Patents

Literature

147results about How to "Act as a binder" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

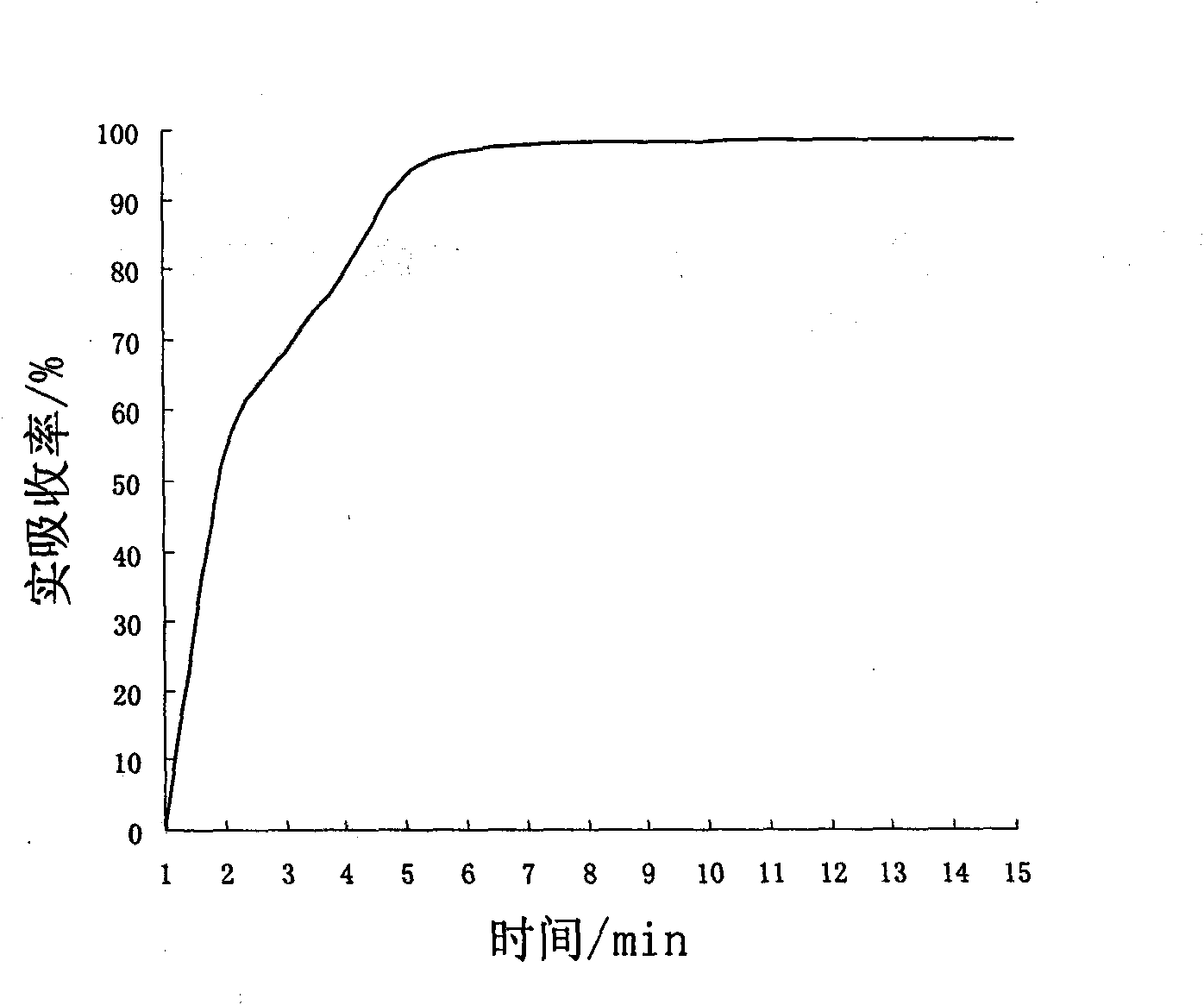

Additive for smelting aluminium alloy and preparation method and application method thereof

The invention relates to an additive for smelting aluminium alloy and a preparation method and an application method thereof, relating to the technical field of nonferrous alloy manufacturing with a special additive. The additive is composed of metal powder, cosolvent, heat-generating agent, detonating agent and moisture proof agent. The preparation method comprises the following steps: raw materials comprising the following by mass percentage, 70-81.5% of metal powder, 15-20% of cosolvent, 2-5% of heat-generating agent, 1-3% of detonating agent and 0.5-2% of moisture proof agent, are fully mixed evenly into compound powder with a ball mill, and the mixture is put into a mould, and is performed with cold pressing by a hydraulic pressure machine so as to obtain the additive for smelting aluminium alloy. The application method of the invention comprises the following steps: a graphite crucible filled with a pure aluminium pig is arranged in a resistance furnace to be heated until the aluminium pig is melted into aluminium liquid, and then the additive is added to react with the aluminium liquid so as to obtain aluminium alloy. Under the condition that the quality of aluminium alloy is not lowered, the additive solves the problems of high dissolving temperature, low absorptivity and unstable absorptivity of the additive.

Owner:HEBEI UNIV OF TECH

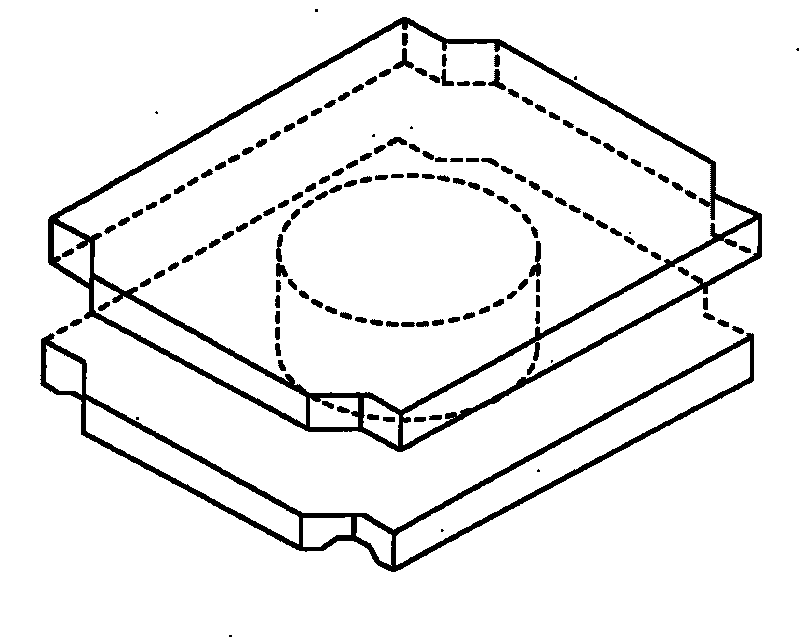

Coil element of winding inductor and manufacturing method thereof

InactiveCN101697309AImprove impact resistanceImprove liquidityTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresMixed materialsEngineering

The invention discloses a coil element of a winding inductor, which comprises a magnetic core, a winding coil winding on the magnetic core and a gluewater solidifying part. The gluewater solidifying unit covers the winding coil and fills a gap between the winding coil and the magnetic core. The gluewater solidifying part is formed by solidifying a magnetic mixed material comprising the gluewater and magnetic powder. The weight ratio of the magnetic powder to the gluewater is no less than 10:8. The invention further discloses a method for manufacturing the coil element of a winding inductor. By adopting the invention, the coil structure is beneficial to being stabilized, the impact resistance of the magnetic core is improved, and the electrical property and the reliability of the product can not be degraded in a process of drastic external vibration.

Owner:SHENZHEN SUNLORD ELECTRONICS

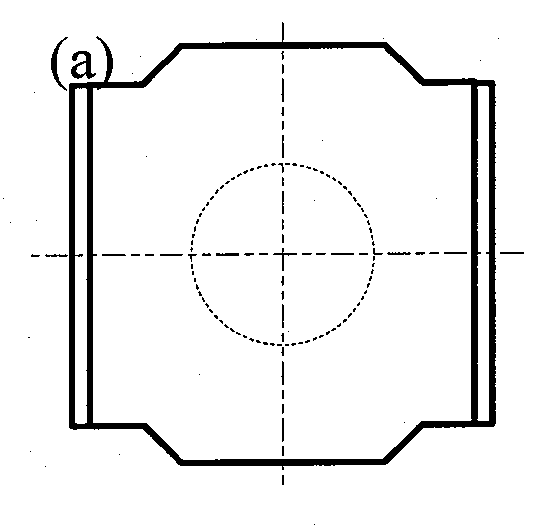

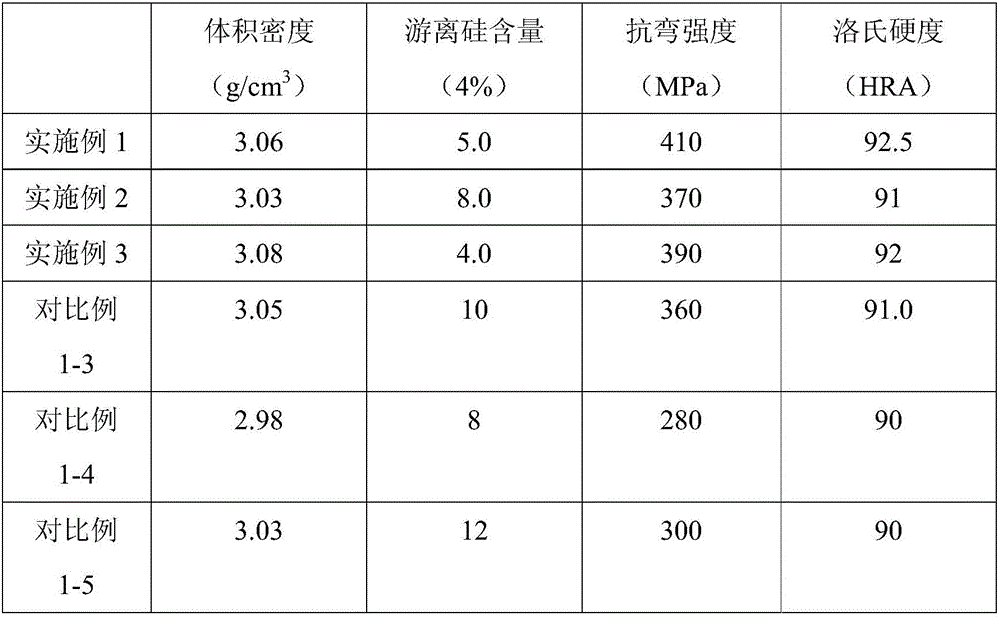

Method for preparing fine-grain silicon carbide ceramic through reaction sintering

The invention discloses a method for preparing fine-grain silicon carbide ceramic through reaction sintering. The method sequentially comprises the following steps: preparing a main material comprising 75-90wt% of silicon carbide micro-powder and 10-15wt% of active carbon powder; adding a dispersant and deionized water to the main material, sequentially adding an aqueous solution of organic matters containing high temperature carbon residue and a water-soluble polymer binder solution, and stirring and mixing above materials in a ball mill to prepare a uniformly-dispersed water-based silicon carbide slip; and sequentially carrying out spray granulation, dry press molding, dewaxing, vehicle working, high temperature siliconising sintering and alkali treatment desilication to obtain the silicon carbide ceramic.

Owner:浙江东新新材料科技有限公司

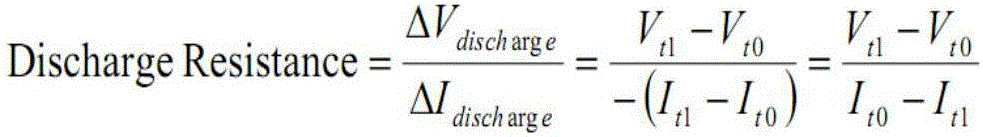

Lithium ion secondary battery and preparation method thereof

ActiveCN102569896AExcellent high power discharge performanceImproved High Power Discharge PerformanceFinal product manufactureElectrolyte accumulators manufactureCharge currentPhysical chemistry

The invention provides a preparation method of a lithium ion secondary battery. The method comprises the following steps of: accommodating a battery pole in a battery shell; injecting non-aqueous electrolyte into the battery shell; and performing charging formation and then sealing the battery shell in which the non-aqueous electrolyte is injected, wherein the non-aqueous electrolyte contains one or more additives; the one or more additives are one or more of aniline monomers and pyrrole monomers; the charging formation comprises one or more constant current charging processes; at least one charging current in the constant current charging is 0.001-0.05 C; and the cut-off voltage of the charging formation is 3.6-4.2 V. The invention also provides the lithium ion secondary battery prepared by the method provided by the invention. The lithium ion secondary battery prepared by the method provided by the invention has superior high-power discharge performance. The method according to the invention is simple and practical and is easy for realizing large-scale production.

