Patents

Literature

169results about How to "Hazard mitigation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

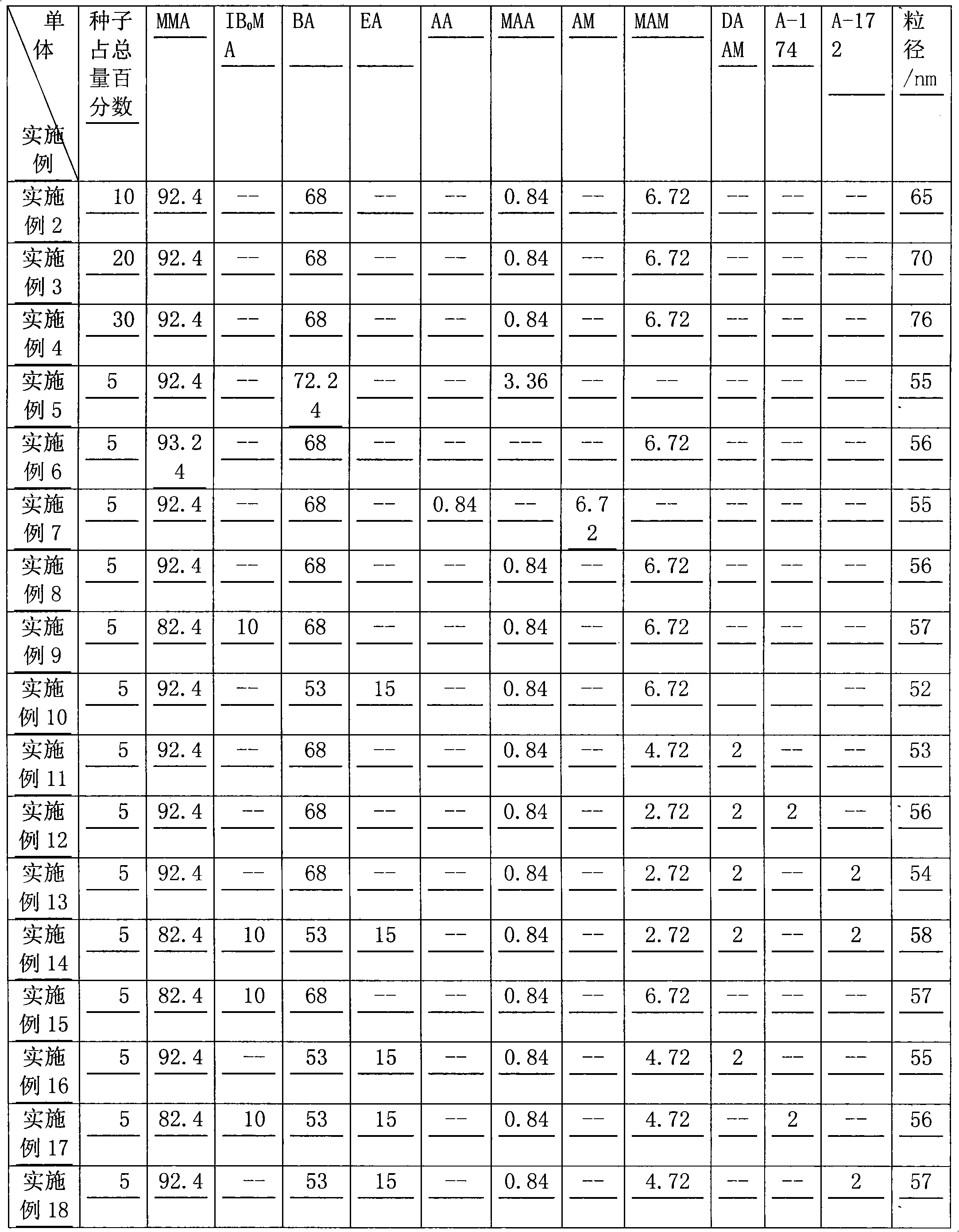

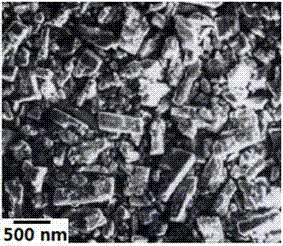

Aqueous acrylic acid series wooden ware sealing paint and method for preparing special emulsion thereof

InactiveCN101817906ASmall particle sizeImprove permeabilityCoating impregnationCoatingsFiberCoating system

The invention relates to aqueous acrylic acid series wooden ware sealing paint and a method for preparing special emulsion thereof. Nano emulsion with small particle diameter and narrow distribution is prepared by using an acrylic acid monomer containing multiple polar groups as a raw material. Multiple aids are added into the emulsion serving as a basic film-forming substance to form the novel aqueous wooden ware sealing paint. The polar functional groups on polymer molecule chains have good wetting property on wood, emulsion particles are easy to permeate into wood fiber conduits and quickly form films in conduit holes, and the paint can effectively prevent the moisture in the aqueous wooden ware paint from permeating into the wood and solves the problem of surface gully caused by the water-swelling wood; and meanwhile, the paint also can effectively seal the substances which are extremely easy to permeate to the outside such as turpentine, tannin and the like acknowledged in the wooden ware industry, and solves common problems for wide application of the aqueous wooden ware paint. The aqueous sealing paint also can be used for a solvent type paint coating system, and effectively prevents a large amount of solvent in the solvent type paint from penetrating into the wood during coating.

Owner:BEIJING UNIV OF CHEM TECH

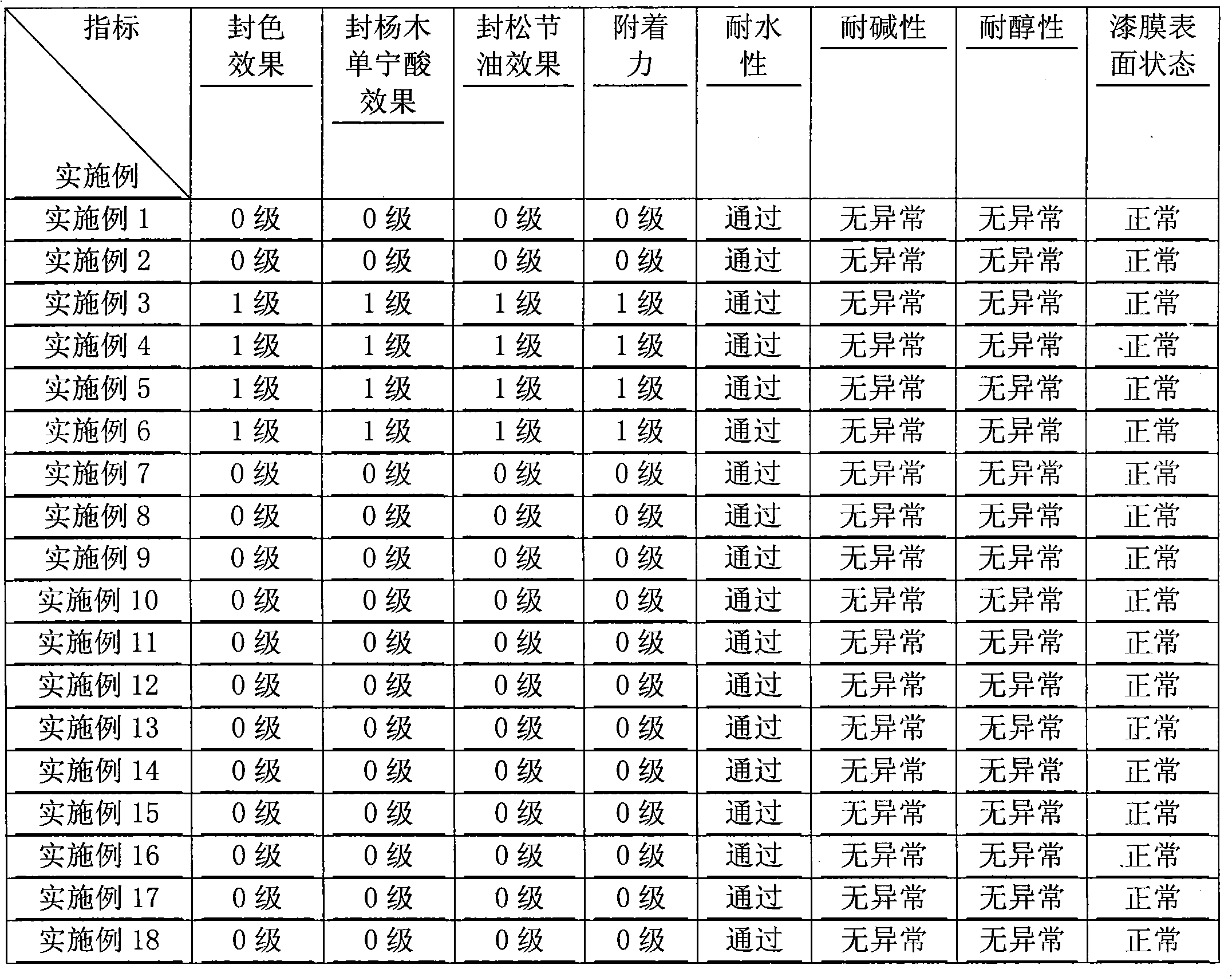

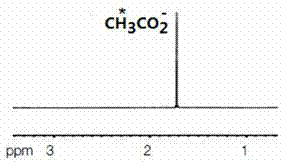

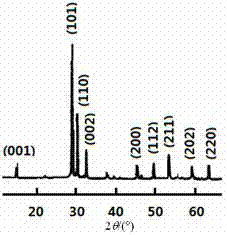

Method for preparing nano lead product by lead plaster of waste lead-acid storage batteries

ActiveCN102820496AHazard mitigationReduce pollutionWaste accumulators reclaimingProcess efficiency improvementSodium acetateAcetic acid

The invention relates to a method for preparing a nano lead product by lead plaster of waste lead-acid storage batteries. The method comprises the following steps of: mixing the lead plaster, sodium acetate, acetic acid and H2O2 according to a ratio, diluting the mixture by de-ionized water, agitating and reacting the diluted mixture at 20-30 DEG C for 6-10 hours, carrying out solid-liquid separation on the mixture after the reaction, adjusting the pH (Potential of Hydrogen) of the mixture to 7.1-7.3, standing the mixture for 1-2 hours, and filtering the mixture to obtain a lead acetate crystal; calcining the lead acetate crystal at 250-350 DEG C for 2-3 hours to obtain nano PbO powder; and mixing the lead acetate crystal, a sulfur source and a surfactant according to a ratio, adding a liquid medium in the mixture, mixing the mixture and the liquid medium uniformly, placing the obtained mixture into a reaction kettle at 120-130 DEG C for 10-15 hours, naturally cooling the mixture to a room temperature, carrying out solid-liquid separation on the mixture, and washing black sediments by water and ethanol to obtain the nano PbS product. The method disclosed by the invention not only provides a raw material and a method for manufacturing the nano lead product, and is good for relieving environmental damages which are possibly caused by a large amount of waste lead-acid storage batteries and realizing high efficiency and low pollution of a lead resource recycling process.

Owner:STATE GRID HENAN ELECTRIC POWER ELECTRIC POWER SCI RES INST +2

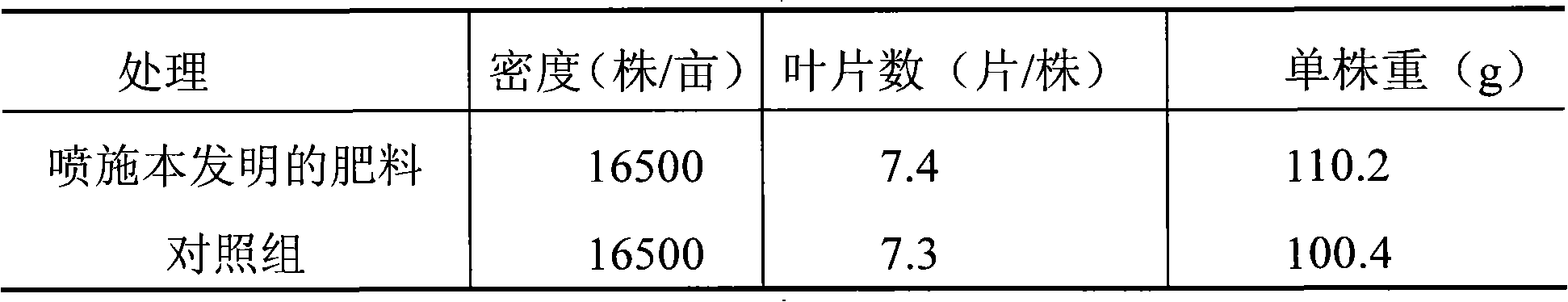

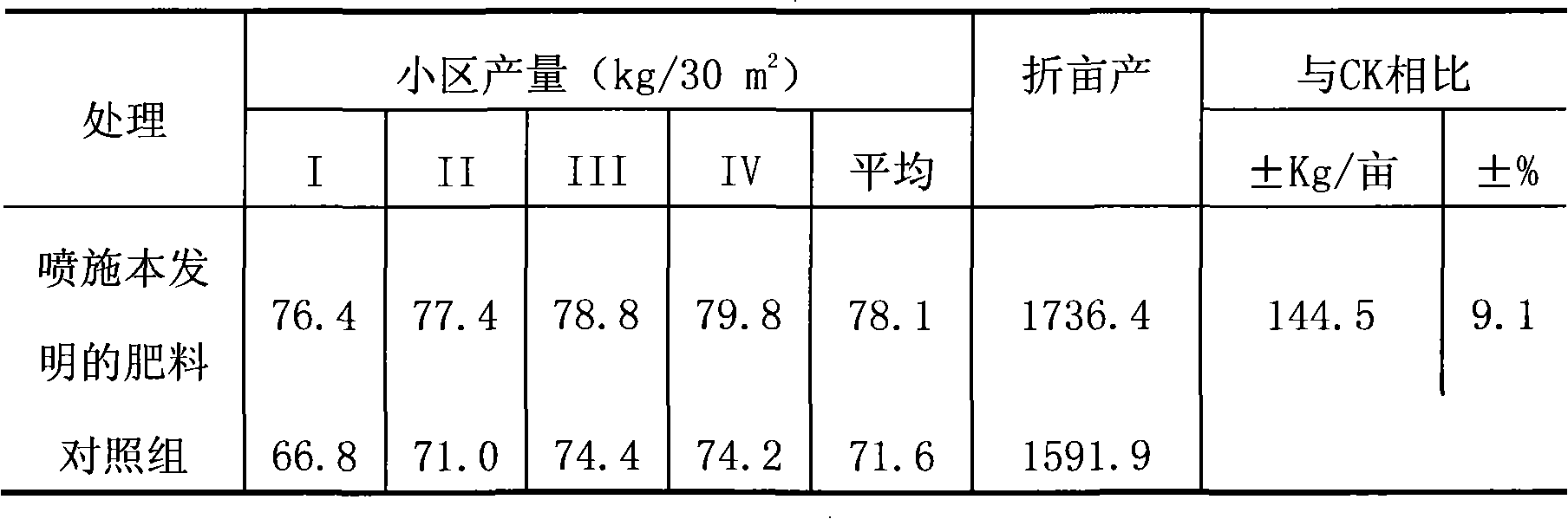

Organic-inorganic compound fertilizer special for watermelons and production method of organic-inorganic compound fertilizer

InactiveCN103588579AIncrease and update organic matterSimple structureFertilizer mixturesContinuous croppingAdhesive

The invention relates to an organic-inorganic compound fertilizer and a production method thereof, in particular to an organic-inorganic compound fertilizer special for watermelons. The organic-inorganic compound fertilizer is characterized by comprising the following raw materials in parts by mass: 40-60 parts of thoroughly-decomposed organic fertilizer, 20-25 parts of urea, 8-12 parts of triple superphosphate, 15-20 parts of potassium sulfate, 1-3 parts of micro element fertilizer, and 8-10 parts of an adhesive. The production method comprises the following steps: the thoroughly-decomposed organic fertilizer is prepared firstly; then, the urea, the triple superphosphate, the potassium sulfate and the micro element fertilizer are evenly mixed and smashed; the fermented thoroughly-decomposed organic fertilizer and the adhesive are thoroughly mixed with the smashed materials, are granulated through a disc, and are dried and screened to obtain the product. The production method is unique; the organic-inorganic compound fertilizer is rich in nutrients, can guarantee excellent quality and high yield of the watermelons, improves soil, prevents diseases, resists continuous cropping, and improves planting benefits.

Owner:NINGXIA KOCEL GRP CO LTD +1

Soil conditioner applicable to deteriorated grassland and preparation method

InactiveCN105295928ASimple production processThe production process is easy to operateOrganic fertilisersSoil conditioning compositionsHumic acidGrowth plant

The invention discloses an environment-friendly soil conditioner, in particular a soil conditioner applicable to deteriorated grassland. The soil conditioner, namely a combined modifier, is prepared according to a preparation method mainly comprising the step of mixing an arbuscular mycorrhizal fungus (AM fungus), a plant growth-promotiong rhizosphere (PGPR) liquid inoculant, humic acid and a matrix. The combined modifier is utilized for improving soil in the deteriorated grassland, can effectively improve the soil physicochemical properties, enhance the soil biological activity, and release the soil fertility, and is environmentally friendly; the preparation method is simple in technical procedure and suitable for industrialized production.

