Patents

Literature

129results about How to "Improve body strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

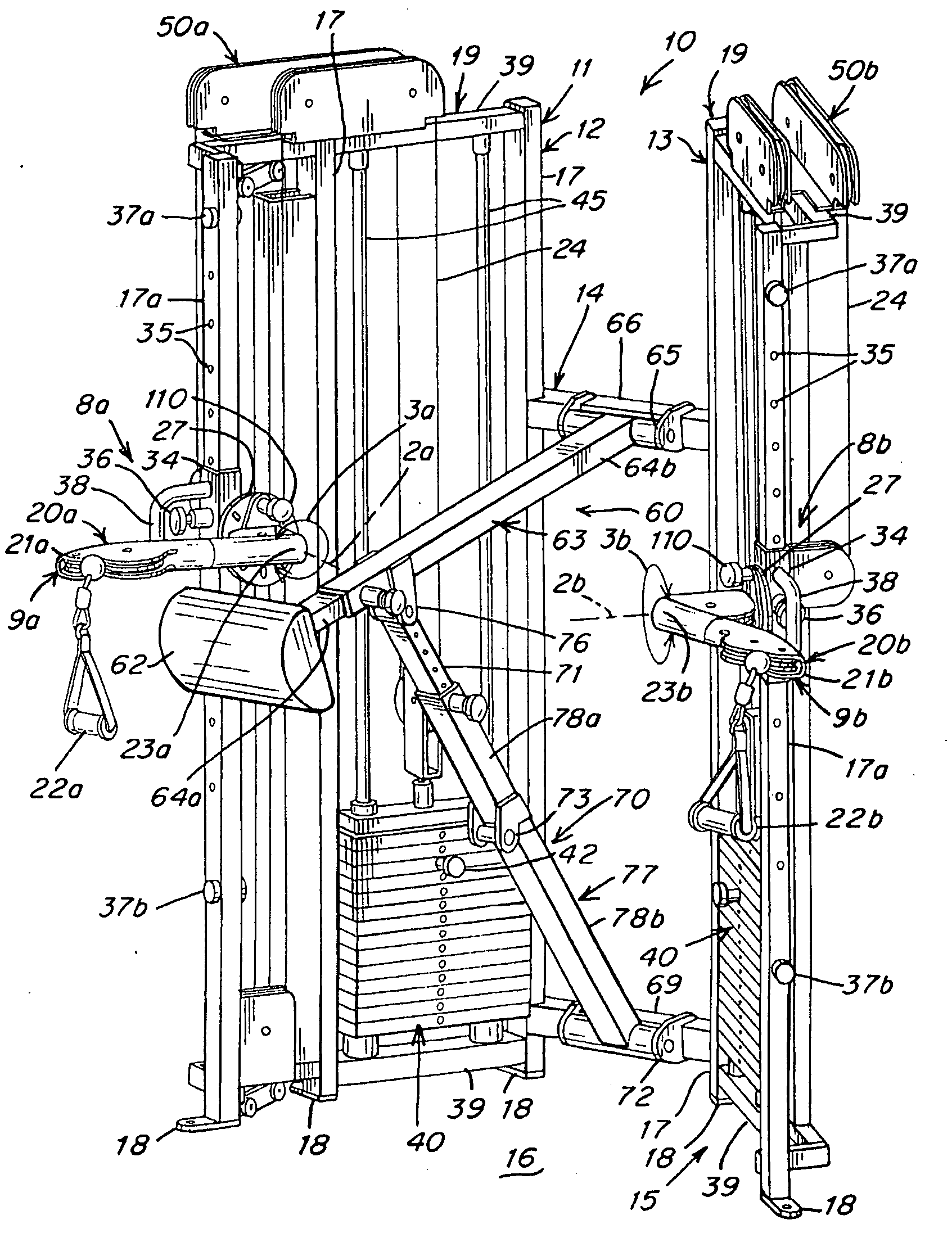

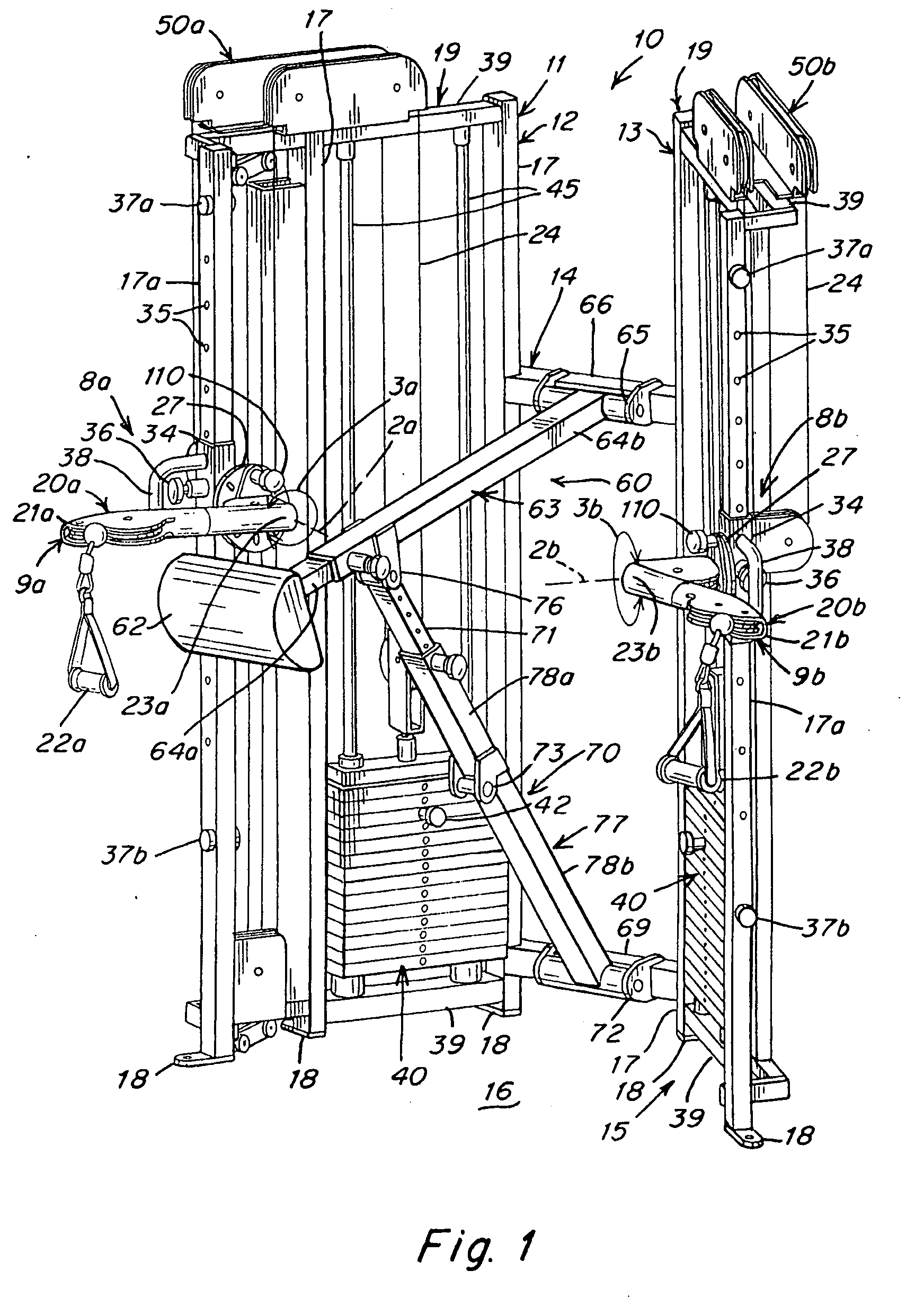

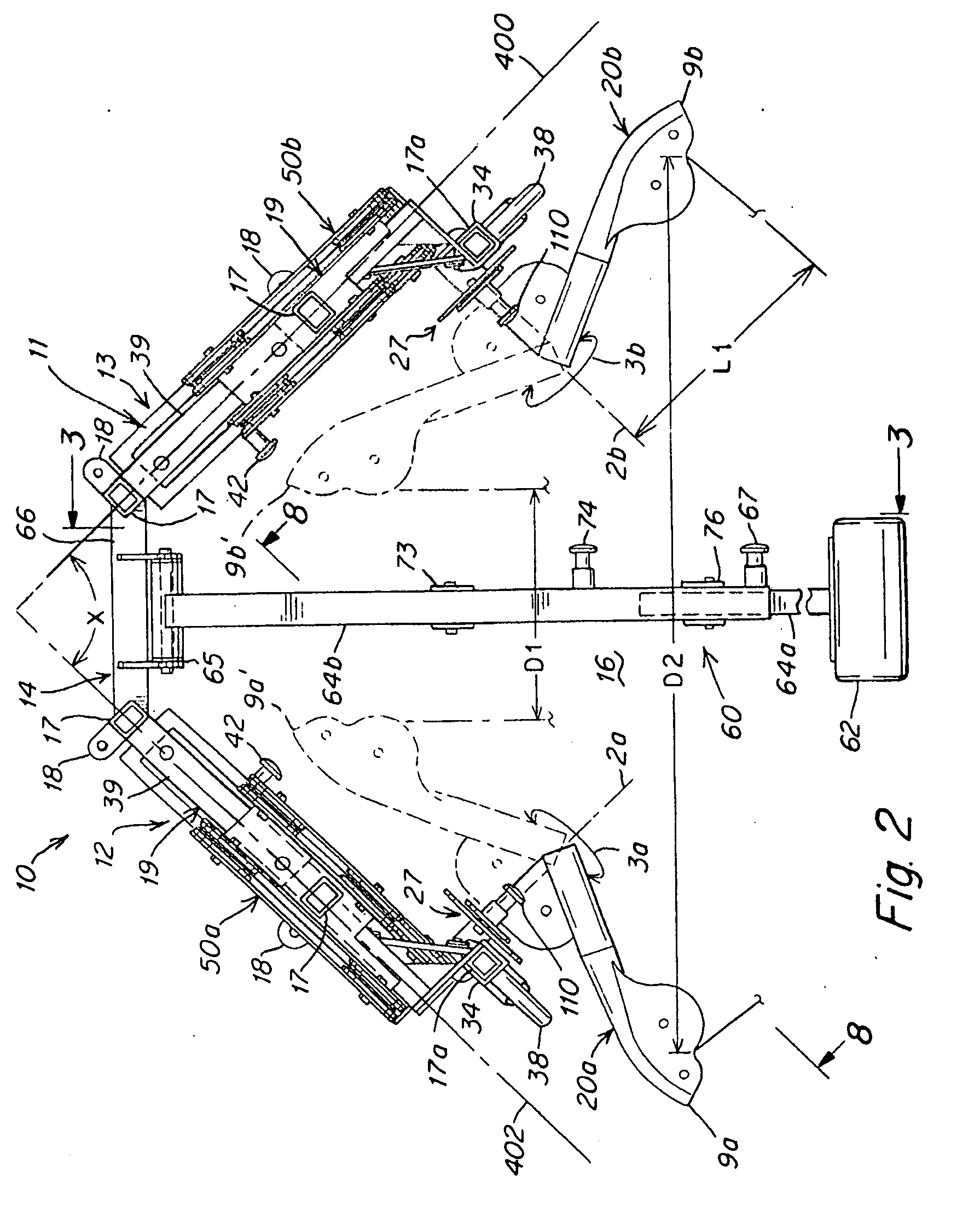

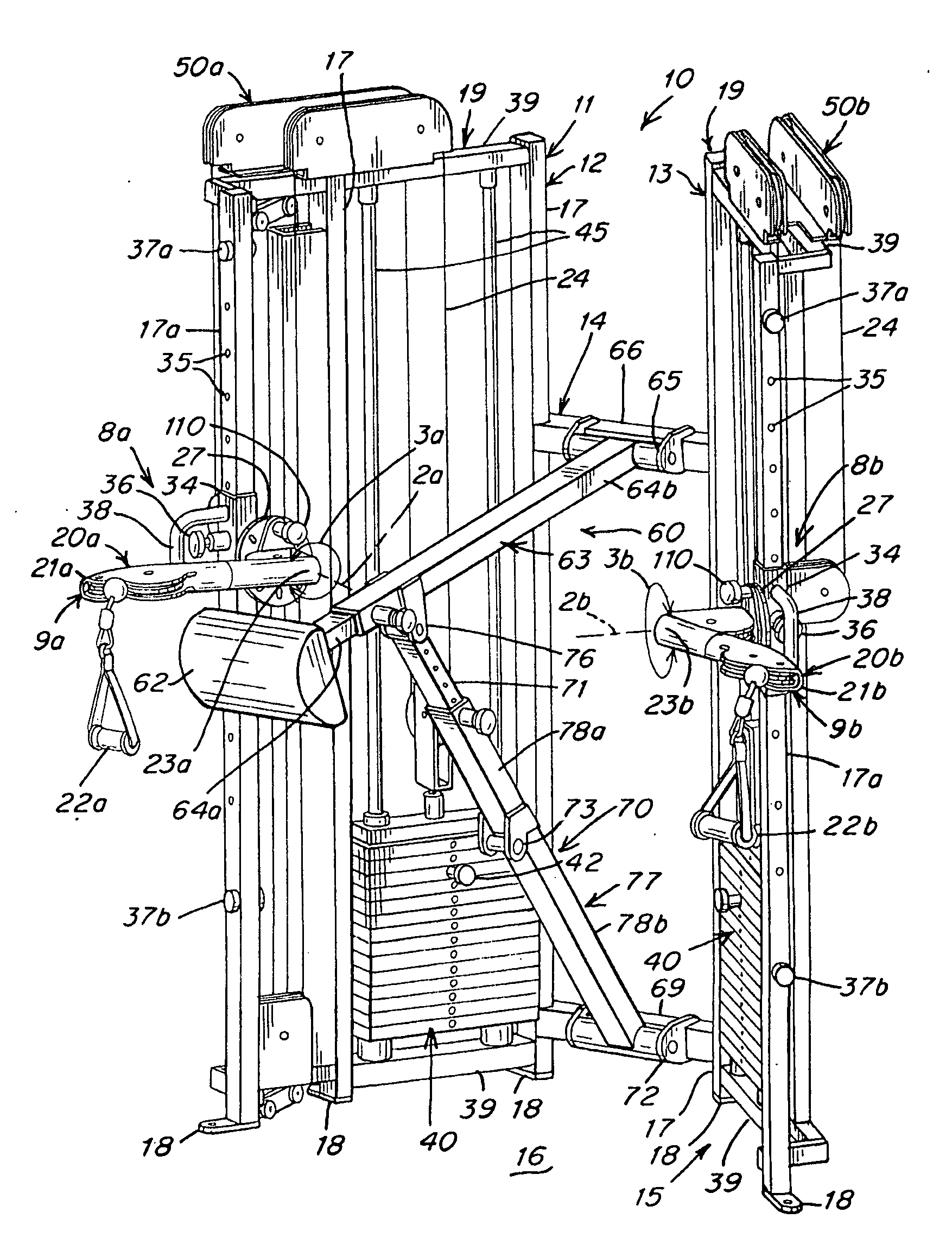

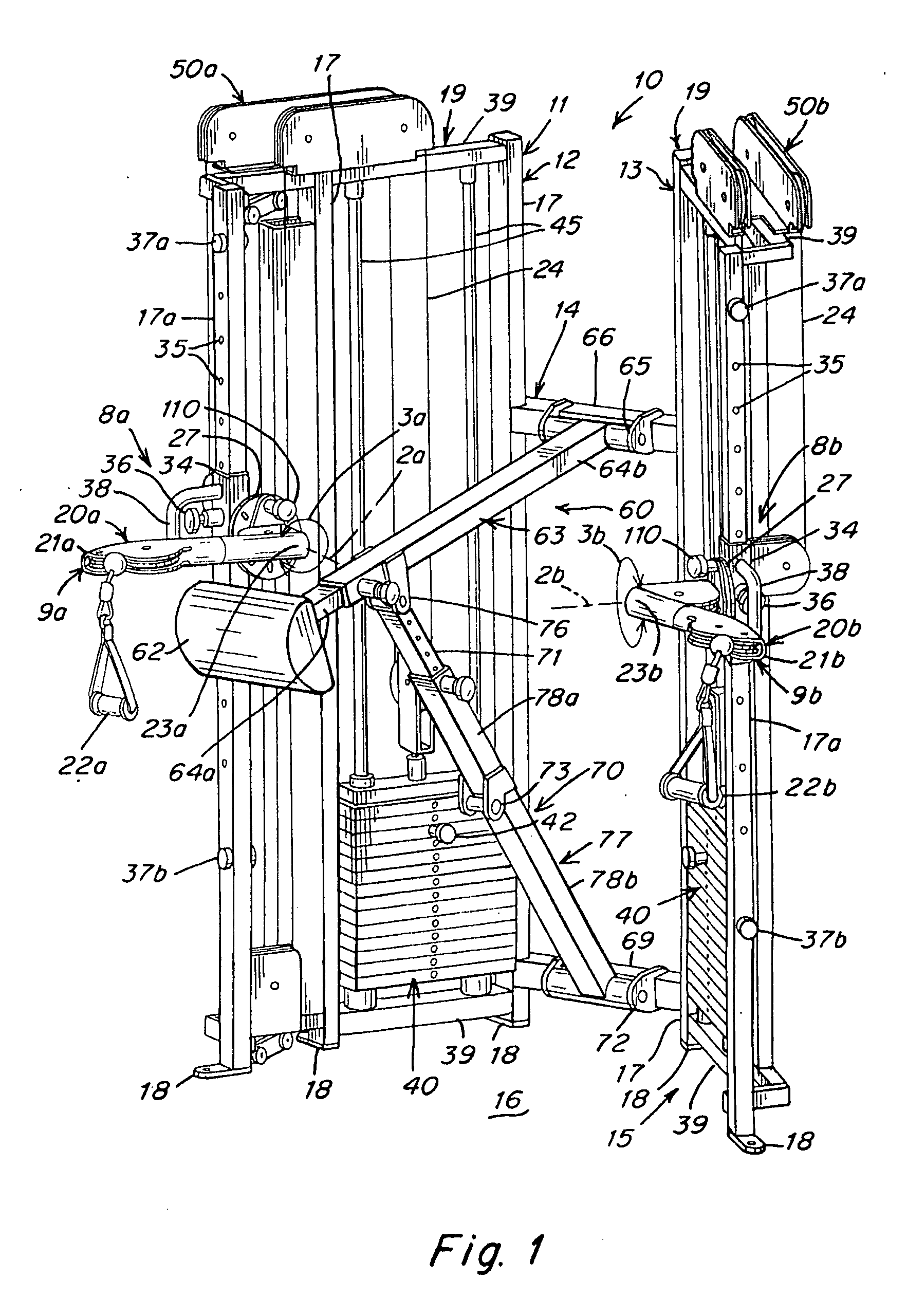

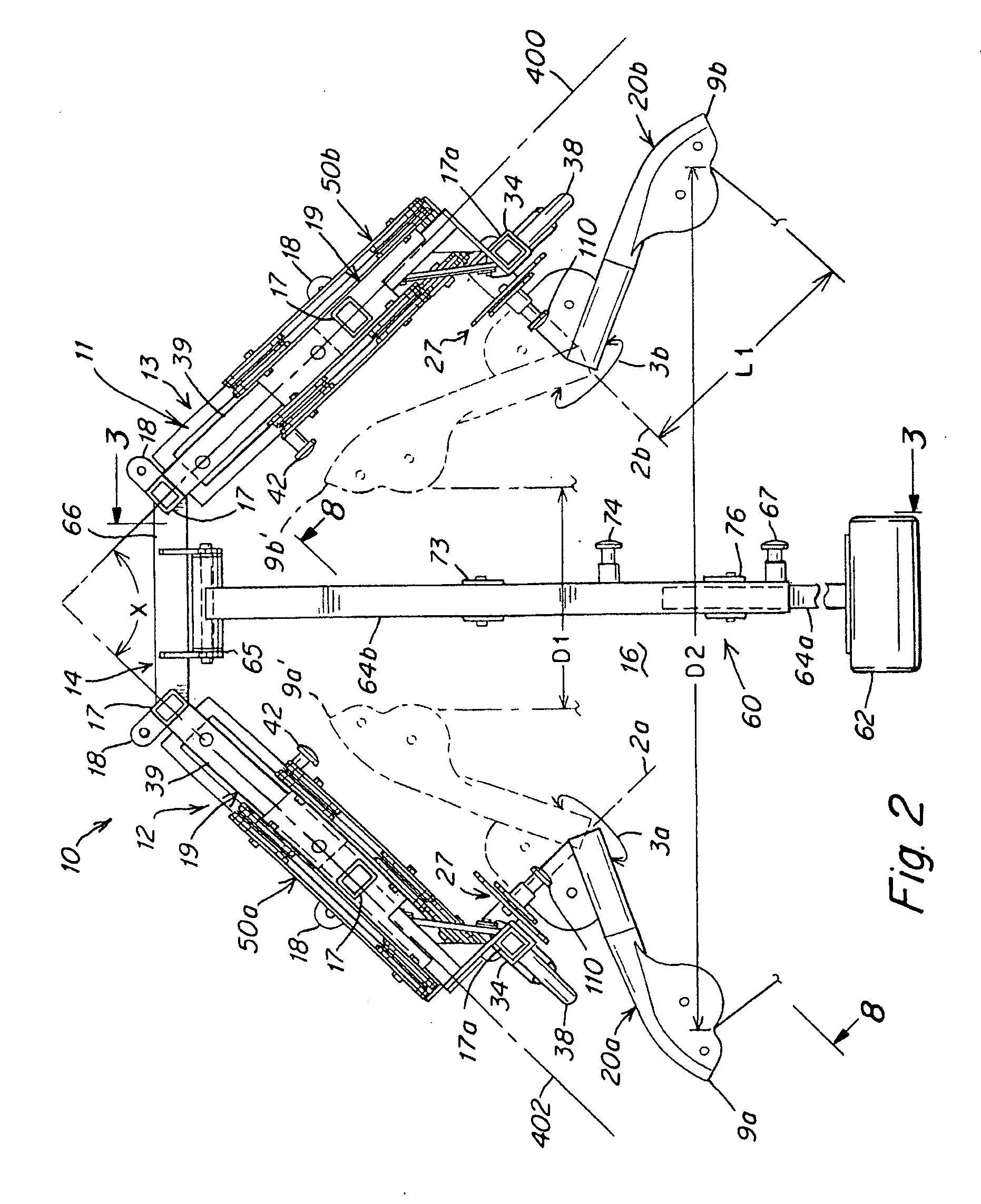

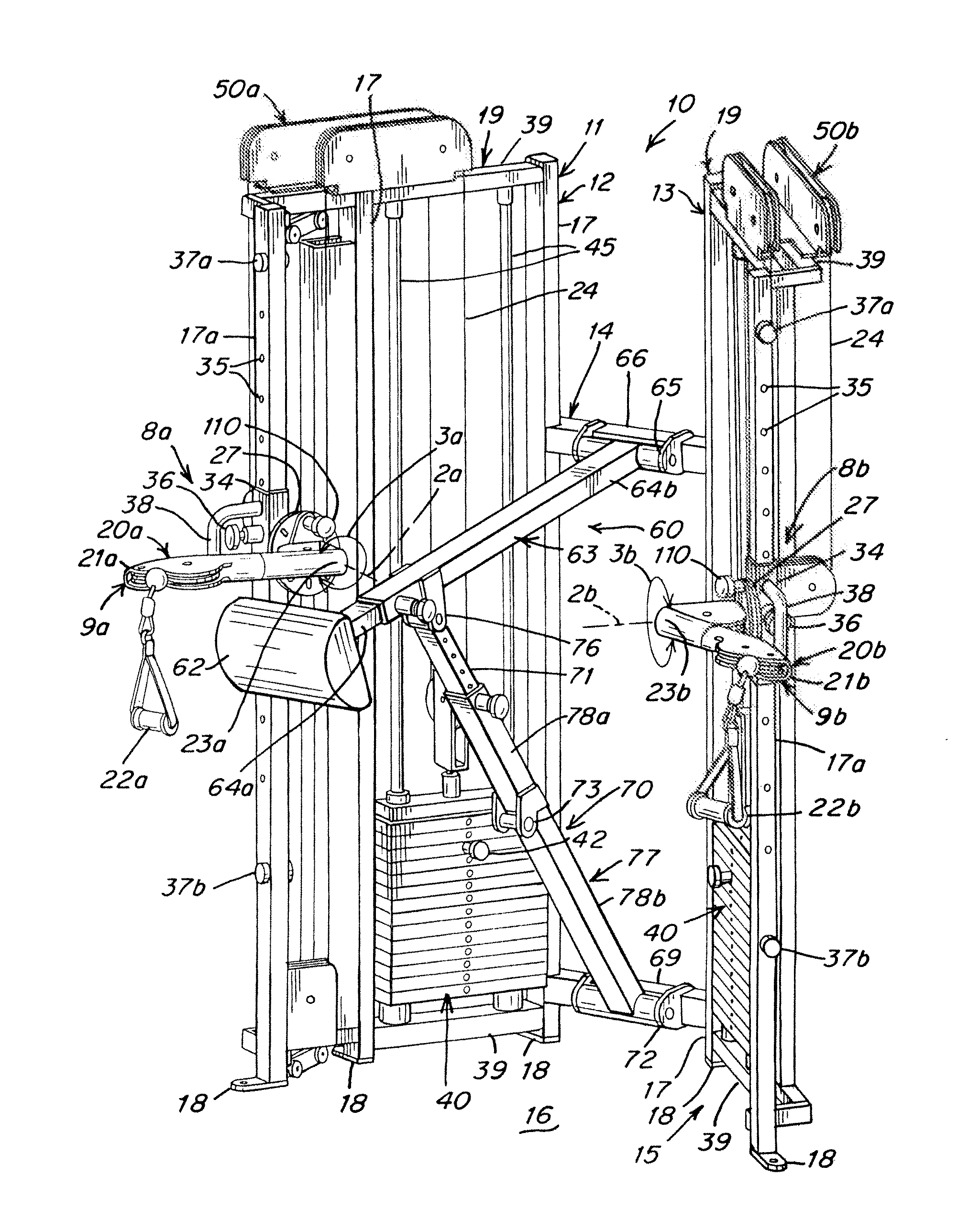

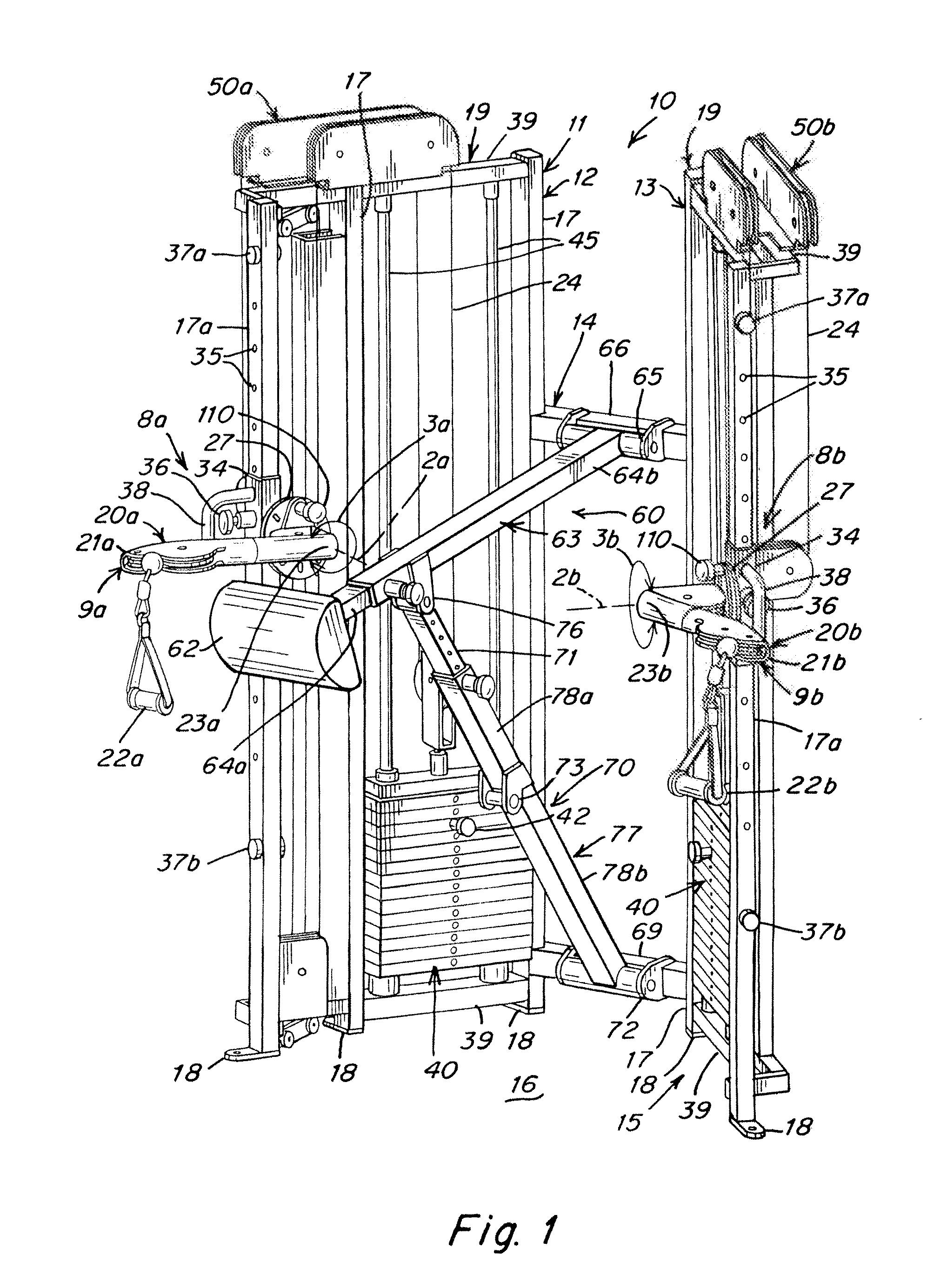

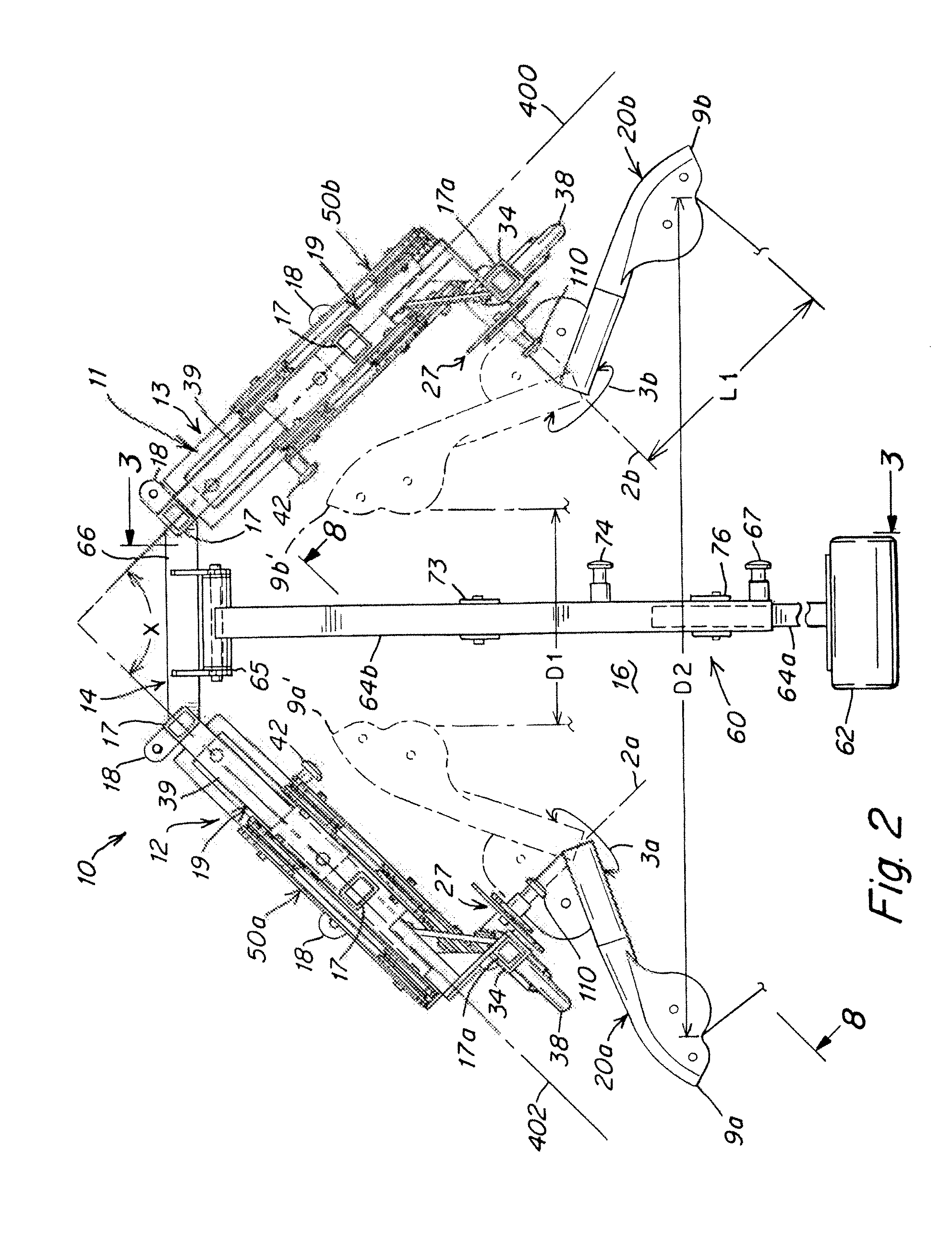

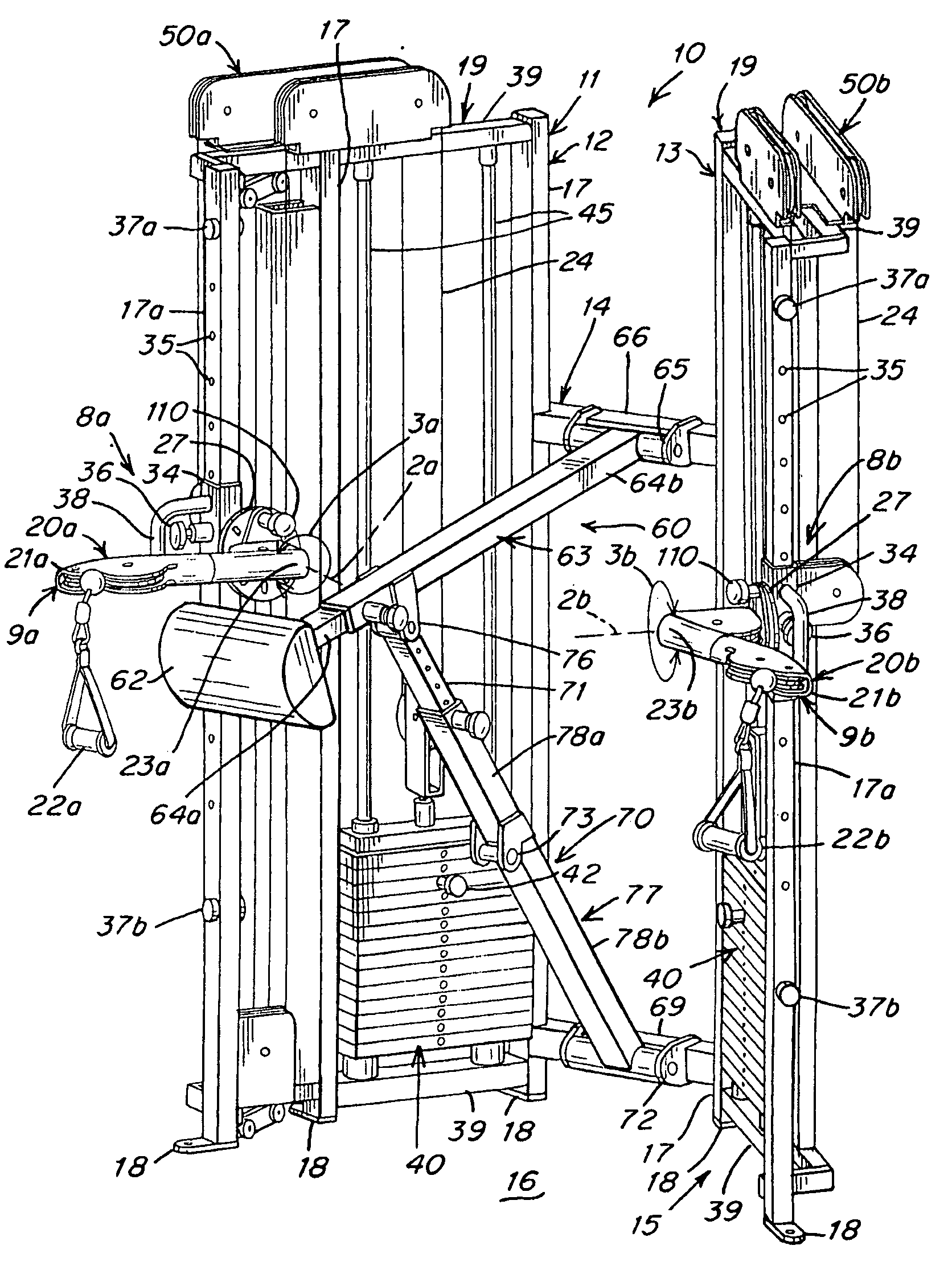

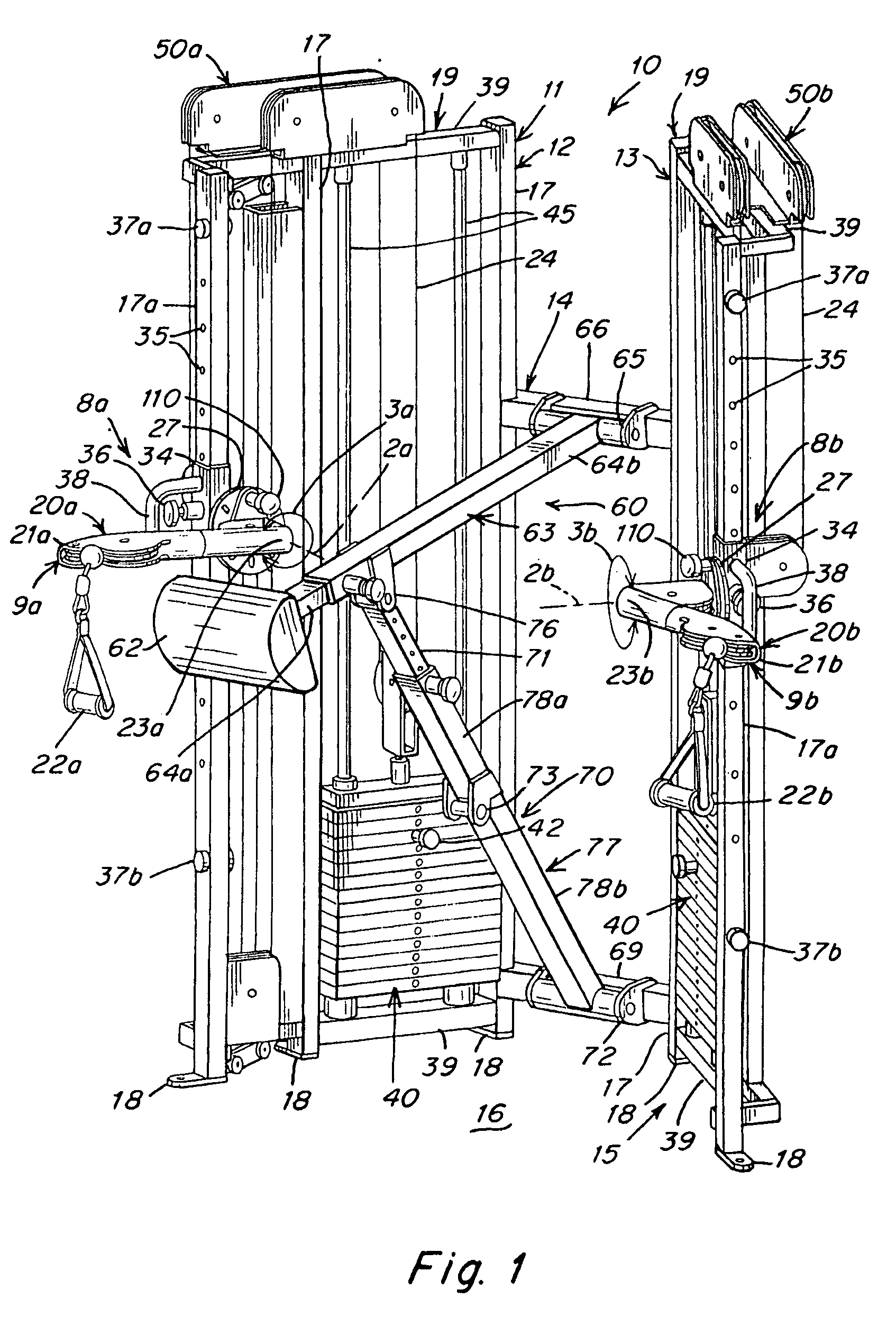

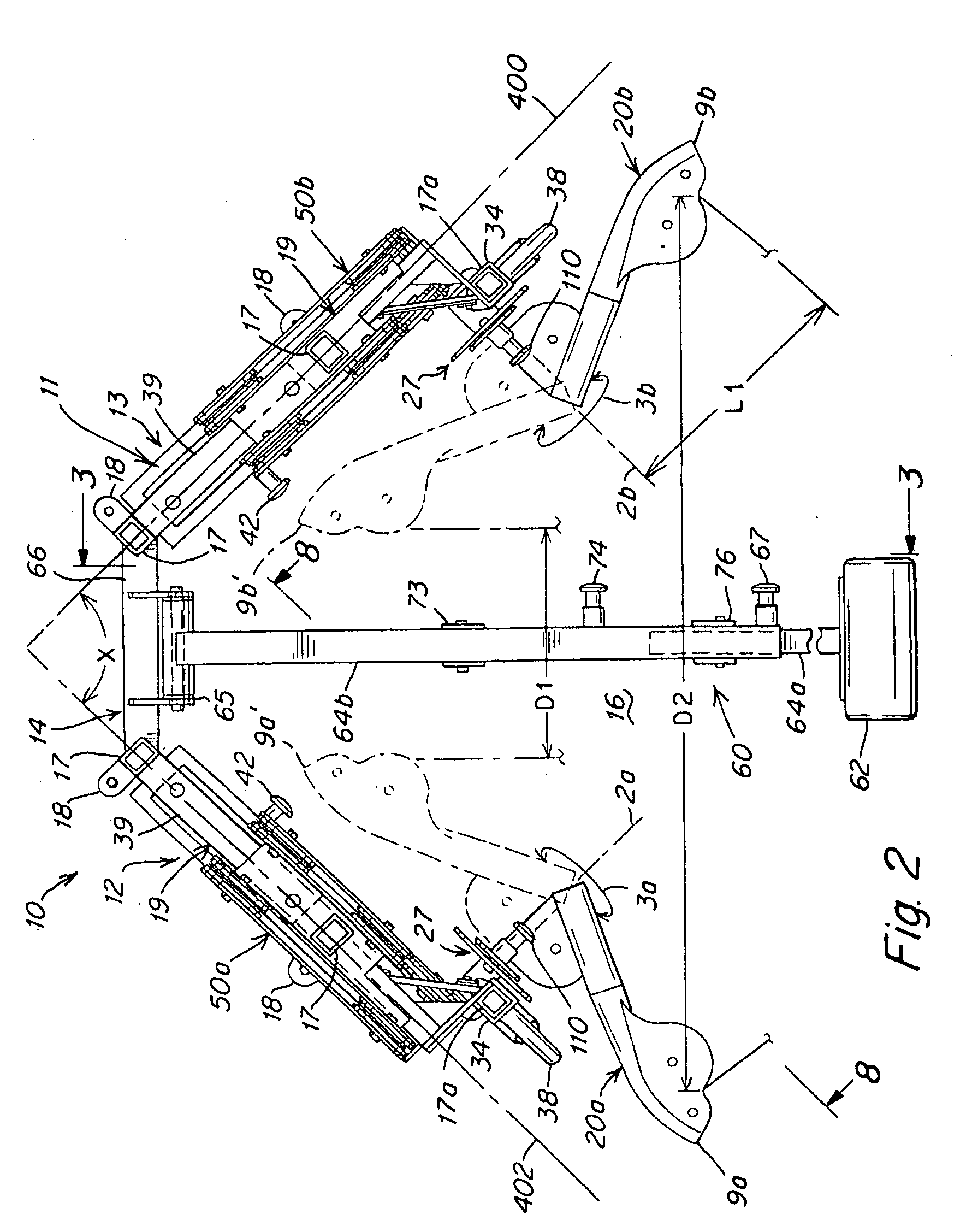

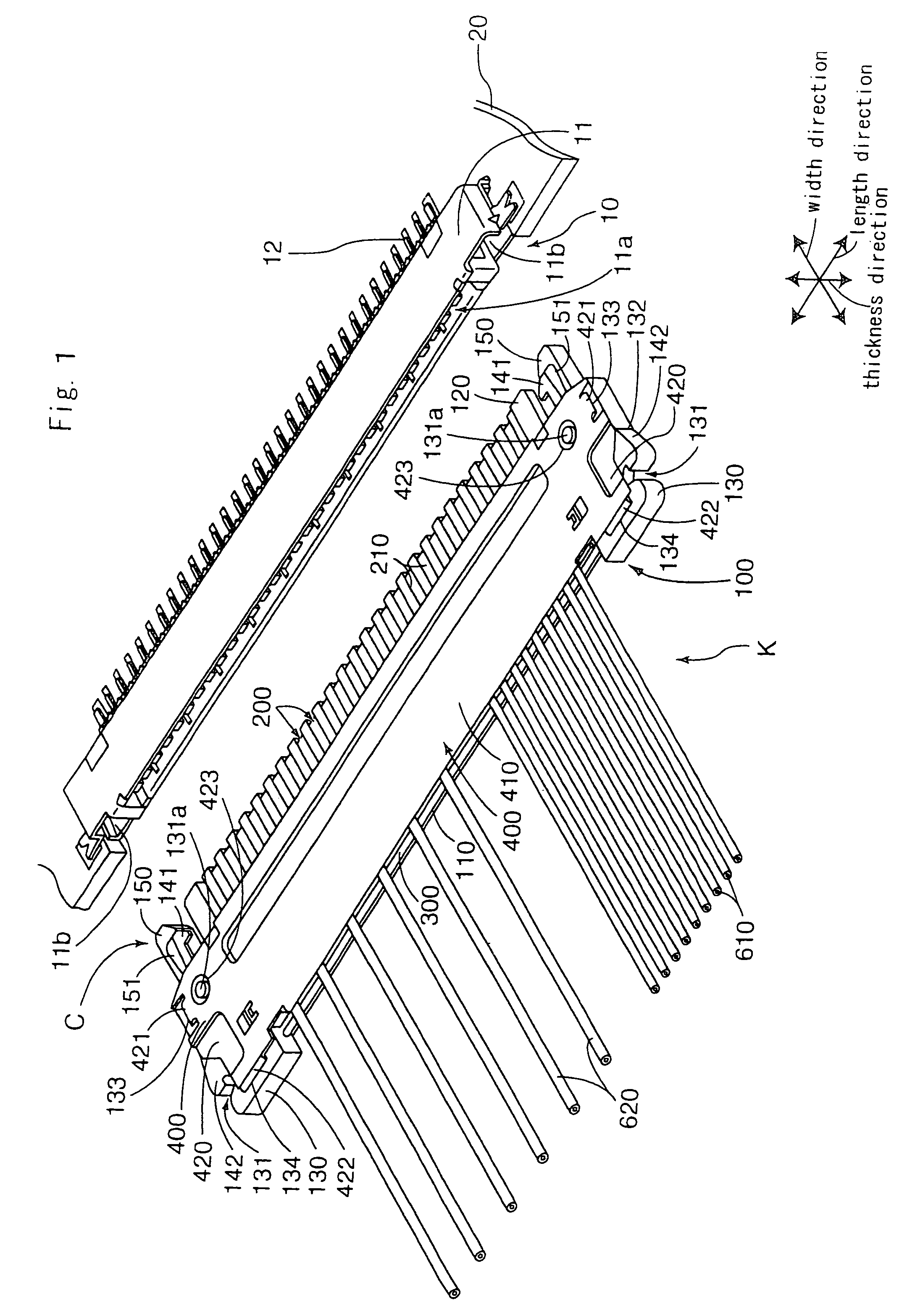

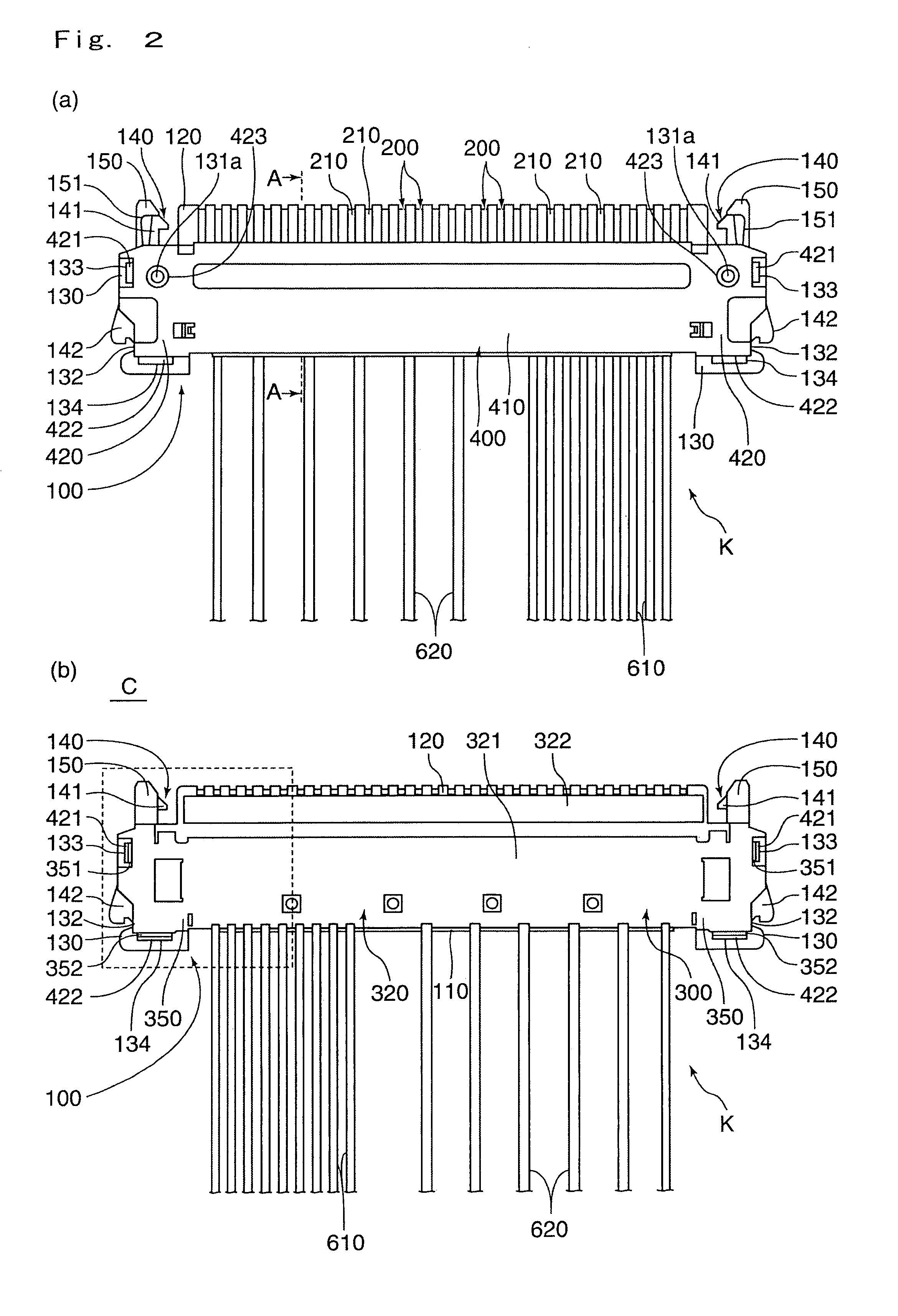

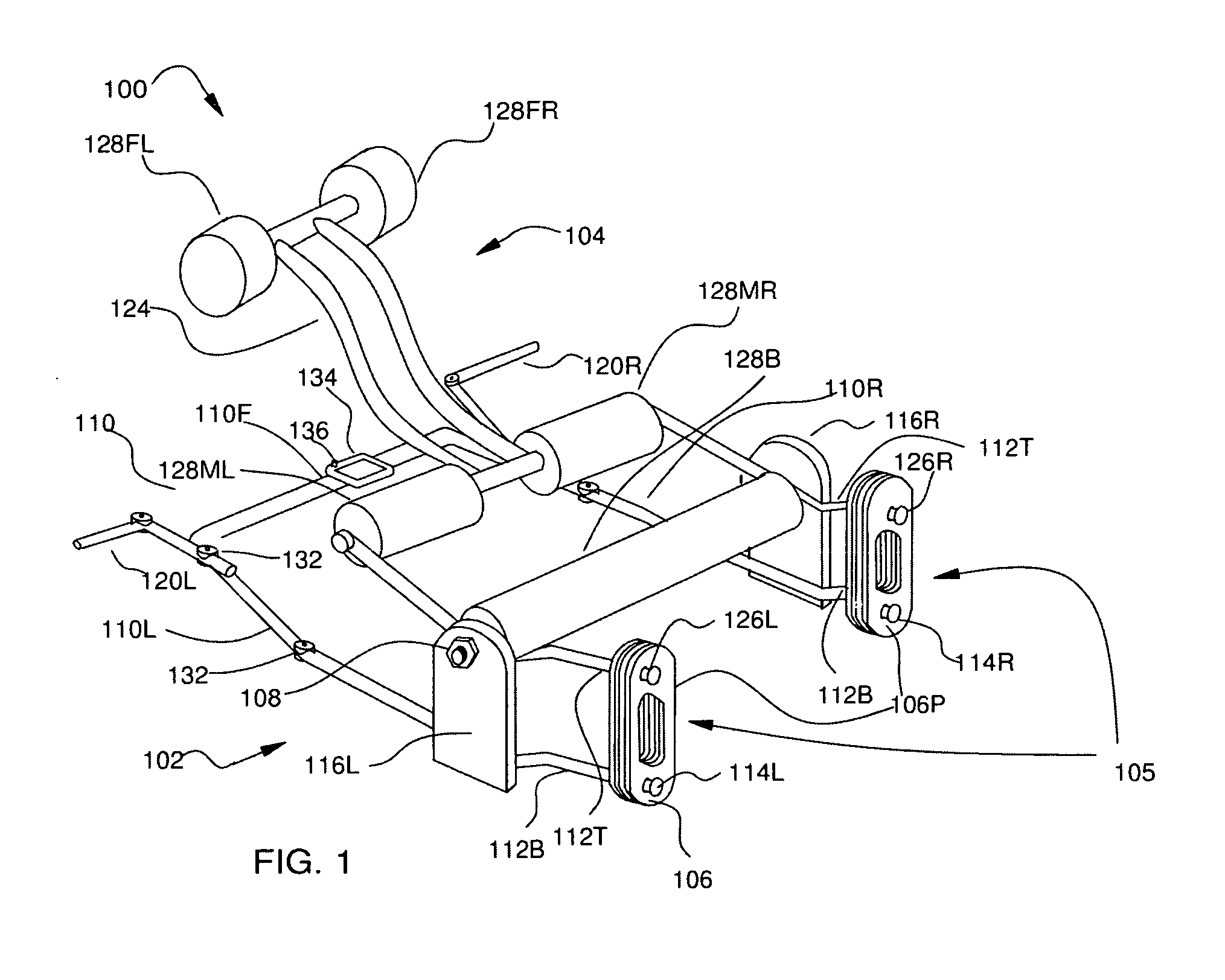

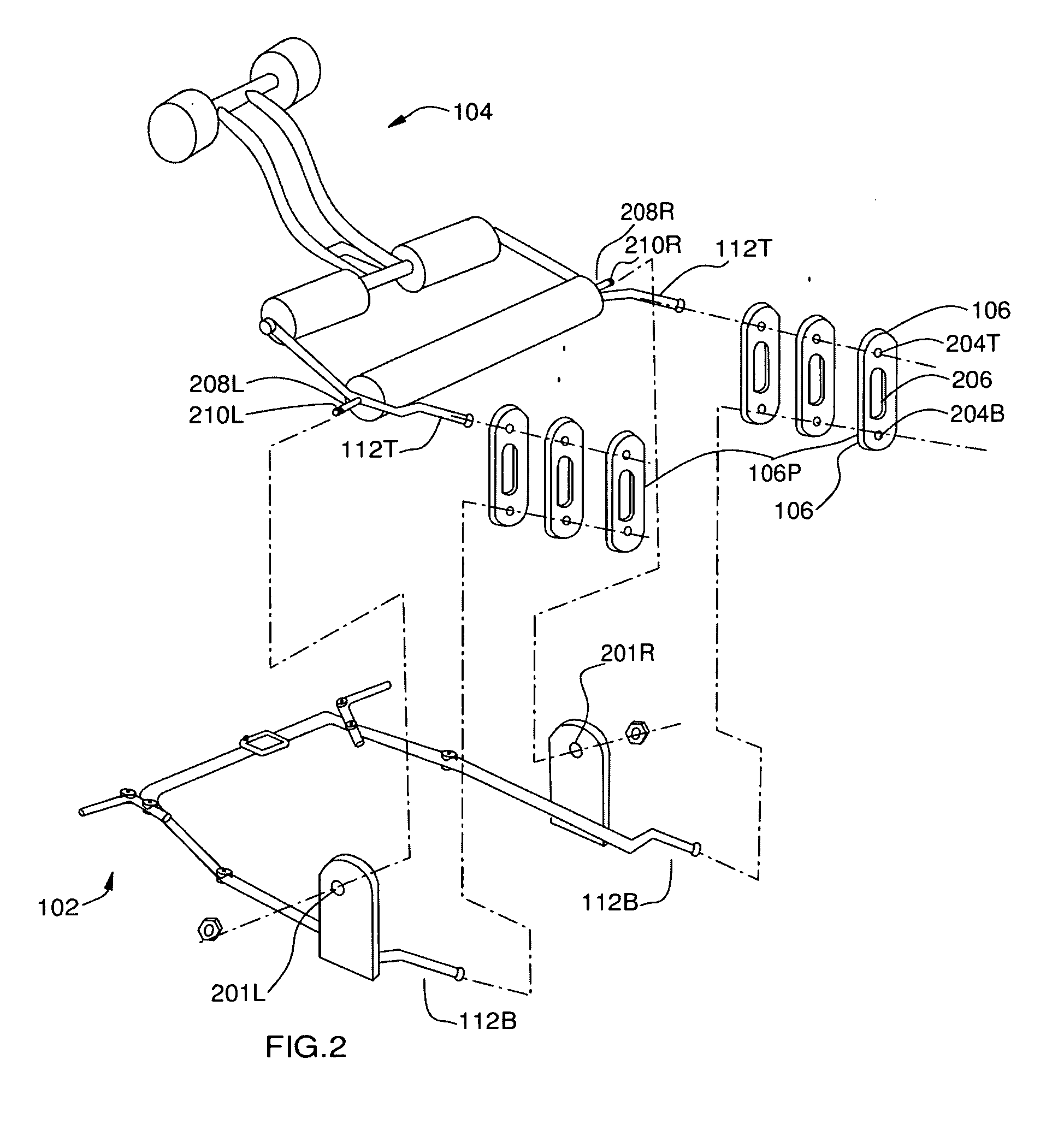

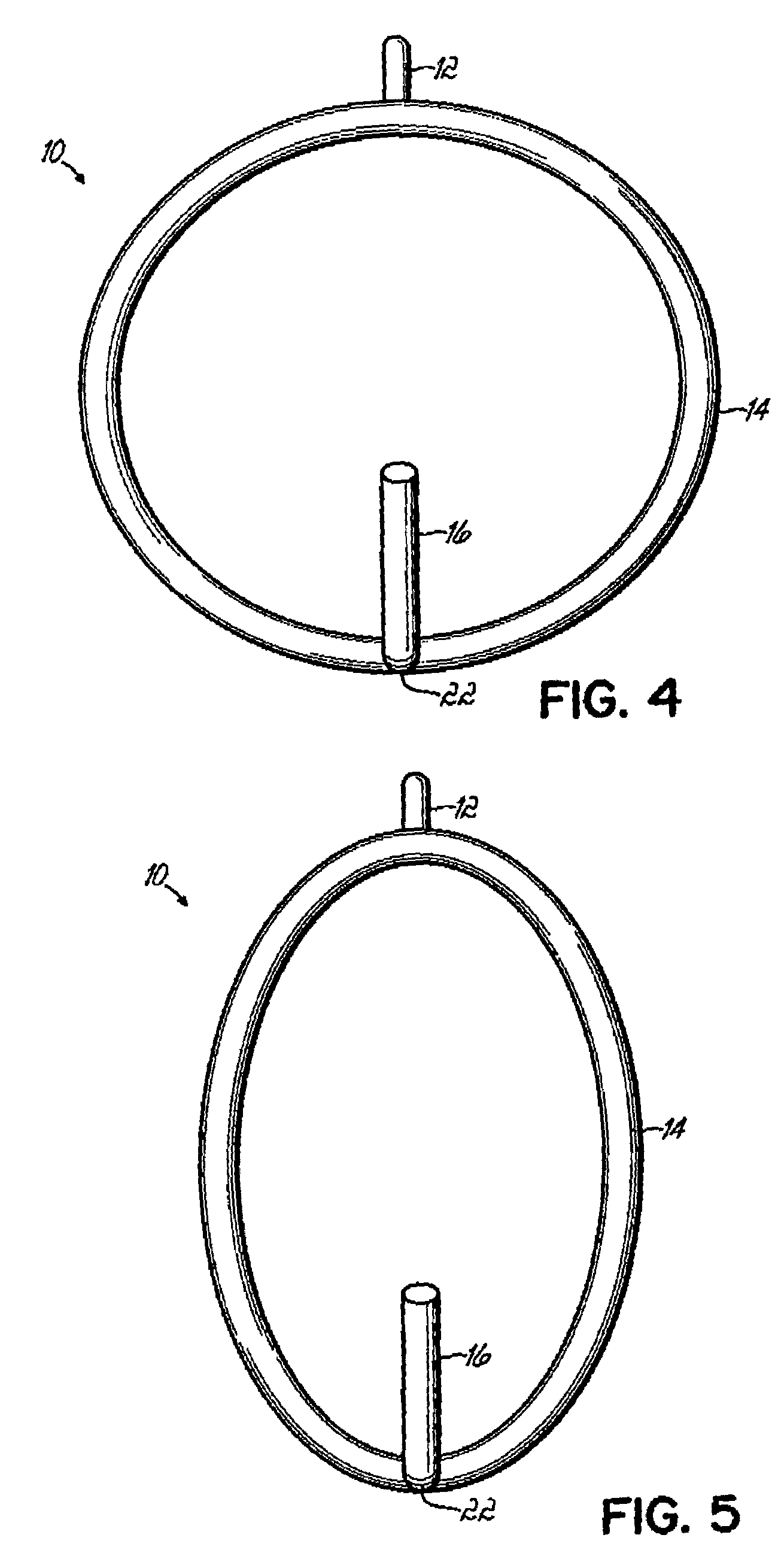

Exercise apparatus and method with selectively variable stabilization

ActiveUS20090170675A1Offsetting weightHigh strengthMuscle exercising devicesMuscle strengthSmall footprint

Exercise apparatus and method with selectively variable stabilization enabling a user to progressively increase his / her core body muscular strength. In various embodiments, the exercise apparatus includes a resistance cabling system providing a user defined line of motion, and a partial stabilizer pad being adjustably positionable offset from the line of motion, wherein the user's core body is positionable against the pad and required to resist the torque created by the offset. The user can progressively increase the distance between the line of motion and partial stabilizer pad, in order to progressively increase the force which the user's core body must resist to maintain an upright stature. In this way, the user can progressively, over time, increase his or her core body strength. A vertically and rotatably adjustable handle / arm assembly, resistance cabling and pulley assembly, and an overall exercise apparatus having a relatively small footprint but allowing multiple variable exercise routines, are also provided.

