Patents

Literature

113results about How to "Realize secondary recycling" patented technology

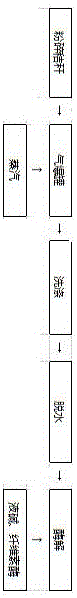

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

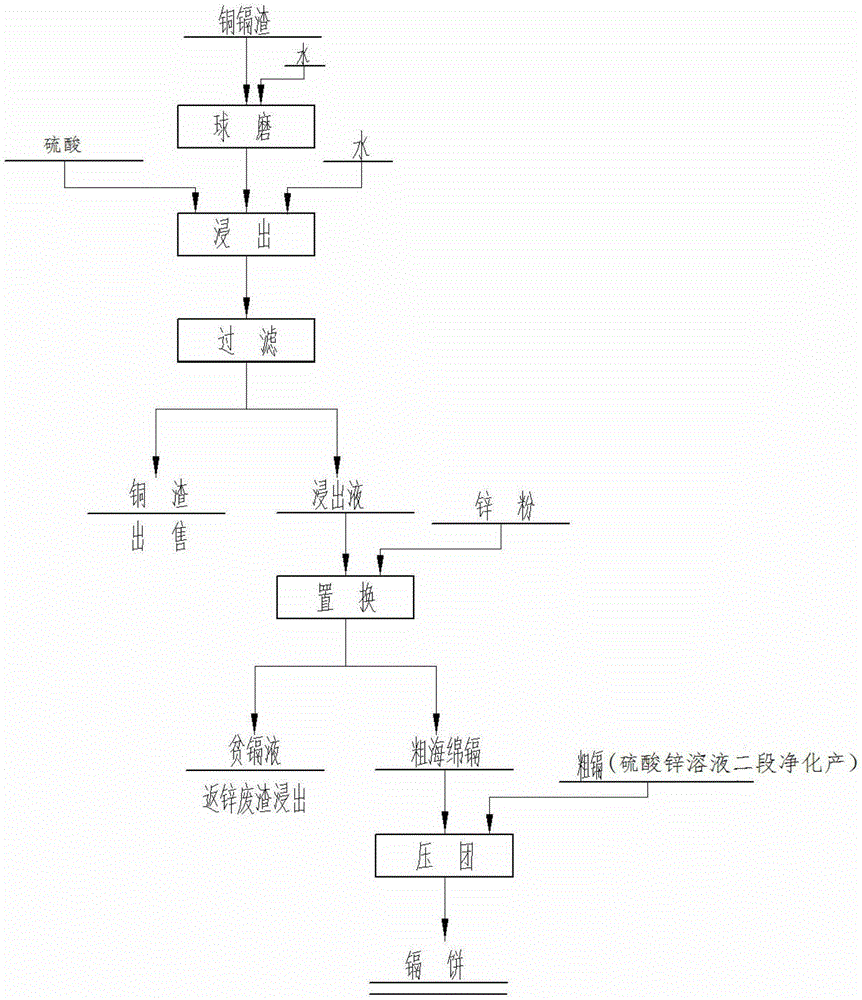

Method for preparing ferronickel by using red mud and laterite-nickel ore

ActiveCN104178624ARich in beneficial chemical ingredientsRealize secondary recyclingFluidised-bed furnacesRed mudLaterite

The invention provides a method for preparing ferronickel by using red mud and laterite-nickel ore. Meanwhile, a novel method is provided for recovery of iron in red mud and production of ferronickel from the red mud and the laterite-nickel ore. According to the method, iron-nickel reduction products in the red mud and the laterite-nickel ore are directly utilized, and low-cost ferronickel can be provided for stainless steel smelting production, ferroalloy casting and alloy steel production. The laterite-nickel ore also contains a little of chromium, and in the production method disclosed by the invention, chromium enters the iron-nickel alloy, so that beneficial chemical components of the iron-nickel alloy are enriched. The contained iron-nickel alloy produced by the method disclosed by the invention is iron-nickel alloy with low P and S content.

Owner:GUANGXI UNIV

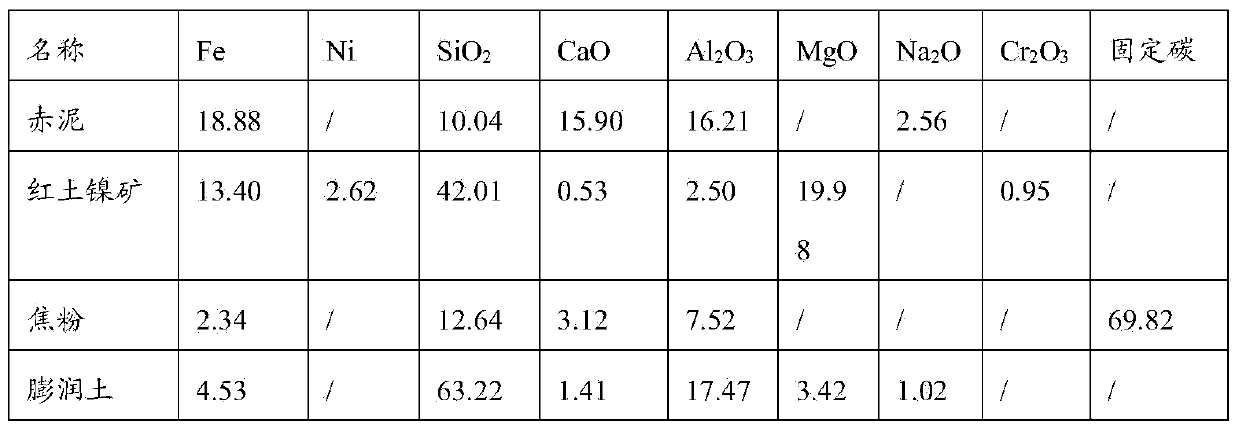

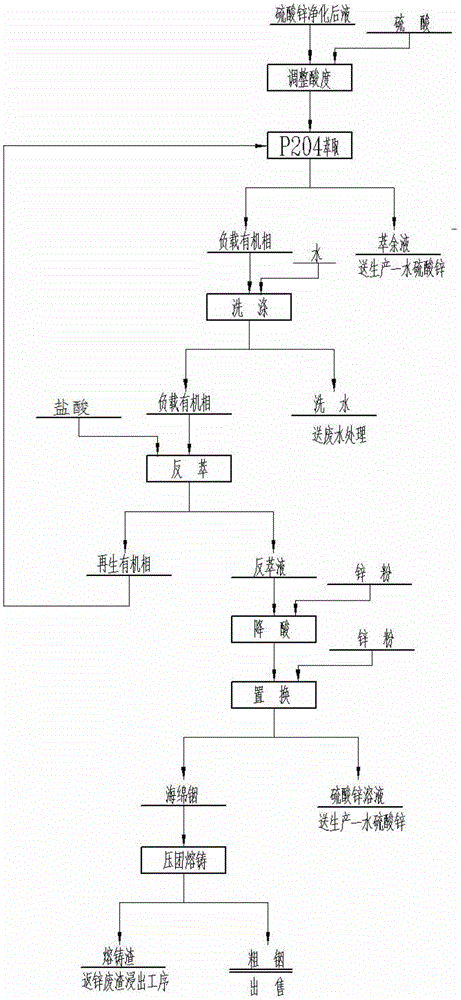

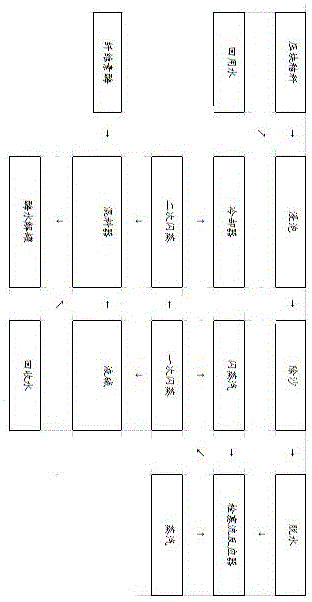

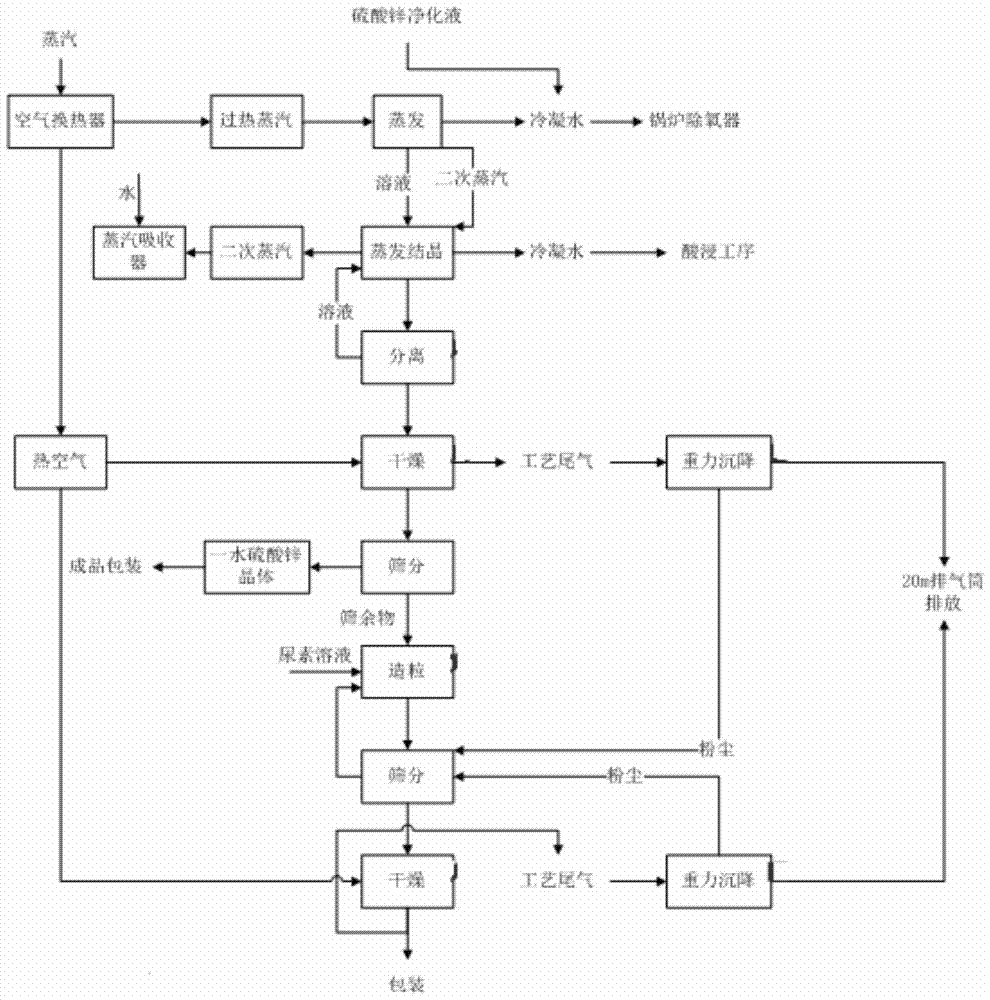

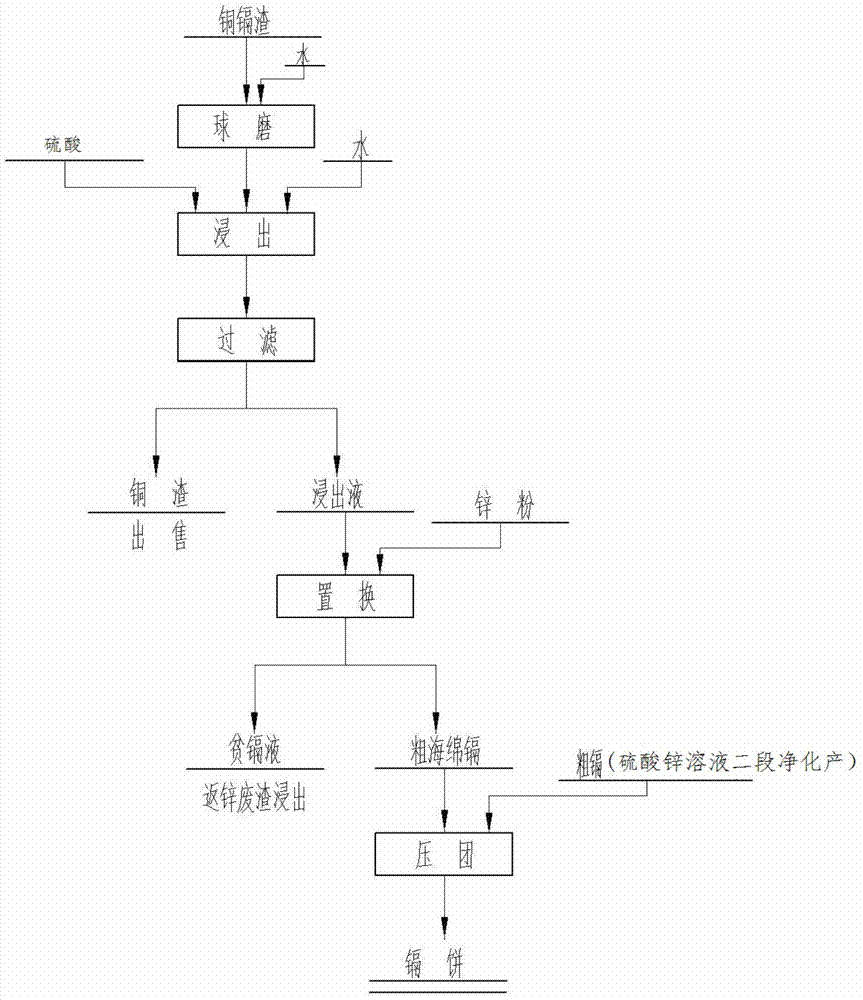

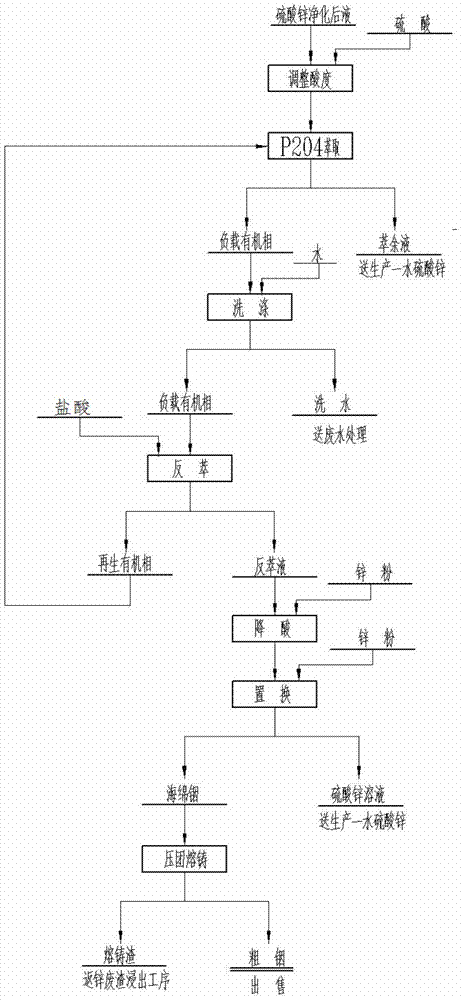

Process for producing zinc sulphate monohydrate from waste acid and waste zinc dross

ActiveCN105274342AAchieve recyclingStructural changeProcess efficiency improvementIndiumCadmium Cation

A process for producing zinc sulphate monohydrate (feed grade) from waste acid and waste zinc dross includes the steps of (a) sulfuric acid leaching, (b) deironing, (c) purification for copper and cadmium removal, (d) dechloridation, (e) defluorination, (f) indium and cadmium extraction and (g) evaporative crystallization. The feed-grade zinc sulphate monohydrate is produced from the waste acid, waste zinc dross and the like, comprehensive utilization of waste is achieved, and the production cost of raw materials is reduced, so that resources are saved. Therefore the waste of massive zinc enterprises in China is recycled to produce economic benefits, the waste is changed into the valuable, a disadvantage is turned into an advantage, secondary utilization of the waste is achieved, comprehensive recycling of waste acid and waste dross resources is achieved, solid and liquid are separated, and the concentration crystallization and drying technology, the energy saving technology and the like are improved. The work of energy conservation, water conservation, comprehensive utilization, environment protection and the like is completed, the social benefits are remarkable, and remarkable environmental protection benefits and economic benefits are achieved.