Owner:SHANGHAI NORMAL UNIVERSITY

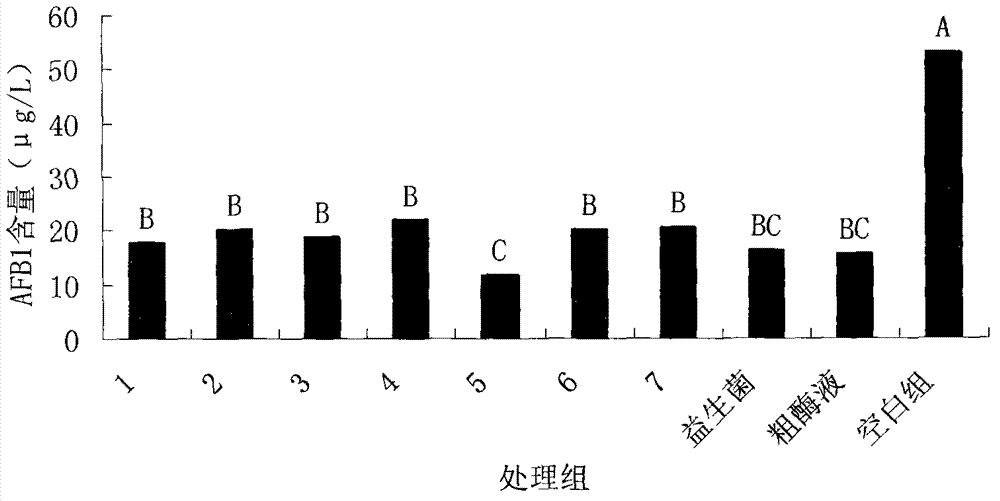

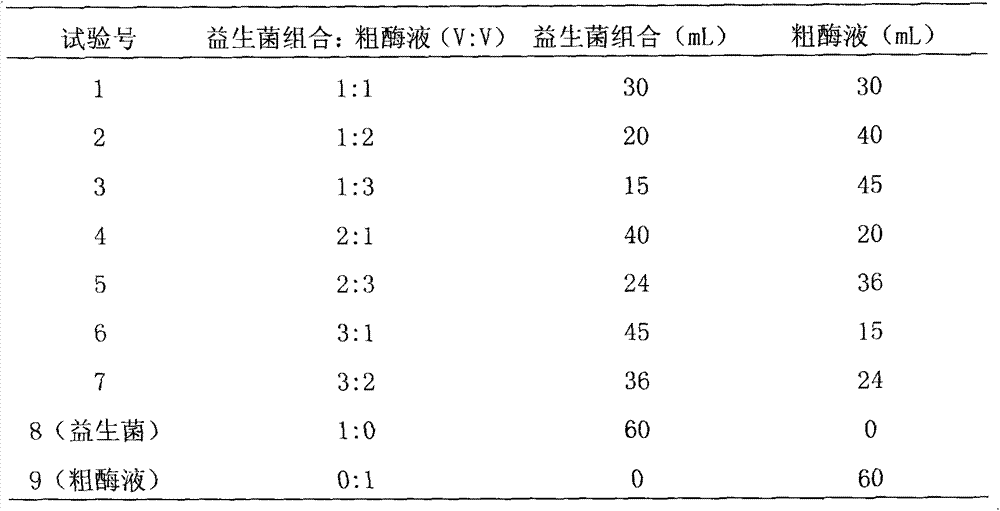

Aflatoxin B1 degradation agent and application thereof

The invention discloses an aflatoxin B1 degradation agent comprising a component a and a component b with a combination ratio of 2 : 3, wherein the component a is prepared by individually culturing lactobacillus casei CGMCC1.62, Bacillus subtilis CGMCC1.504, and Hansenula anomala CGMCC2.881 for 48 hours, mixing with a ratio of 2 : 1 : 1, adding a carrier, and drying under a low temperature; and the component b is prepared by using AFB1 as a carbon source and energy to screen AFB1 degrading bacteria strains, a 26S rDNA identification result showing that a fungi: Aspergillus oryzae is screened to be capable of degrading the AFB1 and the Aspergillus oryzae being with an access No. CGMCC5817 in the China microbiological culture collection center; performing a solid fermentation culture for the AFB1 degrading fungi, extracting a crude enzyme solution of AFB1 degrading enzymes, adding a carrier, and drying under the low temperature. The aflatoxin B1 degradation agent establishes foundations for an application thereof in animal production, pathogenic mechanism researching of AFB1 on a genetic level, and measures taken to mitigate the harm.

Owner:洛阳欧科拜克生物技术股份有限公司

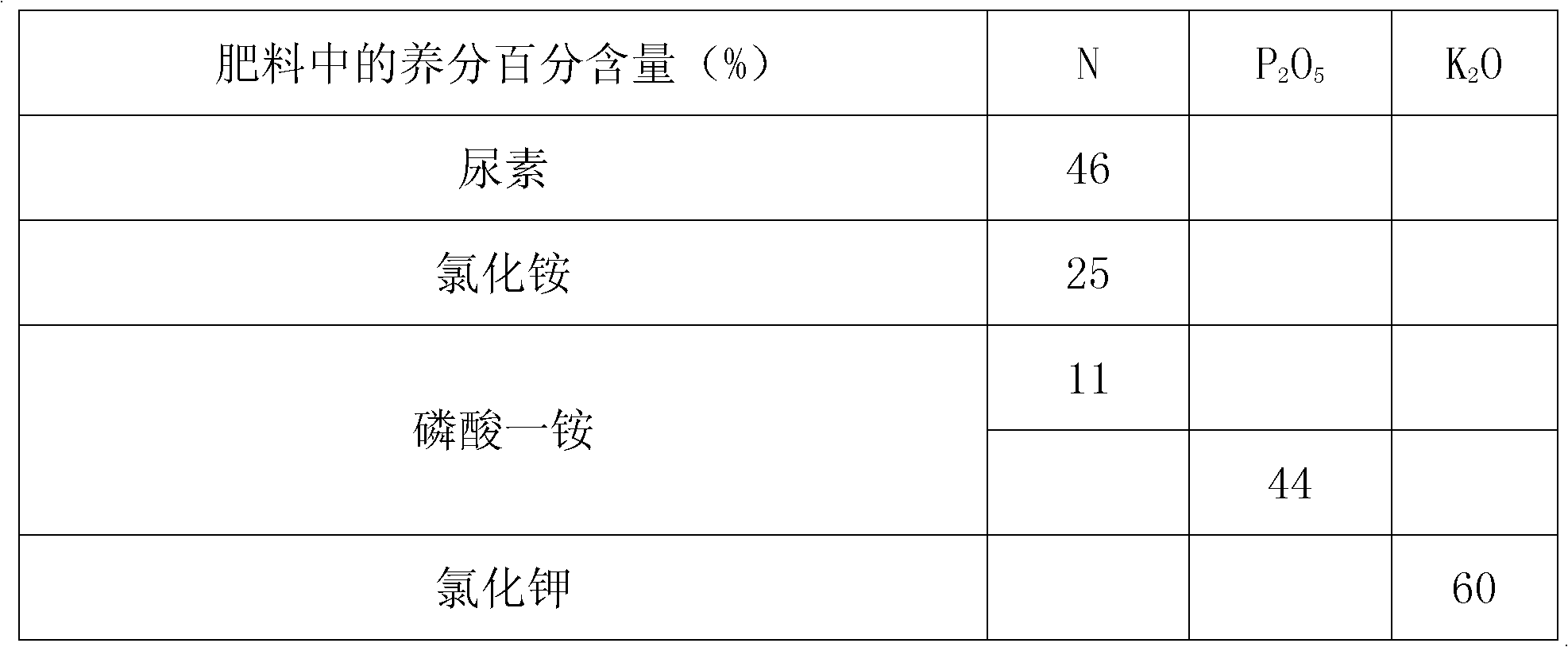

Special fertilizer for sweet potato

The invention relates to a special fertilizer for sweet potatoes. The special fertilizer comprises the following raw materials in parts by weight: 18-25 parts of urea, 12-18 parts of ammonium chloride, 8-12 parts of monoammonium phosphate, 6-10 parts of calcium superphosphate, 35-40 parts of potassium chloride, 10-12 parts of sodium humate, 5-8 parts of grondverbeteraar and 1-3 parts of a PH buffer agent, and the raw materials are mixed together according to the ratio. Compared with the prior art, the special fertilizer blends nutrient components according to the demands of sweet potatoes, the nutrient utilization rate is high, the disease resistance is improved, and the yield of the sweet potatoes is increased.

Owner:广西博白县琼达农业科技有限公司

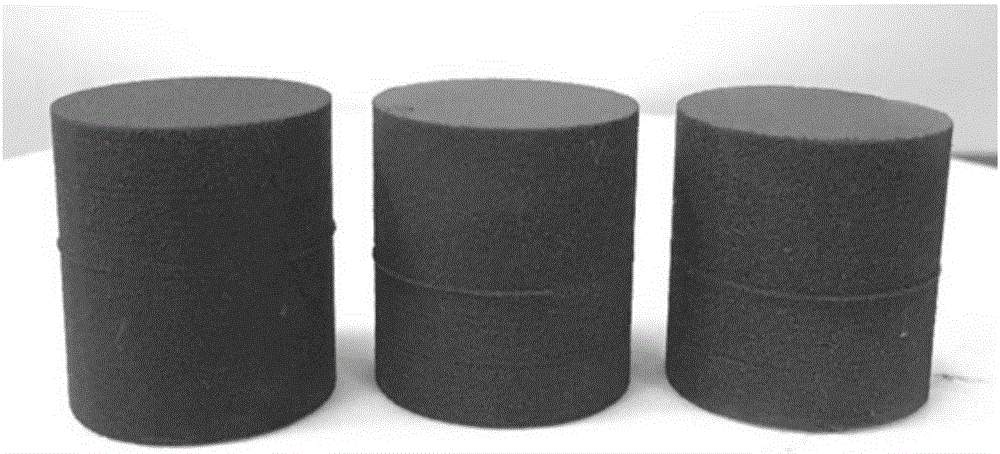

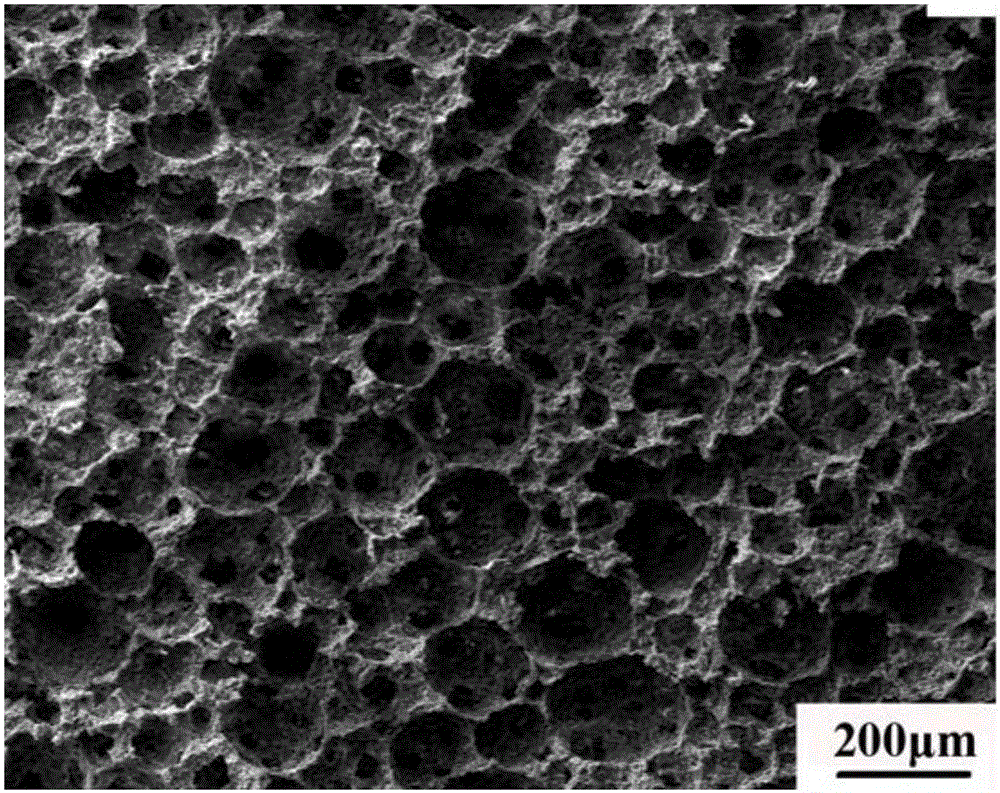

Method for preparing iron tailing porous ceramic through foam-gelcasting/low-temperature sintering

ActiveCN106830989AIncrease profitHigh porosityCeramic materials productionCeramicwareFoaming agentSlurry

The invention discloses a method for preparing iron tailing porous ceramic through foam-gelcasting / low-temperature sintering. The method comprises the following steps: uniformly mixing iron tailing powder and deionized water through a ball milling method to prepare slurry; injecting an organic monomer, crosslinking agent and dispersing agent into the slurry, and further performing ball milling; adding foaming agent and foam stabilizer into the slurry subjected to ball milling, and mechanically stirring at a high speed to enable the slurry to foam; injecting initiator and a catalyst into the foaming slurry, uniformly stirring, pouring the slurry into a mold, performing gelcasting, demolding, and drying; putting the dried porous body in a muffle furnace, and sintering at a temperature lower than 1120 DEG C to obtain the iron tailing porous ceramic. By using the method to prepare the porous ceramic, the solid waste utilization ratio is high; harm of iron tailings to the environment can be effectively relieved; the prepared porous ceramic has the advantages of high porosity, small pore diameter, uniform distribution, controllable casting parameters, low sintering temperature and the like; and the porous ceramic has favorable physical property and mechanical property.

Owner:BEIJING JIAOTONG UNIV

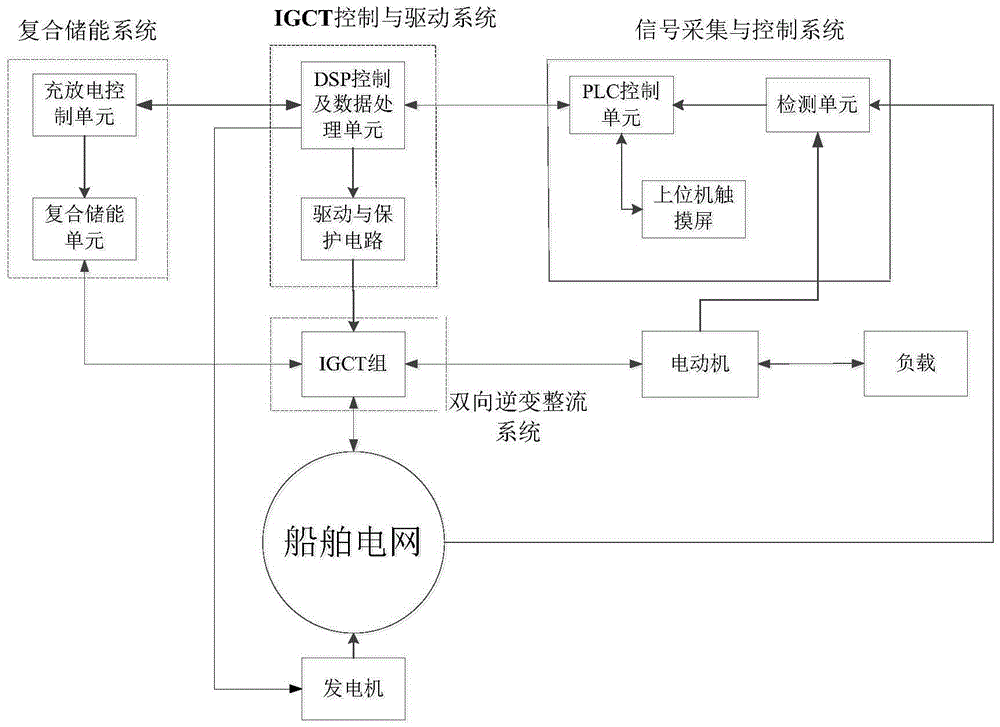

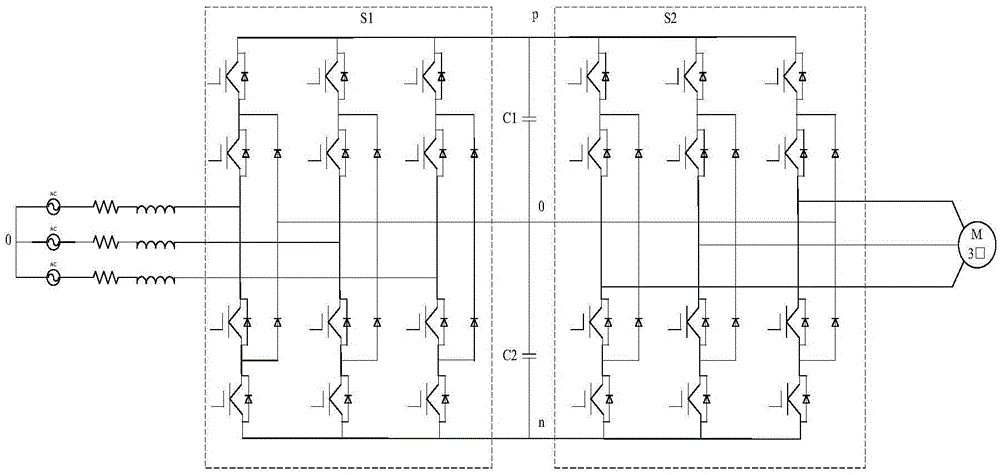

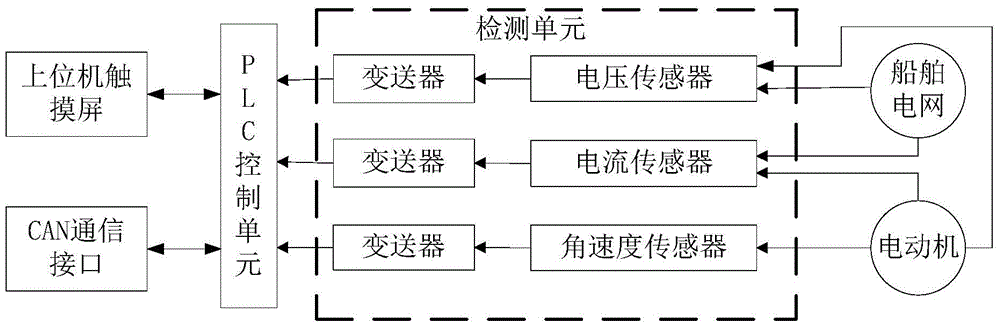

Ship electric propulsion system with harmonic suppressing and regenerative braking functions and control method

ActiveCN105620706ASmooth out load power fluctuationsImprove power qualityPropulsion power plantsPropulsive elementsThree levelHarmonic mitigation

The invention relates to the field of ship electric propulsion, in particular to a ship electric propulsion system with harmonic suppressing and regenerative braking functions and a control method. The system is mainly composed of an IGCT control and drive system, a signal acquisition and control system, a composite energy storage system and a two-way inversion rectification system installed between a motor and a ship power grid. A double-three-level diode clamp type topological structure is adopted in the two-way inversion rectification system in the ship electric propulsion system, the SVPWM control technology is selected in the control method, and therefore the harmonic suppressing and regenerative braking functions are achieved. The composite energy storage system in the ship electric propulsion system can be used for absorbing energy generated in the ship braking process, can also be used for leveling fluctuations of the ship power grid and has the ship power grid stabilizing effect. The ship electric propulsion system has the important application value for improving the electric energy quality of the ship power grid and increasing the energy use rate.

