Preparation method of water permeable brick

A permeable brick and formula technology, applied in clay products, ceramic products, applications, etc., can solve the problems of multiple production processes, bulky ball milling equipment, and long time consumption, and achieve the effects of shortening production time, excellent water permeability, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

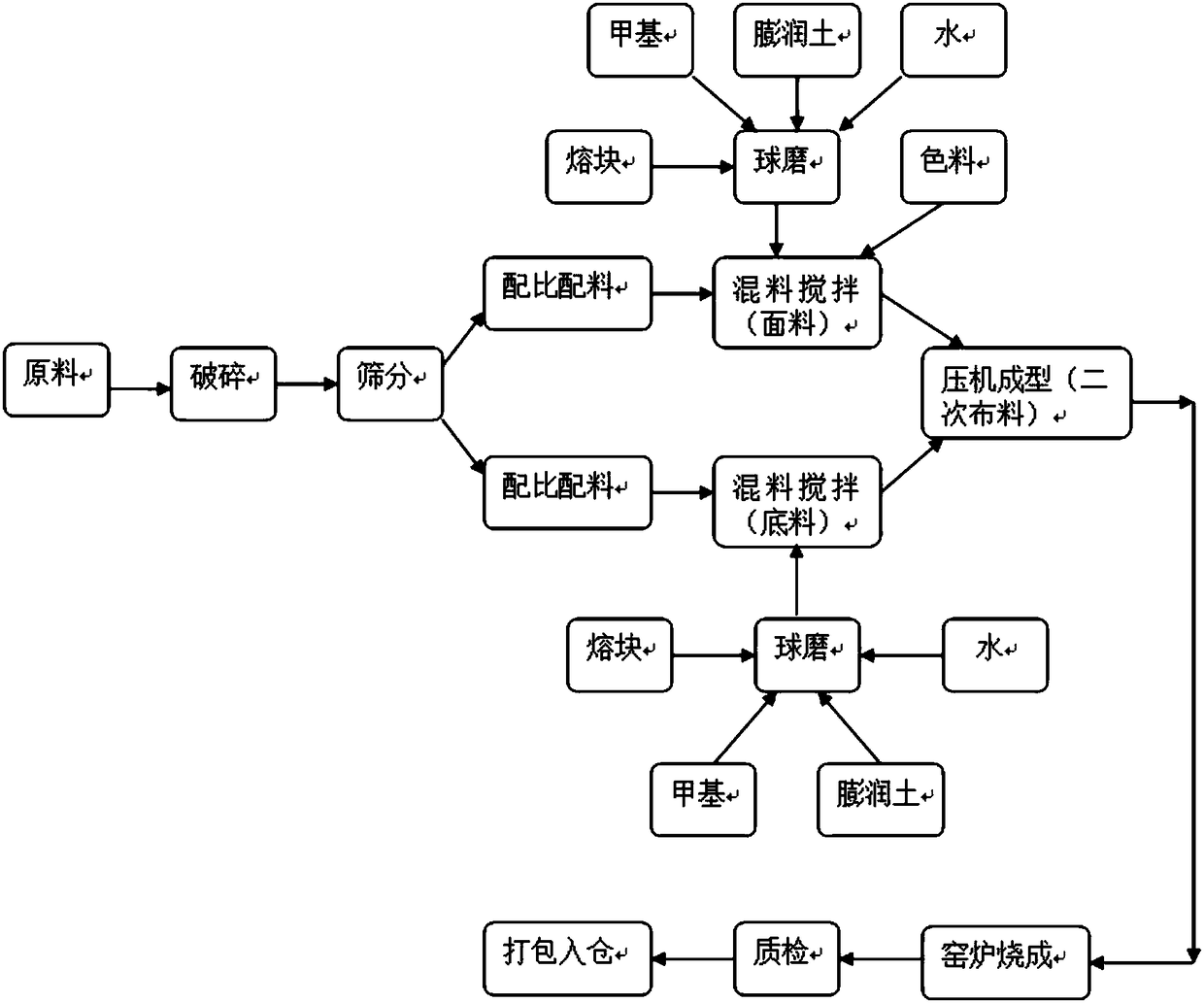

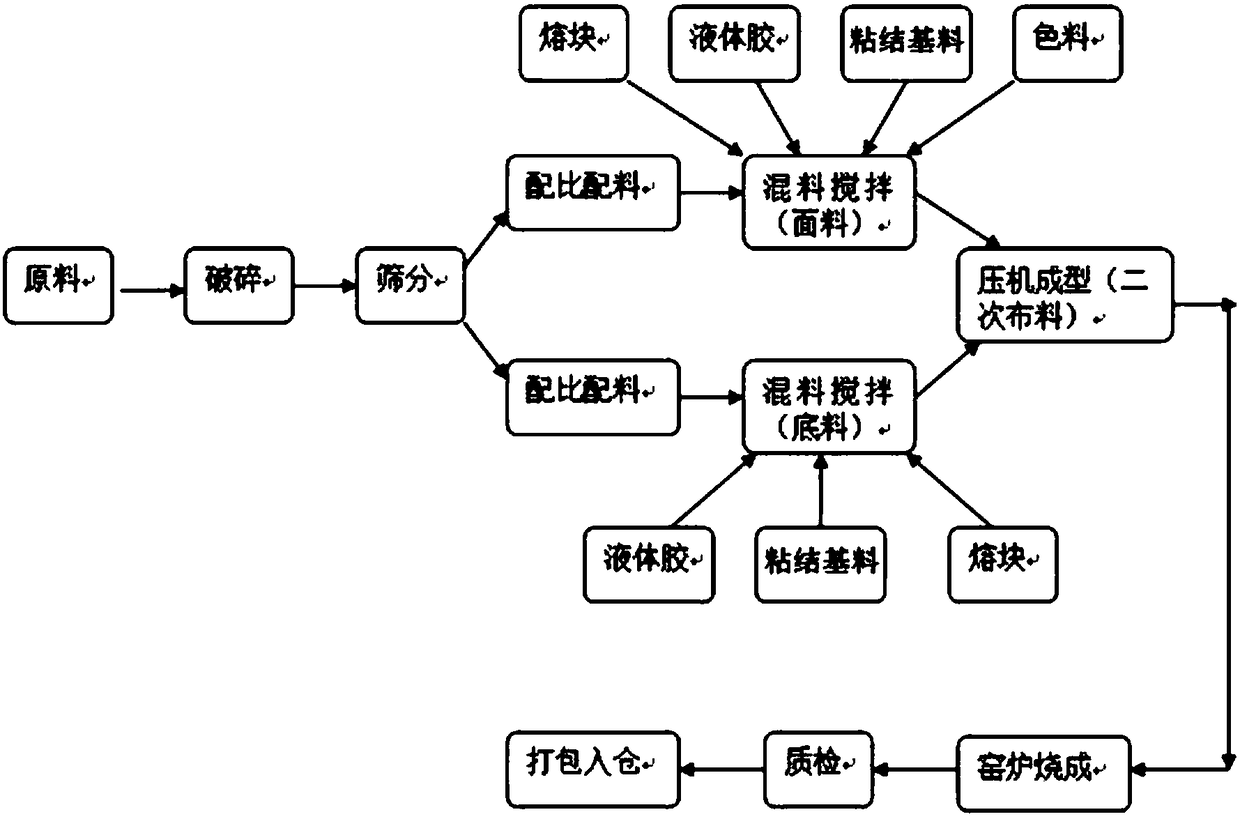

[0042] The invention provides a method for preparing permeable bricks, such as figure 2 shown, including:

[0043] (1) Crushing the aggregate;

[0044] The aggregate includes one or more of waste ceramic tiles, stone fragments, slag, coal gangue, and chain grate slag; wherein, the waste ceramic tiles include waste polished tiles, waste polished glazed tiles, waste interior wall tiles, waste One or more of antique bricks; the stone fragments include one or more of granite, Luoyuanhong, quartz stone, porcelain stone, potassium feldspar, albite; the slag includes iron slag, copper One or more of slag.

[0045] Preferably, the aggregate includes one of waste tiles, stone fragments, slag, coal gangue, and chain grate slag; wherein, the waste tiles include waste polished tiles, waste polished glazed tiles, waste interior wall tiles, waste One of antique bricks; the stone fragments include one of granite, Luoyuanhong, quartz stone, porcelain stone, potassium feldspar, and albite;...

Embodiment 1

[0084] (1) Aggregate is broken, and described aggregate is waste ceramic tile, and described waste ceramic tile is waste polished brick;

[0085] (2) passing the crushed aggregate through sieves of different apertures to obtain aggregate particles of different particle sizes;

