Patents

Literature

120results about How to "Improve insulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Heat preservation covering agent

The invention discloses a heat preservation covering agent which is processed by mixing components of, by weight, 5-8% of metal aluminum powders, 15-30% of boron nitride powders, 5-15% of sodium nitrate, 25-35% of modified expanded perlite, 15-30% of chaff ashes, 10-18% of metal magnesium powders and 5-8% of fluorite powders. The heat preservation covering agent can produce heat so that heat preservation and thermal insulation effects of the covering agent are improved, condensation speeds of metal liquids at casting risers are slowed down, and the capacity for the covering agent to absorb metal liquid included matters is enhanced.

Owner:山国强

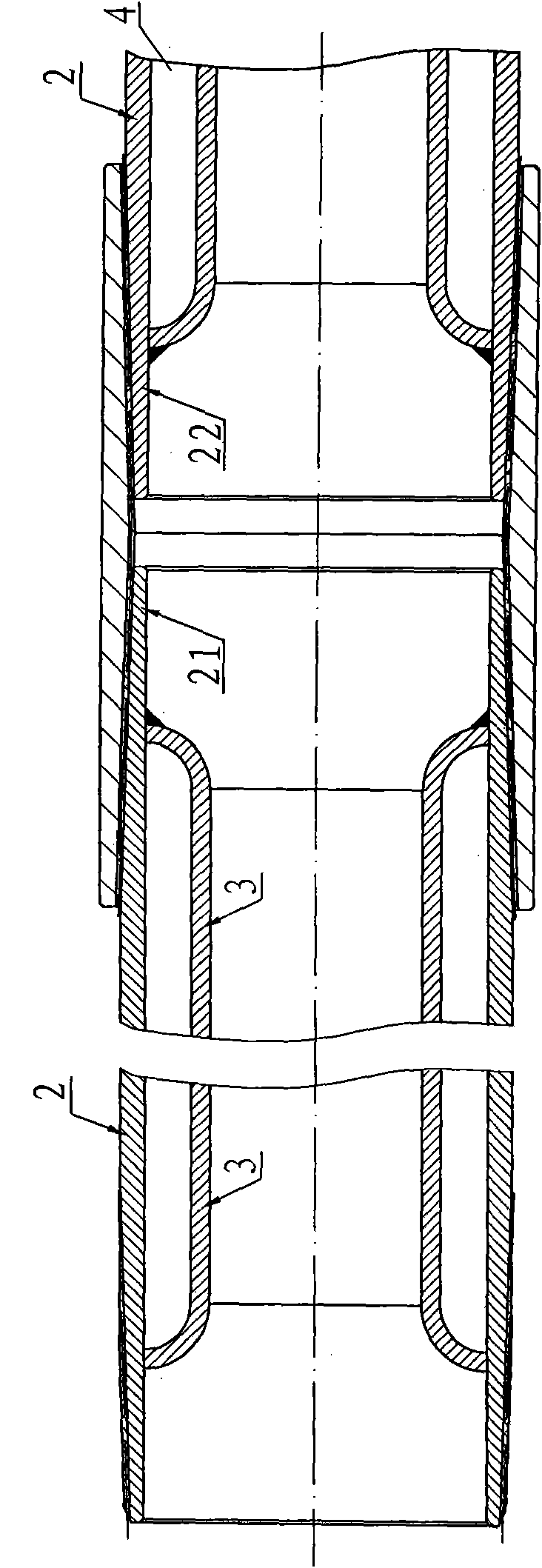

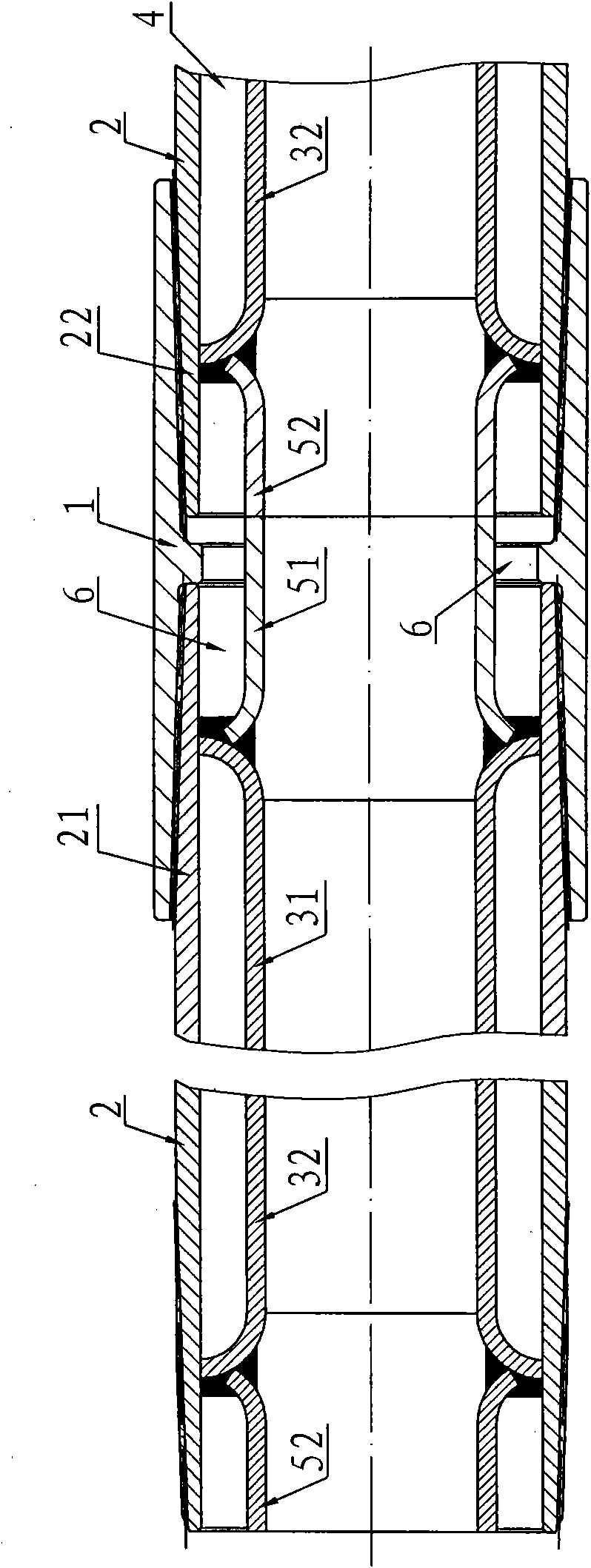

Structure for connecting heat insulation oil pipes

The invention discloses a structure for connecting heat insulation oil pipes, which comprises a coupling, an outer pipe factory end, an outer pipe user end, a pipe body inner pipe factory end, a pipe body inner pipe user end and a pipe end inner pipe, wherein the pipe end inner pipe is arranged between the pipe body inner pipe factory end and the pipe body inner pipe user end, and consists of a left pipe end inner pipe and a right pipe end inner pipe; one end of the left pipe end inner pipe is welded to the pipe body inner pipe factory end; one end of the right pipe end inner pipe is welded to the pipe body inner pipe user end; a sealed pipe end heat insulation cavity is formed between the pipe end inner pipe and the pipe body inner pipe factory end, the outer pipe factory end, the coupling, the pipe body inner pipe user end and the outer pipe user end; and a heat insulation sleeve is arranged in the pipe end heat insulation cavity. The pipe end inner pipe can reduce heat conduction, convection, radiation and heat loss at the coupling, improve the sealing performance of the heat insulation oil pipe coupling and prevent the problem that the heat insulation oil pipe coupling is easy to corrode at high temperature.

Owner:JIANGSU CHANGBAO STEELTUBE CO LTD

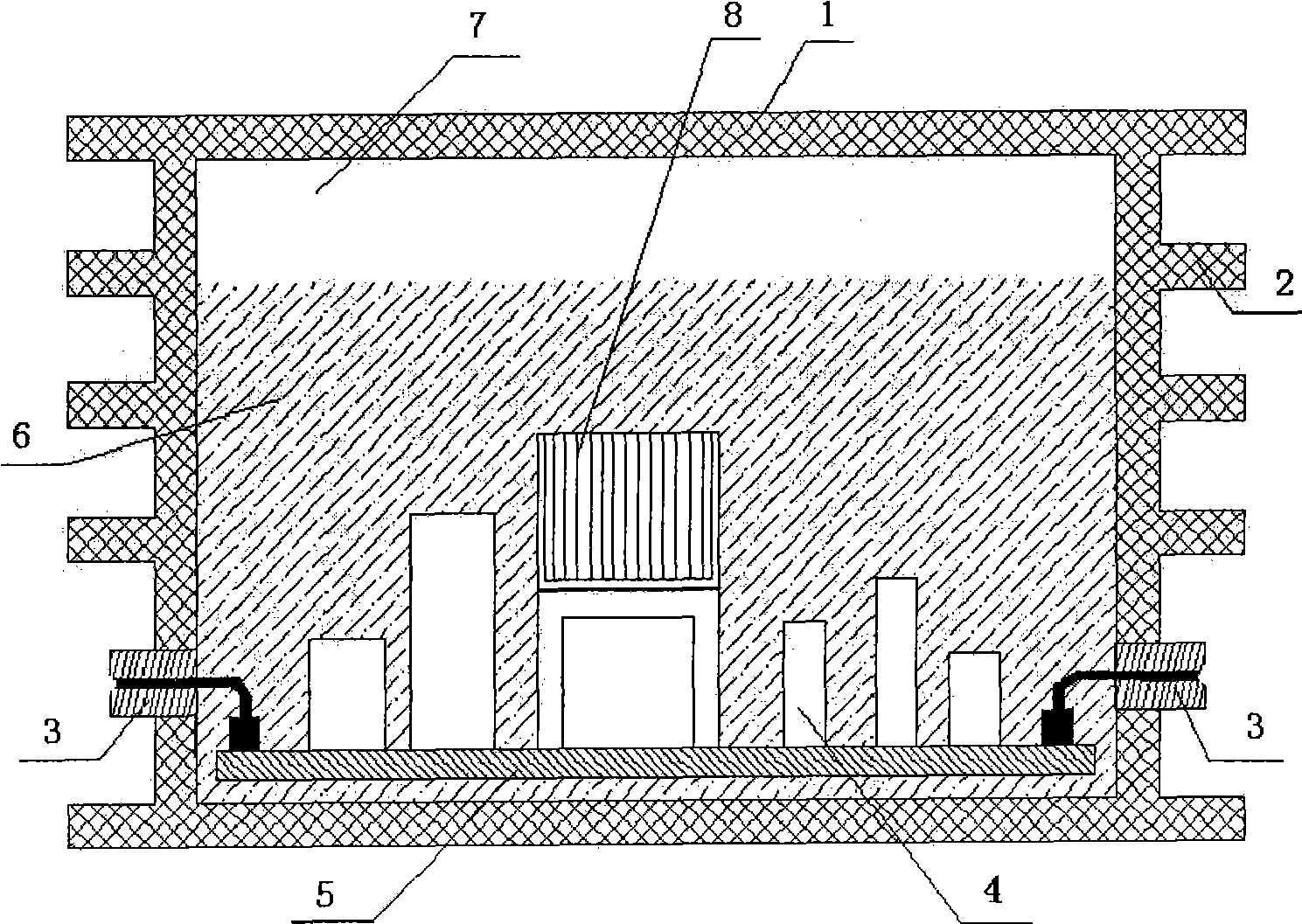

Electronic component, protection method and apparatus for circuit board

InactiveCN101505577AImprove insulationImprove reliabilityHermetically-sealed casingsCooling/ventilation/heating modificationsEngineeringElectronic component

The invention provides a method and a device for cooling, dustproofing and waterproofing for electronic devices and components and a circuit board. The electronic devices and components and the circuit board are fixed in a sealed container; insulative non-corrosive liquid without influence on the electronic devices is filled in the container; and related lead wires of the electronic devices and components and the circuit board are connected outside the container through a sealing element or a connector. The method and the device solve the problem that the electronic components and the circuit board are polluted and influenced by dust, vapor or impurities, greatly improve the insulativity, and also greatly improve the reliability of the electronic components and the circuit board.

Owner:梁威

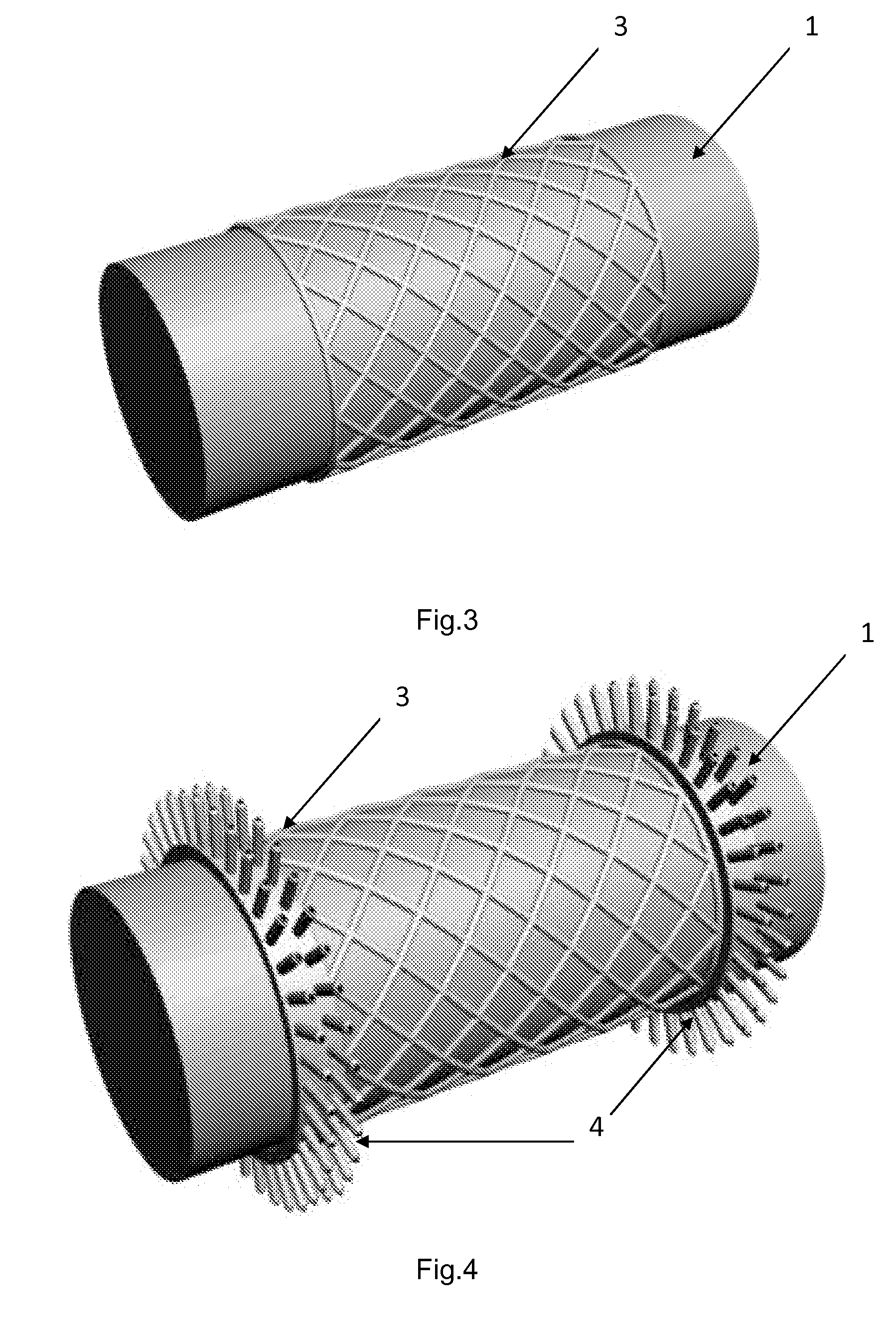

Method for making electrical windings for electrical apparatus and transformers and winding obtained by said method

InactiveUS20090313812A1Simple to useImprove insulationTransformers/inductances detailsInductances/transformers/magnets manufactureThin layerEngineering

This invention relates to a method of manufacturing electrical windings for electrical apparatus and transformers. This method comprises the following steps: manufacturing a metal mandrel defining the internal shape of the winding; installation of an internal insulation and support; installation of side rings; pouring impregnation compound on horizontally turning mandrel for obtaining a thin layer on the operational area of the mandrel and side surface of the side rings; optionally curing this layer; fixation of the first end wire using one of side rings; manufacturing winding with simultaneous pouring of compound onto the mandrel; possibly introducing intermediate insulation and / or reinforcing layers of preimpregnated reinforced plastics; optionally inserting premade sleeves around section of the winding; fixation of the second end wire using one of side rings; possibly introducing external insulation or reinforcing layers of preimpregnated reinforced plastics; possibly manufacturing secondary windings on top of the wound winding; curing the winding; extraction of the cured winding or a set of cured windings from the mandrel.The invention also relates to winding structures obtained by this method.