Owner:WUHAN UNIV OF TECH

Beverage for sobering up

The invention relates to a beverage for sobering up. The technical scheme of the invention is that the beverage comprises 20-25% of distilled water, 15-20% of flowers of lobed kudzuvine, 5-7% of kudzu roots, 3-5% of kudzu stem leaves, 2-4% of lucid ganoderma, 5-8% of hawthorn, 2-3% of ligusticum chuanxiong hort, 2-4% of tangerine peel, 3-5% of wild chrysanthemum flowers, 2-3% of radix bupleuri, 4-6% of dark plum, 1-2% of aloe, 2-4% of epimedium, 1-2% of caulis spatholobi, 1-3% of polygonatum rhizome, 2-3% of fleece-flower roots, 1-3% of mulberry, 3-4% of schisandra chinensis, 2-4% of sedum sarmentosum, 2-3% of patrinia scabioaefolia, 5-7% of isatis roots, 4-8% of forsythia suspense, 3-6% of gentian, 2-3% of scutellaria, 1-2% of gentrin knotweed, 2-3% of turmeric, 3-4% of sticktight, 1-2% of goosefoots, and the like. The advantage of the invention is that the beverage can rapidly alleviate symptoms of dizziness, headache, and gastrointestinal discomfort of human body caused by alcohol, and has the efficacy of liver protection and intestine protection.

Owner:李音

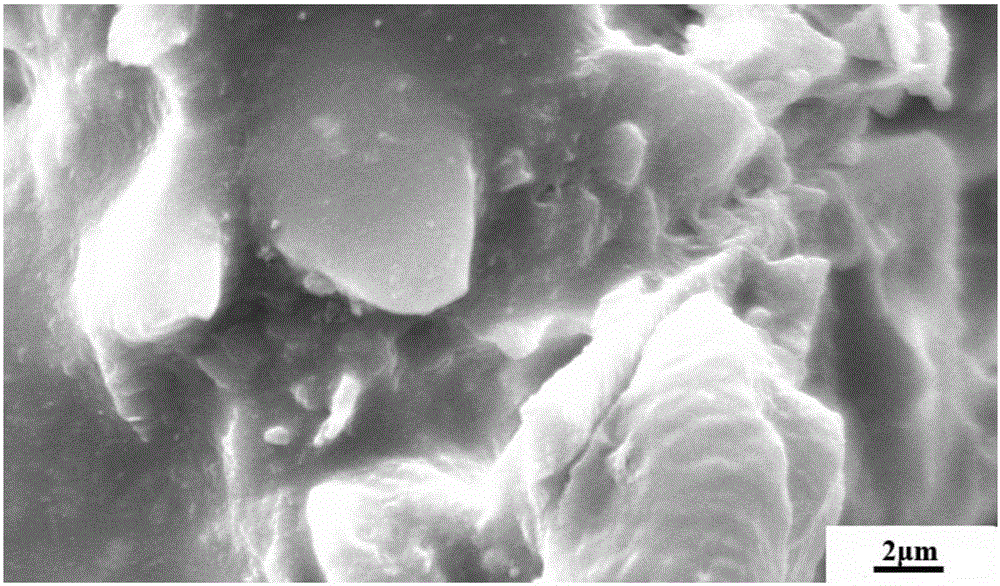

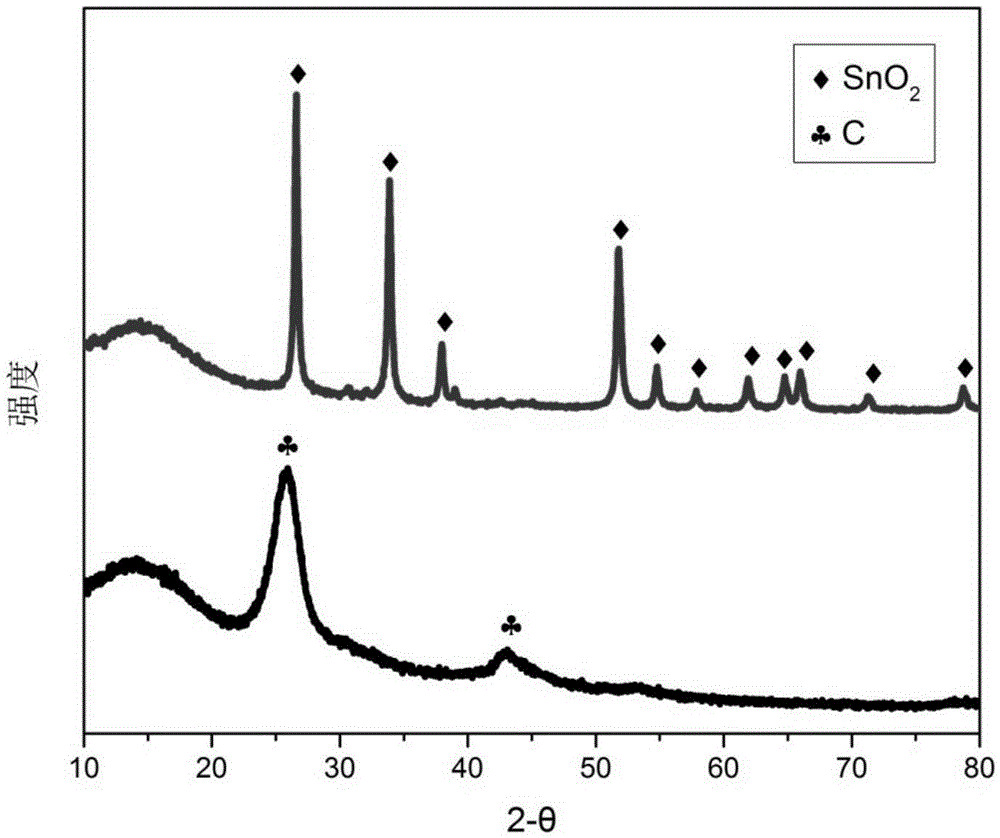

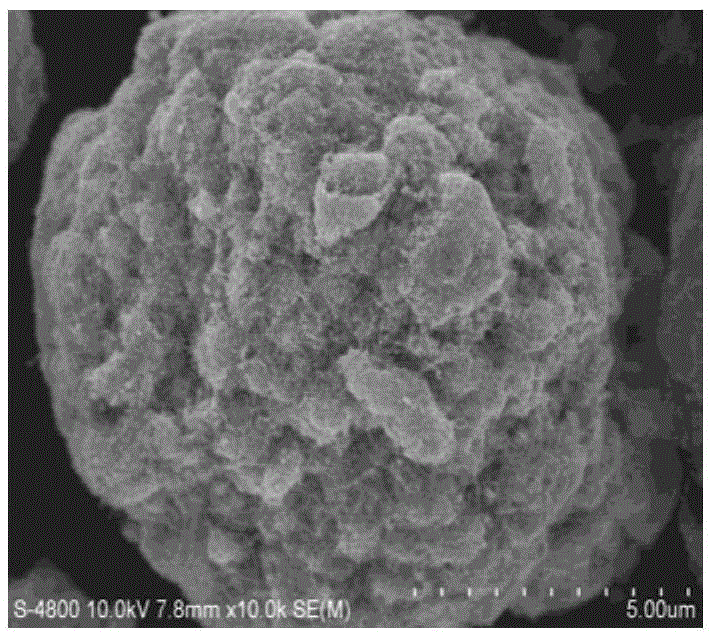

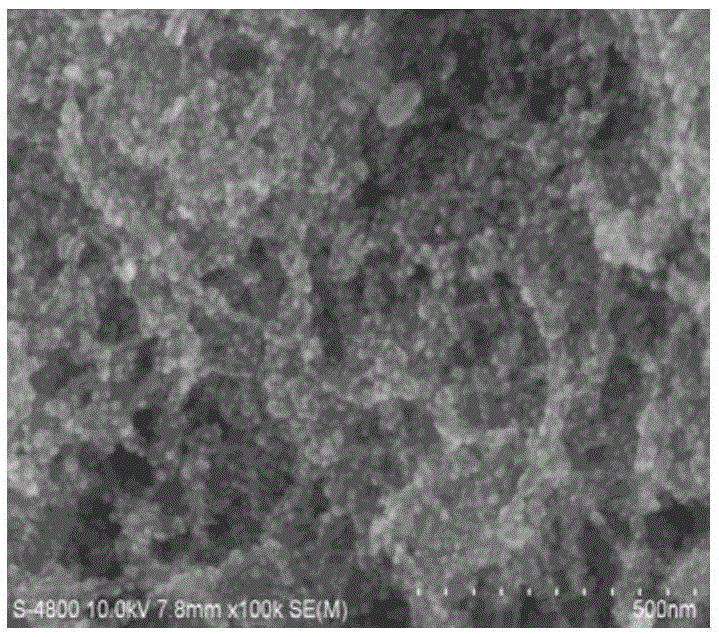

Tin-based nanoparticle-carbon composite material, and preparation method and application thereof

ActiveCN106505188ARelieve tin volume expansionGood specific capacity and cycle stabilityCell electrodesVolume expansionLithium electrode

The invention discloses a tin-based nanoparticle-carbon composite material. The tin-based nanoparticle-carbon composite material comprises a carbon substrate material and tin-based nanoparticles uniformly distributed on the carbon substrate material. The invention also discloses a preparation method for the composite material, wherein the preparation method comprises the steps of enabling tin powder and / or tin alloy powder to be uniformly mixed with a carbon material and a flux; and then heating the formed mixture in an oxygen-containing atmosphere to a temperature which is greater than a tin or tin alloy melting point, and performing thermal insulation to prepare the target product. The tin-based nanoparticles in the composite material are small in dimensions (about 5-20nm), uniform and controllable, and are uniformly distributed on the carbon substrate material, so that the tin content of the composite material can be adjusted at 5-80wt%; therefore, the danger caused by tin volume expansion is greatly relieved, and high specific capacity and cycling stability are achieved, so that the composite material can be used for a negative electrode material of a lithium ion battery; meanwhile, the composite material has simple preparation process, low-price and easily-available raw materials, low cost, and low pollution, is suitable for large-batch industrialization, and also can be expanded to preparation of other metal-based nanoparticle-carbon composite material.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

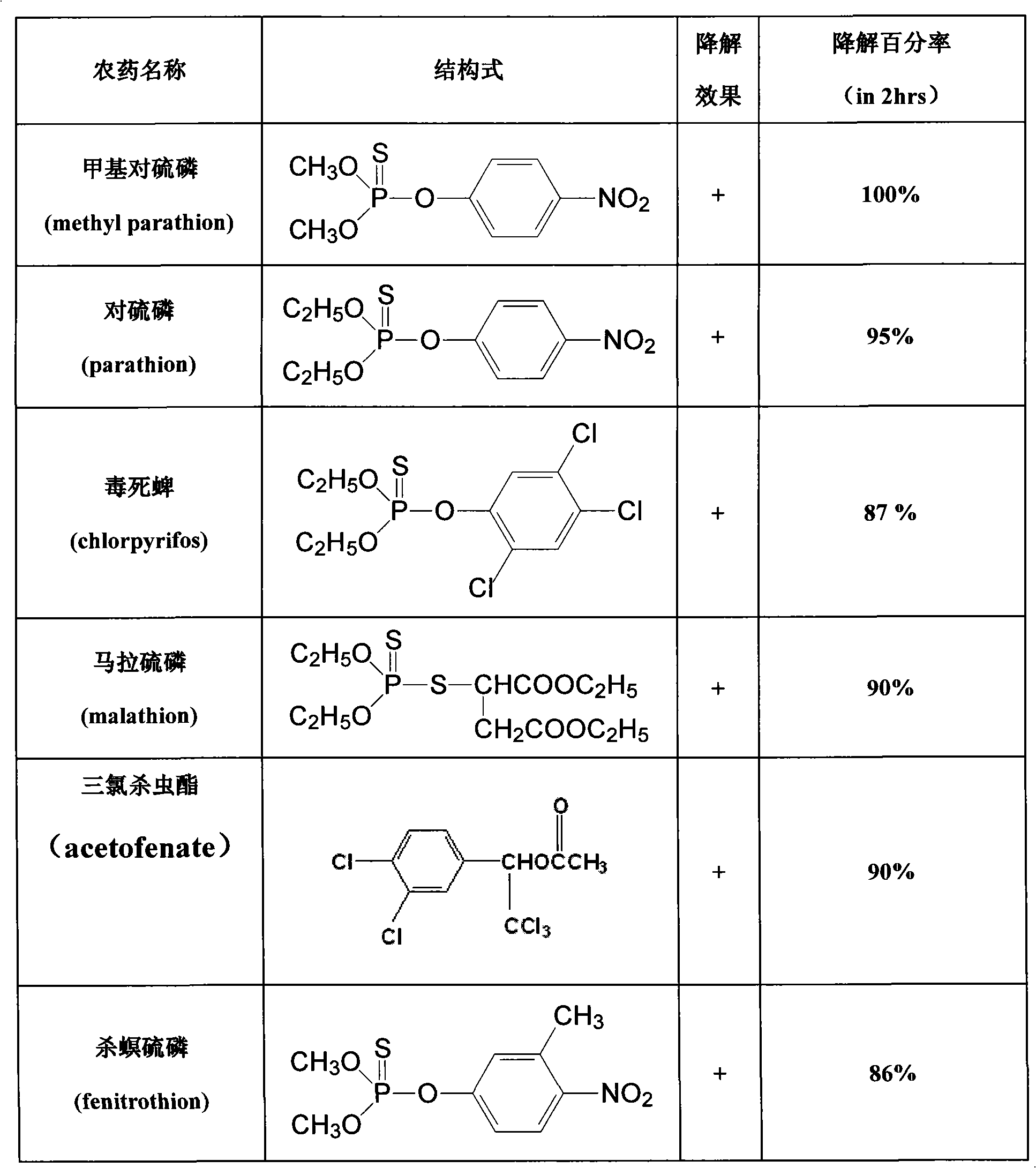

Moisturizing biological fertilizer for degrading pesticide residues

ActiveCN101811914AReduce pollutionHazard mitigationBio-organic fraction processingWaste based fuelPhosphatePesticide residue

The invention discloses a moisturizing biological fertilizer for degrading pesticide residues, which is prepared by adopting the following components as main components: 0.5 to 90 percent of Y-polyglutamic acid, 5 to 45 percent of humic acid, 1 to 15 percent of carboxy-lesterase, 1 to 15 percent of organic phosphorus hydrolase, 0 to 65 percent of naphthyl amine, 0 to 25 percent of urea and 0 to 1.5 percent of citric acid (one water molecule). The moisturizing biological fertilizer can be sprayed to various soils and plants, and has the following advantages of: (1) effectively degrading pesticide residues of esters such as organic phosphate, organic chlorate and the like, and realizing food safety from the source; (2) restoring soil structures, keeping moisture, improving the utilization rate of the fertilizer and realizing production and income increment; and (3) changing the traditional habits and concepts of peasants on use and fertilization. Through large-area test, the yield is increased by over 10 percent; and after the moisturizing biological fertilizer of the invention is used, the pesticide residues of esters such as organic phosphate, organic chlorate and the like in the soils and the crops can be effectively degraded.