Owner:湖南鑫海环保科技有限公司

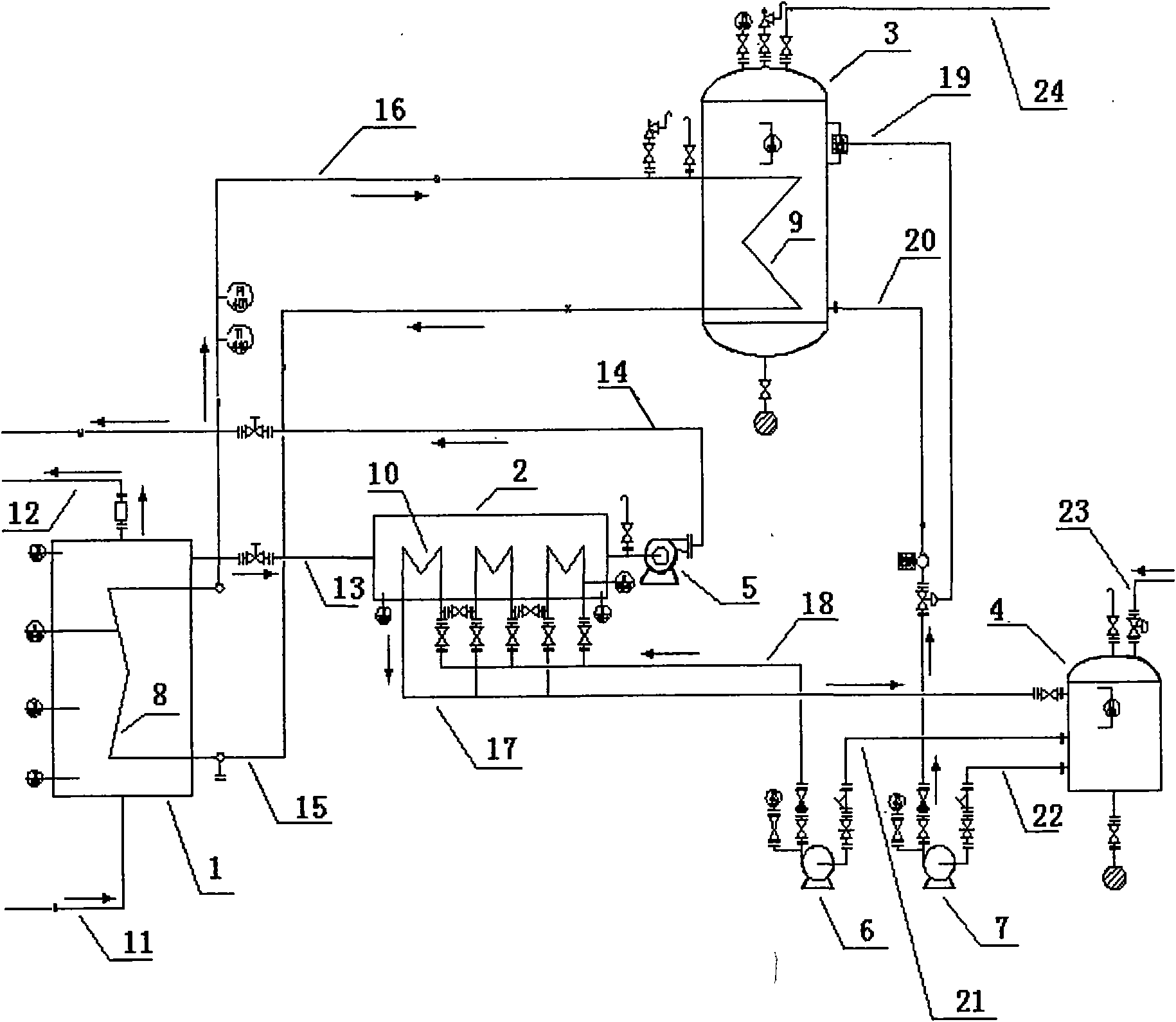

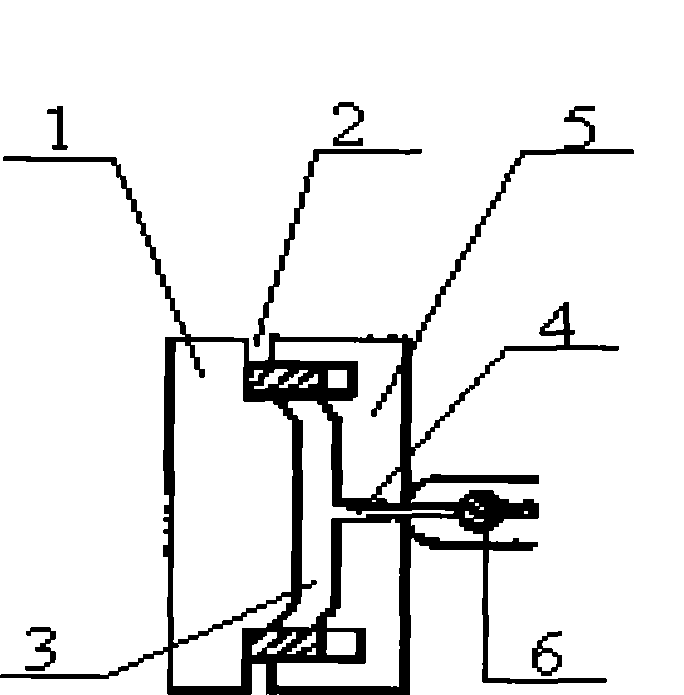

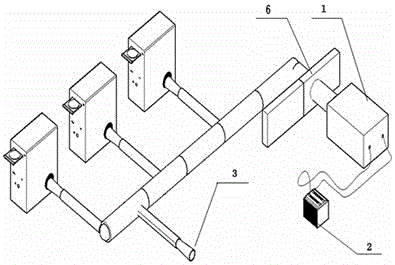

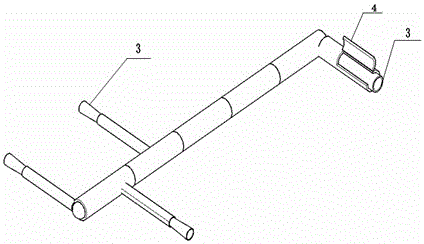

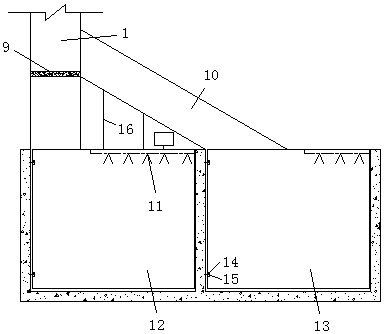

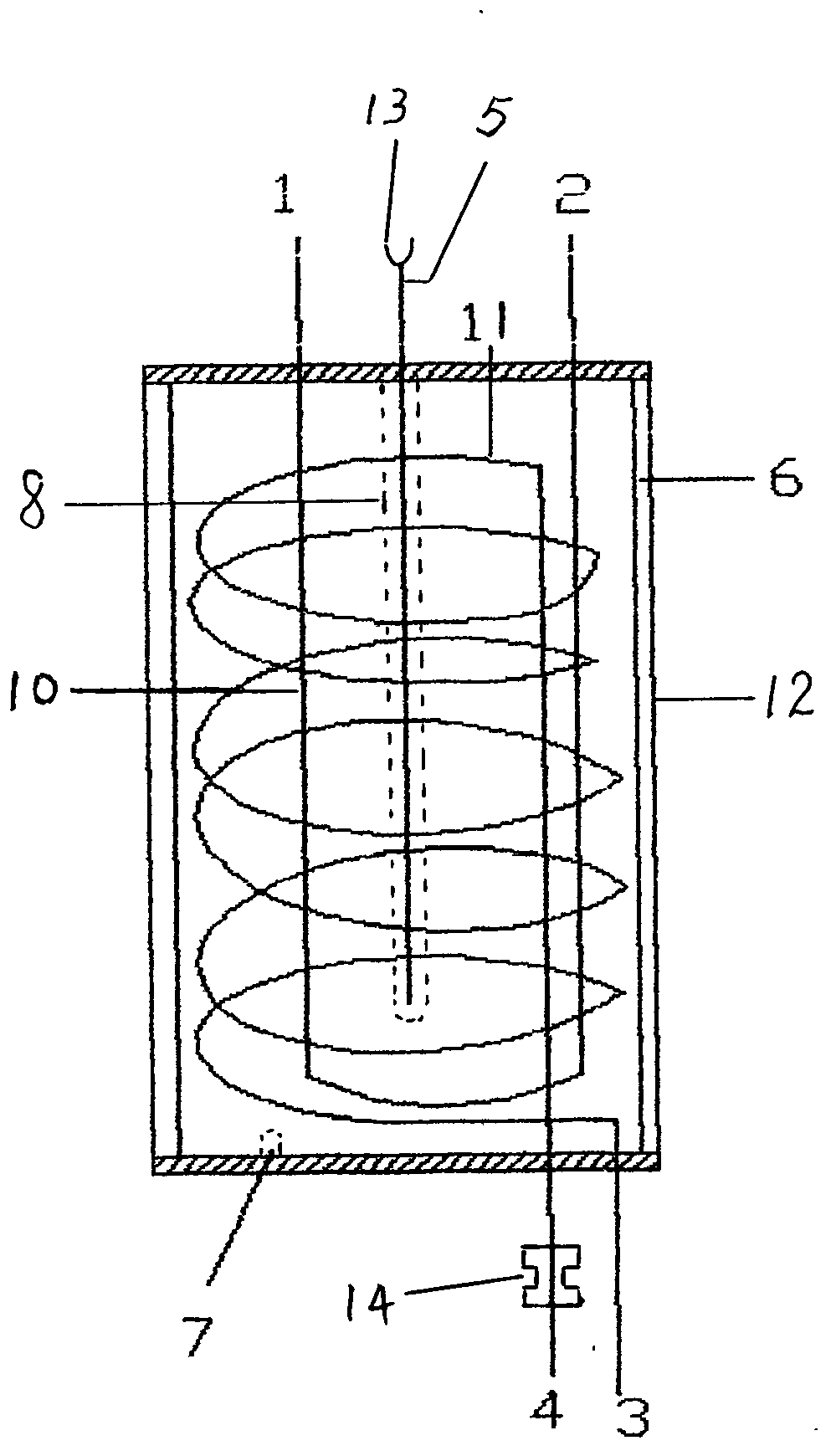

System and method for recovering waste heat of coke-oven crude gas

ActiveCN101619848ATake advantage ofRealize secondary recyclingSteam generation using hot heat carriersThermal energyWater leakage

The invention relates to waste heat recovery of coke-oven crude gas, in particular to a system and a method for recovering waste heat of coke-oven crude gas, which mainly solves the technique problems of causing water leakage to a water jacket of a riser tube, causing tar slag to the inner wall of the riser tube and causing difficult opening and corrosion of a riser-tube cap by adopting a riser-tube vaporization cooler system to recover the waste heat of gas. The invention adopts a technical scheme that the system for recovering waste heat of coke-oven crude gas mainly comprises a high-end heat energy (800 to 500 DED C) absorption device, a low-end heat energy (500 to 280 DEG C) absorption device and a water replenishment system, wherein the high-end heat energy absorption device is connected with the low-end heat energy absorption device through a two-stage cooling input pipeline. The recovery system is connected with a reservoir through a water inlet pipe, is taken as a new-water replenishment channel of an external entering system, is connected with the high-end heat energy absorption device and the low-end heat energy absorption device for heat exchange via the reservoir through a water replenishment pipe respectively, and finally outputs steam generated in a steam drum through a steam output pipe. The method is mainly used to recover the waste heat of coke-oven crude gas.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD +1

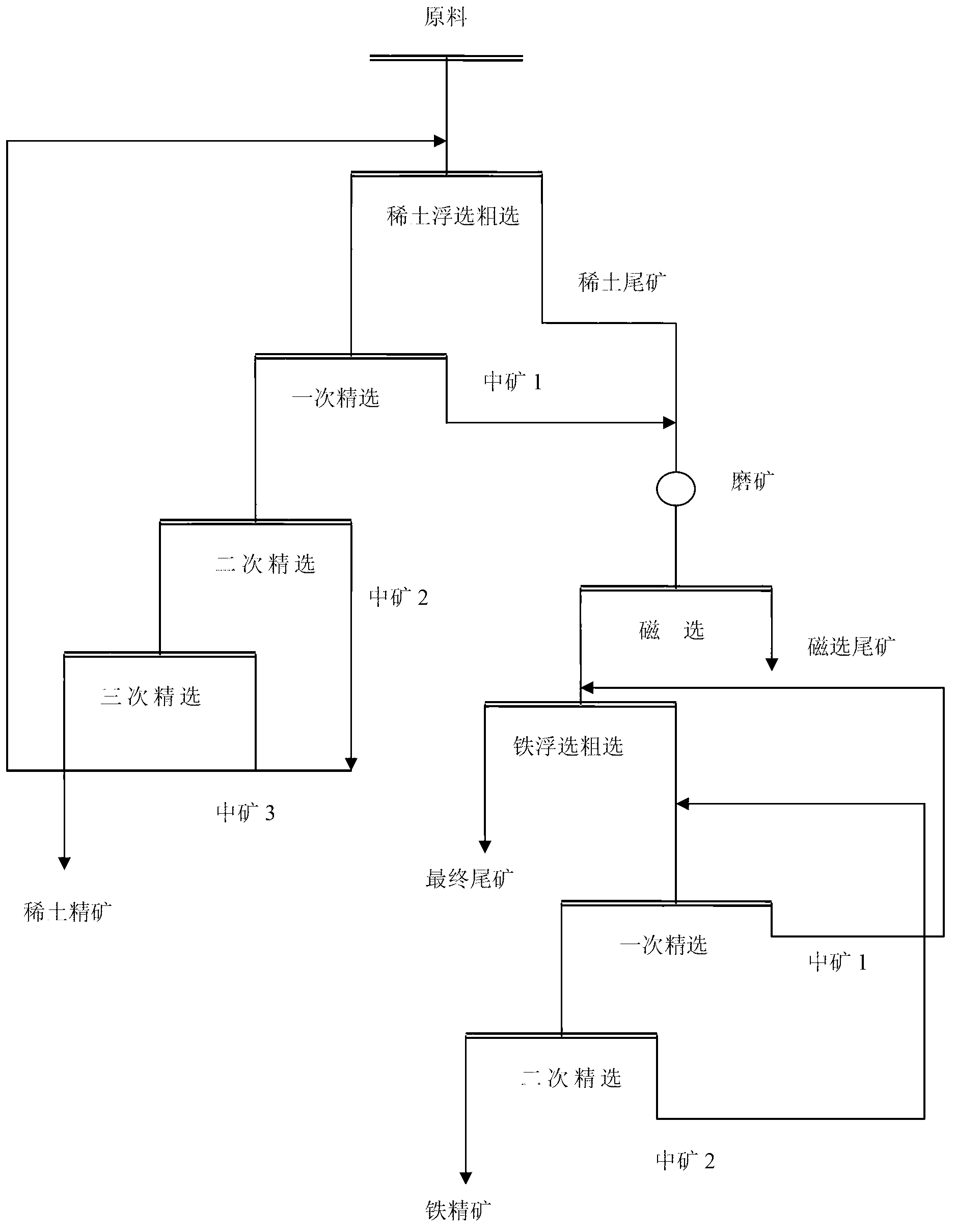

Process for recovering iron and rare earth in baotite low-intensity magnetic separation tailings

The invention belongs to the technical field of mineral engineering and aims at providing a process for recovering iron and rare earth in baotite low-intensity magnetic separation tailings. Iron content in the tailings in the existing technological process of a bayan obo iron mine is about 13% ordinarily, dissemination particles of iron minerals are fine, and the recovering difficulty of the iron minerals in the tailings is caused. The rare earth content is 7%-8% ordinarily, so that the rare earth resource recovering value exists. Rare earth concentrate is obtained from the low-intensity magnetic separation tailings in the existing technological process by adopting a rare earth separation process including primary roughing and a tertiary roughing. Rare earth tailings and middlings 1 in the rare earth recovering process serve as raw materials for recovering the iron minerals, and the raw materials are mixed and grinded to be 96-97% of -325 meshes and then are subjected to magnetic separation at the magnetic field intensity of 600-650kA / m. Magnetic separation rough concentrate serves as iron flotation feeds, ammonium fluosilicate is used as an inhibitor and a potential of hydrogen (pH) regulator, and oxidized paraffin soap and alkyl hydroximic acid with the mass ratio of 8-10:1 serve as collecting agents to perform direct iron flotation to obtain iron ore concentrate.

Owner:包钢集团矿山研究院(有限责任公司)

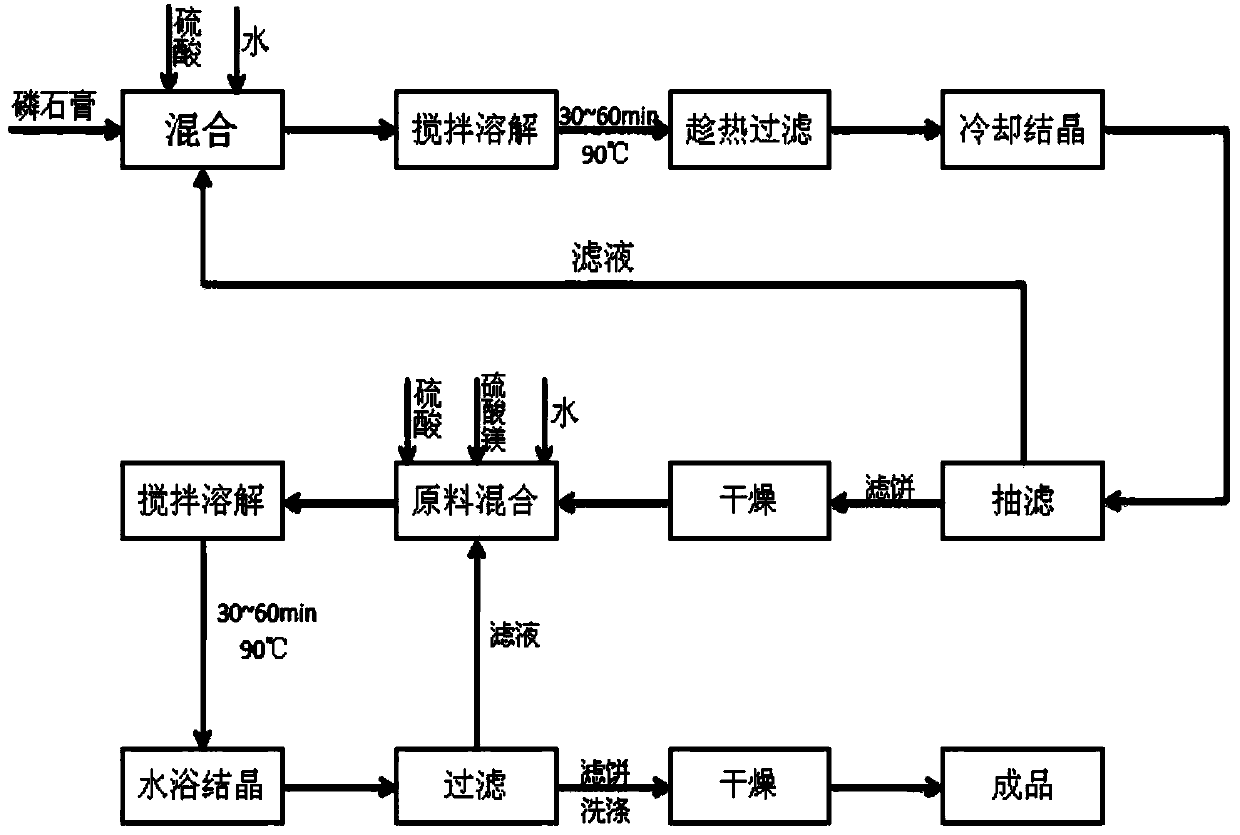

Method for preparing phosphogypsum whiskers by secondary crystallization

InactiveCN103628142AGood solid-liquid ratioSolve the problem of generating large amounts of sewagePolycrystalline material growthFrom normal temperature solutionsWater bathsMagnesium salt

The invention discloses a method for preparing phosphogypsum whiskers by secondary crystallization. The method comprises the steps of weighing dried phosphogypsum, adding a sulfuric acid solution, performing stirring reaction in a water bath, filtering when being hot, abandoning insoluble substances, cooling filtrate at room temperature for crystallization, performing suction filtration, and then retaining a filter cake; adding the sulfuric acid solution and a crystallization promoting agent, namely magnesium salt, performing stirring reaction in the water bath, naturally cooling the solution in the water bath for crystallization, performing suction filtration to obtain the whiskers, washing till neutrality and drying. The crystallization promoting agent is not used in primary crystallization in the method disclosed by the invention, the solid-liquid ratio of raw materials has a good effect, the reaction temperature and the stirring rotational speed are reasonably designed, the secondary crystallization method is created, the problems of short length-diameter ratio, low yield, difficulty in production under non-high pressure conditions and difficulty in succeeding without pretreatment of the phosphogypsum whiskers in the prior art are solved, the problems of phosphorus residue and the like can be solved by recycling a solvent, and the sustained cyclic production can be further realized. The length-diameter ratio of the whiskers produced by the method disclosed by the invention is more than 100, the whiteness is not less than 95%, and the product yield is improved by 10%-15%.

Owner:GUIZHOU KAILIN GRP CO LTD

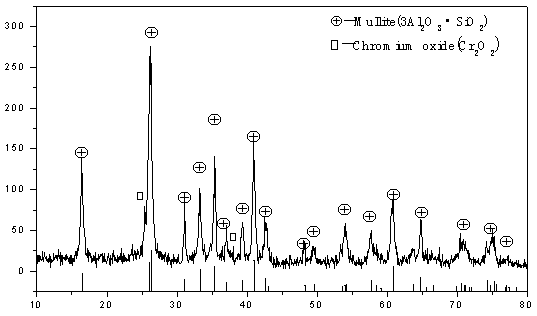

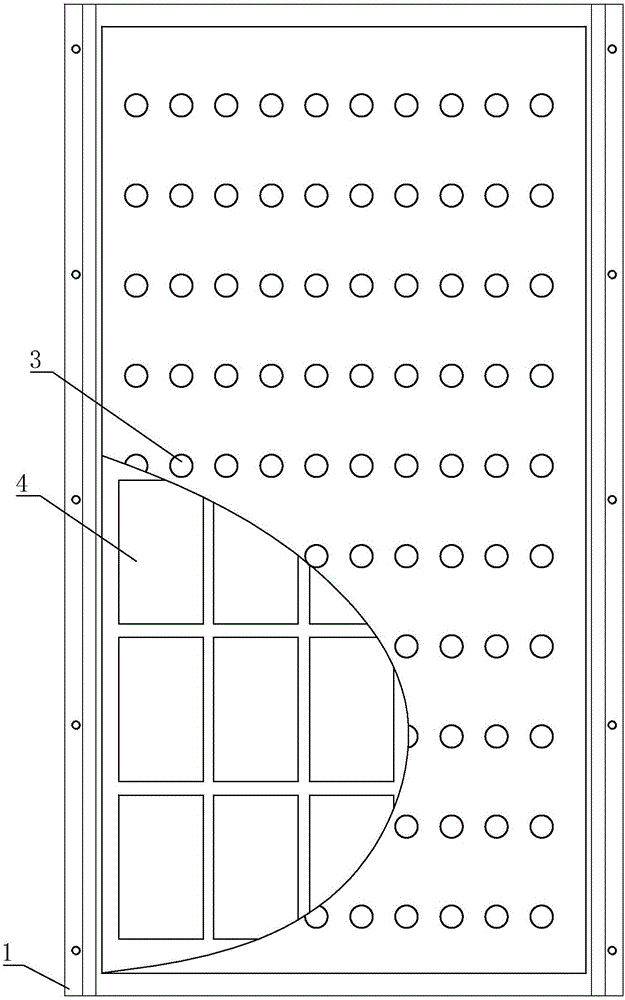

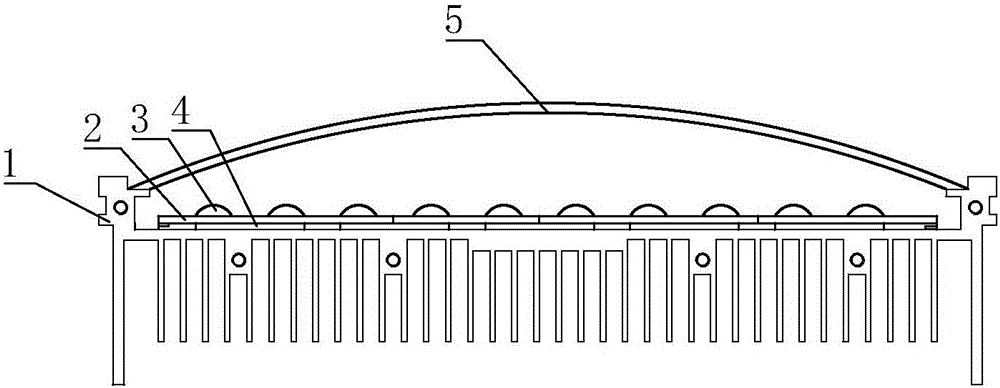

Low-cost manufacture method of high-quality diaphragm and filter plate

InactiveCN101417498AHigh molding densityExtended service lifeDomestic articlesThermoplasticMolten state

The invention relates to a manufacture method of a diaphragm or a filter plate, with low cost and high precision. When a larger die cavity space is left between an upper die and a lower die used for manufacturing the diaphragm or the filter plate, plastics in molten state in an infection machine charging barrel is quantitatively injected into the large die cavity formed by the upper die and the lower die of the die cavity under low pressure through the flow passage in the upper die or the lower die. Then, the periphery of the upper die and the lower die are treated with complete die-closing in closed state under the action of external force, and after the diaphragm or the filter plate in the die cavity is cooled down, the die is opened and the diaphragm or the filter plate is taken out. The method has the advantages that not only the plasticized plastics in the plastic diaphragm cavity are homogeneously extruded to every part of the cavity to be shaped, but also the low-pressure injection molding of the plastics diaphragm is realized and the demand for the mold locking tonnage of a press is reduced, therefore, resource waste and energy consumption are avoided. The method can be suitable not only for thermoplastics and thermosetting plastics, but also for plastic alloy, blending material, recycled thermoplastics, and the like, therefore, the regeneration and reutilization of the resources can be realized.