[0086] (3) The sieved aggregate particles are batched according to the base material formula, and 35kg of 4-20 mesh aggregate and 35kg of 12-40 mesh aggregate are added to 4.2kg of binder and stirred evenly to obtain Bottom material mixture; mix the sieved aggregate particles according to the fabric formula, and add 1.8kg of binder and 0.6kg of colorant to 30kg of 4-20 mesh aggregate to obtain the fabric mixture;

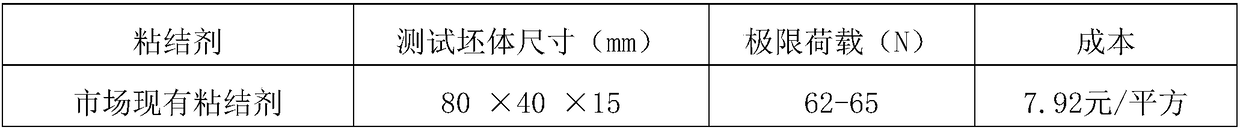

[0087] Wherein, the binder includes a bonding base material and a liquid glue, the weight ratio of the bonding base material and the liquid glue is 1:1, and the bonding base material is bentonite; the liquid glue is a silica sol solution;

[0088] (4) Carry out the mixing and stirring of the...

Embodiment 2

[0092] (1) breaking the aggregate, the aggregate is stone fragments, and the stone fragments include granite;

[0093] (2) passing the crushed aggregate through sieves of different apertures to obtain aggregate particles of different particle sizes;

[0094] (3) Mix the sieved aggregate particles according to the base material formula, add 35kg of 4-20 mesh aggregate, 35kg of 12-40 mesh aggregate and 5kg of <40 mesh aggregate, and add 8kg of bonded agent, and stir evenly to obtain the bottom material mixture; the sieved aggregate particles are prepared according to the fabric formula, and 25kg of 4-20 mesh aggregates are added with 2.5kg of binder and 0.8kg of colorant to obtain fabric mix;

[0095] Among them, the binder includes bonding base material, liquid glue and frit, the weight ratio of the amount of bonding base material, liquid glue and frit is 3:4:1, the bonding base is kaolin, and the liquid glue is polypropylene Amide solution;

[0096] (4) Carry out the mixing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com