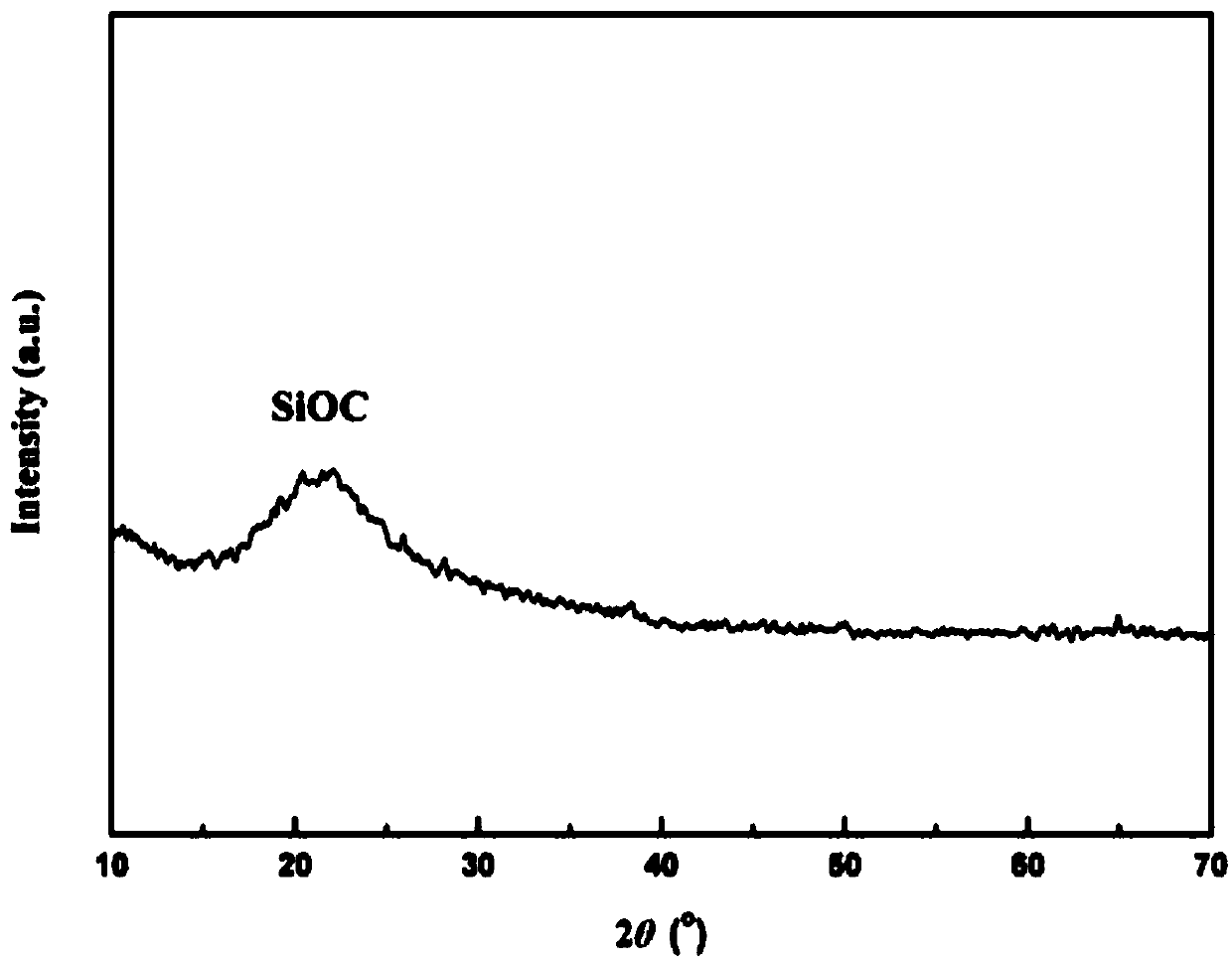

Method for in-situ synthesis of amorphous SiOC nanowire reinforced ceramic core

A ceramic core, in-situ synthesis technology, used in cores, casting molding equipment, casting molds, etc., can solve problems affecting the enhancement effect of ceramic cores, achieve excellent room temperature and high temperature performance, enhance high temperature strength and high temperature creep. The effect of changing performance and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] In this embodiment, a method for in-situ synthesis of an amorphous SiOC nanowire reinforced ceramic core comprises the following steps:

[0024] a. Mix the selected ceramic powder and silicone resin powder by ball milling, control the ball milling time to 24h, and sieve after ball milling to obtain a uniform mixed powder; in the mixed powder, the ceramic powder is silicon dioxide and alumina mixed oxide, the content of the added silicone resin powder is 10wt% of the total weight of the mixed powder;

[0025] b. Compressing the mixed powder uniformly mixed in the step a to obtain a porous ceramic green body; controlling the molding pressure to 20MPa, and the holding time to 3min;

[0026] c. curing the porous ceramic green body obtained in the step b in an atmospheric environment to obtain a porous ceramic green body; controlling the curing temperature to 300° C., holding time for 4 hours, and heating rate to 3° C. / min;

[0027] d. Carry out sintering treatment to the p...

Embodiment 2

[0037] This embodiment is basically the same as Embodiment 1, especially in that:

[0038] In this embodiment, a method for in-situ synthesis of an amorphous SiOC nanowire reinforced ceramic core comprises the following steps:

[0039] a. Mix the selected ceramic powder and silicone resin powder by ball milling, control the ball milling time for 24 hours, and sieve after ball milling to obtain a uniform mixed powder; in the mixed powder, the ceramic powder is silicon dioxide, and the added The silicone resin powder content is 15wt% of the total weight of the mixed powder;

[0040] b. This step is the same as in Embodiment 1;

[0041] c. This step is the same as in Embodiment 1;

[0042] d. This step is the same as in Embodiment 1.

[0043] In this embodiment, silicon resin is used as a binder and a precursor, and ceramic powder is used as a matrix to prepare a ceramic core material reinforced with SiOC nanowires. The precursor silicone resin used in this embodiment can be tr...

Embodiment 3

[0045] This embodiment is basically the same as the previous embodiment, and the special features are:

[0046] In this embodiment, a method for in-situ synthesis of an amorphous SiOC nanowire reinforced ceramic core comprises the following steps:

[0047] a. Mix the selected ceramic powder and silicone resin powder by ball milling, control the ball milling time for 24 hours, and sieve after ball milling to obtain a uniform mixed powder; in the mixed powder, the ceramic powder is silicon dioxide, and the added The silicone resin powder content is 10wt% of the total weight of the mixed powder;

[0048] b. This step is the same as in Embodiment 1;

[0049] c. This step is the same as in Embodiment 1;

[0050] d. Carry out sintering treatment to the porous ceramic preform solidified in the step c in a nitrogen inert atmosphere protection sintering furnace to obtain an amorphous SiOC nanowire reinforced ceramic core, and the control sintering system is:

[0051] First, heat up ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com