Positive electrode for lithium sulfur batteries, preparation and application thereof

A lithium-sulfur battery and electrode technology, which is applied to battery electrodes, circuits, electrical components, etc., can solve the problems of poor electronic conductivity and ion conductivity of elemental sulfur, poor cycle performance of lithium-sulfur batteries, and volume expansion of sulfur electrodes, etc., to reduce the interface Resistance, suppression of conductivity deterioration, and uniform distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

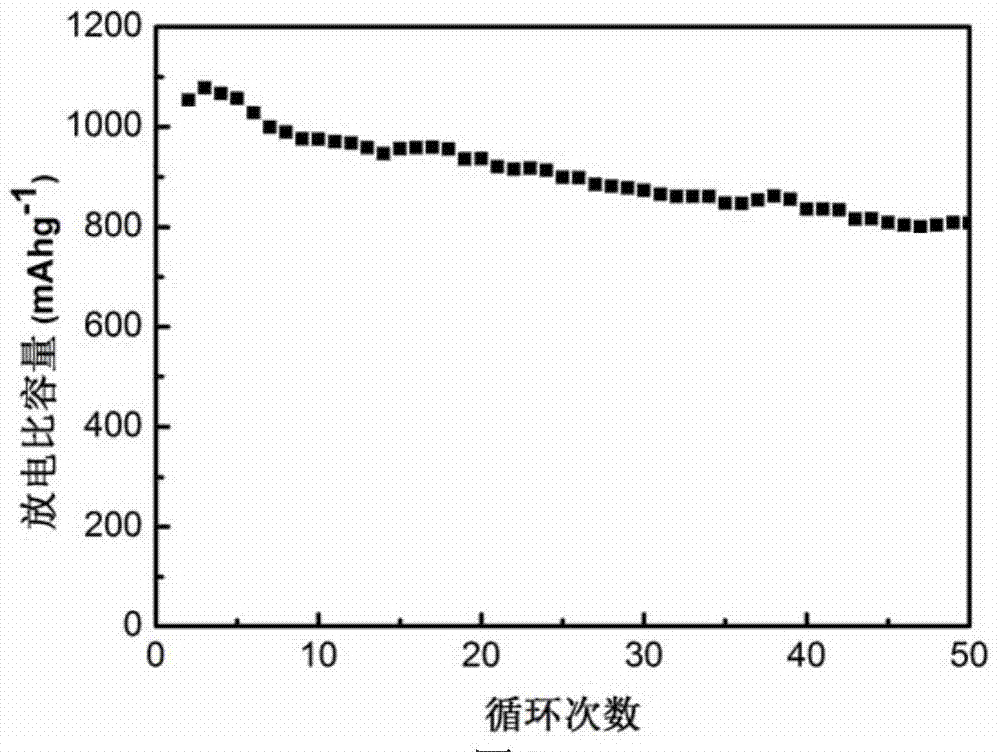

Embodiment 1

[0025] a. Heat and stir the gelatin in deionized water for 1 h, the concentration of the gelatin aqueous solution is 7 wt %, and the heating temperature is 80° C. to obtain the gelatin aqueous solution.

[0026] b. Heat and stir the starch in deionized water for 0.5 h, the concentration of the starch aqueous solution is 10 wt %, and the heating temperature is 90° C. to obtain the starch aqueous solution.

[0027]c. Add the starch aqueous solution to the prepared gelatin aqueous solution while heating and stirring, the mass ratio of gelatin and starch is 4:21, the concentration of the gelatin starch mixed aqueous solution is 15wt%, the heating temperature is 80°C, and the stirring time is 0.5h to obtain gelatin Starch mixed solution.

