Mullite nano-whisker prepared by using pyrite tailing as raw material and preparation method of mullite nano-whisker

A technology of pyrite tailings and nano-whiskers, applied in chemical instruments and methods, single crystal growth, crystal growth and other directions, can solve the problems of low added value, high energy consumption and high cost, and achieve high added value and calcination temperature. Low cost and low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

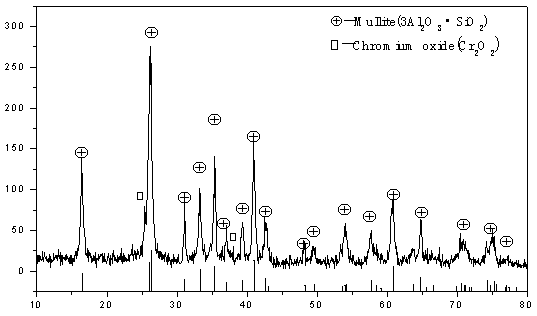

Embodiment 1

[0038] The pyrite tailings used are taken from the flotation tank of a small-scale heavy flotation joint election of an enterprise in southern Sichuan, and its chemical composition weight percentage is: SiO 2 38.41%, A1 2 o 3 32.40%, CaO 3.02%, TiO 2 4.01%, MgO 0.76%, Fe 2 o 3 5.91%, Na 2 O 0.16%, K 2 O 0.35%, SO 30.92%, loss on ignition 14.30%, and the balance is other trace components. The process steps of using the pyrite tailings to prepare mullite whiskers are as follows:

[0039] (1) Ball mill the pyrite tailings at a speed of 400 rpm to a 50-mesh sieve, dehydrate, dry, and grind until passing through a 200-mesh sieve;

[0040] (2) Weigh 50g of pyrite tailings and 170ml of mixed solution with a volume ratio of 1:1 of 25% hydrochloric acid and 25% sulfuric acid, stir in a constant temperature water bath at 60°C for 1 hour, and dehydrate and dry by centrifugation , grinding;

[0041] (3) Calcining the acid-washed pyrite tailings at 400°C for 2 hours to obtain...

Embodiment 2

[0049] The pyrite tailings used are taken from the flotation tank of a small-scale heavy flotation joint election of an enterprise in southern Sichuan, and its chemical composition weight percentage is: SiO 2 38.41%, A1 2 o 3 32.40%, CaO 3.02%, TiO 2 4.01%, MgO 0.76%, Fe 2 o 3 5.91%, Na 2 O 0.16%, K 2 O 0.35%, SO 3 0.92%, loss on ignition 14.30%, and the balance is other trace components. The process steps of using the pyrite tailings to prepare mullite whiskers are as follows:

[0050] (1) Ball mill the pyrite tailings at a speed of 400 rpm to a 50-mesh sieve, dehydrate, dry, and grind until passing through a 200-mesh sieve;

[0051] (2) Weigh 50g of pyrite tailings and 170ml of a mixed solution of 30% hydrochloric acid and 30% sulfuric acid with a volume ratio of 1:1, stir in a constant temperature water bath at 60°C for 1 hour, and centrifuge, dry, and grind ;

[0052] (3) Calcining the acid-washed pyrite tailings at 400°C for 2 hours to obtain composition-ad...

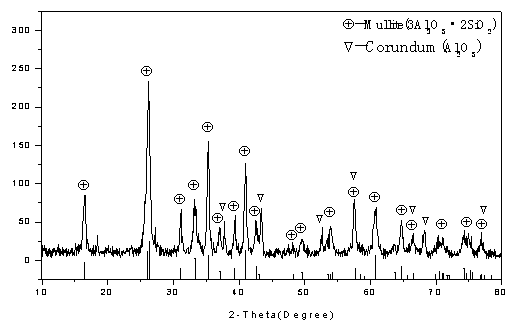

Embodiment 3

[0060] The pyrite tailings used are taken from the flotation tank of a small-scale heavy flotation joint election of an enterprise in southern Sichuan, and its chemical composition weight percentage is: SiO 2 36.99%, A1 2 o 3 30.67%, CaO 3.33%, TiO 2 3.86%, MgO 0.75%, Fe 2 o 3 6.91%, Na 2 O 0.16%, K 2 O 0.36%, SO 3 2.89%, loss on ignition 13.56%, and the balance is other trace components. The process steps of using the pyrite tailings to prepare mullite whiskers are as follows:

[0061] (1) Ball mill the pyrite tailings at a speed of 400 rpm to a 50-mesh sieve, dehydrate, dry, and grind until passing through a 200-mesh sieve;

[0062] (2) Weigh 50g of pyrite tailings and 170ml of a mixed solution of 25% hydrochloric acid and 25% sulfuric acid with a volume ratio of 1:1, stir in a constant temperature water bath at 65°C for 1.5 hours, and centrifuge, dry, and grind ;

[0063] (3) Calcining the acid-washed pyrite tailings at 400°C for 2 hours to obtain composition...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com