Owner:朱兴源

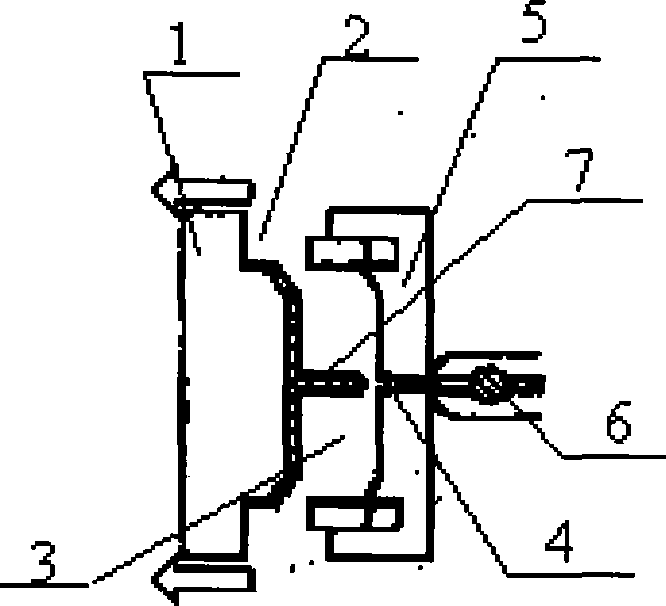

Method for low-temperature smelting of regenerated lead

InactiveCN104451161ASolve serious corrosion problemsExtended service lifeProcess efficiency improvementSlagMaterials science

The invention relates to a method for low-temperature smelting of regenerated lead and belongs to the technical field of preparation of regenerated lead. According to the method provided by the invention, an alkaline environment is provided by sodium carbonate, regenerated lead raw material and / or lead ore powder are / is taken as a lead source, carbon is taken as a reducing agent, alkaline smelting is performed at the temperature of 800-1100 DEG C, three products, namely crude lead or precious lead, smelting slag and smoke gas are produced, most of gold, silver and other precious metals enter crude lead or precious lead, crude lead produced by smelting is settled to the bottom for discharge, sulfur enters the smelting slag in the form of sodium sulfide, after water leaching of the smelting slag, filtrate is concentrated and crystallized in steps to obtain sodium carbonate and sodium sulfide products, and after dedusting of the smoke gas, smoke dust returns into the raw material, and waste gas can be directly discharged after being absorbed by lye. The technical scheme provided by the invention has the advantages of low energy consumption, low cost, environmental friendliness and the like, and further has significant economic benefits and social benefits.

Owner:CENT SOUTH UNIV +1

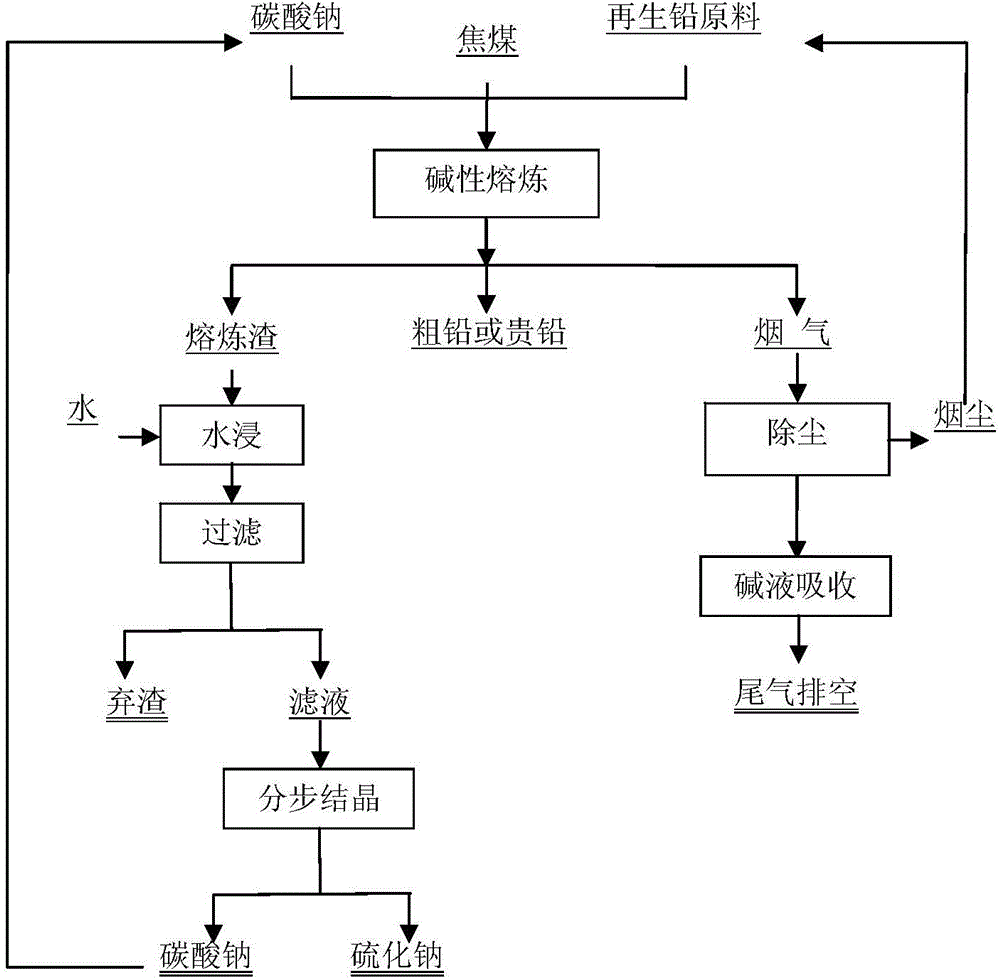

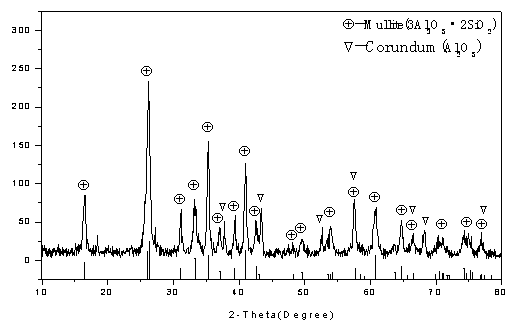

Mullite nano-whisker prepared by using pyrite tailing as raw material and preparation method of mullite nano-whisker

InactiveCN104313695AUniform diameterUniform length distributionPolycrystalline material growthFrom solid statePyriteIron removal

The invention discloses a method for preparing a mullite nano-whisker by using pyrite tailing as a raw material, and belongs to the field of nano-whisker preparation and mineral resource recycling. The method comprises the following steps: preparing the raw material, pickling for removing iron, calcinating for removing C, S and organic matters, preparing a precursor, and performing calcination and acid soaking for removing a glass phase. According to the invention, the prepared nanoscale mullite whisker has good quality, has excellent properties of both the mullite whisker and the nano-whisker, and has a high additional value and a remarkable economic benefit; in addition, the adopted raw material pyrite tailing is waste mineral materials after mineral dressing, so that the products are low in cost of raw materials, and the secondary recycling of pyrite resources is achieved; meanwhile, compared with other preparation methods, the preparation process of the invention requires lower calcination temperature and shorter calcination time, so that reduction of energy consumption is facilitated, thereby reducing production cost and resource consumption, and increasing economic benefits.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

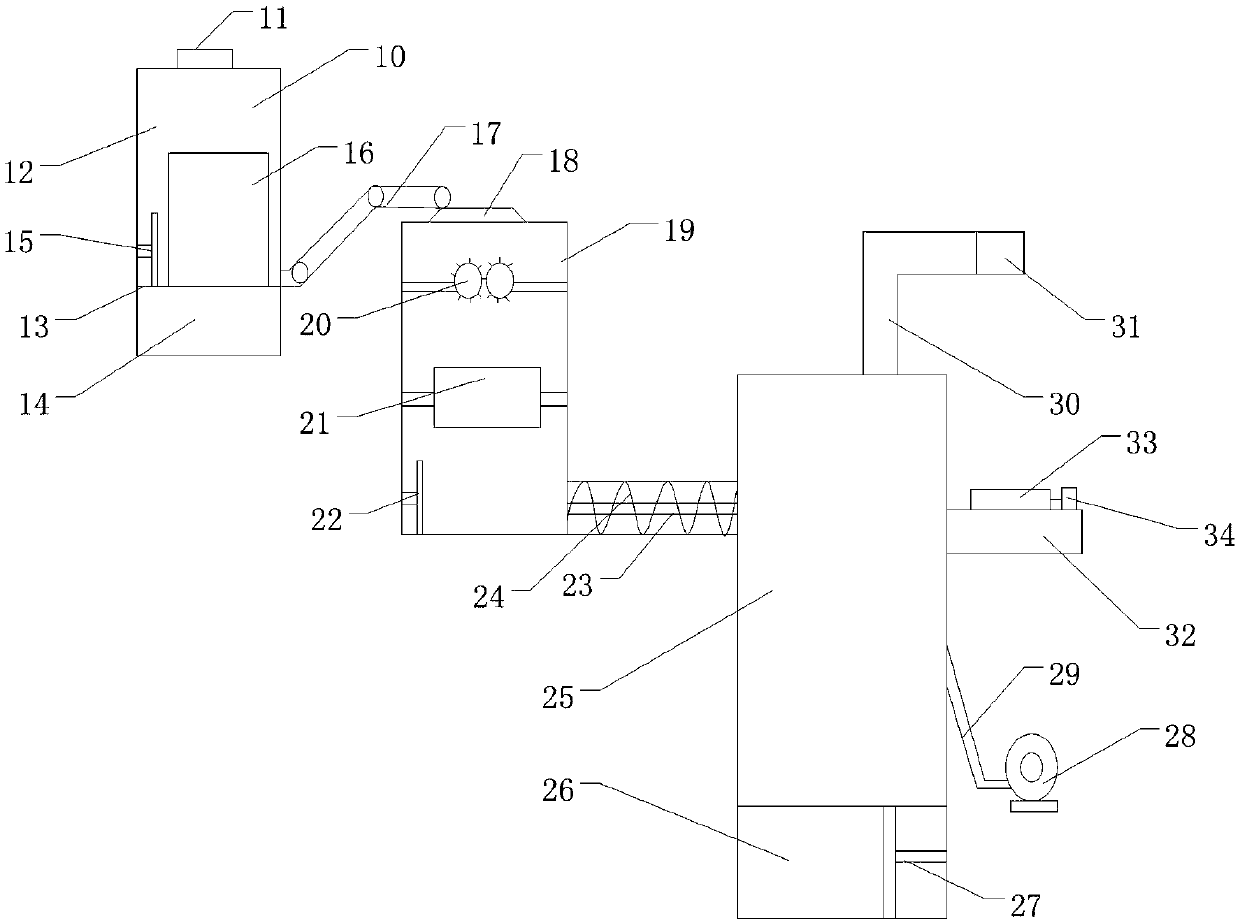

Integrated solid waste treatment system and use method thereof

InactiveCN110076175AReduce processing costsImprove processing efficiencySolid waste disposalIncinerator apparatusWaste treatmentCombustion chamber

The invention discloses an integrated solid waste treatment system and a use method thereof. The integrated solid waste treatment system comprises a solid-liquid separation bin, a crushing separationbin, an incinerator and a control mechanism, wherein the solid-liquid separation bin comprises a first box body, a filter screen, an extrusion device and a first pushing device; the crushing separation bin comprises a second box body, a shear type crusher, a magnetic roller and a second pushing device; the incinerator is separated into an upper combustion chamber and a lower waste residue collection chamber by an isolation screen plate arranged at the bottom; the control mechanism comprises a first power system, a second power system and a controller; the first power system drives the extrusion device, the first pushing device, the second pushing device and a scraper plate to operate; the second power system controls a conveyor belt, the shear type crusher and the magnetic roller to rotate; and the controller controls an air blower to start. According to the integrated solid waste treatment system and the use method of the integrated solid waste treatment system, the integrated treatment of solid waste can be achieved, and the quality and efficiency of solid waste treatment are improved.

Owner:王俊利

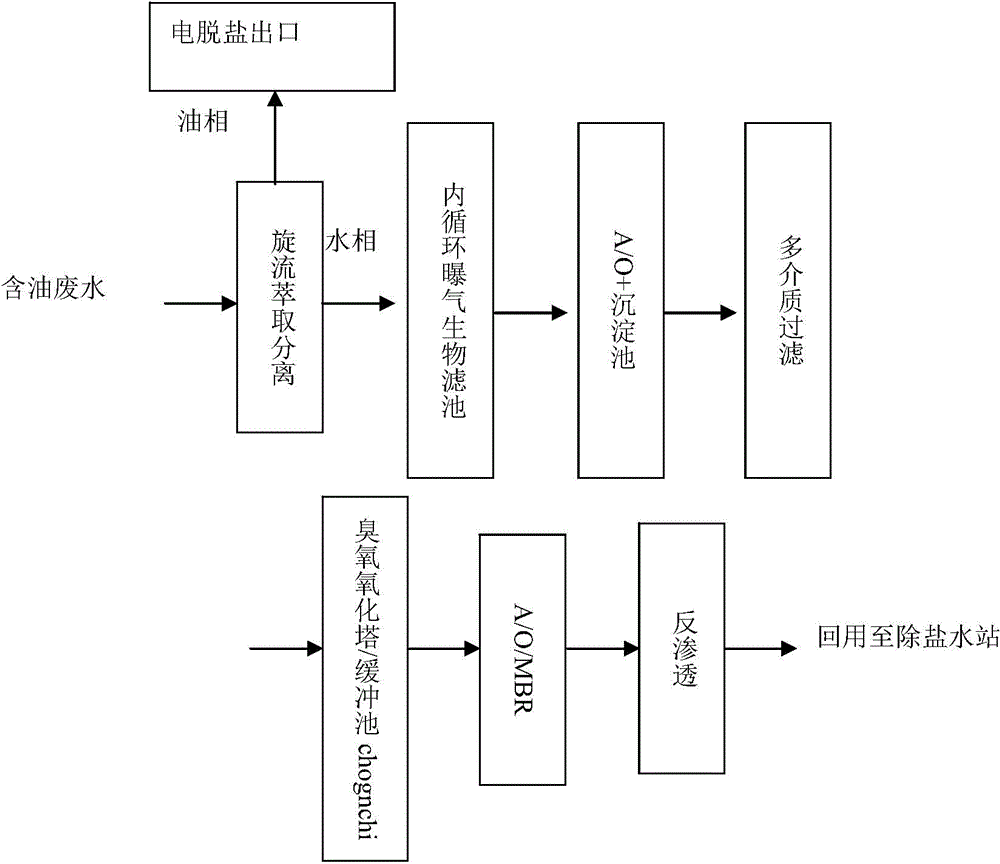

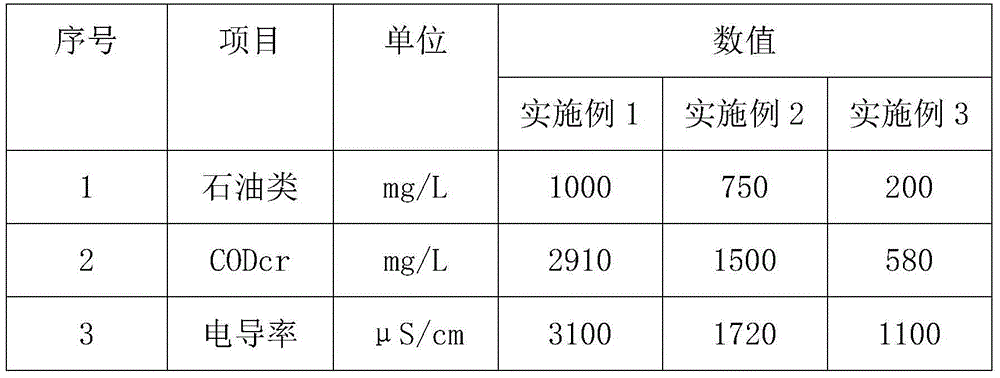

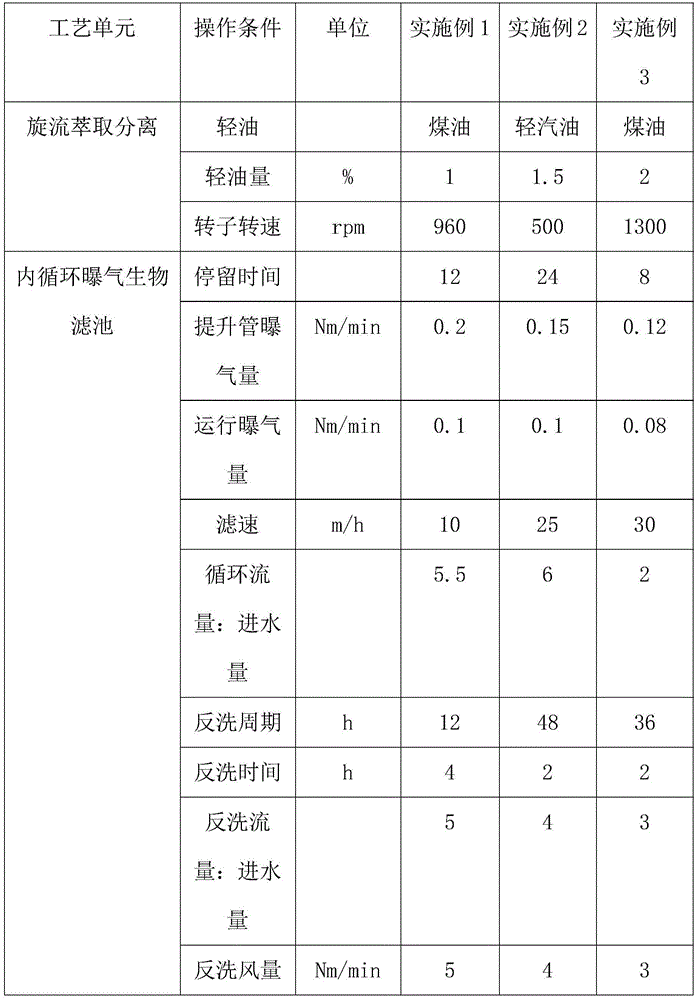

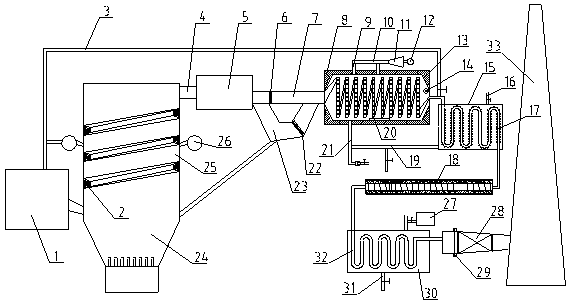

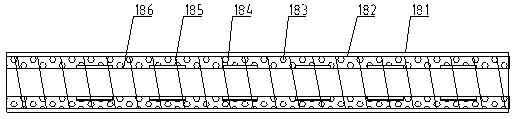

Oil-containing waste water processing and recycling method

ActiveCN105399265AGuaranteed uptimeRealize secondary recyclingGeneral water supply conservationMultistage water/sewage treatmentAsphaltIntegrated devices

The invention relates to an oil-containing waste water processing and recycling method. Oil-containing waste water is processed through a process adopting rotational flow extraction and separation, an internal-circulation biological aerated filtering pool, traditional biochemical treatment, multi-medium filtering, ozone oxidation / a buffer pool, secondary biochemical treatment, and a reverse osmosis system. The Oil-containing waste water comes from an oil-refining enterprise, and specifically is draining of normal / reduced-pressure electro-desalting through an asphalt producing device, draining of electro-desalting through an integrated device, and mixed draining of an alkaline-residue processing apparatus from a sulphur workshop. According to the oil-containing waste water processing and recycling method, light oil is adopted for extracting and separating oil in the oil-containing waste water to remove most of the oil in the waste water, and residual oil and organic matters in the waste water is filtered through the internal-circulation biological aerated filtering pool to stabilize the water quality for later processing and ensure normal stable operation of conventional biochemical treatment. The process of oxidation, secondary biochemical treatment, and desalting is added after the traditional biochemical treatment, so that the oil-containing waste water is finally reused rather than drained.