Owner:PULNIKOV SERGEY

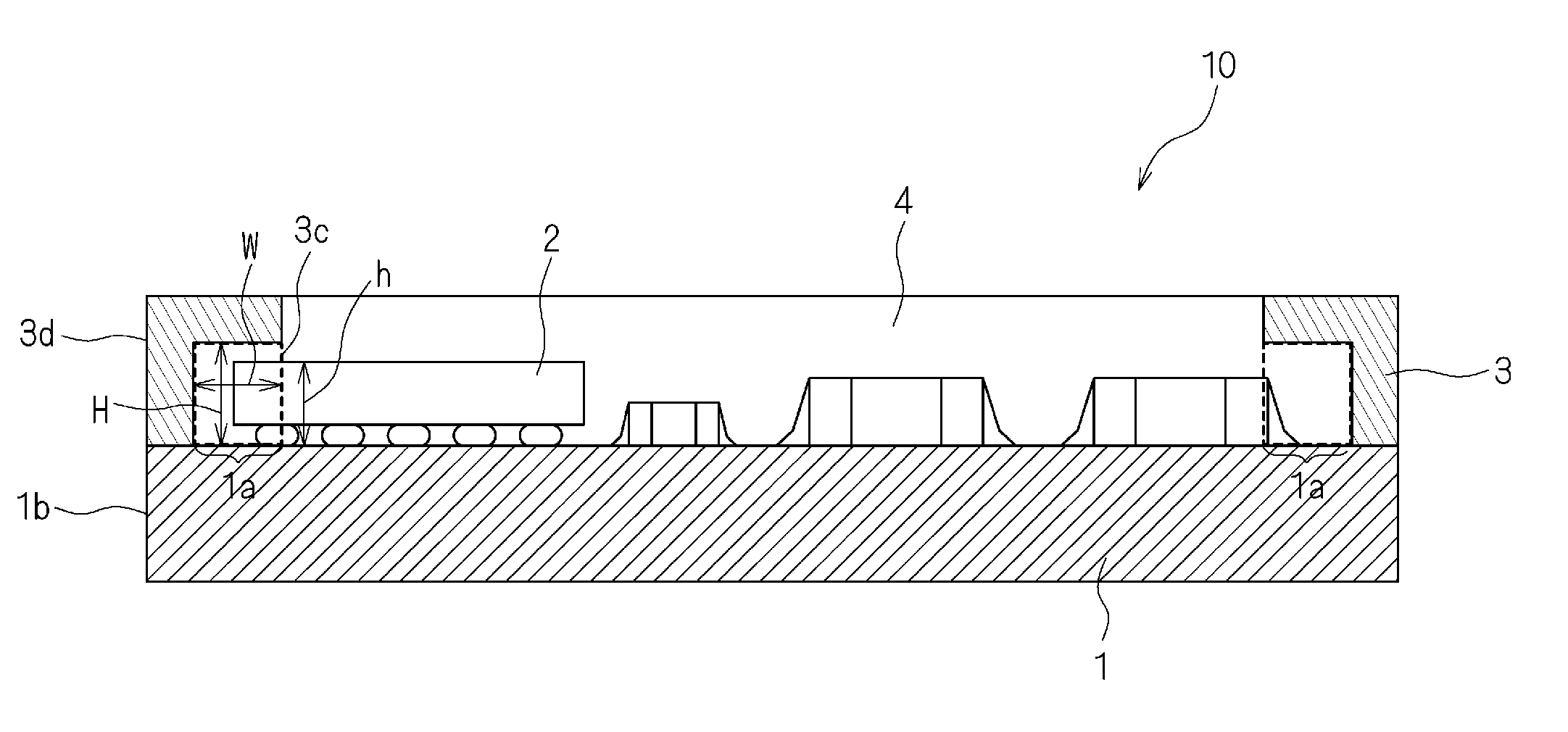

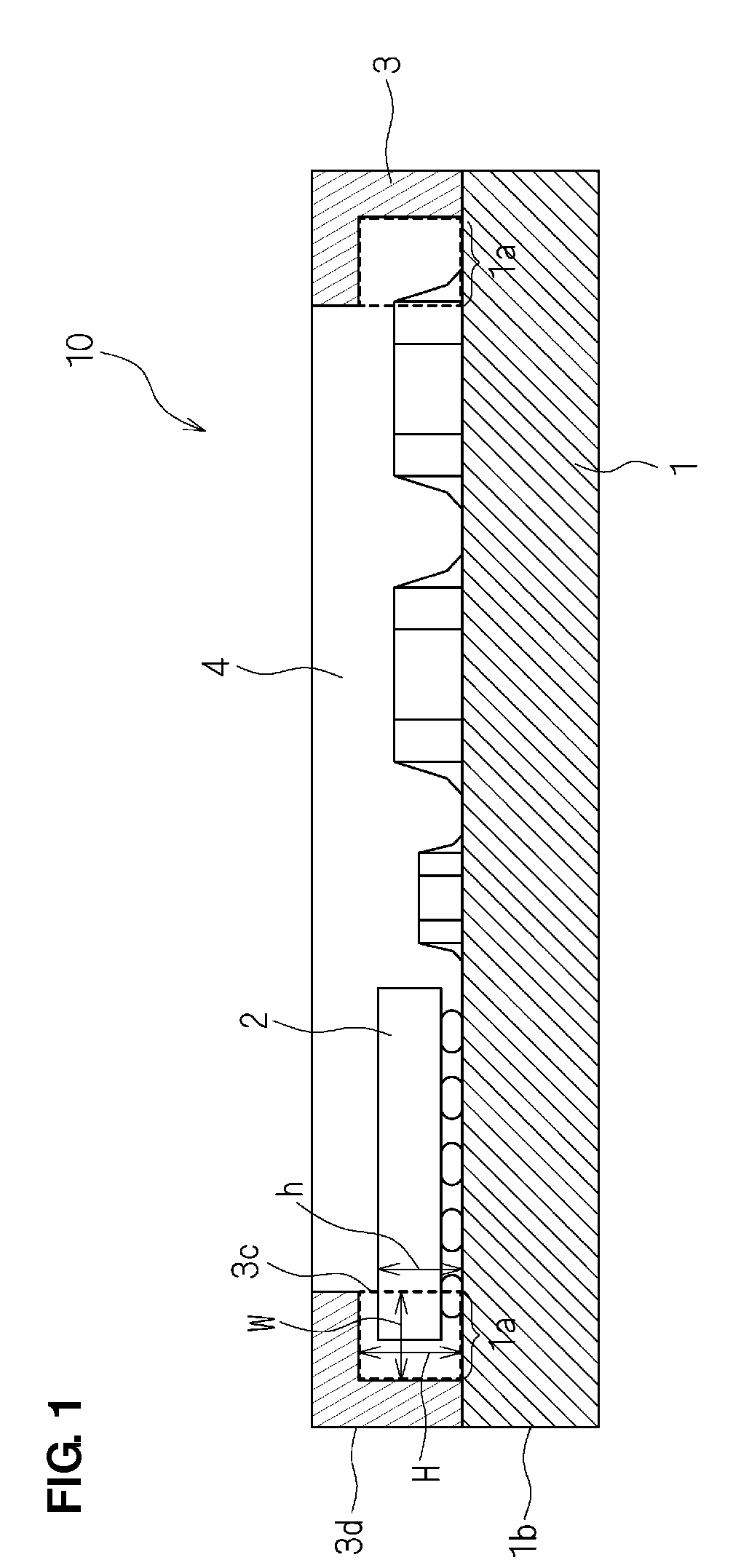

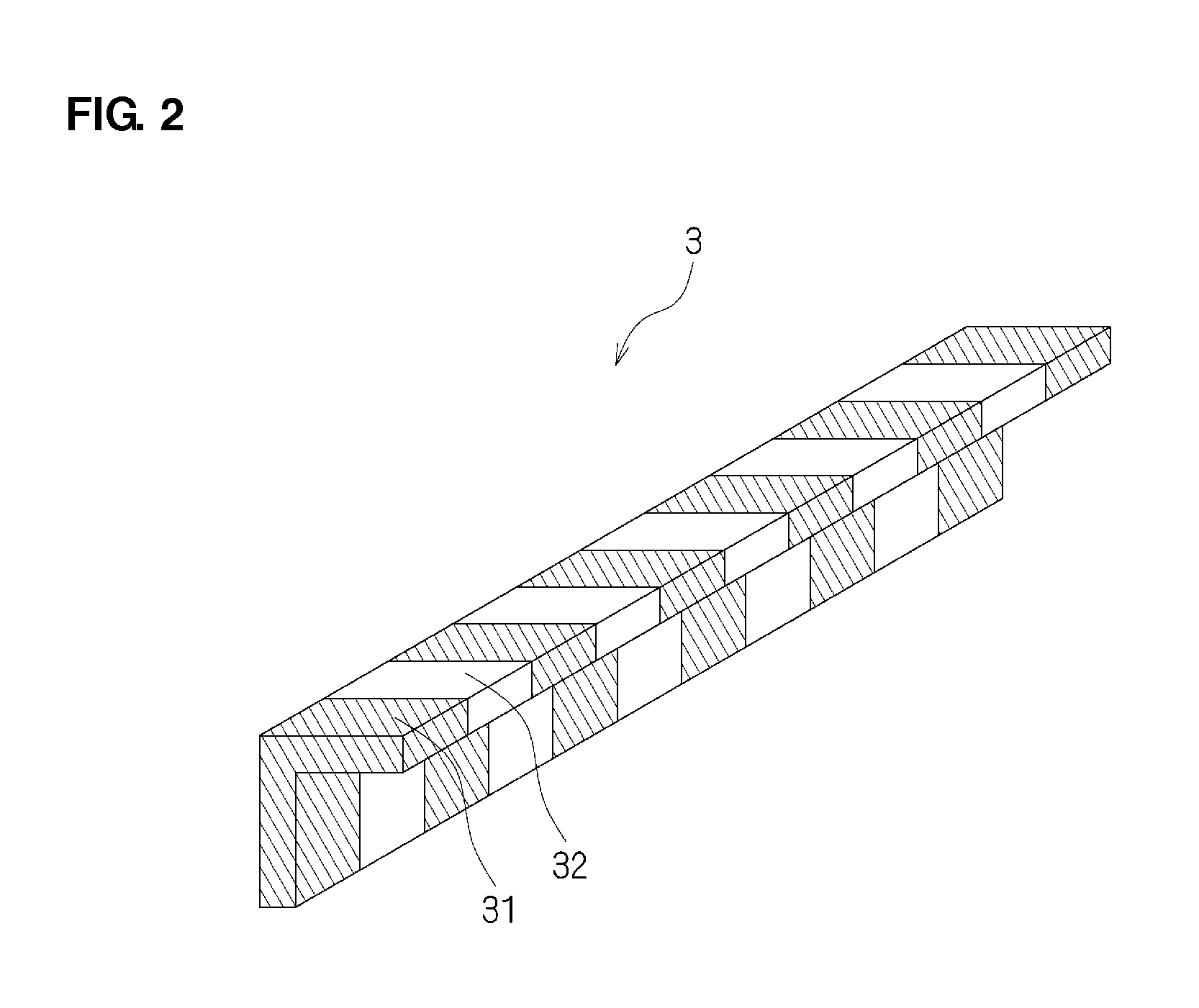

Module substrate and method for manufacturing module substrate

ActiveUS20130223038A1Prevent movement and damageImprove insulationPrinted circuit assemblingSemiconductor/solid-state device detailsStructural engineeringSi substrate

Owner:MURATA MFG CO LTD

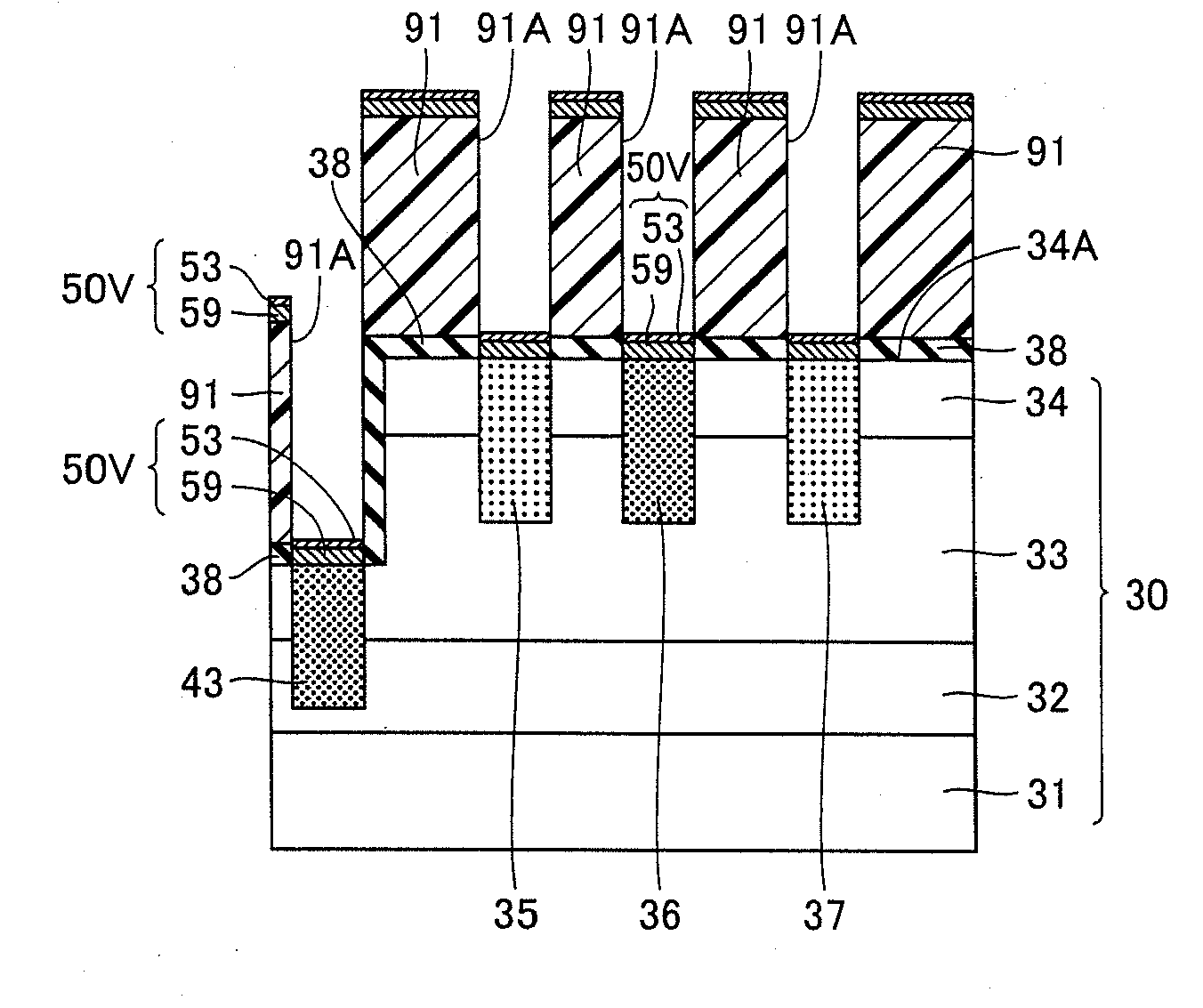

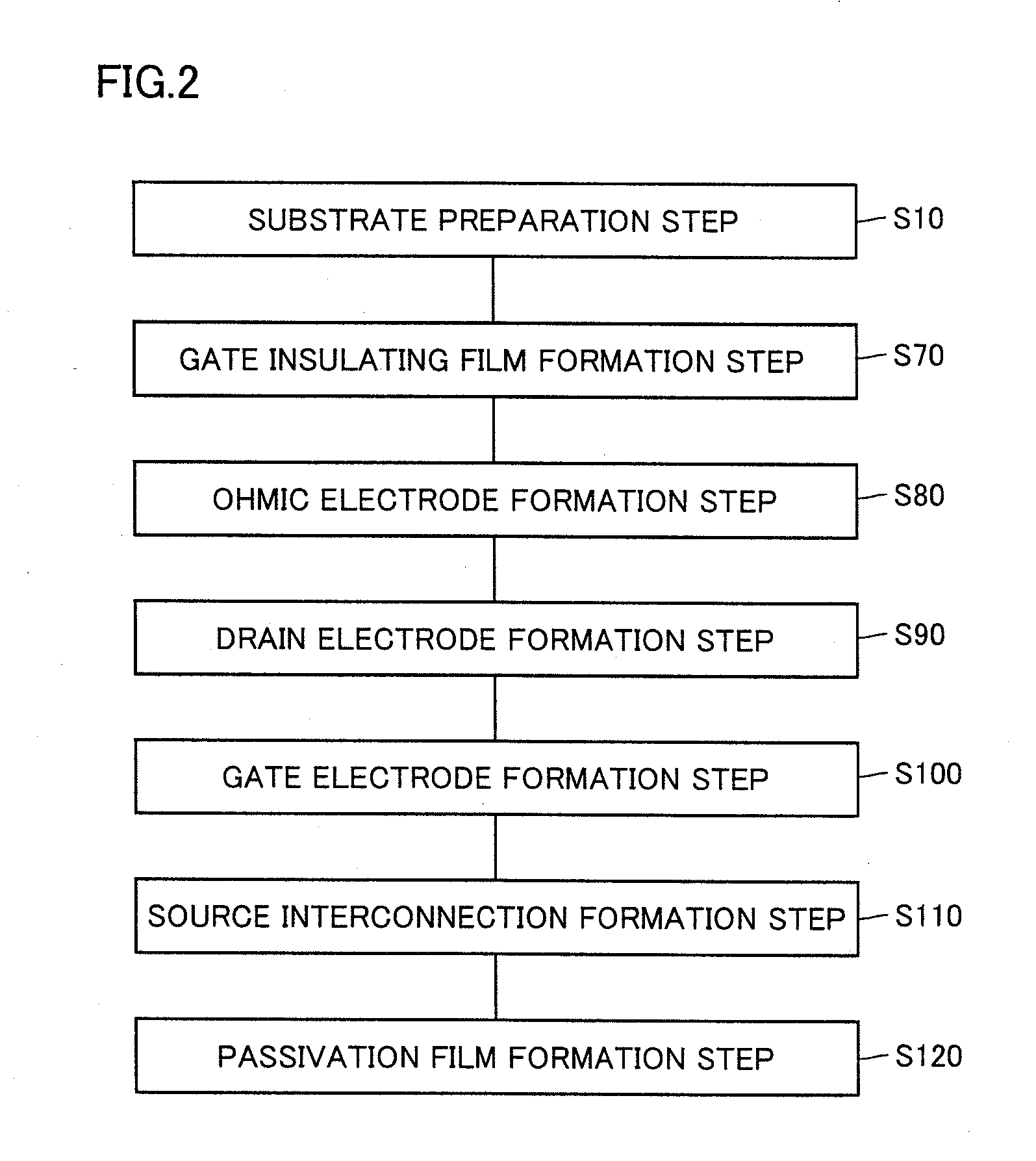

Method of manufacturing silicon carbide semiconductor device

ActiveUS20120184094A1Improve insulationSuppress DiffuseSemiconductor/solid-state device manufacturingSemiconductor devicesSubstrate surfaceSemiconductor

A silicon carbide substrate having a substrate surface is prepared. An insulating film is formed to cover a part of the substrate surface. A contact electrode is formed on the substrate surface, so as to be in contact with the insulating film. The contact electrode contains Al, Ti, and Si atoms. The contact electrode includes an alloy film made of an alloy containing Al atoms and at least any of Si atoms and Ti atoms. The contact electrode is annealed such that the silicon carbide substrate and the contact electrode establish ohmic connection with each other. Thus, in a case where a contact electrode having Al atoms is employed, insulation reliability of the insulating film can be improved.

Owner:SUMITOMO ELECTRIC IND LTD

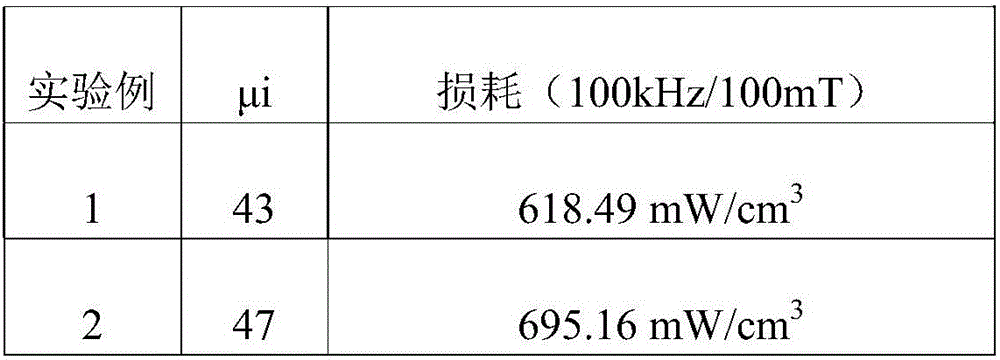

Magnetically soft alloy material and preparation method, power inductor

ActiveCN106710771AImprove insulationReduce eddy current lossTransformers/inductances detailsInductances/transformers/magnets manufactureWater solublePhosphate

The invention discloses a magnetically soft alloy material and a preparation method, a power inductor. The preparation method of the magnetically soft alloy material includes steps of S1, mixing coarse particle powder with fine particle powder; S2, reacting the mixed powder with 1-1.5% of phosphate or nitrate solution by mass; after completing reaction, drying the powder, and acquiring drying powder; S3, mixing and pulping the drying powder, water, water-soluble resin, silicon-containing water solution, dispersing agent, and antifoaming agent; spraying and drying the obtained sizing agent and forming secondary particle powder; in relative to the mass of Fe series alloy material, the addition of the water-soluble resin is 0.1-1 wt%, the addition of silicon-containing solution is 0.05-0.2 wt%; S4, pressing and shaping the secondary particle powder under the pressure strength of 1200-2000 MPa; S5, annealing the pressed product for 60-120 minutes at 700-800 DEG C under the protective gas atmosphere. The magnetically soft alloy material is relatively low in loss, and the initial permeability can meet the application demand.

Owner:SHENZHEN SUNLORD ELECTRONICS

Graystone-fiber-based firefighter uniform material and preparation method

ActiveCN105220272AImprove insulationIncrease water barrierChemical protectionHeat protectionAmmonium polyphosphateEmulsion

The invention belongs to the field of a functional clothing material, and relates to a graystone-fiber-based firefighter uniform material and a preparation method. The clothing material comprises the following raw materials, by weight part: chitosan, graystone fiber, water-soluble ammonium polyphosphate, a hydrogen-contained silicone oil emulsion, hydrogen-contained polyether modified polysiloxane, an antibacterial finishing agent of quaternized organosiloxane, ceramic fiber, anionic plant dye, PBI fiber, Prylanitz fiber, Qutlast acrylic fiber, carbon fiber, acidic formaldehyde, an azoic cross-linking agent, a sodium hydroxide solution, and a neutral poly ionic liquid. According to the invention, by adopting graystone fiber, insulation property, high and low temperature resistance, and heat-insulating property of the materials is effectively improved; by adopting the organosiloxane finishing agent, water-resisting property, high temperature resistance, and antibacterial property of the material is enhanced; and chitosan and the anionic plant dye can adsorb each other to increase the dying efficiency and to promote the dye to diffuse into the fiber. The graystone-fiber-based firefighter uniform material can satisfy the use of a fashion and high-performance firefighter uniform.

Owner:高瑞杰

Hot-compress dip-coating insulation method of copper bar

InactiveCN101582310AImprove insulationReduce labor intensityInsulating conductors/cablesElectricityFluidized bed

The invention relates to an insulation method of copper bars, in particular to a hot-compress dip-coating insulation method of copper bar, solving the defect and insufficiency of the existing insulation method of copper bars. The hot-compress dip-coating insulation method comprises the following steps: 1. a copper bar is cleaned, and the electric interface of the copper bar is protected and bound up; 2. the copper bar is preheated at the temperature of 170 to 190 DEG C, and kept for 20 minutes at the temperature of 170 to 190 DEG C; 3. the preheated copper bar is put in an epoxy encapsulating material fluidized bed, the surface of the copper bar is treated with hot pack by epoxy encapsulating material, and then dusting powder on the surface of the copper bar is quickly twittered; 4. the electric interface of the copper bar, which is treated with hot pack, is protected and eliminated, and the end of the electric interface is trimmed; and 5. at the temperature of 140 to 150 DEG C, the copper bar is solidified for 30 minutes, and then the solidified copper bar is dried. The invention improves the insulativity, the chemical resistance, the weather fastness and the like of the copper bar, lightens labor intensity, saves cost, improves the service life of the copper bar, and solves the inextricable problems of the existing insulation lapping and heat shrinking of tubing.

Owner:YONGJI XINSHISU ELECTRIC EQUIP

Ecological, heat proof, heat insulated and acoustic board, and preparation method

InactiveCN101050085AImprove insulationReduce preparation energy consumptionCeramic shaping apparatusAcoustic boardPolyvinyl alcohol

This invention discloses a method for preparing heat-insulating and sound-absorbing board material, which comprises: inorganic gelation material 10-95 parts, lightweight aggregate 5-90 parts, fibers 0.1-10 parts, air entraining agent 1-20 parts, surfactant 0.1-10 parts, toughening material 0.1-10 parts, and water 60-300 parts. The toughening material is one or more of latex nanopowder, poly (vinyl alcohol) and poly (acrylic acid). The board material has such advantages as good heat insulation, good sound absorbency, long service life, no pollution, and saved resources.