Owner:BYD CO LTD

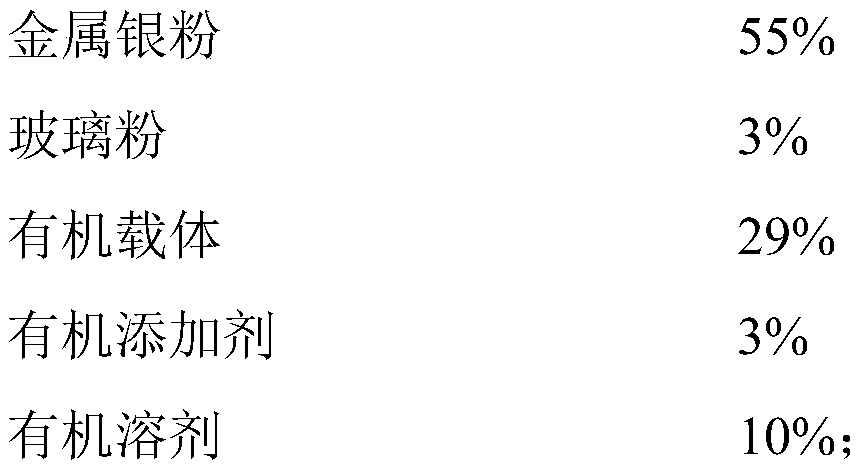

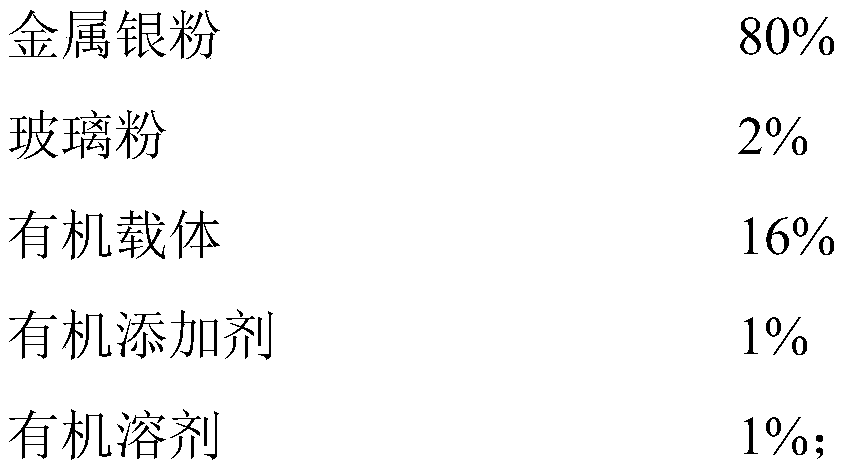

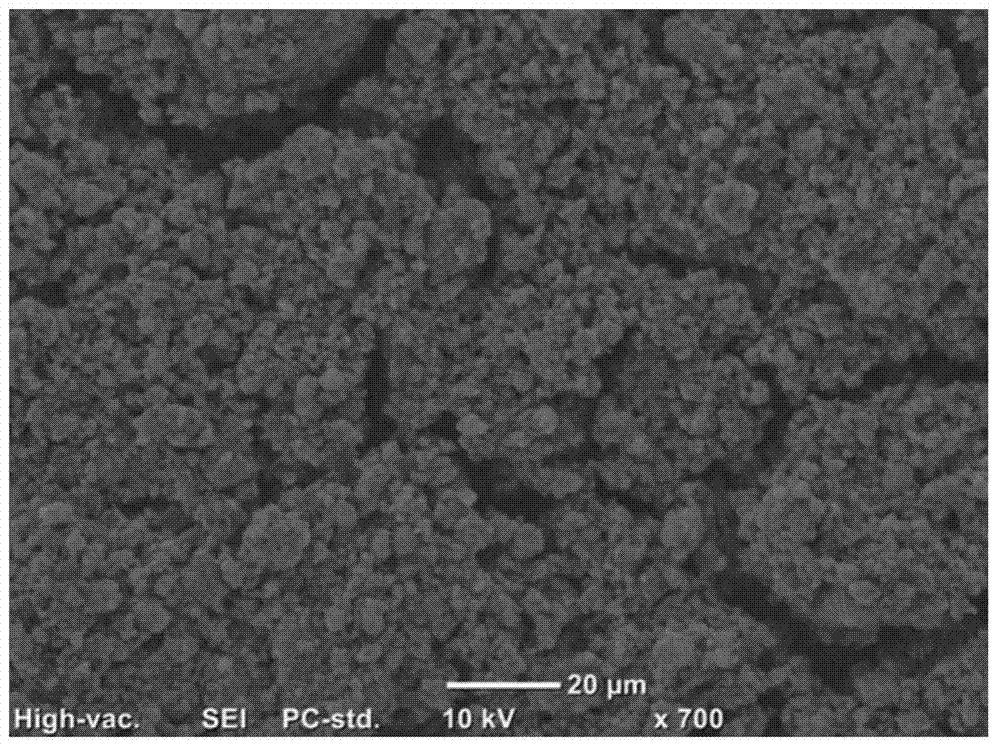

Conductive silver paste for ceramic filter and preparation method thereof

PendingCN111489848ASolve conductivity problemsSolve solder performanceNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver pasteThermal dilatation

The invention relates to conductive silver paste for a ceramic filter and a preparation method of the conductive silver paste. The conductive silver paste comprises the following components in parts by weight: 50-80 parts of metal silver powder, 2-5 parts of glass powder, 10-30 parts of an organic carrier, 1-3 parts of an organic additive and 1-10 parts of an organic solvent, wherein the glass powder is lead-free glass powder, the coefficient of thermal expansion is 110-120*10<-7> / DEG C, and the sintering temperature is 550-750 DEG C. The preparation method comprises the following steps: adding the organic carrier and the organic solvent into a mixer, adding the metal silver powder, the glass powder and the organic additive, fully mixing, transferring a mixture into a high-speed dispersionmachine, and uniformly dispersing at a high speed to obtain a conductive silver paste; and grinding the prepared conductive silver paste in a three-roller mill, and finely adjusting a roller to enable the fineness of the conductive silver paste to be less than 10mu m and the viscosity to be 30-50Pa.S, thereby obtaining the conductive silver paste for the ceramic filter. The conductive silver paste for the filter can form a conductive silver layer which is high in compactness, high in adhesive force, high in conductivity, good in weldability and stable in performance.

Owner:SHANGHAI BAOYIN ELECTRONICS MATERIALS CO LTD

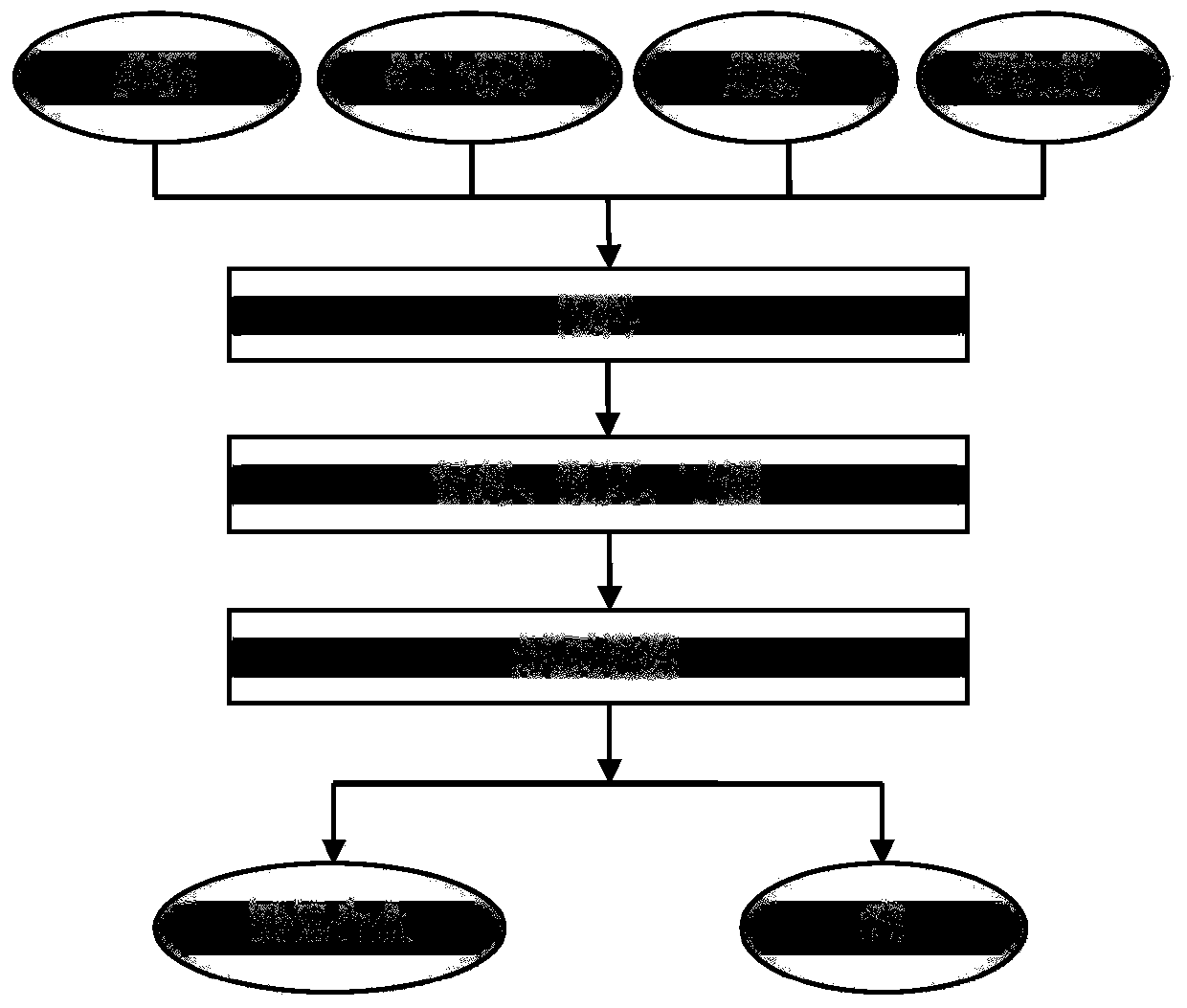

Method for preparing ferronickel by using red mud and laterite-nickel ore

ActiveCN104178624ARich in beneficial chemical ingredientsRealize secondary recyclingFluidised-bed furnacesRed mudLaterite

The invention provides a method for preparing ferronickel by using red mud and laterite-nickel ore. Meanwhile, a novel method is provided for recovery of iron in red mud and production of ferronickel from the red mud and the laterite-nickel ore. According to the method, iron-nickel reduction products in the red mud and the laterite-nickel ore are directly utilized, and low-cost ferronickel can be provided for stainless steel smelting production, ferroalloy casting and alloy steel production. The laterite-nickel ore also contains a little of chromium, and in the production method disclosed by the invention, chromium enters the iron-nickel alloy, so that beneficial chemical components of the iron-nickel alloy are enriched. The contained iron-nickel alloy produced by the method disclosed by the invention is iron-nickel alloy with low P and S content.

