE NEW STUFF SCI TECH +1

Glass paste

Disclosed is a glass paste which is excellent in compatibility of a binder resin component, adhesion to a substrate / dry film resist (DFR), and low-temperature sinterability. This glass paste can be easily ground by sandblasting without causing a breakdown of a partition wall since it has high dried film strength. Specifically disclosed is a glass paste containing a (meth)acrylate copolymer, a cellulose resin, a glass powder and an organic solvent. The (meth)acrylate copolymer is composed of at least one (meth)acrylate monomer A selected from the group consisting of cyclohexyl(meth)acrylate, isobutyl(meth)acrylate, isobornyl(meth)acrylate, ethyl methacrylate, n-propyl methacrylate and isopropyl methacrylate, and a (meth)acrylate monomer B having one or more hydroxy groups. The composition ratio of the (meth)acrylate monomer A in the (meth)acrylate copolymer is 60-99.9% by weight, while the composition ratio of the (meth)acrylate monomer B having one or more hydroxy groups is 0.1-40% byweight.

Owner:SEKISUI CHEM CO LTD

Semi-light Guimo brick for ferrosilicon ladle and preparation method thereof

The invention belongs to the technical field of refractory materials, and particularly relates to a semi-light Guimo brick for a ferrosilicon ladle and a preparation method thereof, and mainly solvesthe technical problems that the conventional high-aluminum brick for the ferrosilicon ladle has a relatively high heat conductivity coefficient and poor insulation performance. The semi-light Guimo brick for the ferrosilicon ladle is characterized by being prepared from the following raw materials in parts by weight: 60-80 parts of high-aluminum bauxite clinker, 2-5 parts of a raw high-aluminum bauxite material, 3-8 parts of fine andalusite powder, 4-7 parts of fine silicon carbide powder, 2-6 parts of Suzhou soil, 3-10 parts of hollow aluminum oxide spheres, 1-3 parts of silica micropowder and 3.5-6 parts of silica sol. The preparation method of the semi-light Guimo brick for the ferrosilicon ladle comprises the following steps: 1), grinding and crushing; 2), performing mixed grinding onthe raw materials; 3), moulding and preparing a blank; 4), drying; 5), firing at high temperature; 6), cooling to obtain a finished product. The semi-light Guimo brick for the ferrosilicon ladle has the advantages of low cost, excellent heat shock-resisting stability, a low heat conductivity coefficient, high heat efficiency and the like.