Owner:CYBEX INTERNATIONAL

Exercise Apparatus

Exercise apparatus and method with selectively variable stabilization enabling a user to progressively increase his / her core body muscular strength. In various embodiments, the exercise apparatus includes a resistance cabling system providing a user defined line of motion, and a partial stabilizer pad being adjustably positionable offset from the line of motion, wherein the user's core body is positionable against the pad and required to resist the torque created by the offset. The user can progressively increase the distance between the line of motion and partial stabilizer pad, in order to progressively increase the force which the user's core body must resist to maintain an upright stature. In this way, the user can progressively, over time, increase his or her core body strength. A vertically and rotatably adjustable handle / arm assembly, resistance cabling and pulley assembly, and an overall exercise apparatus having a relatively small footprint but allowing multiple variable exercise routines, are also provided.

Owner:CYBEX INTERNATIONAL

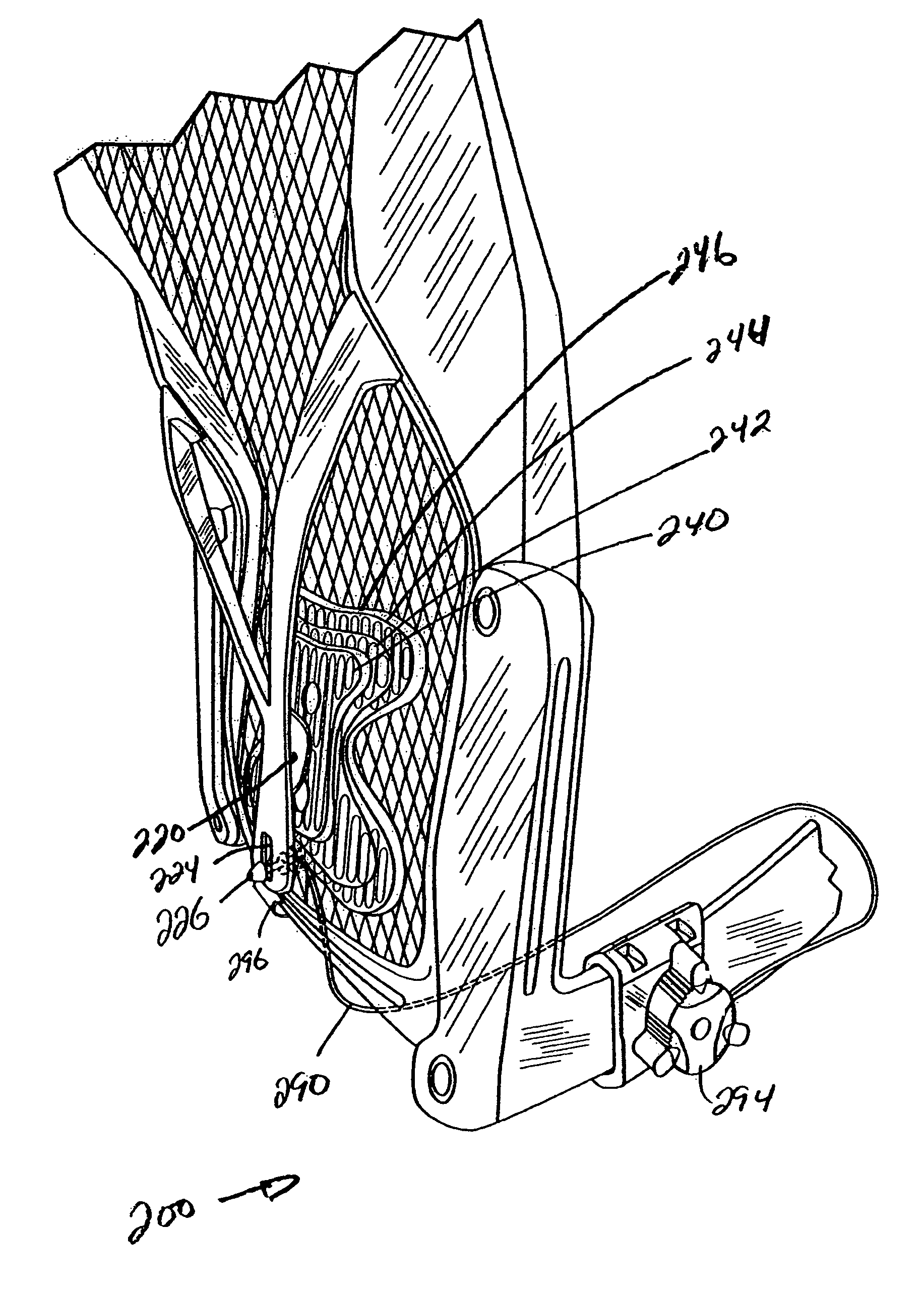

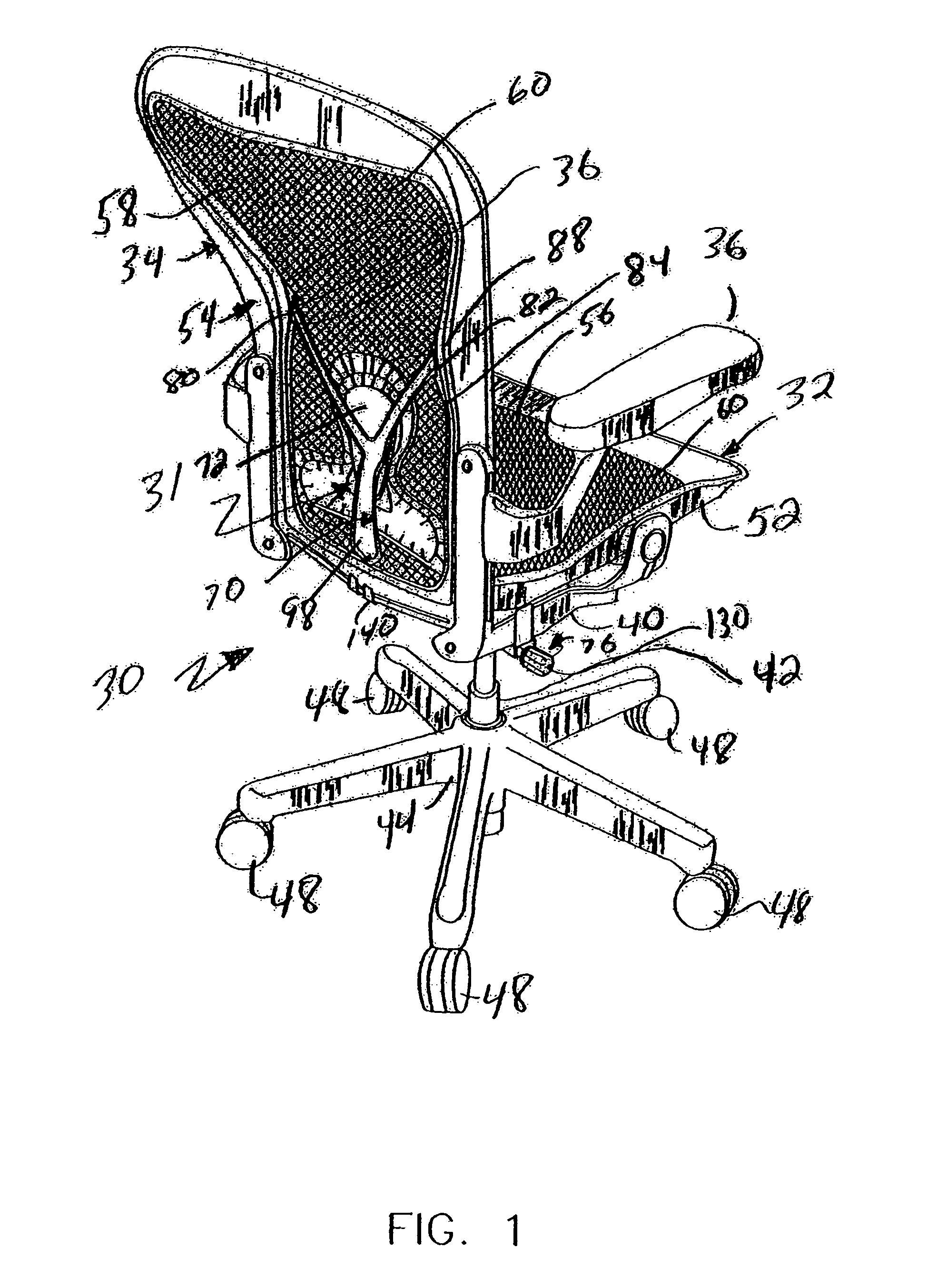

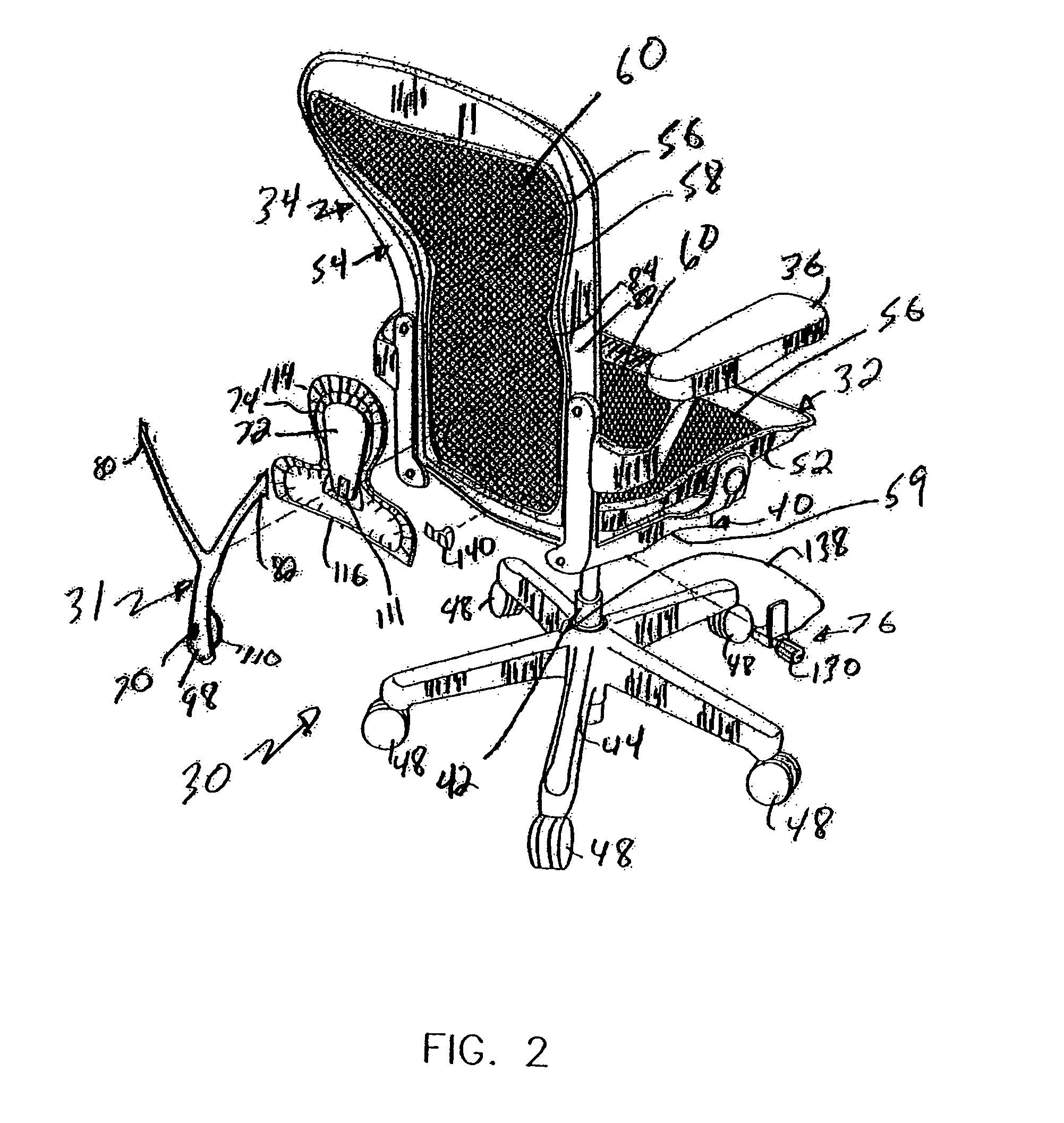

Sacral support member for seating

InactiveUS7878591B2Prevents posterior rotationPromoting a lordotic lumbar spineStoolsAdjustable chairsSacrumEngineering

A chair for providing sacral support including a seat, a backrest, a flexible support member and a sacral support member. The backrest has a frame with a generally central opening. The membrane is formed from an elastic material connected to the frame and extends across the central opening. A sacral support member is positioned proximate the central opening and is configured to apply support to the sacrum of a user sitting on the seat. The sacral support member incorporates a load distribution system and method in order to properly support and fit the anatomical contours of the sacrum and pelvis of a user while seated in the chair.

Owner:MILLERKNOLL INC

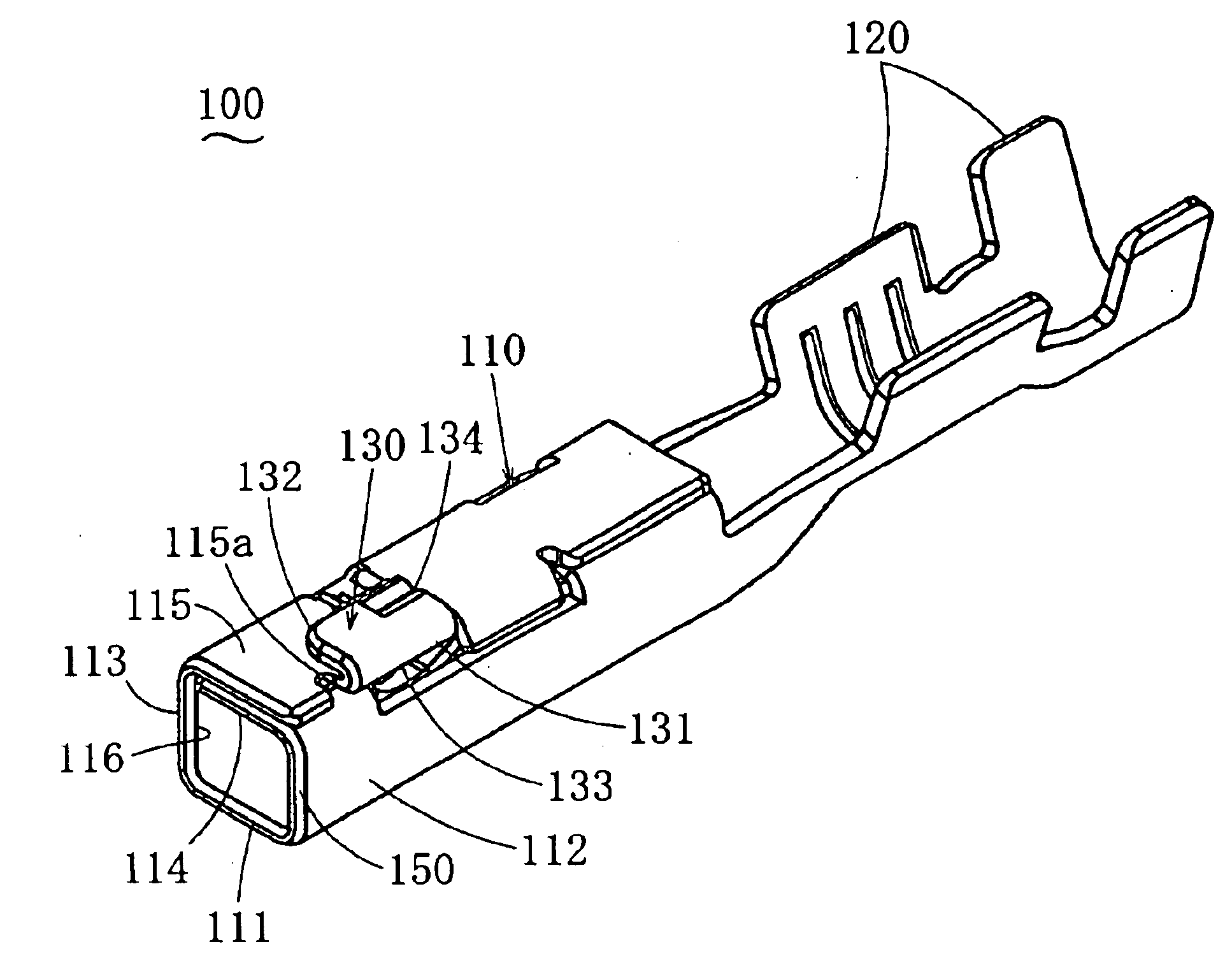

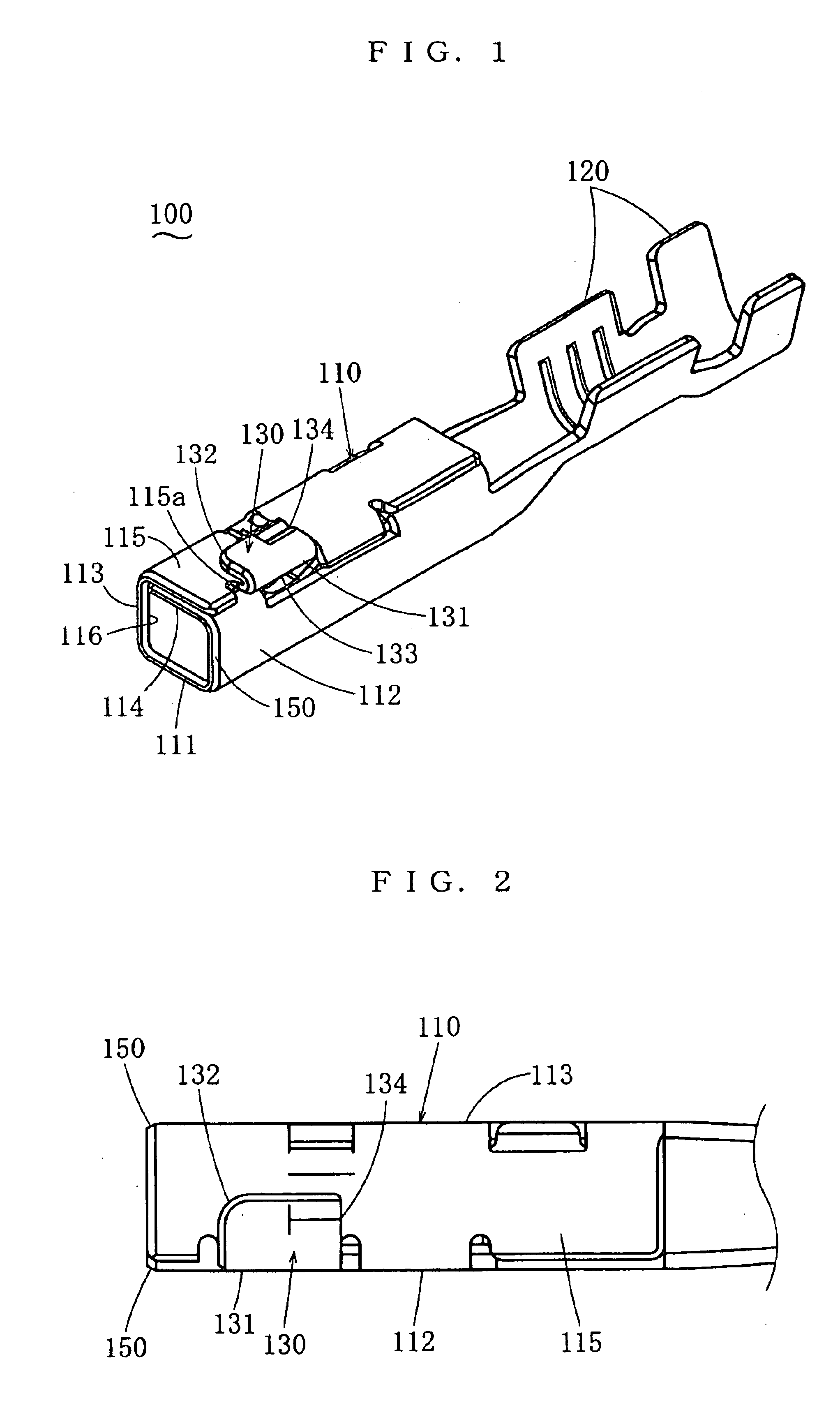

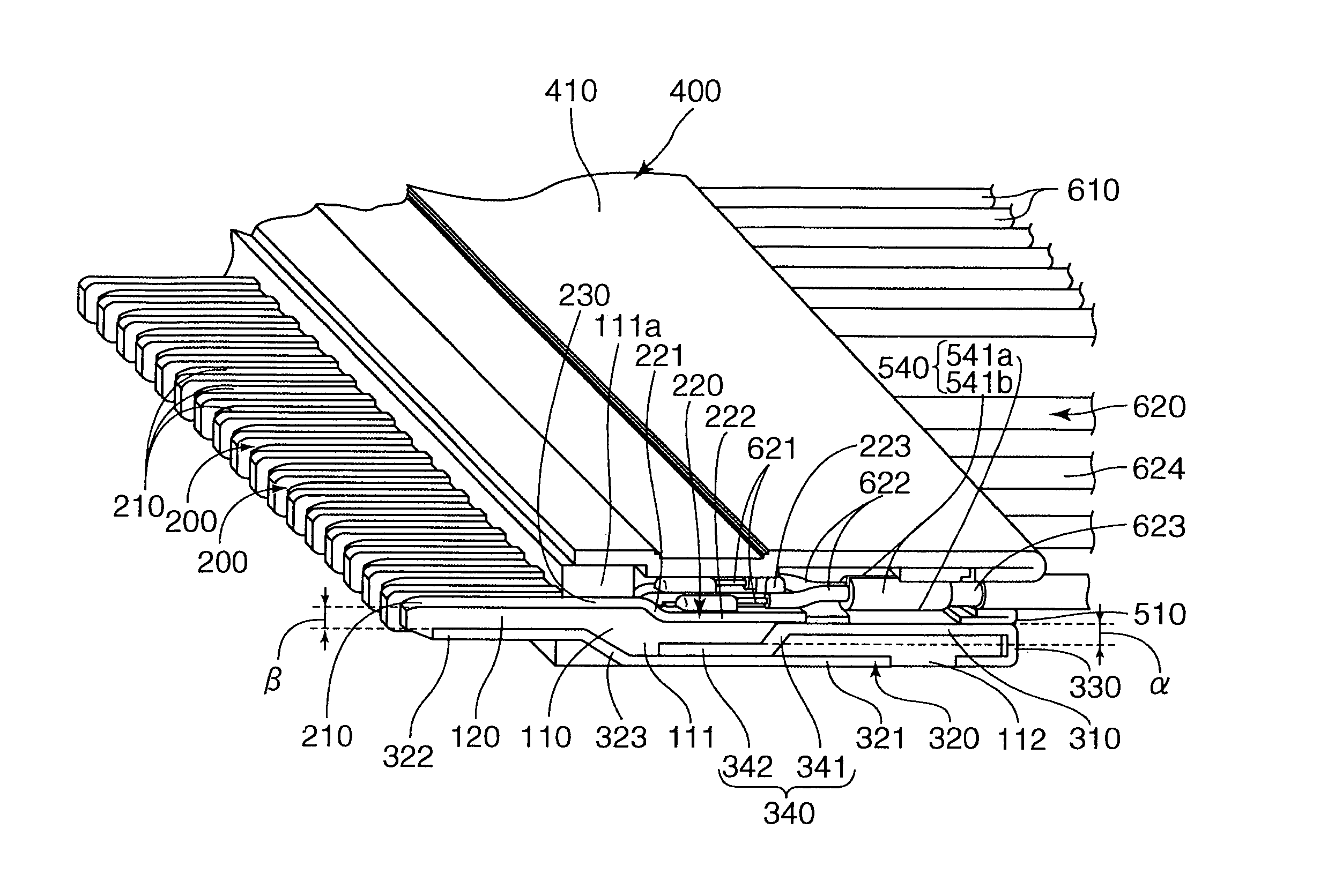

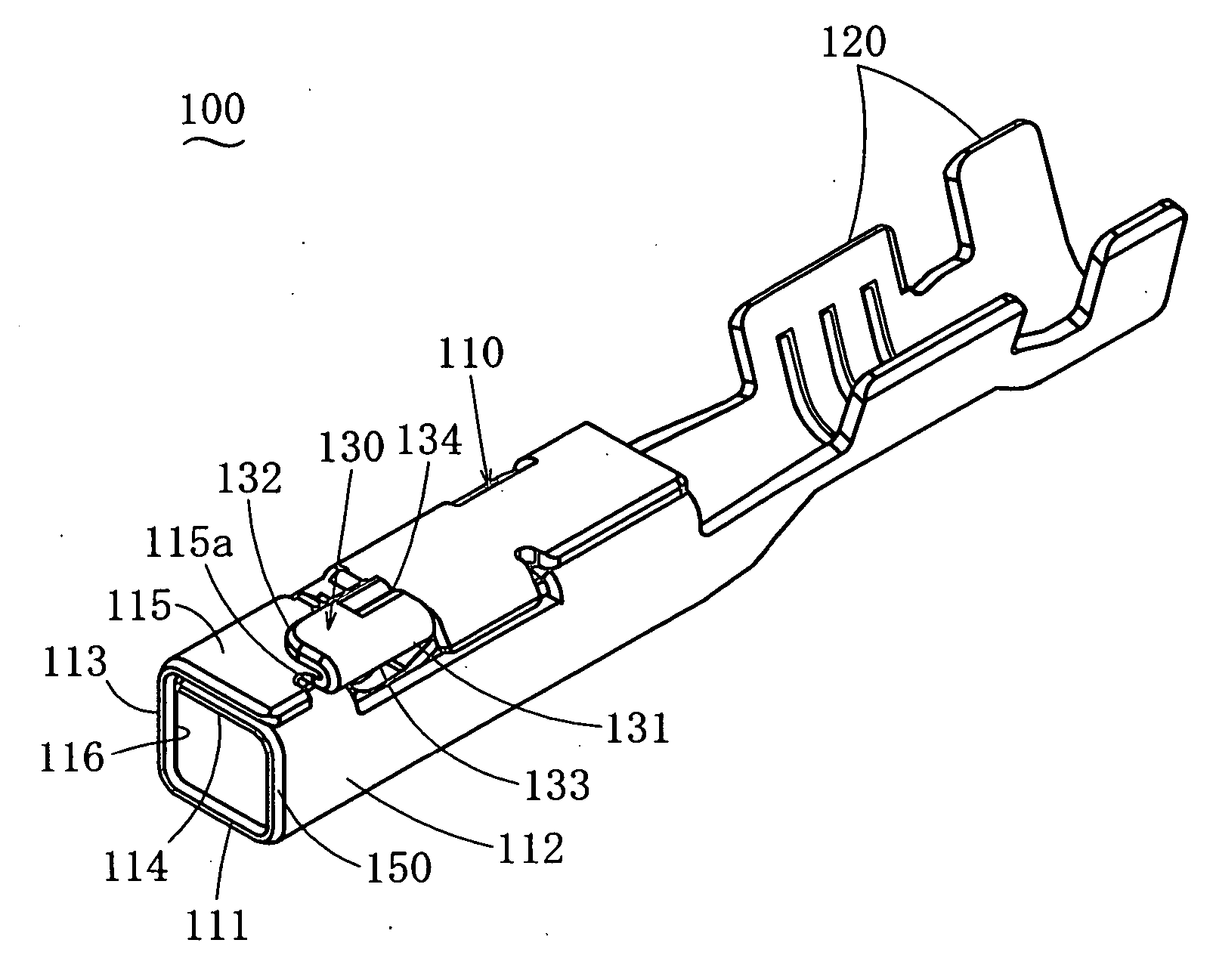

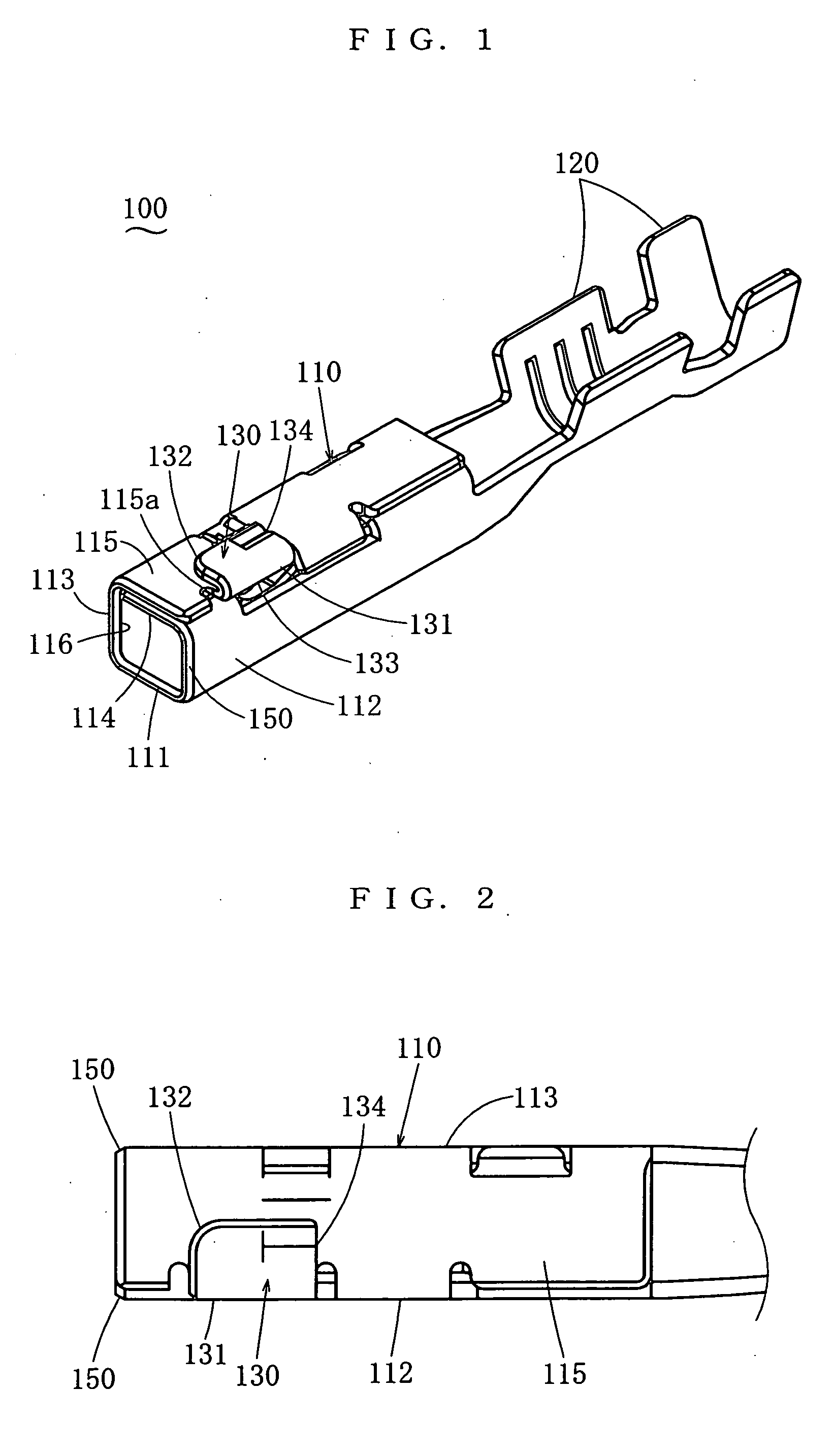

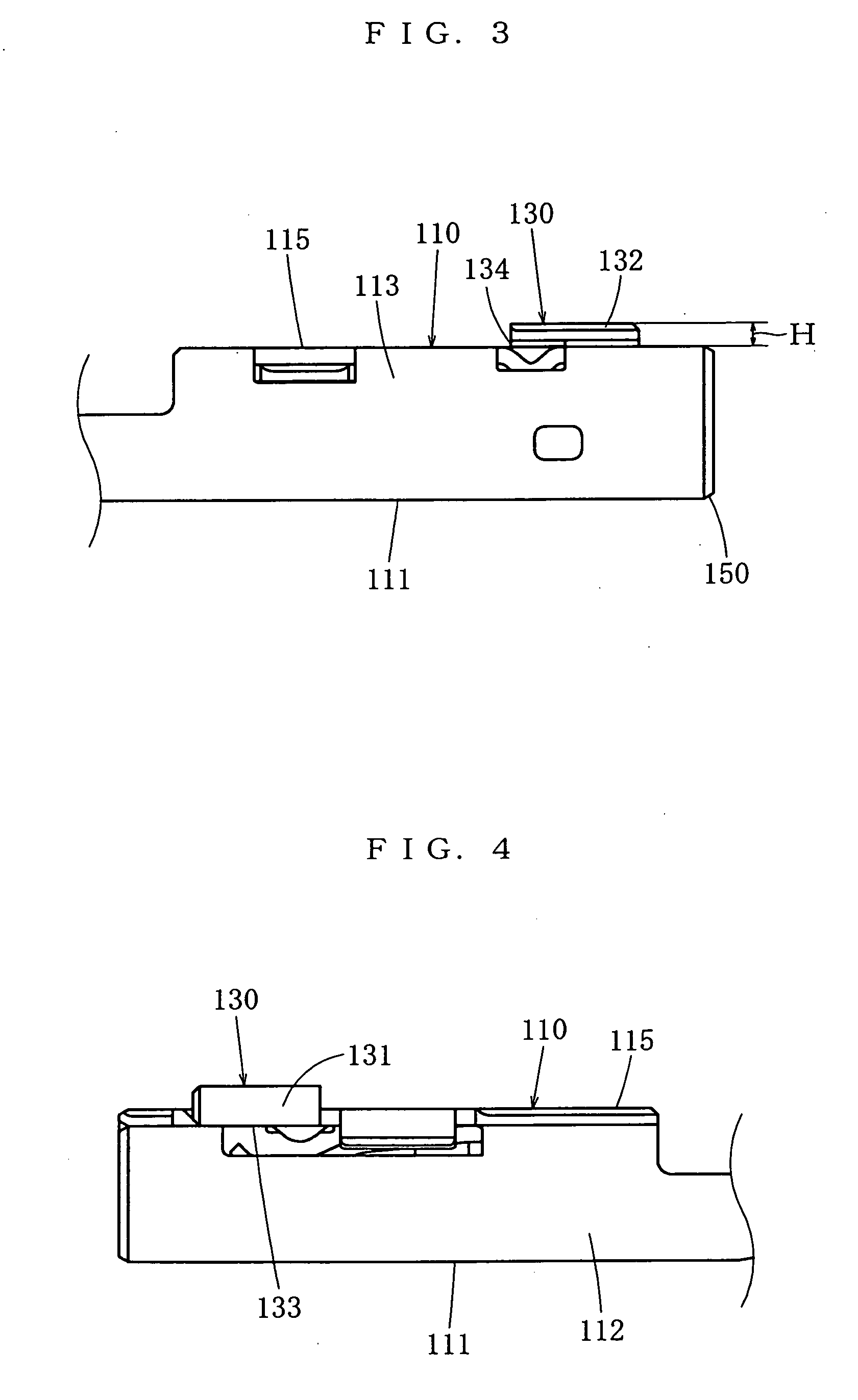

Terminal

ActiveUS6905376B2Reduce loadAvoid deformationSecuring/insulating coupling contact membersCoupling contact membersEngineeringMechanical engineering