Owner:SOUTHWEST JIAOTONG UNIV

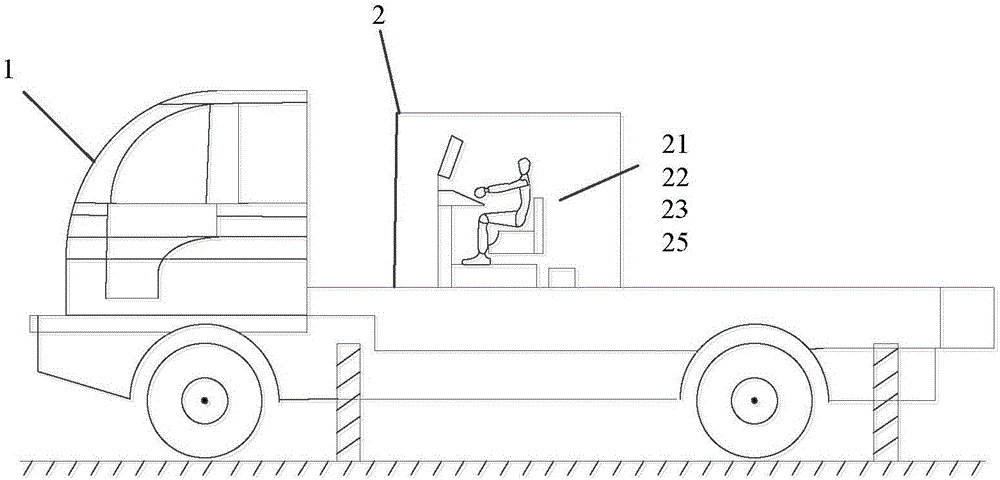

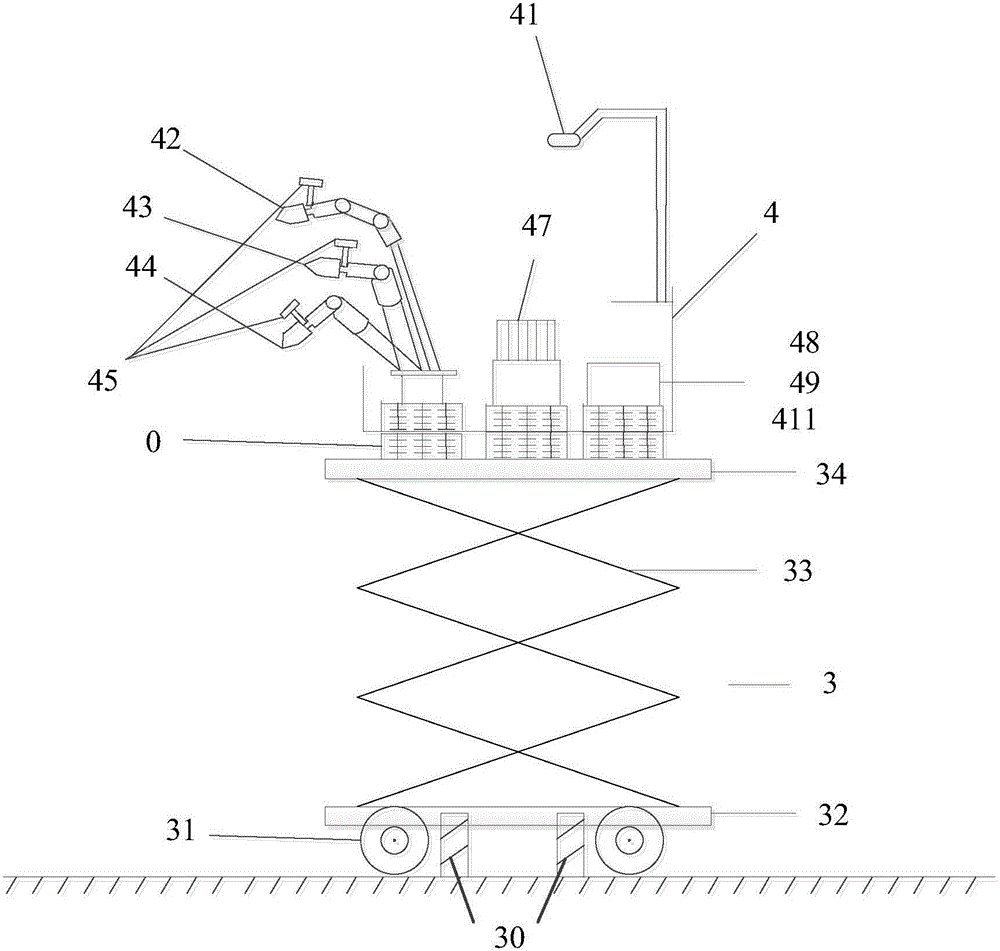

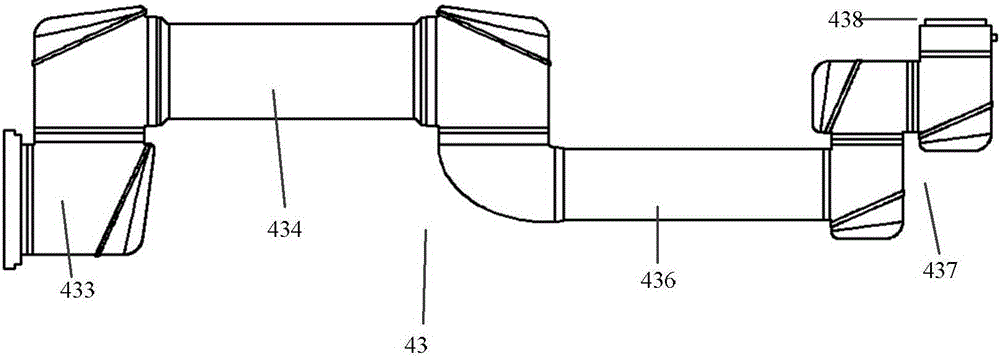

Multilevel insulation protecting system for electrifying operation robot

ActiveCN106426298AImprove insulationEnsure personal safetyManipulatorFiber-optic communicationData transmission

The invention provides a multilevel insulation protecting system for an electrifying operation robot. The multilevel insulation protecting system comprises an insulating trolley, a robot platform, a first mechanical arm, a second mechanical arm, an auxiliary mechanical arm, a full shot camera, a binocular camera, a special tool box for mechanical arm, a first industrial personal computer, a storage battery and a communication module, wherein the robot platform is carried on the insulating trolley; the first mechanical arm, the second mechanical arm, the auxiliary mechanical arm, the full shot camera, the binocular camera, the special tool box for mechanical arm, the first industrial personal computer, the storage battery and the communication module are arranged on the robot platform; a control room is arranged on the insulating trolley; a main manipulator and a display are arranged in the control room; an optical fiber communication module or a wireless communication module is adopted for transmitting data between the control room and the robot platform; an insulating material is sprayed or a piece of high-pressure resisting epoxy glass cloth is wrapped on the surface of the mechanical arm; the binocular camera and the full shot camera both have insulating shells. The multilevel insulation protecting system can guarantee the operation efficiency and automatic level of the electrifying operation and can increase the operation safety performance of the electrifying operation.

Owner:JIANGSU ELECTRIC POWER CO +3

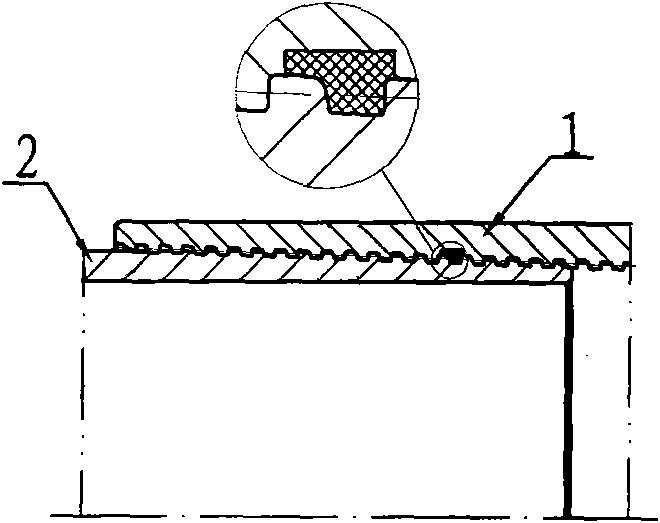

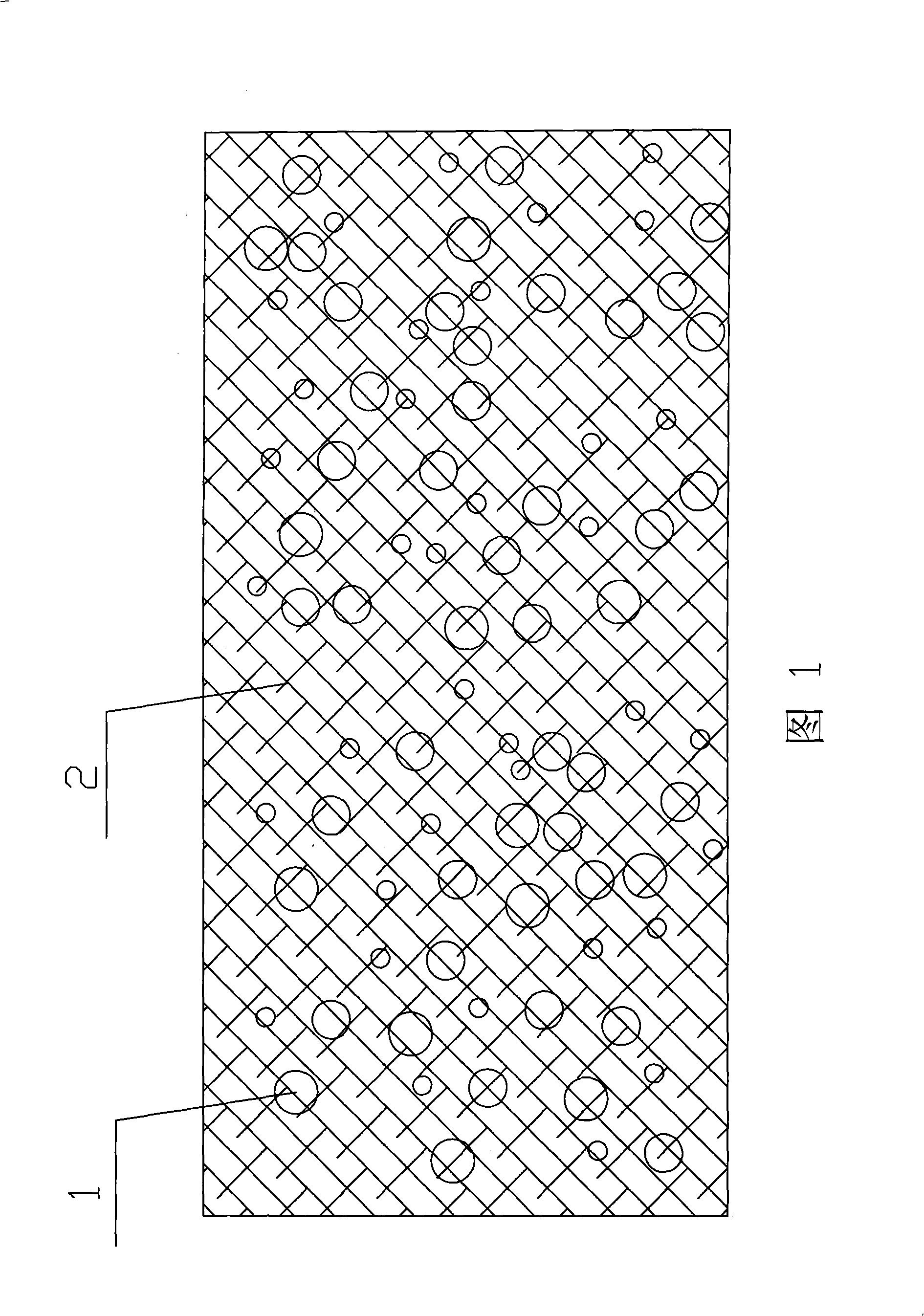

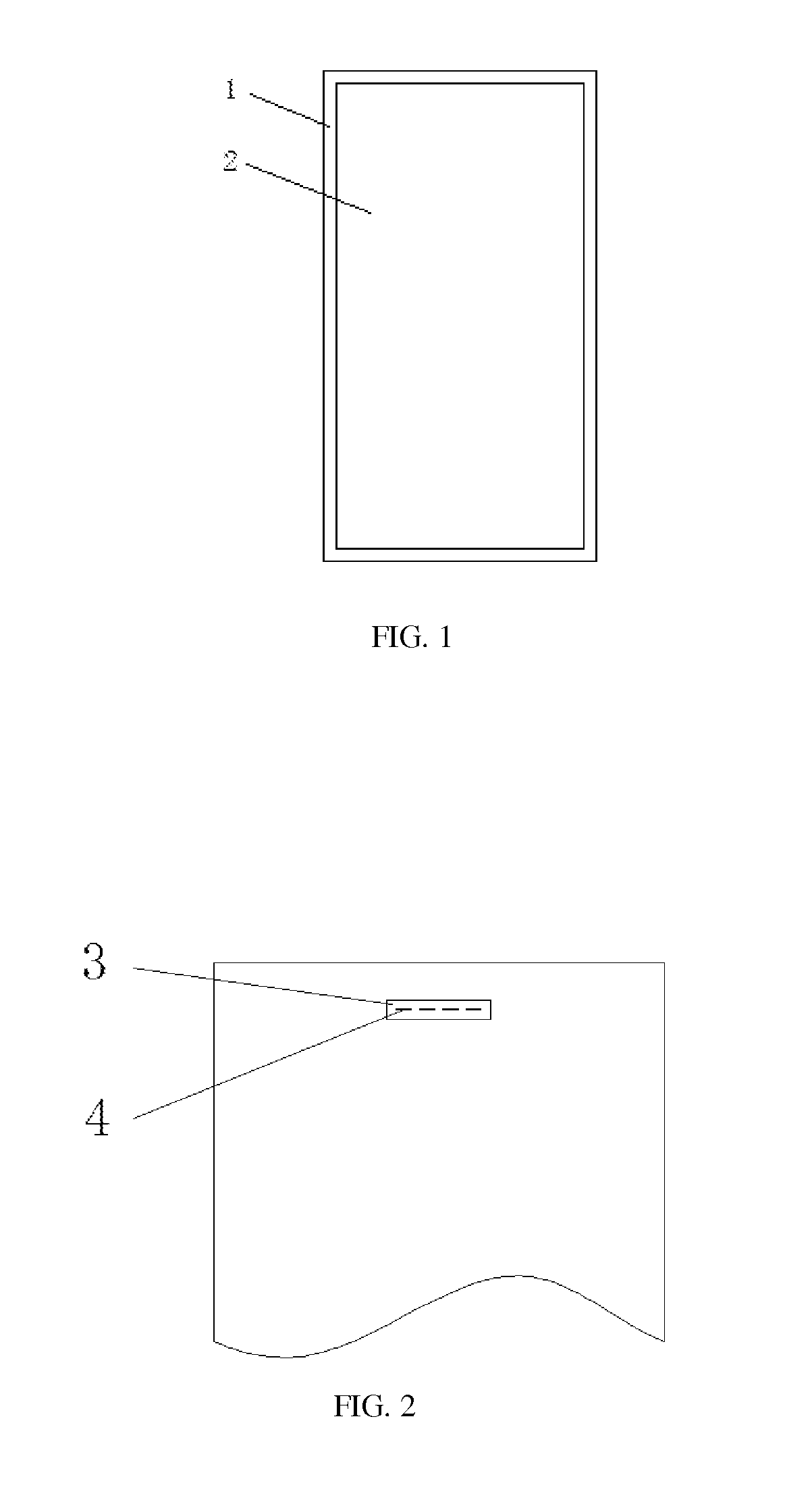

Carbon fiber autoclaved aerated concrete slab and application thereof

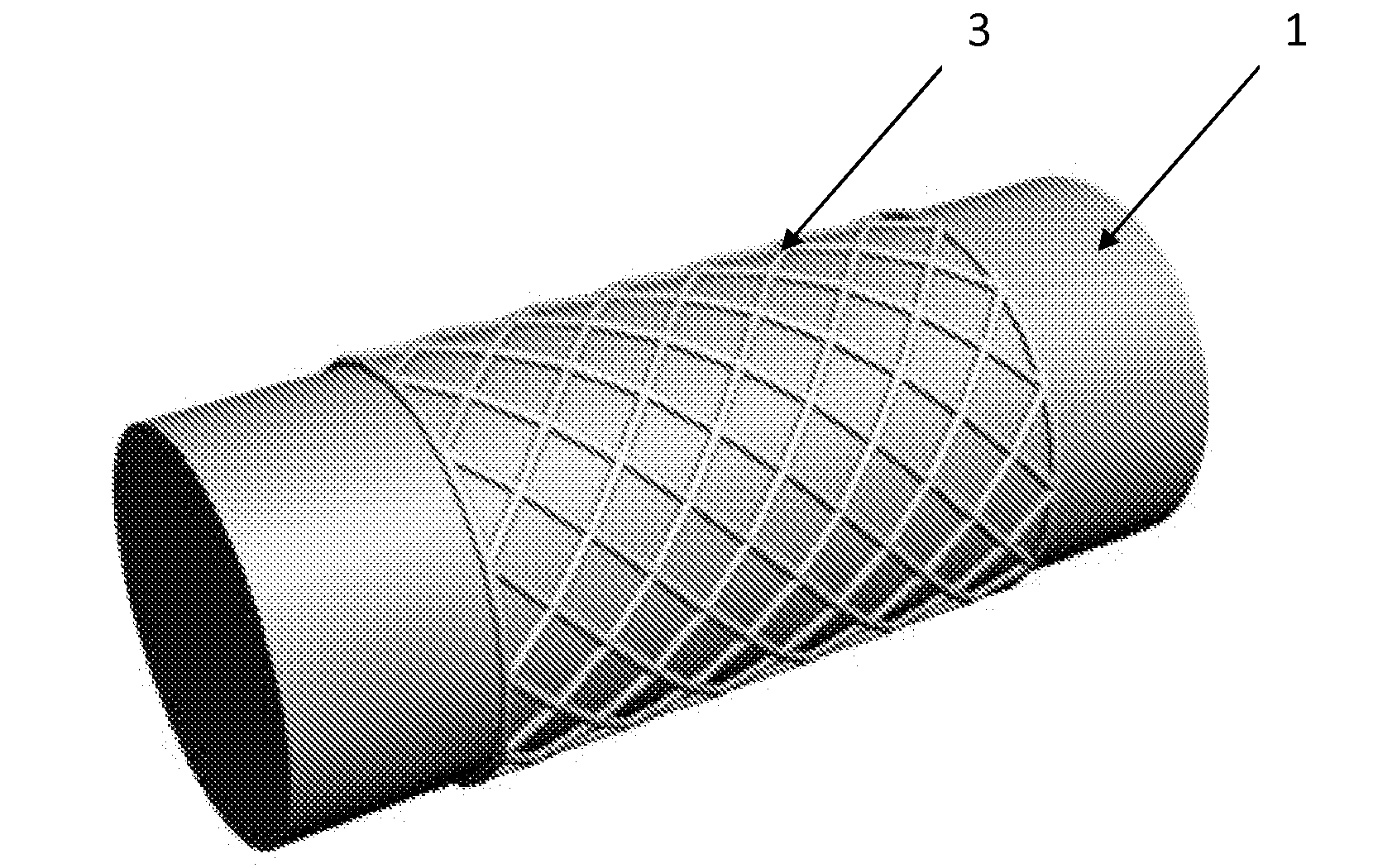

The invention relates to an autoclaved aerated concrete slab containing carbon fibers and an application thereof. The prior precast slabs have large specific gravity, resulting in high weight of buildings and very high cost of foundations. The autoclaved aerated concrete has low specific gravity but poor strength, so as not to be used as supporting parts. The inventive product comprises building concrete structural slabs (1), wherein the concrete is autoclaved aerated concrete, and the concrete in the structural slabs is provided with carbon fibers (2). The product can be used as precast elements for buildings, such as floor slabs, roof slabs and wall slabs, etc.

