Method for preparing hydraulic calcium oxide through papermaking alkali recycling causticized white sludge

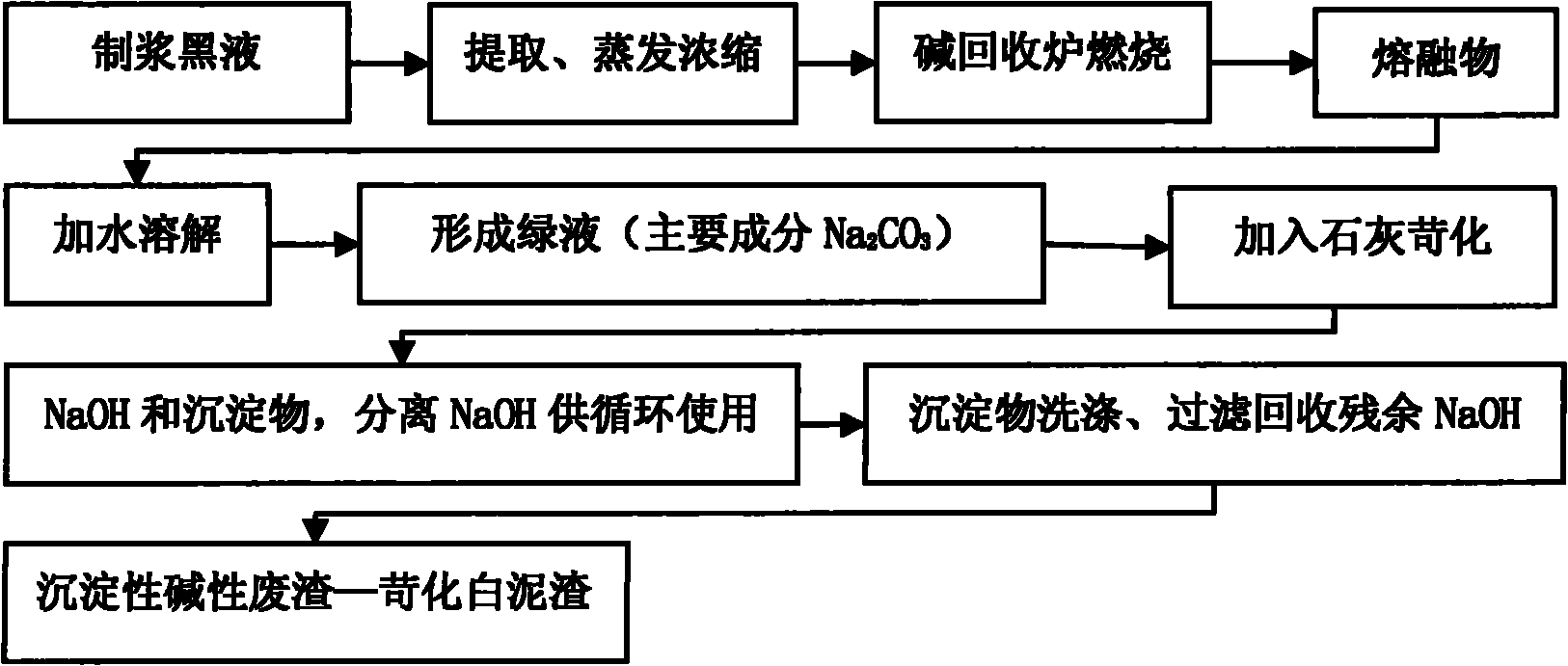

A technology for causticizing white mud and hydraulic setting, which is applied in the field of preparing new building materials, can solve the problems of rare patent discussion, difficult to popularize and high fuel cost, and achieve the effect of saving calcination cost, reducing calcining energy consumption and reducing dust pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

