MXene-based flexible composite negative electrode material and preparation method thereof

A technology of negative electrode material and base flexibility, which is applied in the field of MXene-based flexible composite negative electrode material and its preparation, can solve the problems of difficult high-strength flexibility and high-capacity, and achieves improved capacitance deionization performance, buffer volume expansion, and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

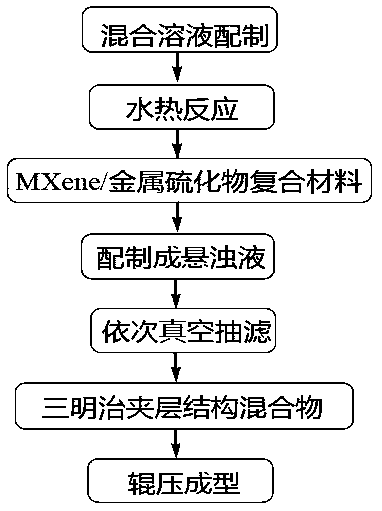

[0028] The invention discloses a method for preparing an MXene-based flexible composite negative electrode material, which includes the following steps:

[0029] (1) Preparation of MXene / transition metal sulfides: Mix metal salts of transition metal elements and sulfur sources, then add MXene material and alkaline solution to obtain a mixed solution, and hydrothermally react in a high-pressure reactor to obtain MXene / transition metal Sulfide complex; the transition metal sulfide is MoS 2 , SnS 2 、CoS 2 、Ni 2 S 3 At least one of them, the weight percentage is 5%-20%; the MXene material is Ti obtained by HF selective etching 3 C 2 Tx, Ti 2 CTx, Ti 3 CNTx, Cr 2 At least one of CTx, wherein Tx is -OH functional group or / and -F functional group. The transition metal element is at least one of titanium, molybdenum, cobalt, nickel and tin, and the metal salt of the transition metal element refers to a kind of nitrate, carbonate, sulfate, chloride of transition metal or more...

Embodiment 1

[0037] A method for preparing an MXene-based flexible composite negative electrode material, comprising the following steps:

[0038] (1) Preparation of MXene / transition metal sulfides: Mix metal salts of transition metal elements and sulfur sources, then add MXene material and alkaline solution to obtain a mixed solution, and hydrothermally react in a high-pressure reactor to obtain MXene / transition metal Sulfide complex; the transition metal sulfide is MoS 2 , the weight percentage is 5%; the MXene material is Ti obtained by HF selective etching 3 C 2 Tx, wherein Tx is a -OH functional group. The transition metal element is titanium, and the metal salt of the transition metal element refers to a transition metal nitrate. The sulfur source is sodium sulfide. The molar ratio of the transition metal sulfide to the sulfur source is 0.2:1. The reaction temperature of the hydrothermal reaction is 100°C, the reaction time is 24h, the solid product is collected after cooling, w...

Embodiment 2

[0046] A method for preparing an MXene-based flexible composite negative electrode material, comprising the following steps:

[0047] (1) Preparation of MXene / transition metal sulfides: Mix metal salts of transition metal elements and sulfur sources, then add MXene material and alkaline solution to obtain a mixed solution, and hydrothermally react in a high-pressure reactor to obtain MXene / transition metal Sulfide complex; the transition metal sulfide is SnS 2 , the weight percentage is 20%; the MXene material is Ti obtained by HF selective etching 2 CTx, wherein Tx is -F functional group. The transition metal element is molybdenum, and the metal salt of the transition metal element refers to a transition metal carbonate. The sulfur source is thiourea. The molar ratio of the transition metal sulfide to the sulfur source is 1.0:1. The reaction temperature of the hydrothermal reaction is 200°C, and the reaction time is 48h. After cooling, the solid product is collected and w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Expansion volume | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com