Owner:GUANGXI UNIV

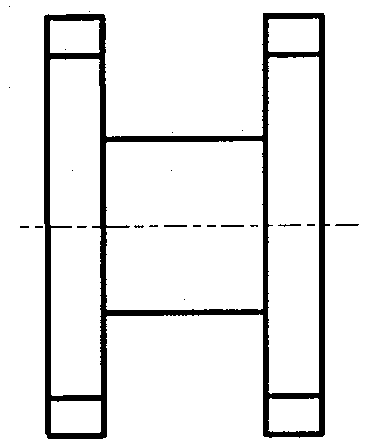

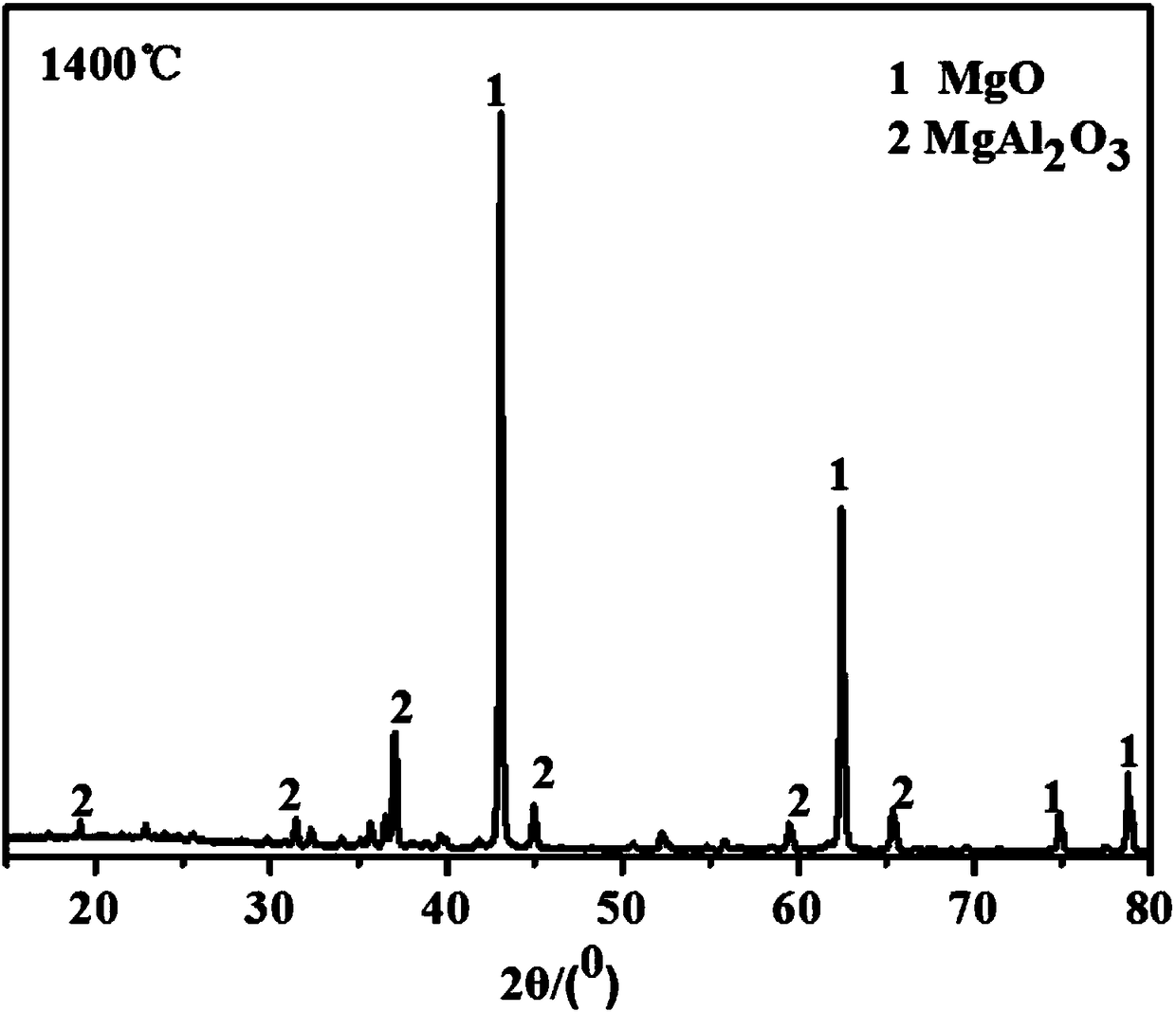

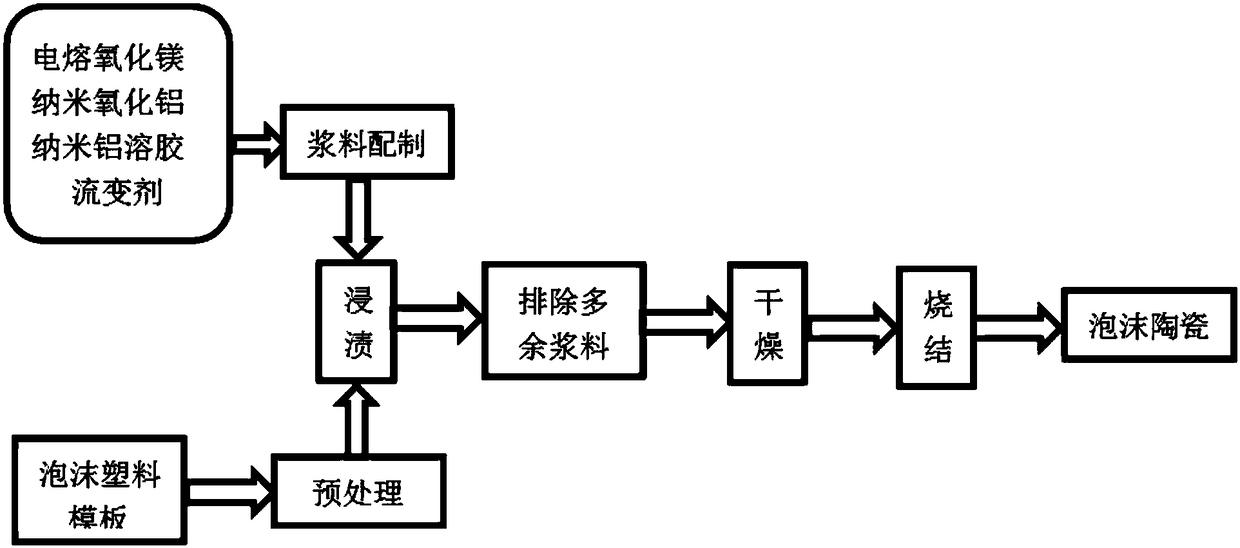

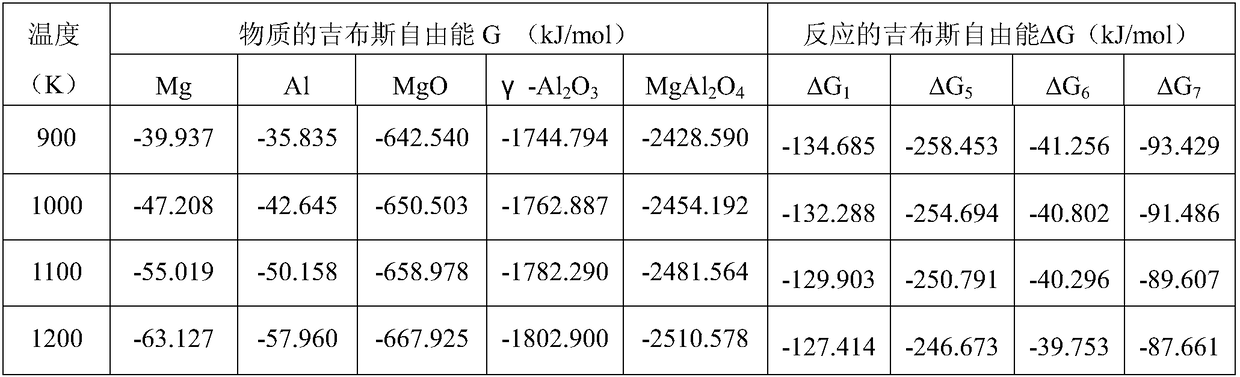

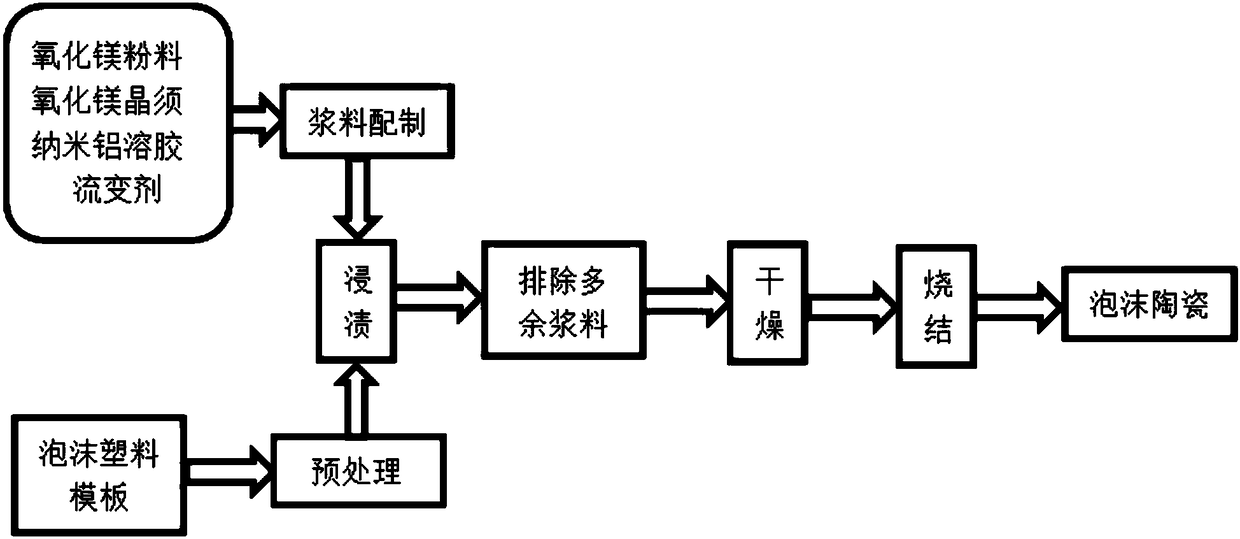

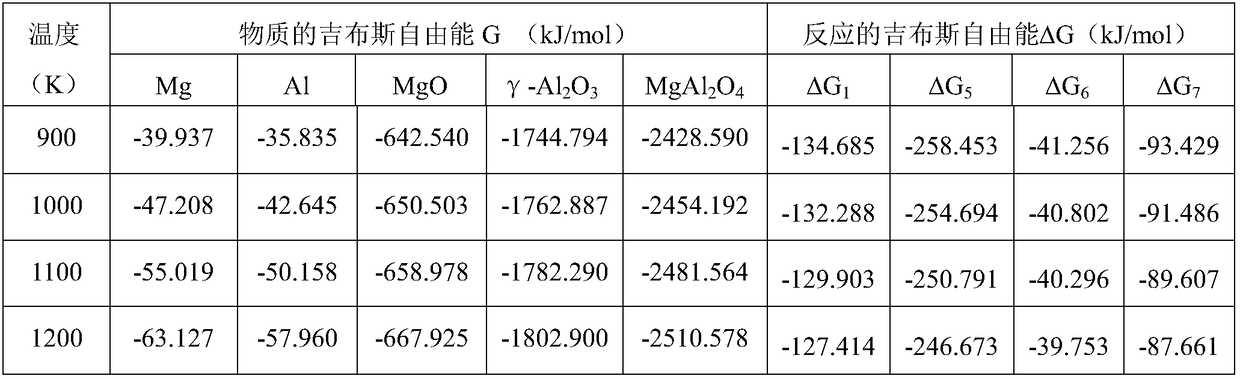

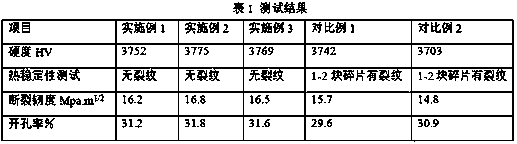

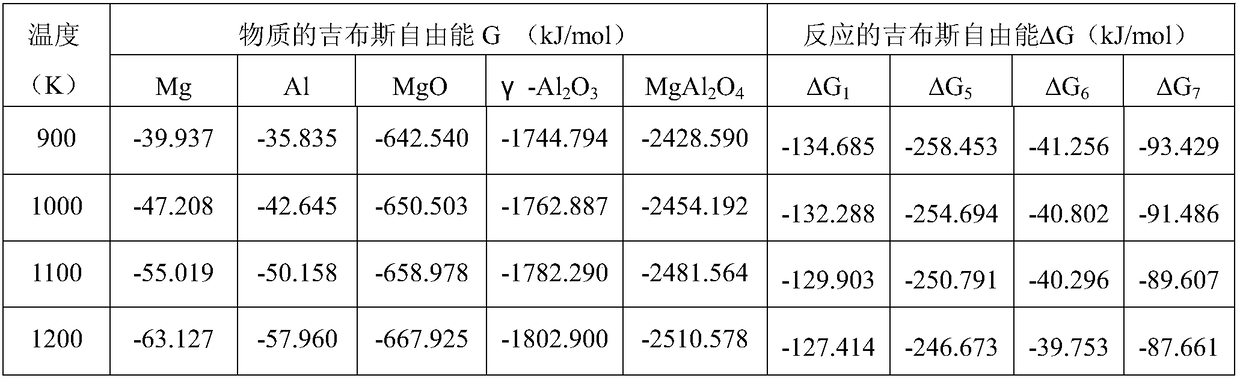

Magnesium aluminate spinel enhanced magnesia-based foamed ceramic filter and preparation method thereof

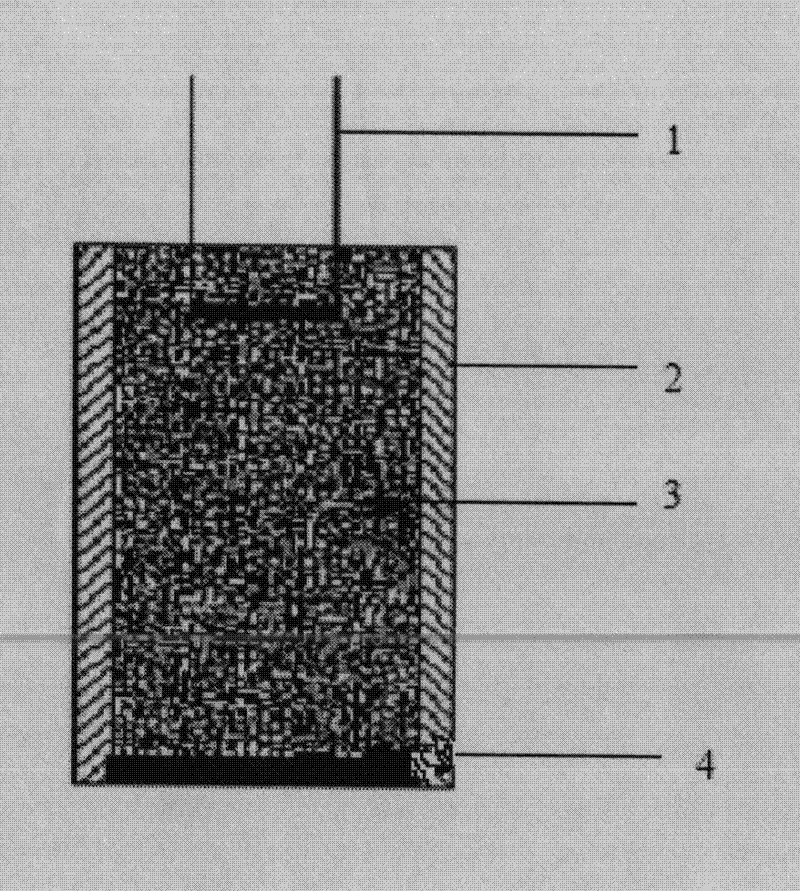

ActiveCN108516803AAct as a binderAvoid damageFiltration separationCeramicwareOxide ceramicNano al2o3