Owner:JST MFG CO LTD

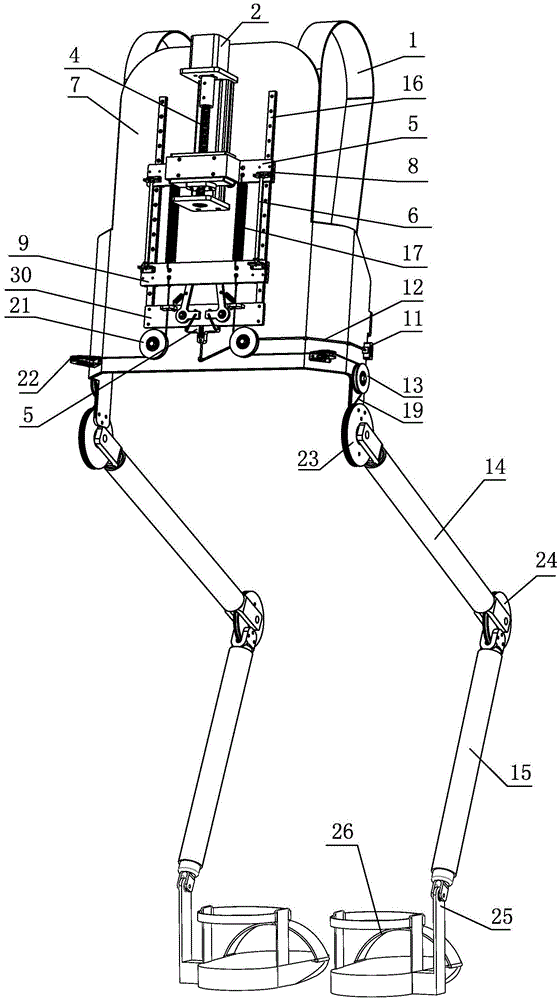

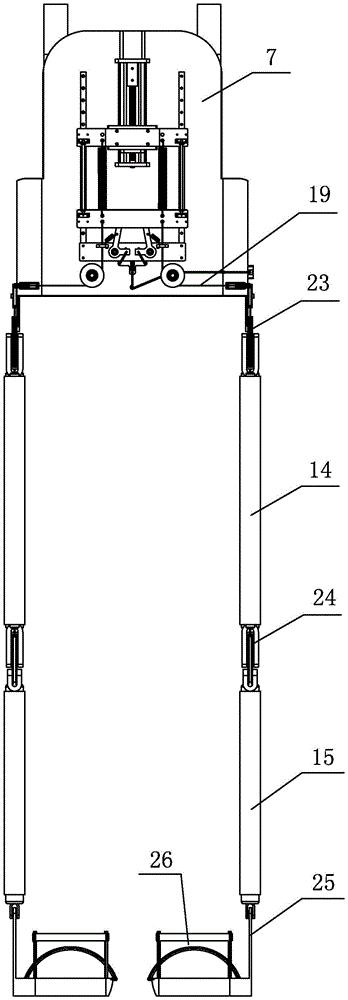

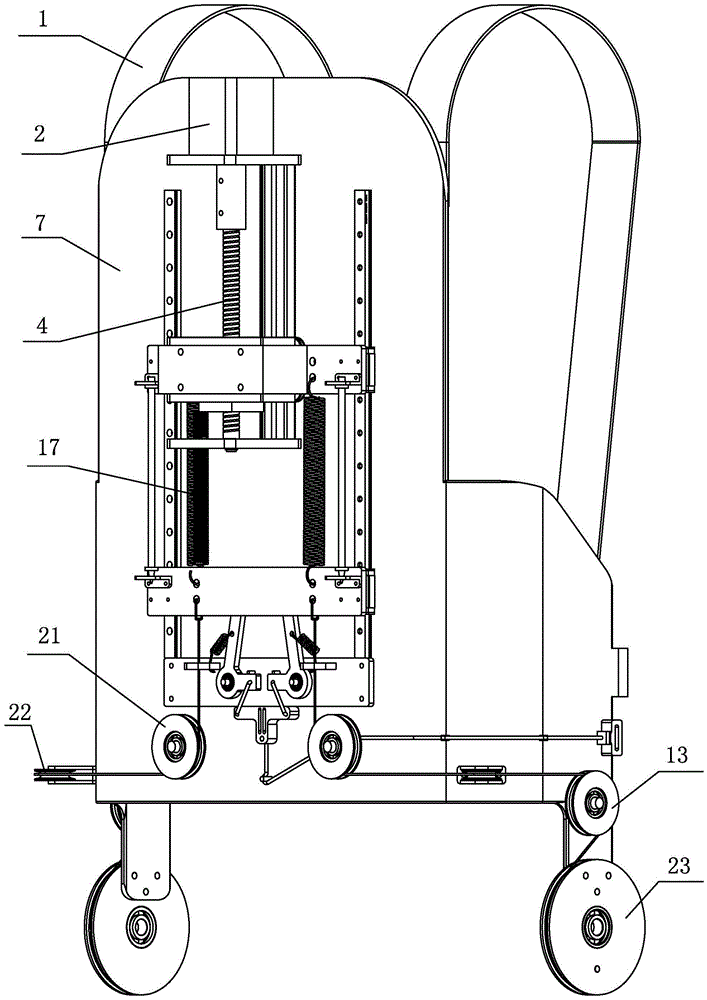

Exoskeleton with function of assisting in jumping through energy storage of springs

ActiveCN105479438AImprove explosive powerIncrease jump heightProgramme-controlled manipulatorThighKnee Joint

The invention discloses an exoskeleton with the function of assisting in jumping through energy storage of springs, relates to an exoskeleton, and solves the problems that a conventional exoskeleton is mainly used for enhancing walking or running, and an exoskeleton used for improving the simple exercise capacity of a human body has not yet been provided. The exoskeleton comprises a left leg, a right leg and a back. Both the left leg and the right leg comprise thighs, calves, feet, hip joints, knee joints and ankle joints. The back is rotationally connected with the thighs through the hip joints. The thighs are rotationally connected with the calves through the knee joints. The calves are rotationally connected with the feet through the ankle joints. The exoskeleton further comprises a driving motor, a lead screw pair, an energy storage spring pulling plate, an energy storage spring releasing plate, a pull ring, a stay cord, a connecting plate, an auxiliary pressure spring mechanism, return poking rods, two hooks, two guide rails, two energy storage springs, two reset springs, two first traction driving steel wire ropes, two second traction driving steel wire ropes, two auxiliary pulleys, two reserving pulleys and two connecting rods. The exoskeleton is used for assisting in walking or jumping.

Owner:HARBIN INST OF TECH

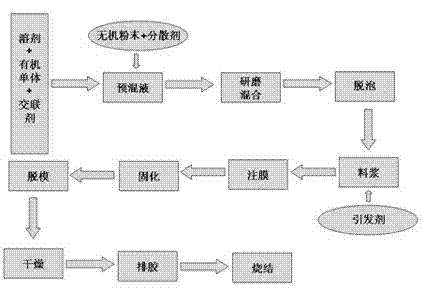

Collidal forming process for preparing high strength light ceramic material

The present invention belongs to the field of ceramic material preparing technology, and is especially colloidal state forming process for preparing light high strength ceramic material. The process includes the following steps: preparing suspension with very low solid phase content with special organic monomer, solvent, initiator or chelating agent, and ceramic powder; in-situ solidification through gel polymerization of monomer or high molecular cross-linking to obtain ceramic biscuit; drying, removing binder and no-pressure high temperature sintering to obtain light high strength ceramic material. The present invention can control the porosity and pore size of the ultimate product through altering the solid phase content in the suspension, the sintering condition and the powder size. The present invention has simple technological process, low cost, environment friendship and other advantages, and the produced ceramic material has wide application range.

Owner:TSINGHUA UNIV

Preparation method of highly oriented tube-shaped through hole porous ceramics

The invention relates to a preparation method of a highly oriented tube-shaped through hole porous ceramic, belonging to the technical field of ceramics. The method is implemented by using high polymer and ceramic powder as raw material, and tertiary butanol as solvent to prepare suspensoid; adding solvent modifier into the suspensoid followed by mixing evenly, injection molding, freezing, curing and forming, transferring into a freezer dryer after de-molding, disintegrating and sintering to obtain ceramic material with through hole length reaching 3-10mm, hole structure being of long tube shape or needle shape and no dendritic forks. Different from the traditional pore-forming method, the invention requires no addition of any pore-former, the solvent forms long column shape crystal to penetrate through a green body, a pore template is formed in the green body, and ceramic powder particles are extruded in the vertical direction of the crystal growth in the crystallization process, meanwhile due to the addition of little amount of adhesive, the ceramic powder particles are adhered tightly, besides, the sublimation and deprivation process of the solvent means applying certain strain on the ceramic powder particles, therefore, the prepared green body is low in density and high in strength.

Owner:TSINGHUA UNIV

Exercise apparatus and method with selectively variable stabilization

Exercise apparatus and method with selectively variable stabilization enabling a user to progressively increase his / her core body muscular strength. In various embodiments, the exercise apparatus includes a resistance cabling system providing a user defined line of motion, and a partial stabilizer pad being adjustably positionable offset from the line of motion, wherein the user's core body is positionable against the pad and required to resist the torque created by the offset. The user can progressively increase the distance between the line of motion and partial stabilizer pad, in order to progressively increase the force which the user's core body must resist to maintain an upright stature. In this way, the user can progressively, over time, increase his or her core body strength. A vertically and rotatably adjustable handle / arm assembly, resistance cabling and pulley assembly, and an overall exercise apparatus having a relatively small footprint but allowing multiple variable exercise routines, are also provided.

Owner:CYBEX INTERNATIONAL

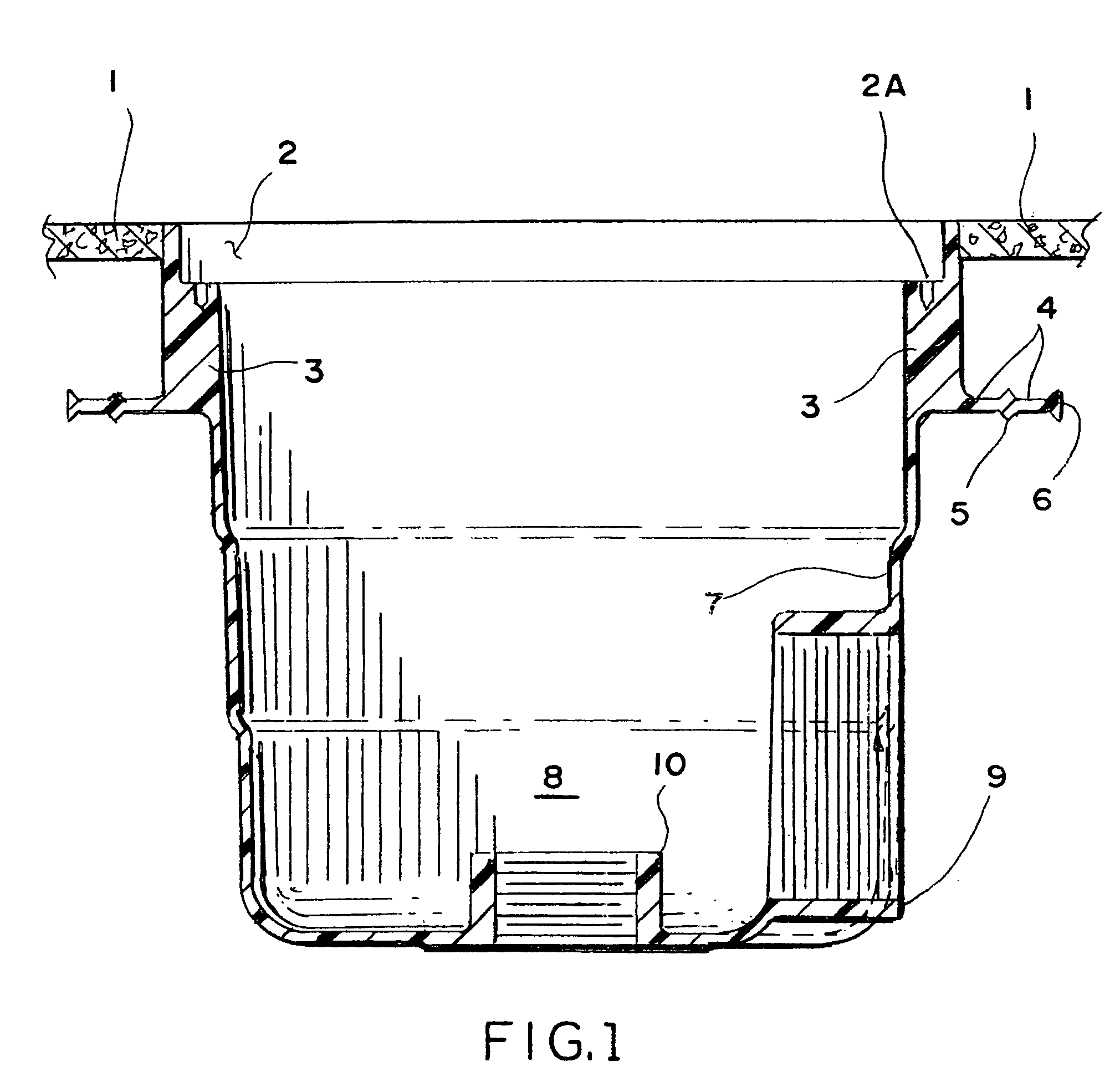

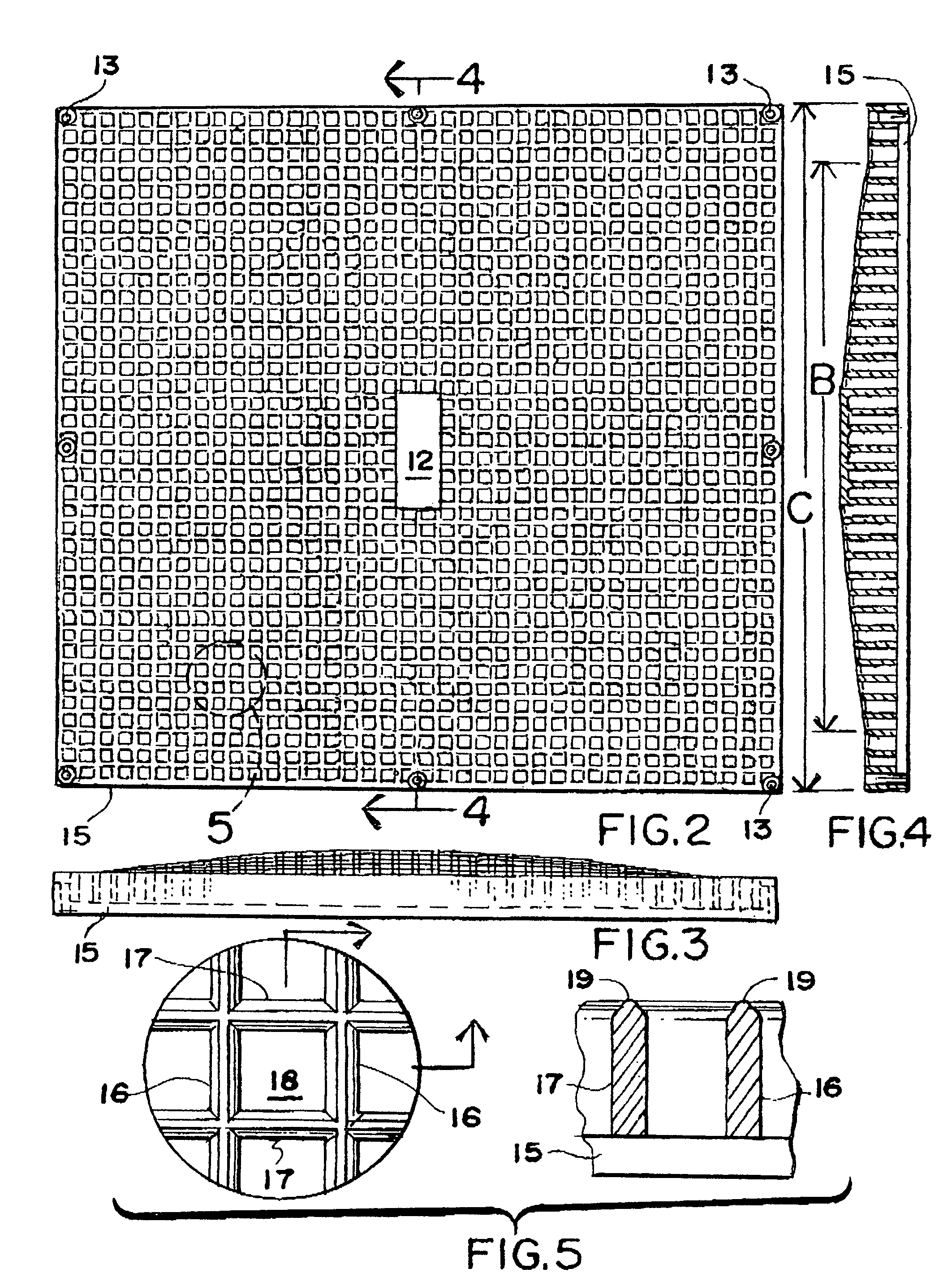

Sump grate for a swimming pool

ActiveUS7419588B2Improve body strengthFatty/oily/floating substances removal devicesSewerage structuresWaste managementSump

A grate cover in combination with a swimming sump being installed in a recess in the top of the sump. The grate cover having a multiple of interstices or openings there through. The size of the interstices being held to a minimum so that fingers of a human cannot be sucked into the openings. The top surface of the grate cover has a curvature thereon while the bottom surface is flat. This way, the forceful suction within the sump cannot obtain enough force to suction the skin of a human against the grate cover to cause any injuries.

Owner:HYDROTECH A CALIFORNIA

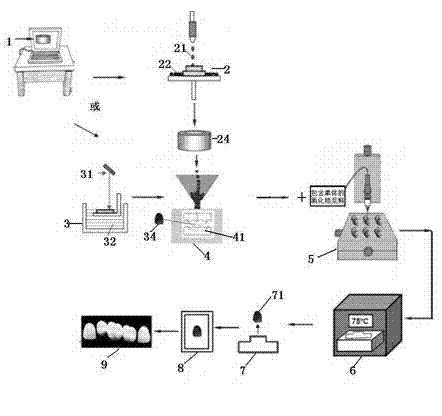

Method for producing zirconia denture through rapid prototype of gel-casting

InactiveCN102755199AHigh material utilizationImprove production efficiencyArtificial teethComputer Aided DesignDentures

The invention discloses a method for producing zirconia denture through rapid prototype of gel-casting. The method comprises the following steps of step one, collecting three-dimensional data of an oral cavity through a computer to generate a three-dimensional computer-aided design (CAD) virtue model of the required denture; step two, producing a male die of the required denture according to the three-dimensional CAD virtue model obtained in the step one; step three, producing a female die by wrapping the male die obtained in the step two; step four, injecting zirconia colloidal slurry into the female die obtained in the step three through a gel-casting process, and performing heating to induce a polymerization reaction to enable the zirconia colloidal slurry to be cured; step five, demoulding and drying the cured zirconia to obtained a blank of the required denture; and step six, sintering the blank to obtain the zirconia denture. The method for producing the zirconia denture through the rapid prototype of the gel-casting has the advantages of being high in material utilization rate, producing efficiency and product density, and good in strength.

