Novel plate crimped dual-chip encapsulated ceramic package

A flat crimping, ceramic shell technology, applied in electrical components, electrical solid devices, circuits, etc., to achieve the effect of increasing the heat dissipation area, high insulation, and improving the ability to resist thermal fatigue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

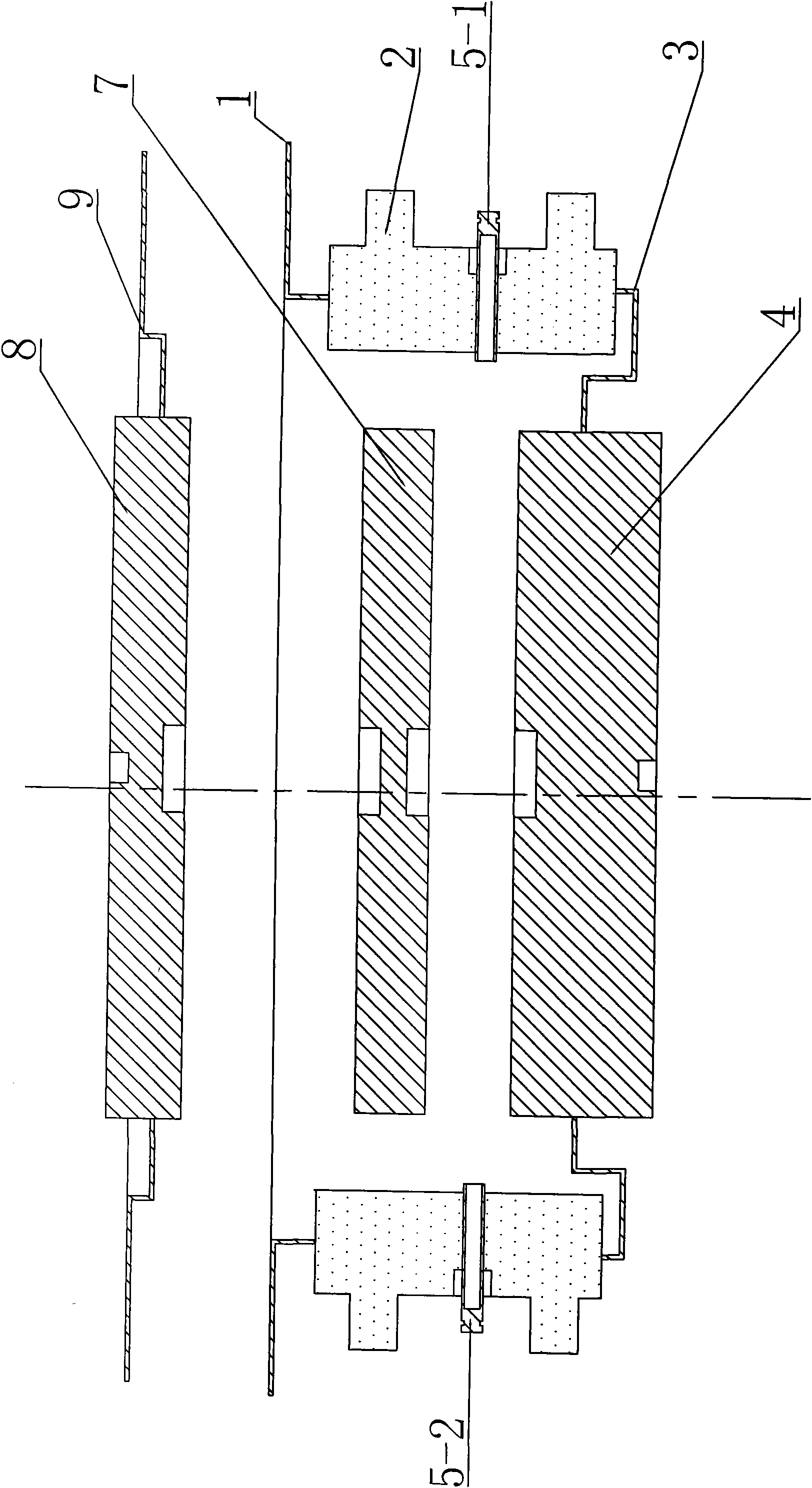

[0024] see figure 1 , the present invention relates to a novel flat crimping double-chip packaging ceramic case, which consists of three parts: a ceramic base, a transition electrode 7 and an upper cover;