Owner:哈尔滨工业大学空间钢结构幕墙有限公司

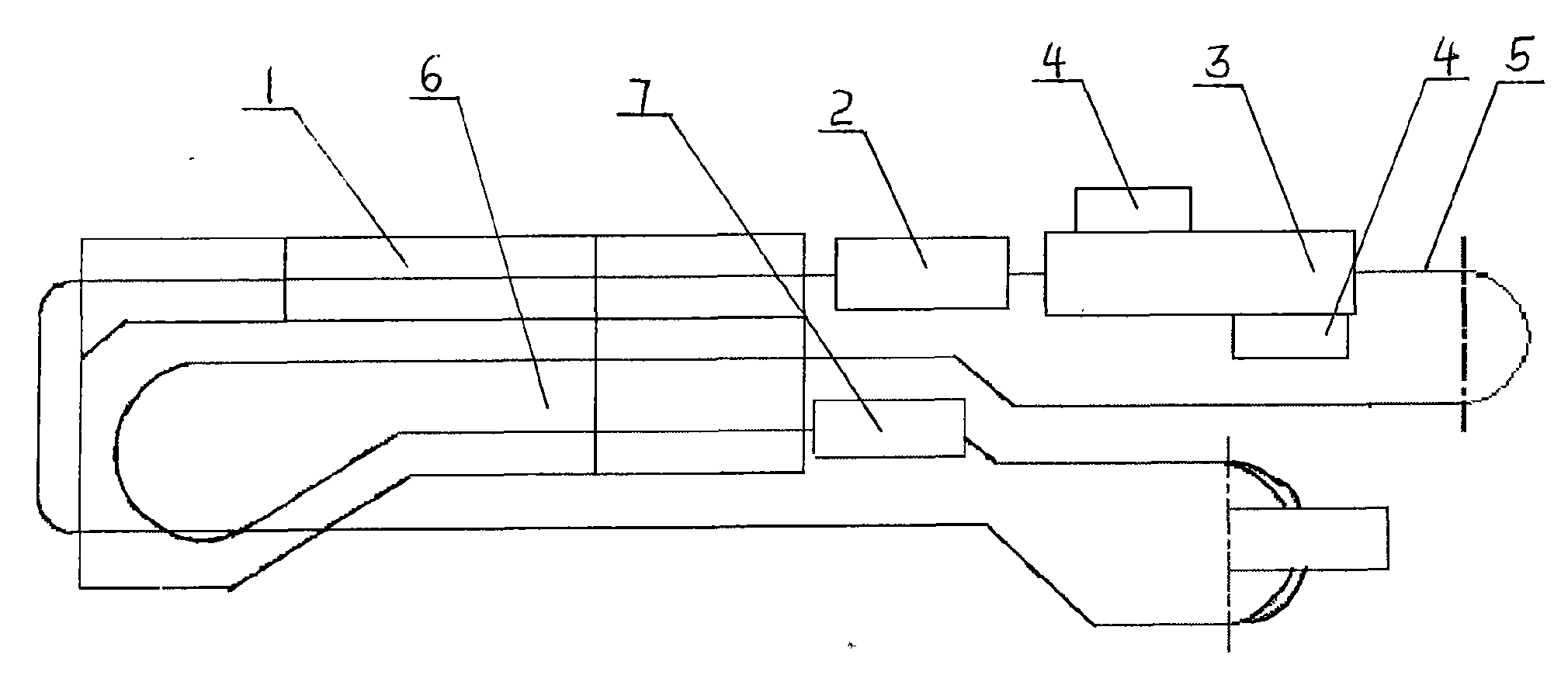

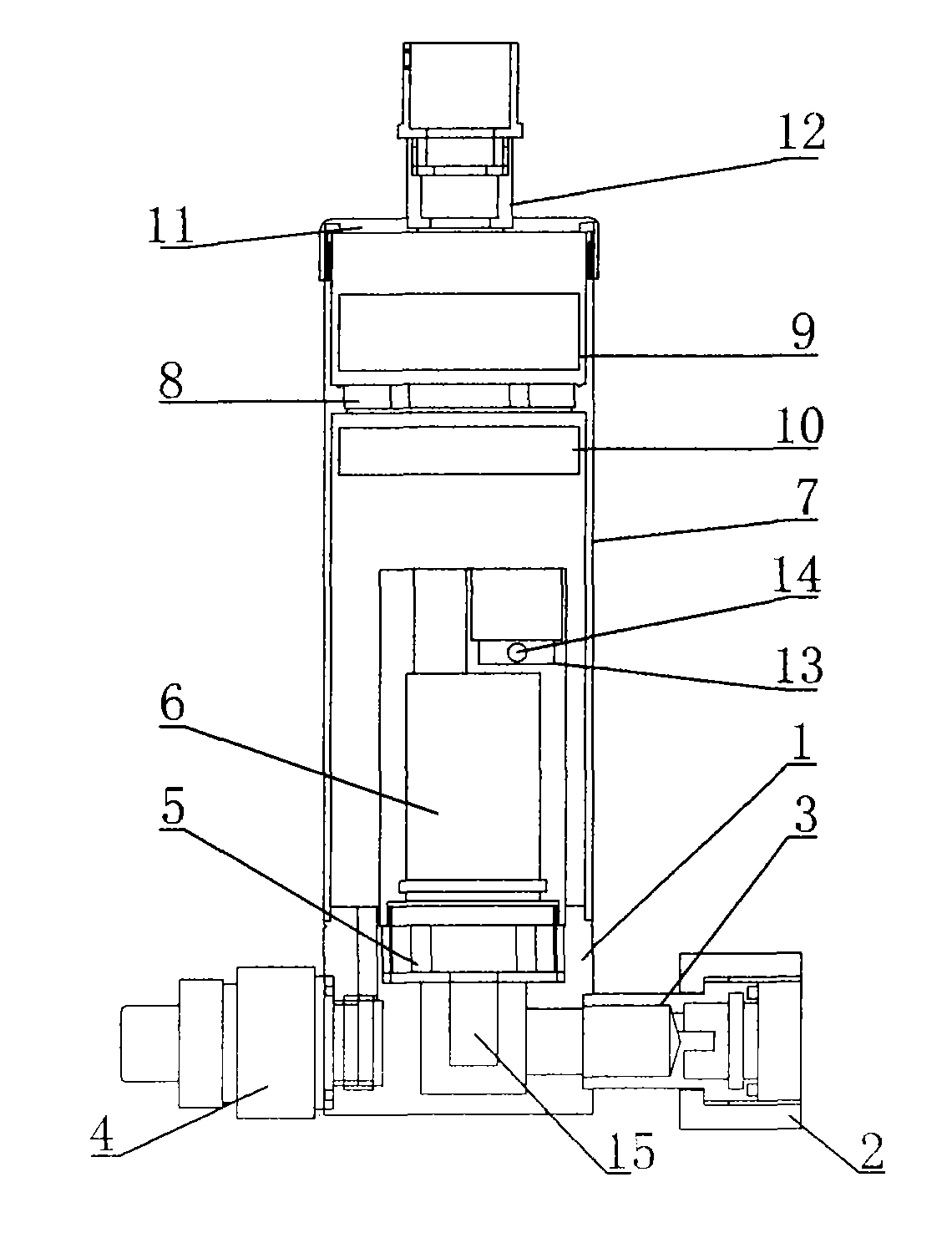

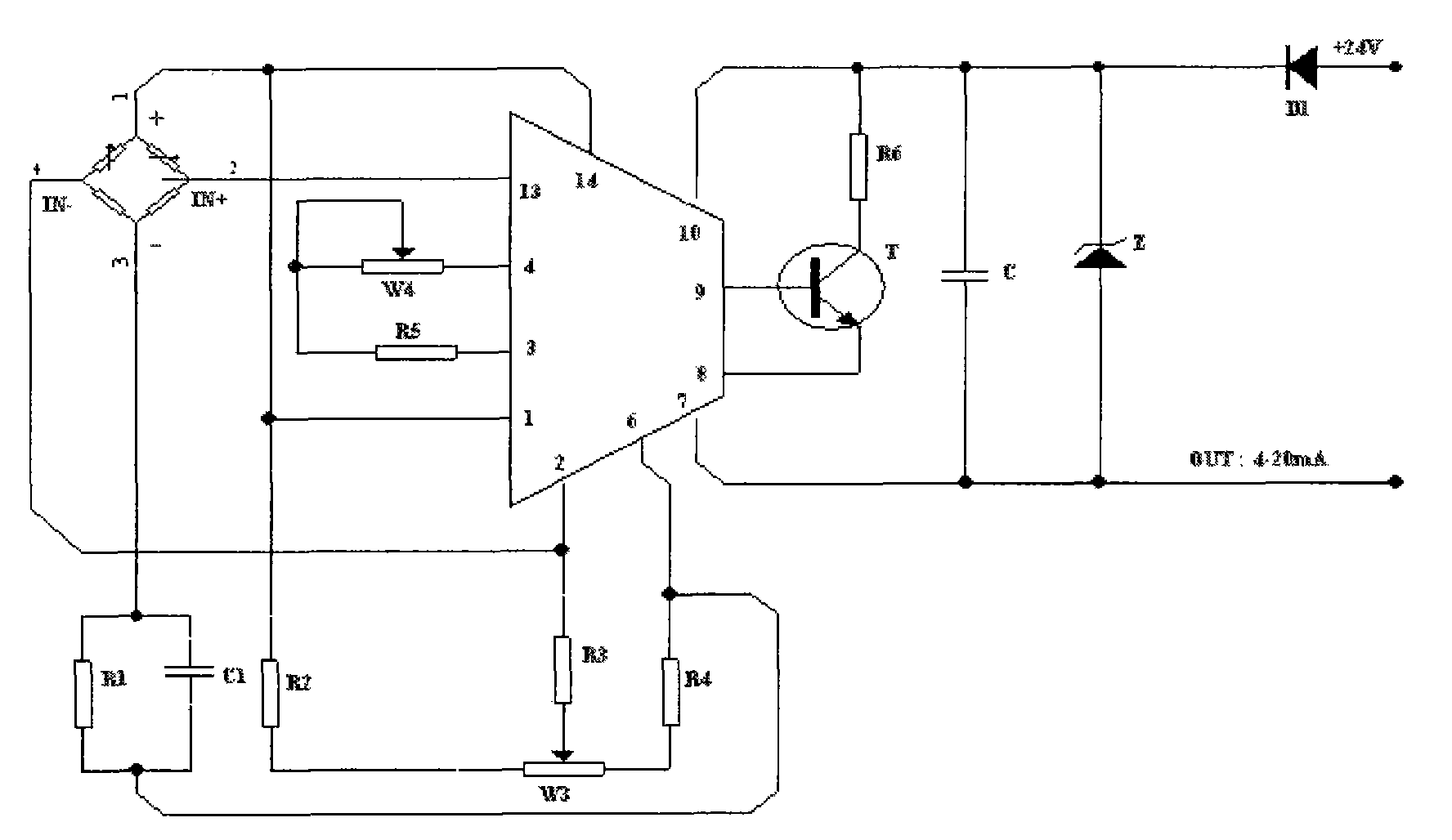

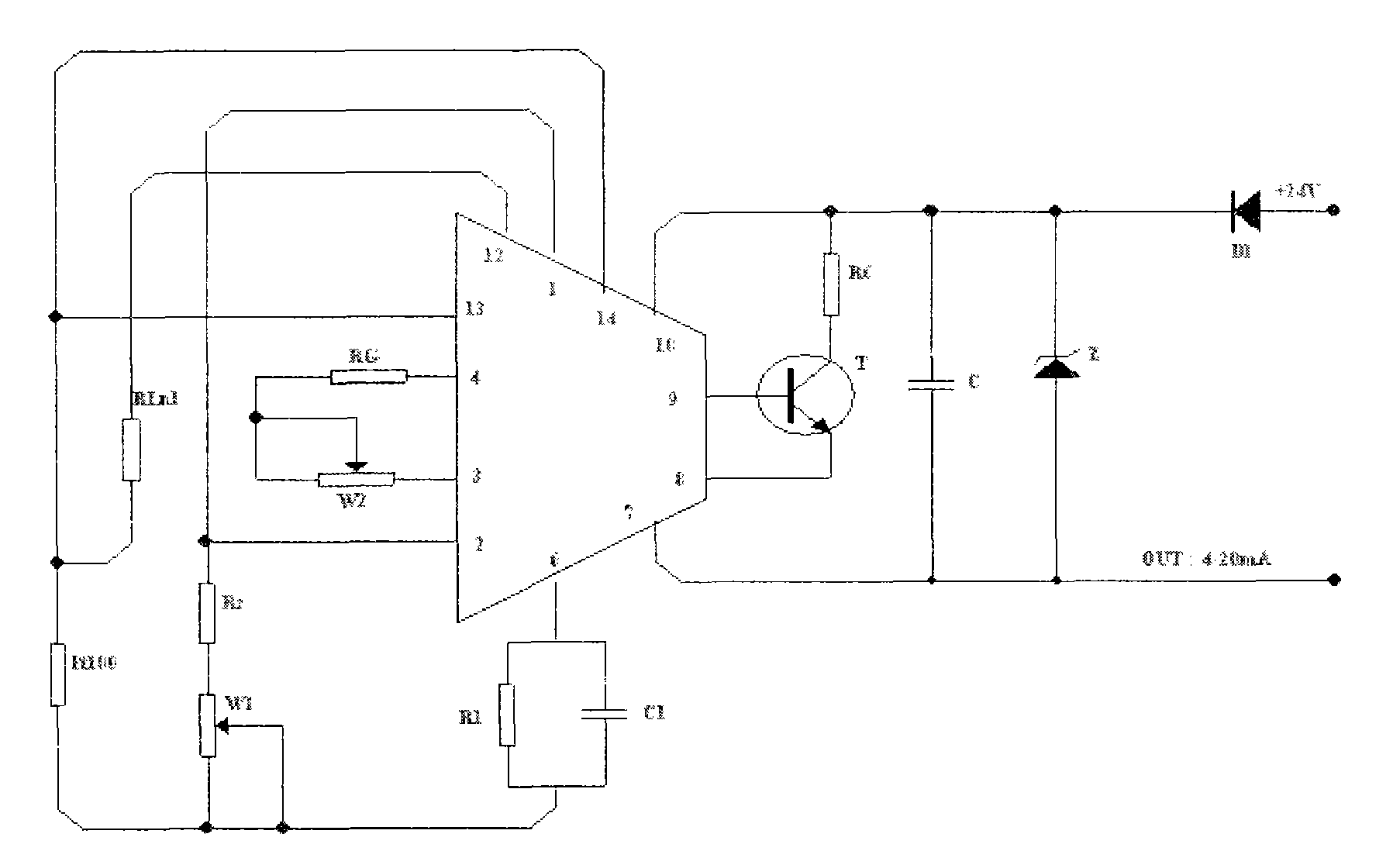

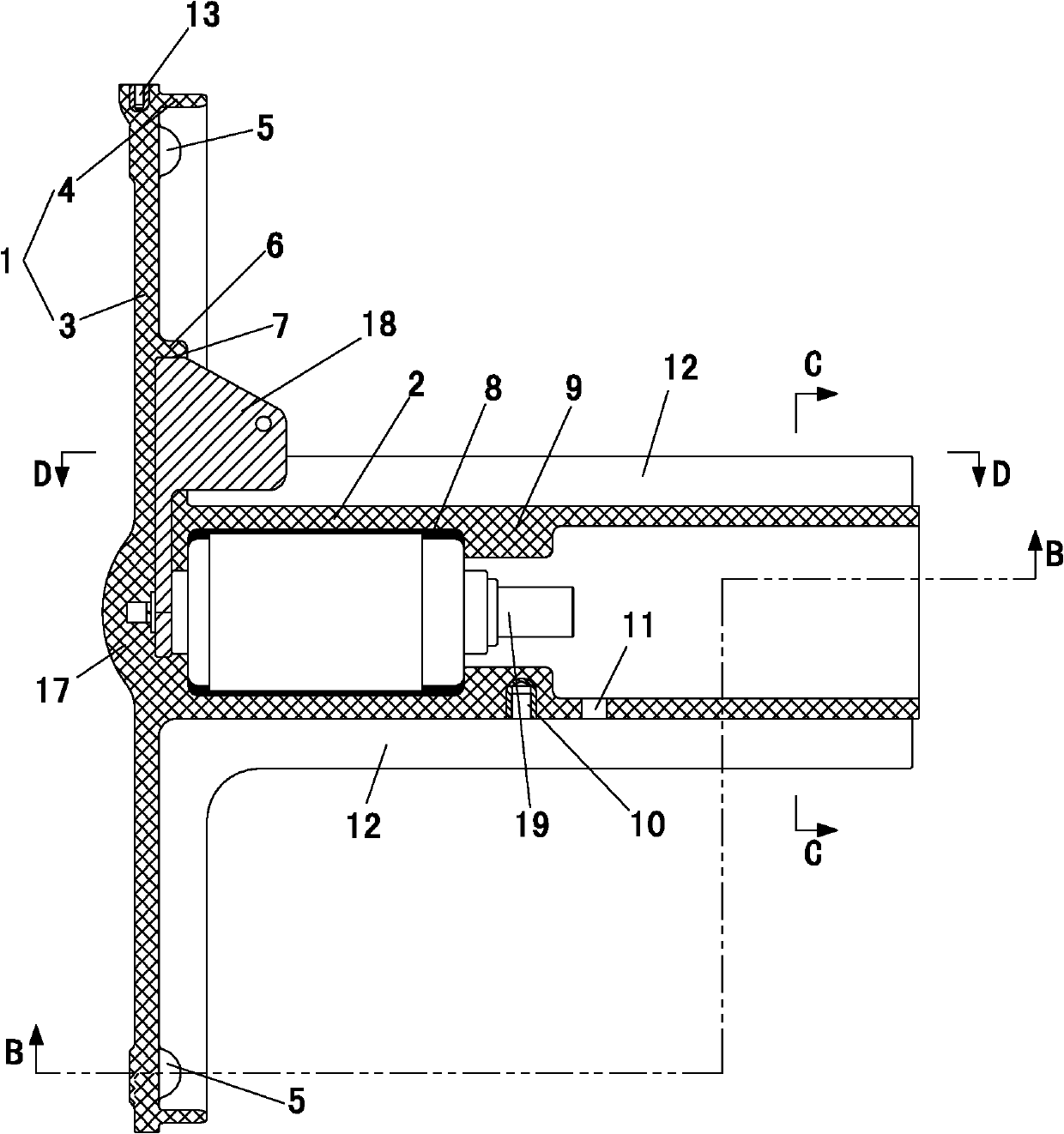

Micro water transmitter for high-voltage switch gas insulated switchgear (GIS) distribution room

InactiveCN102109480AGood sealingImprove insulationThermometers using electric/magnetic elementsFluid pressure measurement by electric/magnetic elementsDew pointEngineering

The invention belongs to the field of transmitters, and in particular relates to a micro water transmitter for a high-voltage switch gas insulated switchgear (GIS) distribution room. The transmitter comprises a body (1), and a connecting piece (3), a sensor bracket (5), a sensor seat (6), a dew point sensor, a pressure sensor, a temperature sensor, a pressure voltage / current (V / I) conversion module and a temperature conversion module which are arranged in the body (1), wherein the top of the sensor bracket (5) is fixedly connected with the bottom of the sensor seat (6); the main body of the dew point sensor is packaged in the sensor seat (6), and the probe part of the dew point sensor is arranged in the inner cavity of the body (1); the top of the sensor seat (6) is provided with a pressure sensor assembling groove for assembling the pressure sensor; the side wall of the pressure sensor assembling groove is provided with a through hole; and the output port of the connecting piece (3) is communicated with the inner cavity of the body (1). The transmitter has high sealing property, insulating property, anti-interference property and response speed.