Owner:河南远东生物工程有限公司

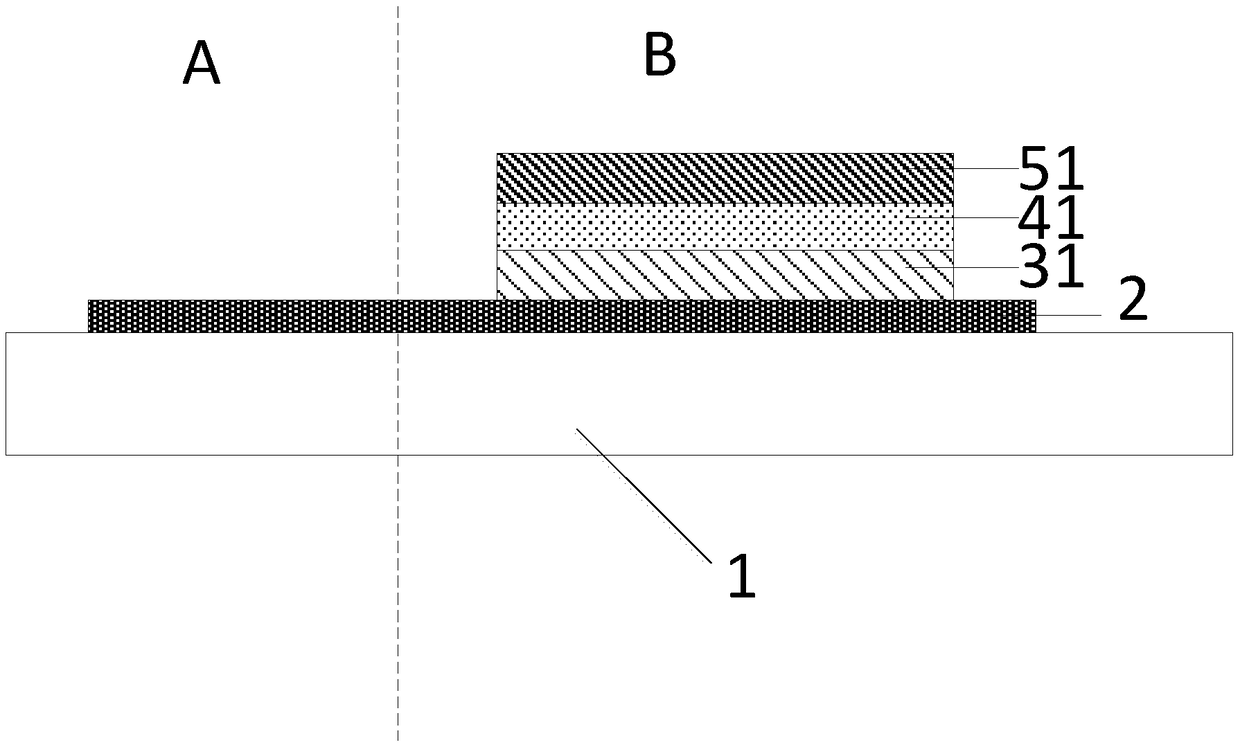

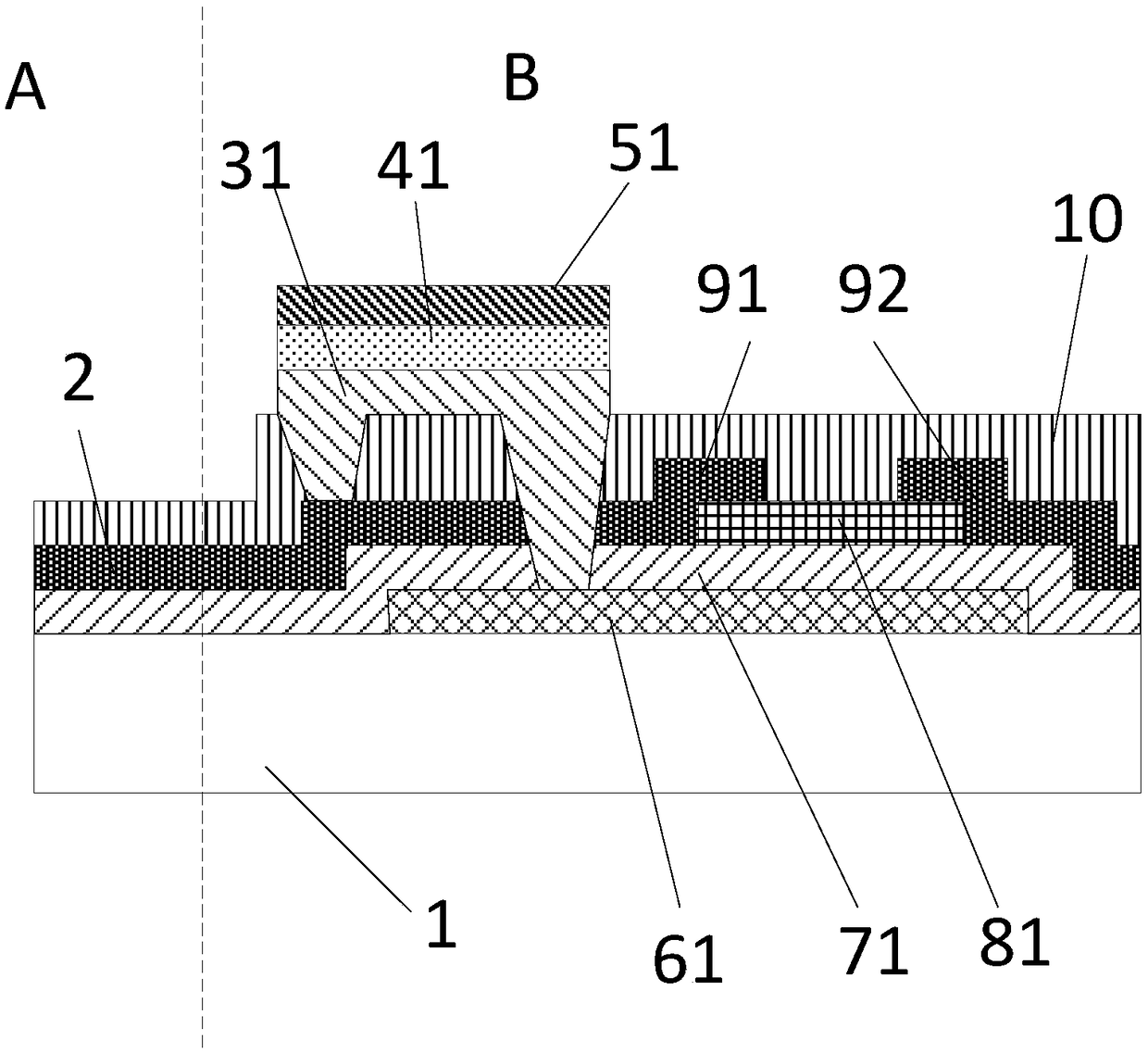

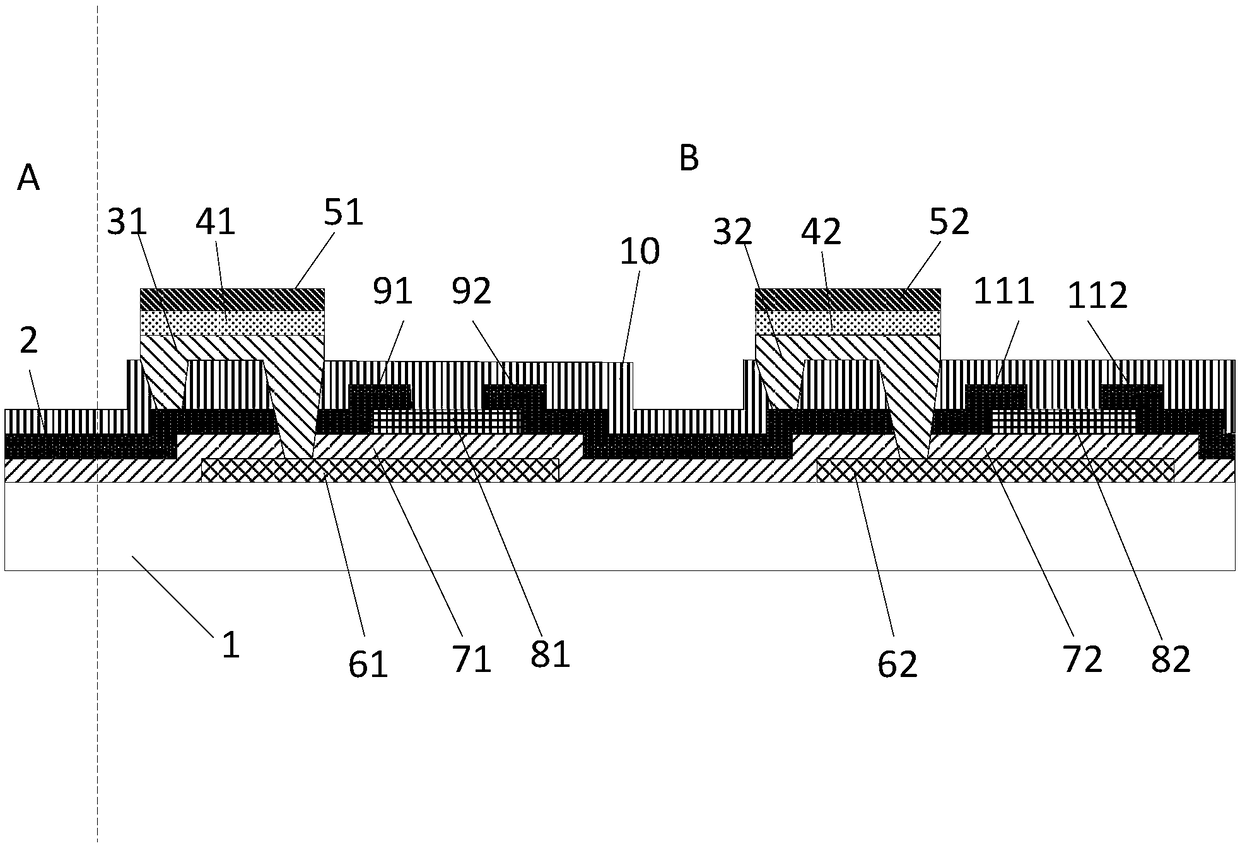

Array substrate, electroluminescent display panel and display device

The invention discloses an array substrate, an electroluminescent display panel and a display device. The array substrate comprises a substrate substrate base plate, an electrostatic transmission signal line located on the substrate base plate, and a first light emitting device located in a non-display region of the substrate substrate. The first light emitting device at least comprises an anode lay, a light emitting layer and a cathode layer; The anode layer of the first light emitting device is connected with the electrostatic transmission signal line, and static electricity transmitted by the electrostatic transmission signal line is released through the cathode layer. By providing a first light emitting device in a non-display area of the array substrate, and connecting the electrostatic transmission signal line located in the display region with the anode layer of the first light emitting device, so as to transmit the static electricity generated in the display area to the anode of the first light emitting device, transmit the static electricity to the cathode layer of the first light emitting device by the structure of the first light emitting device, and release the static electricity in the cathode layer, thereby alleviating the harm caused by the accumulation of static electricity.

Owner:BOE TECH GRP CO LTD +1

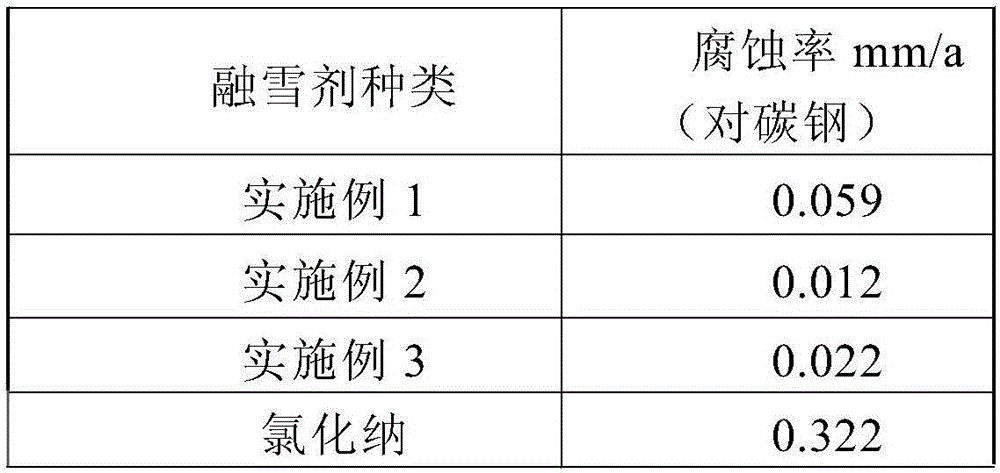

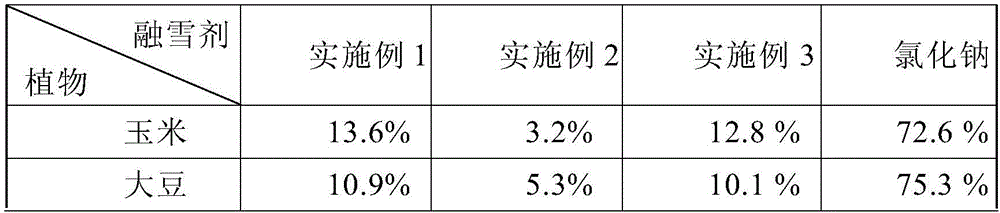

Ecological rehabilitation promoting snow-melting agent and preparation method thereof

ActiveCN105838326APromote absorptionIncrease productionOther chemical processesOrganic fertilisersSnow meltingSolid particle

The invention provides an ecological rehabilitation promoting snow-melting agent and a preparation method thereof .The snow-melting agent is prepared from, by mass, 10-30 parts of polyaspartic acid, 30-50 parts of humic acid, 10-30 parts of acetate and 0-20 parts of chlorine salt .Firstly, humic acid is prepared according to the mass proportion, potassium permanganate and 30% hydrogen peroxide are added, and a combined pre-oxidation reaction is conducted; after the combined pre-oxidation reaction is finished, acetate and chlorine salt are added, stirred and dissolved, and the mixture is cooled to room temperature; polyaspartic acid is added, and after the materials are evenly mixed, the mixture is directly contained in a barrel to serve as a liquid snow-melting agent or is sprayed to be prepared into a solid particle snow-melting agent .The snow-melting agent can be used for melting snow and ice, stimulating plant growth and reducing harm of chlorine salt snow-melting agents left in soil to the environment .Besides, biological degradation can be achieved, a preparation process is simple, production cost is low, and the snow-melting agent is suitable for industrial application.

Owner:BEIJING UNION UNIVERSITY

Method for using agricultural wastes as modifier to repair salinity soil

ActiveCN103597925AEfficient use ofPromote production increaseOrganic fertilisersSoil conditioning compositionsMoistureTillage

The invention discloses a method for using agricultural wastes as a modifier to repair salinity soil. The method includes: commercial organic fertilizer is mixed with straws or straws are mixed with 1% chitosan to serve as the modifier; the commercial organic fertilizer is well mixed with the straws or the straws are well mixed with chitosan solution according to the proportion of 1-3 tons of commercial organic fertilizer per mu, 0.2-0.6 ton of straws per mu, and 1.1-3.3 tons of chitosan solution per mu, the mixture is evenly spread on the ploughed soil, and a rotary cultivator is used for rotary tillage of the soil to allow the secondary salinity soil to be well mixed with the modifier. By the comprehensive action of the agricultural wastes, the soil can keep much moisture, microbial activity of the soil can be stimulated, soil salinity can be degraded fast, and contends of various ions in the soil can be changed. The method has the advantages that the agricultural wastes are used effectively and turned into wealth, crop yield can be increased, crop quality can be improved, economical benefits can be increased, and sustainable agricultural developments can be guaranteed.

Owner:SHANGHAI ACADEMY OF ENVIRONMENTAL SCIENCES

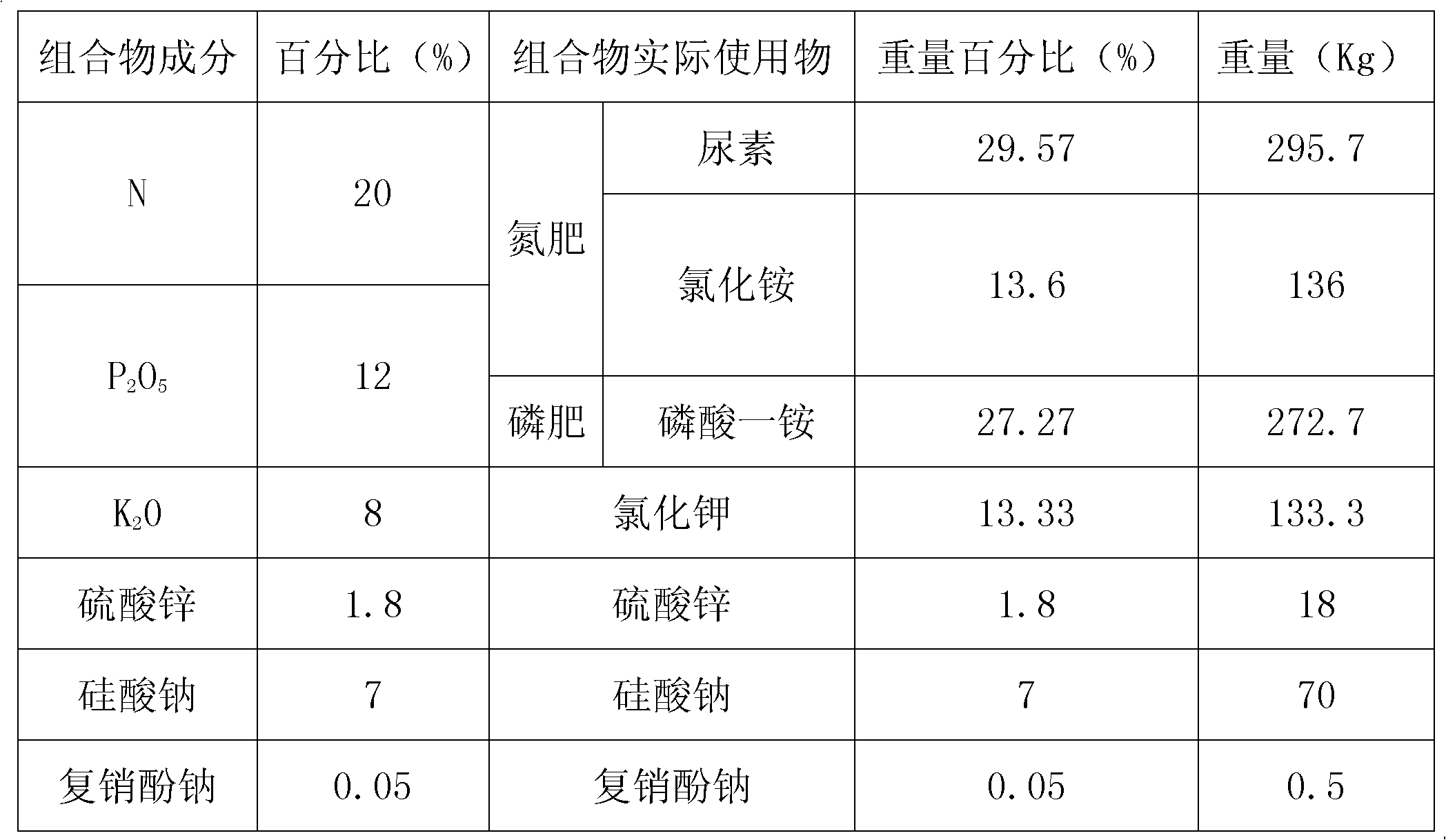

Rice field base application multi-effect nutrient

ActiveCN102010270AImprove abilitiesSatisfy the nutritional needs of rice growth balanceFertilizer mixturesNutrientNitrogen fertilizer

The invention discloses a rice field base application multi-effect nutrient, which comprises the following components in percentage by weight: 43.17 to 58.4 percent of nitrogen fertilizer, 18.18 to 27.27 percent of phosphorus fertilizer, 10 to 16.67 percent of potassium fertilizer, 1.5 to 2 percent of zinc sulfate, 3 to 7 percent of sodium silicate, 0.04 to 0.08 percent of compound niclofolan sodium and 6.9 to 8.3 percent of filler. The nitrogen, phosphorus and potassium fertilizers in the components meet the conditions that N is 20 to 25 percent, P2O5 is 8 to 12 percent and K2O is 6 to 10 percent. The rice field base application multi-effect nutrient can meet reasonable nutrition required for the growth of rice, and also can enhance the disease, insect and adversity resistance of the rice, relieve the harm of toxic substances, promote steady and robust growth of the rice and meet the requirements of high yield and good quality.