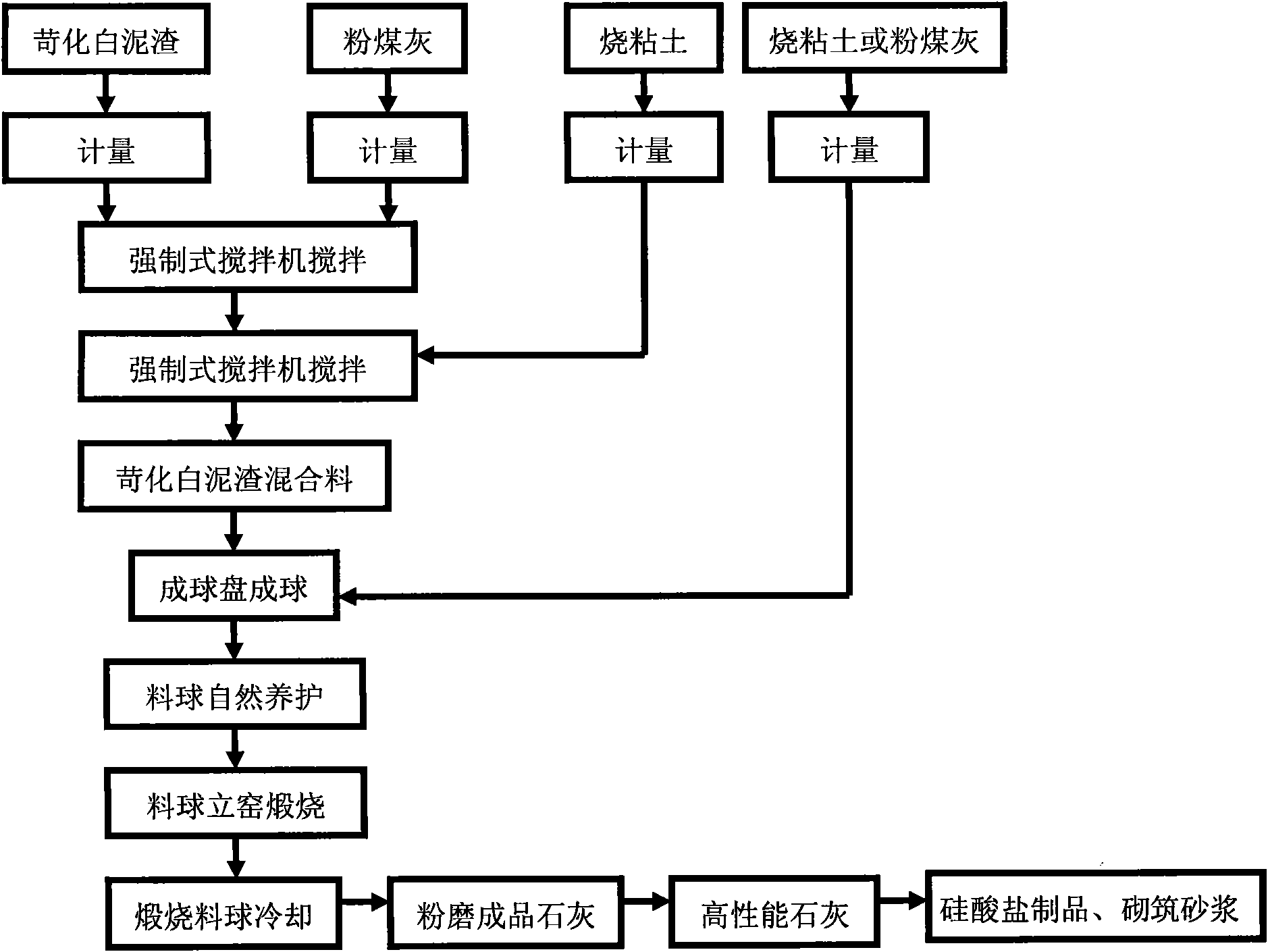

[0044] to combine figure 2 , the method for preparing hydraulic calcium oxide from causticized lime mud by papermaking alkali of the present invention comprises the following steps:

[0045] Step 1: Put 500kg of causticizing white mud slag and 75kg of fly ash into the mixer and stir for 2 to 3 minutes. When the mixture is in a uniform state, add 25kg of burnt clay and continue stirring for 1 to 2 minutes. The mixture is uniformly mixed;

[0046] Step 2: Transfer the prepared mixture into the ball forming equipment, turn it into a ball cylinder (ball plate) at a certain speed, and gradually add 25kg of burnt clay into the cylinder, and turn it into a ball cylinder for 6 to 8 minutes At this time, a sphere with a diameter of 10-30mm can be formed in the cylinder, and the material sphere has a certain initial strength (judged according to its free fall from a height of 1m without breaking);

[0047] Step 3: Naturally stack and maintain the balls obtained in the second step for...

Embodiment 2

[0051] to combine figure 2 , the method for preparing hydraulic calcium oxide from causticized lime mud by papermaking alkali of the present invention comprises the following steps:

[0052] Step 1: Put 500kg of causticizing white mud slag and 50kg of fly ash into the mixer and stir for 2 to 3 minutes. When the mixture is in a uniform state, add 50kg of burnt clay and continue stirring for 1 to 2 minutes. The mixture is uniformly mixed;

[0053] The second step: transfer the prepared mixture into the ball forming equipment, turn it into a ball tube (ball plate) at a certain speed, and gradually add 25kg of fly ash into the tube, and the rotation time of the ball tube is 6-8 In minutes, a sphere with a diameter of 10-30mm can be formed in the cylinder, and the material sphere has a certain initial strength (the initial strength can be judged according to its free fall from a height of 1m without breaking);

[0054] Step 3: Naturally stack and maintain the balls obtained in t...