Owner:SHENYANG ACAD OF INSTR SCI

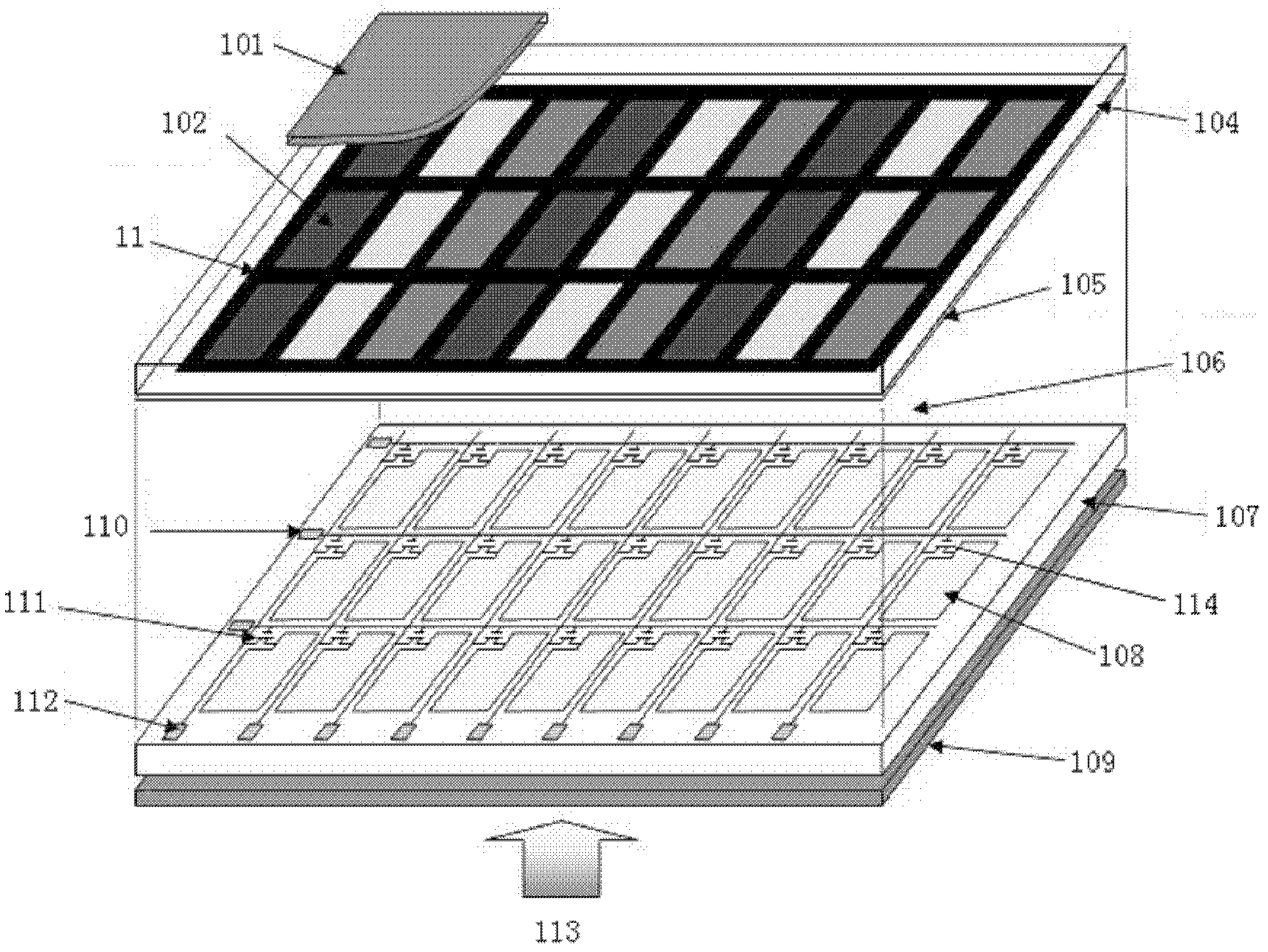

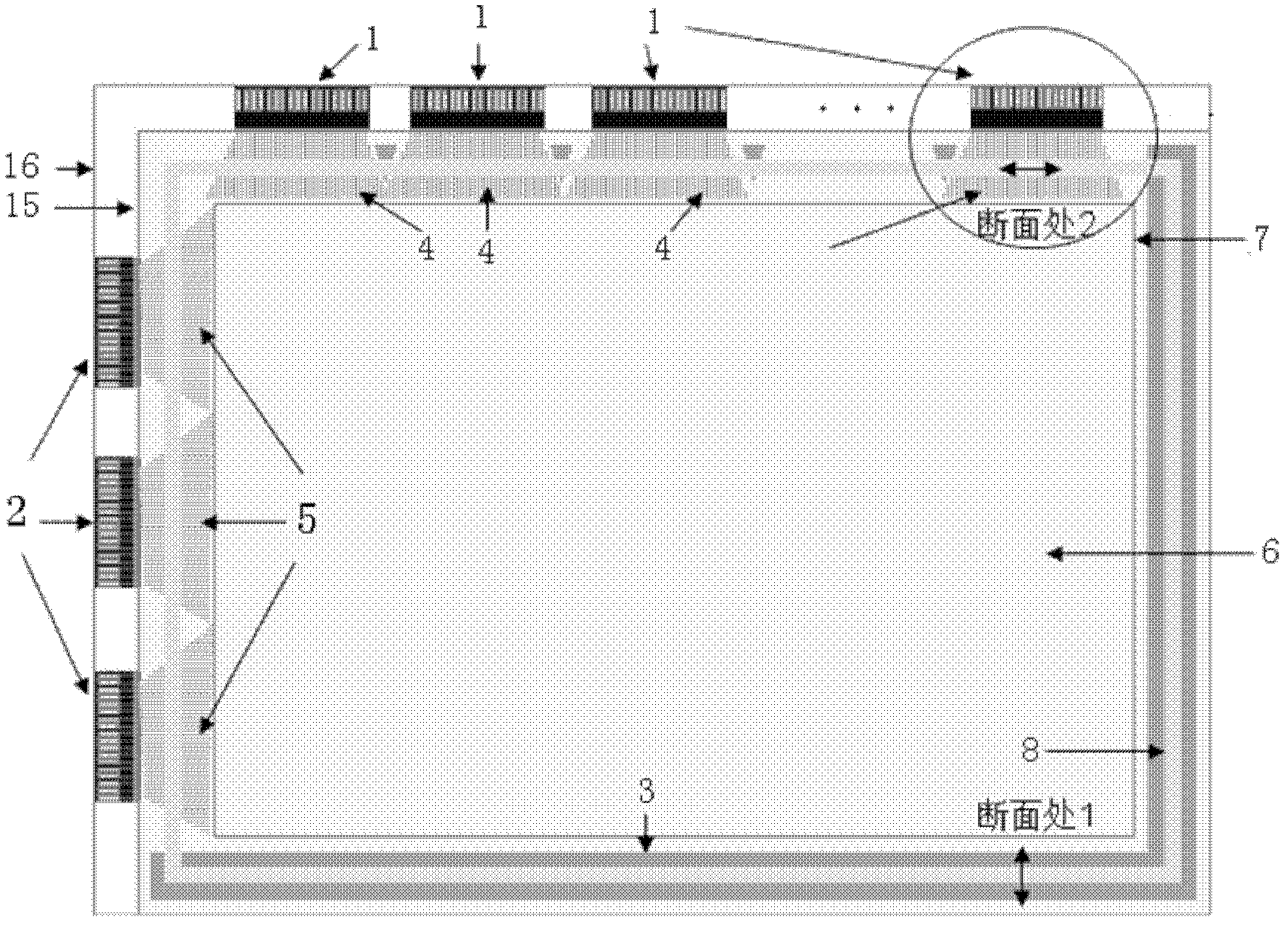

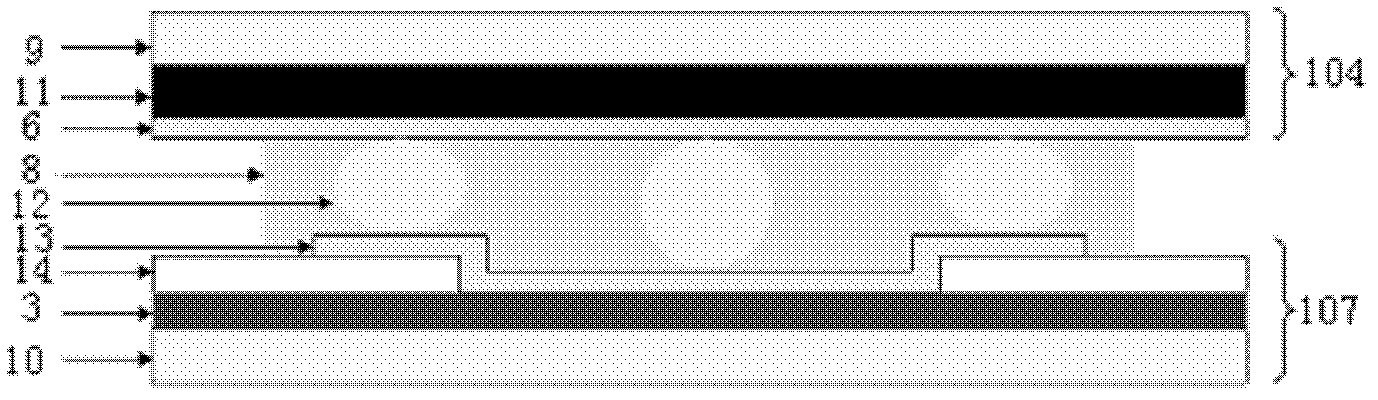

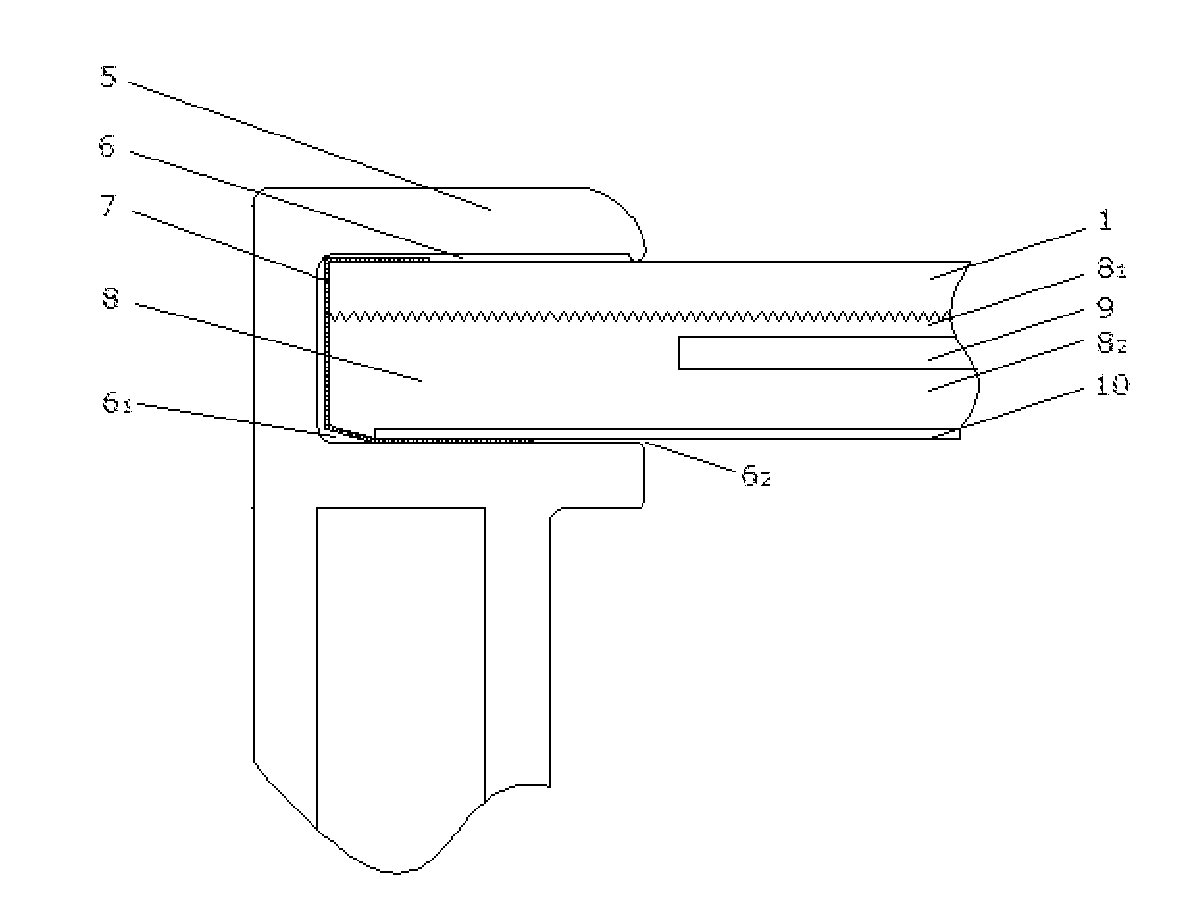

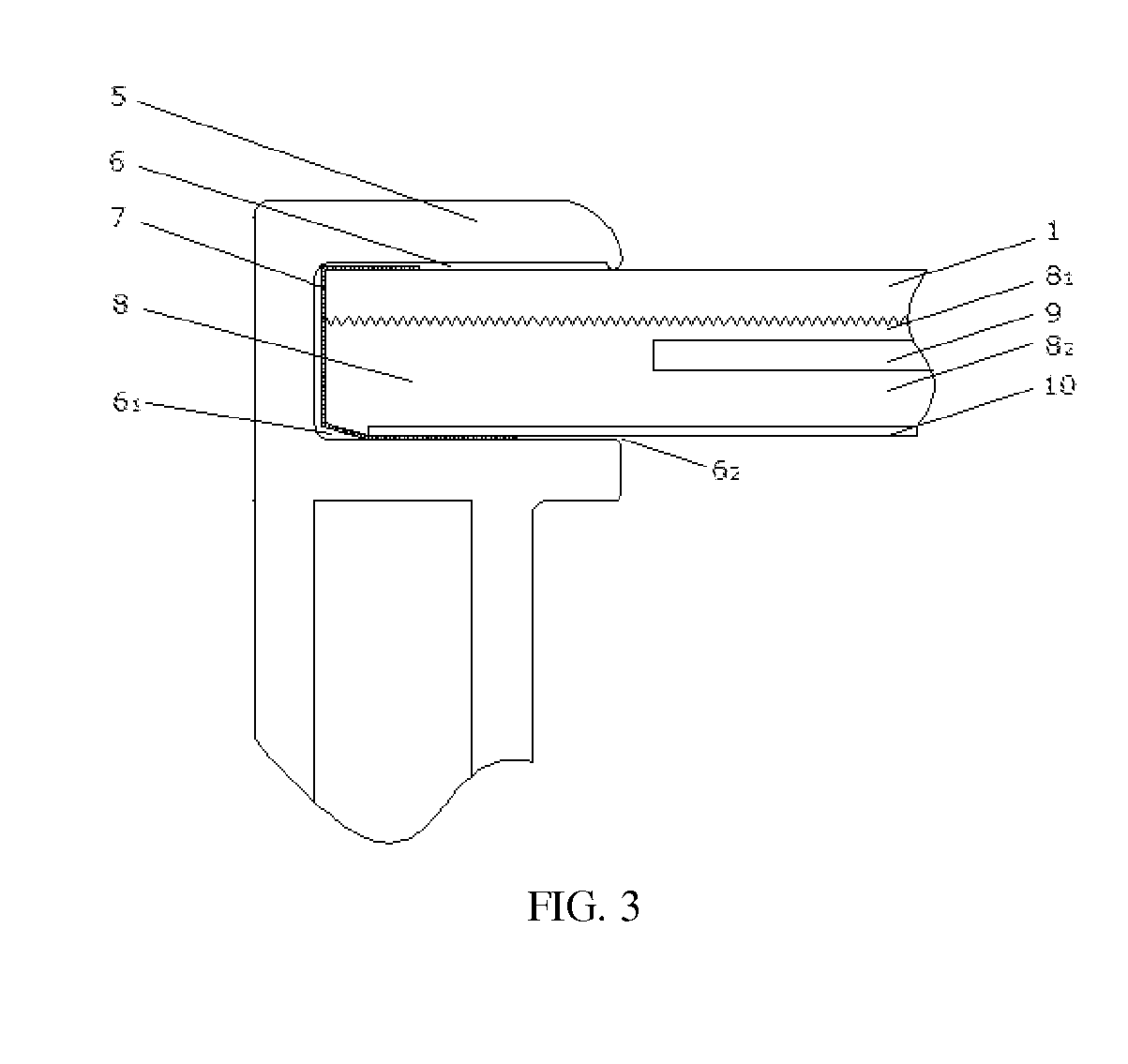

Liquid crystal display device

ActiveCN102253536AImprove insulationAvoid short circuitNon-linear opticsLiquid-crystal displayLiquid crystal

The invention discloses a liquid crystal display device, which comprises a color film substrate, an array substrate arranged opposite to the color film substrate, a conducting layer arranged on the color film substrate, an insulation layer arranged on the array substrate, a data line layer arranged in the insulation layer, a section difference layer arranged on the array substrate of a non-date line region, and a frame sealing rubber layer arranged between the array substrate and the color film substrate, wherein a space between the array substrate and the color film substrate is called as the thickness of a liquid crystal box; the region having the data line layer is defined as a data line region; the region without the data line layer is defined as the non-date line region; and a plurality of gold balls are arranged in the frame sealing rubber layer. The liquid crystal display device effectively prevents short circuit of the data line at the frame sealing rubber coating part on the array substrate and a common electrode on the color film substrate caused by the gold balls in the frame sealing rubber, and reduces the occurrence of displaying bad phenomena so as to improve yield and dependency for long-term use of products.

Owner:NANJING CEC PANDA LCD TECH

Architectural high-insulativity low-smoke halogen-free flame-retardant cable material and preparation method thereof

InactiveCN104945749AImprove insulationEasy extrusion processingPlastic/resin/waxes insulatorsFlame-proof filament manufactureThioxantheneKetone

The invention relates to an architectural high-insulativity low-smoke halogen-free flame-retardant cable material which is prepared from the following raw materials in parts by weight: 0.9-1.1 parts of hollow glass microsphere, 1-1.5 parts of silane coupling agent KH-550, 0.5-1 part of molybdenum disulfide, 20-25 parts of magnesium hydroxide, 20-25 parts of aluminum hydroxide, 9-10 parts of polyacrylonitrile, 6-7 parts of polylactic acid, 3-4 parts of polyoxyethylene, a right amount of dimethylformamide, a right amount of double solvent composed of dimethylformamide and dichloromethane in a volume ratio of 1:1, a right amount of methyl methacrylate, a right amount of isopropyl thioxanthene ketone, 50-55 parts of crosslinked polyethylene and 4-5 parts of metallocene polyethylene. The hollow glass microsphere enhances the insulativity, heat resistance and lubricating property of the cable material, so that the cable material can be extruded and processed more easily. The silane coupling agent KH-550 is added to enhance the binding force between the hollow glass microsphere and resin. The technique solves the problem of the phenomenon of agglomeration due to nonuniform dispersion of the inorganic filler.

Owner:力拓电力合金电缆股份有限公司

Insulating cover for solid insulating fully sealed switch

ActiveCN101997273AImprove insulationSmall and compactHigh-tension/heavy-dress switchesAir-break switchesEngineeringPower transmission

An insulating cover for a solid insulating fully sealed switch belongs to an isolation device in a power transmission and distribution cabinet and comprises a cover and a vacuum bubble sleeve, wherein the cover body is made of epoxy resin materials; the cover comprises a cover plate and a first bolt; the front end of the cover plate is provided with bulge; the vacuum bubble sleeve is vertically arranged in front of the bulge; the bulge is provided with a groove communicated with the vacuum bubble sleeve; the inner cavity of the vacuum bubble sleeve is provided with a shielding layer and a ring-like convex plate; the bottom surface of the vacuum bubble sleeve is provided with two embedded threaded holes and a soft connecting hole; the vacuum bubble sleeve is provided with a second bolt connected with the first bolt into a whole; and the front end face of the vacuum bubble sleeve is provided with two seal grooves. Adopting the epoxy resin insulating materials, the insulating cover improves the insulativity of the insulated switch and has small volume, reduces the volume of the ring network cabinet and is convenient and simple to be spliced with the upper and lower isolation covers, and the seal rings are installed in the seal grooves at the right end of the vacuum bubble sleeve, thus improving the safety of switch operation.

Owner:BEIJING SOJO ELECTRIC

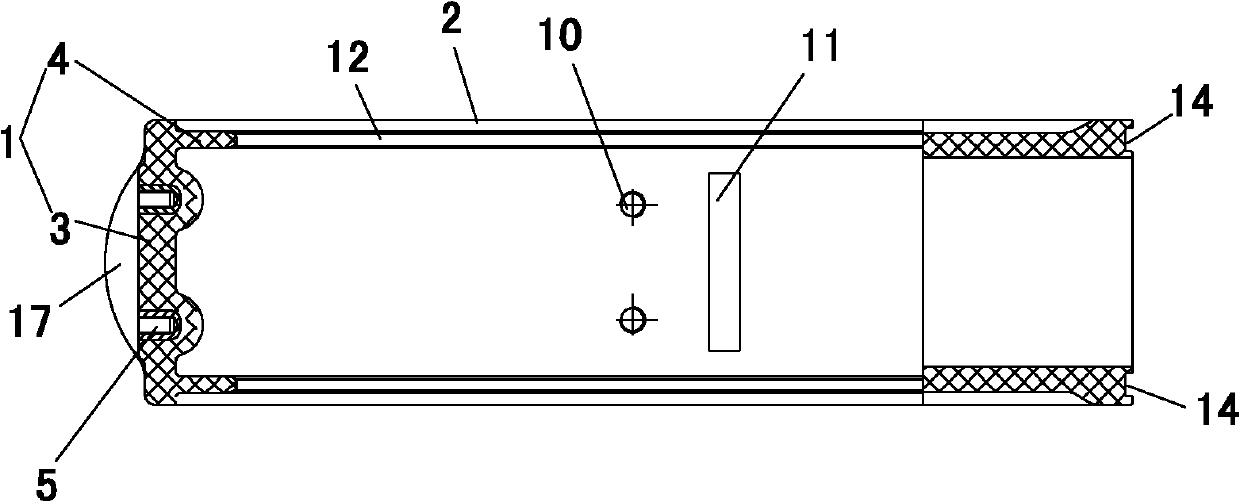

Laminated ceramic capacitor

ActiveCN104246929AExcellent dielectric constantImprove insulationFixed capacitor dielectricStacked capacitorsCapacitanceThin layer

The purpose of the present invention is to provide a laminated ceramic capacitor for achieving a high dielectric constant and thin layers in order to meet the need for smaller size and greater capacity, and moreover having excellent dependability of insulating properties. The present invention relates to a laminated ceramic capacitor having: a laminate of dielectric layers and internal electrode layers laminated in alternating fashion; and cover layers formed as the outermost layers on the top and bottom in the stacking direction of the laminate. In this laminated ceramic capacitor, the dielectric layers comprise a sintered compact containing barium titanate and a silicon compound, and a fresnoite phase of average particle size of 1 [mu]m or less is present within the dielectric layers.