Owner:SHANGHAI I DENTAL TECH CO LTD

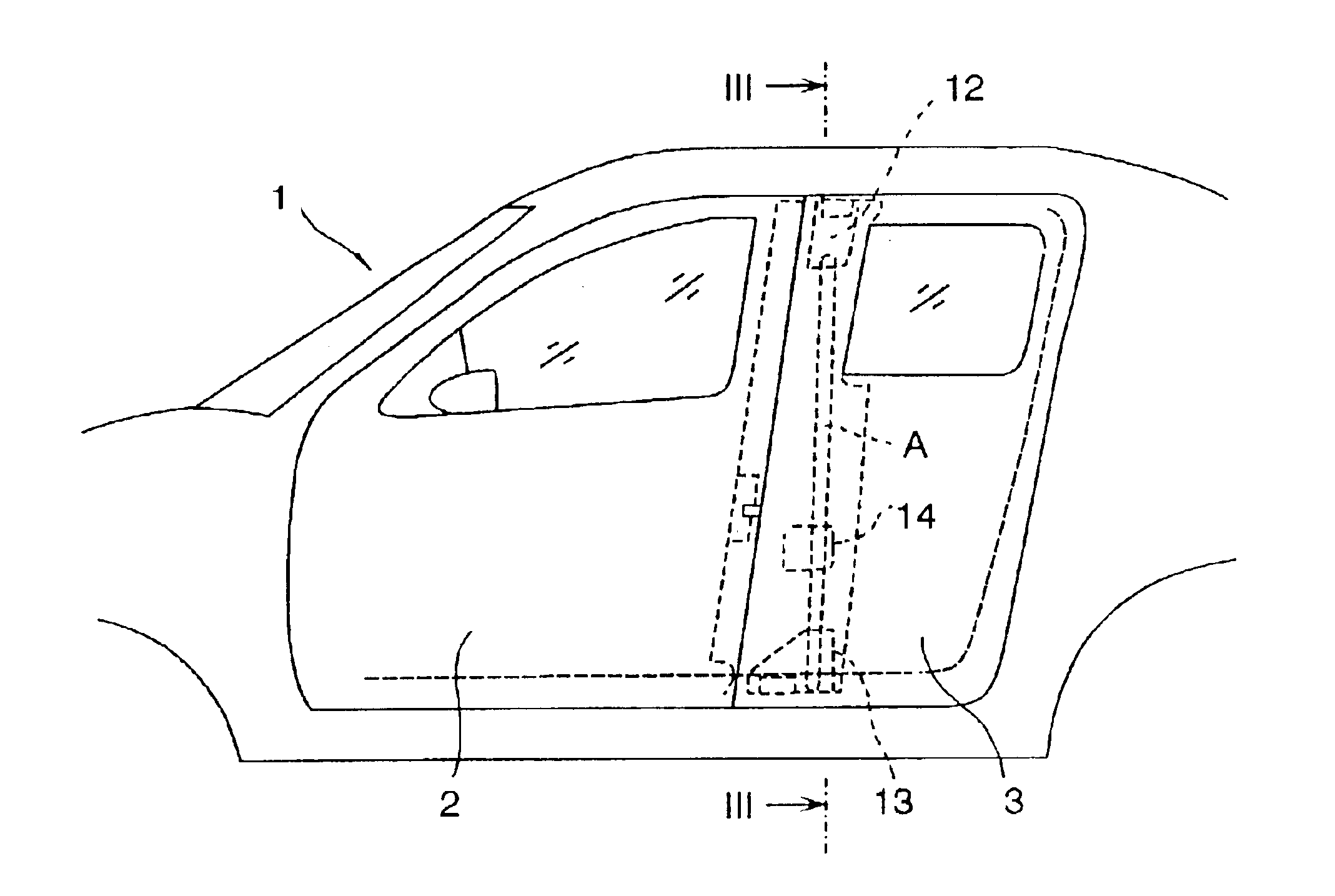

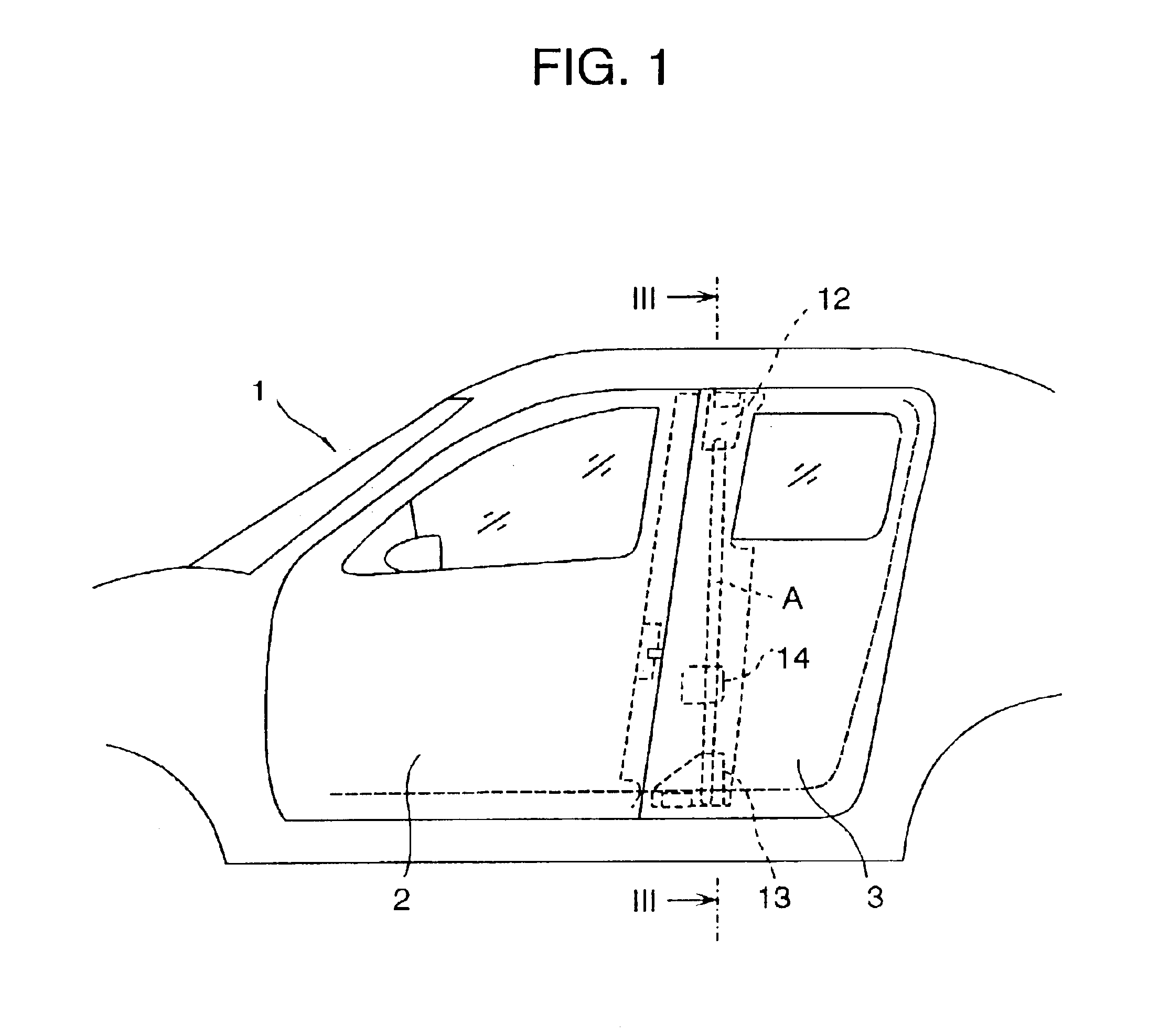

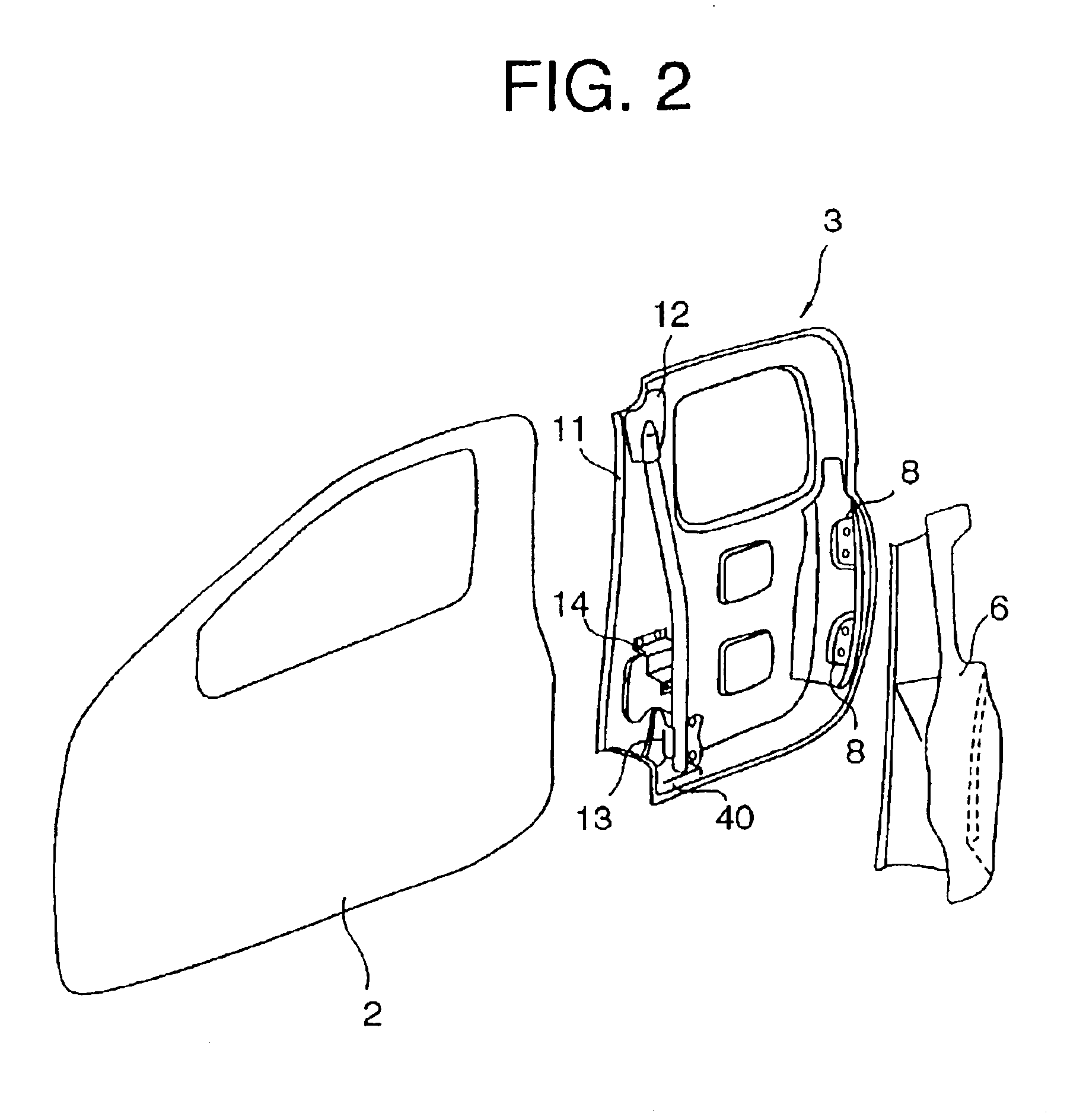

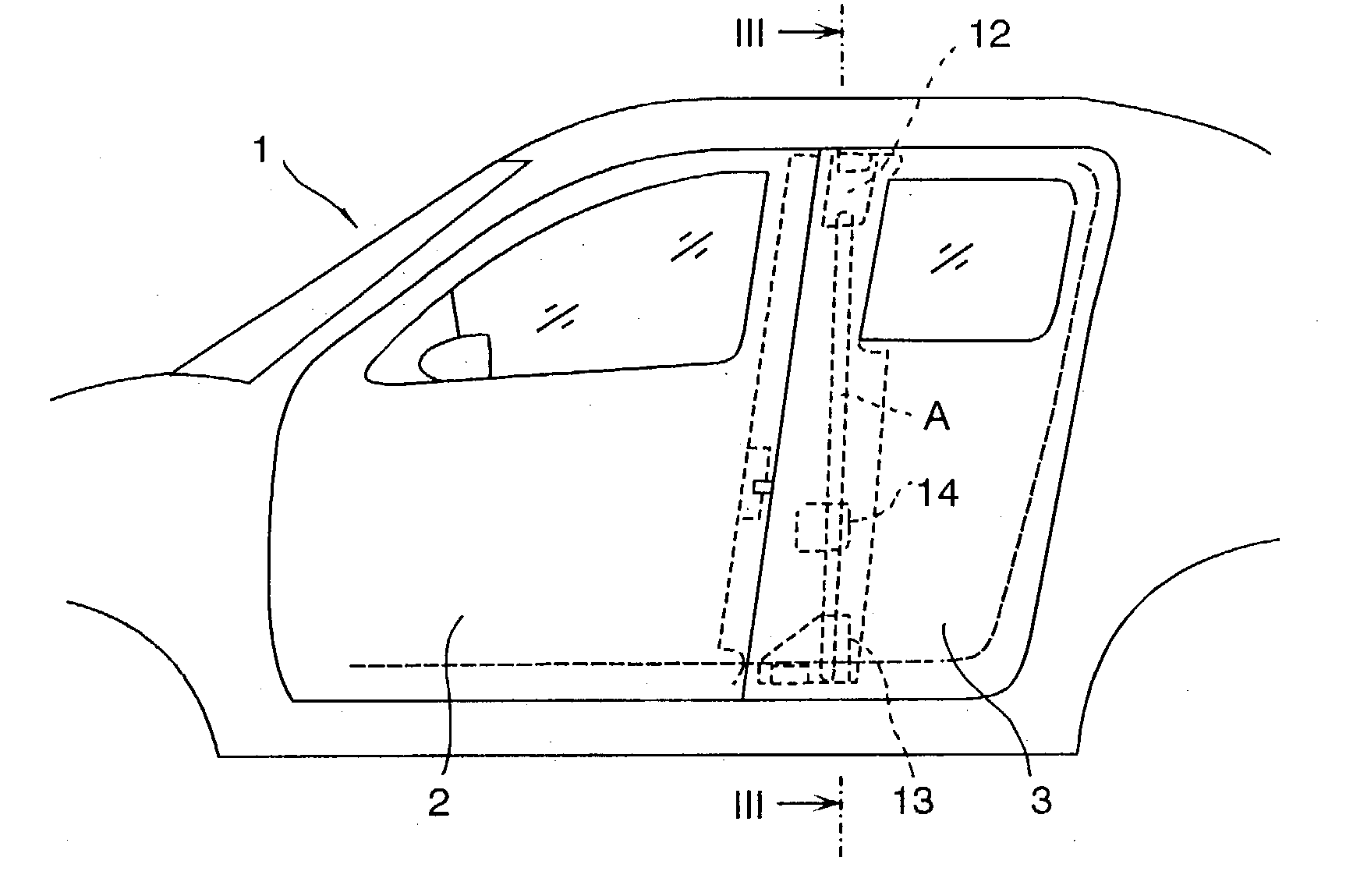

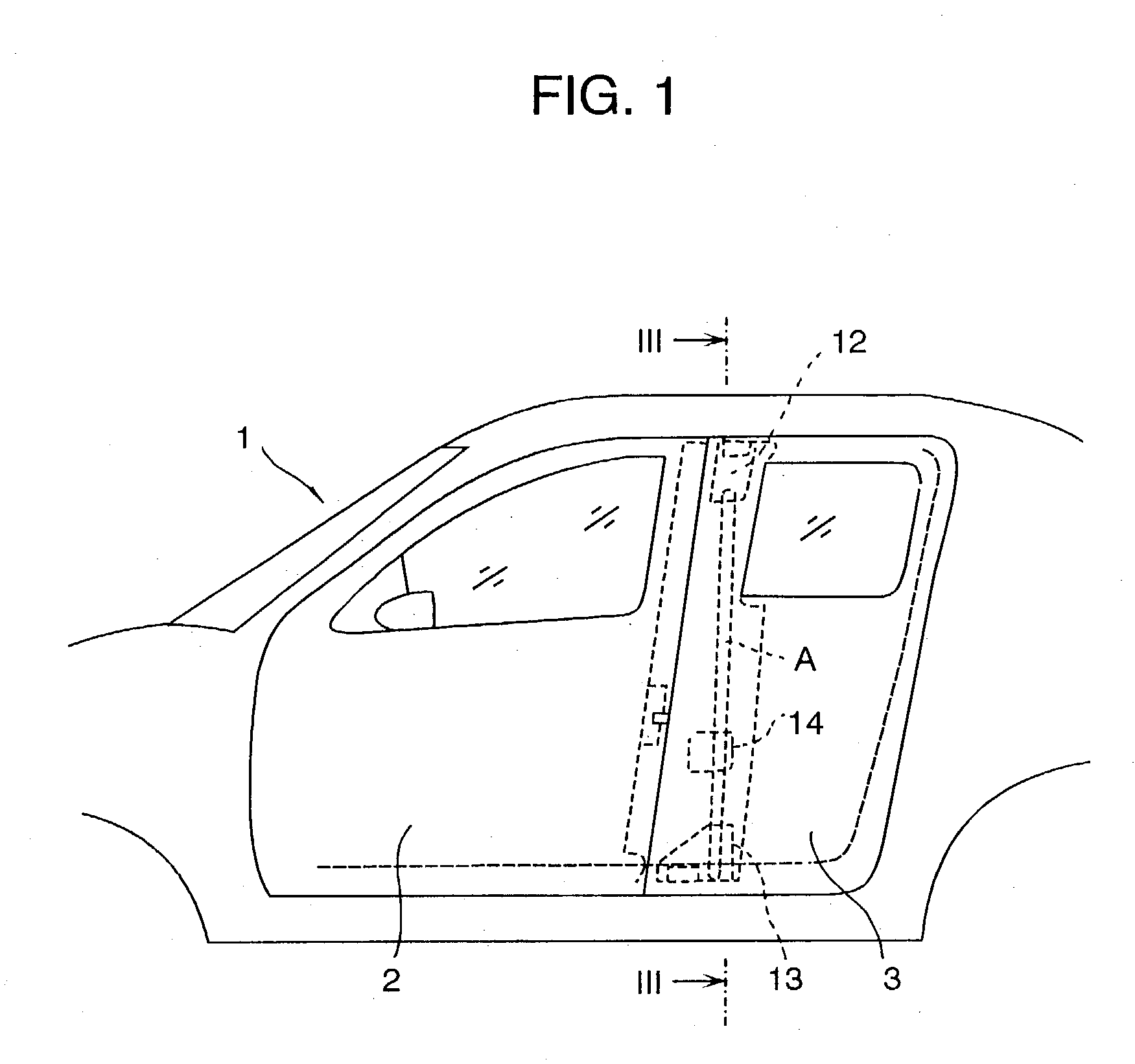

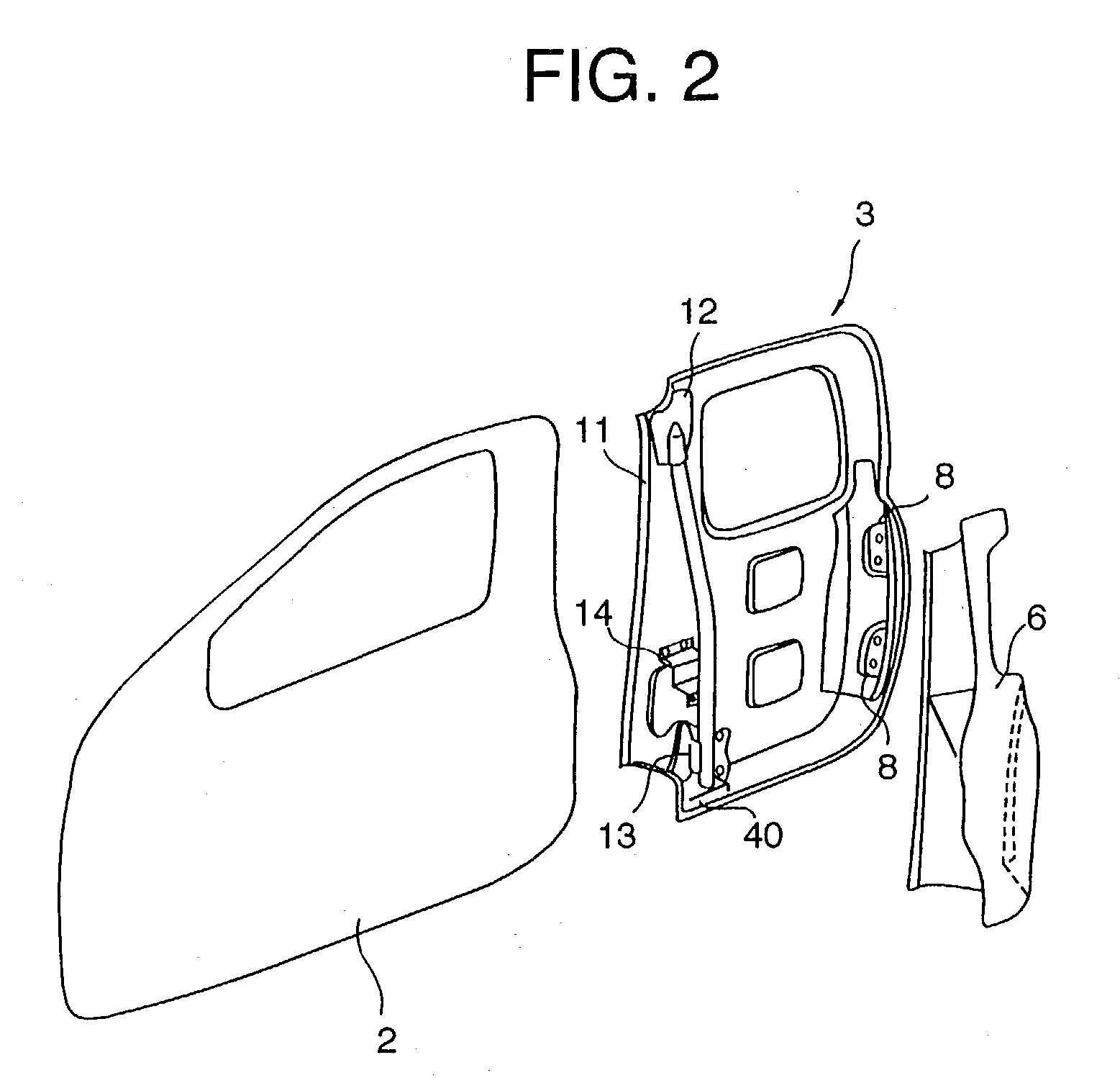

Double door construction for vehicle

A double door structure which has front and rear doors opening outward to form an uninterrupted opening to front and rear seats has an impact load carrying assembly for forming a side body reinforcing structure for protecting passengers against a side collision. The impact load carrying assembly includes an impact bar extending to and overlapping a side sill of a vehicle body, an upper bracket fixedly mounted to the impact bar and located to overlap a roof side rail of the vehicle body and a lower bracket fixedly mounted to the impact bar. The upper bracket mounts a latch and a belt anchor of a seatbelt system thereon and the lower bracket mounts catch pins forming part of a door catch mechanism operative to prevent movement of the door upon an occurrence of a side collision.

Owner:MAZDA MOTOR CORP

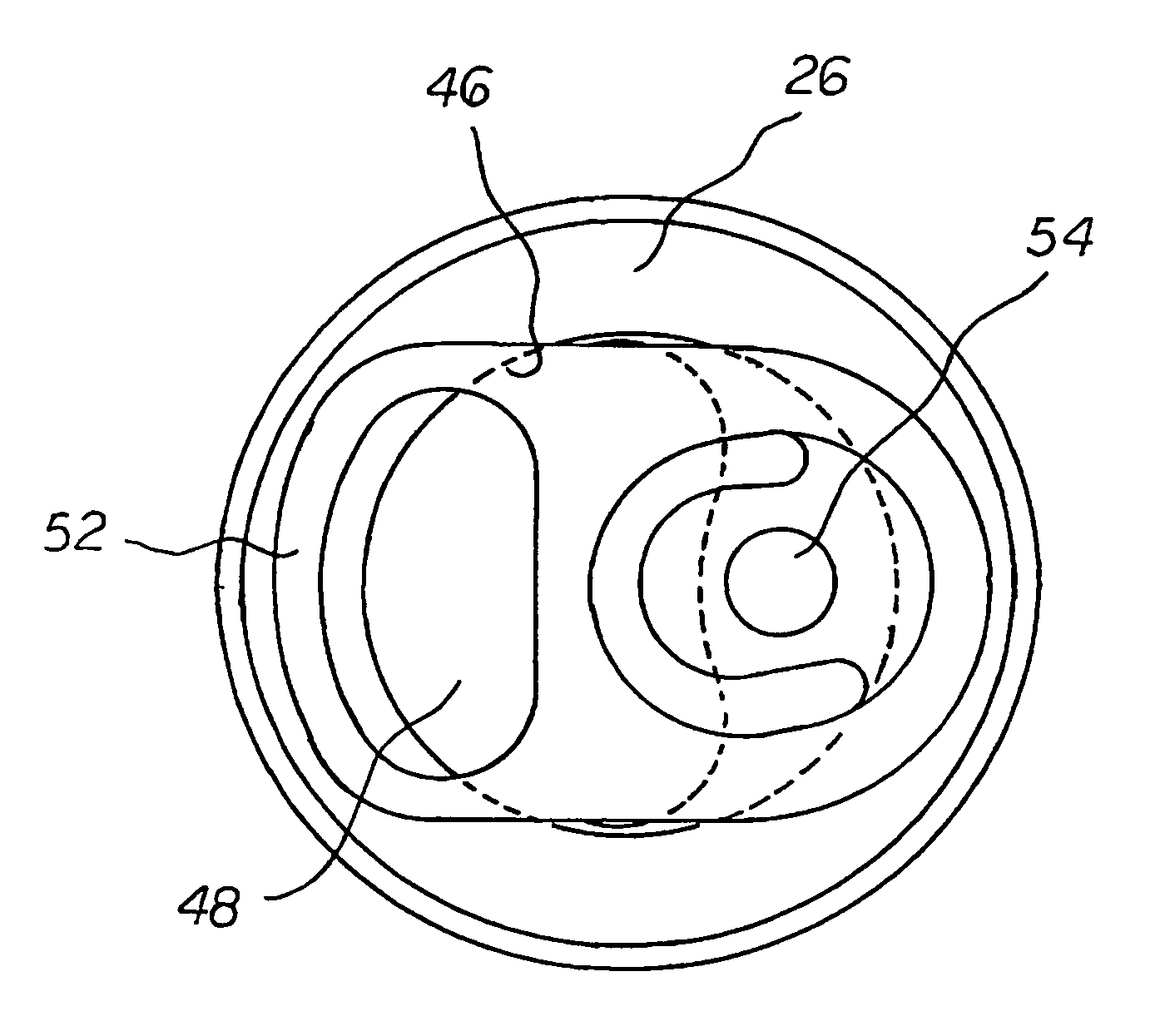

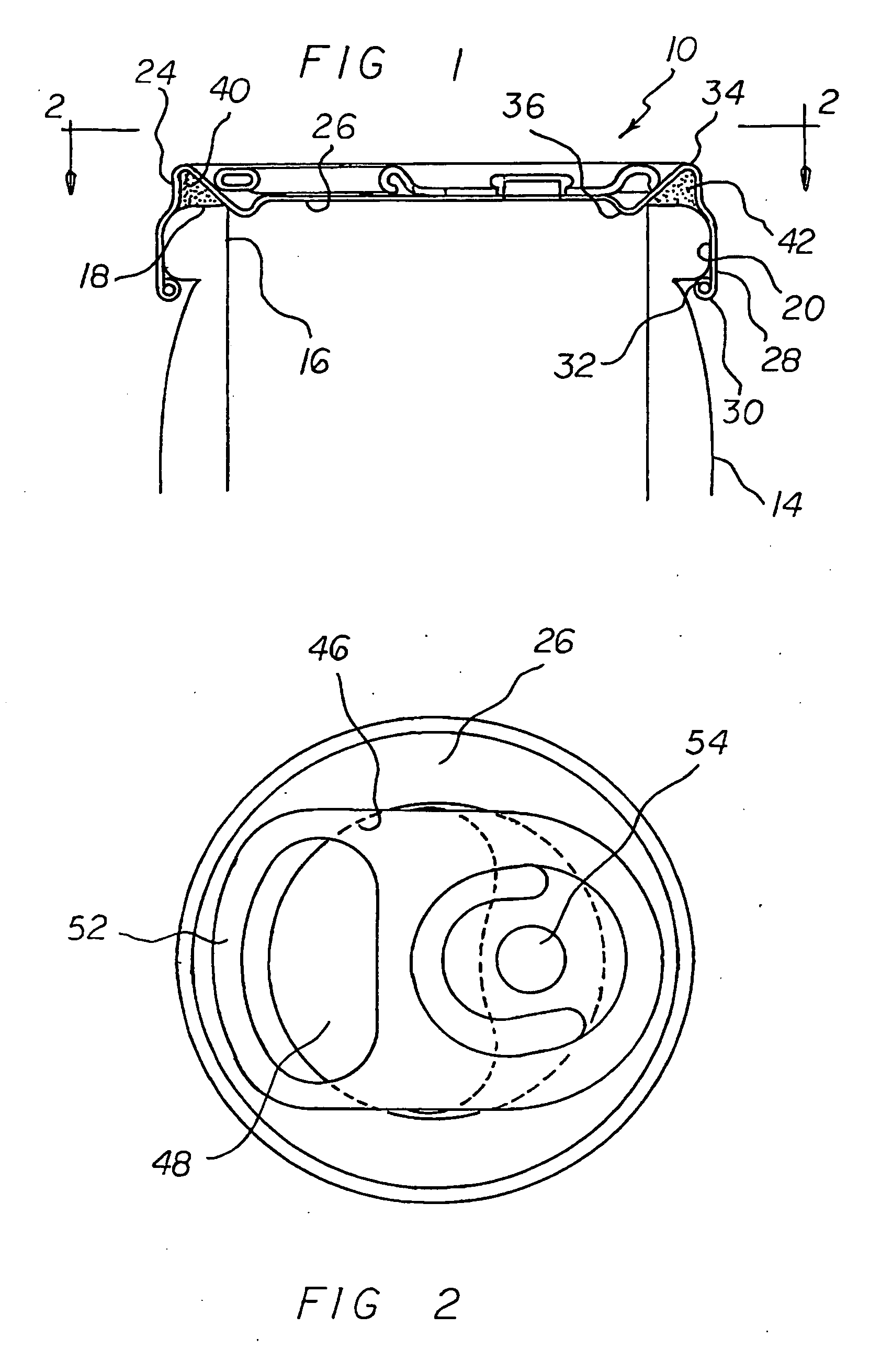

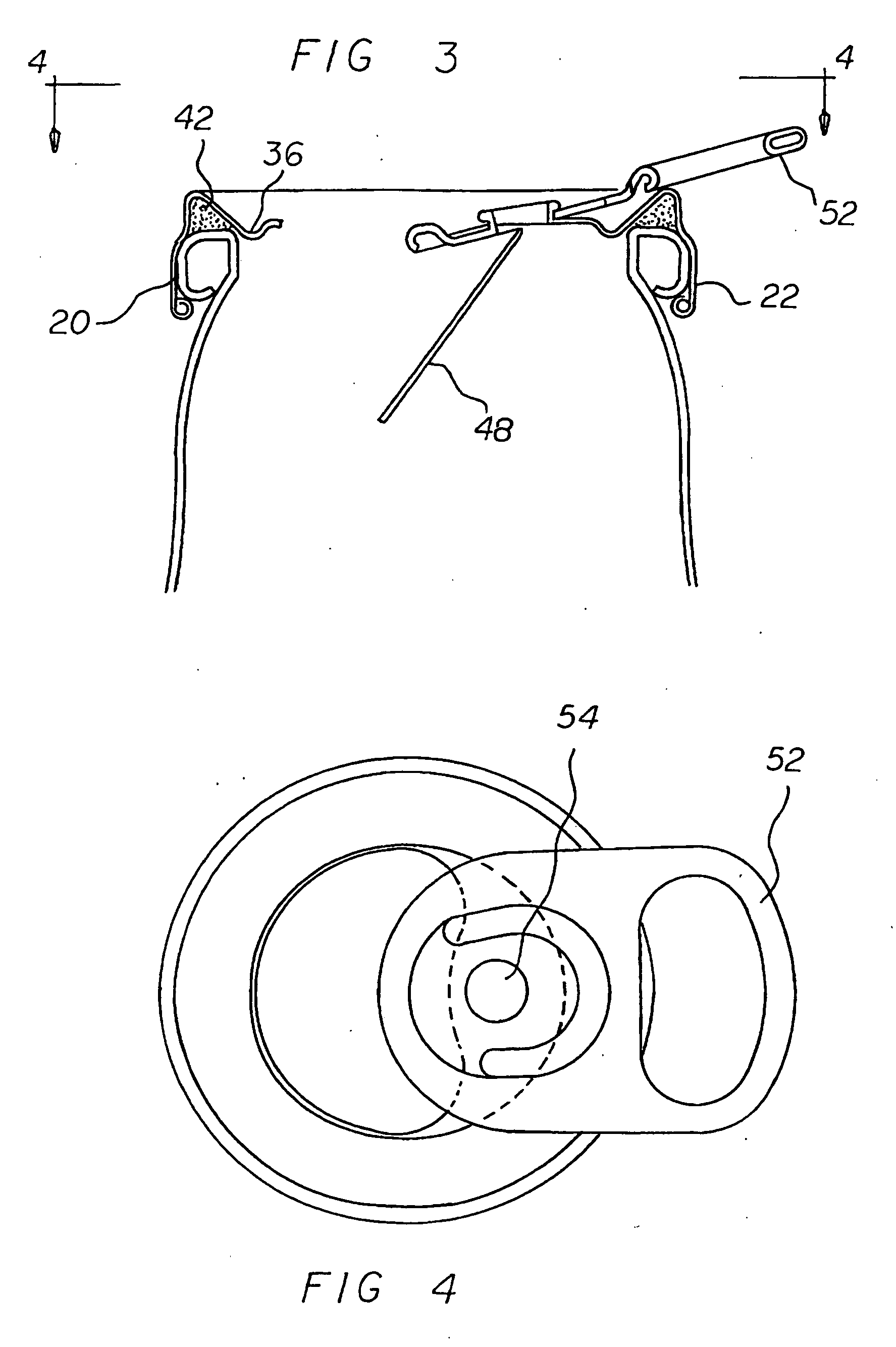

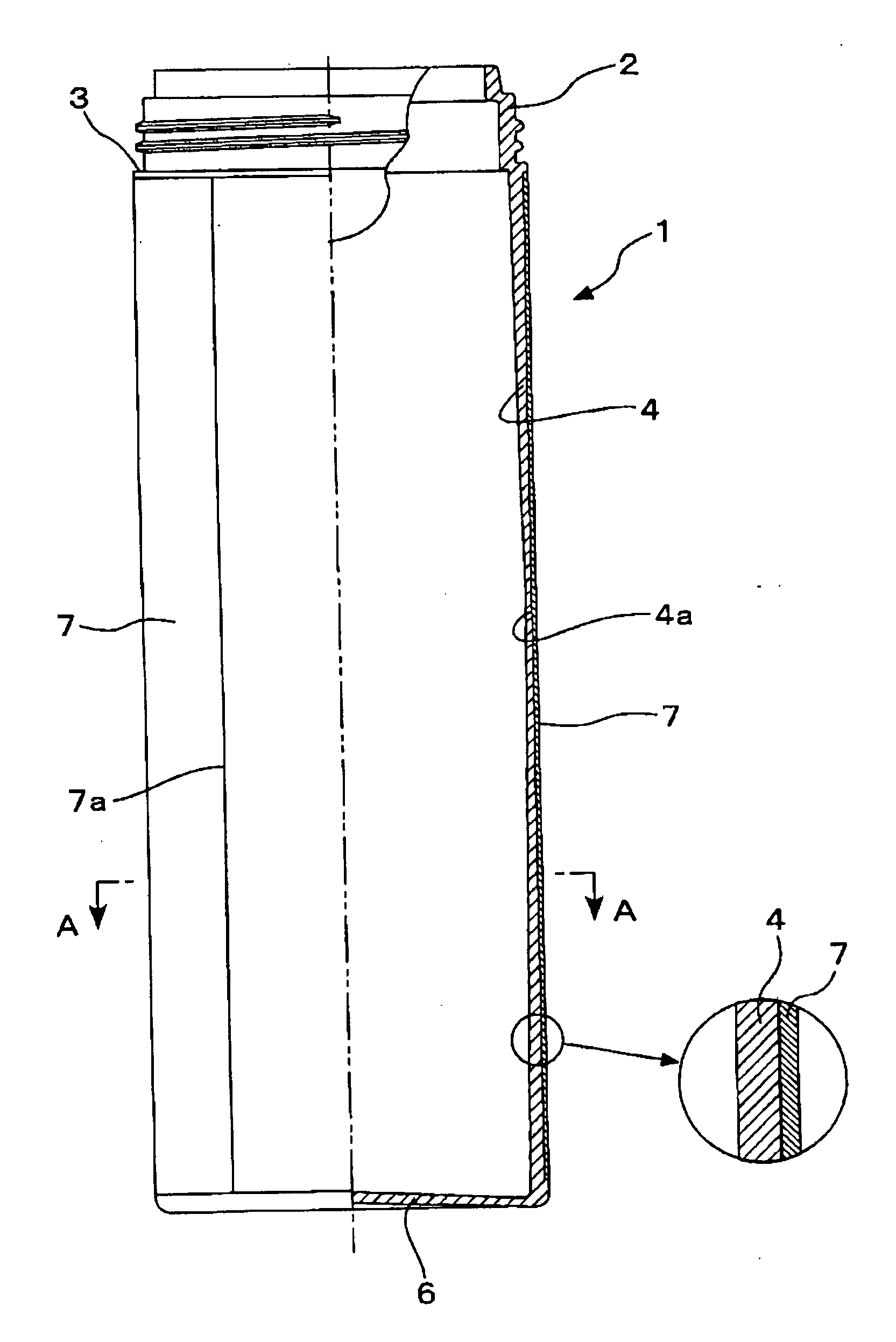

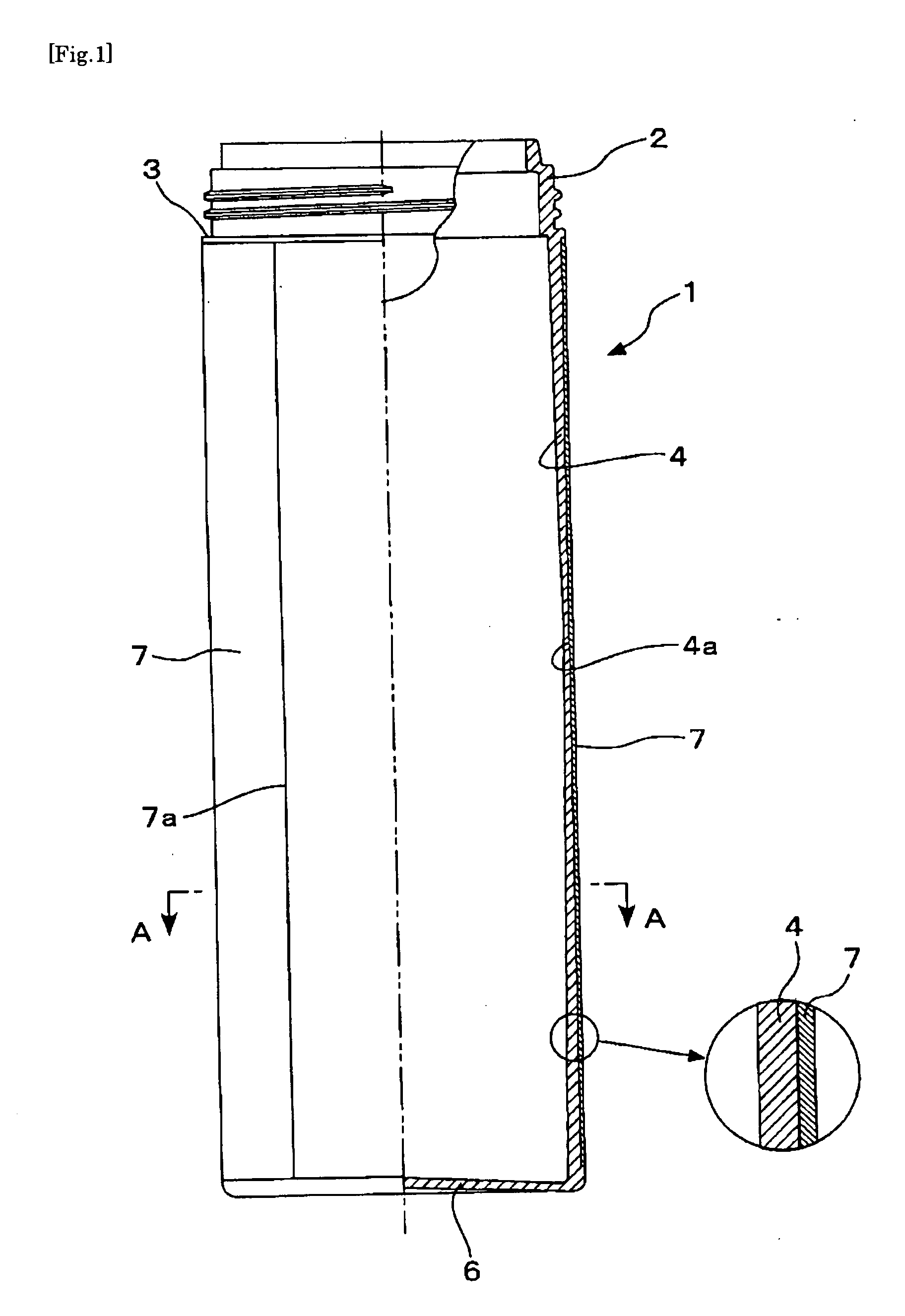

Lift lever crown cap system and method

InactiveUS20100282706A1High strengthImprove body strengthCapsClosure using stoppersEngineeringGeometric configuration

A crown cap is couplable to a container. The crown cap has a central region and a downwardly extending side wall. At least one score line is in a geometric configuration on the central region of the crown cap. The at least one score line forms a tongue. The tongue is adapted to be bent or hinged downwardly. In this manner a passageway is provided for a liquid. A lever is coupled to the crown cap. A post extends through the lift lever and the central region of the crown cap. A tamper-evident secure band is designed into the side wall of the crown cap. A non-corrosive material is used to form the crown cap, lever and attachment post.