Owner:CHINA PETROLEUM & CHEM CORP +1

Smoke purifying and waste heat utilizing system of waste incineration power plant

ActiveCN109395496AIncrease temperatureLow costGas treatmentDispersed particle filtrationDecomposerWaste heat recovery unit

The invention discloses a smoke purifying and waste heat utilizing system of a waste incineration power plant. The smoke purifying and waste heat utilizing system comprises an incinerator body, a steam turbine, a power generator, a smoke purifying treatment device and a smoke discharge chimney. The smoke purifying treatment device comprises a pipeline combustor, a steam generator, a waste heat recoverer, a smoke decomposer, a washing tank and an adsorption purifier which are sequentially arranged from a high-temperature smoke outlet and the smoke discharge chimney. The smoke discharge pipe isarranged between the pipeline combustor and the steam generator. A particle collecting pipe is arranged on the lower side of the smoke discharge pip. A spiral smoke pipe is arranged in the steam generator. A heat pipe is arranged in the waste heat recoverer. An outer cylinder, an inner cylinder and a decomposition ball are arranged in the smoke decomposer. An inner electrode is arranged on the inner side of the inner cylinder. An outer electrode is wound on the outer surface of the outer cylinder. A washing pipe is arranged in the washing tank. The adsorption purifier is filled with adsorptionfiller. By means of the system, the combustion state is improved, combustion efficiency is improved, the dioxin content is reduced, and the waste heat recovery efficiency is improved.

Owner:QUJING YUNDIAN TOUXIN ENERGY POWER GENERATION

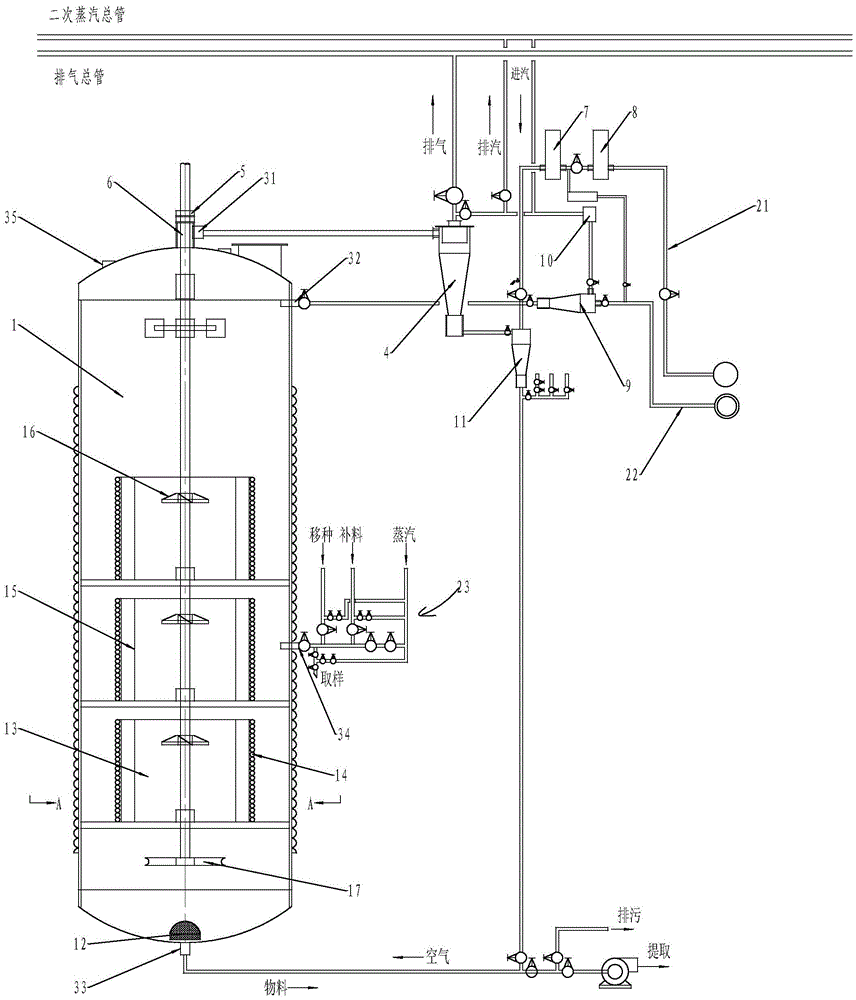

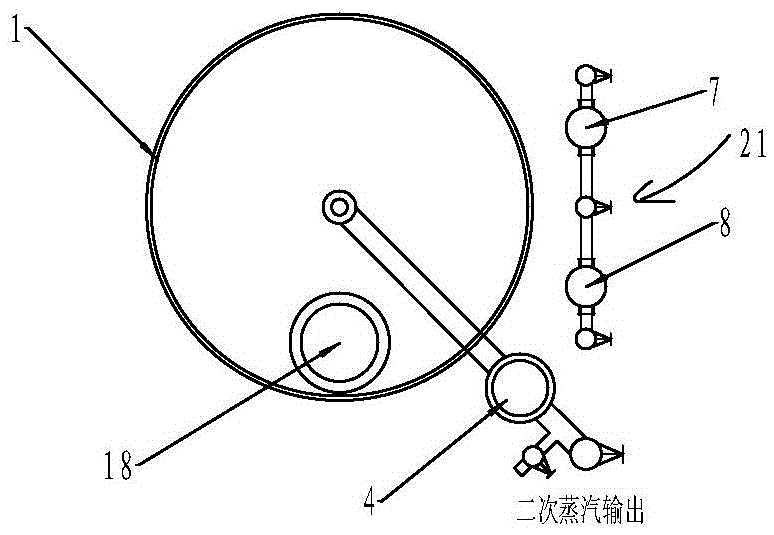

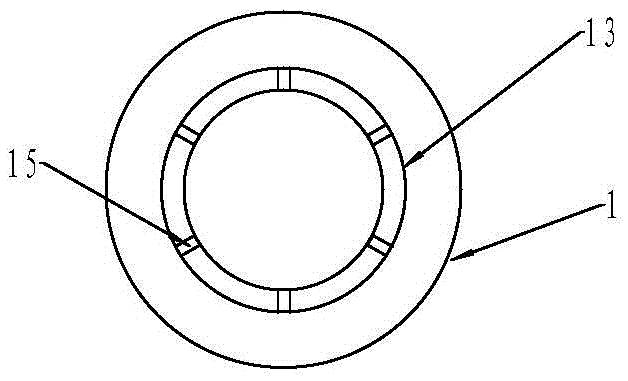

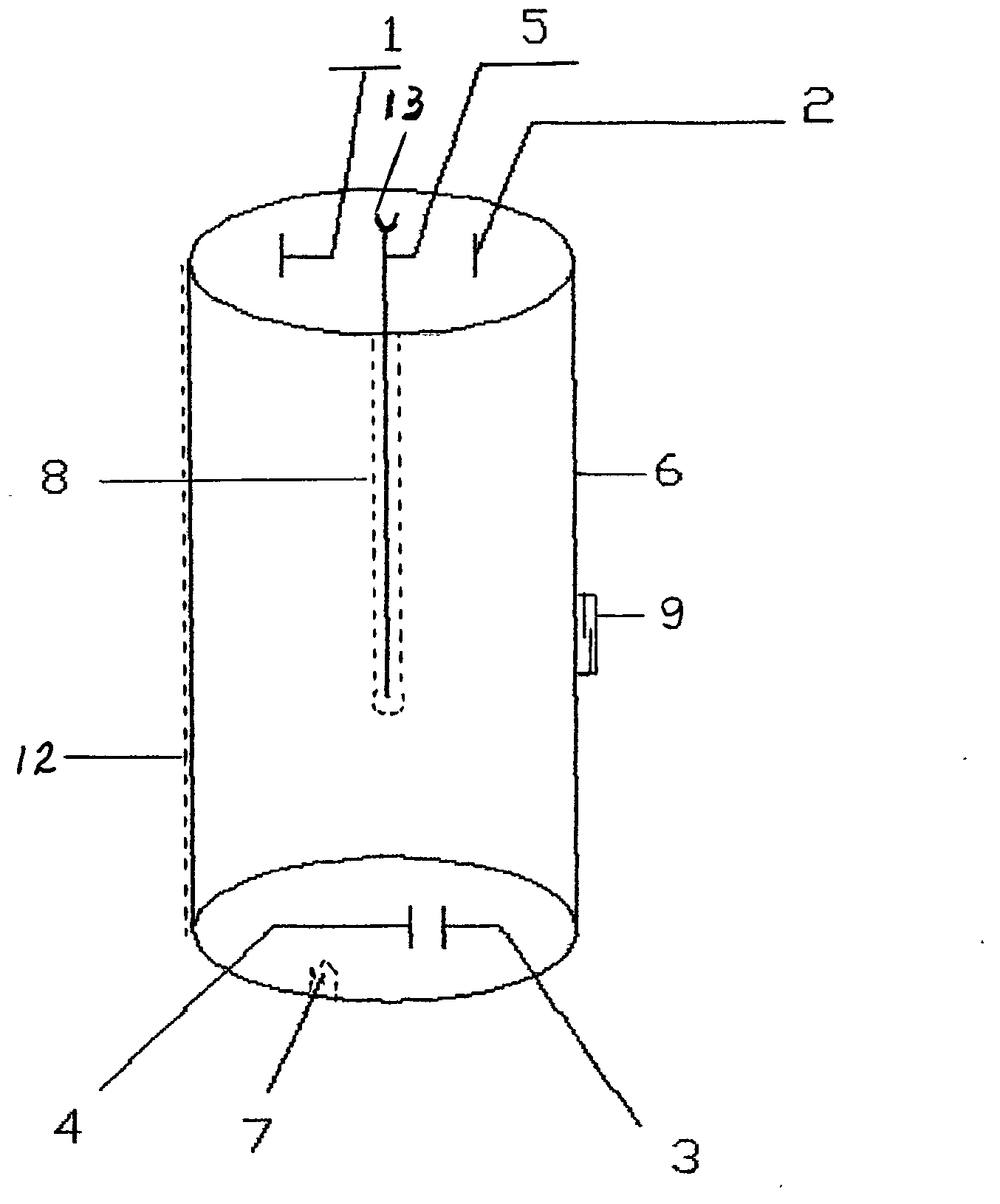

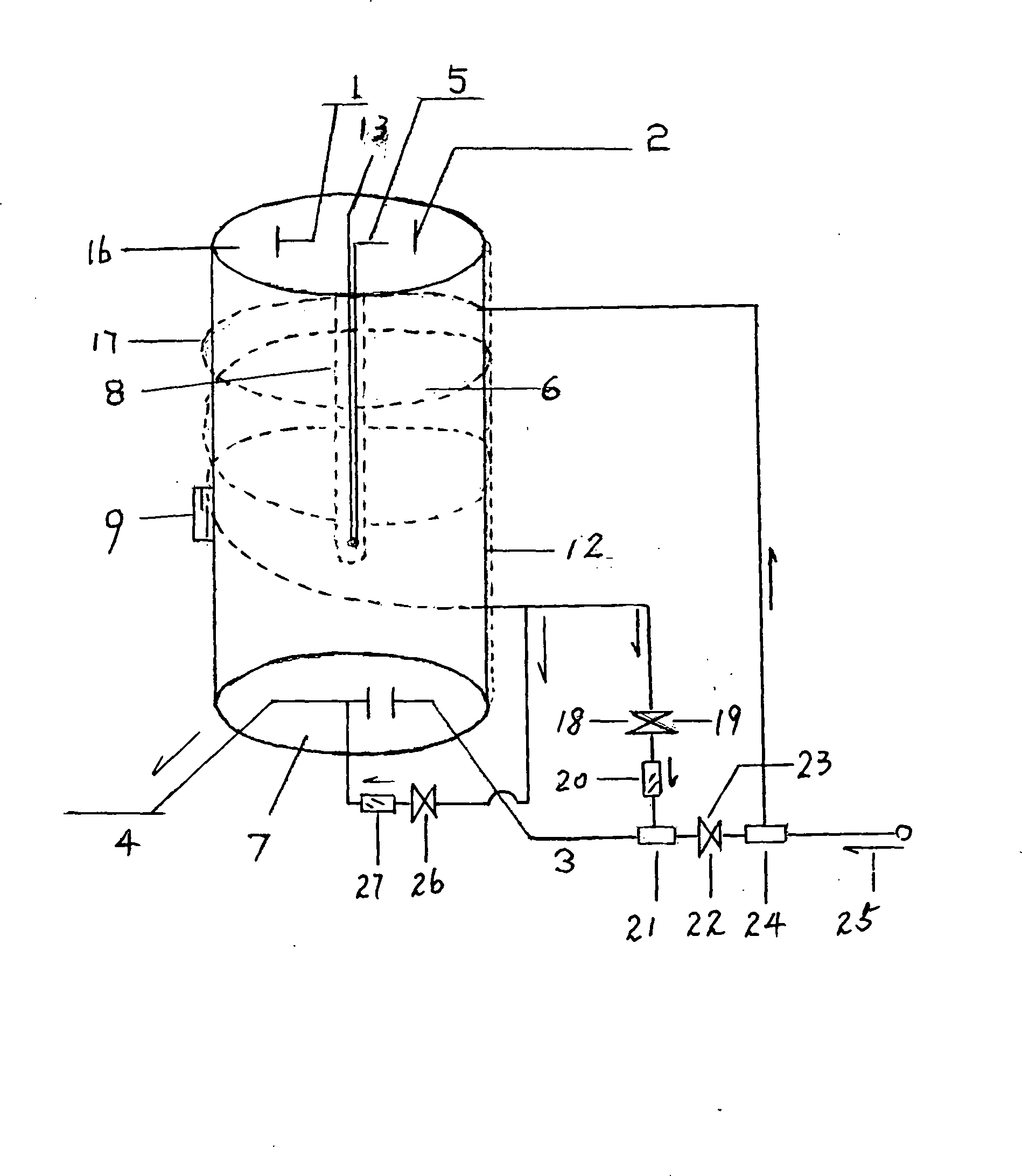

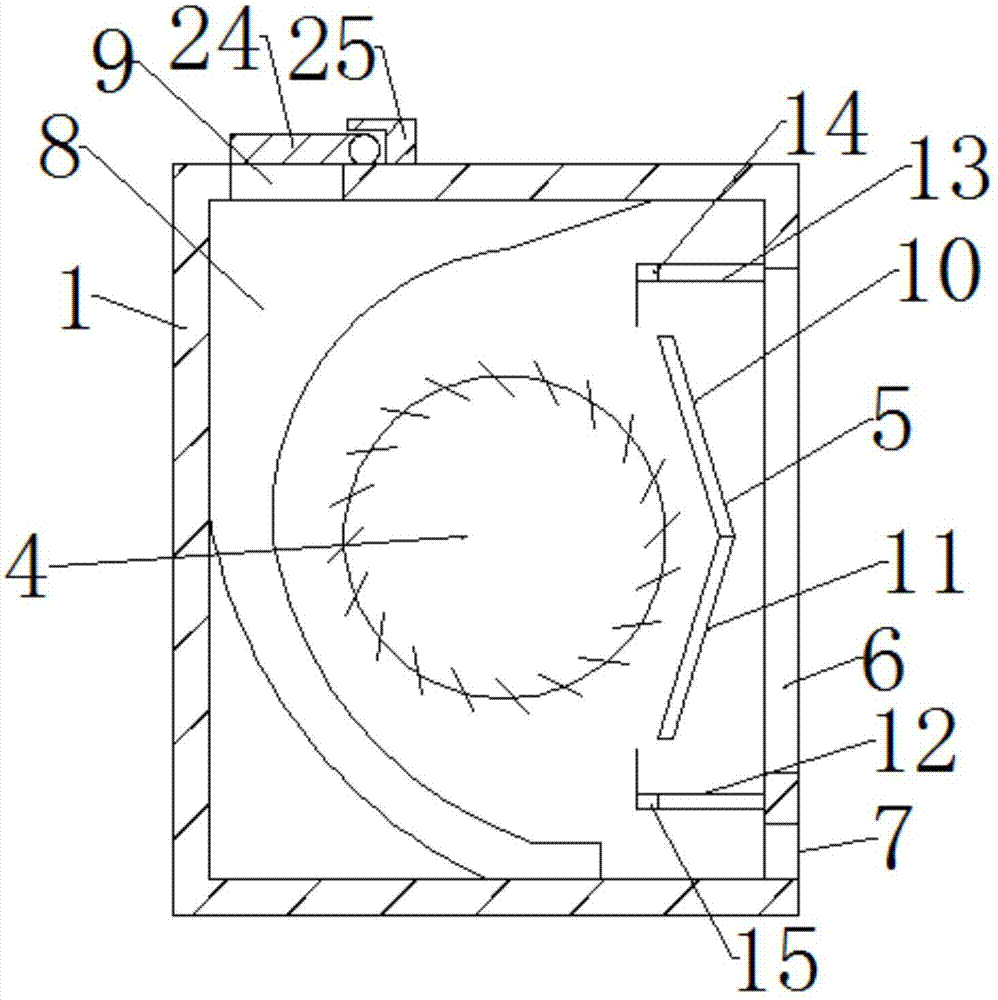

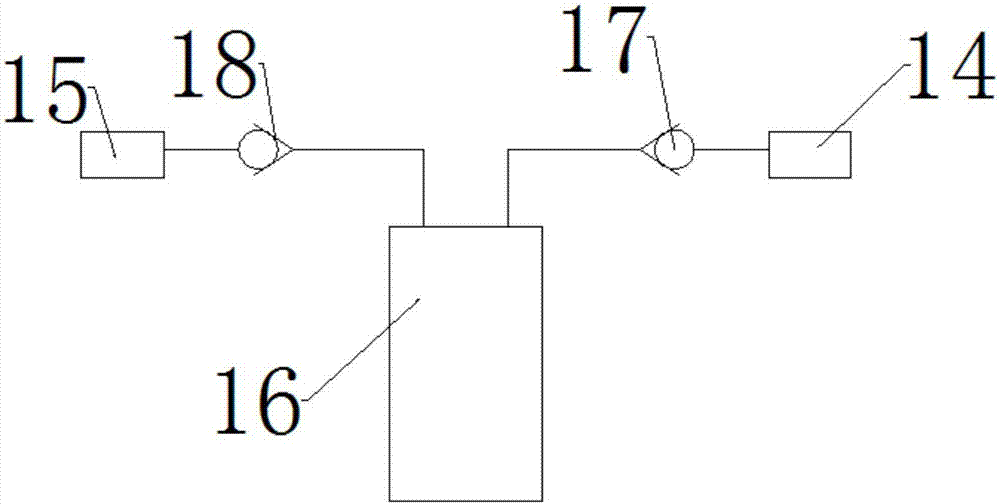

Efficient and energy-saving type biological fermentation tank and matched pipe network system thereof

ActiveCN105462814AReasonable structureImprove structural versatilityBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringFermentation

The invention relates to a biological fermentation production device, in particular to an efficient and energy-saving type biological fermentation tank and a matched pipe network system thereof. The efficient and energy-saving type biological fermentation tank comprises a biological fermentation tank body and a technological pipe network which is connected with the tank body and composed of an air pipe network system, a sterile material pipe network system, a steam pipe network system and the like. The efficient and energy-saving type biological fermentation tank is structurally characterized in that the technological pipe network connected to the tank body is close to the fermentation tank body, the technological pipe network is safer and more reliable in operation, the fermentation tank is reasonable in structure, and the biological fermentation production level is high; the pipe network contamination probability is effectively decreased, and meanwhile the purchase and maintenance cost of valve fittings in the pipe network is lowered. Secondary recycling of disinfection steam is achieved in environmental protection, emission reduction, energy conservation and effect improvement, and sterile air inside the fermentation tank can be recycled.

