Method for preparing nano lead product by lead plaster of waste lead-acid storage batteries

A technology of waste lead-acid batteries and lead compounds, which is applied in the field of preparing nano-PbO from PbS and lead acetate crystals, can solve the problems of nano-PbO and PbS that have not yet been seen, and achieve high efficiency, low pollution, and mitigation of environmental hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A method for preparing nano-lead compounds from waste lead-acid storage battery lead paste, specifically as follows:

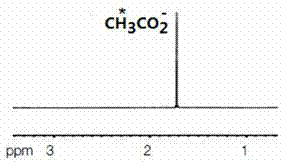

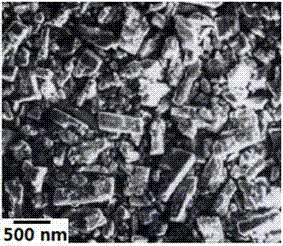

[0021] ①Take 1g of lead paste, 10g of sodium acetate, 35g of acetic acid and 3mL of 30% H 2 o 2 After the aqueous solution was mixed, it was diluted with 250 mL of deionized water, and then stirred at 20° C. for 6 h. Filter after the reaction, adjust the pH of the filtrate to 7.1, let it stand for 1 hour, and filter again to obtain 0.95 g of lead acetate crystals. 1 H NMR spectrum (see figure 1 ) shows that the purity of lead acetate crystals is higher. SEM spectrogram test (see figure 2 ) shows that its structure is formed by stacking cuboids of different sizes, and the particle size of the cuboids is hundreds of nanometers.

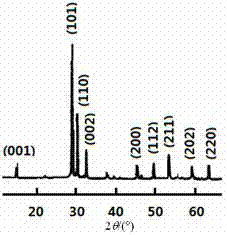

[0022] ②Take 0.1g of lead acetate crystals formed by the reaction and calcinate at 250°C for 2h to obtain 0.06g of powdery product. The product is analyzed by X-ray diffraction test, and the results are shown in image 3 ...

Embodiment 2

[0025] A method for preparing nano-lead compounds from waste lead-acid storage battery lead paste, specifically as follows:

[0026] ①Take 1.5g of lead paste, 16.5g of sodium acetate, 45g of acetic acid and 4.5mL of 30% H 2 o 2 After the aqueous solutions were mixed, they were diluted with 370 mL of deionized water, and then stirred at 25° C. for 8 h. After the reaction was completed, filter, adjust the pH of the filtrate to 7.2, let it stand for 2 hours, and filter again to obtain 1.37 g of lead acetate crystals.

[0027] ②Take 0.2g of lead acetate crystals produced by the reaction and calcinate them at 300°C for 2h to obtain 0.11g of powdered nano-PbO product with a particle size of about 150-250nm.

[0028] ③Mix 1.5mmol (0.488g) of lead acetate crystals formed by the reaction, 2.7mmol (0.203g) of thioacetamide and 3mmol of sodium dodecylsulfonate (0.864g), and then add 45mL of deionized water and 45mL of ethanol After mixing, put it in a polytetrafluoroethylene-lined rea...

Embodiment 3

[0030] A method for preparing nano-lead compounds from waste lead-acid storage battery lead paste, specifically as follows:

[0031] ①Take 2g of lead plaster, 24g of sodium acetate, 50g of acetic acid and 6mL of 30% H 2 o 2 After the aqueous solution was mixed, it was diluted with 500 mL of deionized water, and then stirred and reacted at 30° C. for 10 h. After the reaction was completed, filter, adjust the pH of the filtrate to 7.3, let it stand for 2 hours, and filter again to obtain 1.83 g of lead acetate crystals.

[0032] ② Take 0.3g of lead acetate crystals formed by the reaction and calcinate at 350°C for 3h to obtain 0.17g of powdered nano-PbO product with a particle size of about 150-250nm.

[0033] ③ Mix 2mmol (0.65g) of lead acetate crystals, 4mmol (0.304g) of thiourea, 3mmol (1.092g) of hexadecyltrimethylammonium bromide, 3mmol of OP-10 (about 1.5g), and then add The mixture consisting of 67mL deionized water and 67mL polyethylene glycol, mixed evenly, placed in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com