Autoclaved aerated concrete, steel reinforced concrete composite structure and application thereof

A reinforced concrete and concrete structure technology, applied in the direction of building components, building structures, building materials, etc., can solve the problems of unable to use load-bearing parts, high foundation cost, and heavy building weight, so as to reduce the overall weight and wall Effect of reducing weight and construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

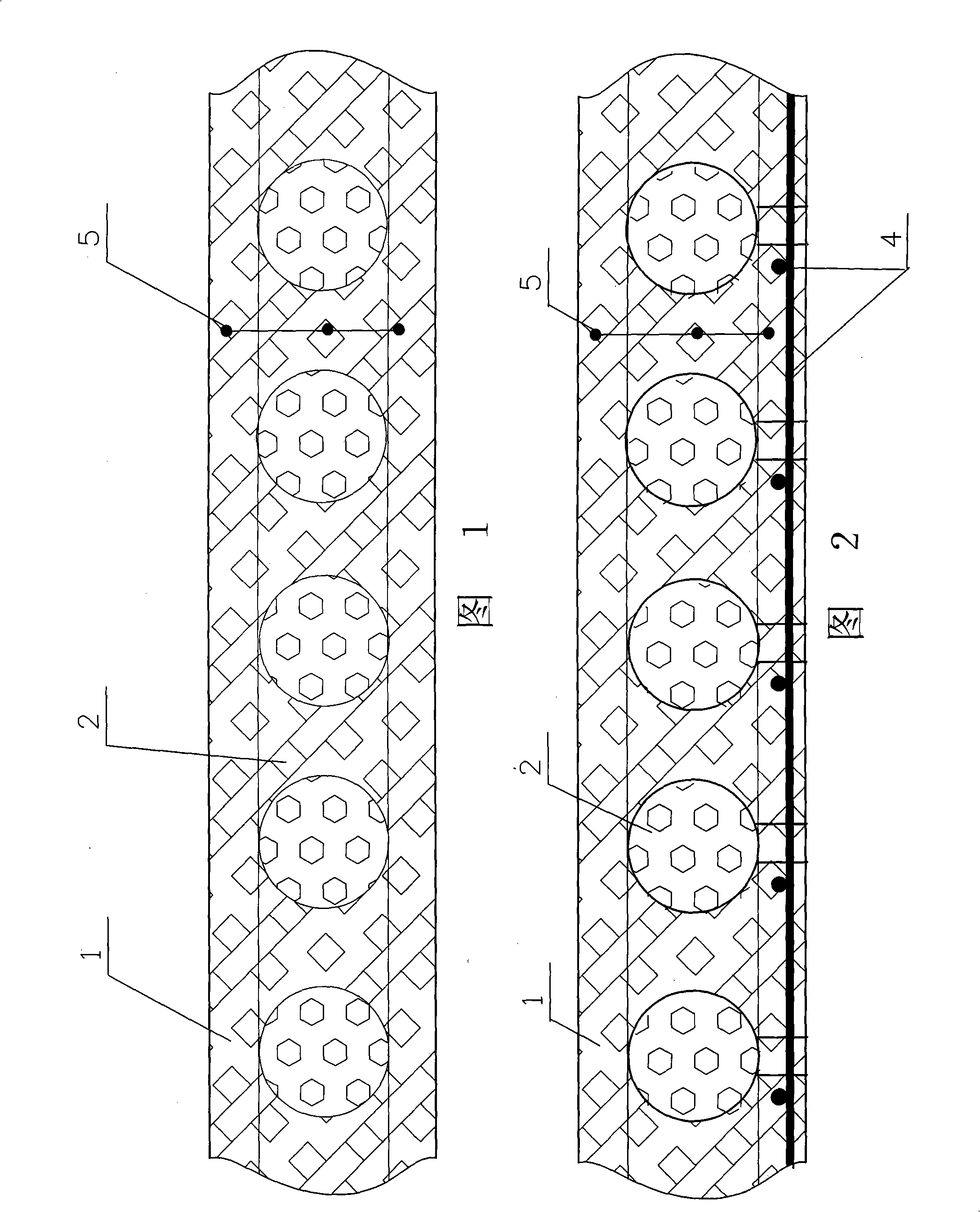

[0021] An autoclaved aerated concrete and reinforced concrete composite structural member, which consists of: a concrete structural member 1 for building with reinforcing steel bars 5, and the low-stress part near the horizontal mandrel in the middle of the member is made of autoclaved aerated concrete 2. The specific width and shape can be determined by usual engineering calculations and the label of aerated concrete.

Embodiment 2

[0023] Among the above-mentioned autoclaved aerated concrete and reinforced concrete composite structural members, the autoclaved aerated concrete member is a columnar prefabricated member 2, and a set of positioning members 3 can be arranged on the side of the columnar as required , During the on-site construction, the position of the aerated concrete precast component in the cast-in-situ slab is ensured by the positioning piece. In the concrete member, tensile steel bars 4 may be provided as required. By increasing the bearing capacity of reinforced load-bearing parts, aerated concrete replaces ordinary concrete at non-load-bearing parts, thereby reducing the weight of non-load-bearing parts, thereby optimizing wall performance

Embodiment 3

[0025] An application of the above-mentioned composite structural member of autoclaved aerated concrete and reinforced concrete as floor slab and roof slab.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com