Owner:王新东

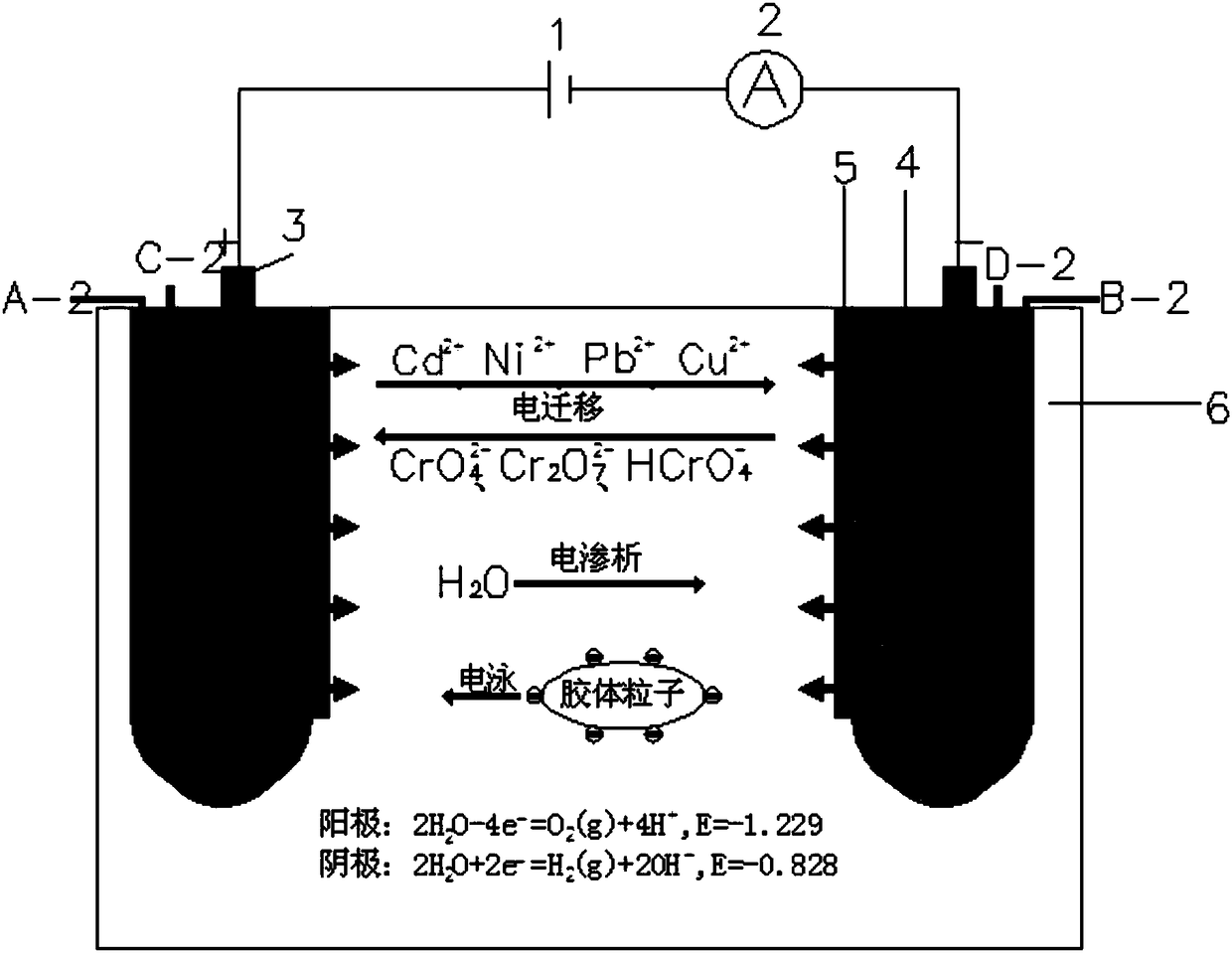

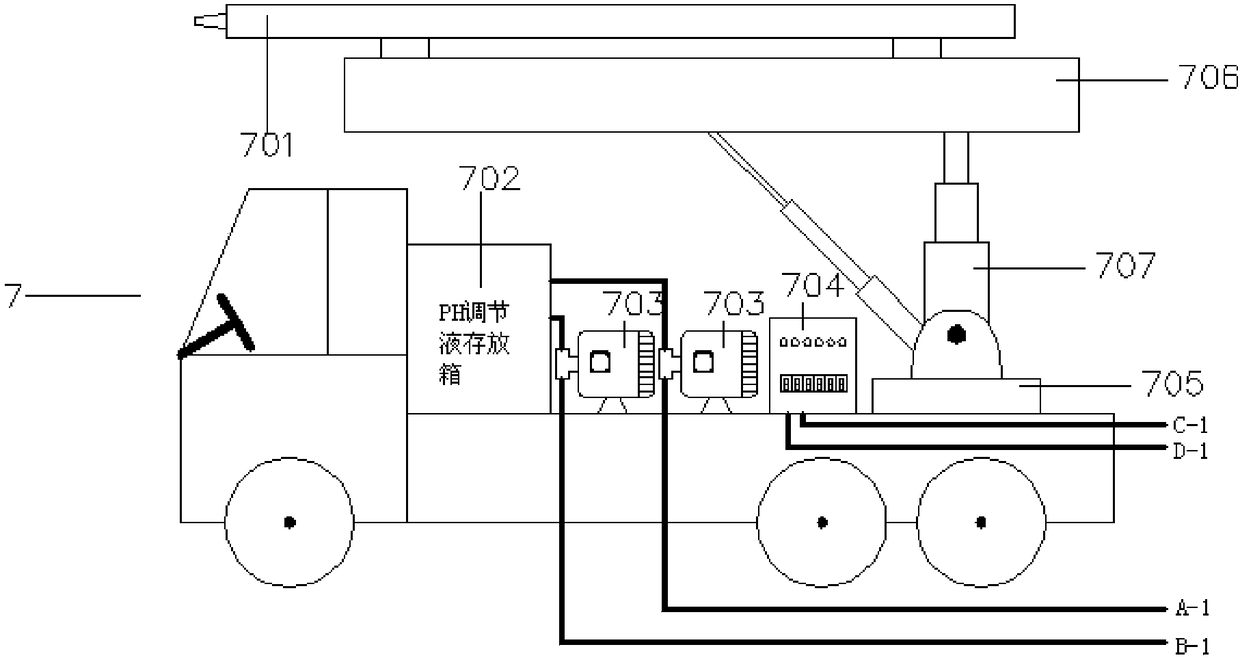

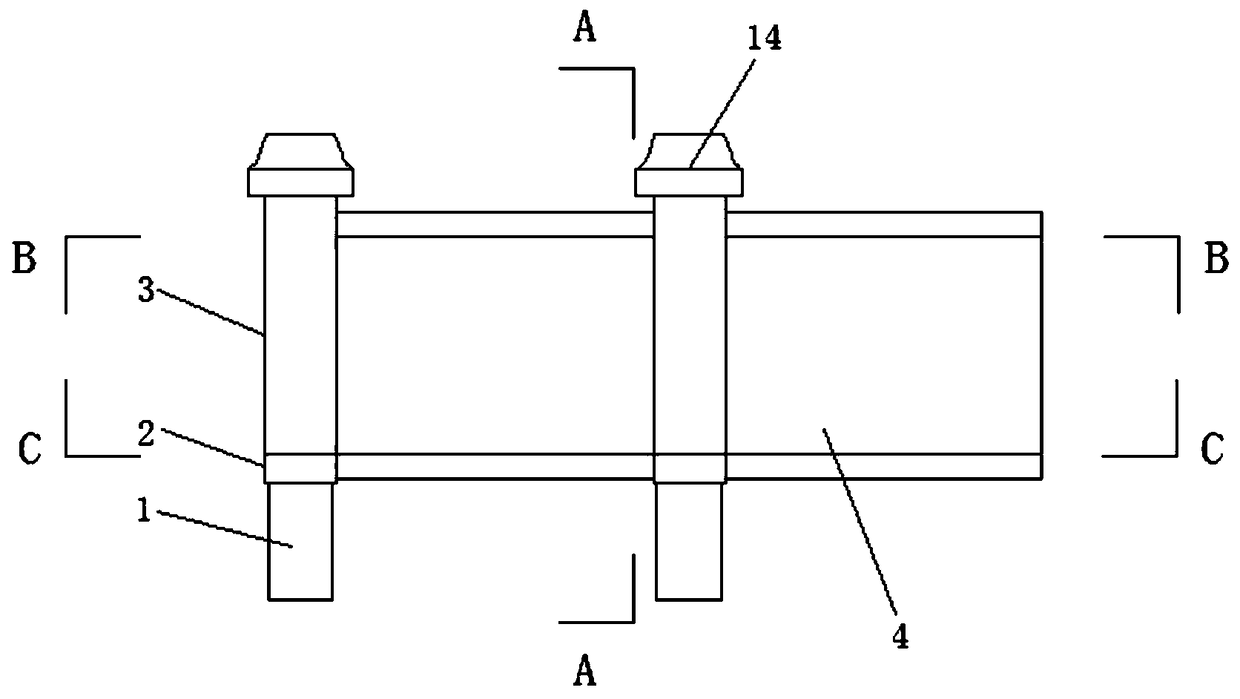

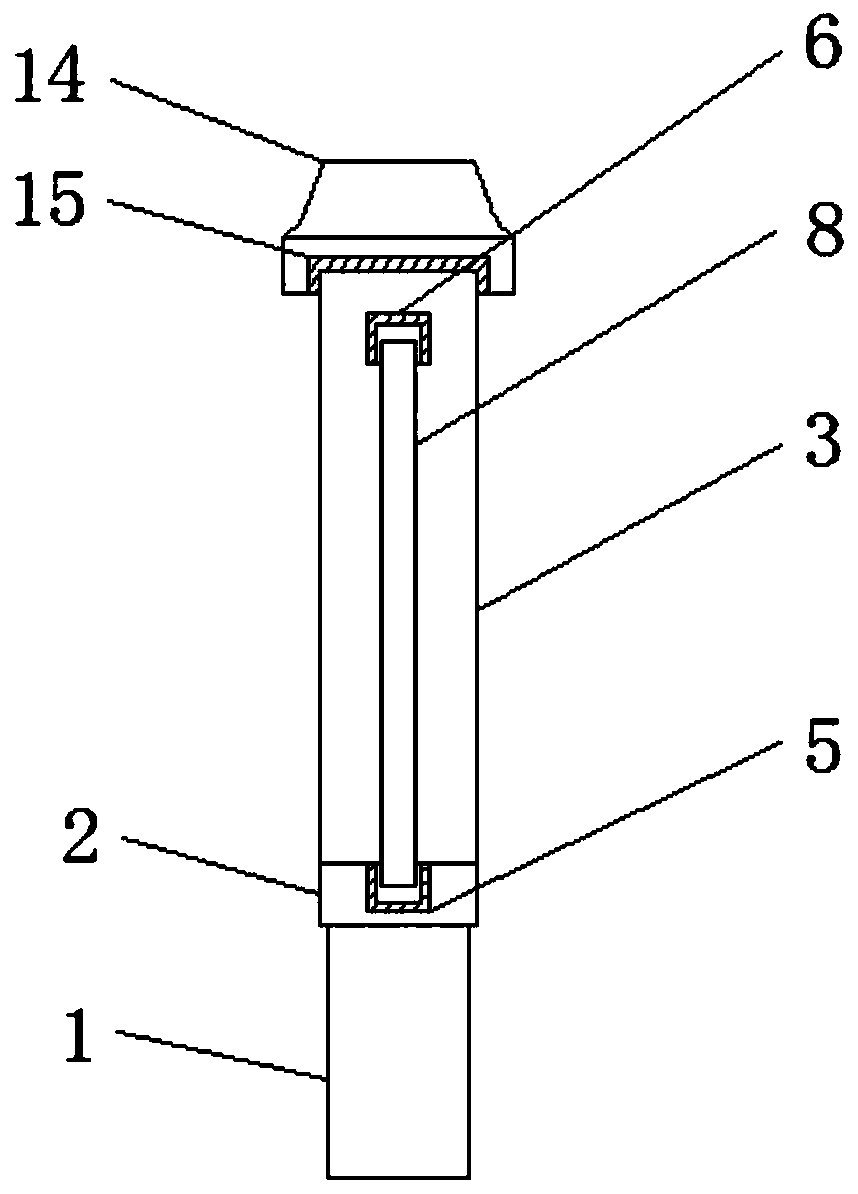

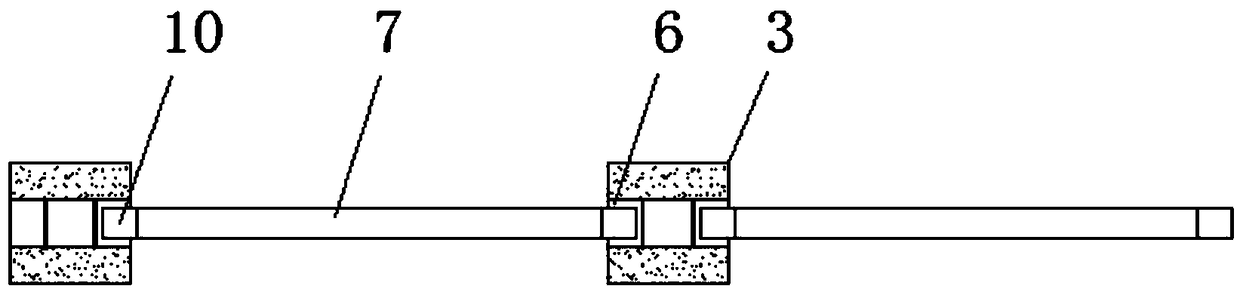

Method and equipment for in-situ electric repair of portable contaminated soil

InactiveCN108555015AImprove in situ repair efficiencyPrevent acidificationContaminated soil reclamationPollution soilEngineering

The invention creatively provides a method and equipment for in-situ electric repair of portable contaminated soil. The method comprises the following steps: firstly punching two holes in suitable positions of the contaminated soil as a cathode tank and an anode tank respectively; secondly, filling the cathode tank and the anode tank with an electrolyte and respectively placing electrodes, whereinthe two electrodes are respectively connected with an anode and a cathode of a power supply, so that the contaminated soil between the power supply and the electrodes forms a conductive path; betweenthe electrodes, arranging an ion adsorption partition plate between the contaminated soil and the electrolyte. The method creatively provided by the invention not only can flexibly and conveniently realize the in-situ repair of the contaminated soil, but also can realize secondary recycling.

Owner:HEBEI UNIV OF TECH

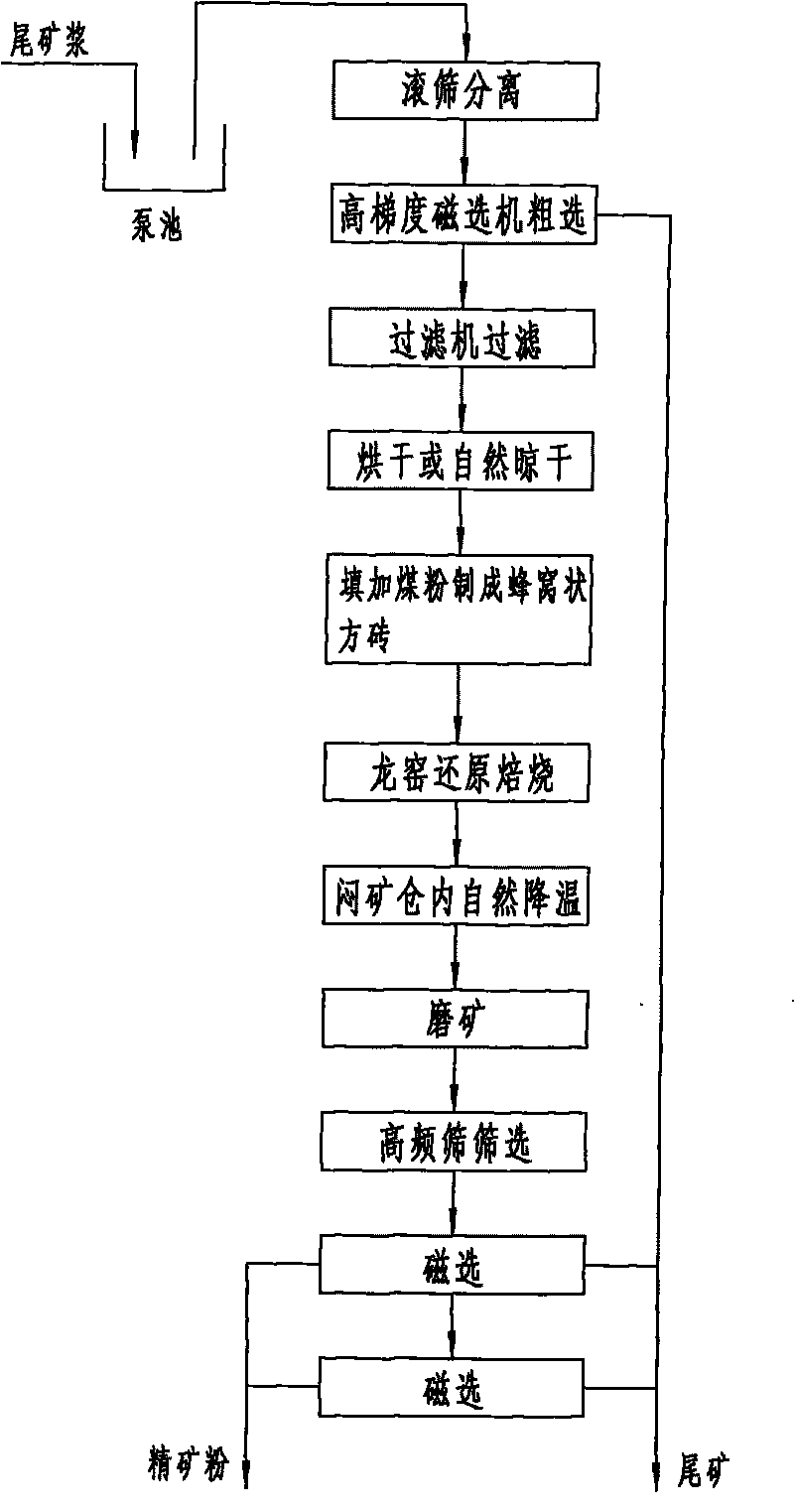

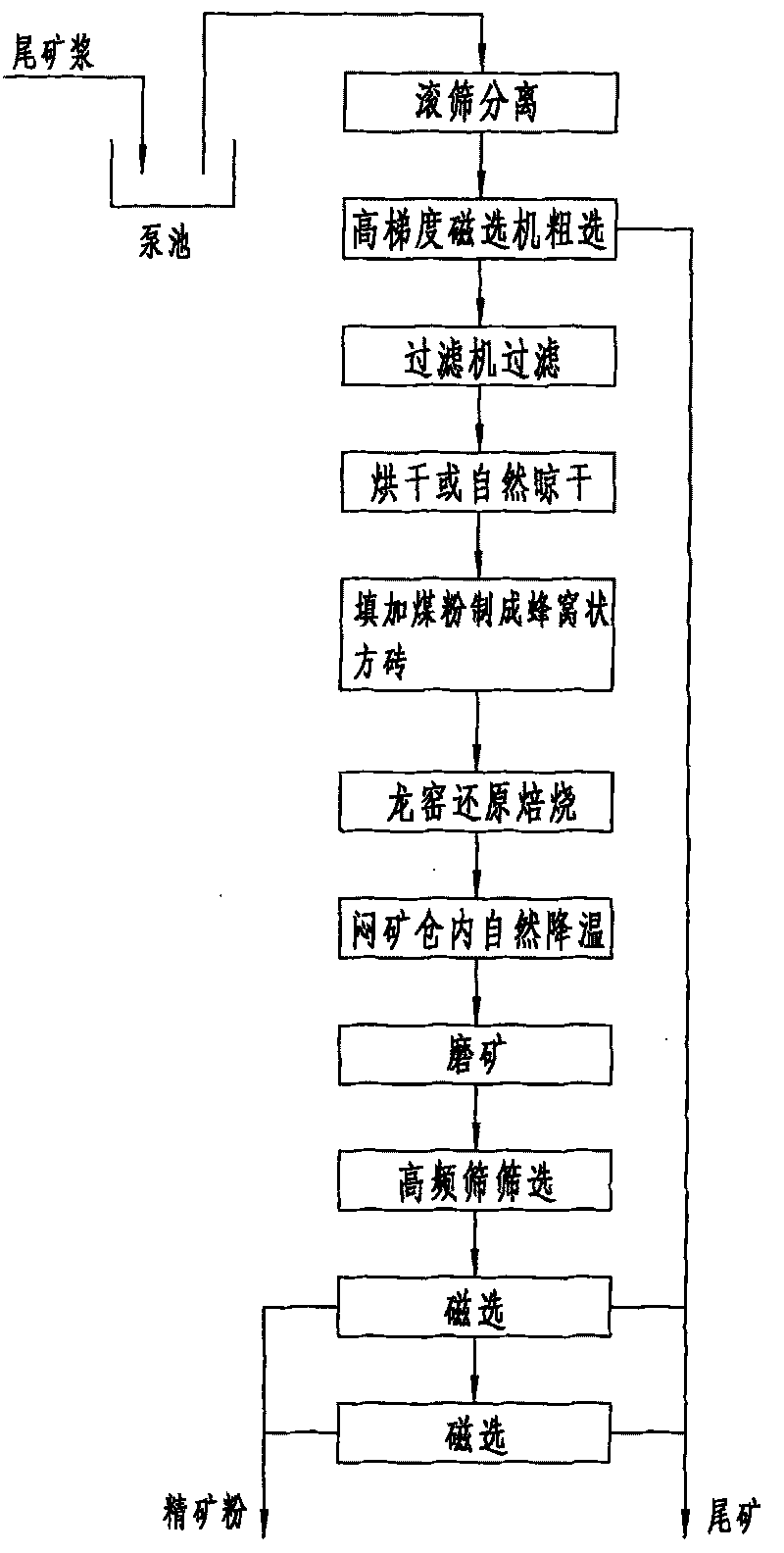

Process for roasting and restoring tailings with weak-intensity magnetism by dragon kiln