Owner:SUPER CLOSURE INT

Double door construction for vehicle

A double door structure which has front and rear doors opening outward to form an uninterrupted to front and rear seats has an impact load carrying assembly for forming a side body reinforcing structure for protecting passengers from a side collision which comprises an impact bar extending to and overlapping a side sill of a vehicle body, upper bracket fixedly mounted o the impact bar and located to overlap a roof side rail of the vehicle body and a lower bracket fixedly mounted o the impact bar. The upper bracket mounts a latch and a belt anchor of a seatbelt system thereon and the lower bracket mounts catch pins forming part of a door catch mechanism operative to prevent movement of the door upon an occurrence of a side collision,

Owner:MAZDA MOTOR CORP

Adjustable assembly for exercise apparatus

ActiveUS20090170669A1High strengthImprove body strengthMuscle exercising devicesMuscle strengthSmall footprint

Exercise apparatus and method with selectively variable stabilization enabling a user to progressively increase his / her core body muscular strength. In various embodiments, the exercise apparatus includes a resistance cabling system providing a user defined line of motion, and a partial stabilizer pad being adjustably positionable offset from the line of motion, wherein the user's core body is positionable against the pad and required to resist the torque created by the offset. The user can progressively increase the distance between the line of motion and partial stabilizer pad, in order to progressively increase the force which the user's core body must resist to maintain an upright stature. In this way, the user can progressively, over time, increase his or her core body strength. A vertically and rotatably adjustable handle / arm assembly, resistance cabling and pulley assembly, and an overall exercise apparatus having a relatively small footprint but allowing multiple variable exercise routines, are also provided.

Owner:CYBEX INTERNATIONAL

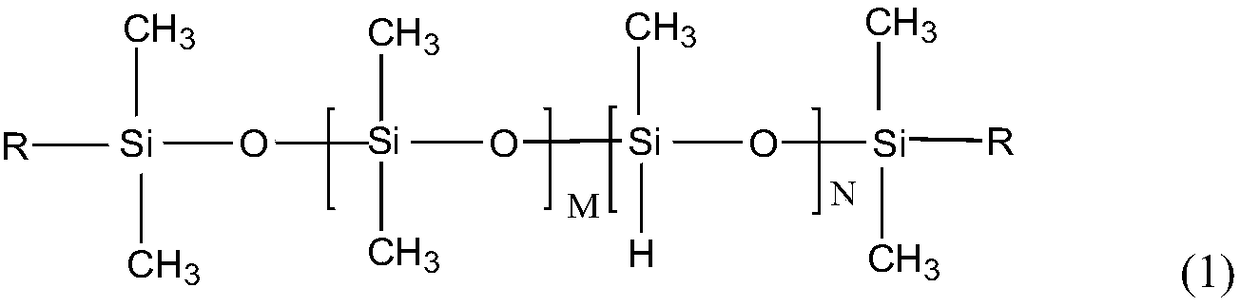

Isocyanate modified two-component silicon rubber adhesive and preparation method thereof

InactiveCN102010689AGood bonding performanceImprove body strengthNon-macromolecular adhesive additivesMacromolecular adhesive additivesAdhesiveMethyl silicone

The invention discloses an isocyanate modified two-component silicon rubber adhesive and a preparation method thereof. The adhesive comprises a component A and a component B which are prepared at the vacuum degree of more than -0.09MPa and the temperature of between 4 and 30 DEG C. A method for preparing the component A comprises the following steps of: (1) adding 100 weight parts of alpha, omega-dihydroxy polydimethylsiloxane, 0 to 500 weight parts of solid filler and 0 to 20 weight parts of pigment into a stirring kettle and fully stirring; (2) adding 0 to 5 weight parts of water and fully stirring; and (3) adding 0 to 50 weight parts of fumed silica in batches. A method for preparing the component B comprises the following steps of: (1) preparing an isocyanate modified silane coupling agent; (2) adding 10 to 50 weight parts of methyl silicone oil, 2 to 20 weight parts of cross-linking agent and 0 to 35 weight parts of solid filler which is dried and dehydrated at a high temperatureinto a reaction kettle and fully stirring; (3) adding 0 to 10 weight parts of silane coupling agent, 10 to 40 weight parts of isocyanate modified silane coupling agent and 0 to 3 weight parts of catalyst and fully stirring; and (4) adding 0 to 10 weight parts of fumed silica in batches and fully stirring.

Owner:TONSAN ADHESIVES INC

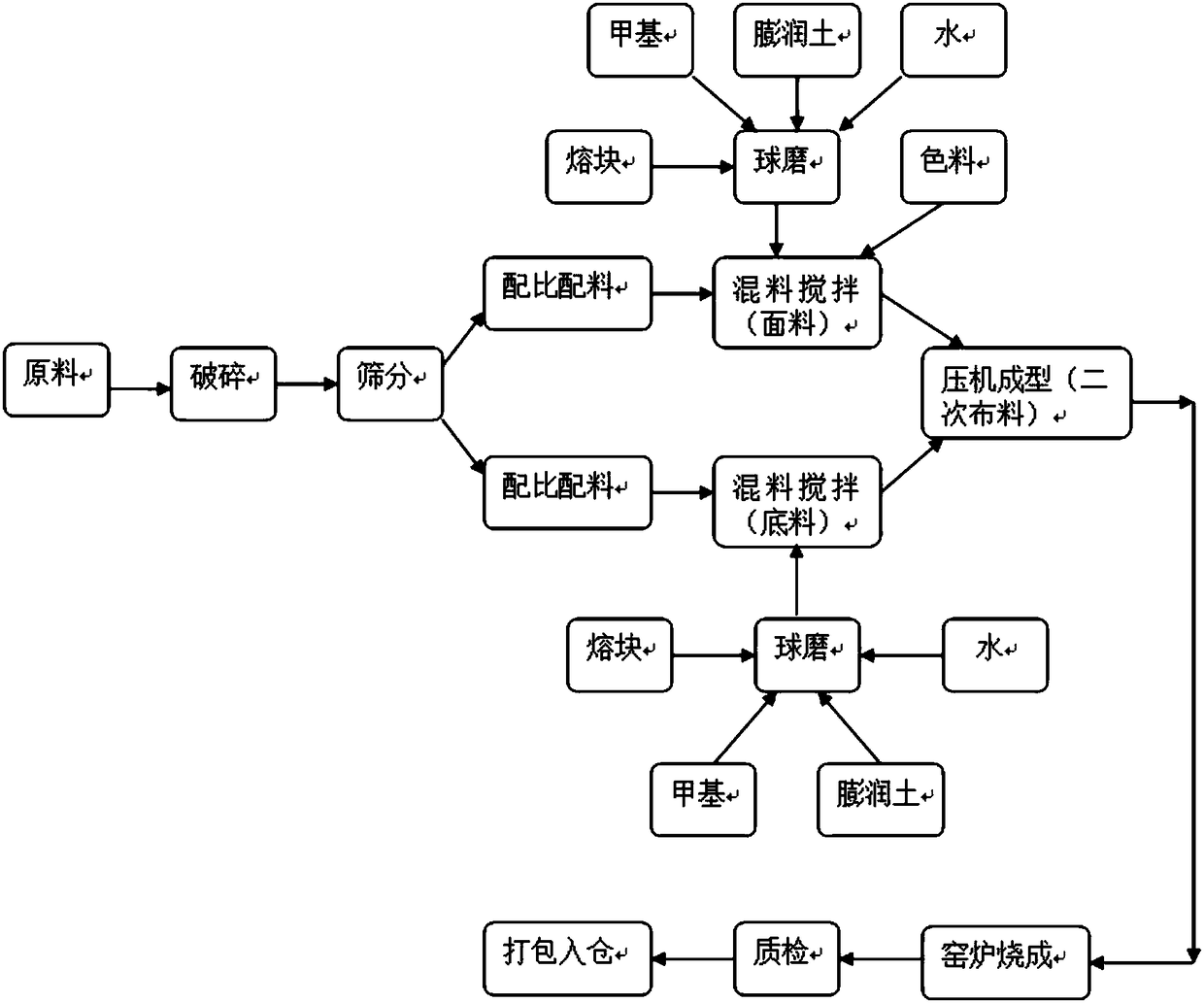

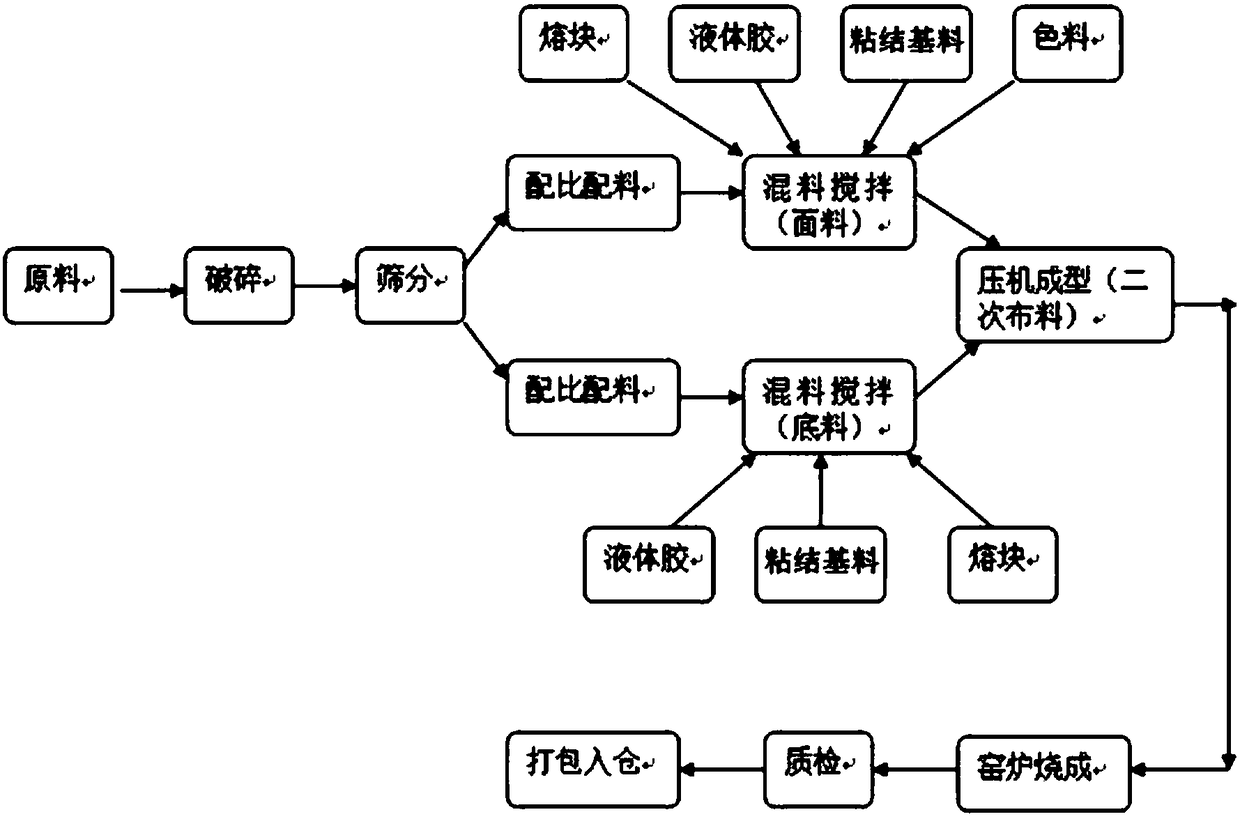

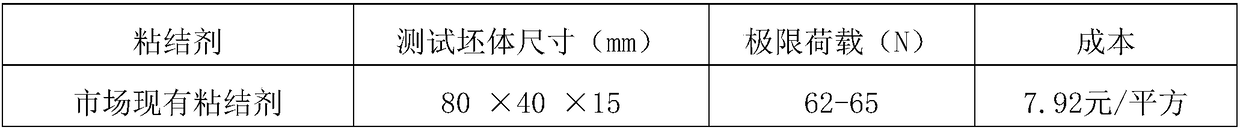

Preparation method of water permeable brick

ActiveCN108083767AGood water permeabilityStrong frost resistanceCeramic materials productionCeramicwarePore diameterSieve

The invention discloses a preparation method of a water permeable brick. The preparation method comprises the steps: (1) crushing aggregates; (2) sieving the crushed aggregates by using sieves with different pore diameters to obtain particles with different particle sizes; (3) proportioning the sieved aggregate particles according to a bottom material formula, adding a bonding agent, and carryingout uniform stirring to obtain a bottom material mixture; proportioning the sieved aggregate particles according to a surface material formula, and adding a bonding agent and pigment to obtain a surface material mixture, wherein the bonding agent comprises a bonding base material and liquid glue; (4) respectively mixing and stirring the bottom material mixture and the surface material mixture; (5)distributing the stirred surface material mixture and bottom material mixture twice, and carrying out compression molding to obtain a green body; and (6) firing the green body in a kiln to obtain a finished product. The water permeable brick prepared by using the preparation method is high in strength, strong in freezing resistance and excellent in water permeability; and the preparation method is few and simple in process and capable of reducing the cost.

Owner:KEDA INDUSTRIAL GROUP CO LTD

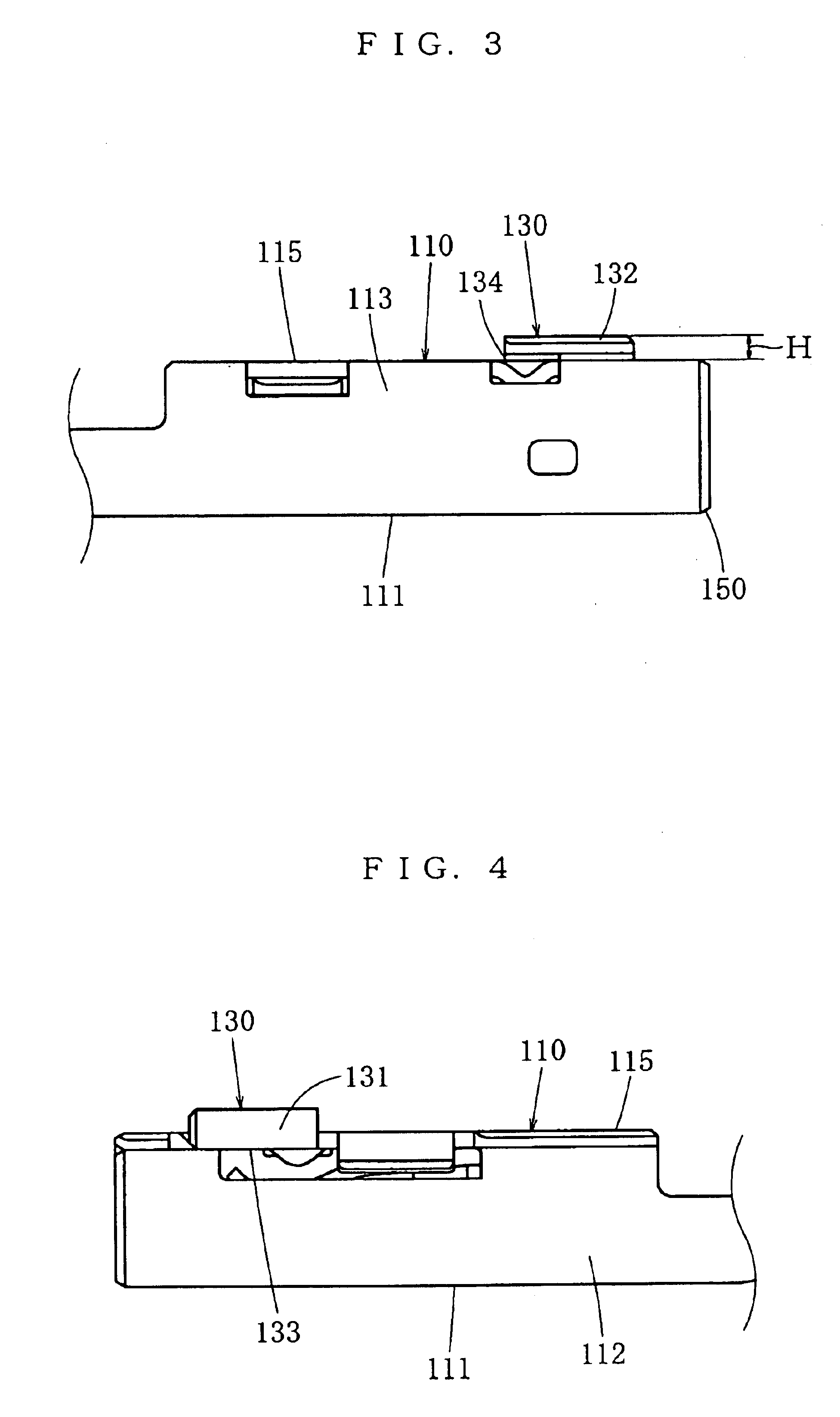

Connector

InactiveUS7637779B2Improve body strengthSuitable shield characteristicsElectrically conductive connectionsTwo-part coupling devicesMechanical engineering

Owner:HOSIDEN CORP

Inmold labeled container and molding process thereof

InactiveUS20100001010A1Accurately determineAccurate settingBottlesLarge containersEngineeringMechanical engineering

Owner:YOSHINO KOGYOSHO CO LTD

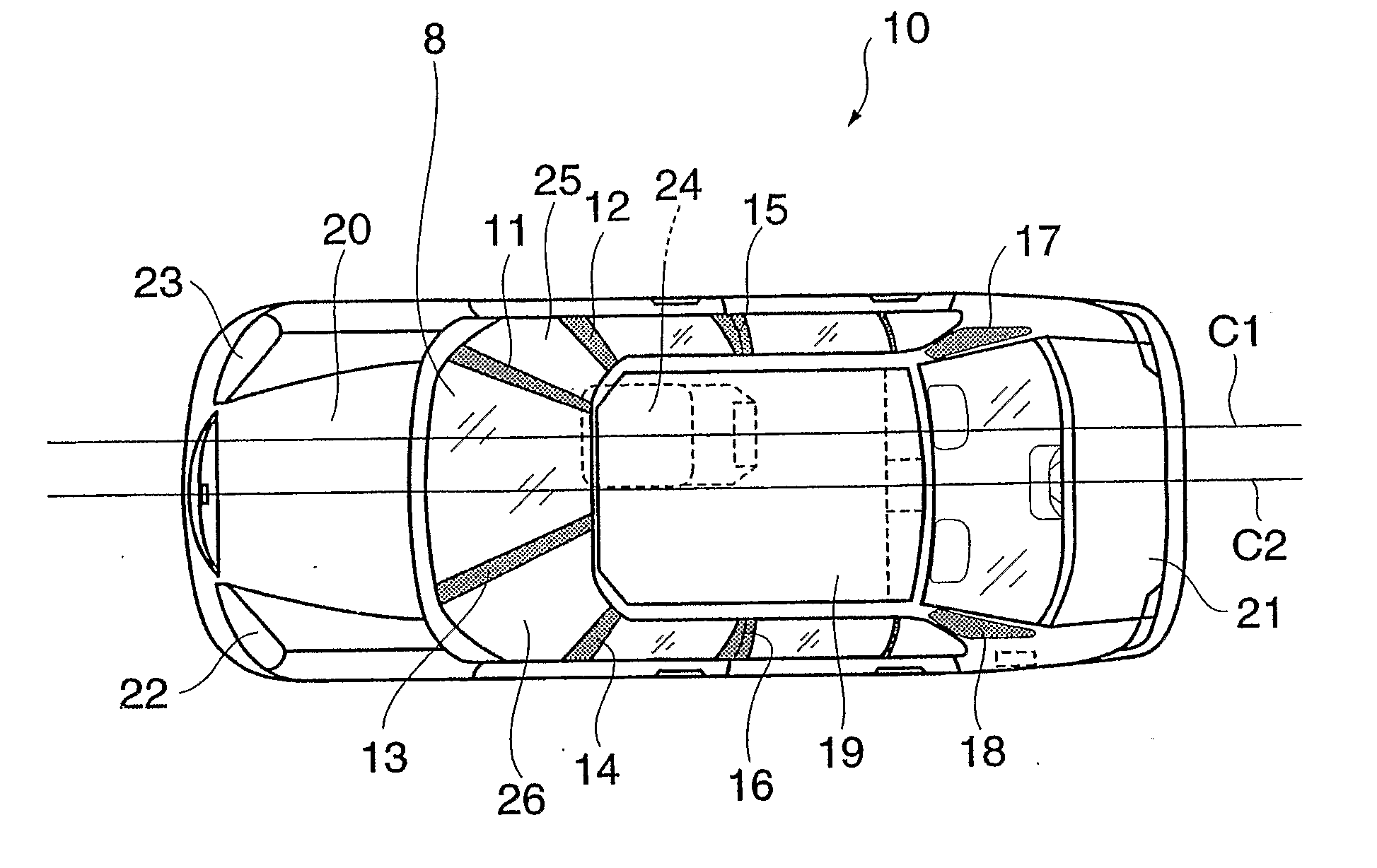

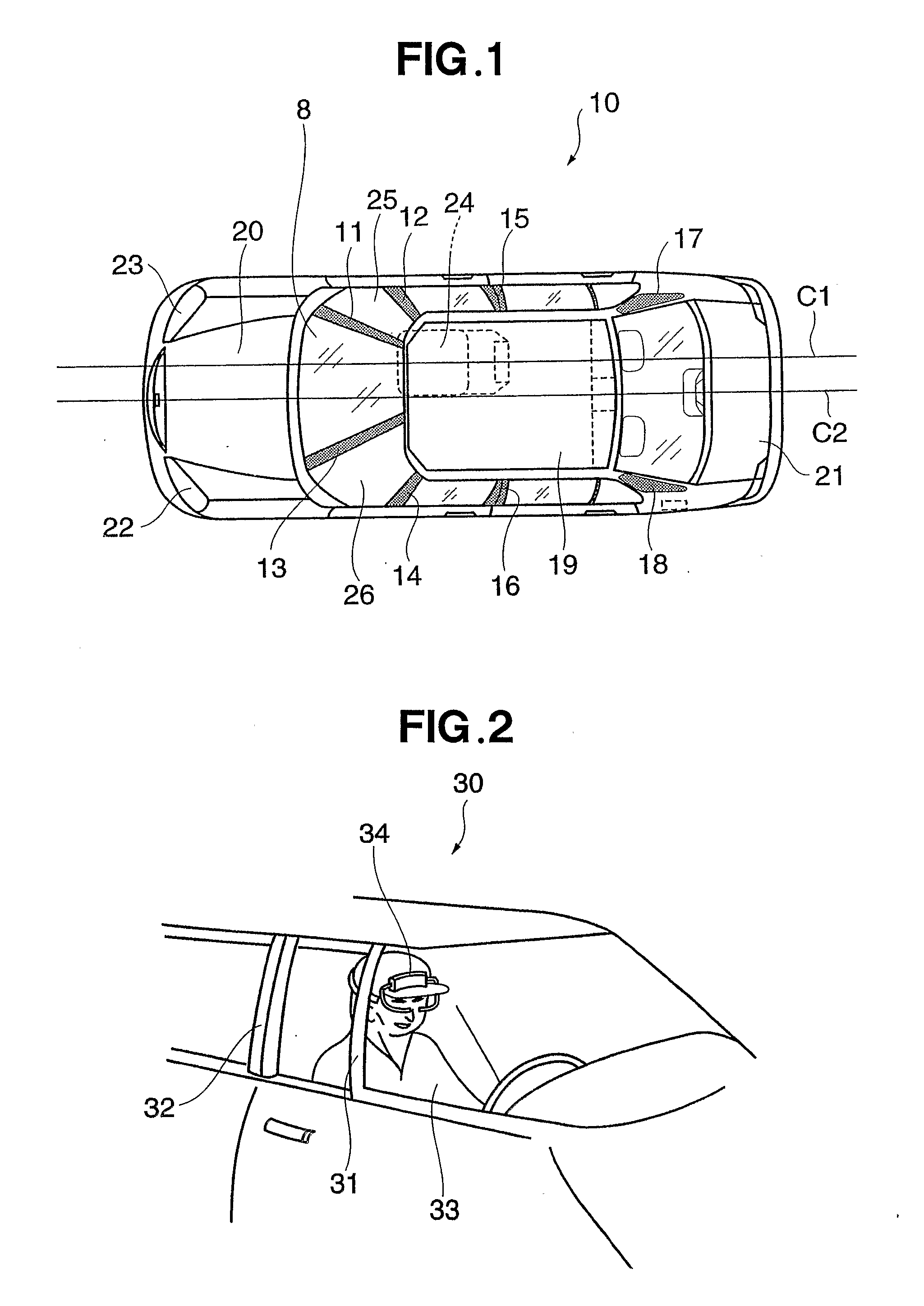

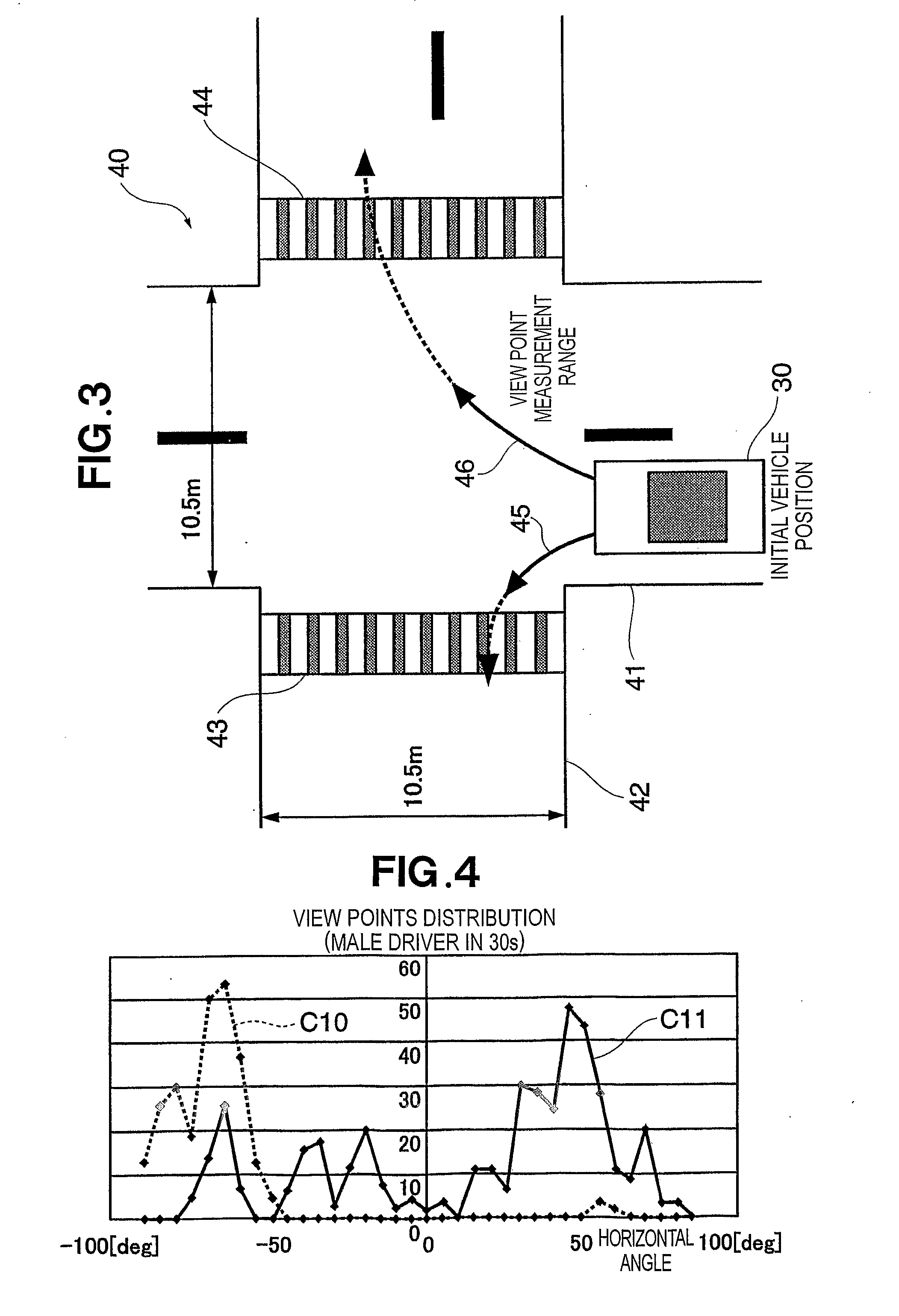

Vehicular Body Structure

ActiveUS20070216189A1Significantly-improved field of visionSimple structureVehicle seatsWindowsEngineering