The invention discloses a magnesium aluminate spinel enhanced magnesia-based foamed ceramic filter with capability of realizing sintering at low temperature, excellent chemical stability and excellentthermal shock resistant performance, and a preparation method thereof. The preparation method comprises the following steps that (1) 10 to 20 percent of nanometer alumina sol, 0.8 to 1.5 percent of rheological agents and the balance of magnesium oxide ceramic powder containing a nanometer aluminum oxide sintering aid are proportioned; deionized water is added; ball milling and uniform mixing areperformed; then, through vacuum exhaust, ceramic slurry with the solid content being 60 to 70 percent is prepared; (2) a polyurethane foamed plastic template is soaked into the ceramic slurry; the polyurethane foamed plastic template is extruded through a roller press for removing the redundant leaching hanging slurry; then, biscuit is prepared; then, the biscuit is heated to 80 to 120 DEG C for drying; (3) the dried biscuit is put into a sintering furnace; the temperature is raised to 1400 to 1600 DEG C; high-temperature sintering is performed; cooling is performed along with the furnace to room temperature; the magnesia-based foamed ceramic filter is obtained.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

All-solid-state lithium-ion battery and manufacturing method thereof

InactiveCN106532109AReduce DC resistanceImprove ionic conductivityFinal product manufactureElectrolyte accumulators manufactureSolventIon

The invention discloses an all-solid-state lithium-ion battery and a manufacturing method thereof. The manufacturing method comprises the following steps of (1) dissolving a polymer electrolyte into a solvent to prepare a glue solution; (2) fully mixing a positive electrode host material, a conductive agent and the glue solution obtained in the step (1), coating a positive current collector, heating the positive current collector and then carrying out co-curing to obtain a positive electrode plate, fully mixing a negative electrode host material, the conductive agent and the glue solution obtained in the step (1), coating a negative current collector, heating the negative current collector and then carrying out co-curing to obtain a negative electrode roll; (3) carrying out mechanical ball milling on a sulfide electrolyte, dissolving the product into the solvent to prepare slurry, coating the surface of the negative electrode roll, heating the negative electrode roll and then curing the negative electrode roll to obtain a negative electrode plate; and (4) assembling the positive electrode plate and the negative electrode plate by adopting a lamination technology to obtain the all-solid-state lithium-ion battery. Compared with the prior art, the all-solid-state lithium-ion battery disclosed by the invention has relatively low DC resistance, relatively high ionic conductivity and good cycle performance.

Owner:SHANGHAI AEROSPACE POWER TECH

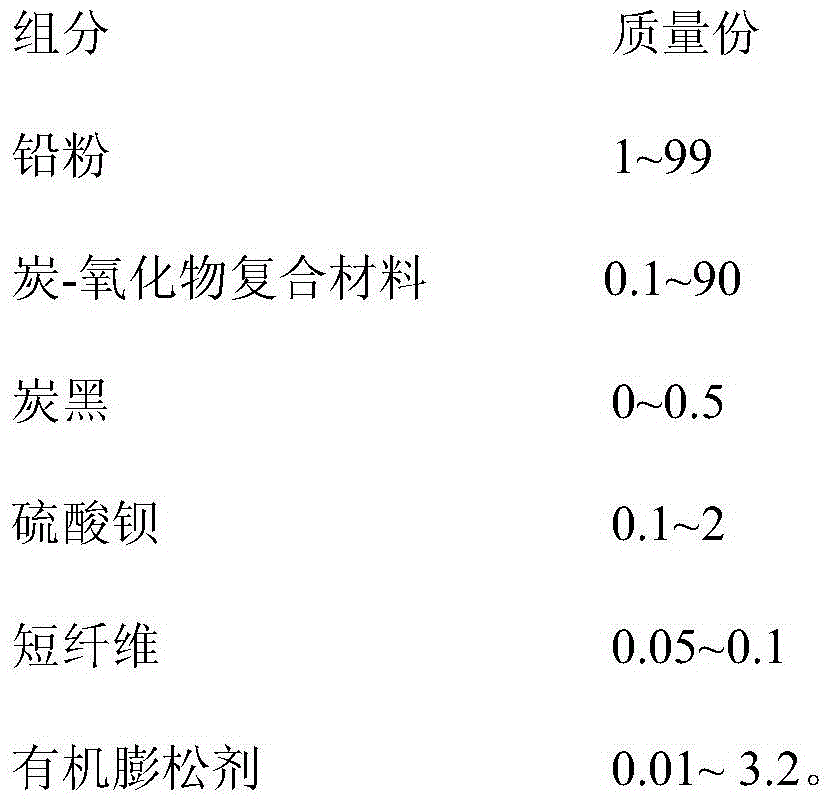

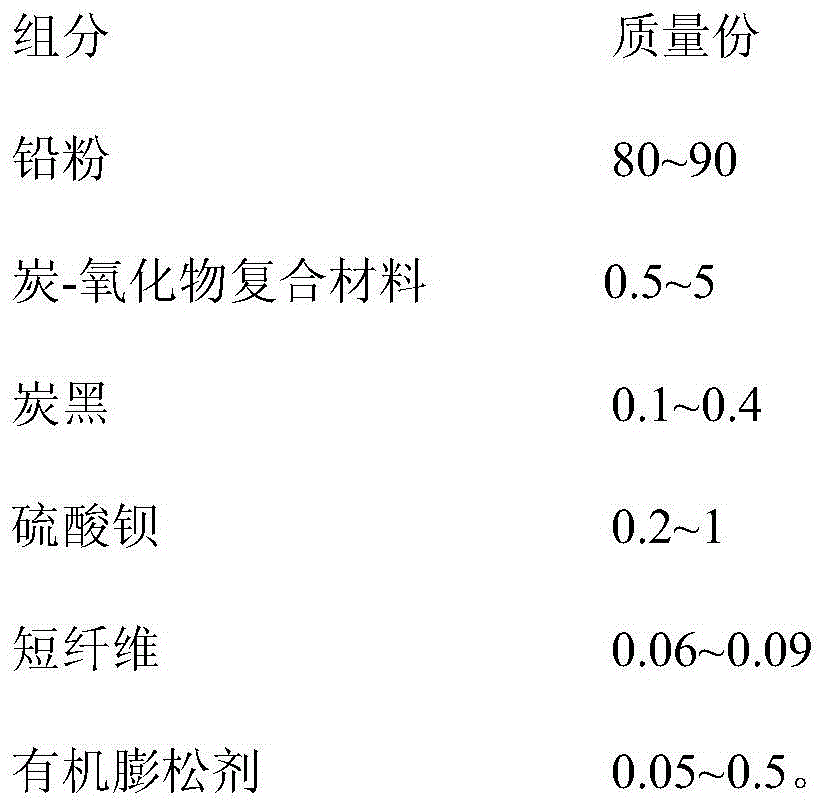

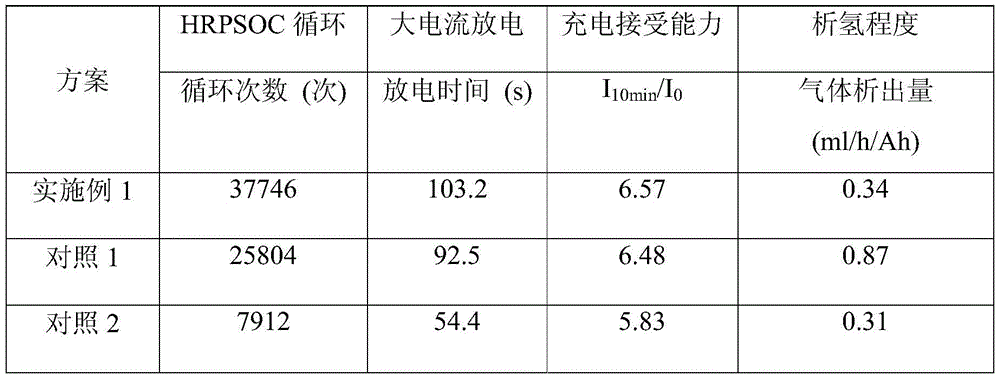

Negative lead paste for lead-carbon battery

ActiveCN105489887ALarge specific surface areaDelayed softening and sheddingFinal product manufactureCell electrodesFiberCapacitance

The invention provides a negative lead paste for a lead-carbon battery. The negative lead paste is prepared from the following components in parts by weight: 1-99 parts of lead powder, 0.1-90 parts of a carbon-oxide composite material, 0-0.5 part of carbon black, 0.1-2 parts of barium sulfate, 0.05-0.1 part of a short fiber and 0.01-3.2 parts of an organic swelling agent. Oxides on the surface and in holes of the carbon material of the lead paste are tightly adsorbed to the periphery of the carbon material in an ionic form, and are recombined on the surface and in the holes of the carbon material in curing and drying processes; and a tiny oxide film is evenly attached to the active surface and the holes of the carbon material by 'dissolving and recombination', so that the bonding degree of the carbon material and the oxides is greatly improved; the conduction characteristics and the capacitance characteristics of the carbon material are put into a fully play; and hydrogen evolution on the surface of the carbon material is limited.

Owner:CHINA ELECTRIC POWER RES INST +3

Battery diaphragm, power battery and vehicle

ActiveCN110299496AReduce polarizationIncrease energy densitySecondary cellsPropulsion by batteries/cellsLithiumPower battery

The invention provides a battery diaphragm including a porous base film and a lithium-replenishing coating attached to one side of the porous base film. The lithium-replenishing coating comprises a lithium-replenishing material and a first binder. The lithium-replenishing material comprises a core and a coating layer on the surface of the core, the material of the core comprises a lithium-ion compound, and the material of the coating layer comprises carbon and metal carbide. The invention also provides a power battery and a vehicle. The power battery includes a positive electrode, a negative electrode and the diaphragm, and the lithium-replenishing coating of the battery diaphragm just faces the positive electrode. The vehicle includes the power battery. According to the invention, the battery is prepared by forming the lithium-replenishing coating at one side of the battery diaphragm and allowing the lithium-replenishing coating of the diaphragm to face a positive electrode piece, thebattery capacity is greatly improved, and the diaphragm has good mechanical properties and high-temperature resistance performance.

Owner:BYD CO LTD

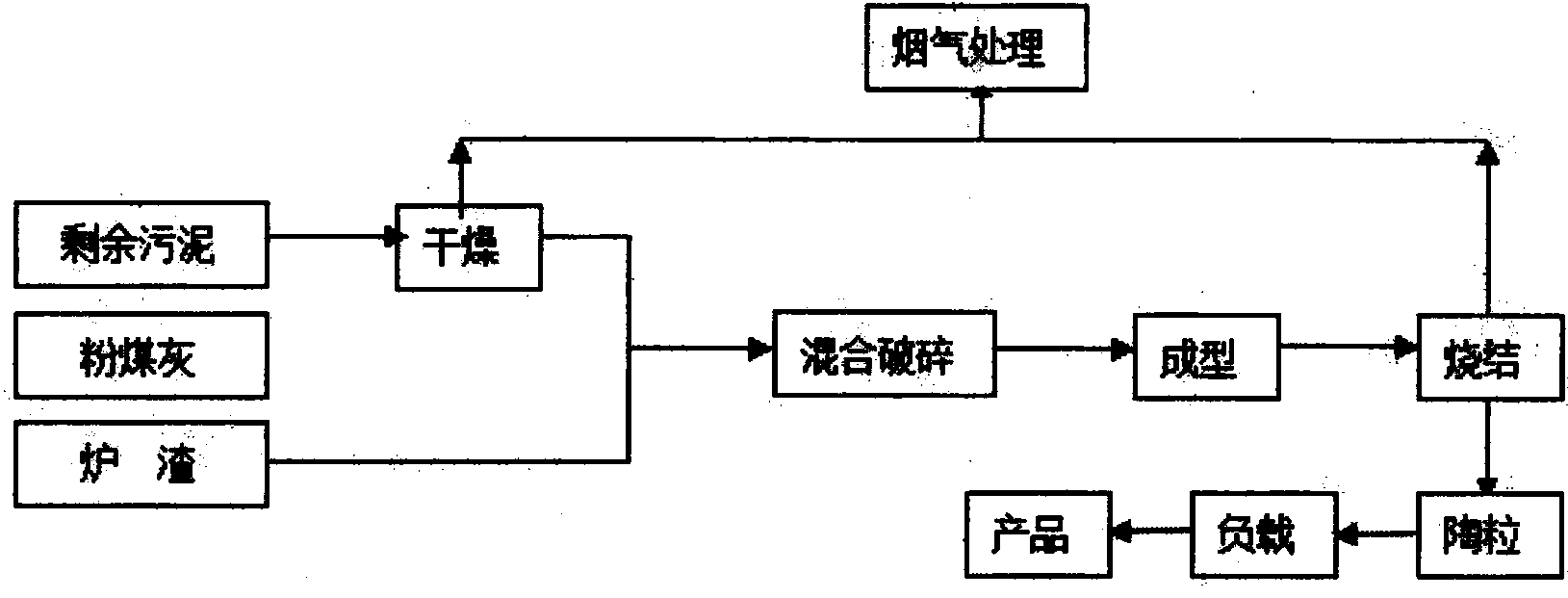

Method for preparing ceramsite with catalyzing function through surplus sludge

The invention discloses a method for preparing ceramsite with a catalyzing function through surplus sludge. According to the method, through different portions of the surplus sludge, coal ash and slag, a little of SiO2 and a little of Al2O3 are added to improve the performance of the ceramsite, and the prepared ceramsite has the catalyzing function through the load of reactive metal. By the adoption of the method, the prepared ceramsite is high in compressive strength and good in all performance, has the catalyzing function and serves as packing of an oxidation pond to treat printing and dyeing wastewater, so that a good effect is achieved, and biofilm formation is easy.