Owner:SICHUAN TAIWO AGRI TECH

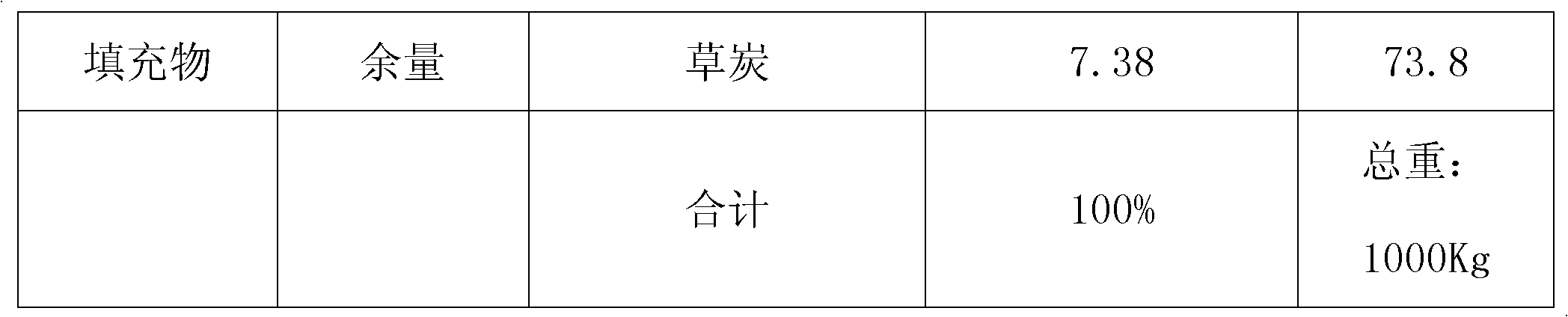

Composite curing agent suitable for peat soil and preparation method thereof

The invention discloses a composite curing agent suitable for peat soil and a preparation method thereof, and belongs to the field of civil building materials. The composite curing agent suitable forpeat soil is made from 100-300 parts of cement as a self-setting material, 70-150 parts of red clay as pore filling, particle dispersion and organic dilution components, 10-30 parts of phosphogypsum as an alkaline excitation component, 3-9 parts of sodium sulfate, 1.5-4.5 parts of sodium chloride as a hydration acceleration component, and 300-400 parts of water as a hydration inducing component. The curing agent can significantly improve the strength of peat and peaty soil, and the performance of the peat and peaty soil as a building foundation and a roadbed filler is optimized. The consumption of cement for curing peat soil is reduced, the red clay is easy to obtain from local sources, the utilization of waste soil in engineering is improved, and the use of phosphogypsum can reduce the environmental pollution caused by phosphogypsum stacking. The raw materials of the composite curing agent are easy to obtain, the preparation is simple, the cost is low, and the curing agent has certainenvironmental and economic benefits.

Owner:KUNMING UNIV OF SCI & TECH

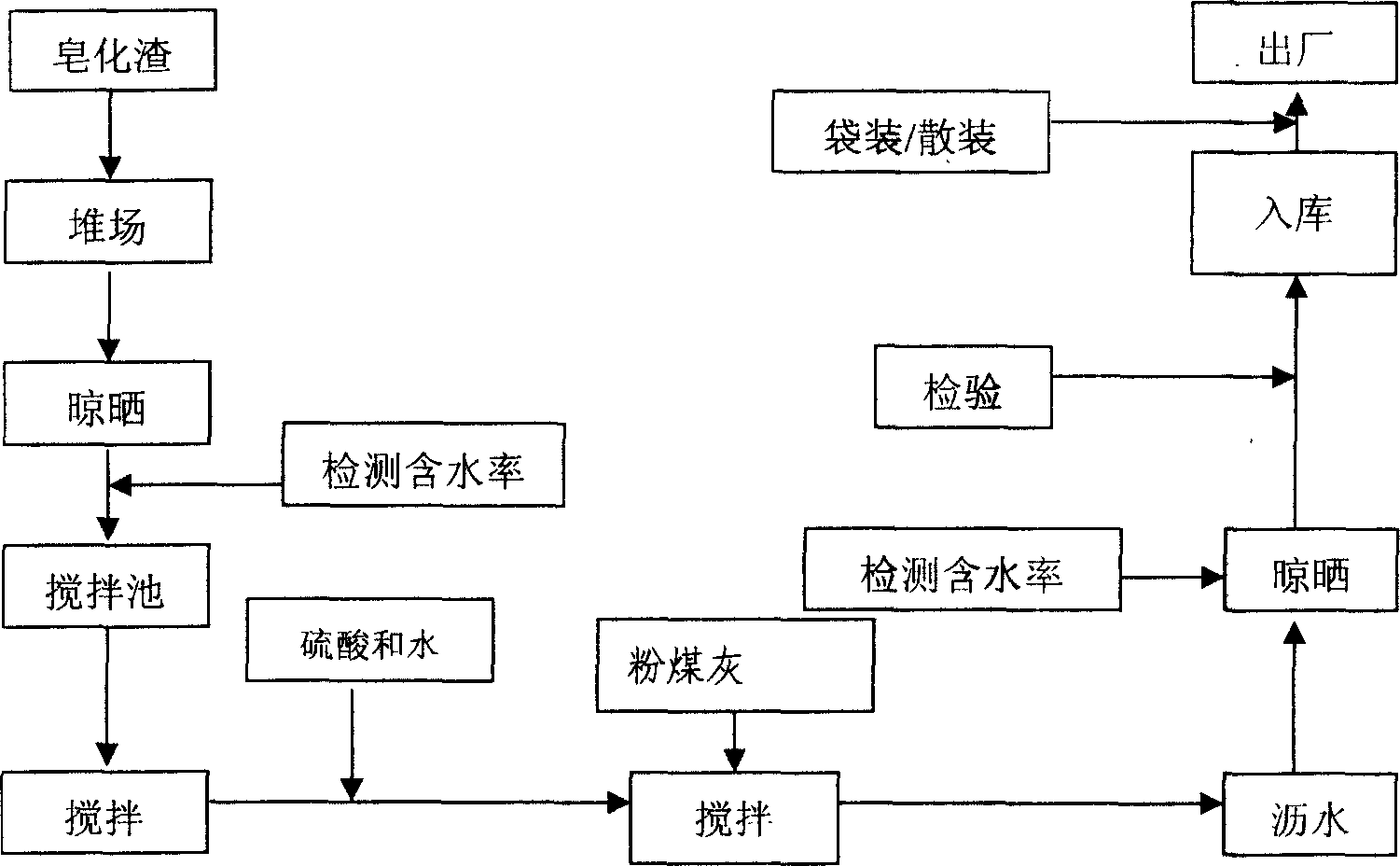

Soft foundation solidification lime used in soft foundation solidification

The invention relates to a soft base curing ash, characterized in that the ash consists of saponification slag and coal ash at a volume percentage of rice3: saponification slag: coal ash= 1: 0.1-0.6, wherein the saponification slag is aired and mixed with hydric sulphate and water, and then mixed with coal ash after drained and aired, at last checked and packed after aired. The invention has advantages that the main materials of the invention are treated chemical industry waste materials as the saponification slag and the coal ash, and the invention can be extensive used in making ground in the sea or the river, weak ground treatment in the railway, the highway, or yards, and civil architectures. The invention not only can remit the pollution damage of the coal ash, but also improves the operating development in weak ground treatment therefore combines the making waste into useful with improving environment and creating economic profits.

Owner:天津市乐金建材制品有限公司

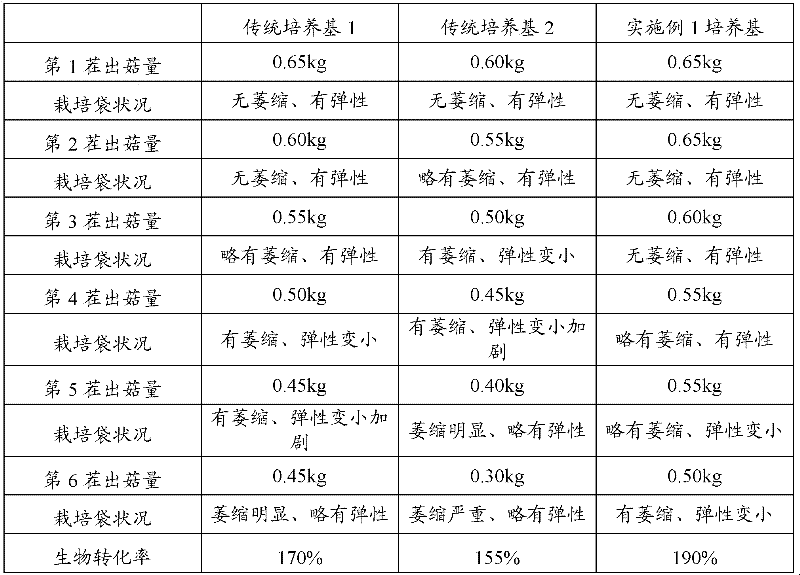

Method for culturing oyster mushroom

The invention discloses a method for culturing oyster mushroom and relates to the field of edible fungus culture. According to the method provided by the invention, oyster mushroom strains are inoculated into bagged culture media subjected to material stirring and sterilization, then, spawn growing culture and mushroom growth management are sequentially carried out until the oyster mushroom is ripe and is harvested; the bagged culture media consists of culture medium waste materials for culturing agaric, rice husks, corn flour, lime and carbendazim; mushroom roots remained after the harvesting are removed, the mushroom growth management is carried out again until the oyster mushroom is ripe and is harvested, and the step is repeated for 5 to 7 times. The method has the advantages that the culture medium waste materials for culturing the agaric, the rice husks, the corn flour, the carbendazim and the lime are used as the culture media for culturing the oyster mushroom, various kinds of nutrition required by the oyster mushroom in the growth process are ensured, the yield of each stubble of mushroom bodies is improved, further, the biological conversion efficiency of the oyster mushroom is improved, simultaneously, the harm of the culture medium waste materials for culturing the agaric to the environment is relieved, multiple purposes are realized by one operation, and the method can be widely popularized in the field of the edible fungus culture.

Owner:YUSHU TENGLONG EDIBLE FUNGUS CULTIVATION SPECIALIZED COOP

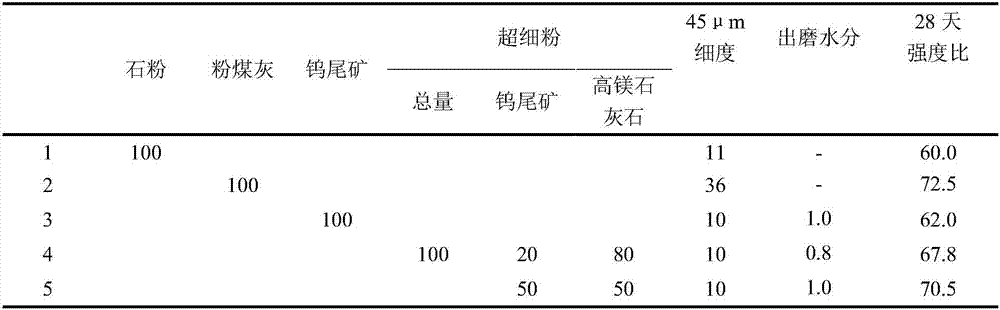

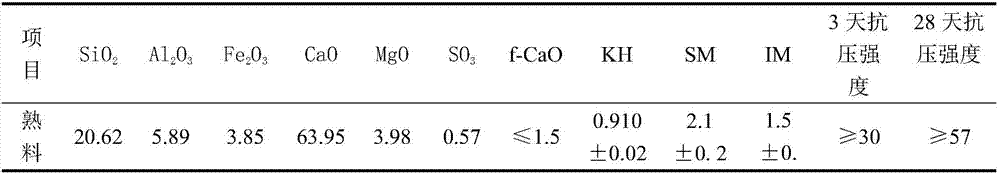

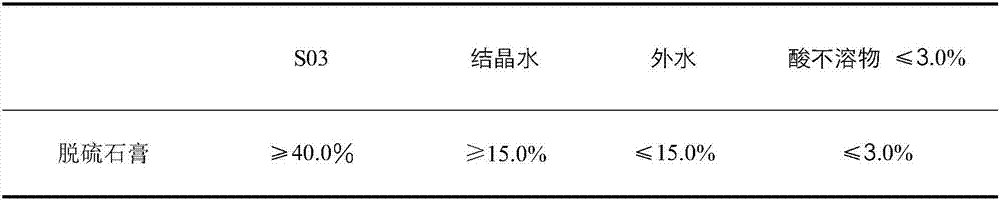

Tungsten tailings general-purpose Portland cement and preparation method thereof

The invention provides tungsten tailings general-purpose Portland cement. The general-purpose Portland cement is prepared from the following raw materials in percentage by weight: 53.00 to 85.00 percent of cement clinker, 0 to 2.50 percent of phosphogypsum, 1.50 to 7.50 percent of desulfurized gypsum, 4.00 to 15.00 percent of limestone, 0 to 1.80 percent of high siliceous sandstone, 1.50 to 7.50 percent of furnace bottom slag, 0 to 10.00 percent of coal ash and 0.50 to 32.50 percent of active ultrafine powder, wherein the active ultrafine powder is mixed powder which is formed by mixing and grinding tungsten tailings and high-magnesium limestone. The invention further discloses a preparation method of the general-purpose Portland cement. The mixed powder of the tungsten tailings and high-magnesium limestone is added in the general-purpose Portland cement, so the flowability and the strength of the cement are enhanced, the utilization rate of the tungsten tailings and the high-magnesiumlimestone is increased, and harm to the environment is relieved.