Owner:HONDA MOTOR CO LTD

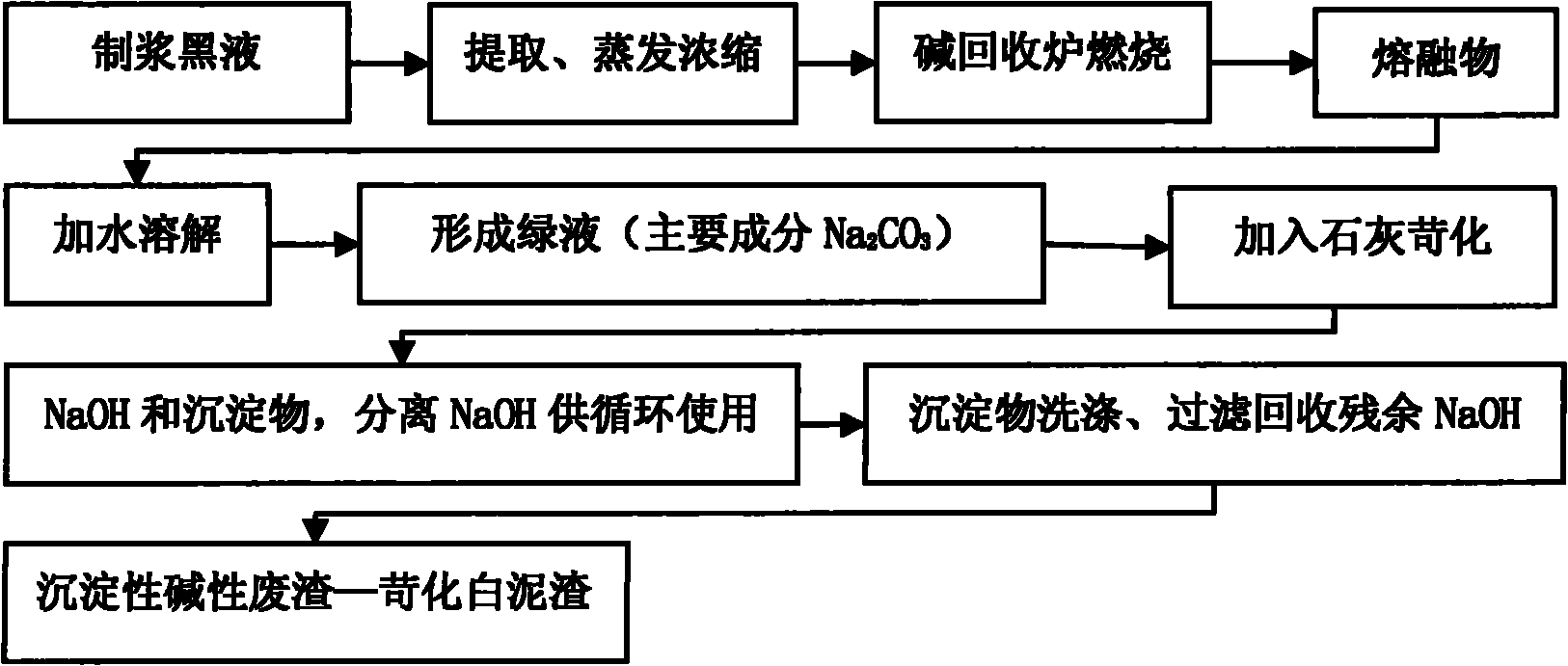

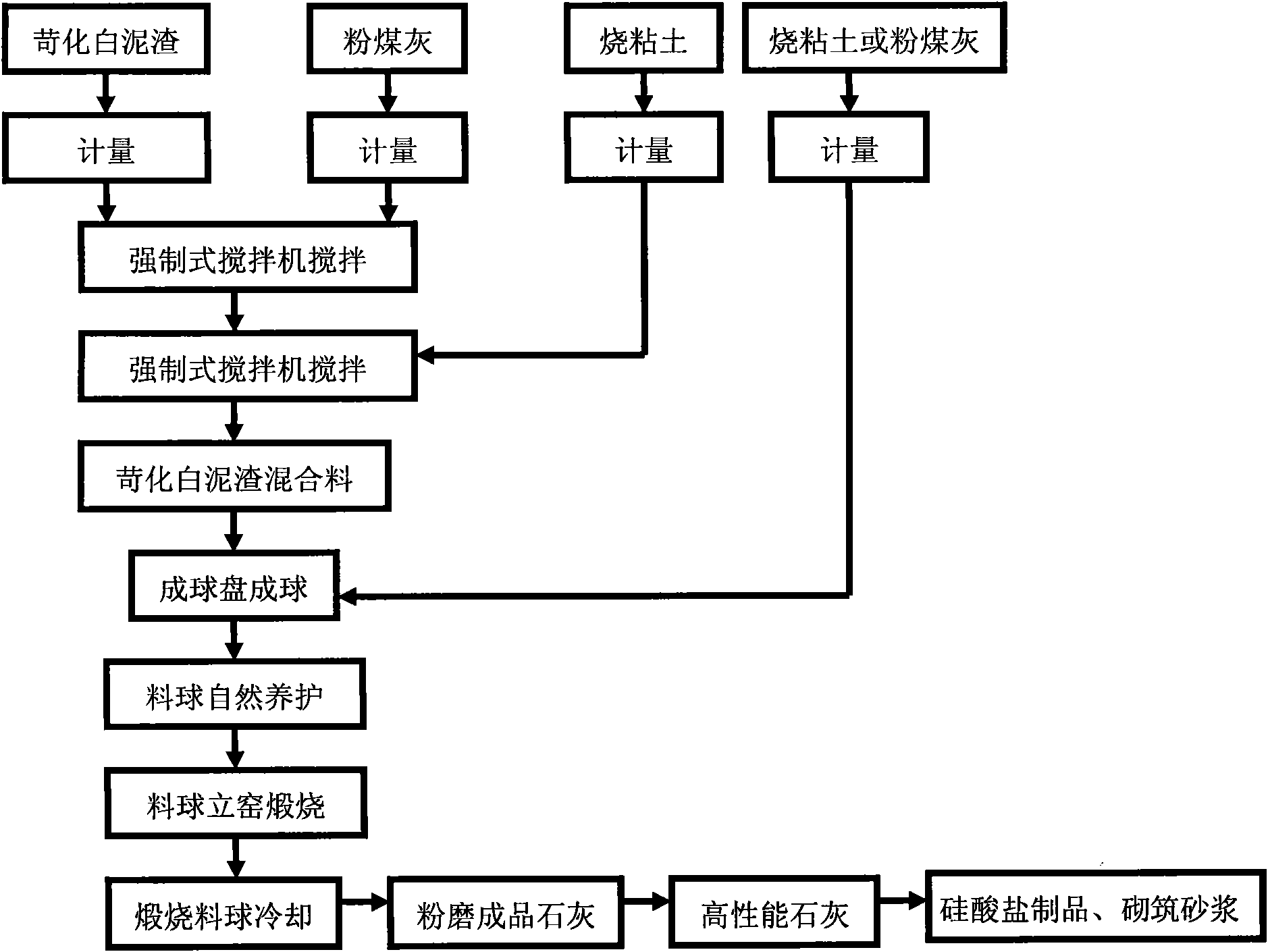

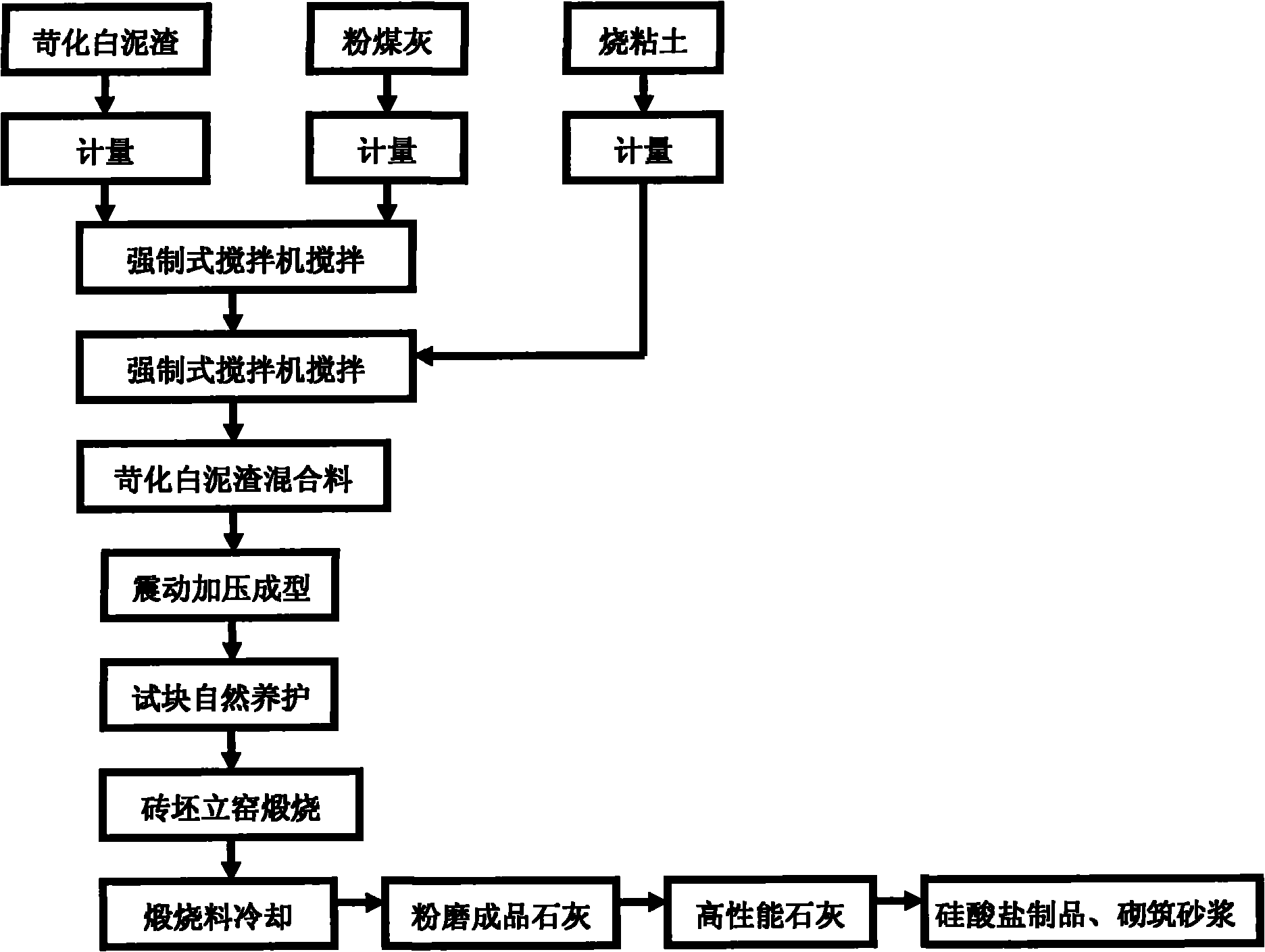

Method for preparing hydraulic calcium oxide through papermaking alkali recycling causticized white sludge

InactiveCN102070309AReduce dust pollutionReduce moisture contentSolid waste managementPapermakingSludge

The invention discloses a method for preparing hydraulic calcium oxide through papermaking alkali recycling causticized white sludge. The method comprises the following steps: preparing a mixture: putting papermaking causticized white sludge and pulverized fuel ash into a forced type stirrer for stirring, and putting burnt clay into the forced type stirrer for evenly stirring to obtain the mixture; molding the mixture: molding by adopting a centrifugal rolling balling method or shaking pressurization method; naturally curing the mixture: putting the molded mixture balls into the natural environment with good ventilation conditions for stacking and curing, and putting adobes into the natural environment with good ventilation conditions for stacking and curing for 7-14 days until the quality of the adobes can not be further reduced and the primary compression strength of the adobes is more than 1MPa; and calcining the material: conveying the cured and dried material balls or adobes intoa shaft kiln for calcining and insulating, then naturally cooling to the room temperature, and milling the calcined products to be used for preparing silicate products. The invention reduces the dustpollution and solves the problem of treatment of pulverized fuel ash.

Owner:NANJING UNIV OF SCI & TECH

SiC whisker-reinforced ceramic-based composite plate and preparation method thereof

The invention discloses a SiC whisker-reinforced ceramic-based composite plate and a preparation method thereof. The SiC whisker-reinforced ceramic-based composite plate comprises the following raw materials by volume percent: 60%-80% of inorganic ceramic powder substrate and 20%-40% of chemical vapor infiltration (CVI)-SiC whiskers, wherein the SiC whiskers are inlaid in the ceramic substrate and are closely combined with the ceramic substrate; the inorganic ceramic powder substrate is silicon carbide, silicon nitride, boron nitride or boron carbide, and the particle size of ceramic powder is 10-100m um. A ceramic preform is prepared by adopting a gel casting method, and the SiC whiskers grow in the preform in combination with a chemical vapor infiltration CVI process to densify the ceramic preform. The SiC whisker-reinforced ceramic-based composite plate is prepared by adopting combination of the gel casting process and CVI process, is improved in breaking tenacity and bending strength and is high in use reliability.

Owner:SUZHOU HONGJIU AVIATION THERMAL MATERIALS TECH CO LTD

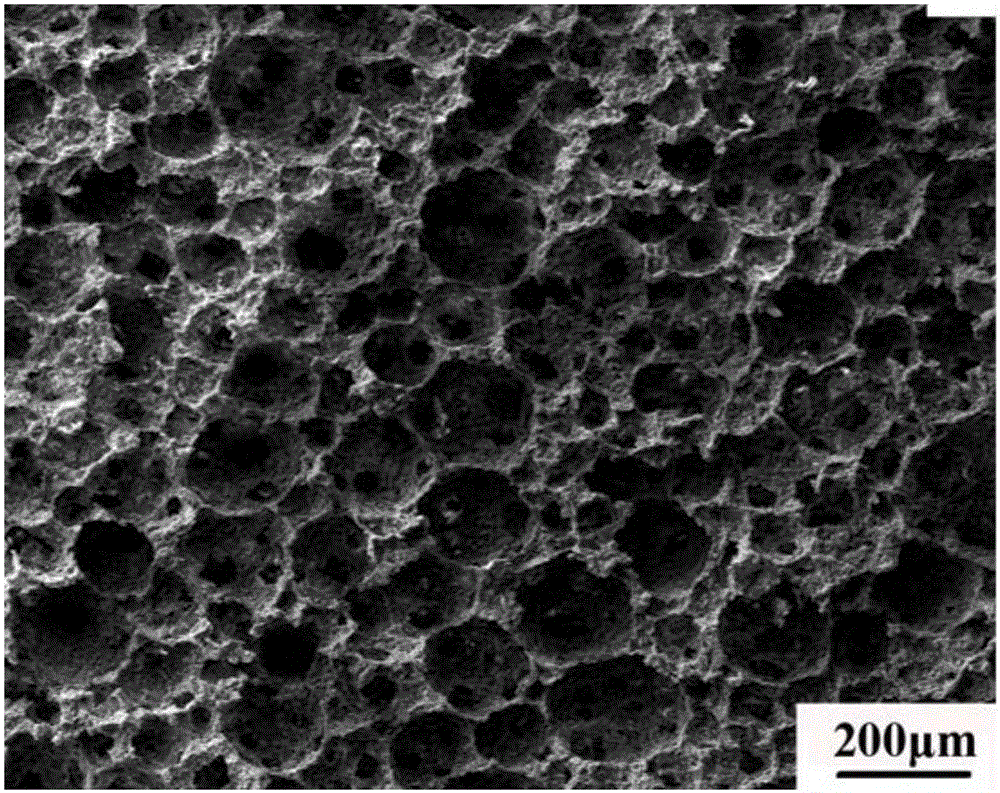

Method for preparing iron tailing porous ceramic through foam-gelcasting/low-temperature sintering

ActiveCN106830989AIncrease profitHigh porosityCeramic materials productionCeramicwareFoaming agentSlurry

The invention discloses a method for preparing iron tailing porous ceramic through foam-gelcasting / low-temperature sintering. The method comprises the following steps: uniformly mixing iron tailing powder and deionized water through a ball milling method to prepare slurry; injecting an organic monomer, crosslinking agent and dispersing agent into the slurry, and further performing ball milling; adding foaming agent and foam stabilizer into the slurry subjected to ball milling, and mechanically stirring at a high speed to enable the slurry to foam; injecting initiator and a catalyst into the foaming slurry, uniformly stirring, pouring the slurry into a mold, performing gelcasting, demolding, and drying; putting the dried porous body in a muffle furnace, and sintering at a temperature lower than 1120 DEG C to obtain the iron tailing porous ceramic. By using the method to prepare the porous ceramic, the solid waste utilization ratio is high; harm of iron tailings to the environment can be effectively relieved; the prepared porous ceramic has the advantages of high porosity, small pore diameter, uniform distribution, controllable casting parameters, low sintering temperature and the like; and the porous ceramic has favorable physical property and mechanical property.

Owner:BEIJING JIAOTONG UNIV

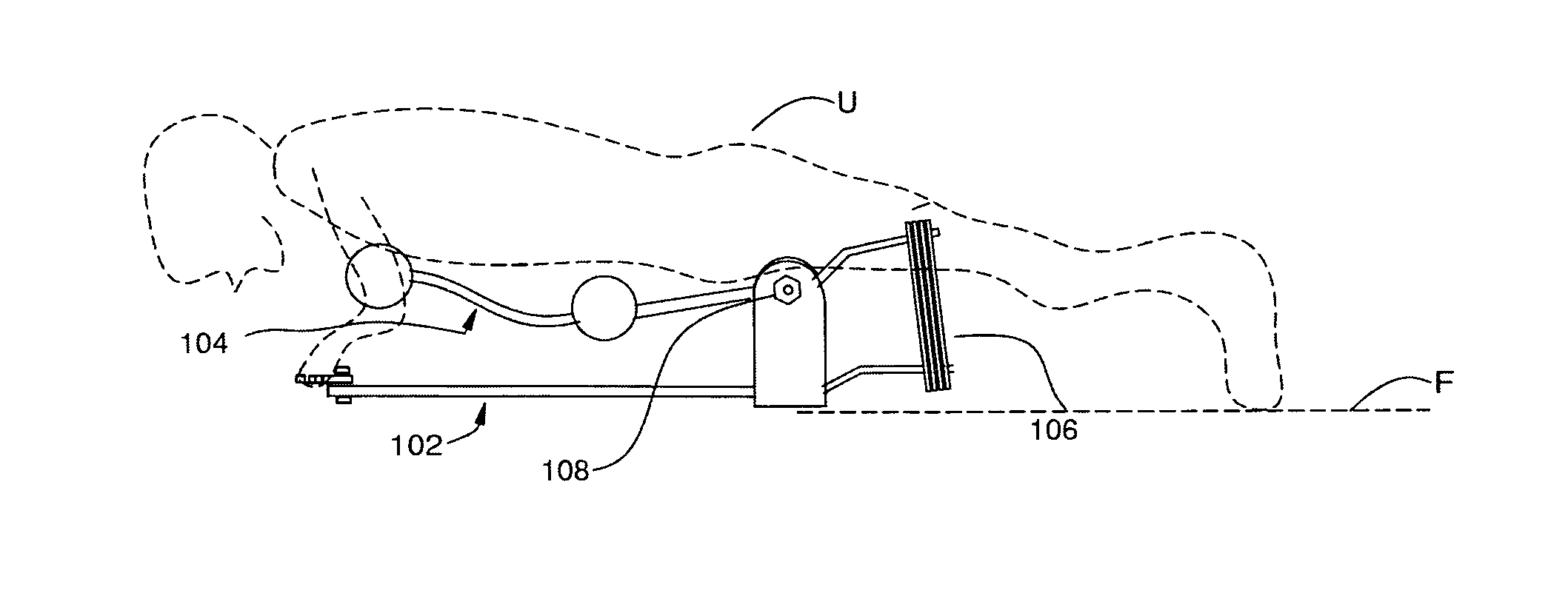

Torso pushup assistance device

A torso pushup assistance device for assisting a user in performing pushups is disclosed. The torso pushup assistance device is comprised of a base component, a torso support component rotationally attached to the base component, and an elastic system that connects the base component to the torso support component in one or more optional configurations. In a first embodiment, the elastic system is comprised of a set of one or more pairs of matched elastic bands that removably connect the rear end of the torso support component to the rear end of the base component. The user lies on the torso support component with his or her feet on the floor, and does pushups in the usual way. Depending on the configuration of the matched elastic bands installed on the torso pushup assistance device, the user's effort varies from a small percentage to a large percentage of the force required to do an unassisted pushup.

Owner:BARRINGER JACK EUGENE

Weightlifting belt hook

Owner:SMITH ROBERT C

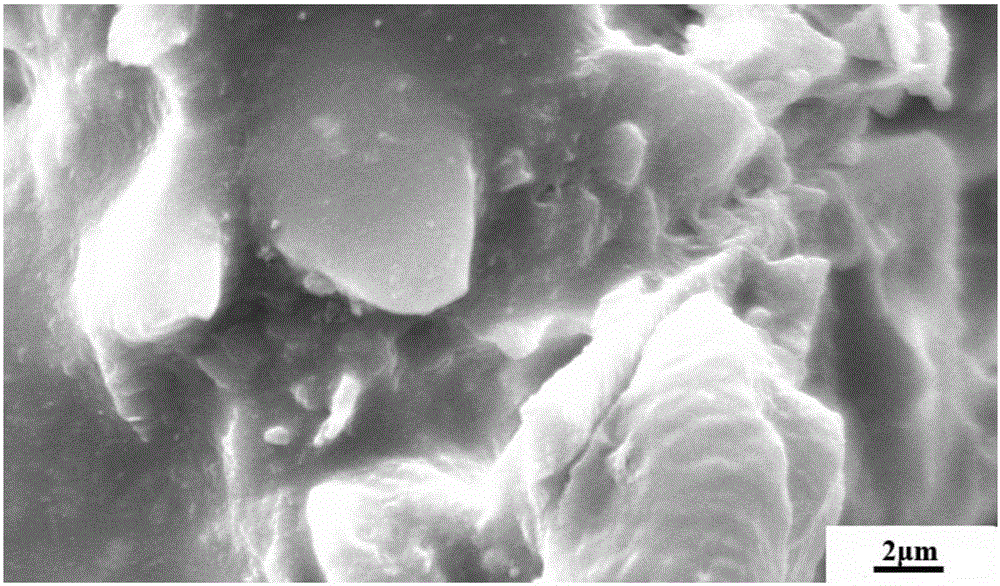

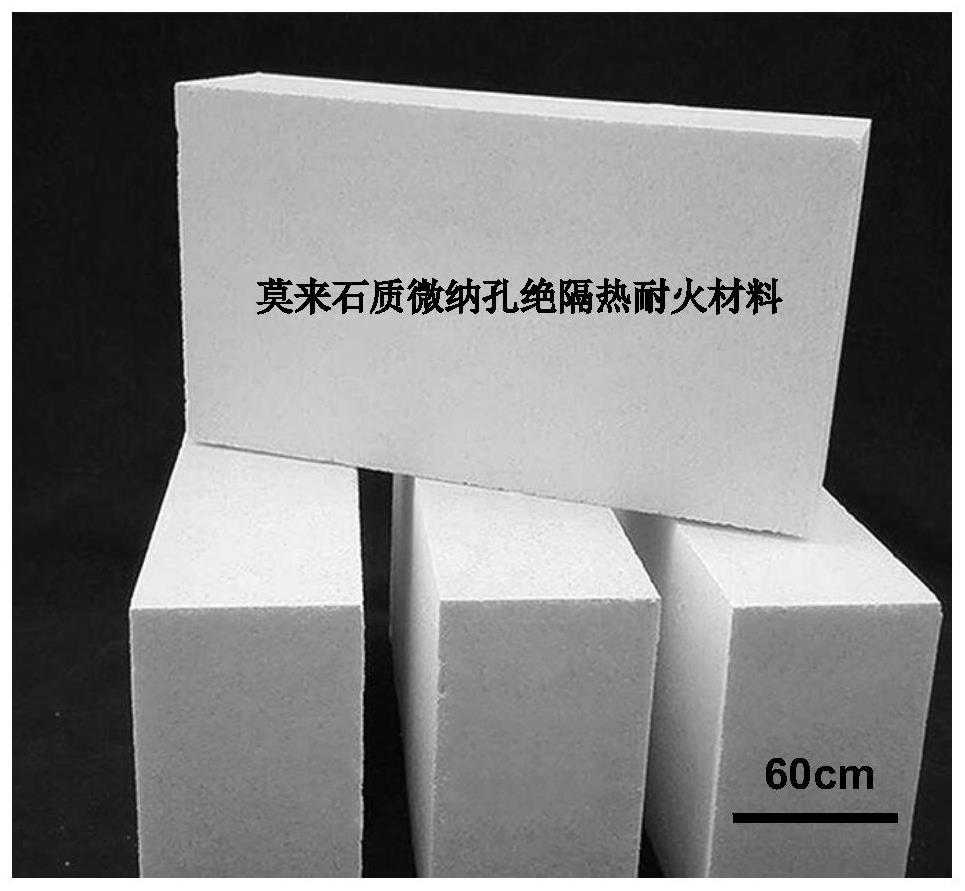

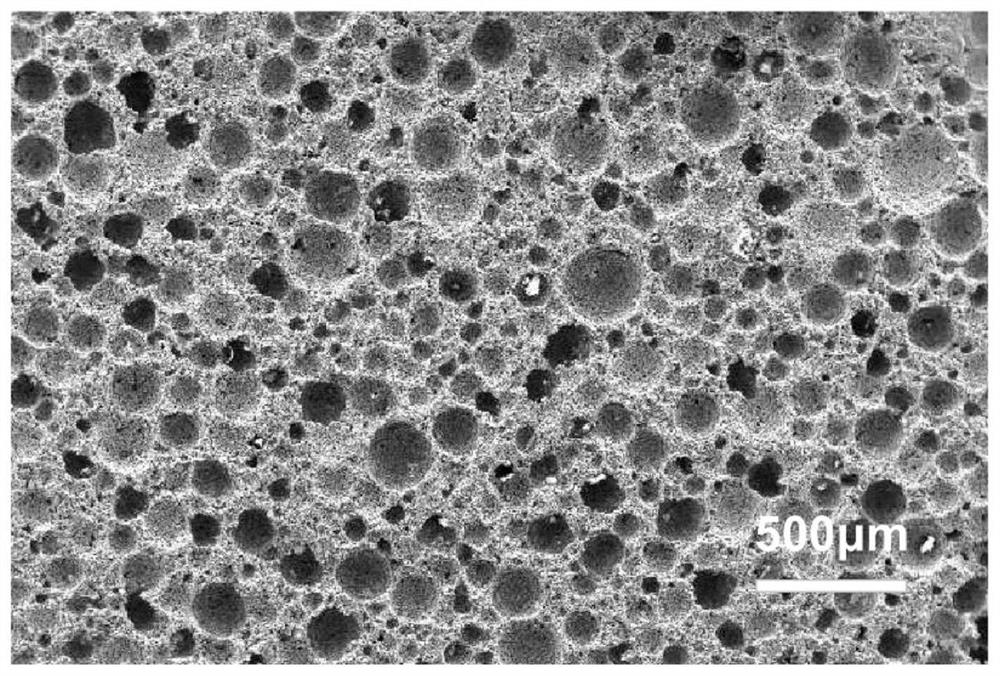

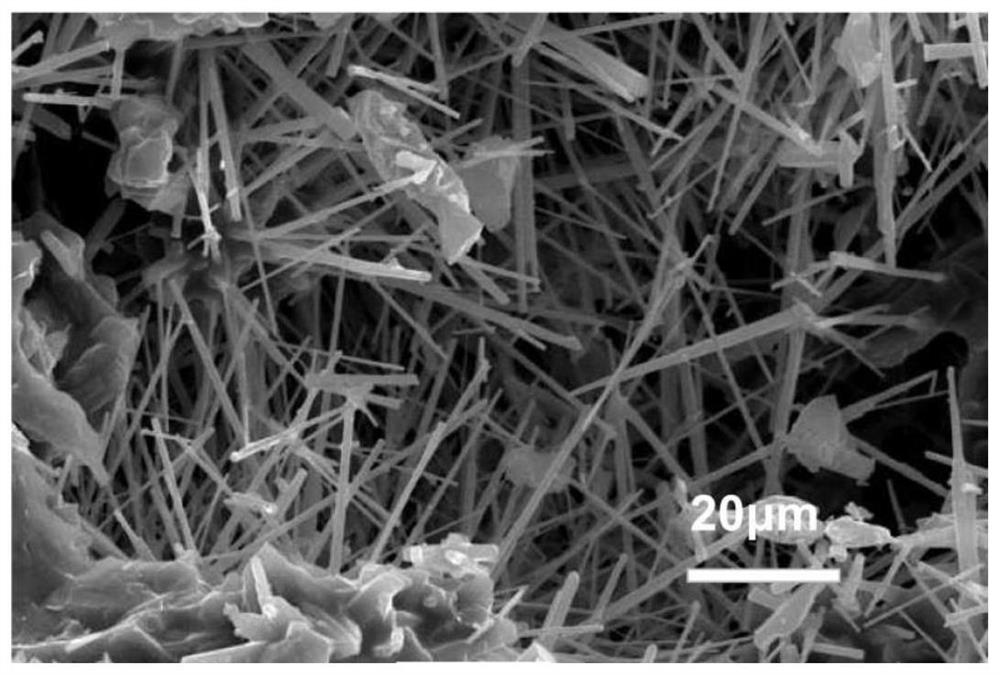

Mullite micro-nano pore heat insulation refractory material and preparation method thereof

The invention belongs to the technical field of refractory materials, and particularly relates to a mullite micro-nano pore heat insulation refractory material and a preparation method thereof. The heat-insulating refractory material is mainly prepared from a base material, an additive and water, and the preparation process is green, environment-friendly, pollution-free, simple and easy to control. The main crystalline phase of the heat insulation refractory material is large-size needle-shaped and columnar mullite. The appearance of the product is white or faint yellow, the pore size distribution of pores is 0.006-200 [mu] m, the average pore size is 0.1-19 [mu] m, and the closed spherical micro-nano pore structure ensures that the product has better heat insulation performance under the conditions of lower volume density and high strength. By regulating and controlling the use amount of each raw material and the process, the finally prepared heat-insulating refractory material can meet the requirements of low heat conductivity and light weight, and also has better mechanical properties.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

Silicon oxide bonded silicon carbide material

InactiveCN105418086AReduce adverse effectsGood high temperature performanceCarbide siliconSilicon oxide

The invention belongs to the technical field of inorganic nonmetallic materials and discloses a silicon oxide bonded silicon carbide material. The silicon oxide bonded silicon carbide material is prepared from, by mass, 60-75% of silicon carbide particles, 18-30% of silicon carbide fine powder, 3-8% of silicon carbide micro powder, 1-3% of silica powder, and 0.3-1.5% of nano-silica, and the total mass percentage of the raw materials is 100%. Liquid phenolic resin serving as a binding agent is also added to the silicon oxide bonded silicon carbide material. The raw materials for preparing the silicon oxide bonded silicon carbide material are evenly mixed with liquid phenolic resin to generate pug, the pug is molded, dried and then sintered in a high-temperature kiln with the highest sintering temperature being 1350-1500 DEG C, then the product is cooled together with the kiln to be indoor temperature so that the silicon oxide bonded silicon carbide material can be obtained. The silicon oxide bonded silicon carbide material has the advantages of being high in purity, excellent in high-temperature performance and high in comprehensive performance.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

Terminal

ActiveUS20040209527A1Avoid deformationStrength of terminal is assuredSecuring/insulating coupling contact membersCoupling contact membersEngineeringMechanical engineering

Owner:JST MFG CO LTD

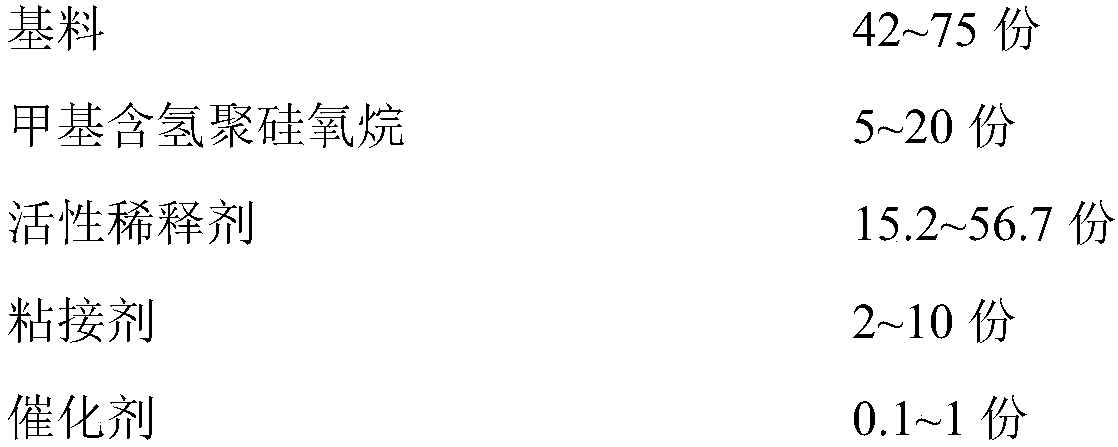

High-strength organic silicon heat-conducting sealant and preparation method

ActiveCN109504340AEasy to useImprove body strengthNon-macromolecular adhesive additivesOther chemical processesSolventAdhesive

The invention relates to a high-strength organic silicon heat-conducting sealant which is prepared from the following raw materials in parts by weight: 42-75 parts of base material, 5-20 parts of methyl hydrogenated polysiloxane, 15.2-56.7 parts of reactive diluent, 2-10 parts of adhesive, 0.1-1 part of catalyst, 0.01-1 part of inhibitor, 5-15 parts of flexibilizer, 10-40 parts of solvent and 100-300 parts of heat-conductive filler. The heat-conducting sealant prepared according to the invention is an additive single-component high-temperature fast curing sealant, with convenience in use, environment-friendly property, high heat conductivity, high strength of main body, excellent adhesion to base material, capability of reducing residue of sealant in parts while repairing and benefit in protecting corresponding parts of electron components.

