Tin-based nanoparticle-carbon composite material, and preparation method and application thereof

A technology of carbon composite materials and nanoparticles, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of uneven filling of tin dioxide, low tin content, small specific capacity, etc., and achieve good specific capacity and cycle stability Sexuality, low cost, and little pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] In some embodiments, the preparation method of the metal-based nanoparticle-carbon composite material includes: uniformly mixing at least fusible metal powder, carbon material, and flux, and then heating the formed mixture in an oxygen-containing atmosphere to the The temperature is above the melting point of the fusible metal and kept warm to prepare the tin-based nano particle-carbon composite material.

[0039] In some embodiments, the preparation method of the tin-based nanoparticle-carbon composite material includes: at least taking tin powder and / or tin alloy powder, uniformly mixing with carbon material and flux, and then placing the formed mixture in an oxygen-containing atmosphere heating to a temperature above the melting point of tin or tin alloy and keeping it warm to prepare the tin-based nanoparticle-carbon composite material.

[0040] In some embodiments, the preparation method includes: heating the mixture to a temperature above the melting point of tin ...

Embodiment 1

[0057] Embodiment 1: the preparation technology of this nano tin carbon composite material comprises the steps:

[0058] ①Take a mixture of 80mg of 70μm tin powder, 100mg of multi-walled carbon nanotubes (diameter about 20-30nm, 12-20 layers) carbon nanotubes, and 100mg of commercially available rosin-type solid flux (Xinguang brand) into the researcher. Mortar, grind for half an hour, then remove the black mixture from the mortar and set aside.