Owner:华润水泥(富川)有限公司

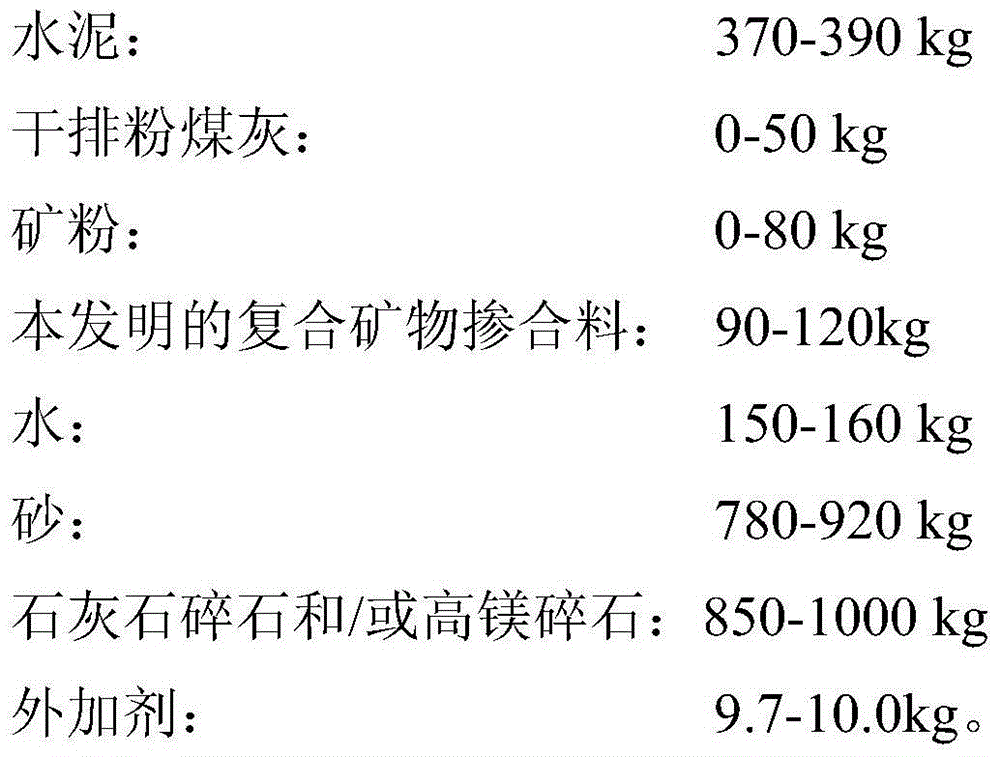

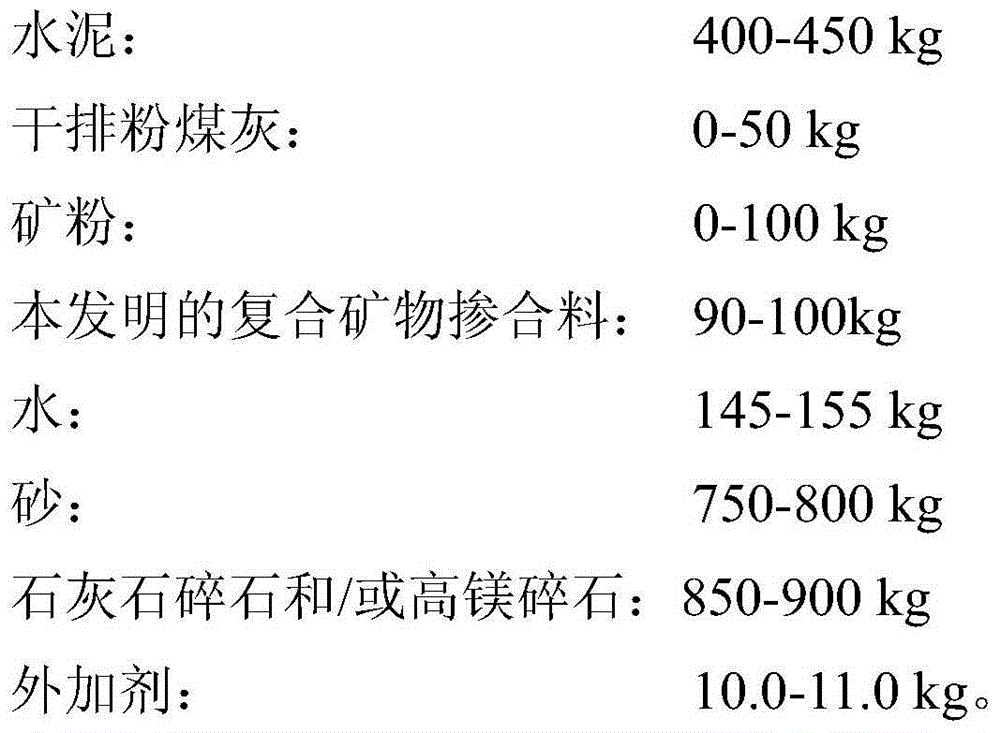

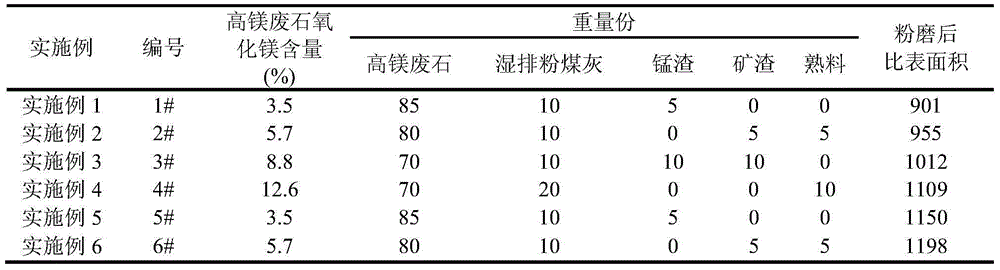

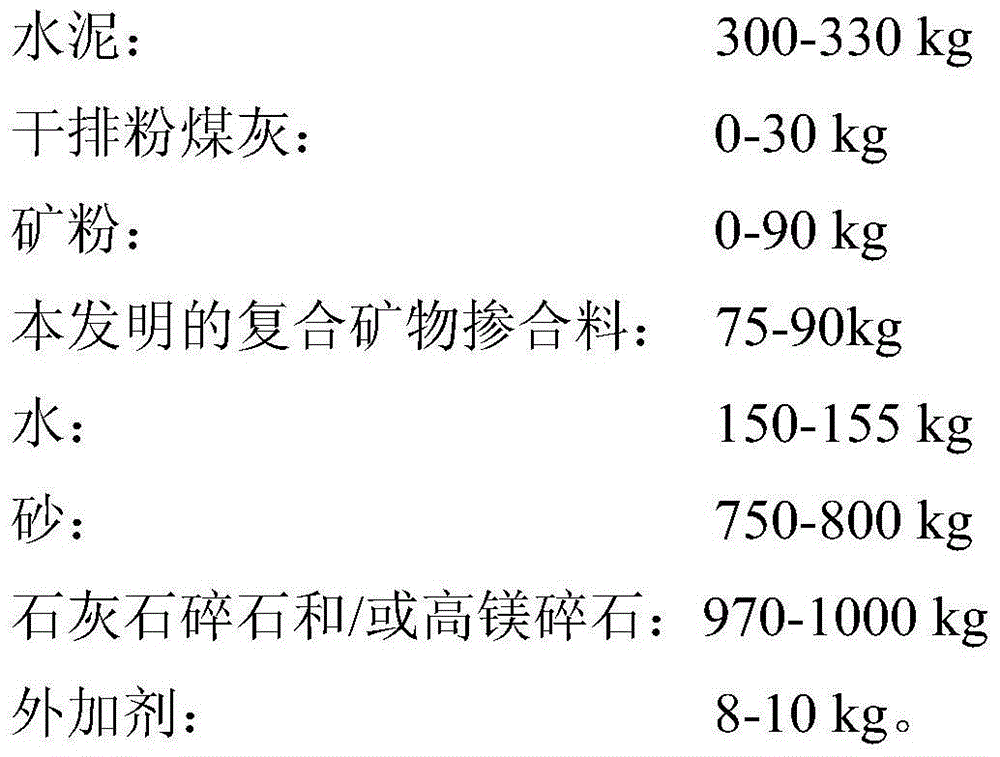

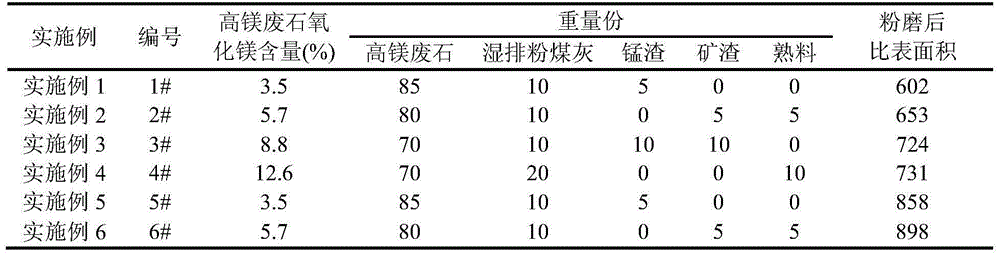

Waste high-magnesium rock flour-based composite mineral admixture and application of same in high-strength concrete

The invention discloses a waste high-magnesium rock flour-based composite mineral admixture and application of the same in high-strength concrete. A preparation method for the admixture comprises the following steps: (1) drying waste high-magnesium rock, wet discharged fly ash and manganese slag until water content is lower than 1.0%; and (2) separately grinding 70 to 85 parts by weight of the dried waste high-magnesium rock, 10 to 20 parts by weight of the dried wet discharged fly ash, 0 to 10 parts by weight of the dried manganese slag, 0 to 10 parts by weight of mineral waste residue and 0 to 10 parts by weight of clinker, and then carrying out mixing or carrying out mixing and then grinding until the specific surface area of the obtained mixture is 901 to 1200 m2 / kg so as to obtain the waste high-magnesium rock flour-based composite mineral admixture. According to the invention, the morphological effect and filling effect of the waste high-magnesium rock flour are utilized to improve compactness of a concrete mixture and fluidity of concrete; slump loss is small, and adsorption of additives like polycarboxylic acid is low; and early strength of the concrete develops fast, and later strength of the concrete develops steadily. Moreover, both the admixture provided by the invention and coarse and fine waste high-magnesium rock aggregate can be applied in the concrete, so the utilization rate of the waste high-magnesium rock is substantially increased.

Owner:华润水泥技术研发(广西)有限公司

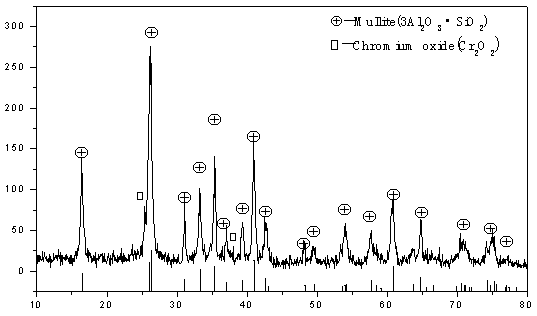

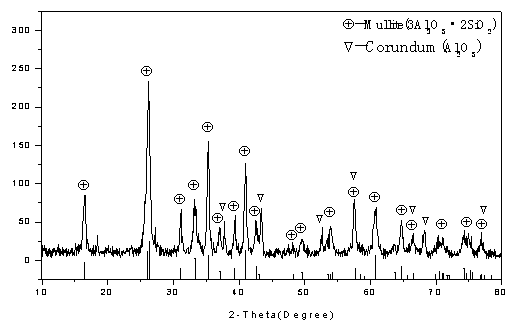

Mullite nano-whisker prepared by using pyrite tailing as raw material and preparation method of mullite nano-whisker

InactiveCN104313695AUniform diameterUniform length distributionPolycrystalline material growthFrom solid statePyriteIron removal

The invention discloses a method for preparing a mullite nano-whisker by using pyrite tailing as a raw material, and belongs to the field of nano-whisker preparation and mineral resource recycling. The method comprises the following steps: preparing the raw material, pickling for removing iron, calcinating for removing C, S and organic matters, preparing a precursor, and performing calcination and acid soaking for removing a glass phase. According to the invention, the prepared nanoscale mullite whisker has good quality, has excellent properties of both the mullite whisker and the nano-whisker, and has a high additional value and a remarkable economic benefit; in addition, the adopted raw material pyrite tailing is waste mineral materials after mineral dressing, so that the products are low in cost of raw materials, and the secondary recycling of pyrite resources is achieved; meanwhile, compared with other preparation methods, the preparation process of the invention requires lower calcination temperature and shorter calcination time, so that reduction of energy consumption is facilitated, thereby reducing production cost and resource consumption, and increasing economic benefits.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

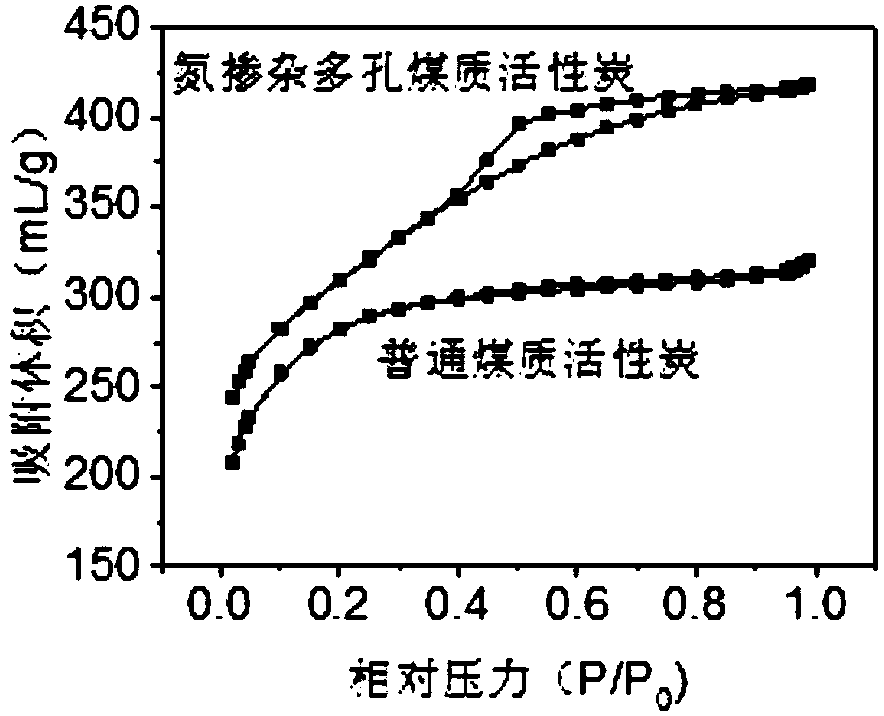

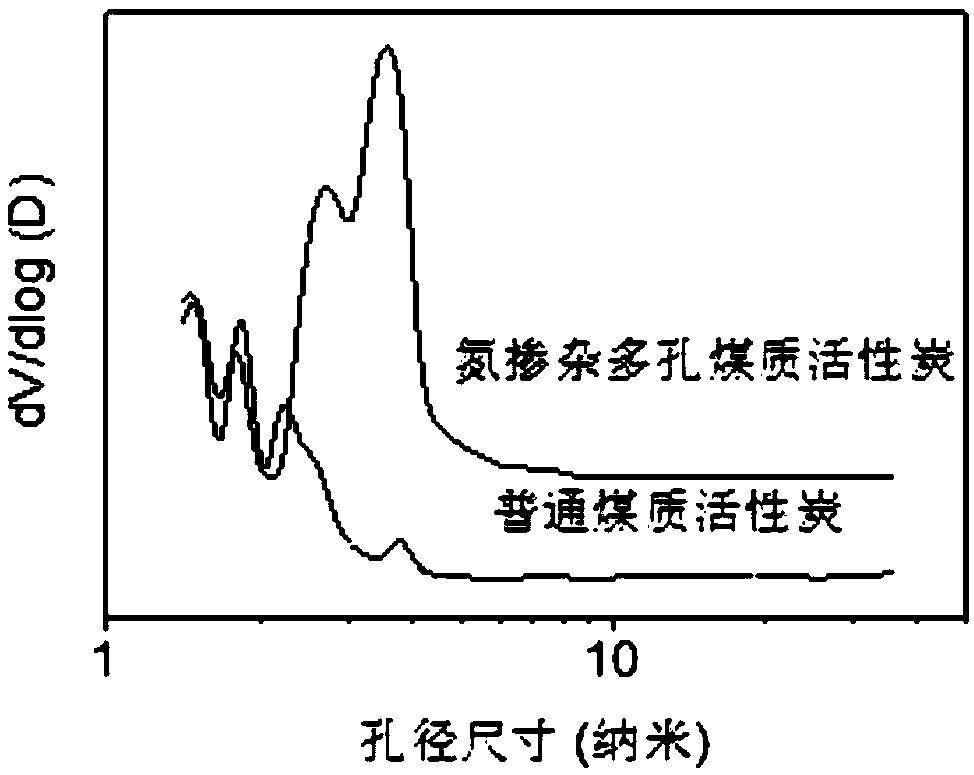

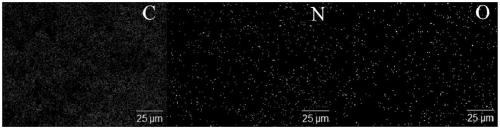

Method for preparing coal-based porous activated carbon material by using cyanamide waste residues as template

ActiveCN109319781AIncrease added valueRealize large-scale productionCarbon compoundsSorbentPorous carbon

The invention relates to the field of preparation of porous carbon materials by a rigid template method, and particularly discloses a method for preparing coal-based porous activated carbon material by using cyanamide waste residues as a template. The method comprises the following steps of crushing the crude coal, grinding into the crude coal particles with granularity of 60 to 200 meshes, addingthe cyanamide waste residues, an adhesive and water, and uniformly mixing; compressing and forming the reaction material, ventilating air, airing, and carbonizing; conveying the carbonized material into an activating furnace, leading activating gas, and activating; finally, sequentially performing pickling treatment and water washing treatment on the crude product of the activated carbon, and drying, so as to obtain the coal-based porous activated carbon material. The method has the advantages that the method is simple, and the operation is easy; the treatment cost of highly-hazardous wastes,such as cyanamide industrial waste residues, can be greatly reduced, the resources can be recycled, and the nitrogen-modified coal-based activated carbon with high added value can be obtained in onestep; the recycled carbon material can be used as an adsorbent or a catalyst carrier, so that the added value of the coal-based activated carbon is greatly increased.