Owner:TAIYO YUDEN KK

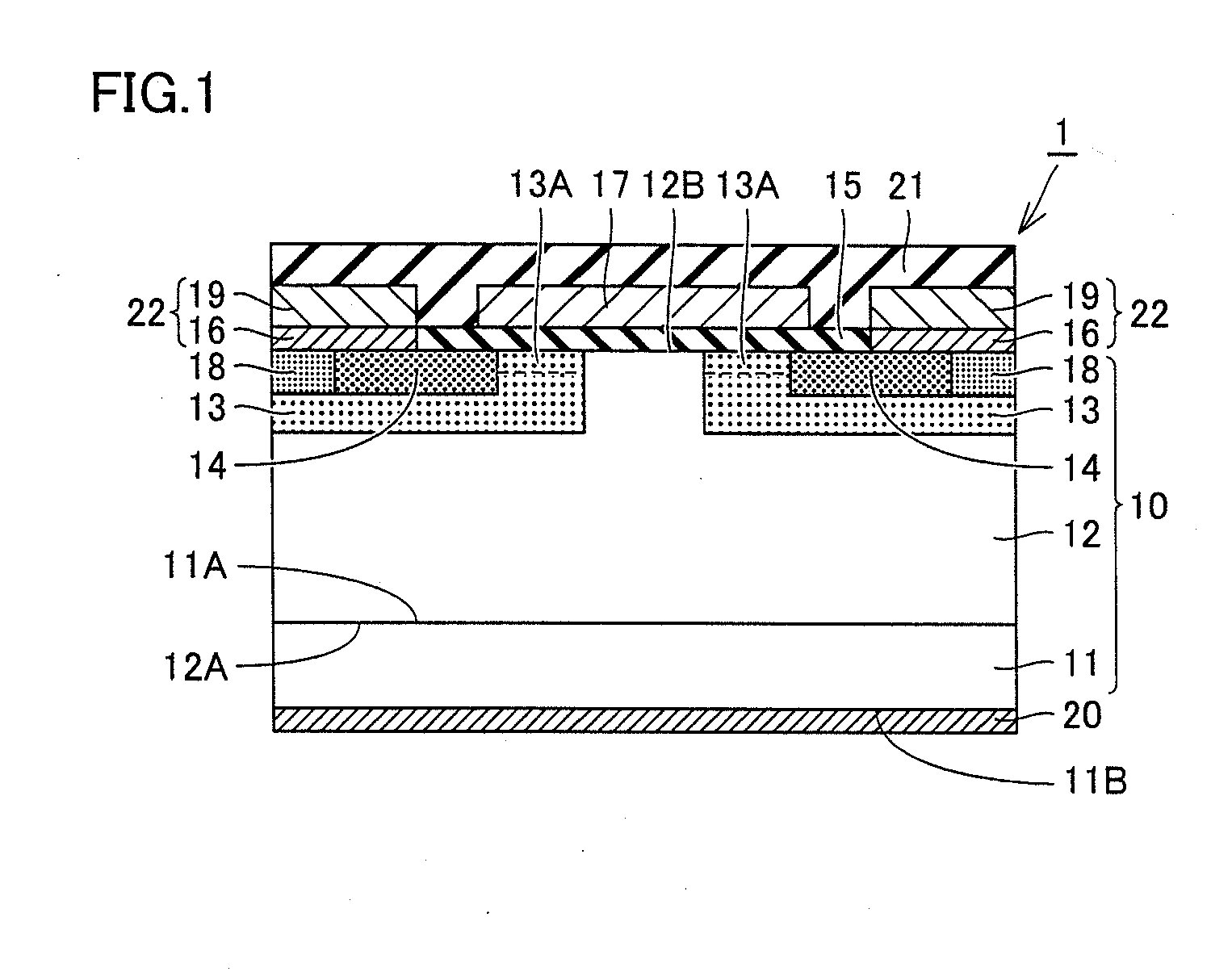

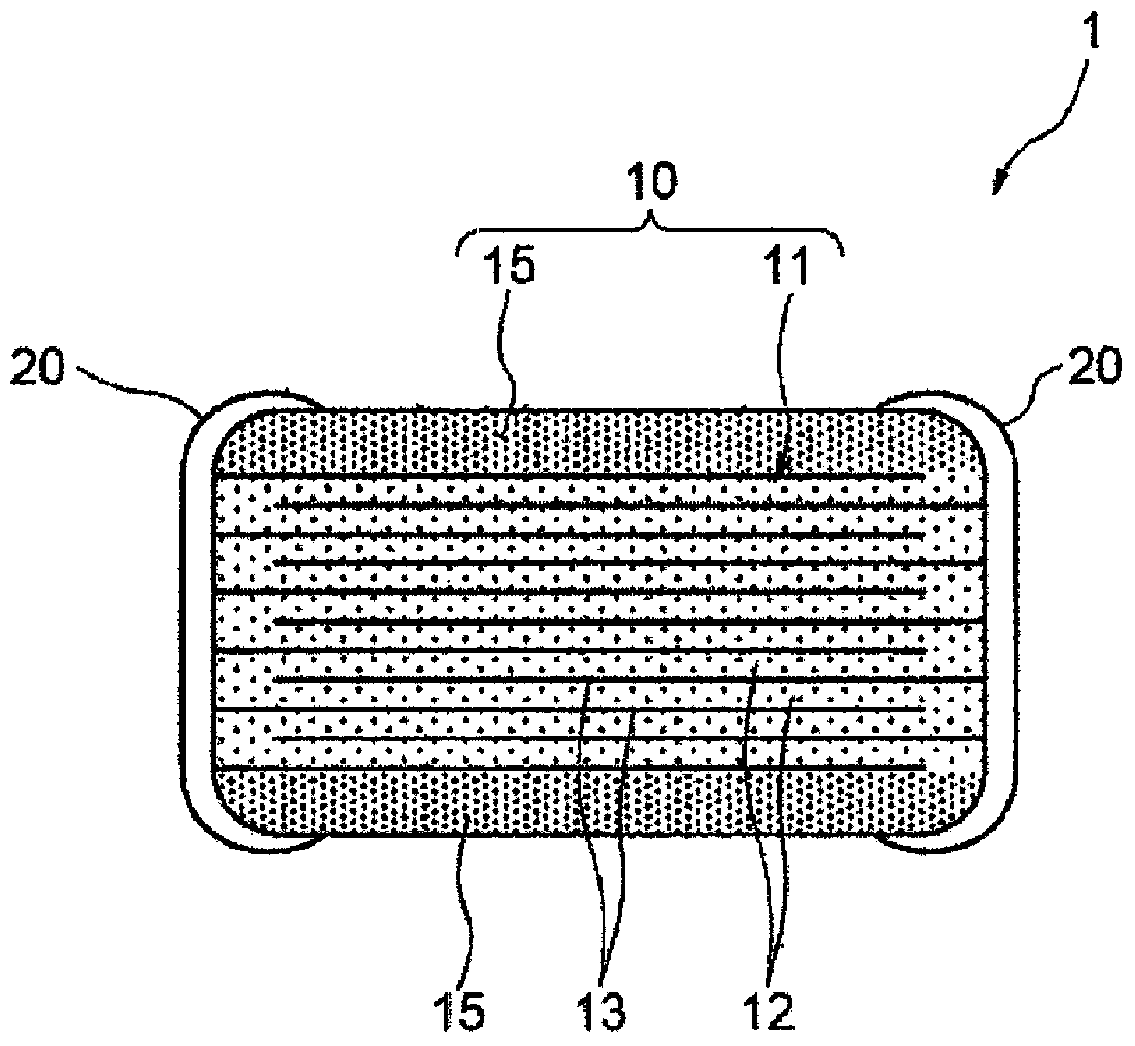

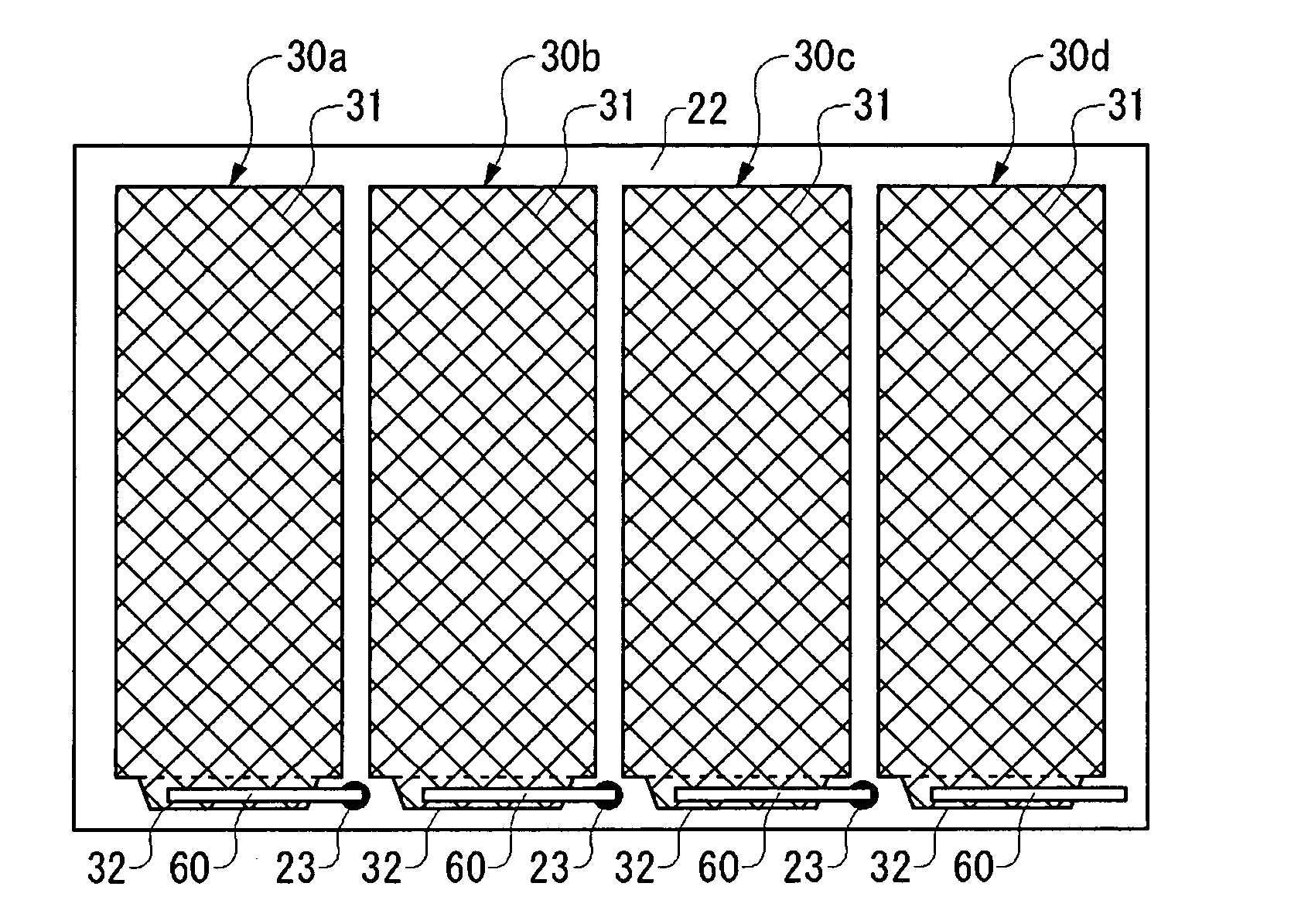

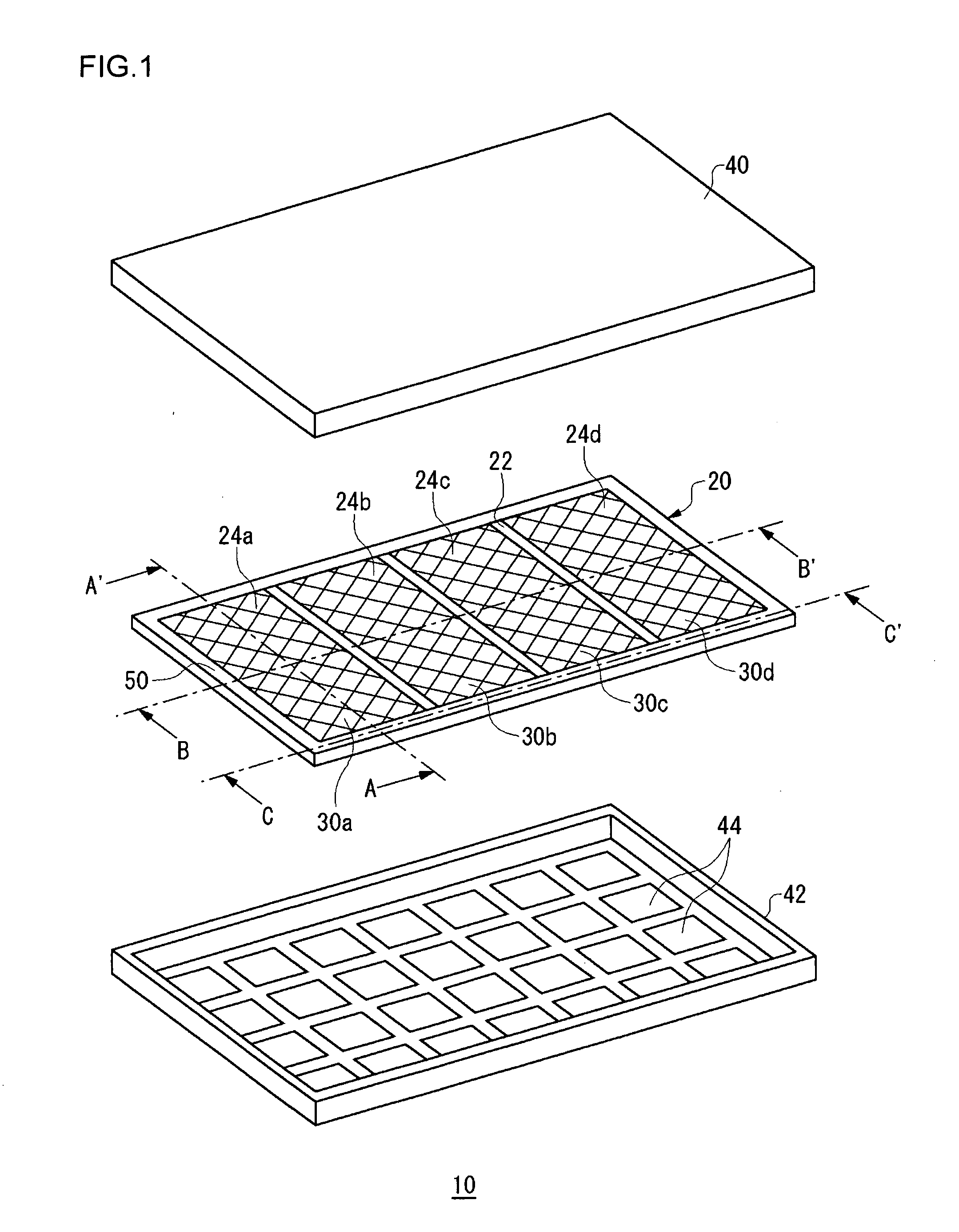

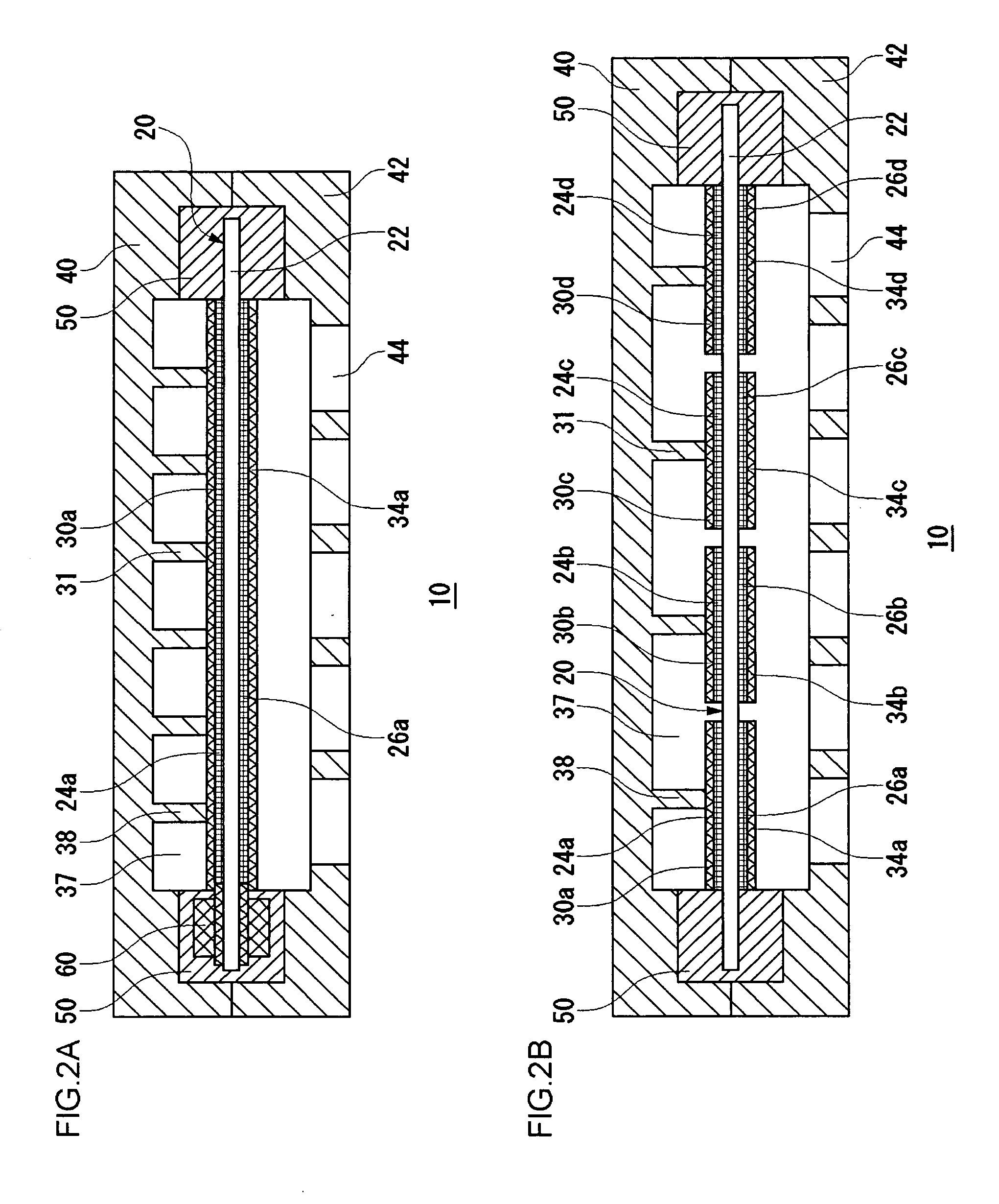

Fuel cell and method for connecting current connectors thereto

InactiveUS20080206619A1Increase distanceImprove insulationLine/current collector detailsFuel cells groupingCurrent collectorEngineering

In a planar-array cell structure, an area required by interconnectors is reduced and a fuel cell is made further compact. A connection part which connects adjacent cells in series is provided within a sealing member provided in a peripheral edge part of an electrolyte membrane where multiple cells are formed in a planar arrangement. For each cell, an anode terminal of a current collector is disposed counter to a cathode terminal of the current collector via the electrolyte membrane. The connection part penetrates the electrolyte membrane and connects the anode terminal of one of the adjacent cells to the cathode terminal of the other of the adjacent cells.

Owner:SANYO ELECTRIC CO LTD

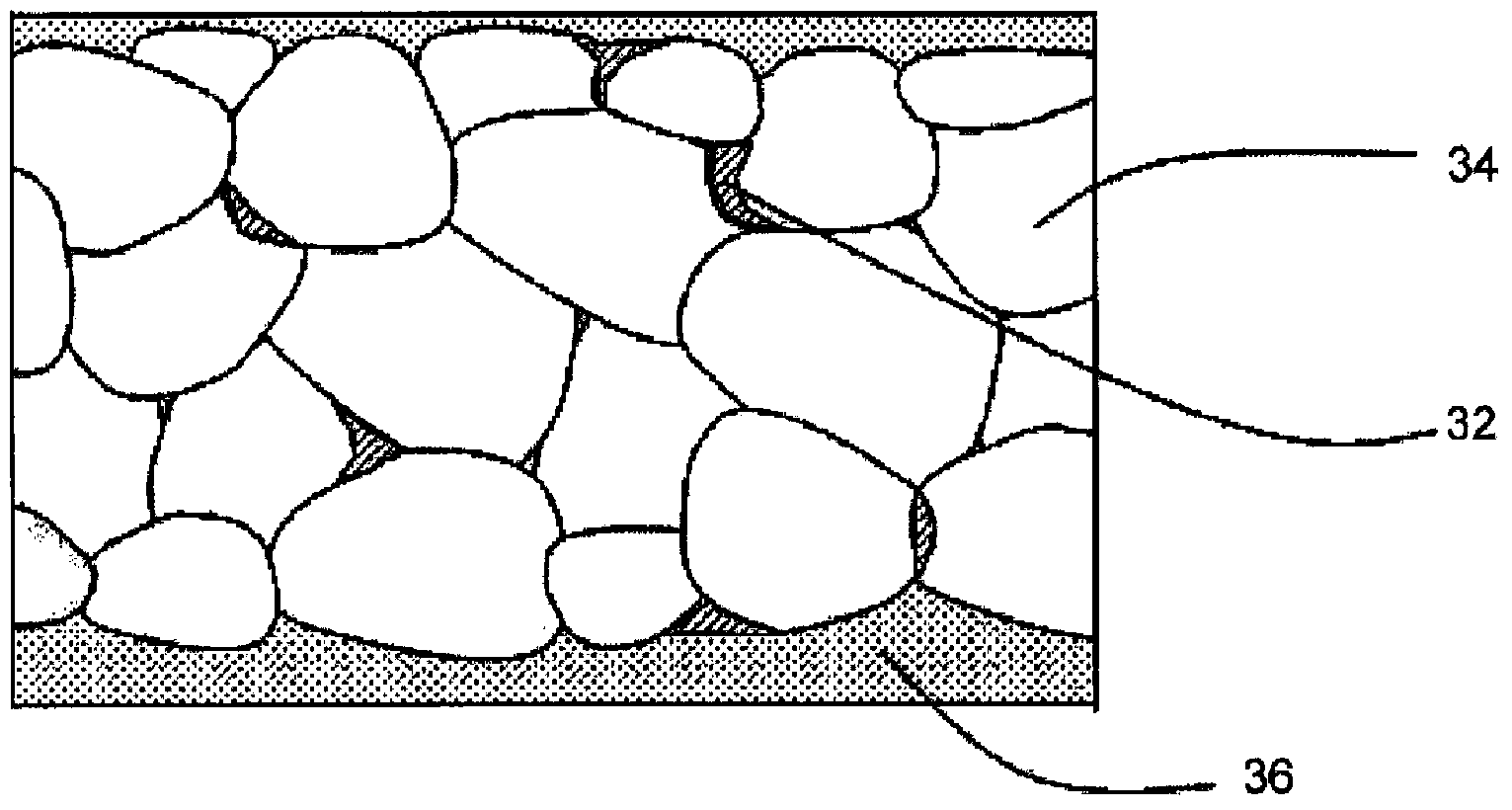

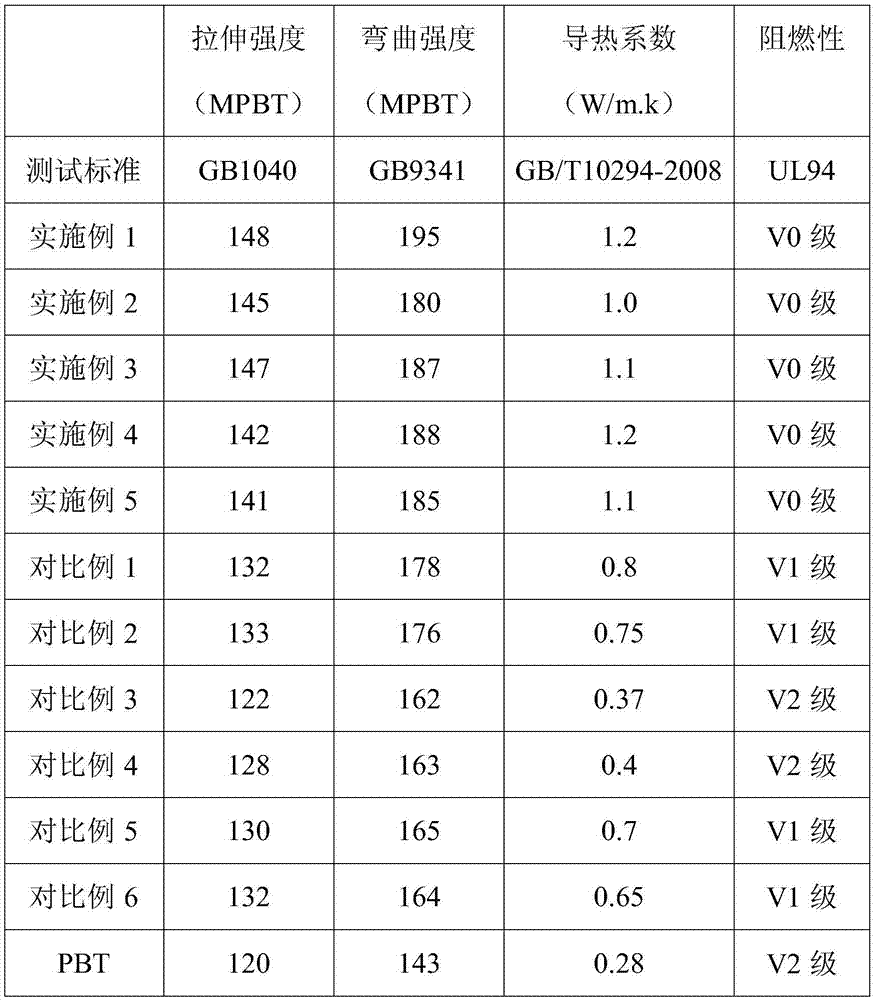

High-efficiency composite PBT heat conduction and dispersion material, and preparation method and applications thereof

The invention provides a high-efficiency composite PBT heat conduction and dispersion material, and a preparation method and applications thereof. The high-efficiency composite PBT heat conduction and dispersion material is prepared from PBT and a heat conduction and dispersion master batch at a mass ratio of 7-9:1-3. The heat conduction and dispersion master batch is prepared from 60 to 80% of polyester fiber, 10 to 20% of a metal oxide, and 10 to 20% of a nitride. The preparation method comprises following steps: the metal oxide, the nitride, and polyester fiver are mixed, an obtained mixture is subjected to extrusion so as to obtain the heat conduction and dispersion master batch, the heat conduction and dispersion master batch is mixed with PBT, and an obtained mixed material is subjected to extrusion so as to obtain the high-efficiency composite PBT heat conduction and dispersion material. The high-efficiency composite PBT heat conduction and dispersion material is a halogen-free environment-friendly flame-retardant material, possesses excellent mechanical properties and high insulating properties, is convenient to process, is low in cost, is a heat conduction and dispersion material with excellent comprehensive properties, and can be widely applied to the fields such as LED illumination, heat conduction and heat dispersion plates, and electric products; heat conductivity coefficient is as high as 1.2W / m.k; and flame resistance is capable of reaching V0 grade.

