Method for preparing iron tailing porous ceramic through foam-gelcasting/low-temperature sintering

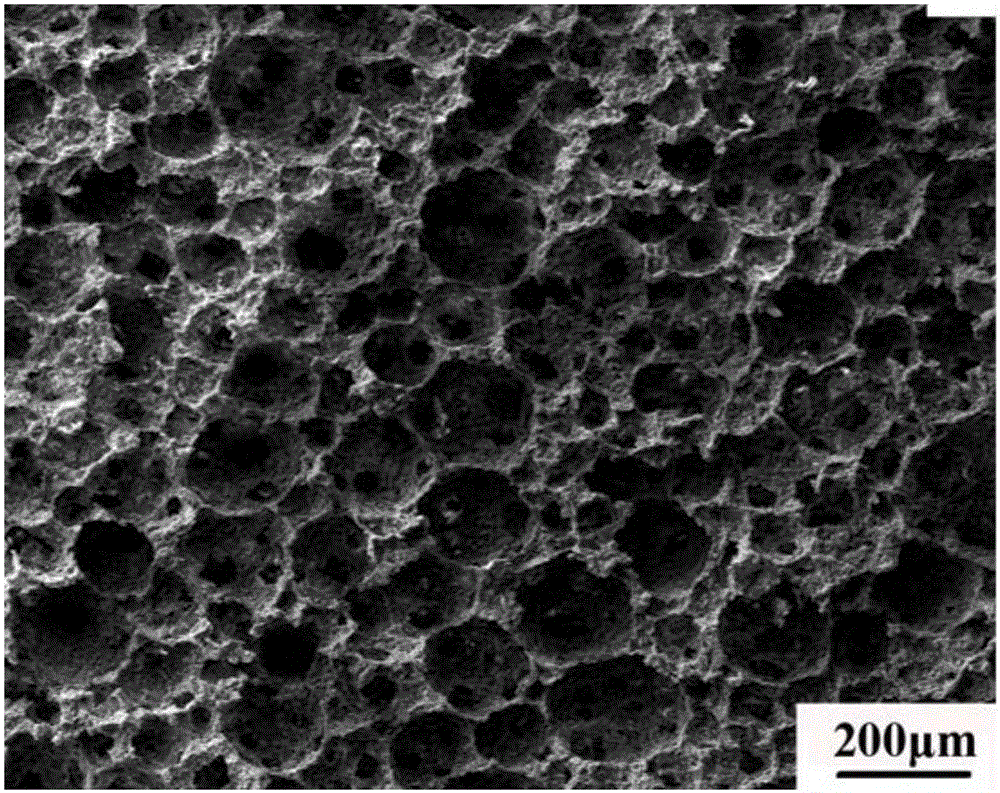

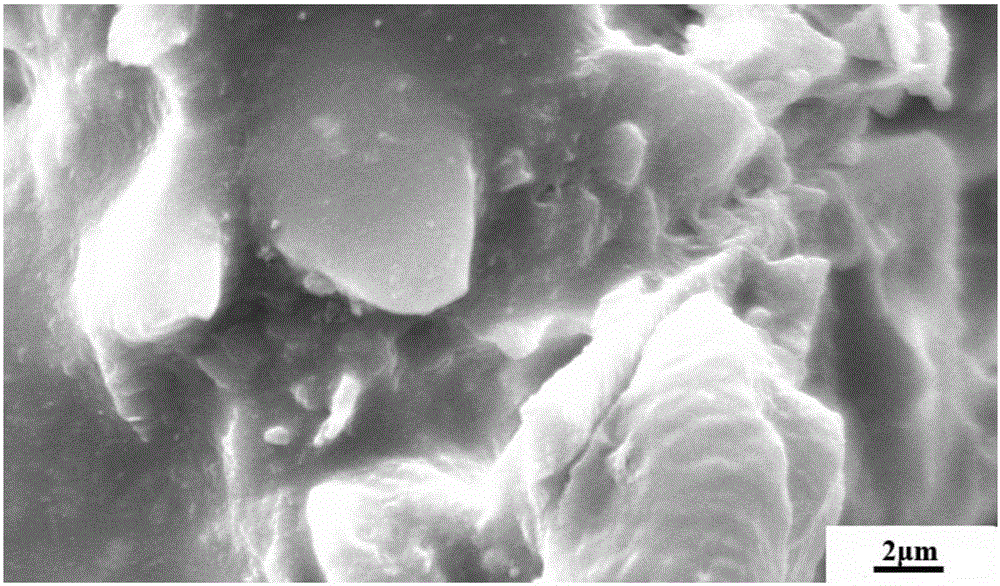

A technology of low-temperature sintering and porous ceramics, which is applied in the direction of ceramic products, ceramic material production, clay products, etc. It can solve the problems of low porosity and uneven pore size distribution of porous ceramics, and achieve controllable forming parameters, good physical properties and mechanical properties. performance, effect of small pore size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