Owner:ZHEJIANG UNIV OF TECH

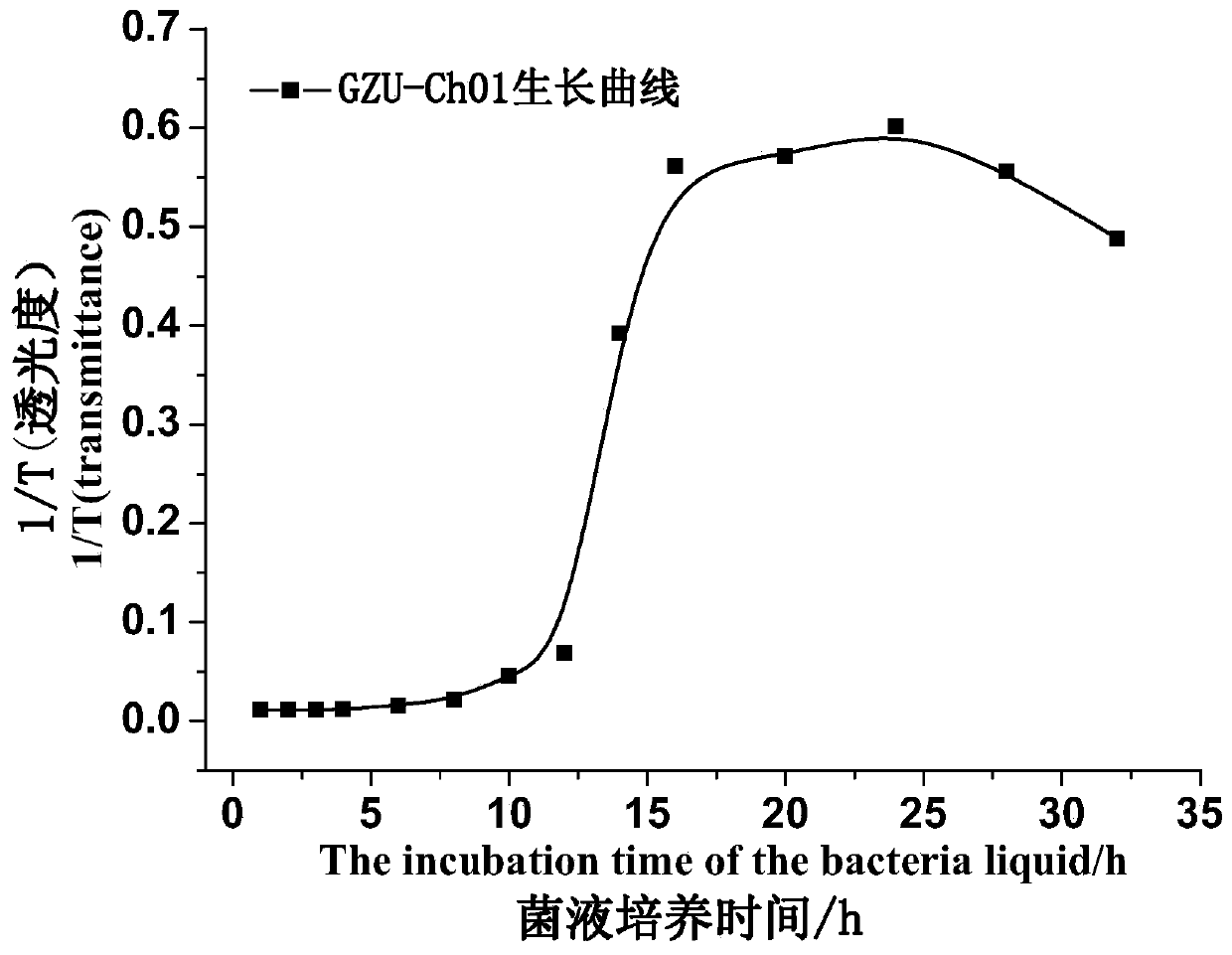

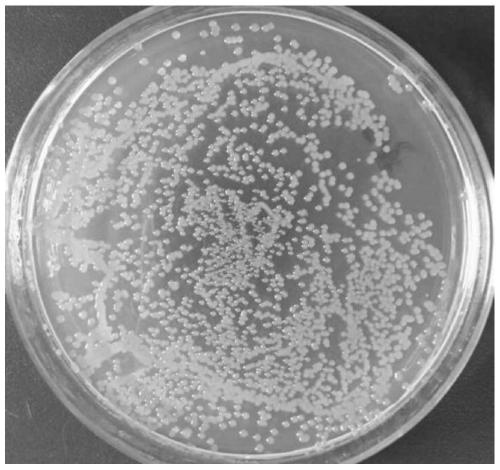

Method for producing microbial fertilizer from coal gangue

ActiveCN109942347AMassive consumptionThe process is simple and reliableFertilizer mixturesLower gradePotassium

The invention discloses a method for producing microbial fertilizer from coal gangue. The method comprises the following steps: with the coal gangue with a basic raw material, doping low-grade phosphorite and potassium mineral, and carrying out dissociation by virtue of golden bacillus GZU-Ch01, so as to prepare the microbial fertilizer. By dissociating the coal gangue by virtue of the golden bacillus GZU-Ch01, useful nutrients in the coal gangue are released, and the preparation of the coal gangue microbial fertilizer is a novel way for the utilization of the coal gangue. The preparation process is simple, and mild in conditions, and is environment-friendly use scheme of the coal gangue.

Owner:GUIZHOU UNIV

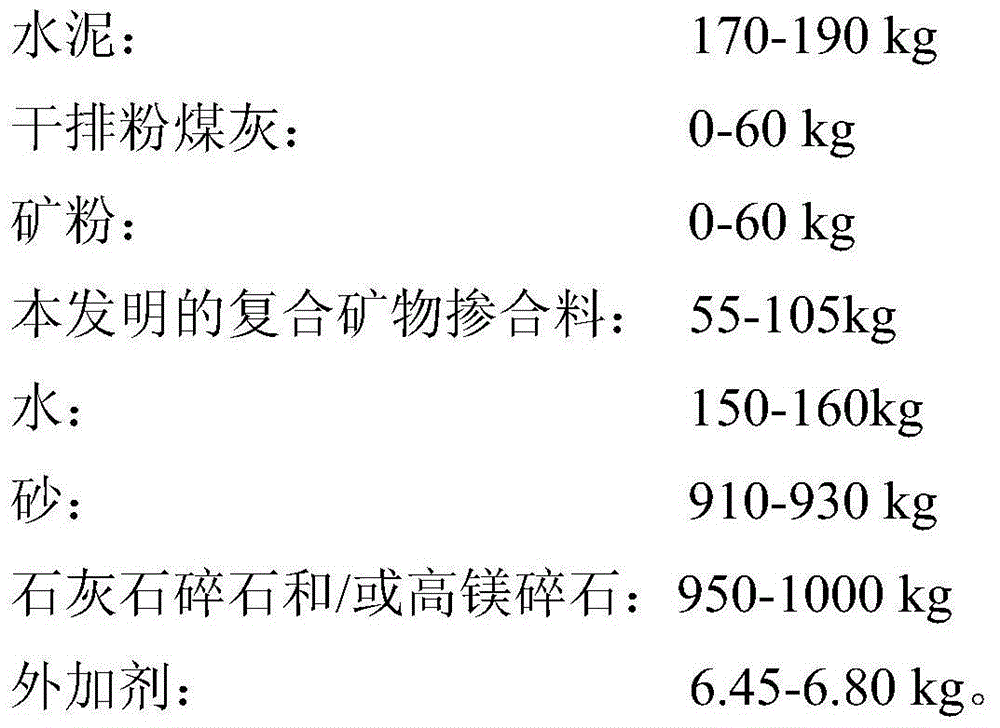

High-magnesium waste stone dust-based composite mineral admixture, and applications thereof in medium-strength concrete

The invention discloses a high-magnesium waste stone dust-based composite mineral admixture, and applications thereof in medium-strength concrete. The high-magnesium waste stone dust-based composite mineral admixture is prepared via following steps: (1) high-magnesium waste stone, wet discharged fly ash, and manganese residue are dried until water content is lower than 1.0%; and (2) by weight, 70 to 85 parts of the dried high-magnesium waste stone, 10 to 20 parts of the dried wet discharged fly ash, and 0 to 10 parts of the dried manganese residue, 0 to 10 parts of mineral waste residue, and 0 to 10 parts of a clinker are smashed into powder respectively and then are mixed, or are mixed and then are smashed into powder with a specific surface area ranging from 601 to 900m2 / kg so as to obtain the high-magnesium waste stone dust-based composite mineral admixture. According to the high-magnesium waste stone dust-based composite mineral admixture, morphology effects and filling effects of high-magnesium waste stone powder are used so as to increase compactness of concrete mixtures, and increase fluidity of concrete; slump loss is less; less additives such as polycarboxylic acid are absorbed; concrete early-stage strength development is accelerated, and later-stage development is stabilized. And in addition, the high-magnesium waste stone dust-based composite mineral admixture can be applied to concrete together with high-magnesium waste stone coarse and fine aggregates so as to increase utilization ratio of high-magnesium waste stone greatly.

Owner:华润水泥技术研发(广西)有限公司

Humic acid-containing water-soluble fertilizer with soil loosening function and preparation method thereof

InactiveCN106542932AHigh porosityEliminate compactionAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersPhosphatePolyacrylamide

The invention discloses a humic acid-containing water-soluble fertilizer with a soil loosening function and a preparation method thereof. The preparation method comprises the step of dissolving and chelating the following raw materials in a reactor: high-quality polyacrylamide crystal which is an agricultural soil loosening agent, water-soluble humic acid, urea, monoammonium phosphate and potassium nitrate to produce the water soluble fertilizer which can be used for breaking through soil hardness, loosening soil, improving air permeability of soil, promoting microorganism activity of soil and enhancing fertilizer seepage force of soil and contains major elements, medium trace elements, humic acid and amino acid. The water-soluble fertilizer combines organic and inorganic matters, combines major elements and trace elements, and has the advantages of balancing nutrition, improving soil, improving the utilization ratio of nutrients and improving the yield and quality of crops.

Owner:YUNNAN AGRICULTURAL UNIVERSITY +1

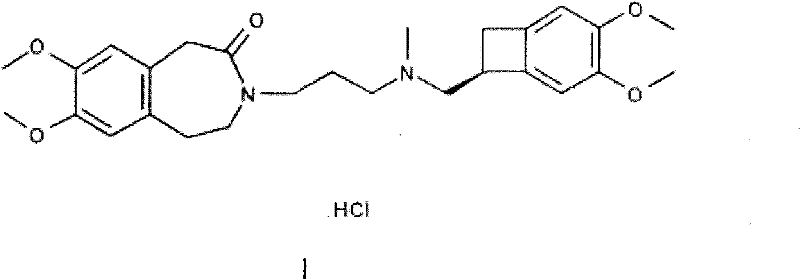

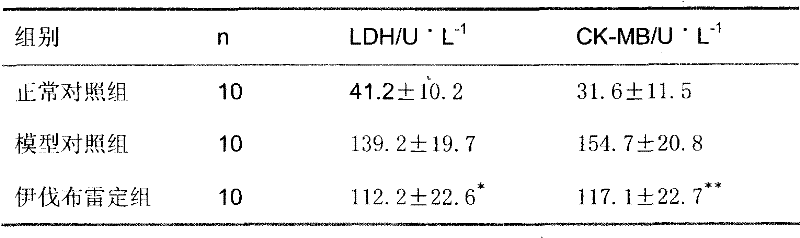

Pharmaceutical composition containing ivabradine and ranolazine

ActiveCN101780091BHazard mitigationGood synergyCardiovascular disorderHeterocyclic compound active ingredientsMedicineAngina

The present invention provides a pharmaceutical composition containing active ingredients ivabradine or a pharmacologically acceptable salt thereof and ranolazine or a pharmacologically acceptable salt thereof. Through research, the present invention finds that the combined use of ivabradine and ranolazine effectively alleviates myocardial ischemia, and shows a good synergistic effect on myocardial ischemia diseases such as angina pectoris and coronary heart disease. Therefore, a method for treating myocardial ischemic diseases with better effect and lower adverse reactions has been found, and a good solution has been found for the unsatisfactory treatment effect of myocardial ischemic diseases in clinical practice.