Embodiment 3

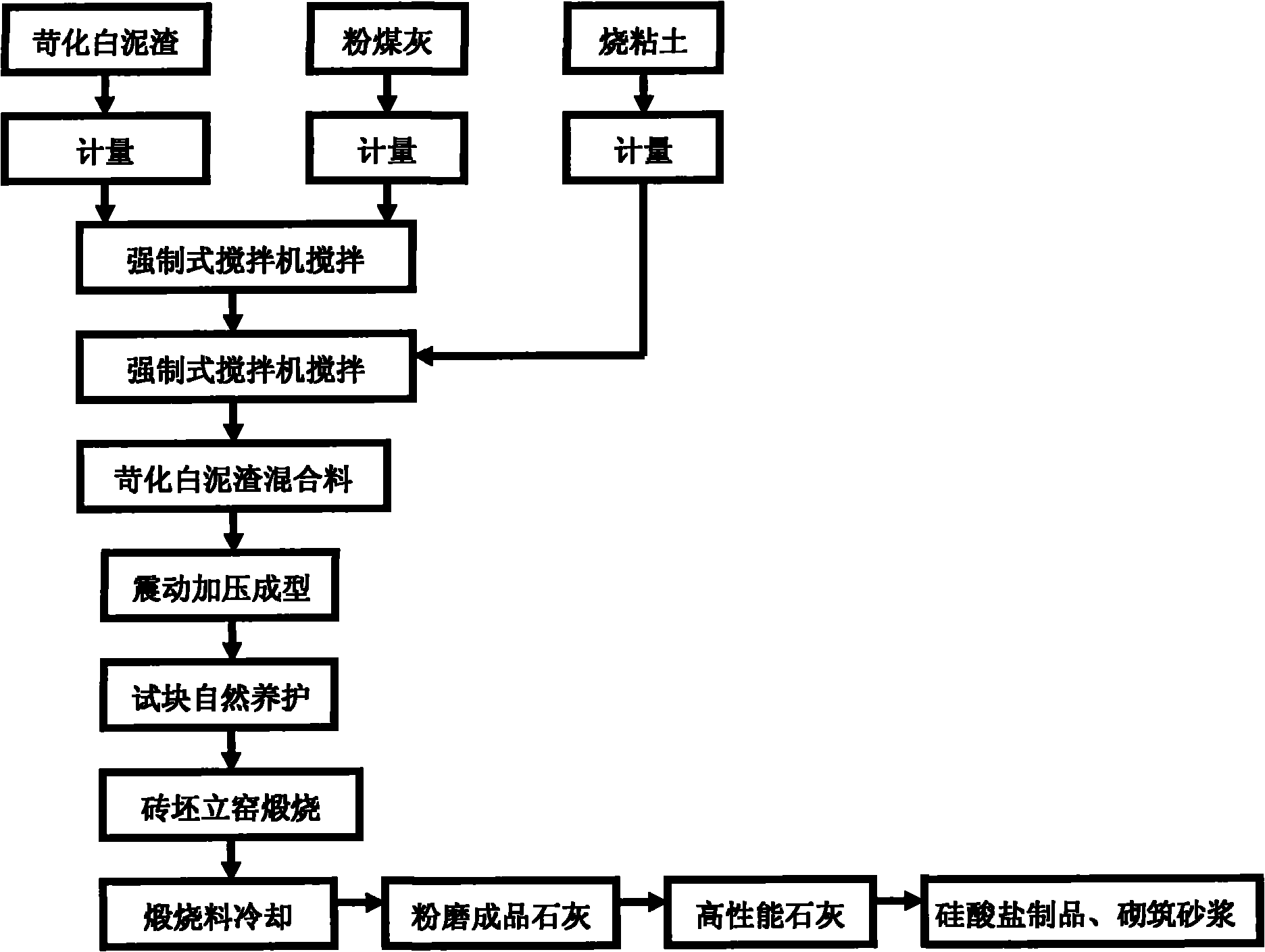

[0058] to combine image 3 , the method for preparing hydraulic calcium oxide from causticized lime mud by papermaking alkali of the present invention comprises the following steps:

[0059] Step 1: Put 500kg of causticizing white mud slag and 50kg of fly ash into the mixer and stir for 2 to 3 minutes. When the mixture is in a uniform state, add 50kg of burnt clay and continue stirring for 1 to 2 minutes. The mixture is uniformly mixed;

[0060] Step 2: Transfer the white mud and slag mixture to the concrete block forming machine, vibrate and press to form, and place the formed body on the test block pallet for natural curing, and transport it to the storage yard after it has a certain initial compressive strength carry out natural conservation;

[0061] Step 3: Naturally stack and maintain the test pieces obtained in the second step for 7 to 14 days until the quality of the adobe is basically no longer reduced, and the compressive strength of the adobe exceeds 1MPa, which c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com