The invention relates to the field of tailings recovering, in particular to a process for roasting and restoring tailings with weak-intensity magnetism by using a dragon kiln, solving the problems of complicated process, great investment, high energy consumption, low tailing recovering ratio and the like existing in the traditional iron tailings recovering technology in China. The process comprises the following steps of: a, separating tailing pulp by a rolling sieve, roughing by a magnetic separator to obtain roughed tailings; b, filtrating and baking / naturally drying the roughed tailings; c, adding coal dust in the roughed tailings according to an appropriate proportion to prepare alveolate shaped quadrels; d, placing the alveolate shaped quadrels into a kiln chamber of the dragon kiln for restoring and roasting, dropping the reduced-restored alveolate shaped quadrels in the kiln chamber in a sealed ore storage bin below, and naturally cooling the alveolate shaped quadrels at an air isolated environment; and e, carting and grinding the cooled alveolate shaped quadrels, sieving by a high-frequency sieve and selecting fined ore powder by the magnetic separator. The process is mature and stable with easy operation and low cost, can increase the tailing recovering ratio by 6-15 percent, is suitable for recycling the tailings, and can be widely popularized with strong adaptability to the tailings.

Owner:马雨田

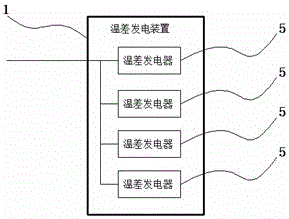

Computer room energy-saving device

InactiveCN105698312ARealize secondary recyclingReduce energy consumptionLighting and heating apparatusGenerators/motorsControl systemRoom temperature

The invention relates to the field of computer room energy saving, in particular to a computer room energy-saving device. The computer room energy-saving device solves the problems that in the prior art, thermoelectric power generation waste gas is exhausted inwards, consequently, the room temperature rises, and due to decentralized installation of thermoelectric generators, management and maintenance are difficult, meanwhile improves the power generation conversion efficiency and reduces the computer room temperature control energy consumption. A hot air collection pipeline is used for collecting hot air exhausted from all devices of a computer room, and then the hot air is guided to a thermoelectric power generation device to be used for power generation; and the waste gas obtained after power generation is exhausted outdoors, the room temperature rising caused by waste gas residual heat is avoided, and energy consumption of a computer room temperature control system is reduced. According to thermoelectric power generation equipment, the multiple thermoelectric generators are integrated, and relative to the decentralized installation manner, the manner of the device facilitates subsequent checking and maintenance; and due to the fact that warm gas passes through the multiple thermoelectric generators, the power generation conversion efficiency is improved.

Owner:HEFEI HONGJI ELECTRON CO LTD

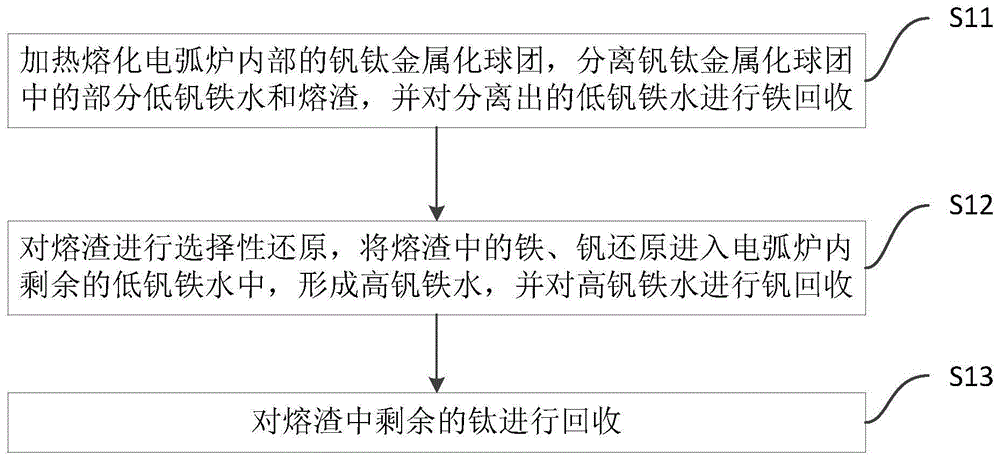

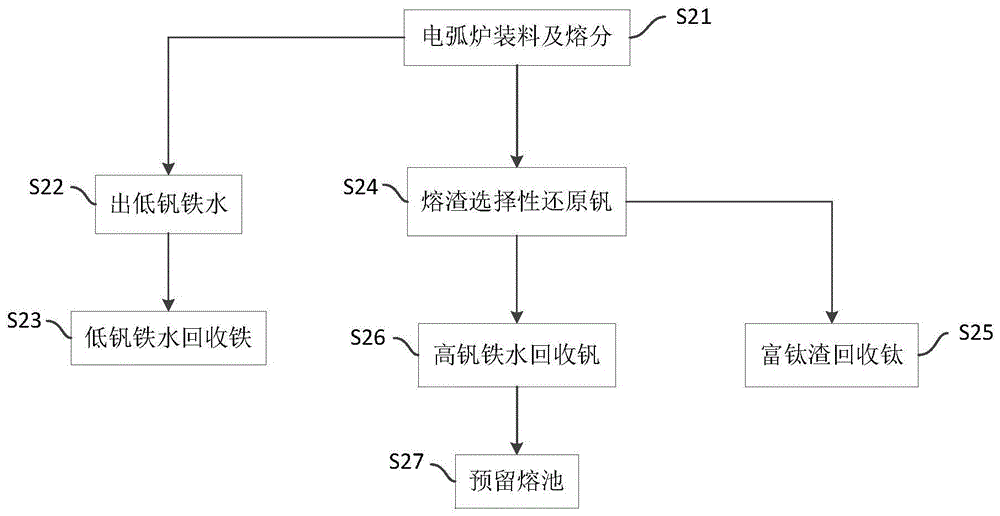

Method for efficiently recycling vanadium, iron and titanium in vanadium-titanium metallized pellet through electric arc furnace

The invention provides a method for efficiently recycling vanadium, iron and titanium in a vanadium-titanium metallized pellet through an electric arc furnace. The method comprises the steps that the vanadium-titanium metallized pellet in the electric arc furnace is heated and melted, part of low-vanadium molten iron and slag in the vanadium-titanium metallized pellet are separated, and iron recycling is carried out on the separated low-vanadium molten iron; selective reduction is carried out on the slag, iron and vanadium in the slag are reduced into the residual low-vanadium molten iron in the electric arc furnace, high-vanadium molten iron is formed, and vanadium recycling is carried out on the high-vanadium molten iron; and the residual titanium in the slag is recycled. By means of the method, expenditure cost can be reduced, CO2 emission can be reduced in the recycling process, and by means of stepped recycling, the vanadium, iron and titanium resources can be separated to the maximum degree, and the most efficient recycling of vanadium, iron and titanium is achieved.

Owner:WISDRI ENG & RES INC LTD

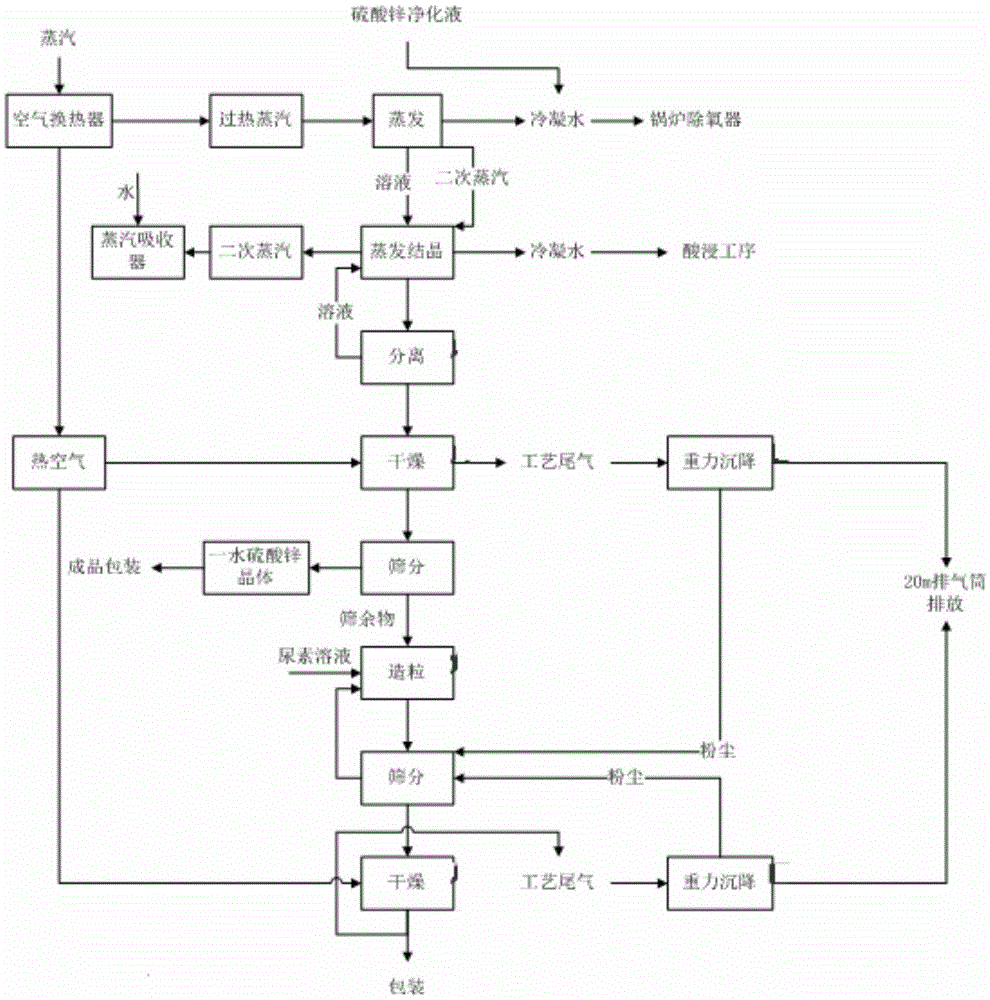

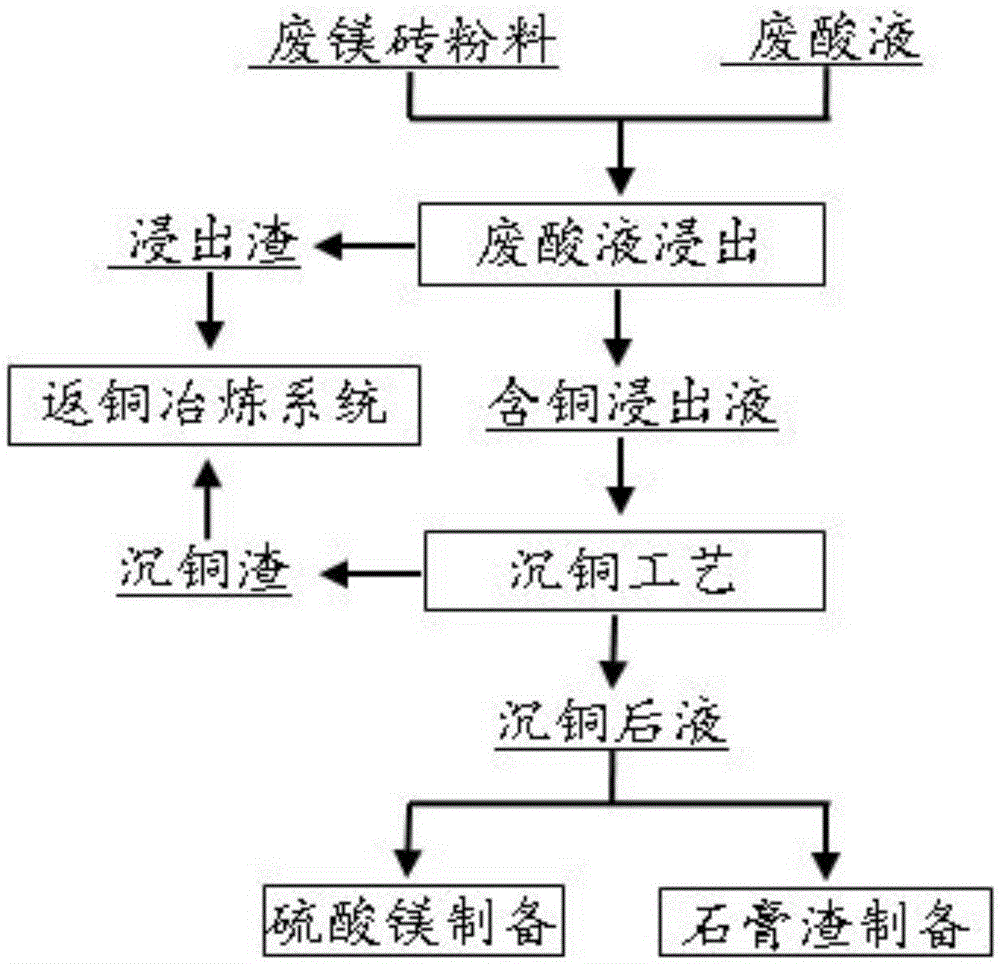

Treatment method for waste copper-bearing magnesite brick

ActiveCN105385853AHigh recovery rateEfficient use ofProcess efficiency improvementPregnant leach solutionBrick

The invention belongs to the technical field of nonferrous metallurgy, and particularly relates to a treatment method for a waste copper-bearing magnesite brick. The method specifically comprises the following steps that 1, the waste magnesite brick is obtained through waste acid pickle generated in the copper smelting process in a leached manner, and then leaching liquid and leaching residues are filtered and separated out; 2, a precipitator or a reducing agent is added into the copper-bearing leaching liquid, copper is precipitated in the manner of indissolvable compounds or simple substances, and precipitated copper residues are filtered out and collected; 3, the leaching residues and the precipitated copper residues are washed and dried to return to a copper smelting system for treatment, and valuable metal such as Cu, Au and Ag is recycled; and 4, liquid obtained after copper precipitation is adopted as raw materials for preparing magnesium sulfate or magnesium-bearing gypsum residues, and magnesium in the liquid obtained after copper precipitation is recycled. Waste is used for treating waste, the method has the advantages that the process is simple, the production cost is low, the equipment investment is small, cleanliness and environment friendliness are achieved, and the industrial production can be achieved easily.

Owner:JIANGXI COPPER TECHNOLOGY RESEARCH INSTITUTE CO LTD

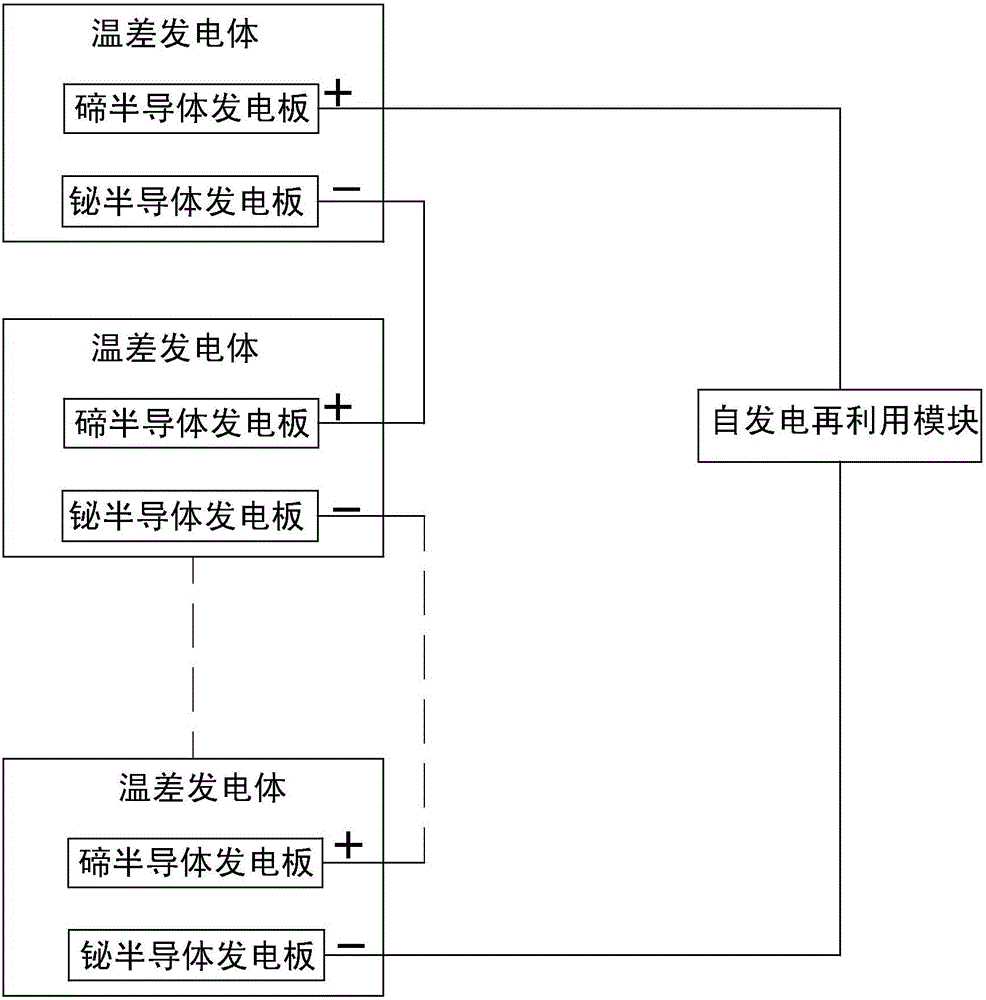

Self-generating LED lamp and application thereof

InactiveCN105782890AImprove cooling effectGuaranteed service lifeElectrical apparatusLighting heating/cooling arrangementsEngineeringAluminum substrate

The invention discloses a self-generating LED lamp and application thereof. The self-generating LED lamp comprises a heat radiator, an LED drive circuit, thermoelectric power generating bodies and a self-generating recycle module, wherein each thermoelectric power generating body comprises a heat power generating plate and a cold power generating plate; the heat power generating plates are in contact with an aluminum substrate; the cold power generating plates are in contact with the heat radiator; after the contact, heat energy generated from luminescence of LED light sources is transferred to the hot power generating plates of the thermoelectric power generating bodies; as the cold power generating plates are in contact with the heat radiator, a Seebeck effect is generated between the hot power generating plates and the cold power generating plates of the thermoelectric power generating bodies, and an electric field is generated between the hot power generating plates and the cold power generating plates to form electromotive force; then, both the hot power generating plates and the cold power generating plates are electrically connected with the self-generating recycle module to form a loop, so as to fulfill the purpose of energy conservation; and part of the heat energy can be recovered by the thermoelectric power generating bodies, so that the heat radiating effect is excellent and the service life of the LED light sources is guaranteed. According to the main application of the self-generating LED lamp, voltage between the hot power generating plates and the cold power generating plates is utilized for operation, and power generated by the self-generating LED lamp can be widely utilized.