Owner:DONGGUAN XUWANG PLASTIC TECH CO LTD

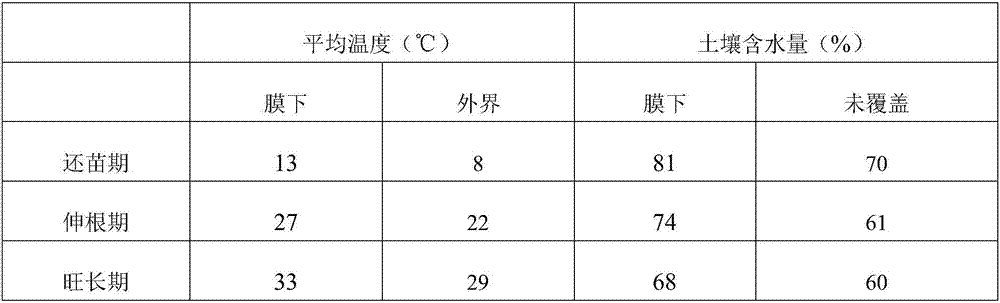

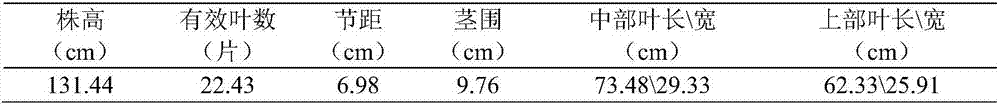

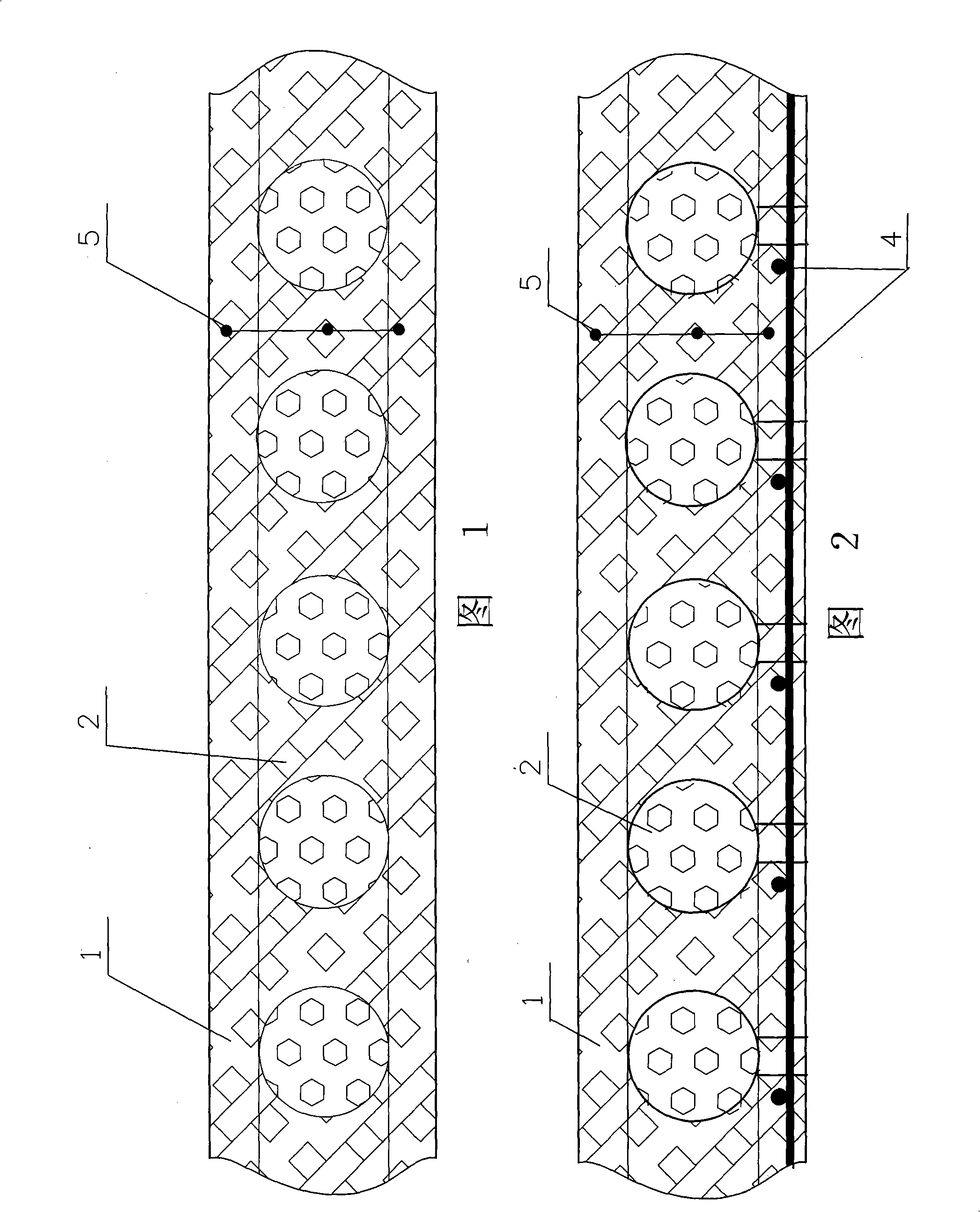

Degradable mulching film coated with waterproof layer

InactiveCN107125061AEasy to layImprove insulationTextiles and paperPlant protective coveringsLarge poreWoven fabric

The invention provides a degradable mulching film coated with a waterproof layer. The degradable mulching film comprises a non-woven fabric layer and the waterproof layer. The non-woven fabric layer is coated with the waterproof layer. The degradable mulching film coated with the waterproof layer is degradable and is automatically degraded when plants grow out and film removal is needed, and the cost for manual recovery is saved. In addition, a single-layer non-woven fabric structure has larger pores, severe breathability is caused, the surface of the non-woven fabric is coated with the waterproof layer under the situation that the heat insulation and water retention effects and the like are reduced somewhat, whole structure density is increased, and accordingly the heat insulation and water retention properties and the like are improved. The degradable mulching film coated with the waterproof layer can be used for planting of crops, such as corn, strawberries, cotton, peanuts and tobaccos.

Owner:广东乐将生物科技有限公司

Low-density, high-flame retardation and high-weatherability bulk molding compound and application thereof

The invention discloses a low-density, high-flame retardation and high-weatherability bulk molding compound and an application thereof. Preparation raw materials of the bulk molding compound comprise high pressure-resistant hollow ceramic beads used as a filling material, unsaturated resin, a low shrinkage agent, a curing agent, a mold lubricant, an antioxidant, a color paste, an inorganic flame retardation filler and glass fibers according to an appropriate ratio, so the density of the above product is reduced, the insulating property, the fireproof property, the rigidity and the hardness of the compound are improved, and the compound has high strength, low density, high weatherability, can be widely applied to the field of integrated ceiling gusset plates and other fields, solves very large technical problems, and has economic and social values.

Owner:JIANGSU ZHAOJUN NEW MATERIAL CO LTD

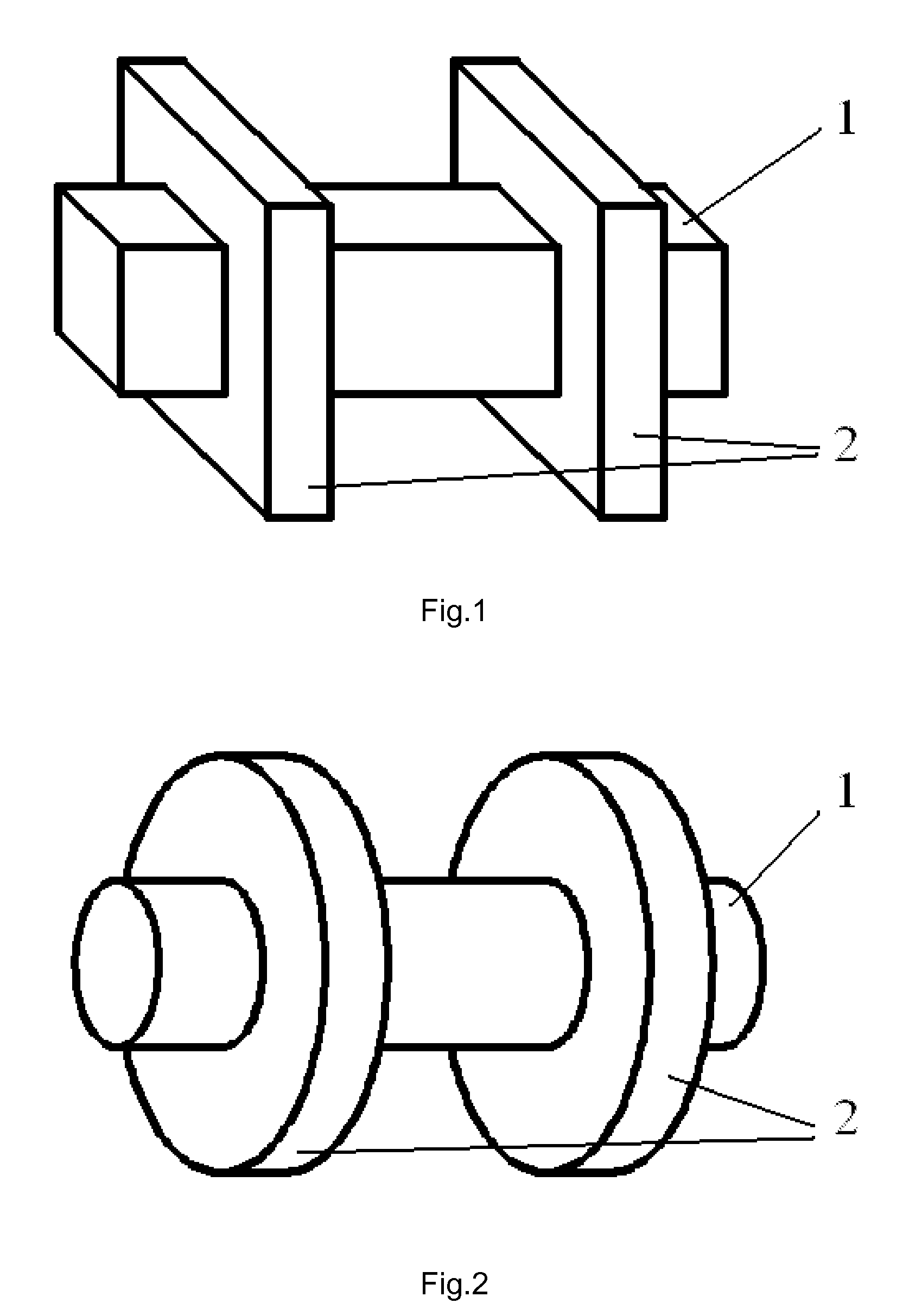

Autoclaved aerated concrete, steel reinforced concrete composite structure and application thereof

InactiveCN101294429AReduce weightReduce floor pressureConstruction materialFloorsFloor slabReinforced concrete

The invention relates to a composite structure of autoclaved aerated concrete and reinforced concrete and an application thereof. The prior precast slabs have large specific gravity, resulting in high weight of buildings and very high cost of foundations. The autoclaved aerated concrete has low specific gravity but poor strength, so as not to be used as supporting parts. The inventive product comprises a building concrete structure member (1) containing reinforced steel bars, wherein the low stress part at the middle of the concrete structure member uses autoclaved aerated concrete (2). The product can be used as precast elements for buildings, such as floor slabs and roof slabs, etc.

Owner:哈尔滨工业大学空间钢结构幕墙有限公司

Heat-accumulating and heat-insulating water storage device of solar water heater

InactiveCN104697207AImprove insulationImprove insulation effectSolar heat devicesSolar thermal energy generationParaffin oilsWater storage tank

A heat-accumulating and heat-insulating water storage device of a solar water heater comprises a barrel body, wherein a phase-change energy storage material is arranged in a heat-accumulating and heat-insulating layer of the barrel body; when the heat-accumulating and heat-insulating water storage device absorbs heat, the phase-change energy storage material changes from a solid state to a liquid state for absorbing heat; when the heat-accumulating and heat-insulating water storage device releases heat, the phase-change energy storage material changes from a liquid state to a solid state for releasing heat; the phase-change energy storage material can be 40-60# paraffin, the specific paraffin grade is selected according to the set temperature of hot water, and the filling way of the paraffin is liquid filling. The heat-accumulating and heat-insulating water storage device can reduce outward heat dissipation of a water storage tank, and greatly improves the heat-insulating effect of the water storage tank; the high-efficiency heat-insulating water tank provided by the invention can retain the temperature drop of water in the water tank to 5 DEG C or below after the night time.

Owner:湖南哲能赫新能源有限责任公司

Method for insulating aluminum backboard of photovoltaic

InactiveUS20140338190A1Improve insulationImprove insulation performanceLine/current collector detailsPhotovoltaicsBackplaneAluminium

A method for insulating an aluminum backboard of a photovoltaic module comprises the following steps: shearing the aluminum backboard such that the dimensions of the aluminum backboard are 4-5 mm smaller those of the glass; forming a square aperture at the position of the electrode lead of the aluminum backboard; insulating the square aperture by cushioning a small insulating material or wrapping the edges with an insulation film when arraying and laying the modules; laminating and trimming the superimposed module components; wrapping the trimmed laminated piece around the edge with the 0.5-1 mm insulation tape; finally, framing up the laminated piece by using a frame filled with silica gel, and installing the terminal box. The invention is convenient to operate and low in investment and has a wide application prospect.

Owner:HANWHA SOLARONE QIDONG

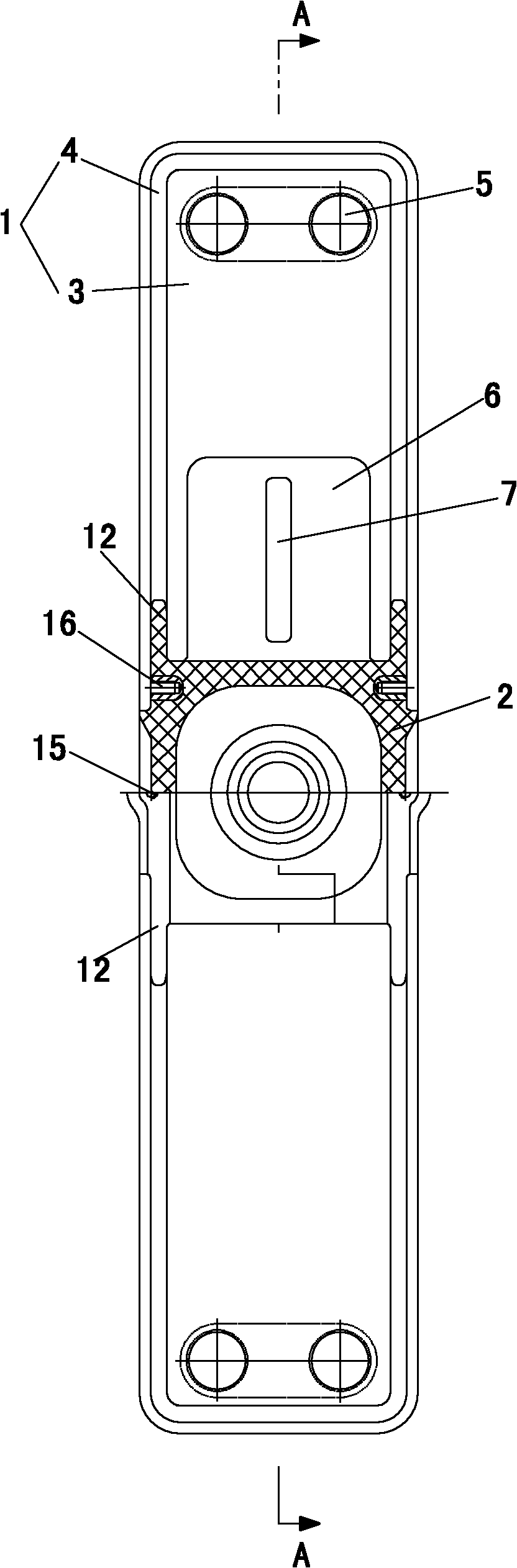

Novel plate crimped dual-chip encapsulated ceramic package

InactiveCN101916745AImprove insulationGood cooling performanceSemiconductor/solid-state device detailsSolid-state devicesMetallurgyFlat panel