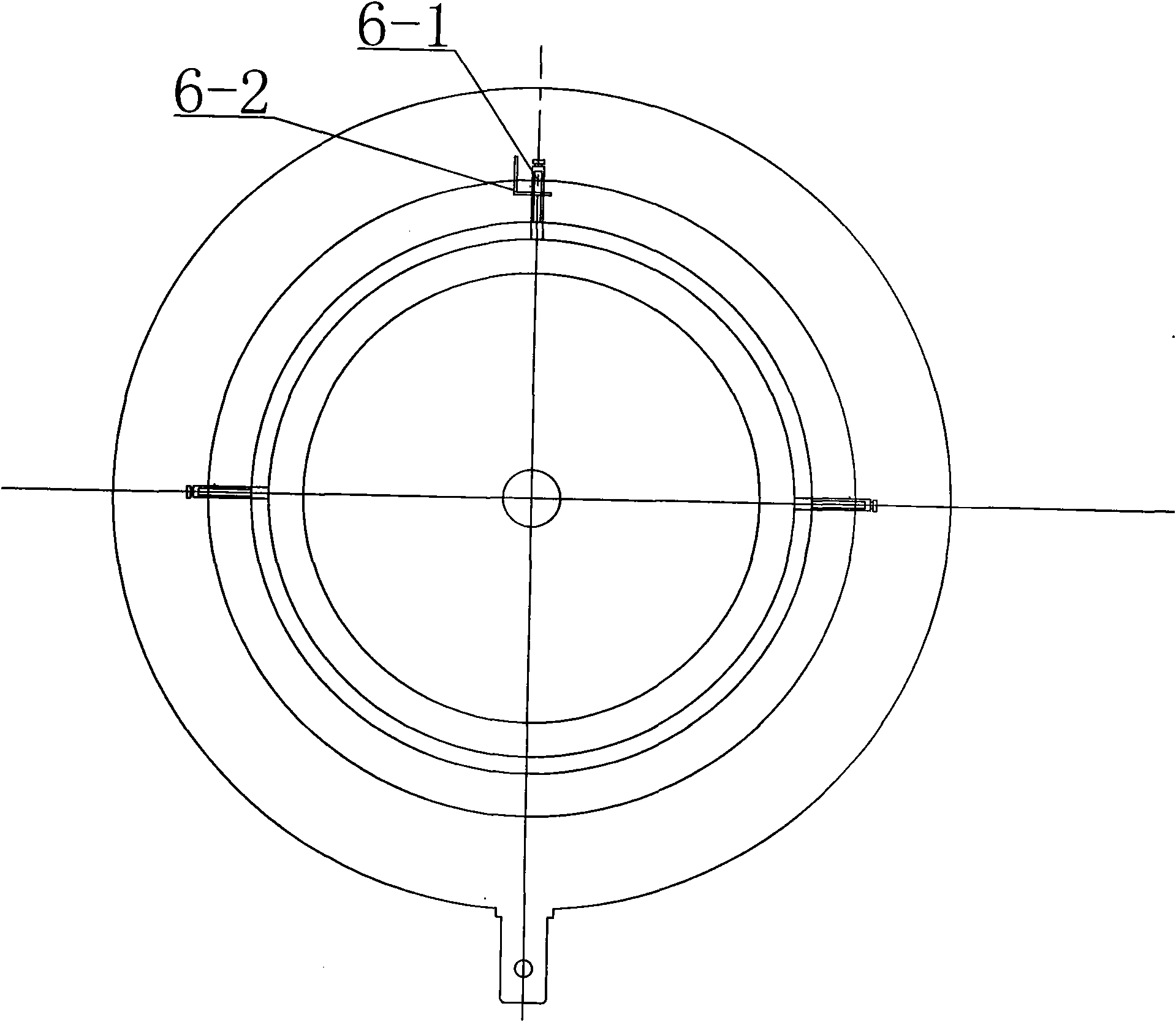

[0025] see Figure 1~2 , the ceramic base is mainly composed of an anode flange 1, a ceramic ring 2, an anode sealing ring 3, an anode electrode 4, a gate lead tube 1 5-1, a gate lead tube 2 5-2, a cathode lead tube 6-1, Composed of cathode inserts 6-2, the inner edge of the anode sealing ring 3 is concentrically welded to the outer edge of the anode electrode 4, the outer edge is concentrically welded to the lower end surface of the ceramic ring 2, and the anode flange 1 is concentrically welded to the upper end surface of the ceramic ring 2, The anode flange 1, the ceramic ring 2 and the anode sealing ring 3 are stacked and welded concentrically from top to bottom, and the first gate lead tube 5-1 and the second gate lead tube 5-2 are horizontally connected to the center...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com