Owner:DONGHUA UNIV

Method to plant Medicago sativa in saline-alkaline soil and improve soil and fertilizer condition

InactiveCN107711397AImprove convenienceImprove survival rateFlowers cultivationCalcareous fertilisersMicrobial agentSlag

The invention discloses a method to plant Medicago sativa in saline-alkaline soil and improve soil and fertilizer condition. The method comprises: applying an improving fertilizer, plowing, performingrotary tillage and leveling the land, sowing, managing the field, and harvesting, wherein the improving fertilizer is made from desulfurization gypsum, activated carbon, flyash, plant stalk granules,bentonite, zeolite, urea, ammonium phosphate, blast furnace slag particles and a microbial agent having a weight ratio of (30-40):(10-14):(6-10):(16-18):(8-12):(4-8):(3-5):(3-5):(4-6):(1-3). saline-alkaline soil is improved by taking the measures such as saline-alkaline soil improving fertilizer and planting Medicago sativa, the survival rate and yield of Medicago sativa are high, the improving of the whole saline-alkaline soil is excellently effective, and the improving process is green and free of pollution. Therefore, the method is an application technique worthy of wide popularization.

Owner:WEIFANG YOURONG IND

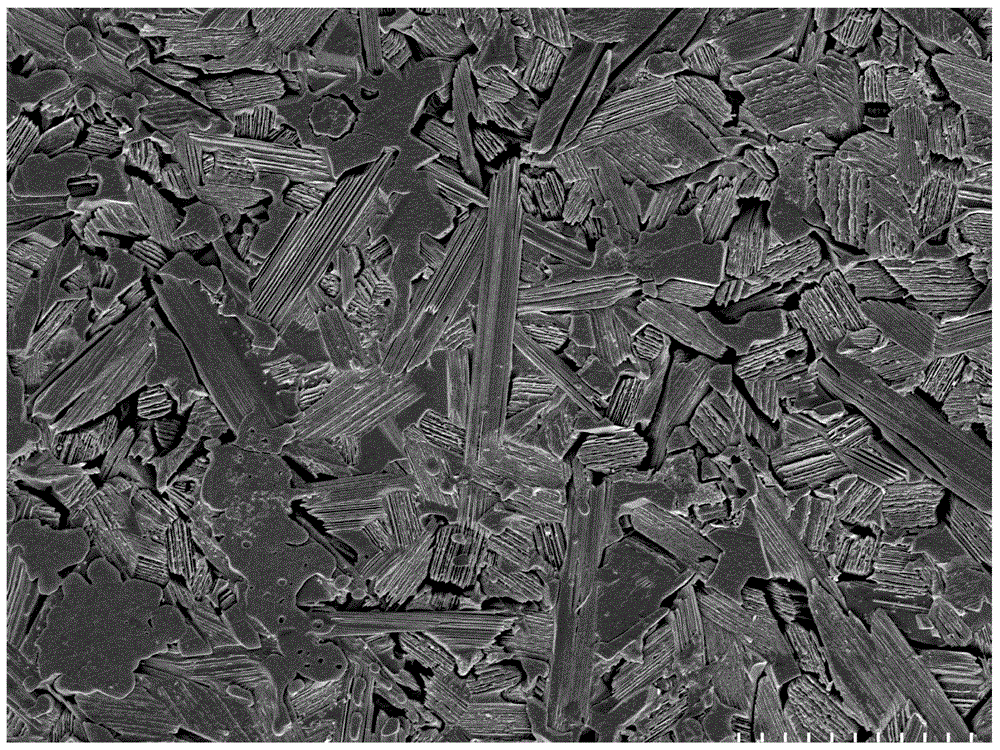

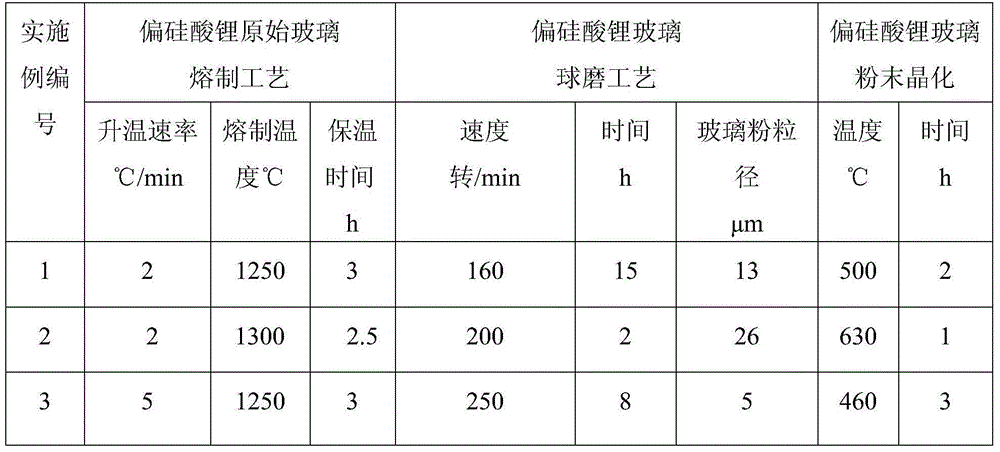

Lithium disilicate microcrystalline glass material prepared by using hybrid reaction sintering method and method

The invention provides a lithium disilicate microcrystalline glass material prepared by using a hybrid reaction sintering method and the method. Raw materials for the material comprise lithium metasilicate crystal powder M, quartz sand glass powder S and lithium disilicate basic glass powder D, wherein a mol ratio of M to S to D is 1: 1-2: 0-8. The method comprises the following steps: subjecting lithium metasilicate glass and lithium disilicate basic glass to melting, water quenching and ball milling so as to prepare glass powder; subjecting lithium metasilicate glass powder to crystallization to obtain a crystal; adding the quartz sand glass powder and the lithium disilicate basic glass powder D; and uniformly mixing the above-mentioned three powders and carrying out sintering in a vacuum hot-pressing furnace so as to prepare lithium disilicate microcrystalline glass. The lithium disilicate microcrystalline glass produced by using the method has bending strength of 255 to 420 MPa and fracture toughness of 2.6 MPa.m1 / 2 to 3.5 MPa.m1 / 2. Compared with the prior art, the invention has the following advantages: production cost is reduced; desired pigments can be added into the mixed powder before sintering, which enables the problem of difficult color matching in a melting method to be overcome; a long rod-like crystal grain with length 5 times the size of a single glass powder sintered body is prepared; and a novel approach is opened up for toughening the lithium disilicate microcrystalline glass.

Owner:XI AN JIAOTONG UNIV

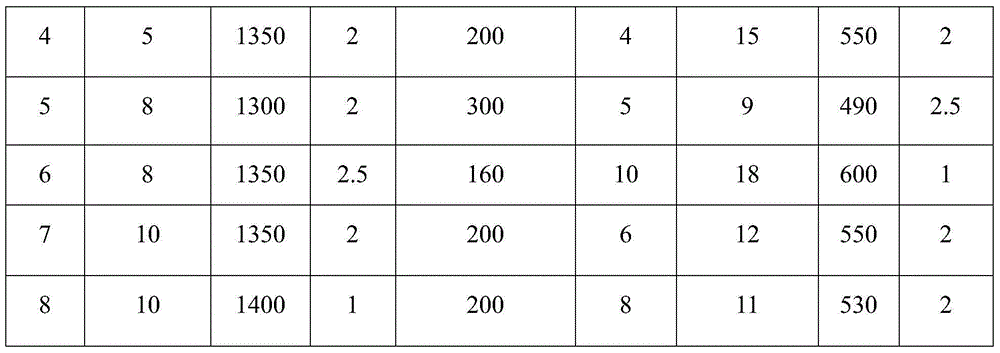

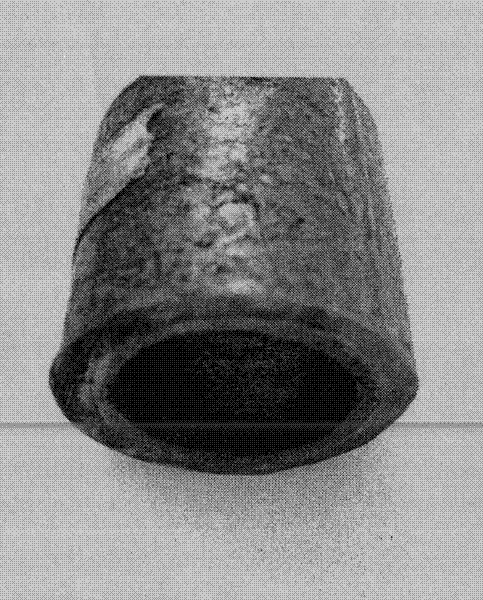

Manufacturing method for ceramic-lined composite steel pipe

InactiveCN102505117AHigh application valueSimple processMetallic material coating processesWear resistantCorrosion

The invention relates to a manufacturing method for a ceramic-lined composite steel pipe, and belongs to the field of pipeline transportation materials. The invention provides an additive, wherein the additive consists of rare earth oxide Y2O3 or La2O3 and silicon dioxide SiO2; the rare earth oxide Y2O3 or La2O3 and the silicon dioxide SiO2 are added into a thermit according to a proportion; the additive accounts for 1-3 percent of the total weight of reaction materials; and after drying, the ceramic-lined composite steel pipe is synthesized by a self-propagating process. The method has the advantages of increasing the compactness of a ceramic layer, improving the hardness of the composite steel pipe, enhancing the wear resistance, improving the corrosion resistance and prolonging the service life, along with fine and smooth inner surface and good texture. The overall performance of the ceramic-lined composite steel pipe is improved, so that the ceramic-lined composite steel pipe becomes an ideal wear-resistant pipeline transportation material; meanwhile, the rare earth resource advantage of China is brought into full play; and the application value of rare earth in the ceramic-lined composite steel pipe is effectively improved.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