Owner:孝义市和中兴矿产有限公司

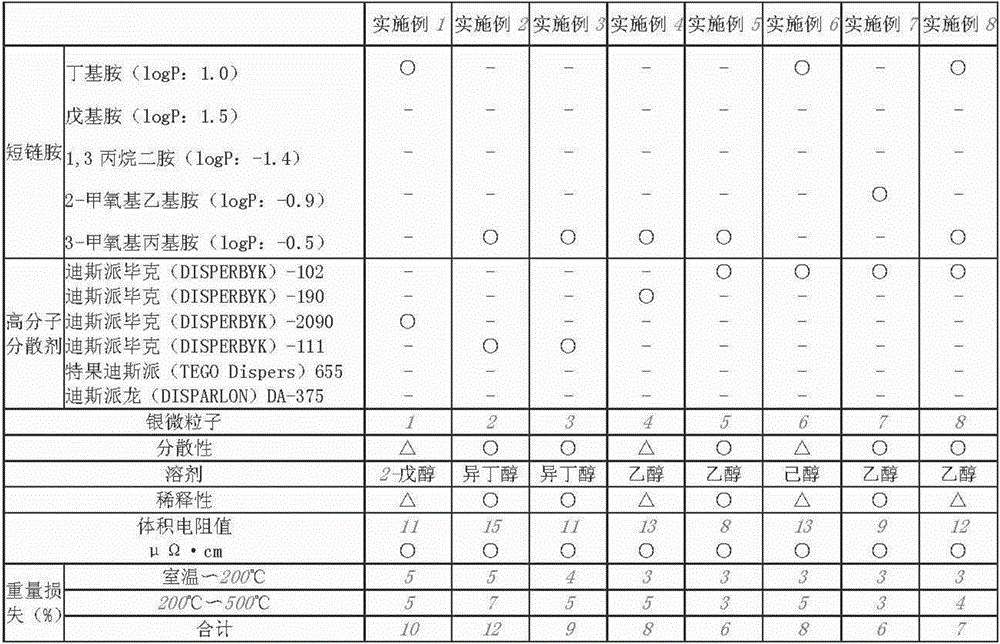

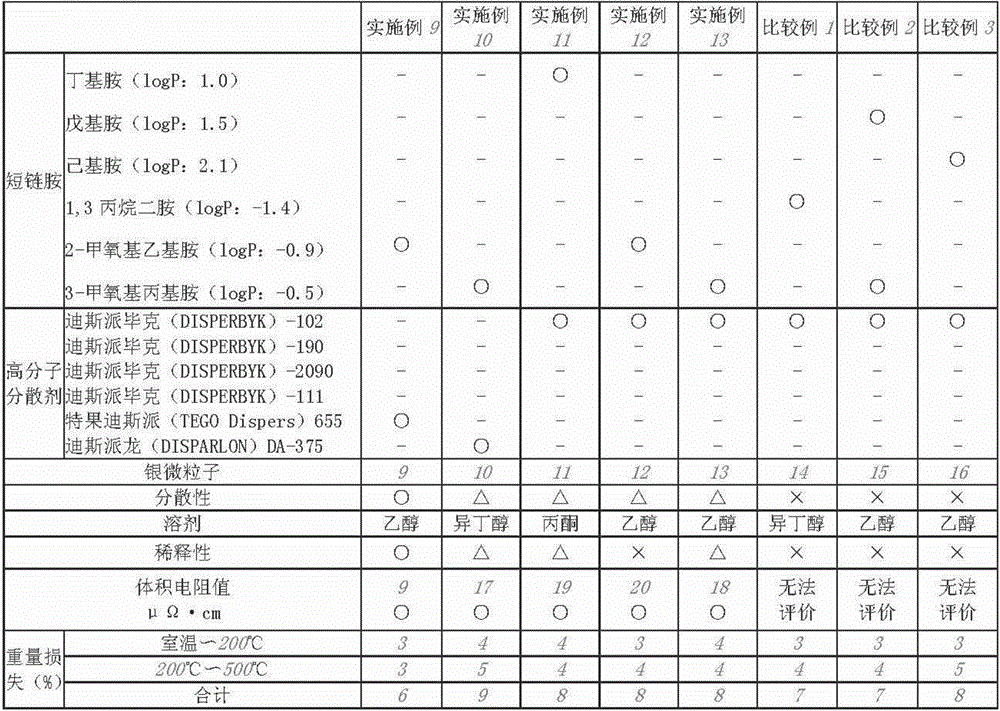

Fine silver particle dispersion, fine silver particles, and method for producing same

ActiveCN106660129AExcellent dispersibility and low temperature sinterabilityGood dispersionTransportation and packagingNon-conductive material with dispersed conductive materialSolventSilver particles

Provided are a fine silver particle dispersion which exhibits low temperature sinterability and in which fine silver particles are uniformly dispersed in a variety of solvents (and especially highly polar solvents); fine silver particles that exhibit low temperature sinterability and excellent dispersibility in a variety of solvents (and especially highly polar solvents); a dispersion obtained using the fine silver particles; and a method for producing same. The fine silver particle dispersion is characterized by containing fine silver particles, a short chain amine having 5 or fewer carbon atoms, and a highly polar solvent and in that the partition coefficient (logP) of the short chain amine is -1.0 to 1.4.

Owner:BANDO CHEM IND LTD

A kind of basic magnesium sulfate whisker in-situ synthesis magnesium aluminum spinel reinforced magnesium oxide based ceramic foam filter and preparation method thereof

ActiveCN108530094BAvoid obstructionAct as a binderFiltration separationProcess efficiency improvementOxide ceramicPhysical chemistry

Owner:FENGYANG L S NET FORMING CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com