Ecological rehabilitation promoting snow-melting agent and preparation method thereof

A technology of ecological restoration and snow melting agent, which is applied in the field of compound salt to achieve the effect of increasing added value, increasing crop yield and promoting ecological restoration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The proportion of each component is: 10 parts of polyaspartic acid, 40 parts of humic acid, 30 parts of acetate, 20 parts of chloride salt;

[0026] The specific implementation steps are: weigh 100g of humic acid and dissolve it in 500ml of distilled water at room temperature, raise the temperature to 40°C, add 50g of potassium permanganate and 100ml of hydrogen peroxide with a mass concentration of 30% under stirring, and add acetic acid after 90min of reaction Calcium 75g, calcium chloride 50g, stir to dissolve and cool down to room temperature, then add 62.5ml of polyaspartic acid with a solid content of 40%, and stir evenly to obtain a liquid deicing agent, or spray it into a solid granular deicing agent.

Embodiment 2

[0028] The ratio of each component is: 30 parts of polyaspartic acid, 50 parts of humic acid, 20 parts of acetate and 0 part of chloride salt.

[0029] The specific implementation steps are: weigh 100g of humic acid and dissolve it in 500ml of distilled water at room temperature, raise the temperature to 30°C, add 50g of potassium permanganate and 200ml of hydrogen peroxide with a mass concentration of 30% under stirring, and add magnesium acetate after reacting for 120min 40g, stir to dissolve and cool down to room temperature, then add 150ml of polyaspartic acid with a solid content of 40%, and stir evenly to obtain a liquid snow melting agent, or spray it into a solid granular snow melting agent.

Embodiment 3

[0031] The proportion of each component is: 20 parts of polyaspartic acid, 30 parts of humic acid, 30 parts of acetate and 20 parts of chloride salt.

[0032] The specific implementation steps are: weigh 100g of humic acid and dissolve it in 500ml of distilled water at room temperature, raise the temperature to 35°C, add 50g of potassium permanganate and 150ml of hydrogen peroxide with a mass concentration of 30% under stirring, and add acetic acid after 120min of reaction Calcium 100g, magnesium chloride 66.6g, stirring and dissolving, cooling down to room temperature, then adding 166.7ml of polyaspartic acid with a solid content of 40%, stirring evenly to obtain a liquid deicing agent, or spraying into a solid granulated deicing agent.

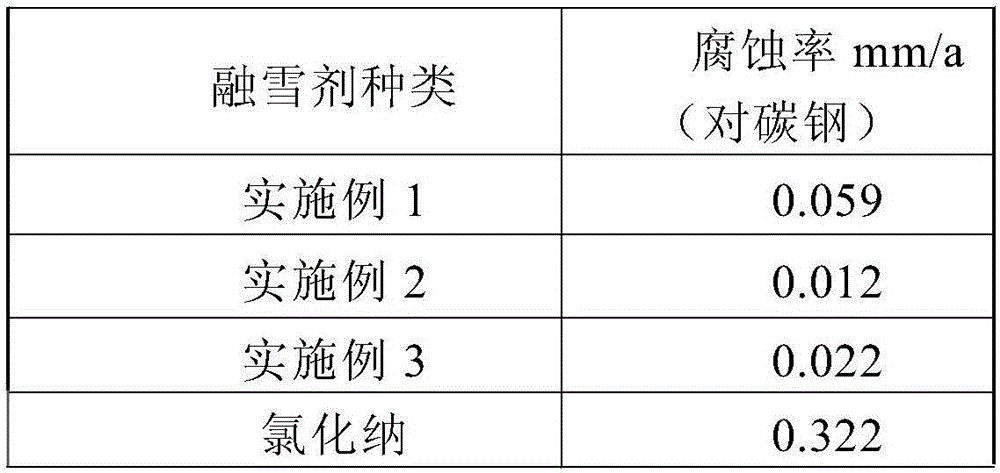

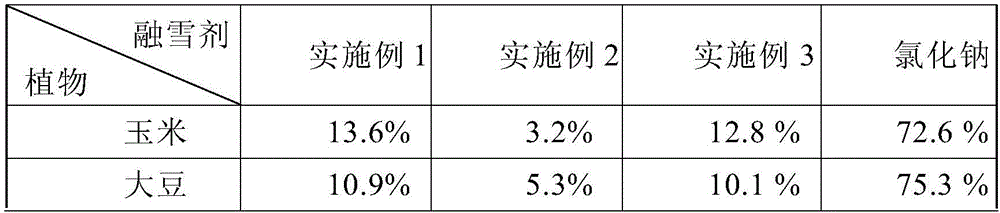

[0033] 2. Determination of snow-melting ability, corrosiveness and influence on plant seed germination rate of the prepared snow-melting agent

[0034] Dilute the deicing agent prepared in Examples 1 to 3 into a solution with a solid content...

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com