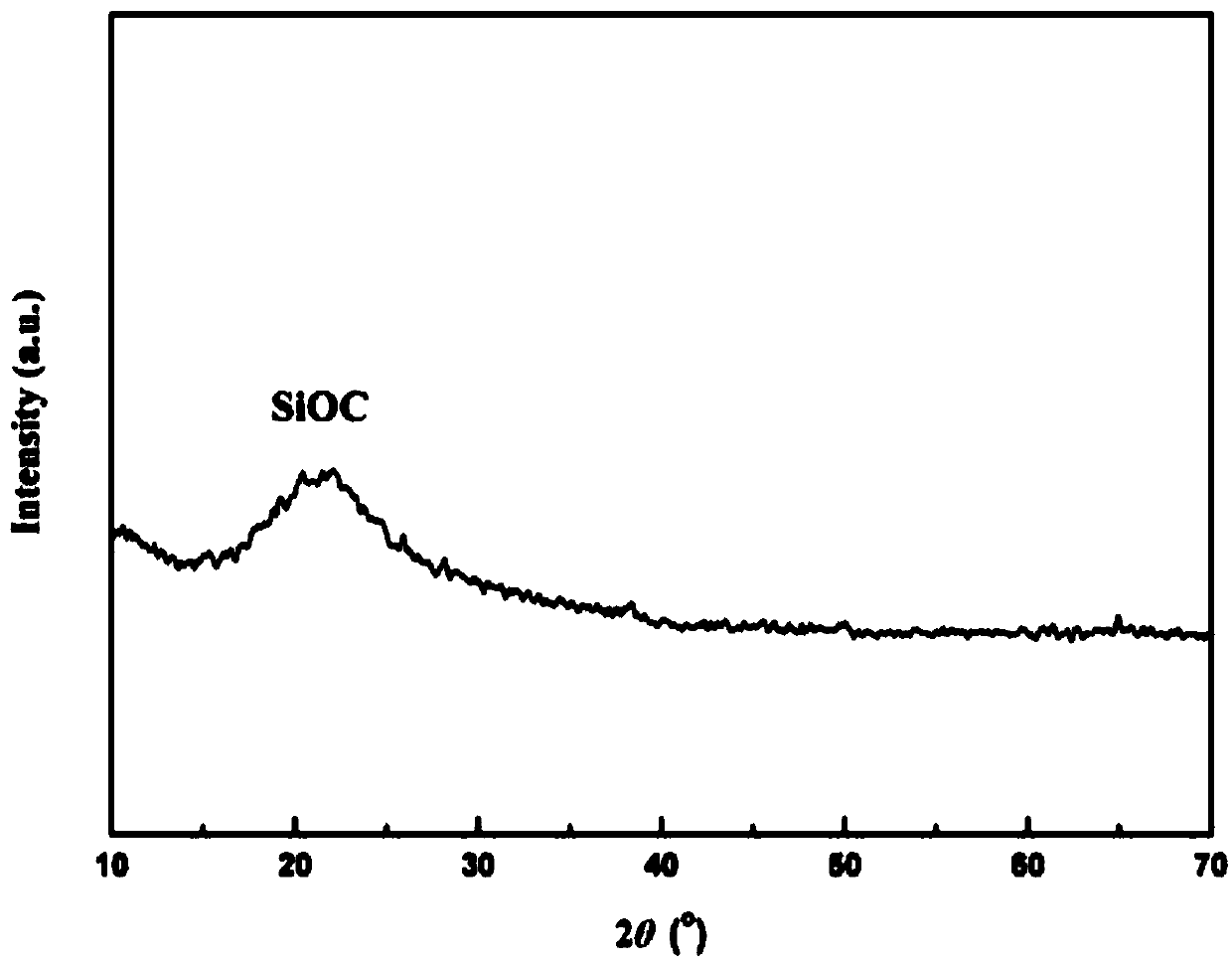

Method for in-situ synthesis of amorphous SiOC nanowire reinforced ceramic core

InactiveCN107698270AHigh temperature strengthMalleableFoundry mouldsFoundry coresCompression moldingNanowire

The invention discloses a method for in-situ synthesis of an amorphous SiOC nanowire reinforced ceramic core. The method comprises the following steps: performing ball milling mixing on selected ceramic powder and silicon resin powder to obtain required mixed powder, performing compression molding on the obtained powder to obtain a porous ceramic biscuit, then performing curing treatment under anatmospheric environment, and performing sintering treatment on the cured sample in an atmosphere sintering furnace to finally obtain the amorphous SiOC nanowire reinforced ceramic core material, wherein a communicating nitrogen gas atmosphere is used for protection in the whole sintering process. According to the invention, the silicon resin is used as a binder and a precursor, and the ceramic powder is used as a substrate to prepare the SiOC nanowire reinforced ceramic core material; and the ceramic core prepared by the method has excellent room-temperature and high-temperature performance, and improves a finished-product yield of high-efficiency air-cooling blades. The process of the method is simple, the preparation costs are lower, and the prepared ceramic core has excellent performance. The preparation process of the method is simple, the operability is strong, the production period is short, and the costs are low.

Owner:SHANGHAI UNIV +1

Pretreated corn steep liquor and direct spray using method thereof in livestock and poultry feed

InactiveCN106858042AImprove palatabilityHigh nutritional valueAnimal feeding stuffPretreatment methodPhytase

The invention discloses pretreated corn steep liquor and a direct spray using method thereof in a livestock and poultry feed. The moisture of the corn steep liquor can be effectively reduced, and besides, toxic and nutrition-resistant factors in the corn steep liquor are effectively removed, so that the pretreated corn steep liquor can be directly used for feeding livestock and poultry. In particular, the pretreatment method of the corn steep liquor comprises the following steps of (1 ) adding alkali liquor to the corn steep liquor, performing stirring treatment, and regulating the pH of the corn steep liquor to be 5.2-5.3; (2) adding phytase to the corn steep liquor of which the pH is regulated, and performing stirring and uniform mixing treatment; and (3) separately inoculating the corn steep liquor after being subjected to enzymolysis in step (2) with cultured bacillus amyloliquefaciens (Bacillus amyloliquefaciens) and aspergillus niger ( Aspergillus niger ), performing fermentation culturing, and after culturing is finished, obtaining the corn steep liquor.

Owner:山东益客食品产业有限公司

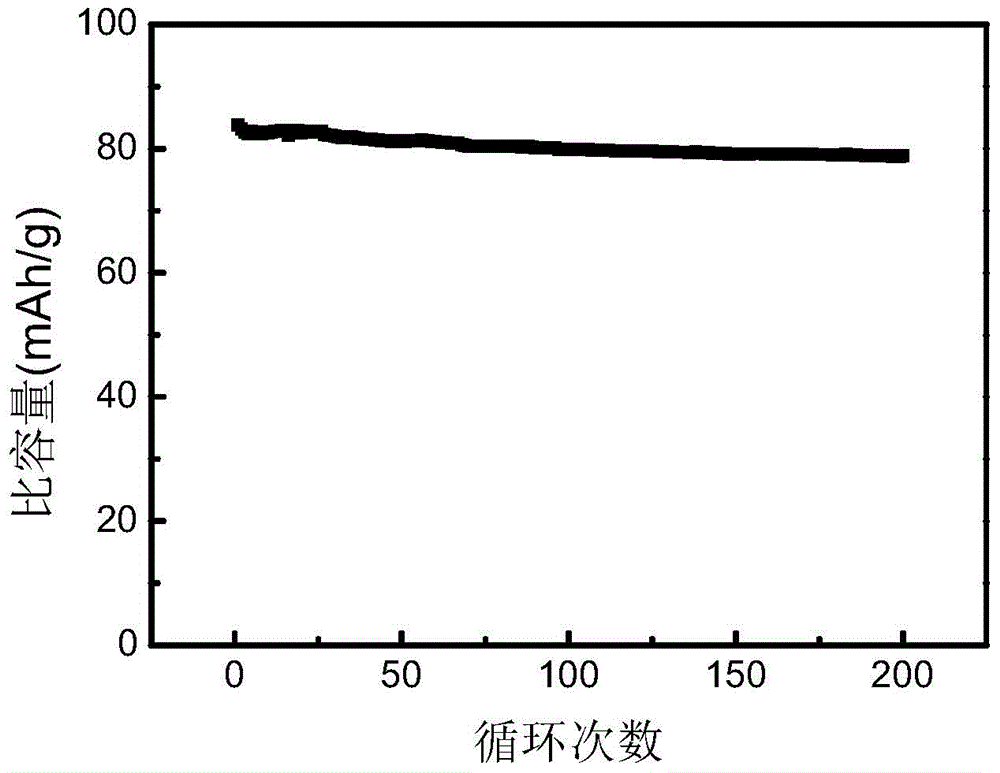

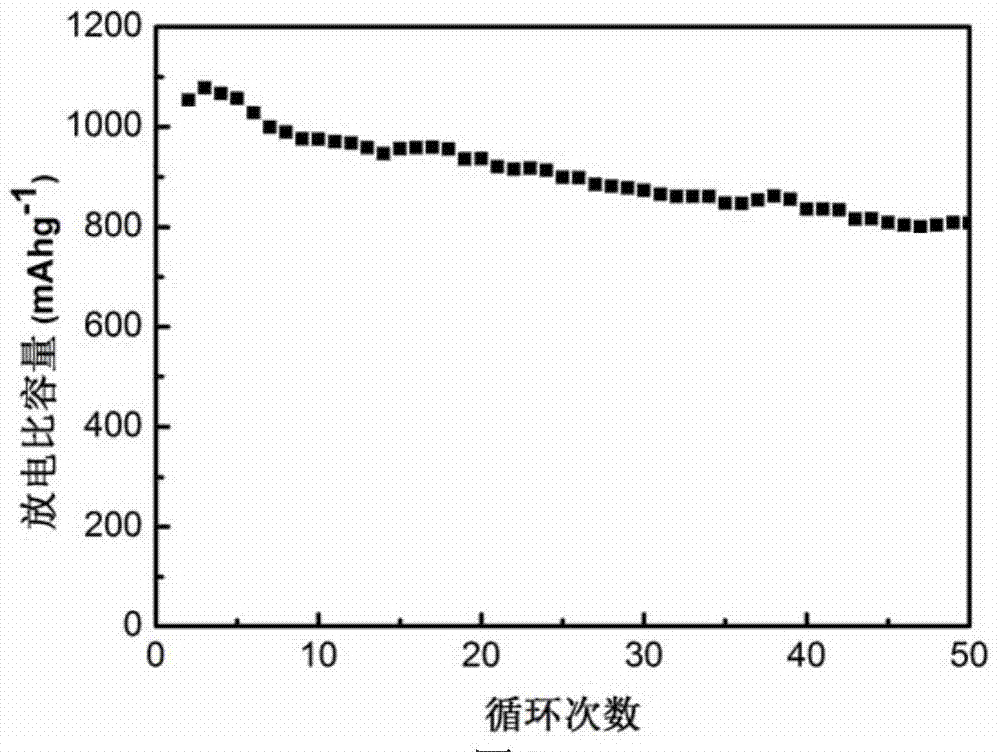

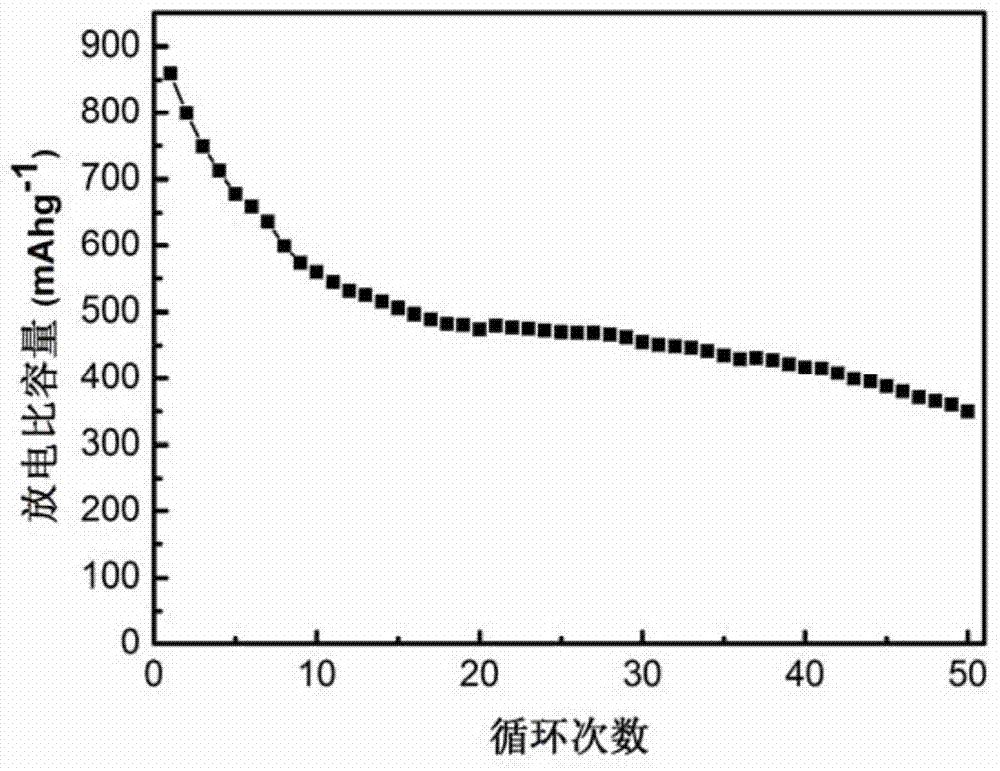

Sodium ion battery electrode and preparation method thereof

The invention discloses a sodium ion battery electrode and a preparation method thereof, wherein the preparation method comprises the steps: (1) mixing graphene, an active material and ethanol, carrying out ultrasonic dispersion, to obtain a dispersed material liquid, wherein the mass ratio of graphene to the active material is (1:9)-(5:5), and the active material is a component I or a component II; (2) carrying out suction filtration on the dispersed material liquid through a microporous filter membrane, to obtain a composite material; and (3) drying the composite material, and thus obtaining the product. According to the preparation method of the sodium ion battery electrode, conventional binders and current collectors in the field are not used, the electric conductivity of the electrode is improved, moreover, the preparation method is simple in technology, low in equipment requirements and short in production cycle, and the prepared sodium ion battery electrode has good stability. The sodium ion battery electrode is excellent in electrochemical performance, high in charge and discharge capacity, excellent in rate performance, and good in cycle performance.