Owner:WEIFANG MINGRUI OPTOELECTRONICS TECH

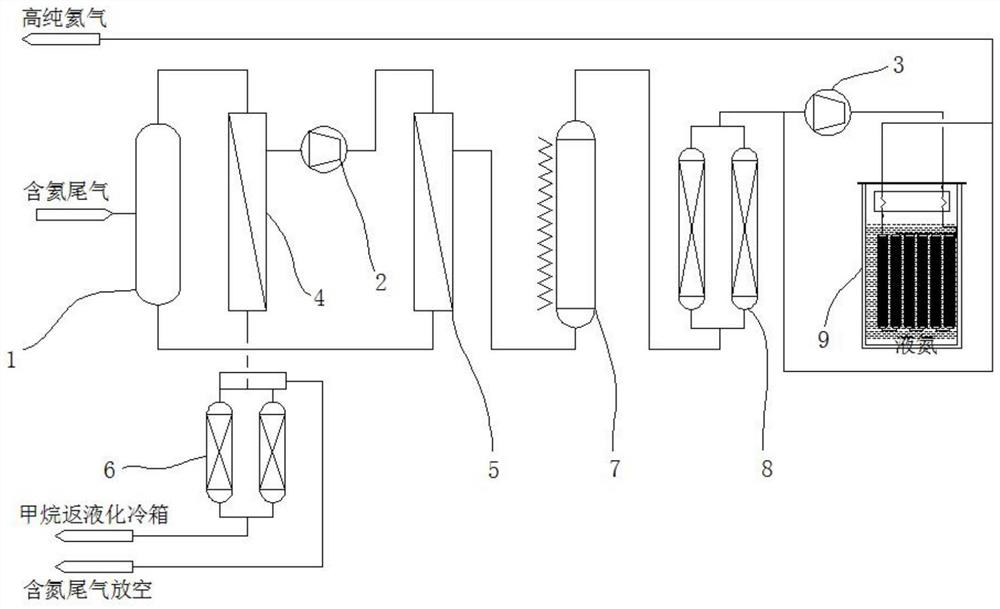

Method and equipment for co-production of high-purity helium through natural gas liquefaction

The invention relates to a method and equipment for co-production of high-purity helium through natural gas liquefaction. The method comprises the following steps: taking non-condensable tail gas or BOG as raw material gas, and firstly introducing the raw material gas into a gas inlet buffer tank for flow stabilization treatment; then entering a first-stage membrane separator assembly for membrane separation and then sequentially passing through a gas buffer tank A and a compressor; then entering a second-stage membrane separator assembly; extracting and separating high-purity hydrogen and crude helium from the gas through a hydrogen recovery tower, and enabling the tail gas to enter a PSA denitrification device; purifying the crude helium again through a PSA drying and purifying device; and then treating the helium by a helium compressor and a low-temperature purifier to obtain high-purity helium. The equipment comprises the gas inlet buffer tank, the first-stage membrane separator assembly, the gas buffer tank A, the compressor, the second-stage membrane separator assembly, the hydrogen recovery tower, the PSA drying and purifying device, the helium compressor and the low-temperature purifier which are connected in sequence. The method and the equipment are used for recovering, separating and purifying helium-containing components of the non-condensable tail gas or the BOG in a cold box of a natural gas liquefaction factory, the high-purity hydrogen and helium can be obtained at the same time, and meanwhile the LNG yield is increased.

Owner:安徽中科皖能科技有限公司

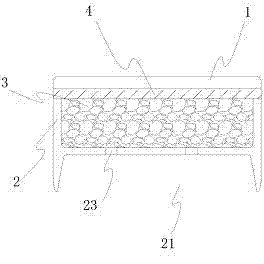

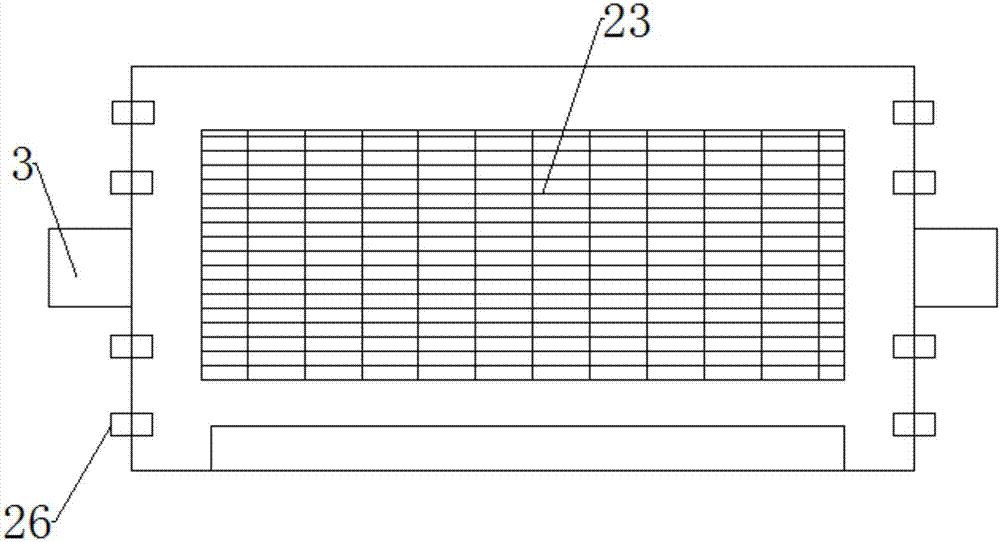

Building prefabricated wall and production technology

InactiveCN109236033AReduce pollutionReduce noise pollutionFencingCeramic shaping apparatusWall plateBuilding construction

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

Dust removal equipment for melting furnace

InactiveCN109084595AAvoid crackingPrevent sprayingDispersed particle separationCharge treatment typeSlagFlue

The invention discloses dust removal equipment for a melting furnace. The dust removal equipment comprises a dust removal cover body. A plurality of baffle groups are arranged in rows on the circularsurface of the lower end of the dust removal cover body. Each baffle group comprises a plurality of baffles arranged at intervals from top to bottom, and every two adjacent baffles are connected through an iron chain. A transverse flue is arranged at the upper end of the dust removal cover body. A cover plate is arranged at the smoke outlet end of the transverse flue. A smoke outlet is formed in the upper end of the transverse flue, and a slag outlet is formed in the lower end of the transverse flue. The slag outlet of the transverse flue is communicated with the interior of a separation cylinder through a pipeline. A vertical smoke exhaust channel is fixedly arranged in the position, at the smoke outlet, of the transverse flue. The dust removal equipment is beneficial to application and popularization.

Owner:四川凯隆轩工程材料有限公司

Straw pretreatment method for cellulosic ethanol in straw

InactiveCN106834362AGuarantee hydrolysisGuarantee the fermentation environmentBiofuelsFermentationPretreatment methodHigh energy

The invention discloses a straw pretreatment method for cellulosic ethanol in straw. Pretreatment technologies for agricultural wastes such as the industrially produced straw mainly comprise acidic hydrolysis, alkaline hydrolysis, adding of chemicals for explosion and other pretreatment processes at the present, and have the problems of complicated treatment process, relatively high energy consumption and pollution to the environment to different extends. The straw pretreatment method for the cellulosic ethanol in the straw comprises the following steps: pre-soaking: removing sand from the straw through a sand remover to remove impurities; dewatering: pressurizing and heating a plug flow reactor through steam with pressure of 15 kg / cm<2> till the pressure is 13.5 kg / cm<2> and the temperature is 190 DEG C, retaining the pressure for 20 minutes, then discharging the straw, and carrying out two-stage flash distillation in a material discharging process of the plug flow reactor; gas production in the second stage of flash distillation during flash distillation: recycling steam from the first stage of flash distillation, producing gas from the second stage of flash distillation, cooling the gas through a cooler, and discharging the gas into a sewage treatment device. The straw pretreatment method is applied to the field of bio-refinery.

Owner:黑龙江中丹建业生物能源有限公司

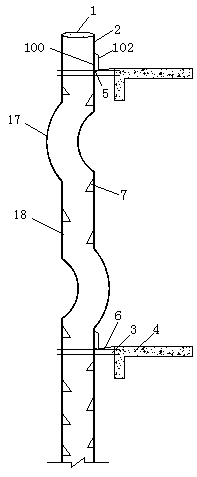

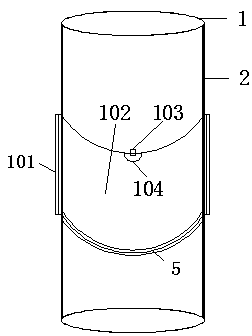

Vertical construction waste transporting passage for building

The invention discloses a vertical construction waste transporting passage for a building. The vertical construction waste transporting passage comprises a first waste passage, a second waste passage,a first waste collection chamber and a second waste collection chamber. The first waste passage is fixed to floor edges, externally provided with a sound absorbing material and formed by interval connection of a plurality of straight passages and bent passages. Inner edges of the straight passages are provided with buffer joints, and the straight passage of each floor is provided with a feeding port which is externally provided with a seal plate. A sieve is arranged below the first waste passage, the second waste passage is obliquely arranged at the sieve, the first waste collection chamber is positioned below the first waste passage, the second waste collection chamber is positioned below the second waste passage, spraying pipes are arranged in the first waste collection chamber and thesecond waste collection chamber, and both the first waste collection chamber and the second waste collection chamber are externally provided with dodge gates. The vertical construction waste transporting passage has advantages of simple structure, convenience and quickness in mounting, low noise, no flying dust and improvement of construction waste transporting efficiency.

Owner:SHANGHAI BAOYE GRP NANJING BUILDING +1

A process for producing zinc sulfate monohydrate by utilizing waste acid and waste zinc slag

ActiveCN105274342BRealize comprehensive utilizationReduce manufacturing costProcess efficiency improvementIndiumEthyl Chloride

Owner:湖南鑫海环保科技有限公司

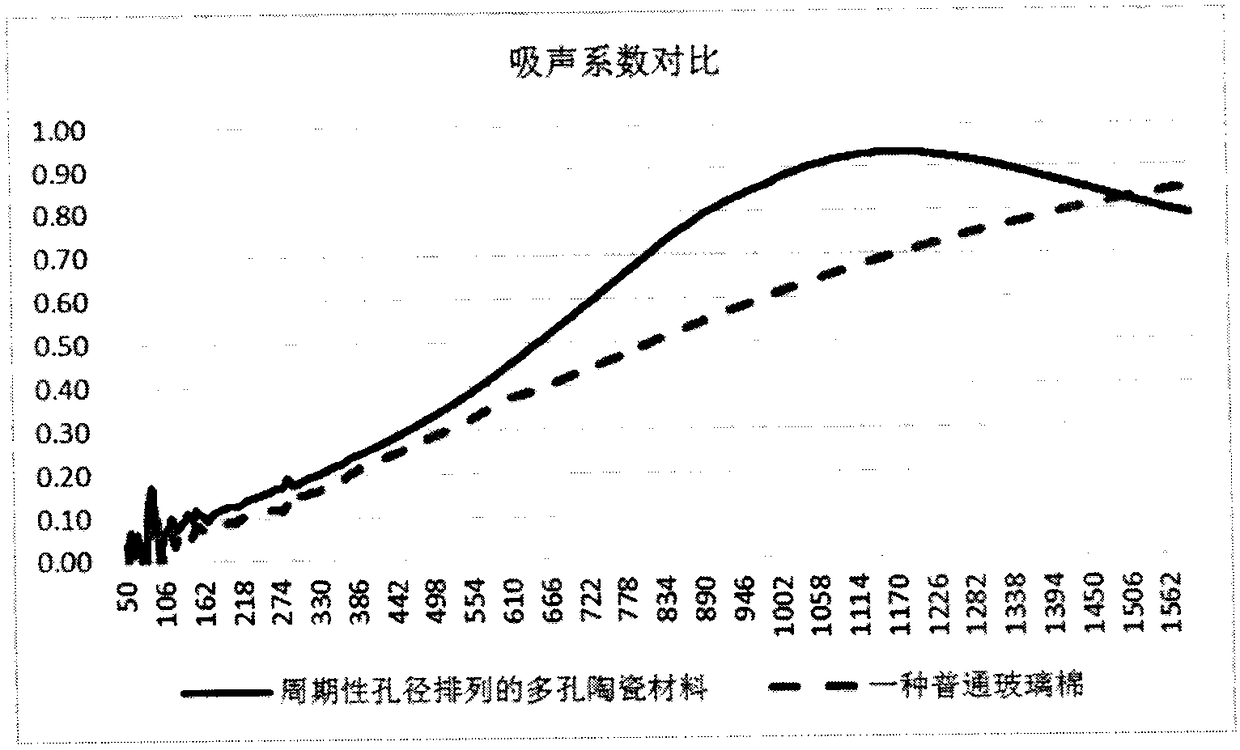

Porous ceramic sound absorption material designed on basis of photonic crystal theory and production method thereof

InactiveCN108455999AAvoid secondary environmental pollutionImprovement of design conceptCeramicwareFiberMaterial Design

The invention relates to a porous ceramic sound absorption material designed on basis of photonic crystal theory and a production method thereof. The porous ceramic sound absorption material is prepared from a ceramic framework, wherein micropores which are periodically arranged are formed in the ceramic framework; the porous ceramic sound absorption material is characterized in that the porosityis 40-70%, the pore diameter is 0.0001-0.001m, the flow resistance rate is 2500-12500Pa.s / m<2>, and the thickness is 20-100mm. The porous ceramic sound absorption material designed on basis of the photonic crystal theory can replace the traditional sound absorption material in multiple places, is capable of avoiding the secondary environment pollution of the inorganic fiber materials such as glasswool caused by dust formation, and can be applied to the outdoor environment; compared with other sound absorption materials, the porous ceramic sound absorption material has incomparable superiority.

