Tungsten tailings general-purpose Portland cement and preparation method thereof

A technology of Portland cement and tungsten tailings, applied in the field of building materials, can solve problems such as poor workability and workability of tungsten tailings, and achieve the effects of stable performance, poor workability and performance improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

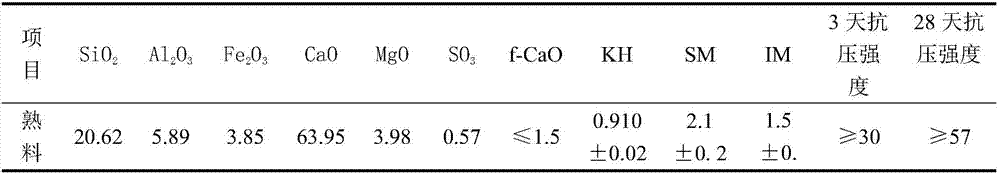

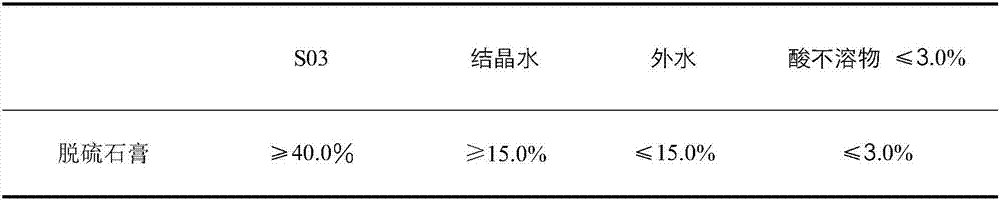

[0040] A general-purpose Portland cement for tungsten tailings, made from the following raw materials in weight percent:

[0041] Cement clinker: 63.00%; Desulfurization gypsum: 4.00%; Bottom slag: 6.00%; Limestone: 11.00%; Fly ash: 8.00%; Active superfine powder: 8.00%;

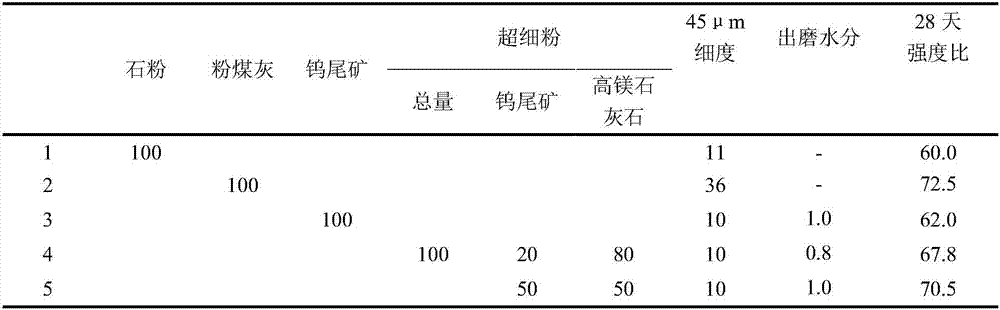

[0042] The active superfine powder is a mixed powder obtained by mixing and grinding tungsten tailings and high magnesium limestone. Prepare superfine powder according to the ratio of tungsten tailings: high magnesium limestone = 1:1, and the fineness of 45μm can reach 10%.

[0043] A preparation method for universal portland cement of tungsten tailings, comprising the following steps:

[0044] S1. Preparation of active ultrafine powder

[0045] 1) Drying or drying the tungsten tailings in the open air until the moisture content is 12%;

[0046] 2) Mix the tungsten tailings treated in step 1) with high-magnesia limestone evenly and grind them into powder, control the fineness to 10% through a square hole si...

Embodiment 2

[0050] A general-purpose Portland cement for tungsten tailings, made from the following raw materials in weight percent:

[0051] Cement clinker: 63.00%; Desulfurization gypsum: 4.00%; Bottom slag: 2.00%; Limestone: 11.00%; Fly ash: 6.00%; Active superfine powder: 14.00%;

[0052] The active superfine powder is a mixed powder obtained by mixing and grinding tungsten tailings and high magnesium limestone. Prepare superfine powder according to the ratio of tungsten tailings: high magnesium limestone = 1:1, and the fineness of 45μm reaches 11%.

Embodiment 3

[0054] A general-purpose Portland cement for tungsten tailings, made from the following raw materials in weight percent:

[0055] Cement clinker: 63.00%; desulfurized gypsum: 4.00%; furnace bottom slag: 2.00%; limestone: 11.00%; fly ash: 6.00%, active superfine powder: 14.00%;

[0056] The active superfine powder is a mixed powder obtained by mixing and grinding tungsten tailings and high magnesium limestone. Prepare superfine powder according to the ratio of tungsten tailings: high magnesium limestone = 1:2, and the fineness of 45μm reaches 11%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com