Owner:SHANGHAI SINOPOLY JIAHUA BATTERY TECH +1

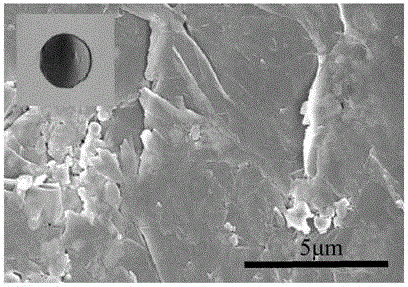

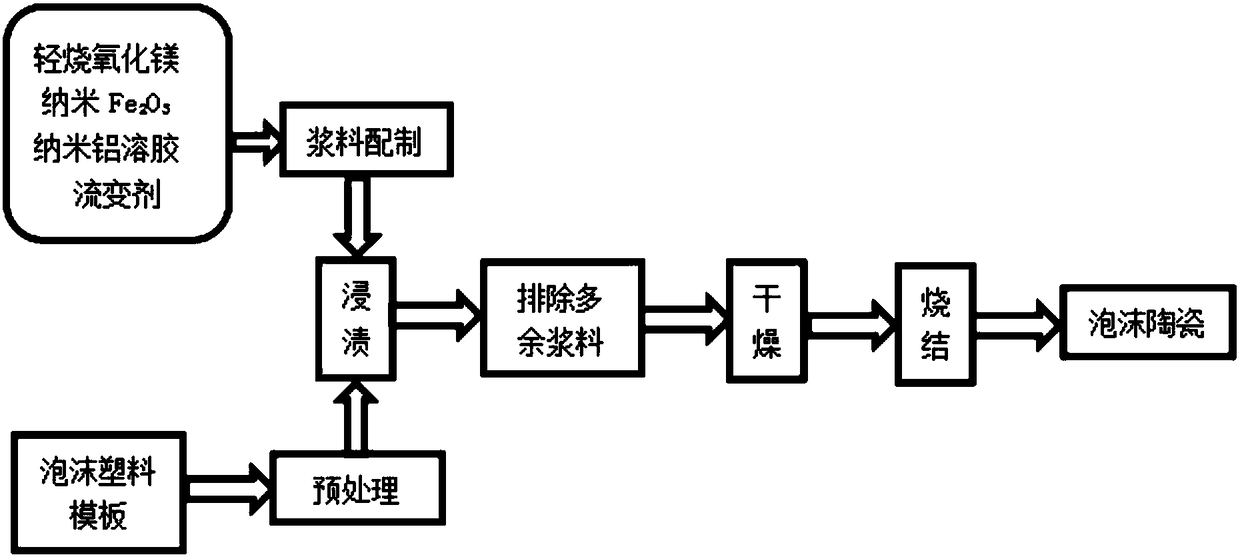

Magnesium oxide whisker in-situ synthesis magnesium aluminate spinel enhanced magnesium-oxide-based foam ceramic filter and preparation method thereof

ActiveCN108484182AAvoid obstructionAct as a binderFiltration separationCeramicwareRoom temperatureSlurry

The invention discloses a magnesium oxide whisker in-situ synthesis magnesium aluminate spinel enhanced magnesium-oxide-based foam ceramic filter with chemical stability and excellent thermal shock resistance capable of sintering in a low temperature and a preparation method thereof. The preparation method comprises the following steps: (1) according to a mass percent, compounding by 15%-25% of nano-aluminum sol, 0.8%-1.5% of rheological agent, and the balance of magnesia ceramics powder containing magnesium oxide whisker, adding deionized water, ball-milling, uniformly mixing, and preparing ceramic slurry of which the solid content is 60%-70% through vacuum exhaust; (2) immerging a polyurethane foamed plastic template in the ceramic slurry, extruding the polyurethane foamed plastic template through a roller press so as to remove redundant immerging slurry, preparing a biscuit, heating the biscuit to 80-120 DEG C, and drying; and (3) placing the dried biscuit in a sintering furnace, warming to 1400-1600 DEG C, and sintering in a high temperature, cooling to room temperature along with the furnace, to obtain the magnesium-oxide-based foam ceramic filter.

Owner:JIANGSU FAVOUR AUTOMOTIVE NEW STUFF SCI TECH +1

Method for improving saline and alkaline land by utilizing alfalfa-beet-cotton-maize rotation

InactiveCN107710947APromote formationReduce usageCalcareous fertilisersMagnesium fertilisersFresh waterPollution

The invention discloses a method for improving a saline and alkaline land by utilizing alfalfa-beet-cotton-maize rotation. By the method, the saline and alkaline land is improved by ditching and draining, pressing salt into fresh water, adding improved fertilizer or compound fertilizer, performing ploughing and rotary tillage, planting alfalfa, beet, cotton and maize year by year and returning straws. The method has prominent improvement effect on the whole saline and alkaline land, and the improvement process is environment-friendly and pollution-free. Therefore, the method is an applicationtechnology worthy of large-area popularization.

Owner:WEIFANG YOURONG IND

Bridge cable polyethylene protective primer and preparation method thereof

The present invention relates to a bridge cable polyethylene protective primer, which is prepared by mixing the following ingredients in parts by weight of 120 to 160 parts of xylene, 10 to 30 parts of trimethylbenzene, 10 to 30 parts of chlorinated polypropylene, 10 to 20 parts of chlorinated polyethylene, 0.5 to 2 parts of acrylic resin, 0.1 to 0.5 parts of fluorine-containing surfactant, and 0.1 to 0.5 parts of antifoaming agent. The preparation method of primer provided by the present invention realizes producing the bridge cable polyethylene protective primer fast. The primer provided by the invention acts as a binder between polyethylene and finishing paint fluorocarbon coatings, which makes finishing paint fluorocarbon coatings firmly stick to the surface of polyethylene, uneasy to blister or to peel off. The primer plays a role of protecting polyethylene.

Owner:GUANGZHOU CHENGXIN ROAD ENG EXAMINATION

Production method of aluminum silicon sol reinforced silicon carbide kiln furniture

ActiveCN105384450AImprove mechanical propertiesImprove antioxidant capacitySolid massSilicon dioxide

The invention discloses a production method of aluminum silicon sol reinforced silicon carbide kiln furniture. With silicon carbide particles as a matrix as well as silicon dioxide sol and aluminium oxide sol as binding agents, the production method of the aluminum silicon sol reinforced silicon carbide kiln furniture sequentially comprises the following steps: 1) uniformly mixing the silicon carbide particles, silicon dioxide sol and aluminium oxide sol to obtain mixture, wherein the solid mass content of the silicon dioxide sol is 30-70%, and the solid mass content of the aluminum oxide sol is 10-40%; 2) ageing the mixture for 22-26 hours, and then moulding, wherein the moulding pressure is 120-160MPa; and then drying a product obtained through moulding for 10-14 hours in an environment at the temperature of 40-60 DEG C, and then firing for 72-96 hours at the temperature of 1450-1700 DEG C, so that the aluminum silicon sol reinforced silicon carbide kiln furniture is obtained.

Owner:ANJI KELING MAGNETIC MATERIAL

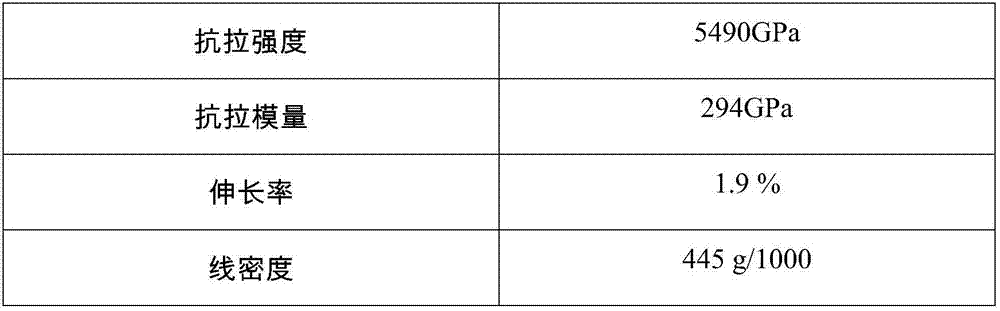

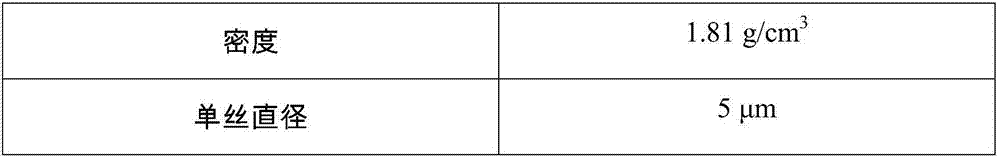

Preparation method for full carbon fibre composite paper

InactiveCN107460777AEnsure synergyGood dispersionSpecial paperPaper/cardboardOrganic solventPlant fibre

The invention discloses a preparation method for full carbon fibre composite paper. The method comprises the following steps: pulping plant fibres; performing dipping treatment on carbon fibres with an organic solvent; treating the carbon fibres with a concentrated acid or a concentrated alkali; performing ultrasonic treatment on the carbon fibres which are treated with the acid or the alkali in a first coupling agent; soaking the plant fibres, which are subjected to pulping treatment, with a second coupling agent; adding water and defibering the treated carbon fibres and the treated plant fibres in a fluffer together; adding a dispersing agent into the fluffer and defibering the dispersant and the fibres together; and manufacturing paper with pulp and forming the paper pulp by using a Kothen method automatic paper making system, and squeezing and drying to obtain synthesized fibres; carbonating the obtained synthesized fibres in the environment with the protection of high-temperature nitrogen. The full carbon fibre composite paper prepared by the preparation method has relatively high finished paper uniformly, high mechanical strength, relatively high heat resistance and high electrical conductivity, and solves the difficult problem that the full carbon fibre paper cannot be made by adopting a conventional method.

Owner:SOUTH CHINA UNIV OF TECH

High-alkalinity slag nickel-based alloy welding rod and preparing method thereof

ActiveCN106271206AGood antioxidant protectionReduce surface tensionWelding/cutting media/materialsSoldering mediaOxidation resistantFluoride calcium

The invention discloses a high-alkalinity slag nickel-based alloy welding rod and a preparing method thereof. Slag formed through welding of high-alkalinity coatings composed of various carbonate and villiaumite alkaline slagging substances has a very good anti-oxidization protection function on nickel-based molten pool metal; meanwhile, part of calcium carbonate is replaced with barium carbonate, part of sodium fluoride is replaced with barium fluoride, the excessively large surface tension of liquid slag due to the too high content of the single calcium carbonate and the single calcium fluoride can be obviously reduced as well, and good covering uniformity of the slag on a liquid molten pool is achieved. Potassium fluoborate is adopted as a coating additive and is evenly scattered in powder through hydroscopicity of the potassium fluoborate to improve the pressing and coating performance of the coatings, capillary holes in the surface and the interior are sealed and blocked after condensation, and therefore the beneficial effects that the strength of the coatings is improved, and the surface smoothness of the welding rod coatings is improved are achieved.

Owner:NANJING INST OF TECH

Hydrophobic porous ceramic product and preparation technology thereof

The invention relates to the technical field of ceramic products and specifically relates to a hydrophobic porous ceramic product and a preparation technology thereof. The hydrophobic porous ceramic product comprises a green body and a glaze material; the green body comprises the following raw materials in parts by weight: 27 parts of silicon nitride, 16 parts of zirconium dioxide, 12 parts of clay, 24 parts of aluminum silicate, 16 parts of cordierite, 19 parts of silicon carbide, 14 parts of kieselguhr, 11 parts of albite, 18 parts of aluminum oxide and 13 parts of fluxing agent; the glaze material comprises the following raw materials in parts by weight: 21 parts of dolomite, 23 parts of silicon carbide, 14 parts of calcium oxide, 17 parts of potassium feldspar, 5 parts of clay and 2 parts of sodium hexametaphosphate. The preparation technology comprises the following steps: modifying raw materials of the green body; injection-molding; de-waxing and biscuit-firing; glazing; sintering. The technology provided by the invention is simple and is suitable for large-scale production. The produced ceramic product has the advantages of high mechanical strength, porous hydrophobic property and high temperature resistance.