Owner:张晓琳

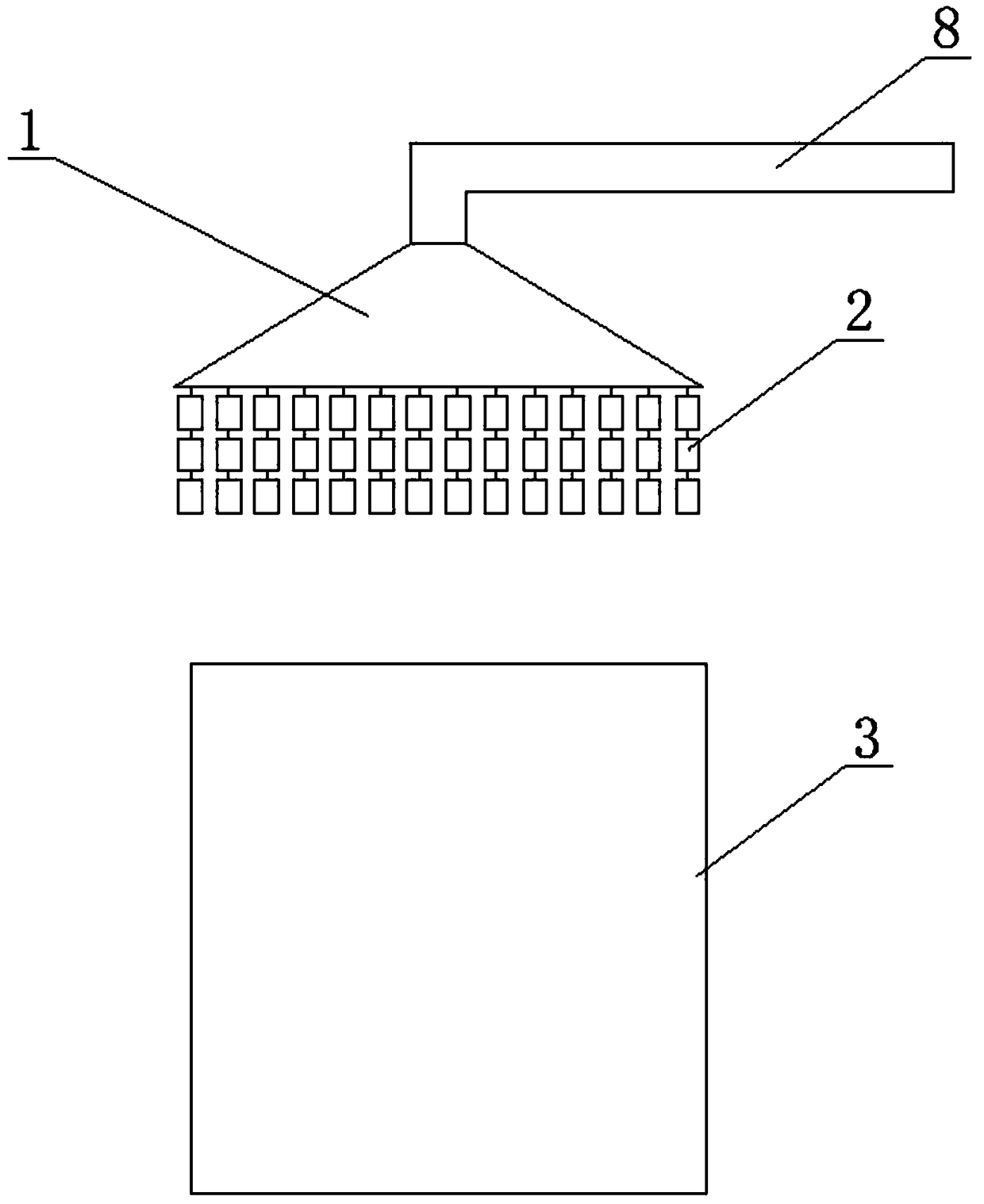

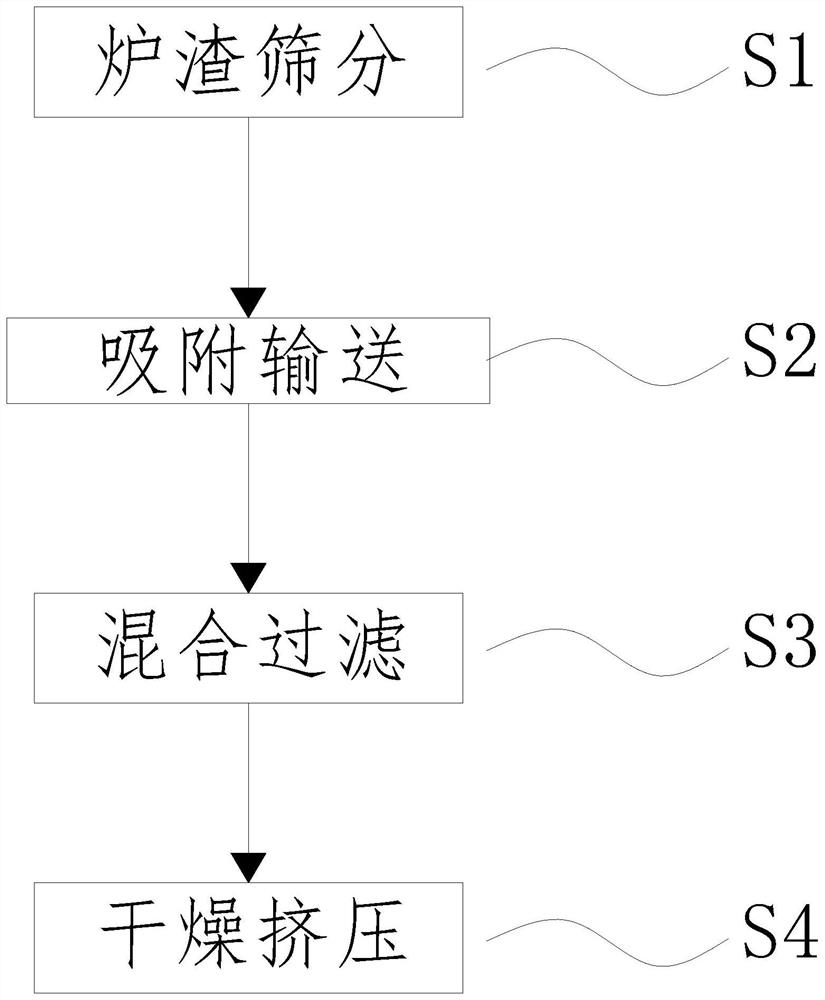

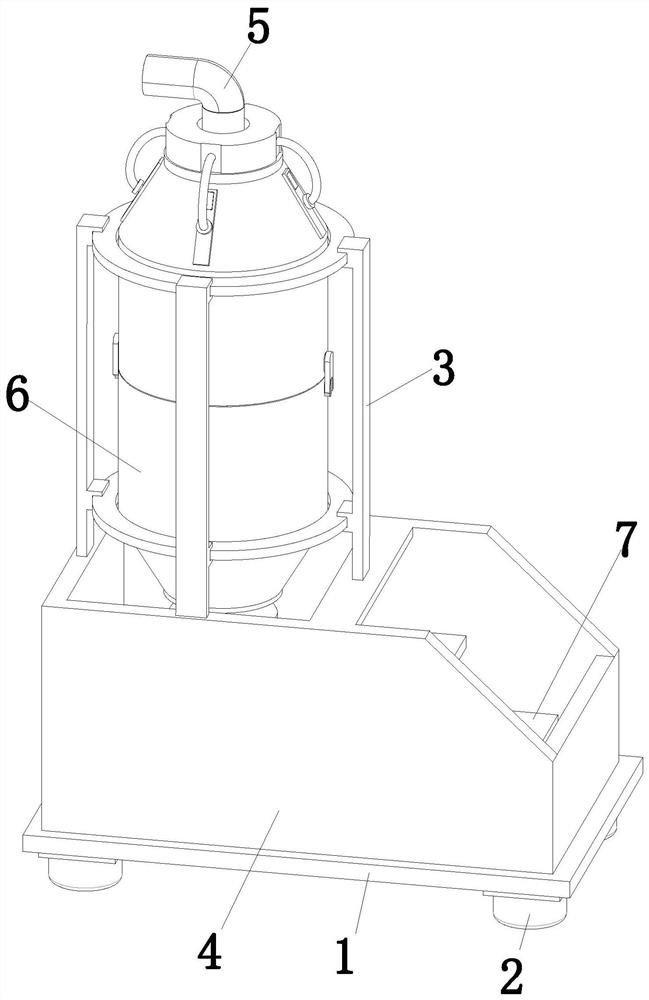

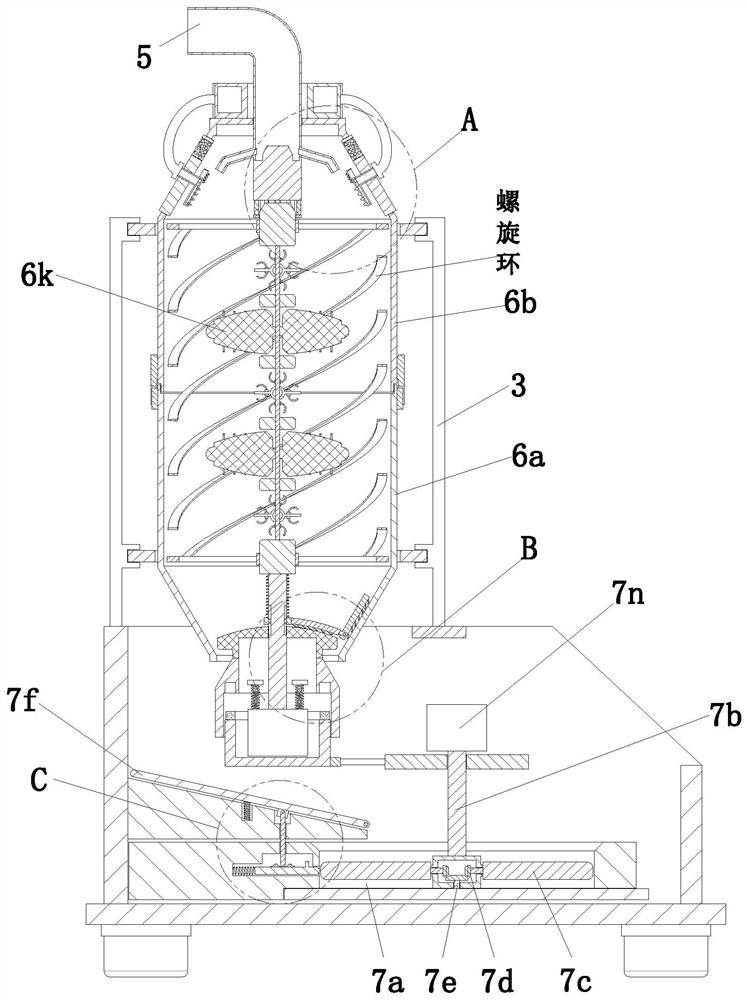

Industrial boiler slag solid waste comprehensive environment-friendly treatment method

InactiveCN113244721ARealize secondary recyclingQuick installationTransportation and packagingSolid waste disposalBoiler furnaceBoiler slag

The invention relates to an industrial boiler slag solid waste comprehensive environment-friendly treatment method, in particular to an industrial boiler slag solid waste comprehensive environment-friendly treatment device which comprises a mounting bottom plate, supporting legs, a supporting frame, a collecting box, a feeding port, a mixing mechanism and a stirring mechanism. The method can solve the problems that in the process of an industrial boiler slag solid waste comprehensive environment-friendly treatment method, the mixing proportion and the mixing degree of dust and water mist are difficult to control, mixed dust slurry is difficult to effectively scrape, mixed loose dust slurry is difficult to convey and guide, and the adhesion and accumulation phenomena of the dust slurry are generated, the mixed dust slurry is difficult to push and flatten in the circumferential direction, and the drying efficiency and the forming effect of the slurry dust are reduced.

Owner:苏哲

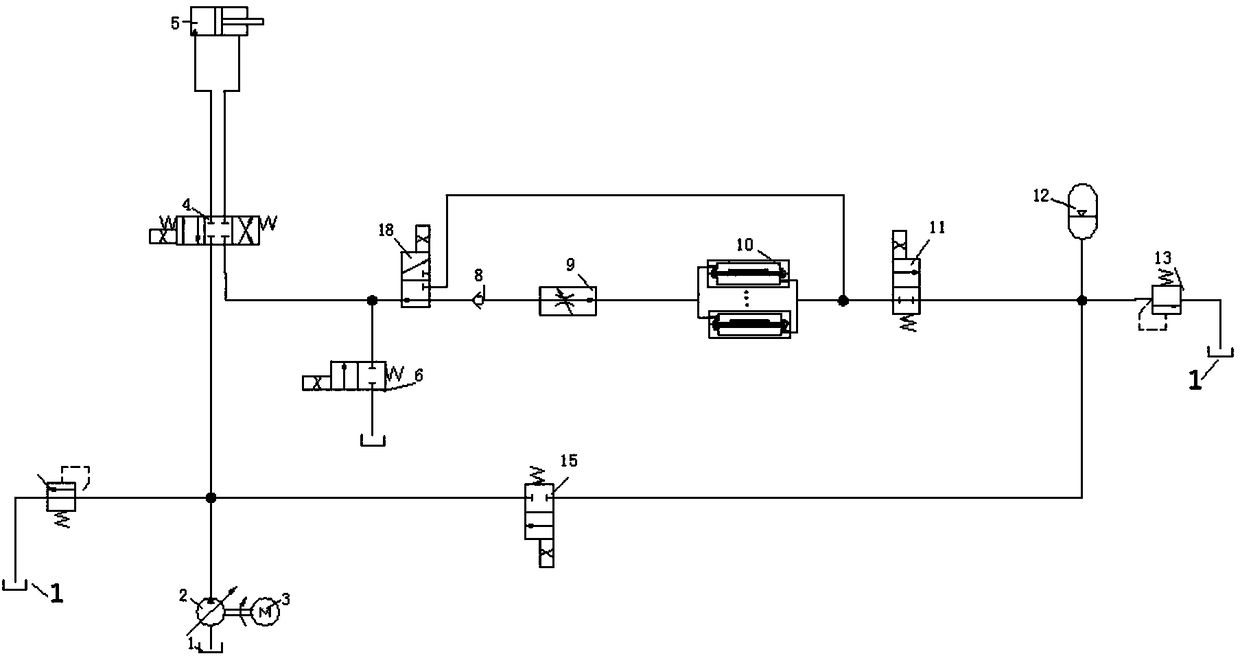

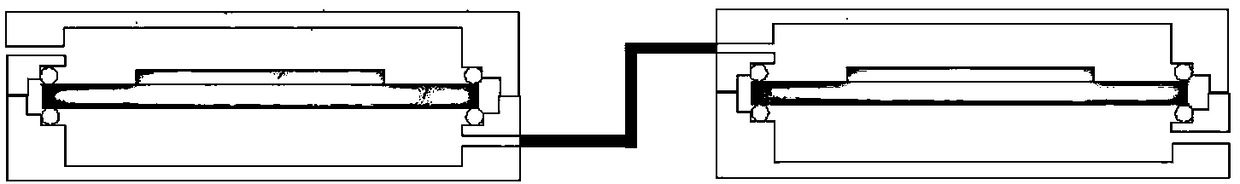

Hydraulic movable arm potential energy recovery system and method

PendingCN108533578AAchieve separate recyclingRealize secondary transformation and utilizationFluid-pressure actuator componentsElectricityHydraulic cylinder

The invention discloses a hydraulic movable arm potential energy recovery system and method. The hydraulic movable arm potential energy recovery system comprises an oil tank, a variable pump, a motor,a three-position four-way reversing valve, a hydraulic cylinder, a first two-position two-way reversing valve, a piezoelectric transducer and an energy accumulator. The oil tank and the motor are both connected to the variable pump, the output end of the variable pump is connected with a first inlet of the three-position four-way reversing valve, a first outlet of the three-position four-way reversing valve is connected with an inlet of the hydraulic cylinder, and an outlet of the hydraulic cylinder is connected with a second inlet of the three-position four-way reversing valve; a second outlet of the three-position four-way reversing valve is connected with an inlet of the first two-position two-way reversing valve, and a first outlet of the first two-position two-way reversing valve isconnected with the piezoelectric transducer; and the piezoelectric transducer is connected with an inlet of the energy accumulator, and an outlet of the energy accumulator is connected to the variablepump. According to the hydraulic movable arm potential energy recovery system and method, a piezoelectric power generating technology is applied to a hydraulic system with the energy accumulator forenergy recovery so as to achieve secondary energy recovery, hydraulic energy is rapidly converted into electric energy to be stored, and then recovery and reusing of the energy are achieved.

Owner:CHANGAN UNIV

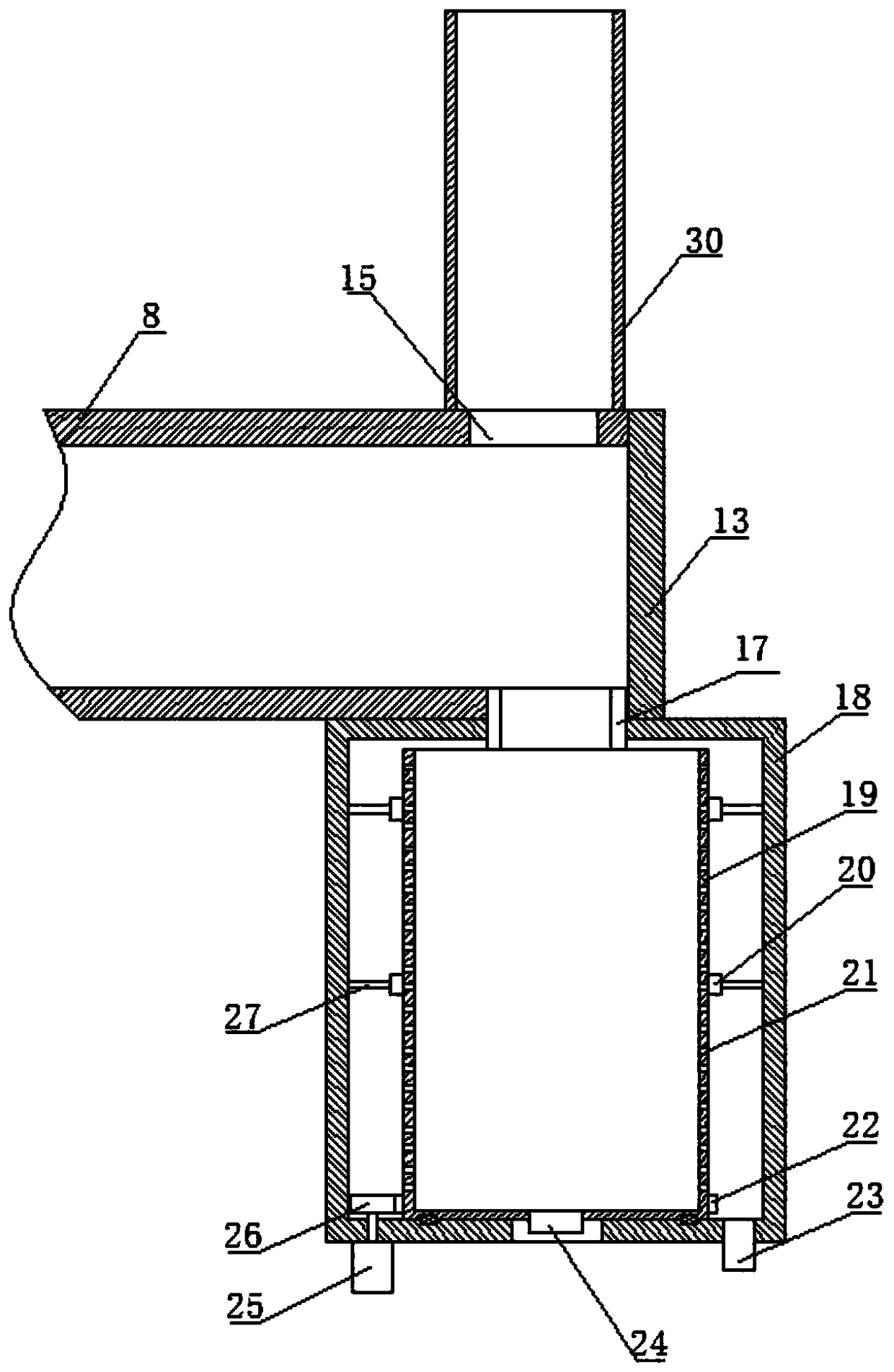

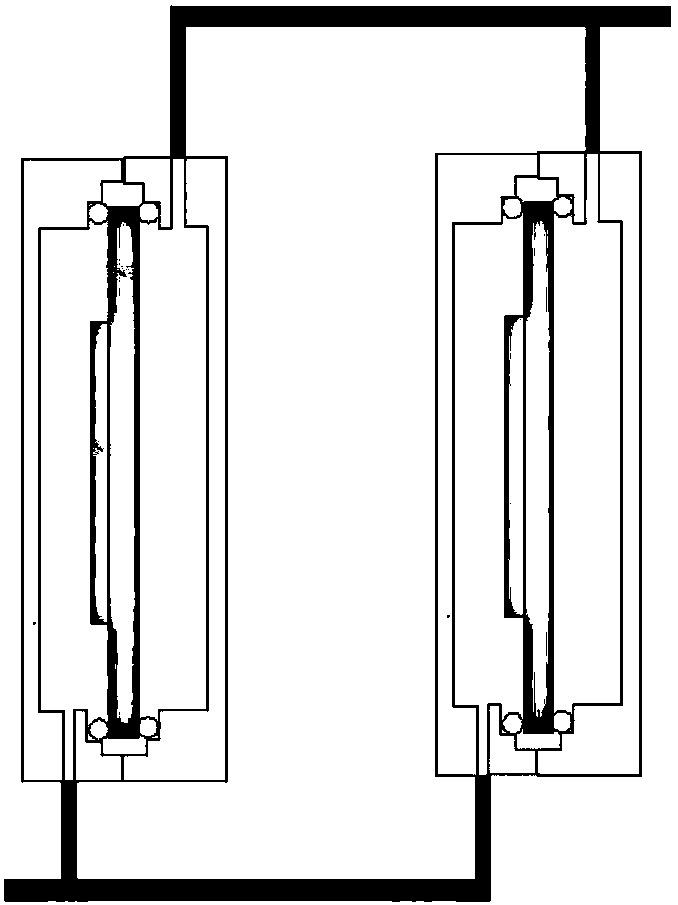

Instantaneous-heating type electric heater with heat energy secondary recycling

The invention discloses an instantaneous-heating type electric heater with heat energy secondary recycling. The instantaneous-heating type electric heater with heat energy secondary recycling comprises a cylindrical water-electricity integrated electric heater, a heat energy secondary recycling spiral coil pipe, a secondary heat recycling water inlet electromagnetic valve, a pressure temperature controlling switch, a check valve, a secondary recycling water inlet tee-junction, a water inlet electromagnetic valve, an electromagnetic valve controller, a water inlet tee-junction, a pressure detecting controller and a computer controller, wherein the cylindrical water-electricity integrated electric heater is formed by mains supply L pole, a mains supply N pole, a cold water inlet, a hot water outlet, a spiral coil pipe inside a casting body and an electric heating pipe in a casting mode. One end of the spiral pipe inside the casting body is a hot water outlet and the other end of the spiral pipe inside the casting body is a cold water inlet. The spiral pipe inside the casting body is connected with a water pipe of a water dispenser or a gas water heater to form a water heating system in a matched mode. The spiral pipe inside the casting is a water pipe of the water-electricity integrated electric heater, and is connected with a water pipe of the spiral pipe inside the casting body to form a water secondary recycling reheating system after forming a waste heat reusing and recycling device with the heat energy recycling spiral pipe,.

Owner:陈明初 +1

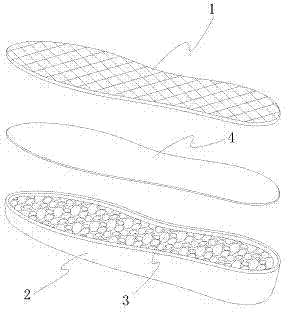

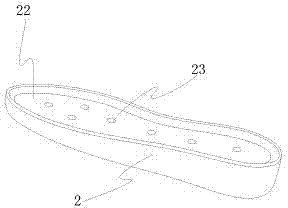

Damping sole

The invention relates to a damping sole which decreases sole laying processes, shortens production cycle, omits glue treatment agents, reduces hazardous substances and environmental pollution and facilitates mass production. The damping sole comprises a rubber outsole and a rubber insole, unvulcanized rubber is placed in a die and heated to medium well to form the rubber outsole and the rubber insole, a filling groove is formed in the rubber insole, exhaust holes are formed in the groove bottom of the filling groove, the inside of the filling groove is filled with elastic materials, an unvulcanized rubber piece is arranged between the rubber outsole and the rubber insole and covers a notch of the filling groove in the rubber insole, the rubber outsole covers the unvulcanized rubber piece, and the rubber insole, the unvulcanized rubber piece and the rubber outsole are vulcanized in the die again and then integrally formed.

Owner:FUJIAN DENGTAI TECH CO LTD

Reversible parking air conditioning system for recreational vehicle

PendingCN107379915ARealize secondary recyclingAir-treating devicesVehicle heating/cooling devicesCold airEngineering

The invention discloses a reversible parking air-conditioning system for a caravan, which comprises an air-conditioning inner unit housing and an air-conditioning outer unit matching the air-conditioning inner unit housing. One side wall of the caravan is provided with an opening. Machine housing, the side of the air conditioner inner machine housing is provided with a rotating shaft, the rotating shaft is connected to the edge of the opening by driving, the inside of the air conditioner inner machine housing is horizontally provided with a cross-flow fan, and the front of the cross-flow fan is provided with For the heat exchange module, an air return port is provided on the front side of the air conditioner inner unit casing, the air return port is facing the heat exchange module, an air outlet is provided at the lower end of the front side of the air conditioner inner unit case, and an air outlet is provided below the air return port The rear of the cross-flow fan is provided with a cavity, the top of the cavity is provided with an air inlet, and the bottom of the cavity is connected to the air outlet through a pipe. The invention can reuse the cold air in the caravan to enjoy the air conditioner outdoors. Bring comfort up.

Owner:SHENZHEN WOHAISEN TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com