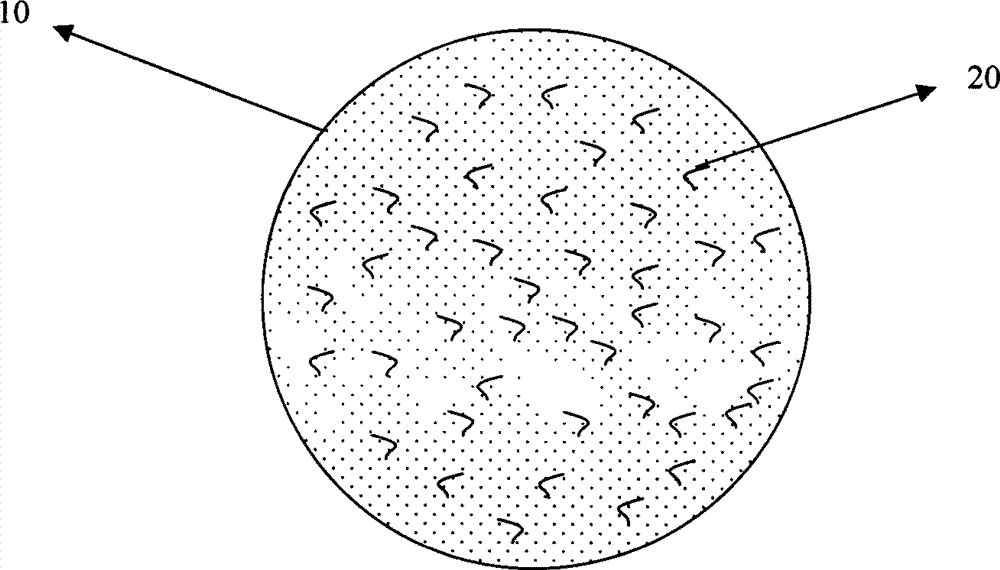

SiC whisker-reinforced ceramic-based composite plate and preparation method thereof

A composite plate and ceramic-based technology, which is applied in the field of ceramic-based composite plates and its preparation, can solve the difficulty of separating silicon carbide whiskers from reaction residues, affect the reinforcing effect of silicon carbide whiskers on substrates, and reduce silicon carbide whiskers Quality and other issues, to achieve the effect of improved fracture toughness and bending strength, high reliability in use, and good reinforcement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Add monomer acrylamide and cross-linking agent methylenebisacrylamide to the aqueous solution to form a premix solution with a concentration of 15%;

[0023] (2) Add the premix liquid and dispersant ammonium polyacrylate to the proportioned inorganic ceramic powder according to the requirement of 55% solid phase volume fraction, adjust the pH to 11, and ball mill and mix for 15 hours to make a slurry;

[0024] (3) After the slurry is exhausted, add the initiator ammonium persulfate, fully stir and remove the air bubbles, inject it into the mold cavity, add the catalyst tetramethylethylenediamine, gel for 45 minutes, and place it in a stable place after demoulding;

[0025] (4) Put the above green body into an oven with a temperature of 70°C and a drying time of 12 hours;

[0026] (5) After drying, degumming at 600°C removes the molding agent to obtain a prefabricated body, and then surface processing, the precision reaches the sealing material level;

[0027] (6) P...

Embodiment 2

[0030] (1) Add monomer acrylamide and crosslinking agent methylenebisacrylamide to the aqueous solution to form a premix solution with a concentration of 20%;

[0031] (2) Add the premix liquid and the dispersant ammonium polyacrylate to the proportioned inorganic ceramic powder according to the requirement of 60% solid phase volume fraction, adjust the pH to 10, and ball mill and mix for 20 hours to make a slurry;

[0032] (3) After the slurry is exhausted, add the initiator ammonium persulfate, fully stir and remove the air bubbles, inject it into the mold cavity, add the catalyst tetramethylethylenediamine, gel for 60 minutes, and place it in a stable place after demoulding;

[0033] (4) Put the above green body into an oven with a temperature of 80°C and a drying time of 10 hours;

[0034] (5) After drying, degumming at 700°C removes the molding agent to obtain a prefabricated body, and then surface processing, the precision reaches the sealing material level;

[0035] (6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com