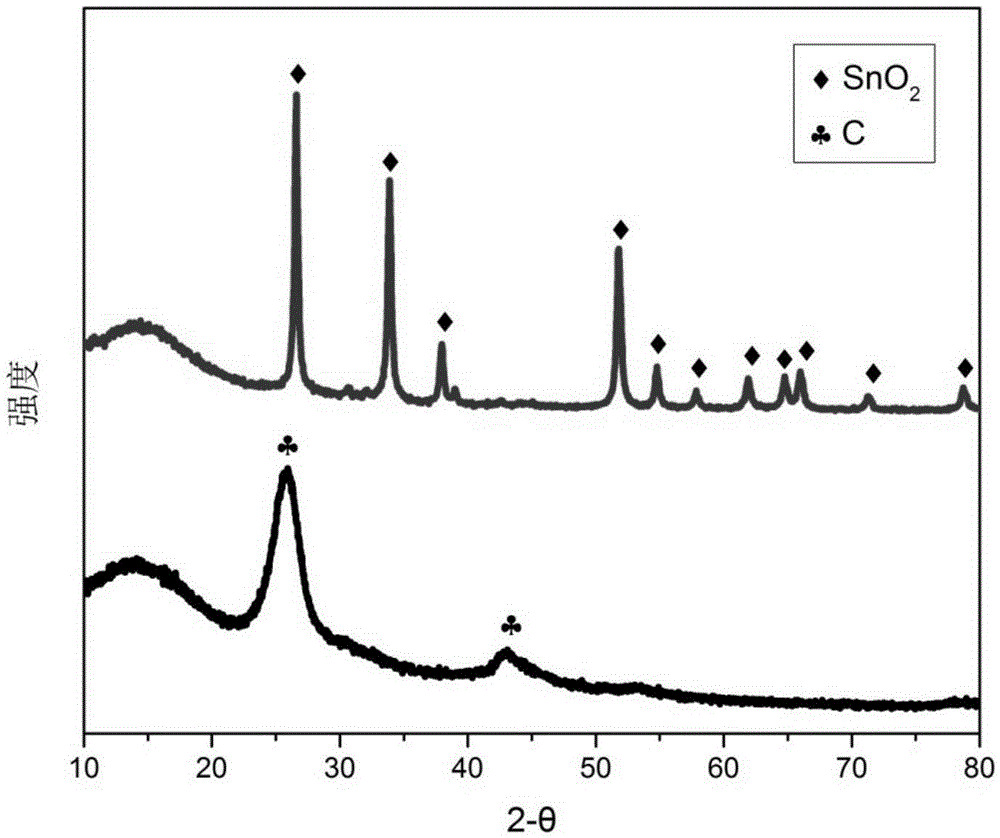

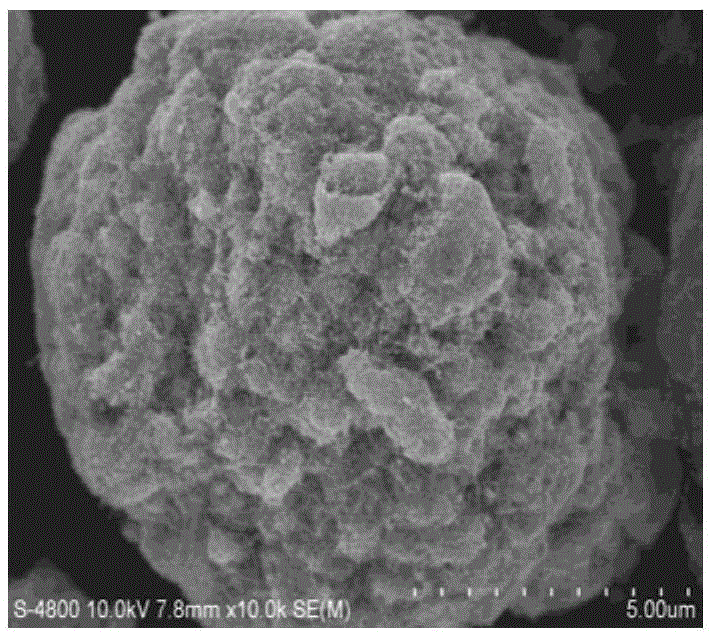

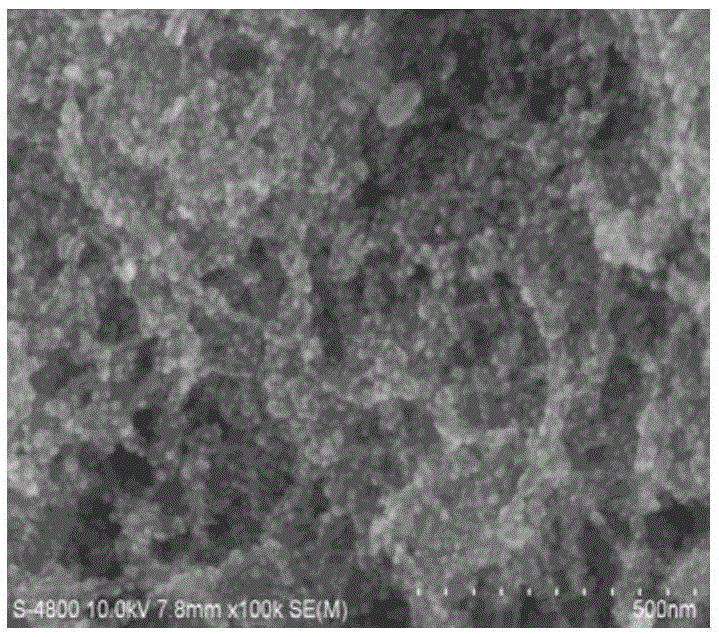

[0059] ②Put the mixture powder prepared in step ① into a small tin furnace, stir and heat the mixture powder at 300°C until no smoke is generated, then cool and take out the black powder, which is the nano-tin-carbon composite material (tin-based nanoparticle-carbon composite material), for its phase characterization results, please refer to figure 1 , for structural characterization results please refer to Figure 2a-2b , 3a-3b.

[0060] The prepared nano-tin-carbon composite material and carbon black conductive agent are mixed a...

Embodiment 2

[0061] Embodiment 2: the preparation technology of this nano-tin-carbon composite material comprises the following steps:

[0062] ① Take 80mg of 70μm tin-antimony alloy powder, 100mg of multi-walled carbon nanotubes (diameter about 20-30nm, 12-20 layers) and 100mg of commercially available rosin-type solid flux (Xinguang brand) and mix them in a small tin furnace In, add 3ml ethanol, stir and set aside.

[0063] ② Stir and heat the mixture in the small tin furnace filled with materials in step ① at 232°C until no smoke is generated, then cool and take out the black powder, which is the nano-tin-carbon composite material (tin-based nanoparticle-carbon composite material).

[0064] The prepared nano-tin-carbon composite material and carbon black conductive agent are mixed and placed in the NMP solution of PVDF, and the slurry is evenly coated on the copper foil, wherein the tin-based nanoparticle-carbon composite material and conductive carbon black and PVDF The mass ratio of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com