Owner:福建省泉州市契合工贸有限公司

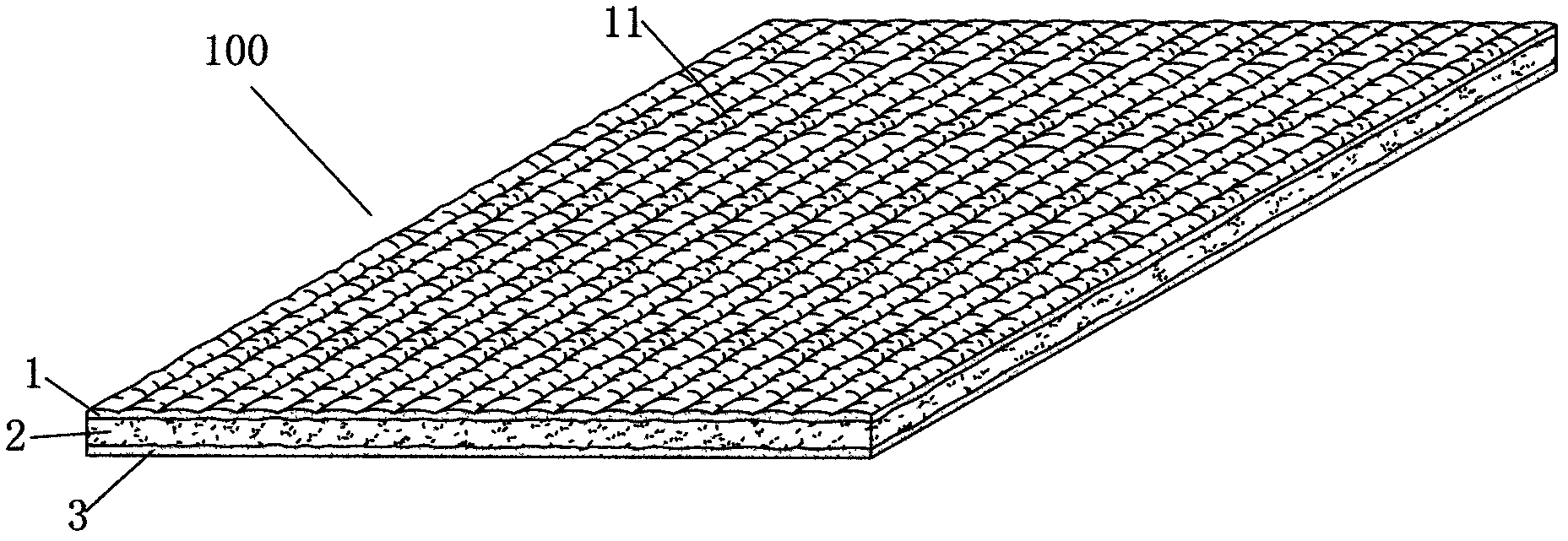

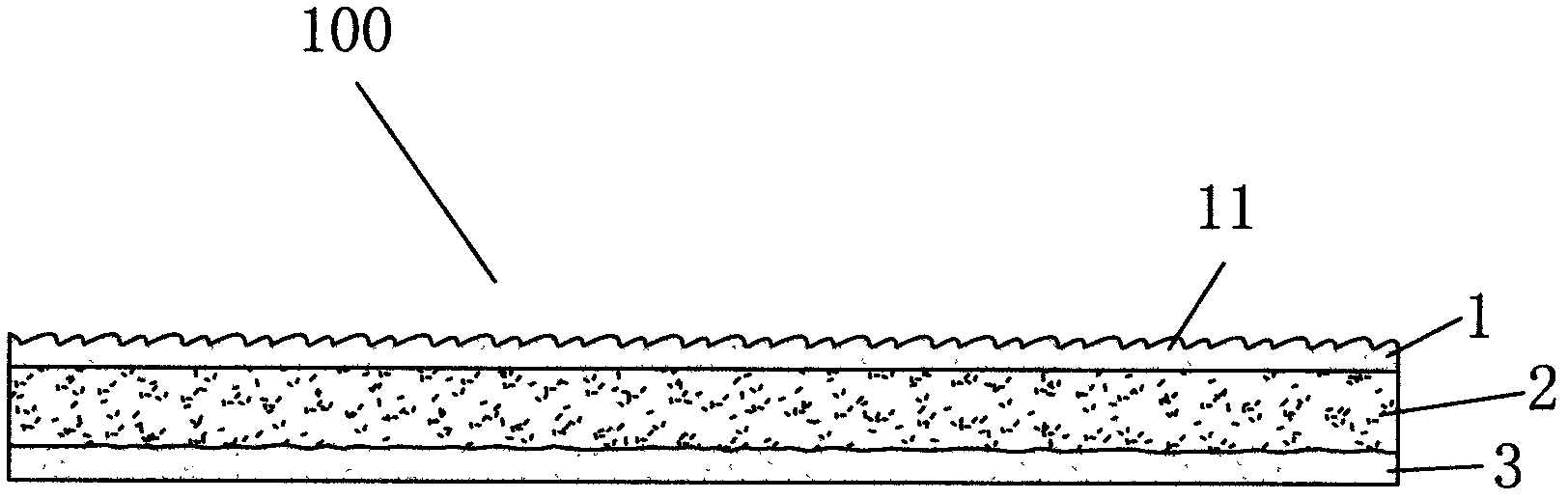

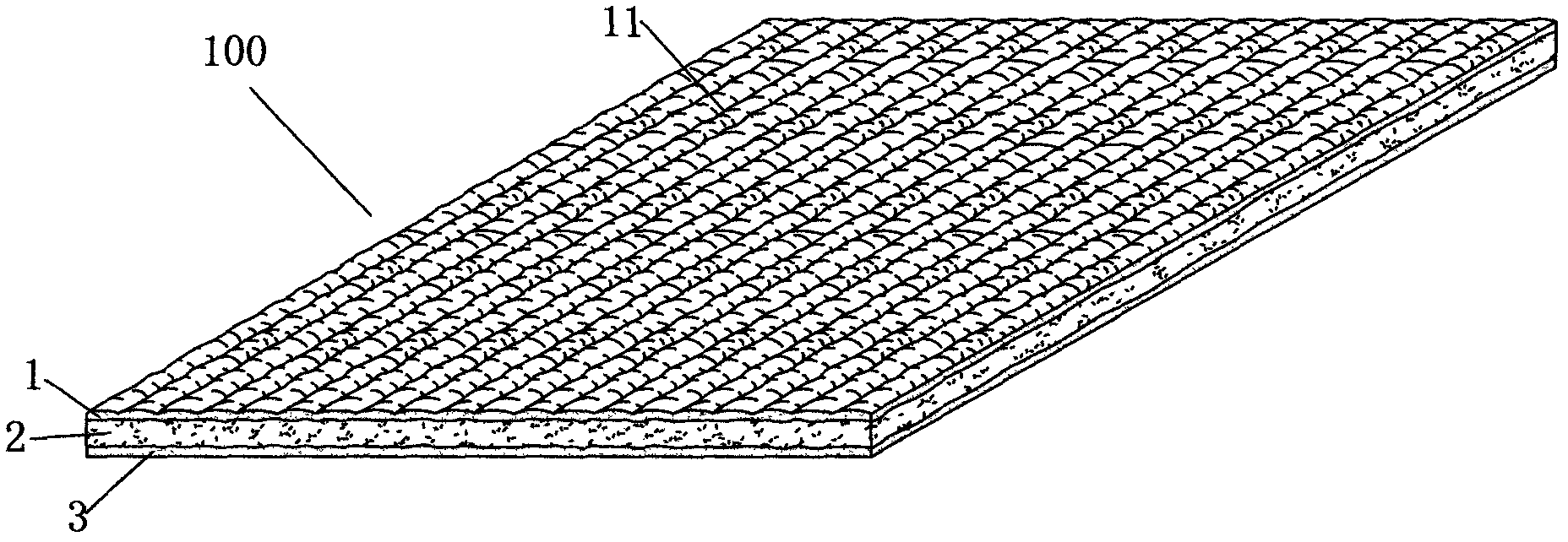

Runway system with excellent impact adsorption capability

InactiveCN102619154AEase of patching and leveling workImprove impact absorption performanceSynthetic resin layered productsGround pavingsSurface layerInternational standard

The invention discloses a runway system with excellent impact adsorption capability, which comprises a wear-resisting surface layer positioned on an upper layer, an elastic middle layer positioned on a middle layer and an elastic macromolecule bottom layer positioned on a bottom layer, wherein the wear-resisting surface layer and the elastic middle layer are bonded to form an integral-shaping prefabricating double-layer structure, and the elastic macromolecule bottom layer is a macromolecule self-leveling layer. According to the runway system with the excellent impact adsorption capability, the cost is saved, the elasticity is better, the impact adsorption capability is stronger, and each physical index reaches the international standard.

Owner:蔡陈敏

Positive electrode for lithium sulfur batteries, preparation and application thereof

ActiveCN104716300AEasy to charge and dischargeImprove permeabilityCell electrodesHigh volume manufacturingMass ratio

The invention relates to a positive electrode for lithium sulfur batteries, preparation and application thereof. The positive electrode includes a carbon sulfur compound, a binder, and a pore forming agent. The binder is a mixture of gelatin and starch in a mass ratio of (1-80):(20-99), the pore forming agent is yeast, the carbon sulfur compound and the binder are in a mass ratio of 8-9.5:0.5-2, and mass ratio of the yeast to the mixture of gelatin and starch is 1-10:90-99. The positive electrode provided by the invention adopts gelatin, starch and yeast as the raw materials, and the raw materials are wide and easy for mass production. Also, the method involves no toxic and harmful reagent, has no pollution, is environment-friendly, convenient and easy to learn, and has good reproducibility. In addition, the manufacturing cost is low, and the efficiency is high.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Novel method for utilizing blue-green algae in Taihu lake

InactiveCN104232232AAchieving processing powerRealize the full utilization of biomassBiofuelsSolid fuelsDry weightResource utilization

The invention discloses a novel method for utilizing blue-green algae in the Taihu lake, and belongs to the field of waste resource utilization and biomass energy. The method comprises the following steps: dewatering and drying the blue-green algae in the Taihu lake until the water content of the blue-green algae in the Taihu lake is 8 to 25 percent; dewatering and drying other biomass waste until the water content of the other biomass waste is 8 to 25 percent, crushing the dewatered and dried biomass waste to 5 to 10 mm; uniformly mixing 20 to 100 percent of the dried blue-green algae in the Taihu lake and other 0 to 80 percent of biomass raw materials, all by dry weight, and performing extrusion forming on the mixture by using a forming machine at the forming pressure of 100 to 300 MPa and the forming temperature of 70 to 170 DEG C to obtain solid fuel. The forming method for a mixed biomass fuel, disclosed by the invention, has the characteristics that 1) the method is simple, feasible and environment-friendly, the treatment efficiency is high, the cost of raw materials is low, and large-scale industrial production is facilitated; 2) the blue-green algae in the Taihu lake is added into the solid fuel, so that the forming is facilitated, and the combustion characteristics of the fuel are improved; 3) the recycling of the blue-green algae in the Taihu lake is realized, and meanwhile, the source of the raw materials of the solid fuel is enriched.

Owner:JIANGNAN UNIV

Lightweight partition board and making method thereof

InactiveCN107162632AHigh compressive strengthHigh tensile strengthConstruction materialCeramicwareFiberFoaming agent

The invention discloses a lightweight partition board and a making method thereof, and relates to the technical field of partition boards. The lightweight partition board comprises 55-65 parts of Portland cement, 45-50 parts of modified fiber particles, 42-43 parts of modified clay, 40-42 parts of paraffin-diatomite phase transition gel, 37-40 parts of latex, 35-37 parts of phosphate, 32-35 parts of hollow glass beads, 27-29 parts of a foaming agent, 23-25 parts of a plasticizer, 21-22 parts of a fire retardant and 65-68 parts of water. The lightweight partition board has the advantages of good comprehensive strength, good tensile strength, good cracking resistance, good suspending ability, good sound and heat insulation effect, low production cost and high economic promotion benefit.

Owner:合肥市旺友门窗有限公司

MA-MF composite spinel reinforced magnesium oxide based foam ceramic filter and preparation method thereof

The invention discloses a MA-MF composite spinel reinforced magnesium oxide based foam ceramic filter capable of realizing low temperature sintering and excellent chemical stability and thermal shockresistance and a preparation method thereof, the preparation method comprises the following steps: (1) proportioning 15% to 25% by mass of nano-aluminum sol, 0.8% to 1.5% by mass of a rheological agent, and balance of magnesium oxide ceramic powder containing a nano-ferric oxide sintering aid, and adding anhydrous ethanol for even mixing by ball milling to obtain ceramic slurry having a solid content of 60% to 70%; (2) immersing a polyurethane foam plastic template into the ceramic slurry, extruding the polyurethane foam plastic template by a roll press to remove excess immersing slurry to obtain a green body, and removing an ethanol solvent in a ventilating chamber at 40 DEG C to 50 DEG C to dry the green body; and (3) putting the dried green body in a sintering furnace, heating to 1350 to 1550 DEG C for high temperature sintering, and cooling in the furnace to room temperature to obtain the magnesium oxide based ceramic foam filter.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Controlled-release compound fertilizer formed by corn stalks and preparation method thereof

The invention relates to a controlled-release compound fertilizer formed by corn stalks and a preparation method thereof. According to the controlled-release compound fertilizer formed by corn stalksdisclosed by the invention, adsorption of corn stalk pulp is utilized, so that nutrients added into the fertilizer are uniformly adsorbed to the peripheries of stalk particles, and a mixed fertilizeris tightly adhered together by hot-press forming. The nutrients are gradually released through decomposition of the stalks, and are completely released until the stalks are completely degraded underground while any microorganism does not need to add or any special condition is not needed, so that the controlled-release compound fertilizer has good slow release feature and wide applicability. The controlled-release compound fertilizer formed by corn stalks is simple in preparation process, and biomass does not need to carbonize or coat; the preparation period is short, and fermentation is not needed; the cost is low, and other additives except from the nutrients do not need to add; and transportation and application are easy.

Owner:SHENYANG AGRI UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com