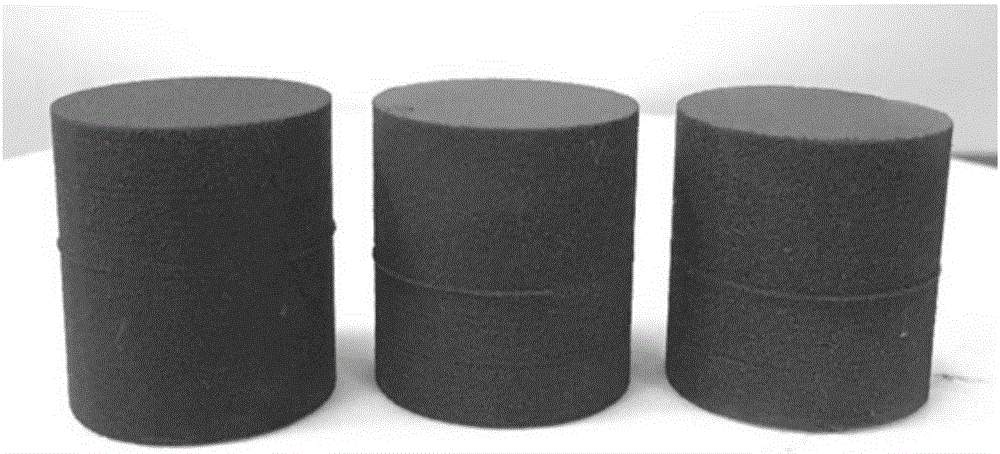

Embodiment 1

[0050] Iron tailings: The raw materials used in this example are muddy fine-grained iron tailings produced by Shouyun Mining Group Co., Ltd. in Miyun District, Beijing after iron ore selection in 2015. The particle size distribution is 0.3-130 μm, and the diameter is 2 , 14.7wt% Fe 2 o 3 , 8.7wt% MgO, 6.8wt% Al 2 o 3 , 6.6wt% CaO, 1.6wt% K 2 O, 1.5 wt% other components.

[0051] Weigh 45g of iron tailings powder, 90g of agate balls, and 55ml of deionized water, and put them into a ball mill tank for roller milling and mixing for 22 hours to prepare a slurry with a tailings content of 45wt%. Weigh 5.5g of organic monomer, 0.55g of crosslinking agent and 0.8g of dispersant and inject into the slurry to continue ball milling for 2 hours. Weigh 0.1 g of foaming agent and 0.02 g of foam stabilizer and inject into the slurry, and mechanically stir for 10 minutes at a stirring speed of 1200 r / min for foaming. Weigh 1.25g of catalyst and 0.6g of initiator into the foam-containing...

Embodiment 2

[0057] Iron tailings: the raw materials used in this embodiment are the same as in embodiment 1.

[0058] Weigh 30g of iron tailings powder, 60g of agate balls, and 70ml of deionized water, and put them into a ball mill tank for roller milling and mixing for 6 hours to prepare a slurry with a tailings content of 30wt%. Weigh 7g of organic monomer, 0.7g of crosslinking agent and 0.2g of dispersant and inject into the slurry to continue ball milling for 12 hours. Weigh 0.15 g of foaming agent and 0.04 g of foam stabilizer and inject into the slurry, and mechanically stir for 20 minutes at a stirring speed of 650 r / min for foaming. Weigh 1.75g of catalyst and 0.3g of initiator into the foam-containing slurry and stir evenly. Pour the slurry into a glass mold. After the slurry gel is formed, it is demolded and dried. Put the formed body into a muffle furnace, raise the temperature to 900° C. for 2 hours, then raise the temperature to 1050° C. and keep it for 12 hours to prepare...

Embodiment 3

[0061] Iron tailings: The raw material used in this example is the muddy fine-grained iron tailings produced by Shouyun Mining Group Company in Miyun District, Beijing after iron ore selection in 2016. The particle size distribution is between 0.2 μm and 180 μm. Particles of 58 μm accounted for 90%, and the average particle size was 12.4 μm. The mass percentage of tailings composition is as follows: 56.3wt% SiO 2 , 13.5wt% Fe 2 o 3 , 9.6wt% MgO, 8.9wt% Al 2 o 3 , 7.2wt% CaO, 2.8wt% K 2 O, 1.7 wt% other components.

[0062] Weigh 40g of iron tailings powder, 80g of agate balls, and 60ml of deionized water, and put them into a ball mill tank for roller milling and mixing for 12 hours to prepare a slurry with a tailings content of 40wt%. 4g of organic monomer, 0.4g of crosslinking agent and 1.8g of dispersant were weighed and injected into the slurry to continue ball milling for 10 hours. Weigh 0.08g of foaming agent and 0.02g of foam stabilizer and inject into the slurry,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com