Owner:YANTAI DARBOND TECH

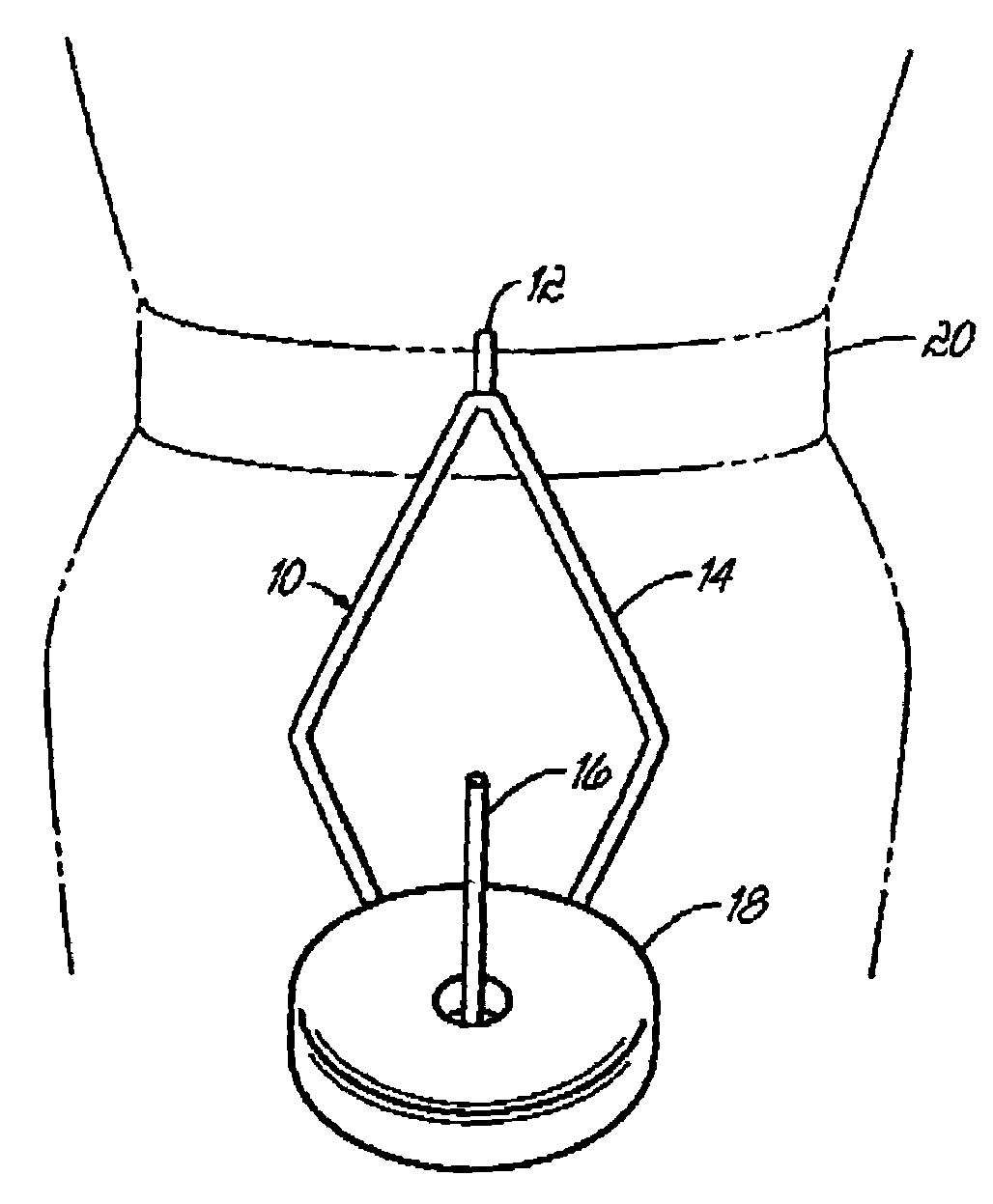

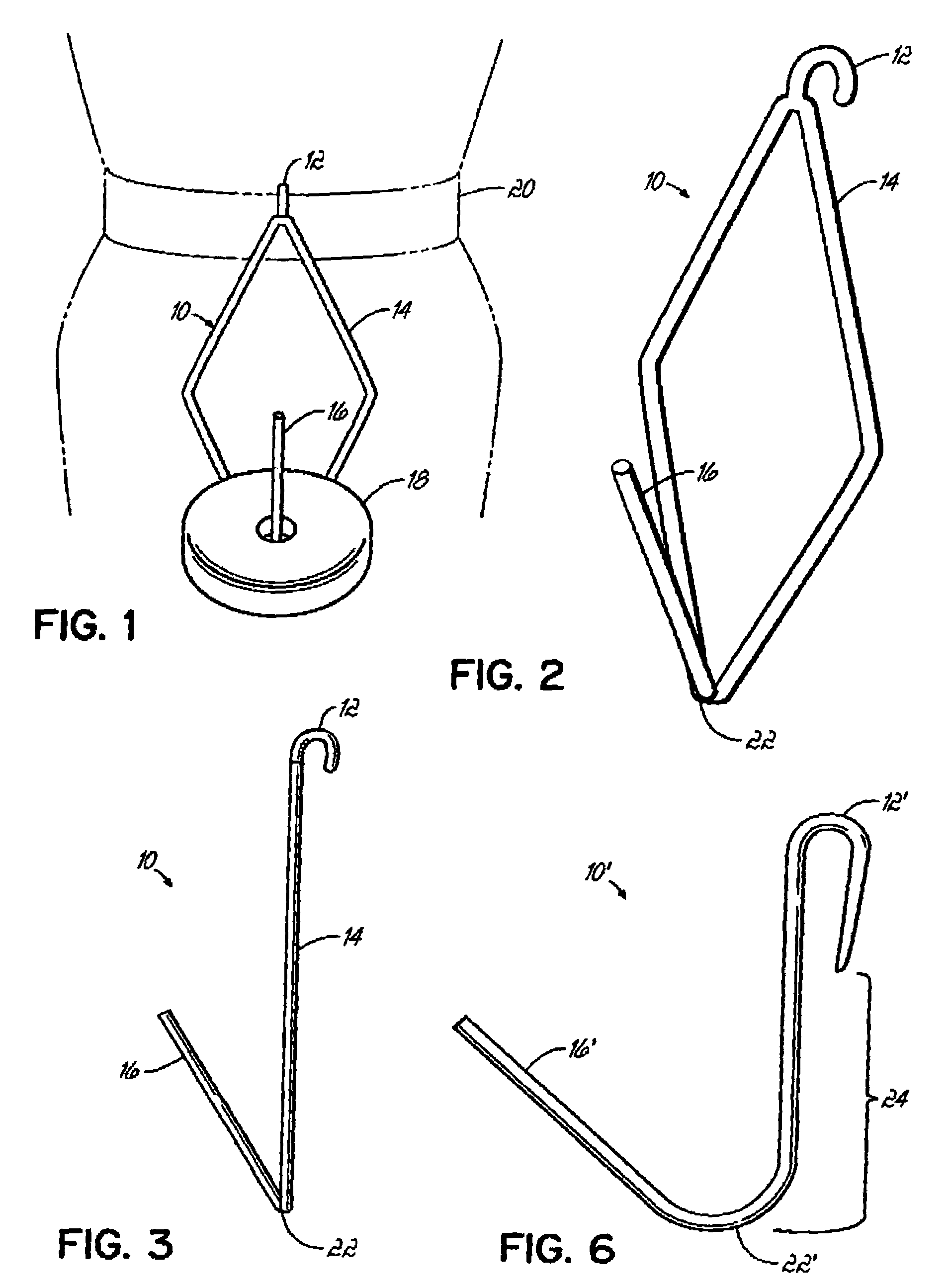

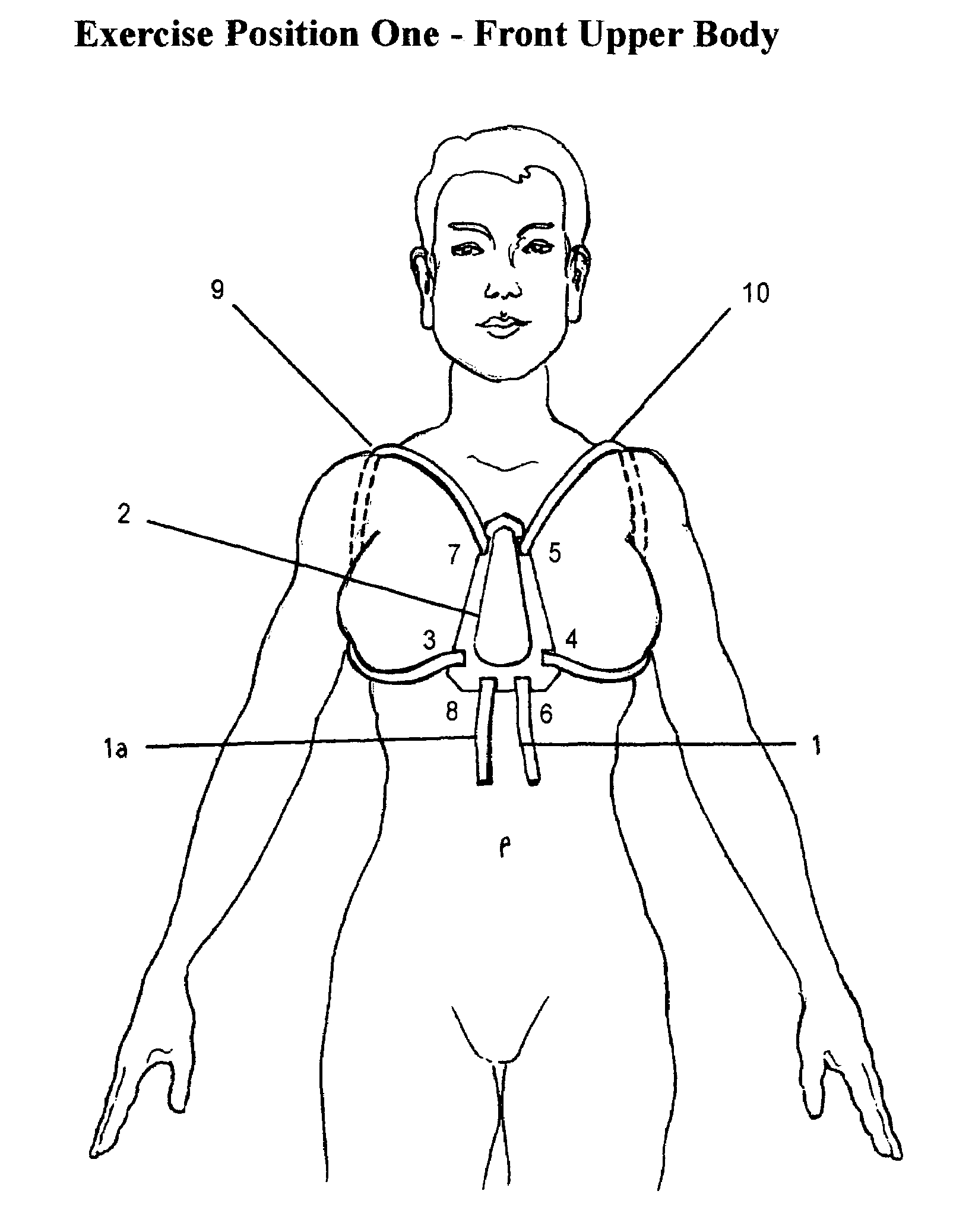

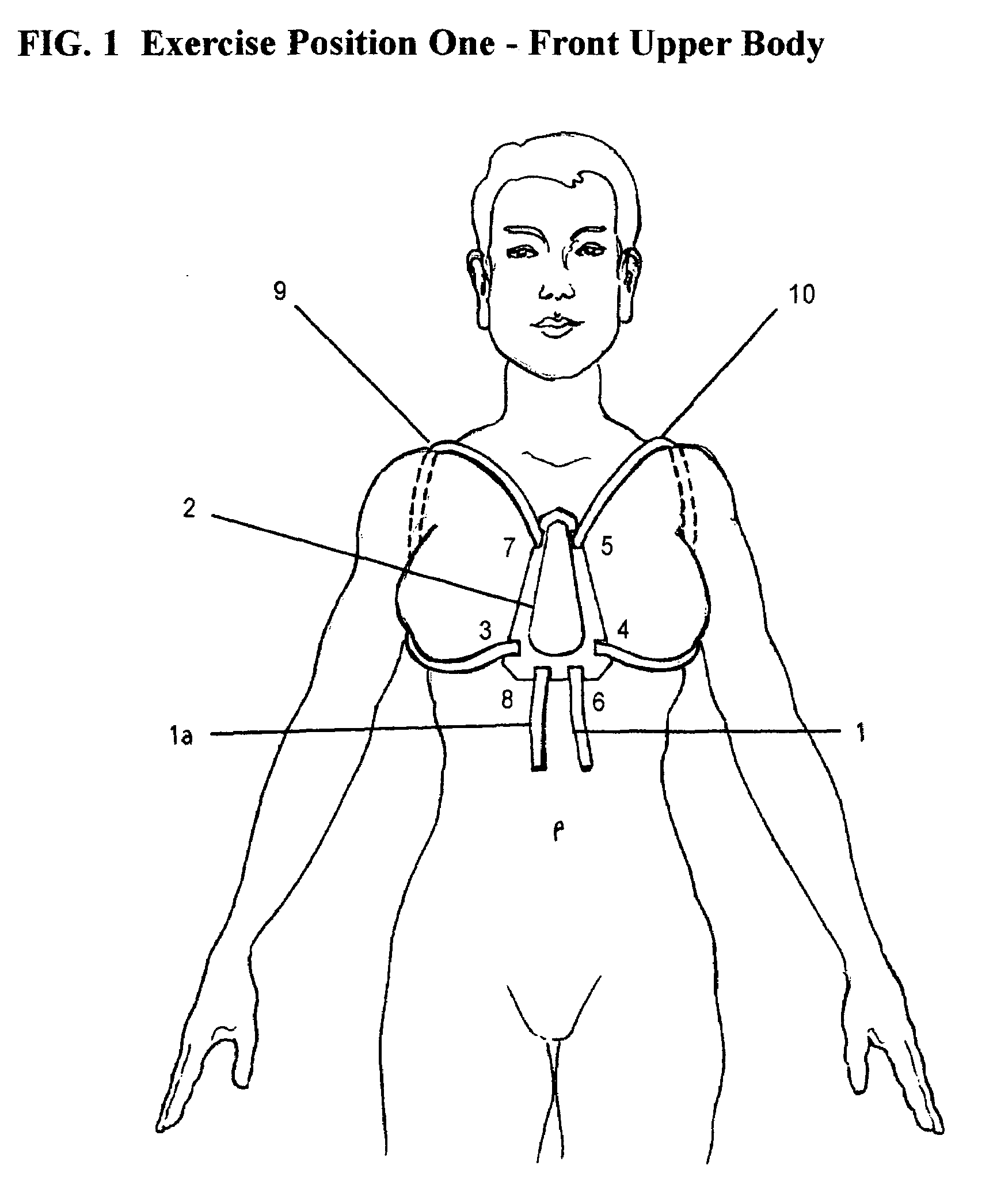

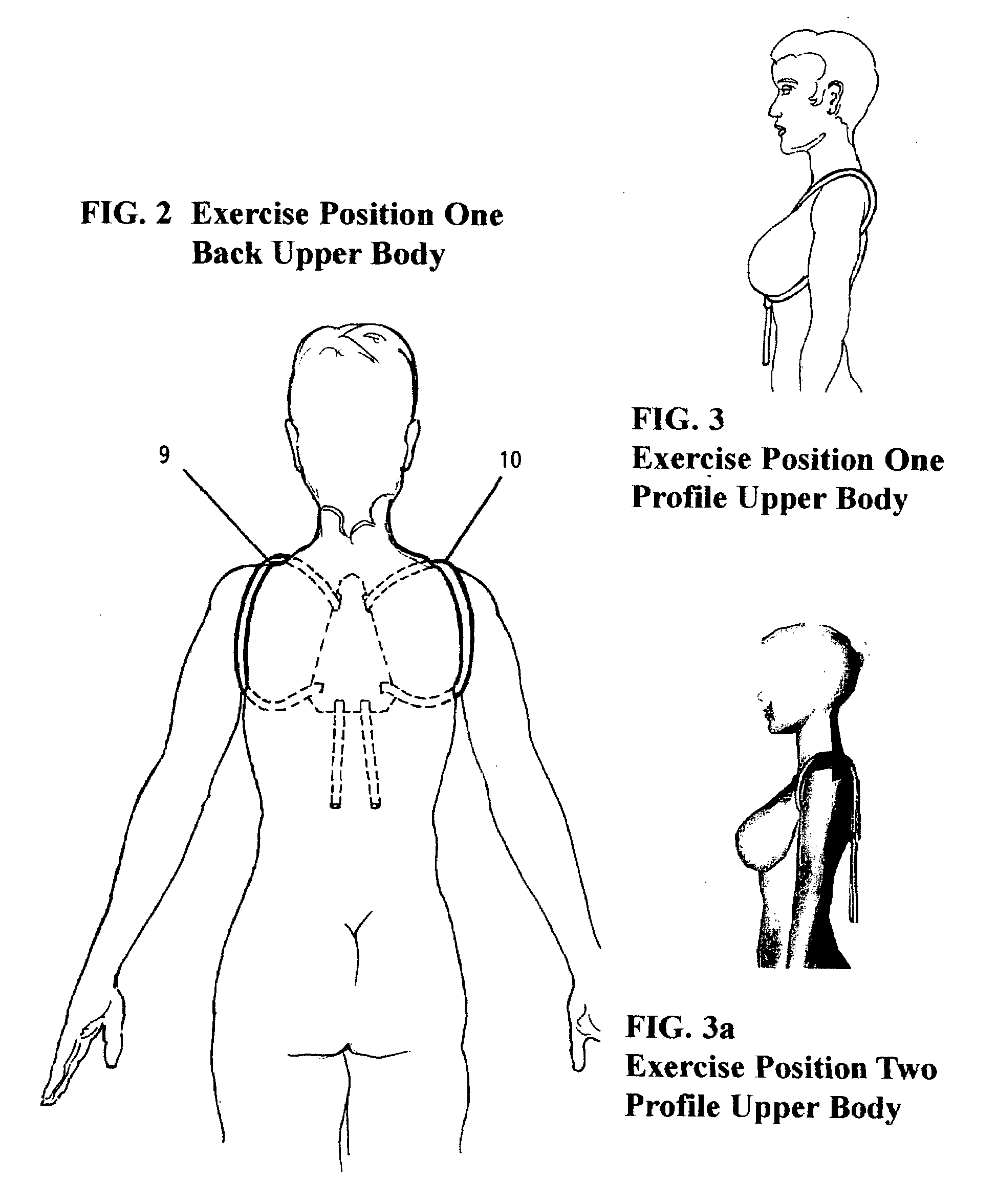

Wearable elastic upper body strengthening exercise device.

InactiveUS20080076645A1Continuous strengthEasy to useResilient force resistorsMuscle groupRange of motion

The invention relates to a wearable elastic upper body strengthening exercise device designed for use by a person who wants to build upper body strength. The device consists of one length of rubber tube or similar elastic material and a triangular fixture that holds this tube in two loops designed to fit around each shoulder. The tension of these shoulder loops can be adjusted to fit any size body frame, and can be affixed to provide a range of tension. The device allows the user a full range of motion while the resistance encourages a strengthening of affected muscle groups.

Owner:BROWN COLLON

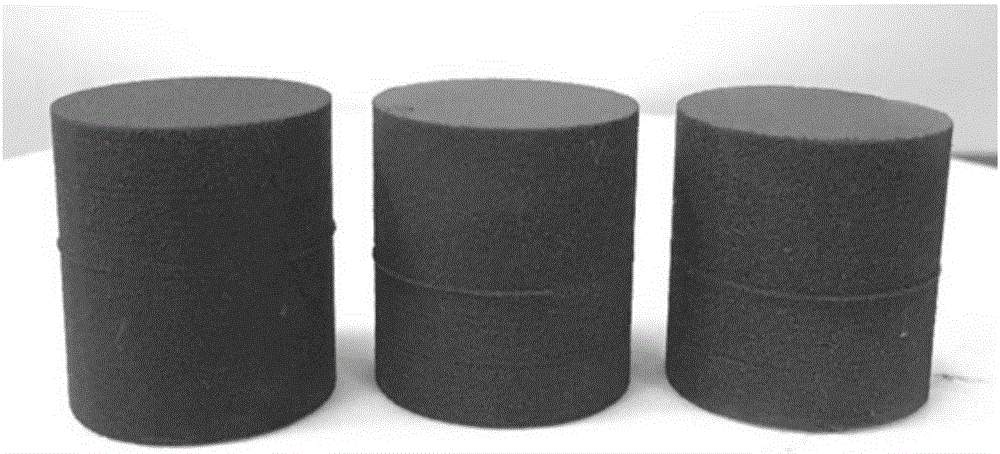

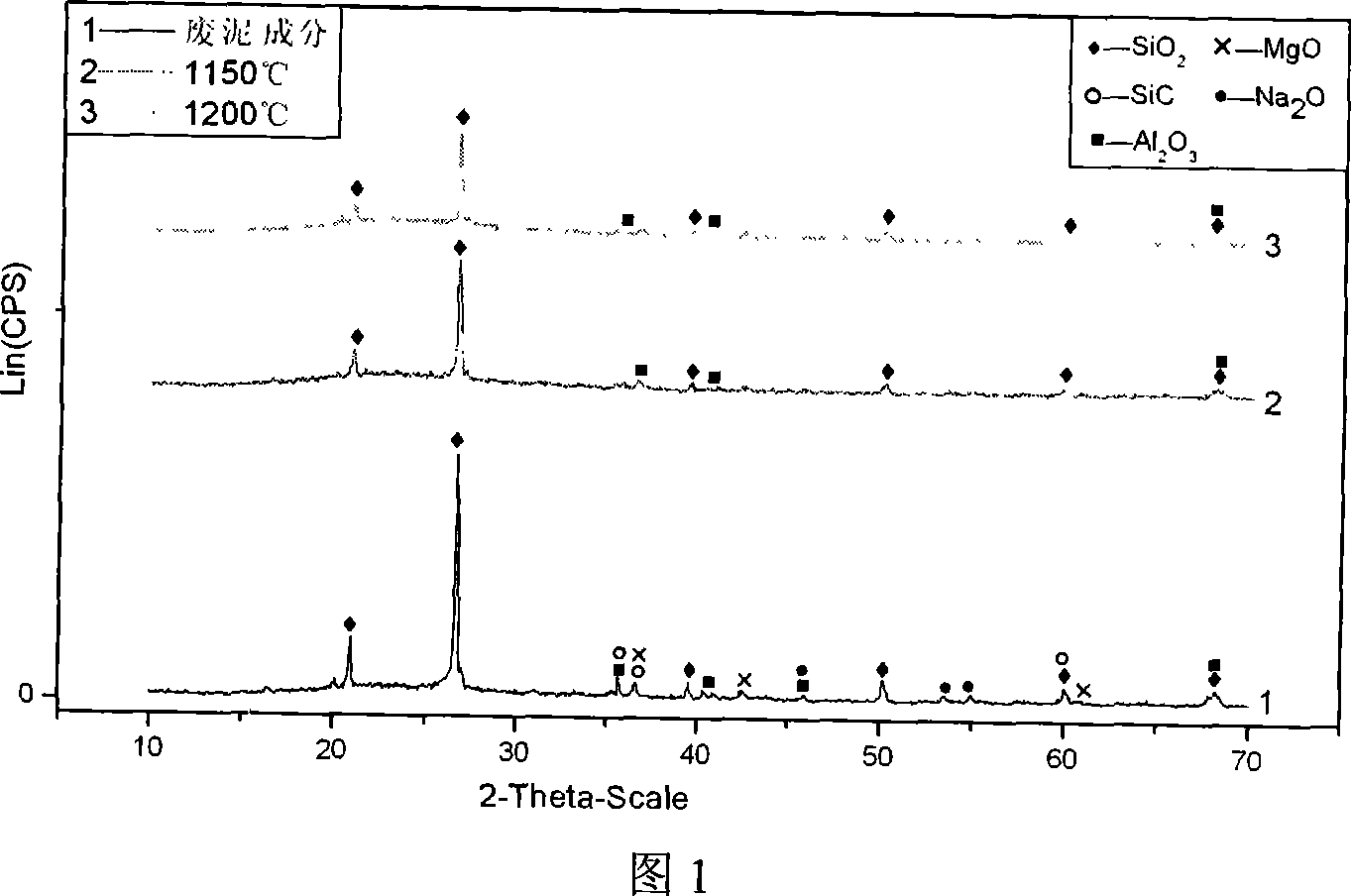

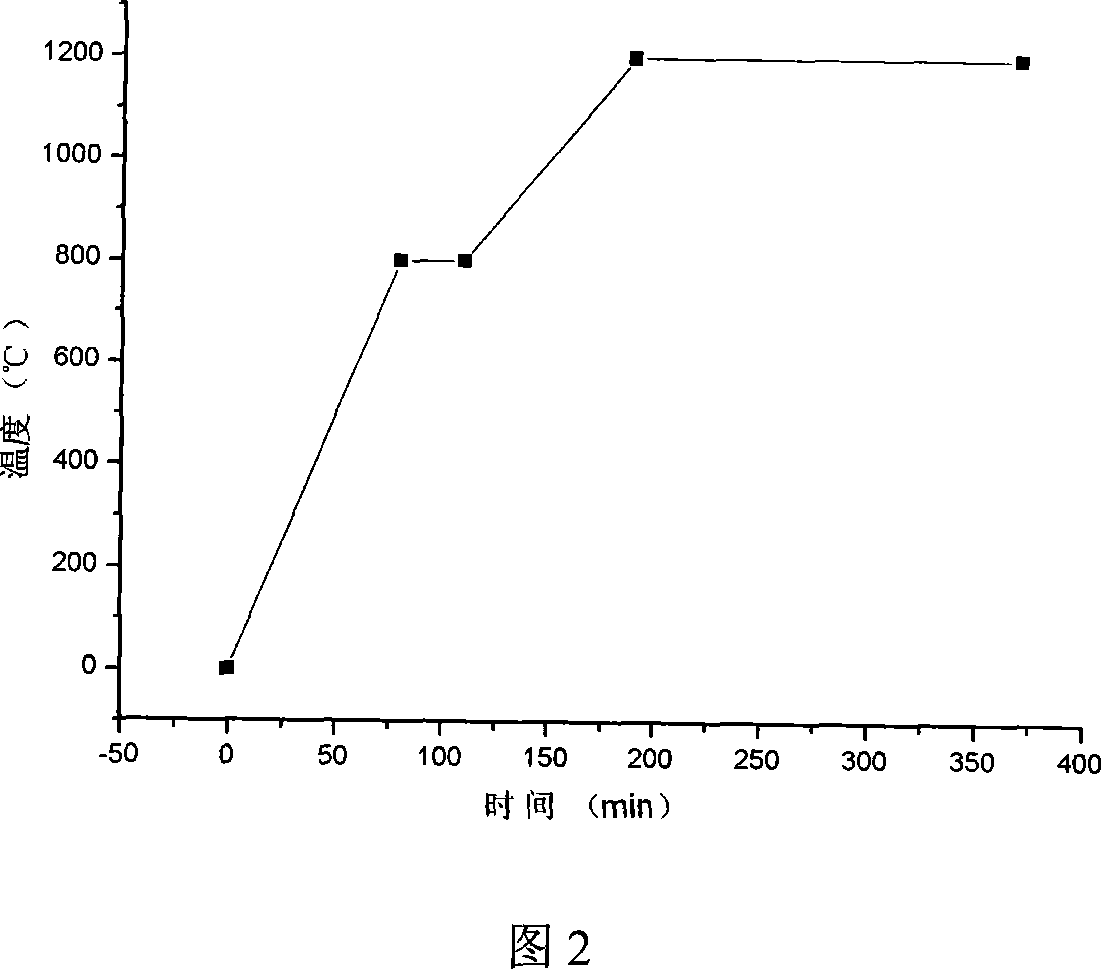

Ceramic-base high-strength lightweight buoyancy material

The present invention discloses a preparation method for new type ceramics-based buoyancy material with light weight and high intensity, wherein the polishing waste sludge from the ceramics factory serves as the main material, the porous ceramic material which has high sealed porosity content and prepared by dry pressing, injection moulding, atmospheric pressure sintering, high temperature chemical blowing process serves as the matrix of the new type ceramics-based buoyancy material, and epoxy resin serves as the fortified outer wall. Compared with the prior art, the buoyancy material of the present invention has excellent endurance and weathering resistance, sea-water corrosion resistance, aging resistance, small specific absorption of volume, high mechanical strength, simple preparation process, low cost and convenience for industrialisation. The internal pore of the porous ceramics has an uniform distribution and the sealed porosity is more than 95% due to the high temperature foaming in situ. The new type buoyancy material has low density and high compression strength. The porous ceramic material prepared by sintering at 1180 DEG C has a density of 0.35g / cm<3> and a compression strength of more than 7 MPa. The buoyancy material which is modified by epoxy resin has a density of 0.52g / cm<3> and a compression strength of more than 20 MPa.

Owner:OCEAN UNIV OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com