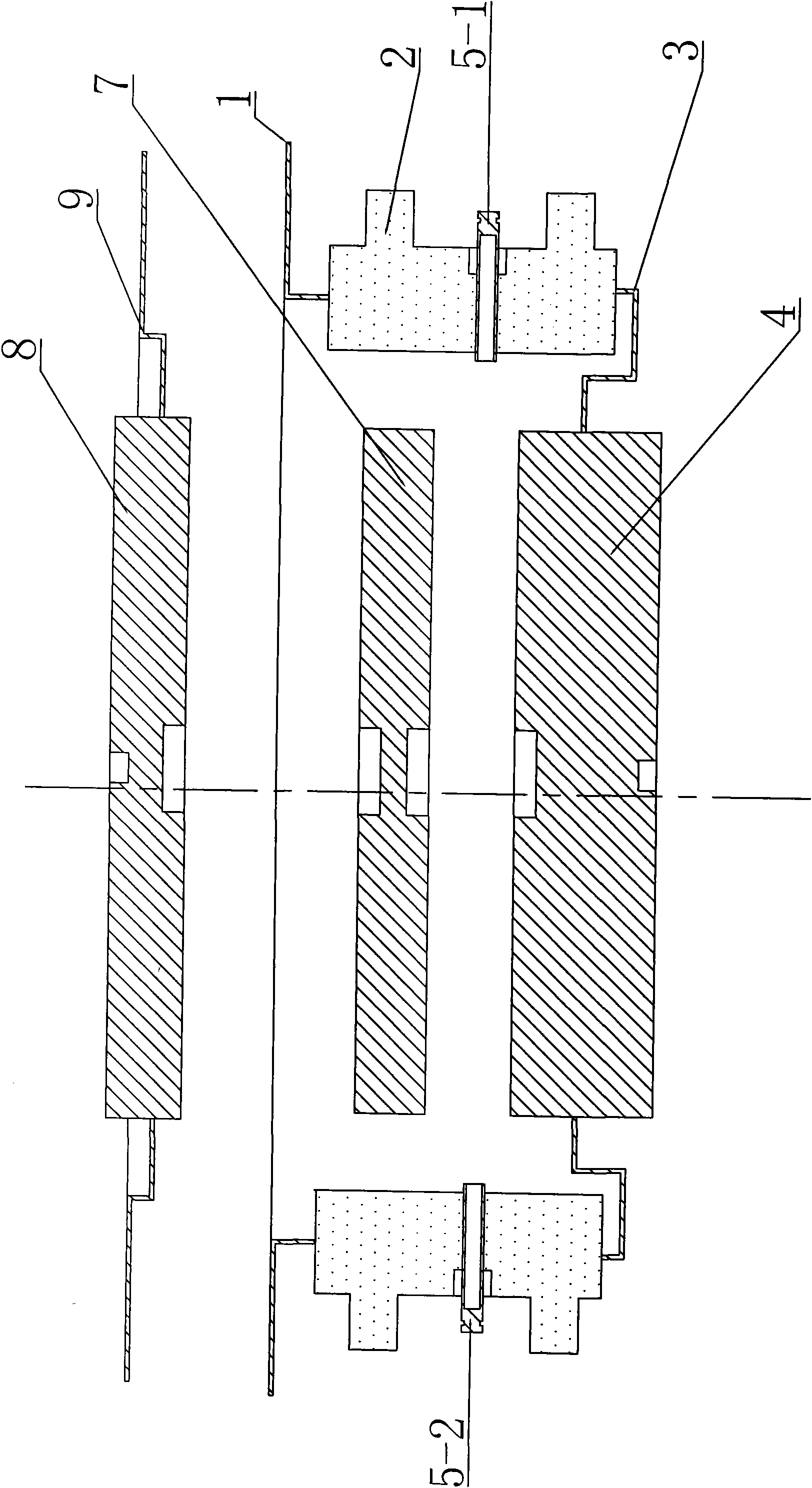

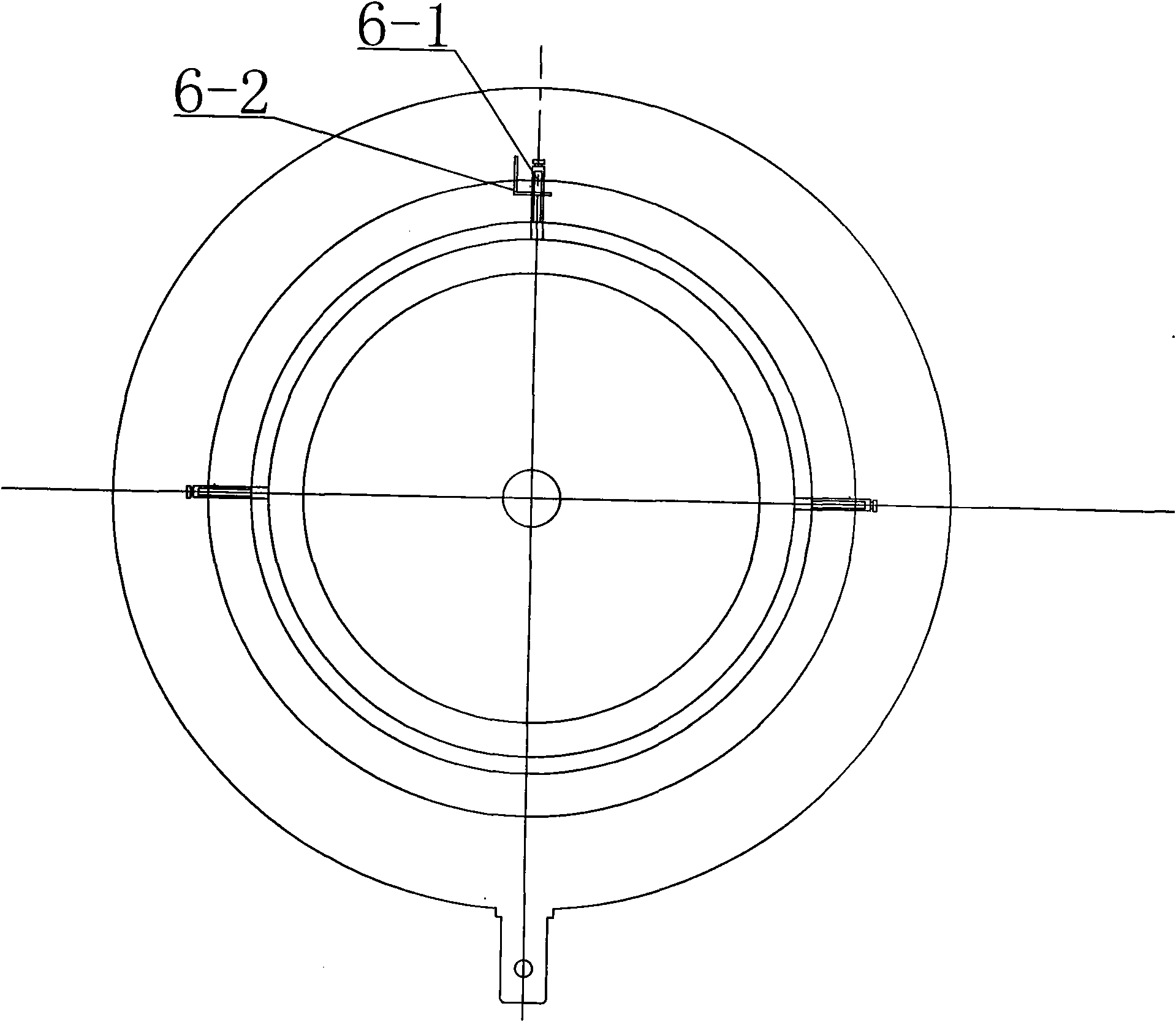

The invention relates to a novel plate crimped dual-chip encapsulated ceramic package, which consists of a ceramic base, a transition electrode (7) and an upper cover, wherein the ceramic base mainly comprises an anodic flange (1), a ceramic ring (2), an anodic sealing ring (3), an anodic electrode (4), a first gate fairlead (5-1), a second gate fairlead (5-2), a cathodic fairlead (6-1), and a cathodic insert (6-2); the transition electrode (7) is arranged between the ceramic base and the upper cover; and the upper cover mainly comprises a cathodic electrode (8) and a cathodic flange (9) which is concentrically welded on the other edge of the cathodic electrode (8). The new plate crimped dual-chip encapsulated ceramic package of the invention can realize serial encapsulation of two chips.

Owner:江阴市赛英电子股份有限公司

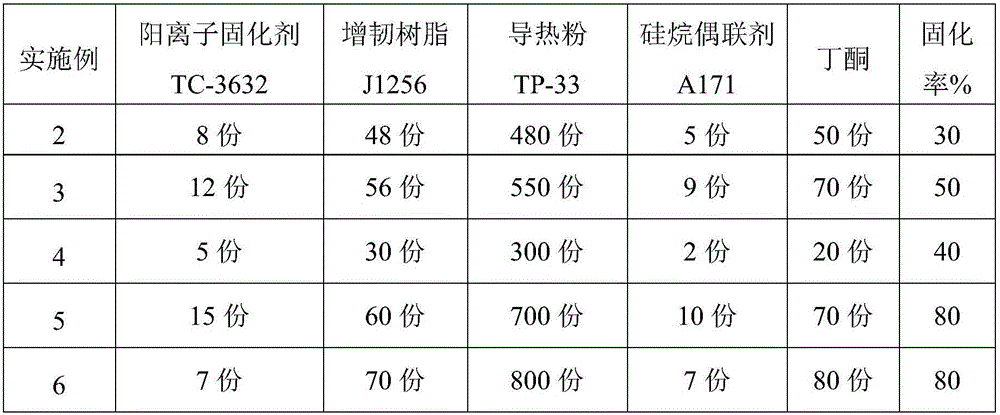

Heat conduction adhesive sheet and preparation method thereof, electronic element and household appliance

ActiveCN105713527AImprove insulationImprove adhesionNon-macromolecular adhesive additivesFilm/foil adhesivesSilane couplingAdhesive

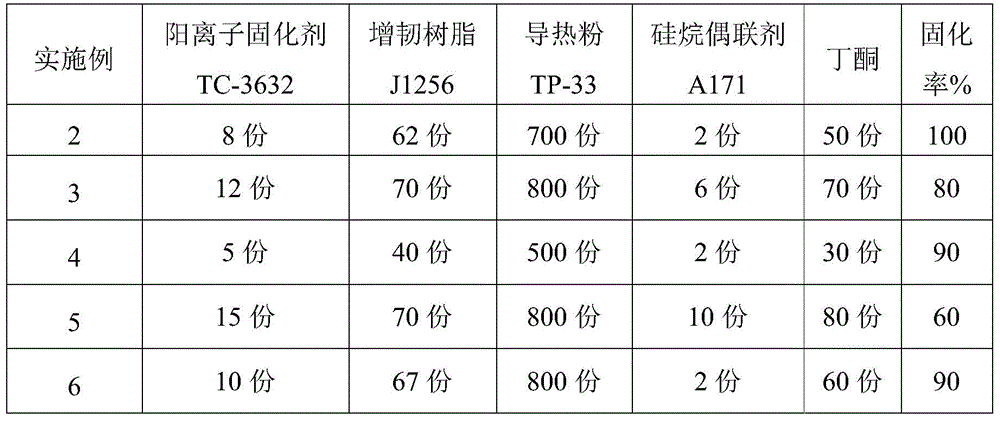

The invention discloses a heat conduction adhesive sheet and a preparation method thereof, an electronic element and a household appliance. The heat conduction adhesive sheet comprises a first heat conduction adhesive layer and a second heat conduction adhesive layer which are composited together. The curing rate of the first heat conduction adhesive layer ranges from 60% to 100%, and the curing rate of the second heat conduction adhesive layer ranges from 30% to 80%. A heat conduction adhesive composition for preparing the heat conduction adhesive sheet comprises epoxy resin, and with 100 parts by weight of epoxy resin as a criterion, the heat conduction adhesive composition further comprises 5-15 parts by weight of cation curing agent, 40-70 parts by weight of toughening resin, 500-800 parts by weight of heat conduction powder, 2-10 parts by weight of silane coupling agent, 30-80 parts by weight of butanone and 1-5 parts by weight of antifoaming agent. According to the heat conduction adhesive sheet formed by compositing the two heat conduction adhesive layers with different curing rates, high insulativity of the heat conduction adhesive sheet can be maintained, and meanwhile the heat conduction adhesive sheet has high heat conductivity and high bonding capacity.

Owner:珠海格力绿色再生资源有限公司 +1

Antioxidant nano modified transformer oil and preparation method thereof

The invention discloses antioxidant nano modified transformer oil. The antioxidant nano modified transformer oil is prepared from, by weight, 100-150 parts of naphthenic base oil, 5-10 parts of castor oil, 0.1-0.15 part of nanosilicon dioxide hollow spheres, 0.3-0.5 part of 2,6-butylated hydroxytoluene, 0.1-0.15 part of benzotriazole, 0.3-0.5 part of propylgallate, 0.01-0.015 part of quercetin,0.01-0.015 part of tetraethoxysilane, 0.1-0.15 part of sodium cetostearyl sulphate and 0.01-0.015 part of vinyltriethoxysilane. The transformer oil has excellent insulation and heat dissipation performance, is stable in property and long in service life, further has the advantage of good antioxidant performance, and is high in practicality.

Owner:葛袁园

Additive for thermal insulation paint and preparation method, and water-based paint containing additive

The invention provides an additive for a thermal insulation paint, which comprises microcapsule vitrified microbead, nano oxide, dispersant, modifier, thickening agent, defoaming agent and water, wherein the microcapsule vitrified microbead is prepared by filling a phase-change energy storage material in the hollow part of the vitrified microbead and coating a seal film composed of acrylic acid and first nano silicon dioxide on the surface. The invention also provides a preparation method of the additive and a water-based paint containing the additive. The water-based paint containing the additive has the advantages of obvious thermal insulation effect, great difference between the coating surface temperature and space temperature, and favorable thermal insulation effect.

Owner:常熟市江南粘合剂有限公司

Low-cost nontoxic thermal barrier coating and manufacturing method thereof

InactiveCN105088125AImproves antioxidant propertiesImprove insulationMolten spray coatingLap jointOxidation resistant

The invention discloses a low-cost nontoxic thermal barrier coating. The oxidation resistance of the ceramic phase and the permeability of matrix metal can be improved after modification through adding of aluminum powder and high-temperature calcination; part of particles are not fully melted in plasma jetting in the spraying process, the deformation degree is slightly weak in the matrix striking process, a porous structure in lap joint is prone to forming, and the heat insulation property of the coating is improved; through a modification method, Y3+ and Ce4+ in zirconium dioxide lattices replace Zr4+, and oxygen vacancy and a partial stress field are generated, so that phonon scattering in the lattices is increased, and the heat conductivity is obviously lowered; moreover, the atomic weight of the solid solution atom Ce is far larger than that of Y, the phonon scattering intensity in the coating can be remarkably improved, so that the heat conductivity is lowered. The low-cost nontoxic thermal barrier coating is good in process stability, low in cost and high in product particle uniformity and purity, has good sintering resistance and high temperature thermal stability, and is environmentally friendly and suitable for large-scale industrial production.

Owner:MAANSHAN LANKE REMFG TECH

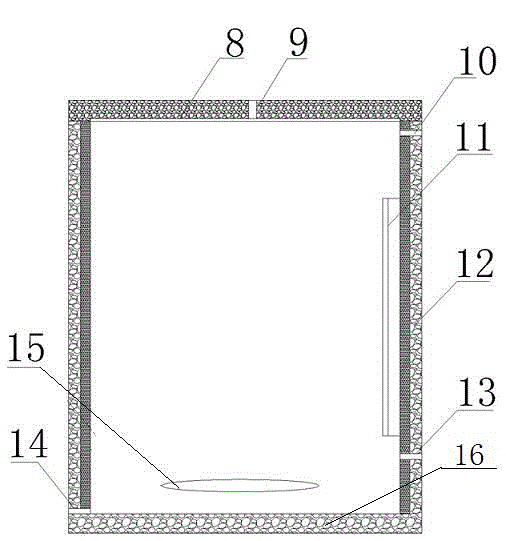

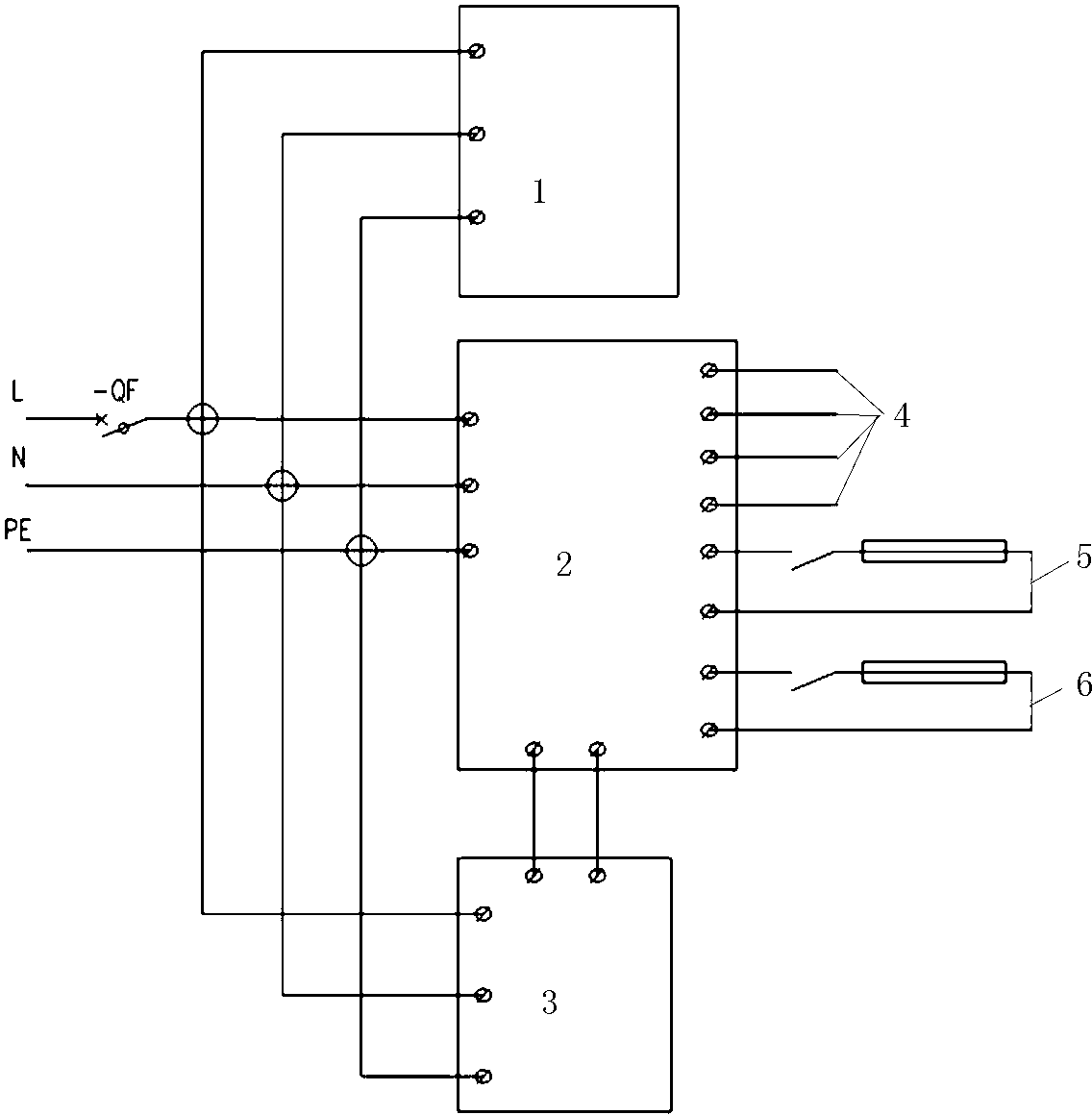

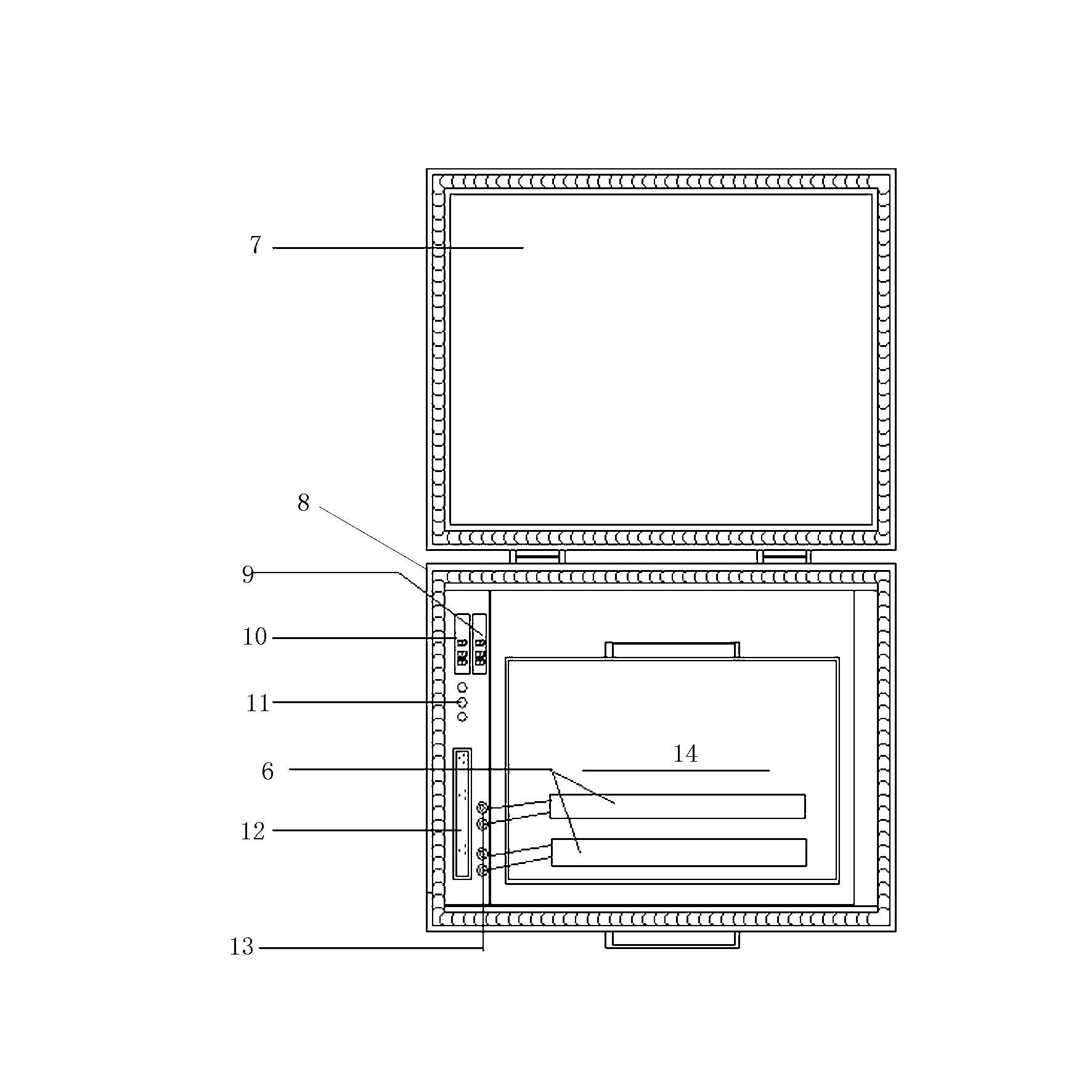

Constant-temperature protection box of electrical device detection instrument

ActiveCN103019275AAvoid damageNot affectedAuxillary controllers with auxillary heating devicesElectronic systemsElectric power equipment

The invention relates to a constant-temperature protection box of an electrical device detection instrument. The box comprises a box body, wherein a combined socket, a direct current power supply and a comprehensive measuring and control device are arranged on the box body, the combined socket is connected to the direct current power supply, the direct current power supply is connected to the comprehensive measuring and control device, one side of the comprehensive measuring and control device is connected to a sensor and a heating device, and the other side of the comprehensive measuring and control device is provided with L, N and PE wiring terminals. By the aid of the box, the problem that the electrical device detection instrument cannot work normally at the lower temperature is solved, the electrical device detection operation can be completed timely and the electronic system works safely and reliably.

Owner:FUSHUN POWER SUPPLY COMPANY OF STATE GRID LIAONING ELECTRIC POWER SUPPLY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com