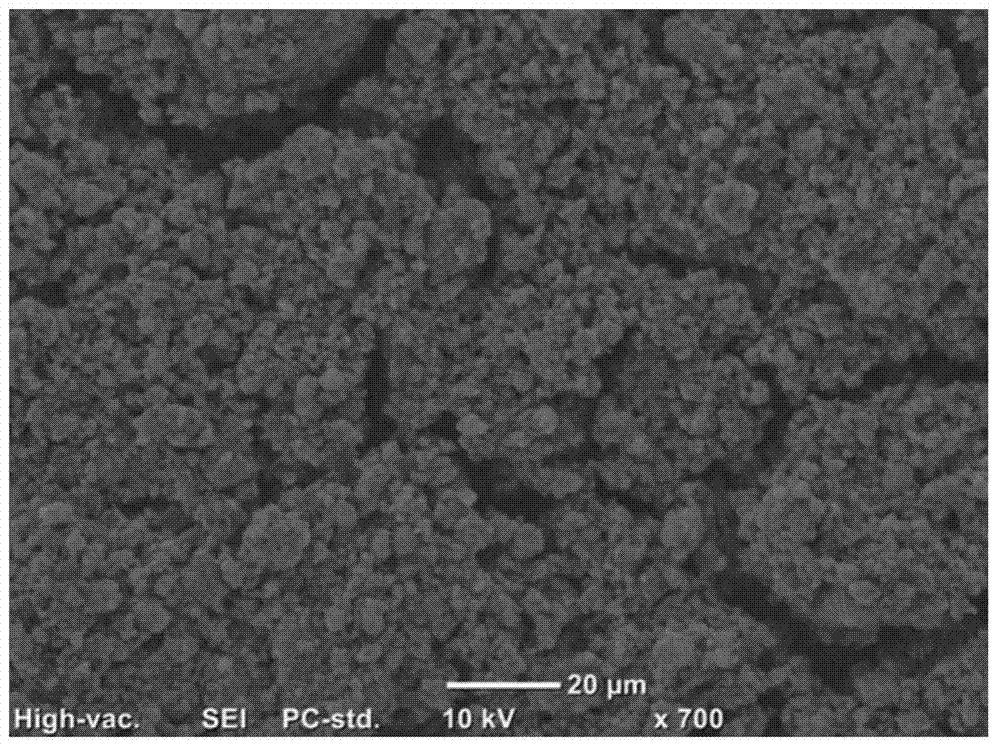

[0028] d Add the gelatin starch mixed solution as an electrode binder to the carbon-sulfur composite, add deionized water, heat and stir for 2 hours, the mass ratio of the carbon-sulfur composite to the binder is 9:1, and the heating temperature ...

Embodiment 2

[0036] a. Heat and stir the gelatin in deionized water for 1 h, the concentration of the gelatin aqueous solution is 7 wt %, and the heating temperature is 80° C. to obtain the gelatin aqueous solution.

[0037] b. Heat and stir the starch in deionized water for 0.5 h, the concentration of the starch aqueous solution is 10 wt %, and the heating temperature is 90° C. to obtain the starch aqueous solution.

[0038] c. Add starch aqueous solution to the prepared gelatin aqueous solution while heating and stirring, the mass ratio of gelatin and starch is 1:4, the concentration of gelatin starch mixed aqueous solution is 15wt%, the heating temperature is 80°C, and the stirring time is 0.5h to obtain gelatin Starch mixed solution.

[0039] d Add the gelatin starch mixed solution as an electrode binder to the carbon-sulfur composite, add deionized water, heat and stir for 2 hours, the mass ratio of the carbon-sulfur composite to the binder is 9:1, and the heating temperature is 80°C ...

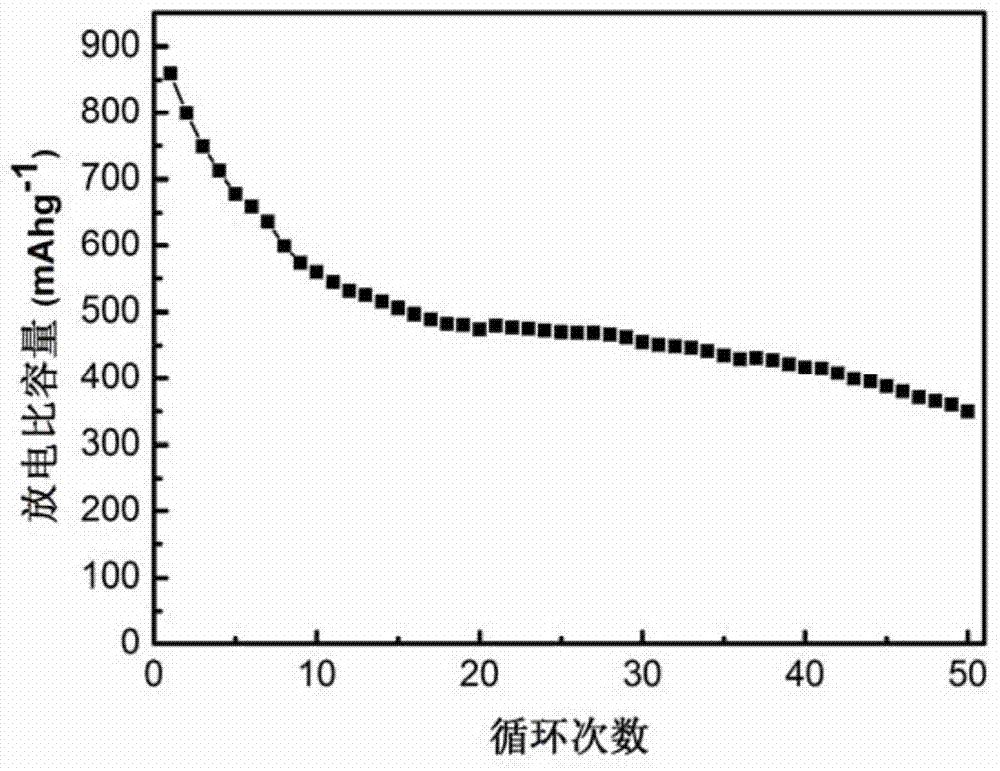

Embodiment 3

[0047] a. Heat and stir the gelatin in deionized water for 1 h, the concentration of the gelatin aqueous solution is 7 wt %, and the heating temperature is 80° C. to obtain the gelatin aqueous solution.

[0048] b. Heat and stir the starch in deionized water for 0.5 h, the concentration of the starch aqueous solution is 10 wt %, and the heating temperature is 90° C. to obtain the starch aqueous solution.

[0049] c. Add starch aqueous solution to the prepared gelatin aqueous solution while heating and stirring, the mass ratio of gelatin and starch is 6:19, the concentration of gelatin starch mixed aqueous solution is 15wt%, the heating temperature is 80°C, and the stirring time is 0.5h to obtain gelatin Starch mixed solution.

[0050] d Add the gelatin starch mixed solution as an electrode binder to the carbon-sulfur composite, add deionized water, heat and stir for 2 hours, the mass ratio of the carbon-sulfur composite to the binder is 9:1, and the heating temperature is 80°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com