Owner:LUNAN PHARMA GROUP CORPORATION

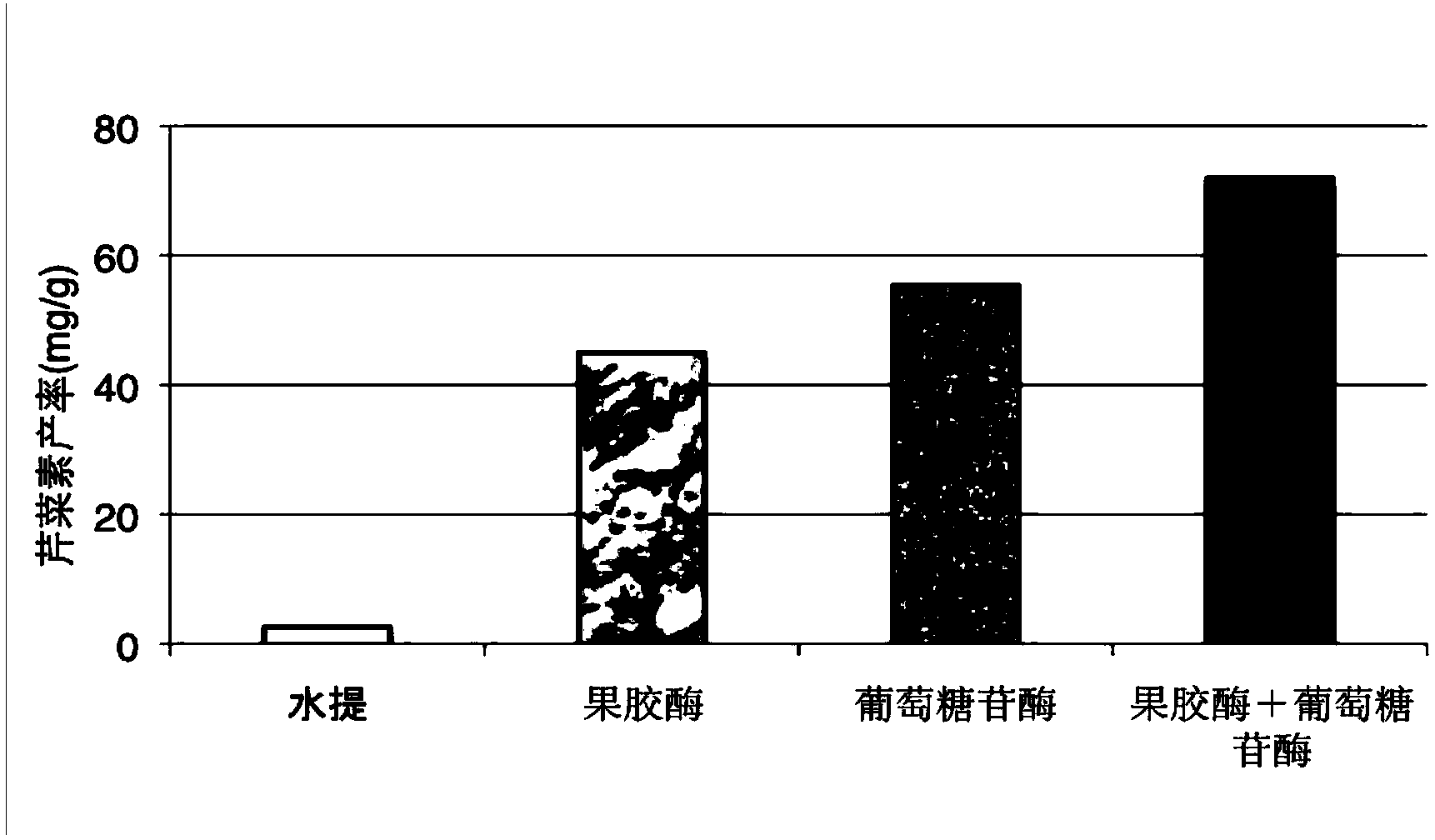

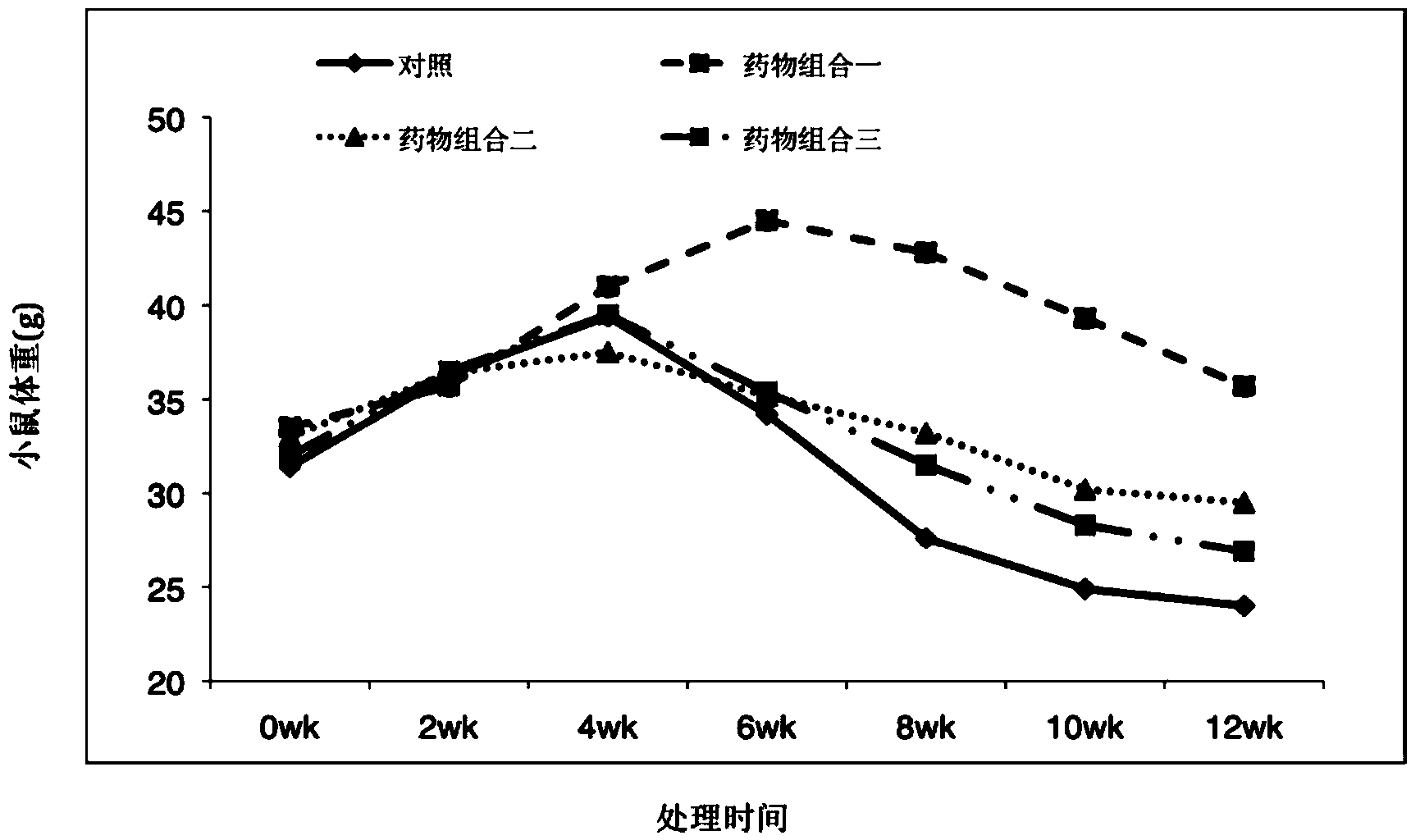

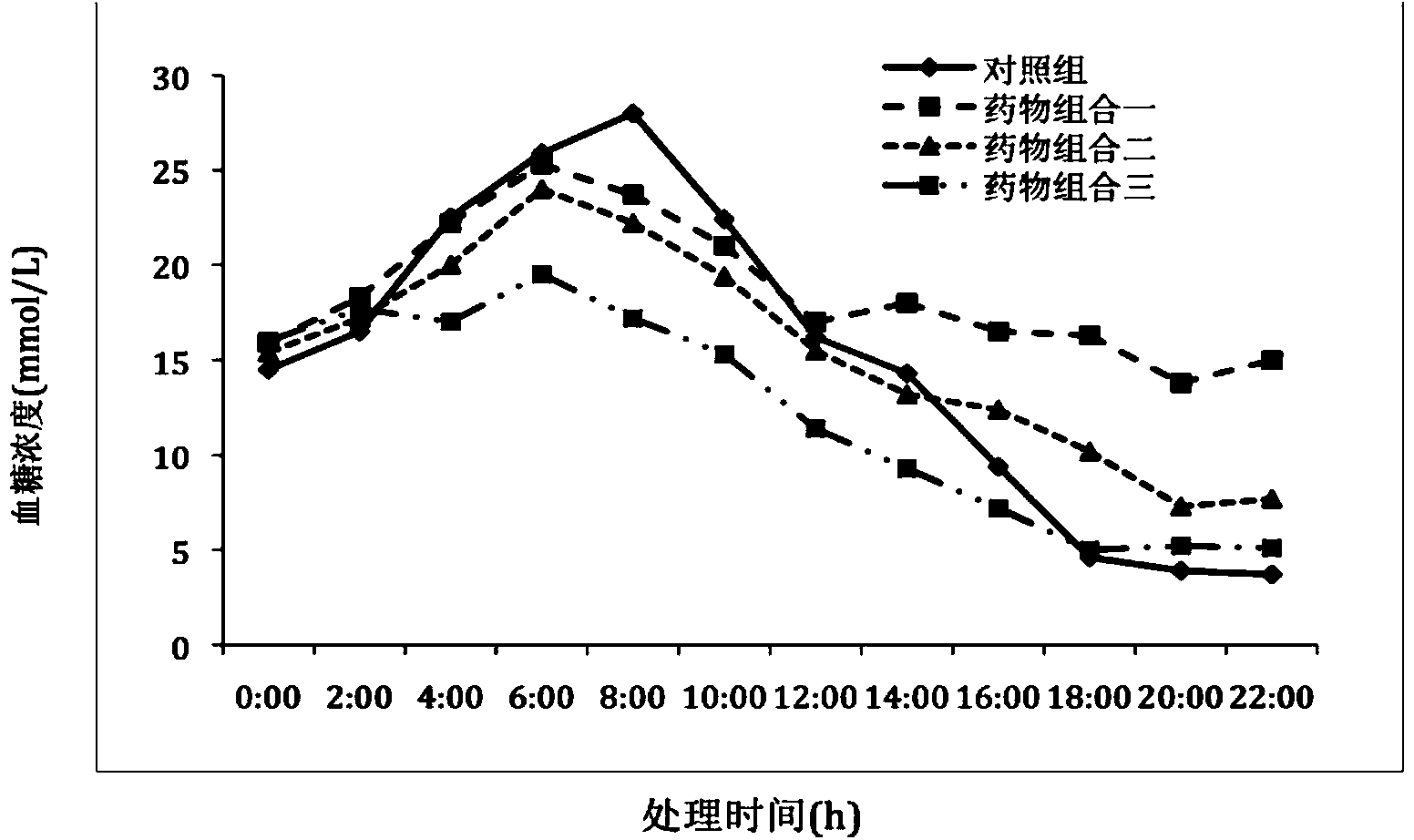

Extraction method of apigenin, pharmaceutical composition for treating diabetes and application thereof

ActiveCN103641807AEffective blood sugar control functionLower blood sugar concentrationOrganic active ingredientsOrganic chemistryAlgluceraseChemistry

The invention relates to the pharmaceutical technical field. The extraction method of apigenin comprises the steps of 1) enzymatically hydrolyzing celery which is taken as a substrate for 10 hours at 30-35 DEG C through a mixing solution of apigenin which is 33-37% and glucosidase which is 43-47% in mass percentage concentration; and 2) ultrasonically extracting enzymatic hydrolysate obtained from the step 1) through an ethanol solution of 70%, condensing an extracting solution, extracting respectively through petroleum ether and ethyl acetate, evaporating the extracting solution, dissolving through ethanol of 70%, and separating and extracting through a high performance liquid chromatograph. The pharmaceutical composition for treating diabetes consists of apigenin and glucobay at mass ratio of 1: (2-5). The extraction method, which extracts apigenin through a multi-enzymatic process, greatly improves extraction yield. The pharmaceutical composition disclosed by the invention not only can effectively control blood sugar but also can avoid circumstances of low blood sugar and rapid weight loss of a patient due to simple use of a diabetes medicine.

Owner:南通大学技术转移中心有限公司

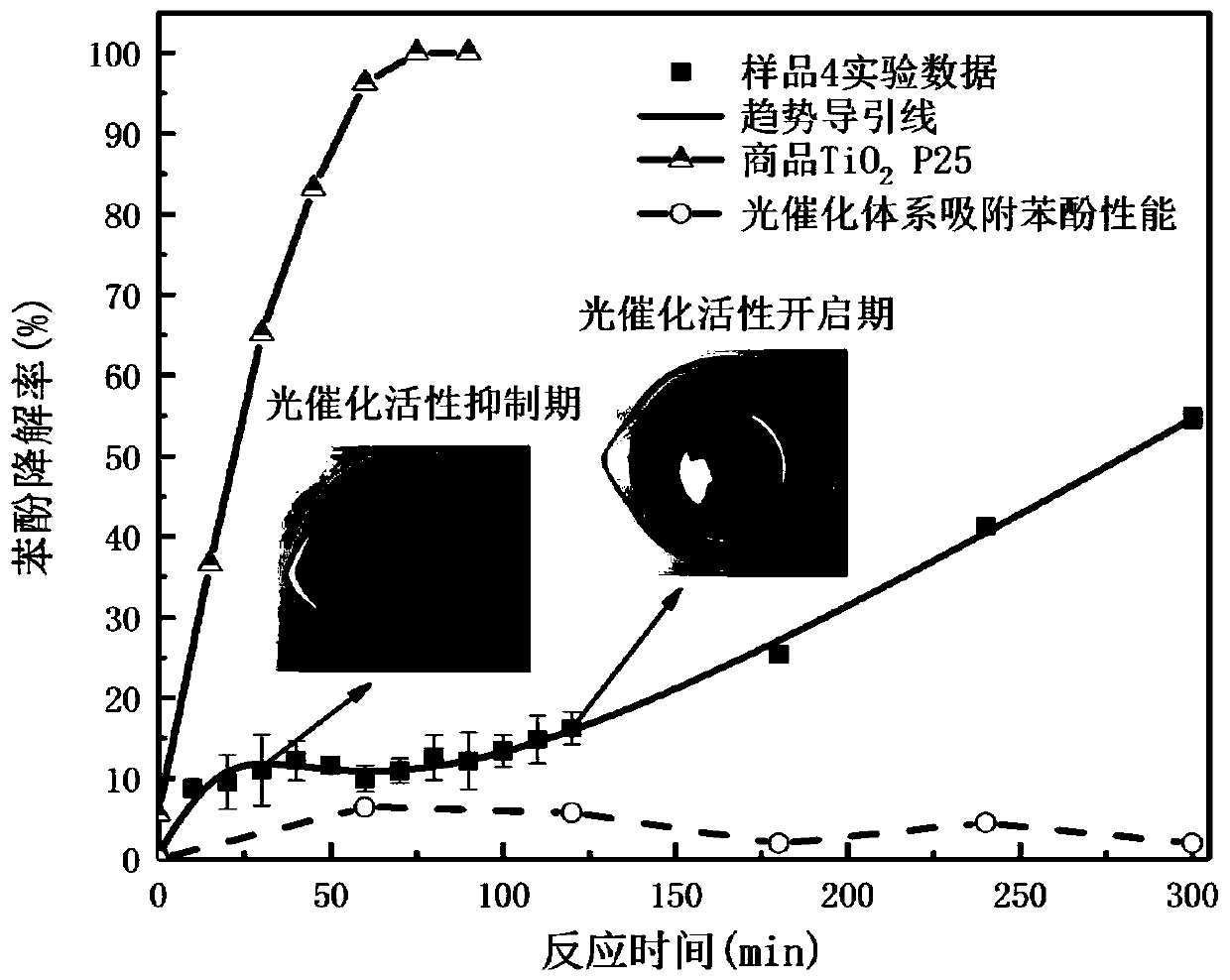

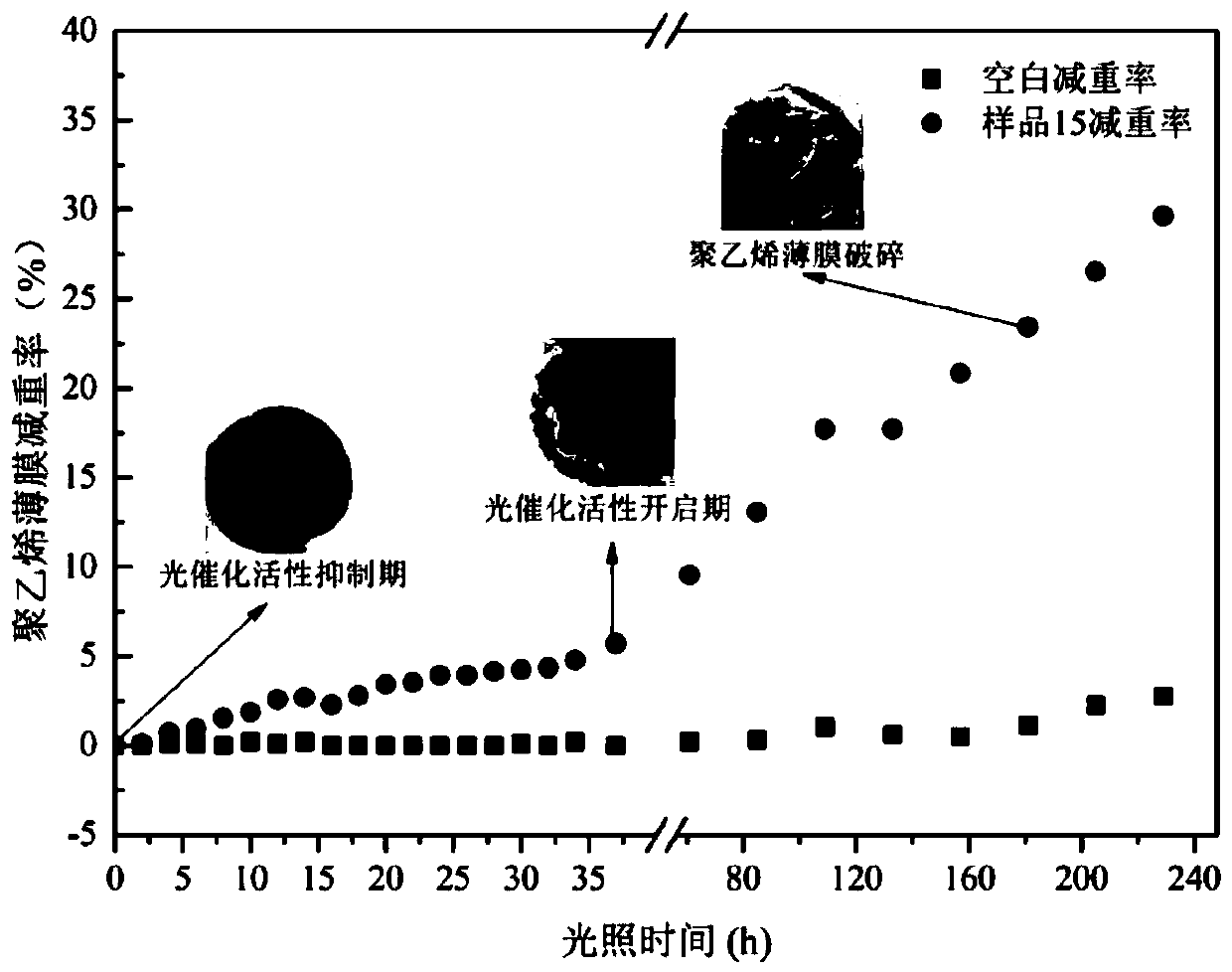

Photocatalytic system with photoresponse switch and self-indication property as well as preparation method and application

ActiveCN110075930AAdjustable photocatalytic activityImprove stabilityOrganic-compounds/hydrides/coordination-complexes catalystsBulk chemical productionElectron holeColor changes

The invention discloses a photocatalytic system with a photoresponse switch and self-indication property as well as a preparation method and application, particularly discloses to the application of the universality of the photocatalytic system to the field of plastic controllable self-indication degradation. The invention relates to a combined photocatalytic system utilizing a photocatalyst, a photo-induced electron-hole consumption agent and a photo-induced electron-hole consumption agent complex, and utilizes color change before and after reaction of the photo-induced electron-hole consumption agent and the photo-induced electron-hole consumption agent complex to construct the photocatalytic system with the photoresponse switch and the self-indication property. In the initial period, the photocatalytic system is in a certain color, does not have photocatalytic activity, is changed in color after being illuminated a certain time, and has efficient photocatalytic activity. The photocatalytic system can serve as a filler to be added into plastic, provides controllable self-indication degradation for the plastic, ensures that the plastic has high stability during a usage period andhas efficient degradation efficiency during an abandoning period, and reminds a consumer of the beginning of the abandoning period of the plastic through the color change.

Owner:EAST CHINA NORMAL UNIV

Spirit-nourishing health-care wine and preparation method thereof

InactiveCN102031220ATo promote metabolismEnhance immune functionOrganic active ingredientsAnthropod material medical ingredientsSalvia miltiorrhizaVitamin C

The invention relates to a health-care wine and a preparation method thereof, in particular to a spirit-nourishing health-care wine and a preparation method thereof. The health-care wine comprises the following components by weight: 1-10g of cordyceps sinensis, 2-20g of corn cervi pantotrichum, 5-20g of rhodiola rosea, 10-30g of smoked oak, 3-30g of american ginseng, 5-30g of salvia miltiorrhiza bunge, 5-30g of lucid ganoderma, 5-20g of Indian buead, 5-30g of Angelica sinensis, 5-50g of astragalus mongholicus, 20-50g of honey, 1-20mg of vitamin C, 250-100mg of vitamin B, and 10-300mg of amino acid. By utilizing the health-care wine provided by the invention, the liver can be protected from being damaged by the wine, and the combined use of all the medicines can adjust the balance of yin and yang of the body so as to achieve the functions of nourishing the liver and the kidney and improving the functions of the kidney.

Owner:HUBEI CHINA TOBACCO IND +1

Plant growth type ecological concrete used for slope protection and preparation method of concrete

The invention relates to plant growth type ecological concrete used for slope protection and a preparation method of the concrete, and belongs to the technical field of environmentally-friendly materials. The concrete and method disclosed by the invention utilize waste clay brick aggregate, the waste clay brick aggregate has the characteristics of certain strength and continuous gaps, the aggregate is crushed and covered by cement mortar for strengthening treatment, the used cement mortar includes nutrients such as soluble silicon, calcium and magnesium and a plurality of microelements, a compound fertilizer can increase soil fertility and improve a content of nitrogen, phosphorus and potassium in soil, ferrous sulfate is used to neutralize alkalinity of plant-growth type porous concrete,so that a planting substrate in the porous concrete can adapt to plant growth; and in the hardened concrete, sodium polyacrylate resin that is in contact with one another forms communicating space forgrowth of plant roots, and the sodium polyacrylate resin provides moisture and nutrients for plant growth, can be repeatedly accumulated and release moisture after rainfall or spraying is performed,play an inner curing role on the concrete, reduce shrinkage cracking and improve strength.

Owner:王敏

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com